1. Introduction

Zobo is a popular Nigerian beverage produced from the petals of

Hibiscus sabdariffa, valued for its unique taste, low cost, and numerous health benefits [

1]. Its low cost compared to other commercial soft drinks has made it a staple across diverse socioeconomic groups [

2]. Beyond its sensory appeal, zobo contains essential nutrients and bioactive elements, which contribute to its therapeutic roles in managing blood pressure, cholesterol levels, blood sugar, liver function, and weight [

3,

4,

5].

In traditional zobo processing, dried hibiscus petals are usually sorted and cleaned by hand, then boiled over open flames with natural ingredients like pineapple peels, ginger, and cloves. Following extraction, the mixture is allowed to cool before being sweetened, filtered through a cloth or mesh, and served cold. Notwithstanding its ease of use, this approach has a number of drawbacks, such as inaccurate ingredient measuring, a lack of hygienic control, a high labor cost, energy waste from prolonged heating, and uneven product quality [

6].

A key limitation in the traditional process is its absence of controlled heating, which often results in the breakdown of thermolabile nutrients like vitamin C and anthocyanins [

7]. Inadequate filtration and reuse of cloth filters pose additional risks of microbial contamination and reduced clarity [

8].

Despite its nutritional appeal, traditional zobo processing is often undermined by lack of process standardization, poor temperature control, and unhygienic filtration practices [

2]. Manual boiling without precise thermal regulation can result in degradation of heat-sensitive compounds like vitamin C and anthocyanins [

9], or conversely, enable microbial instability due to inadequate pasteurization [

10]. Using reusable cloth filters or basic sieves in traditional filtration compromises clarity and raises microbial safety concerns, particularly when not properly cleaned or sterilized [

11]. Studies in Nigeria demonstrate that such practices frequently allow microbial counts to exceed acceptable safety thresholds [

6,

12].Traditional processes fail to effectively control shelf-life or microbial stability and are associated with rapid deterioration when not refrigerated [

13].

Attempts have been made to diversify and mechanize the processing methods of zobo to offer options that cater to different needs, from immediate consumption to long-term storage [

14,

15].

Although the existing literature shows some progress in mechanizing zobo production, most efforts remain partial and small-scale, lacking the integration, intelligence, and scalability needed for modern commercial operations. In particular, the absence of precise process control, especially in temperature regulation and filtration during extraction and pasteurization, contributes to inconsistent quality, nutrient loss, and reduced shelf life [

16,

17]. This highlights a significant opportunity for innovation in developing a fully automated, smart, temperature-controlled zobo processing plant that effectively addresses these gaps.

Given these challenges, this study proposes and evaluates a fully integrated, smart-regulated zobo processing plant designed to improve efficiency, consistency, and compliance with national health and safety standards. The system incorporates innovation in automated temperature control, continuous two-stage filtration, homogenized mixing, and rapid cooling through a heat exchanger governed by a centralized programmable logic controller (PLC).

This paper presents a comparative analysis of zobo produced using this automated plant and the traditional method. The assessment is based on nutritional compliance with NAFDAC requirements, shelf life, sensory evaluation, and process consistency across five production batches. This study aims to demonstrate the advantages of automation in standardizing indigenous beverage production while promoting energy efficiency, hygienic safety, and economic scalability.

3. Results and Discussion

3.1. Nutritional Composition Analysis

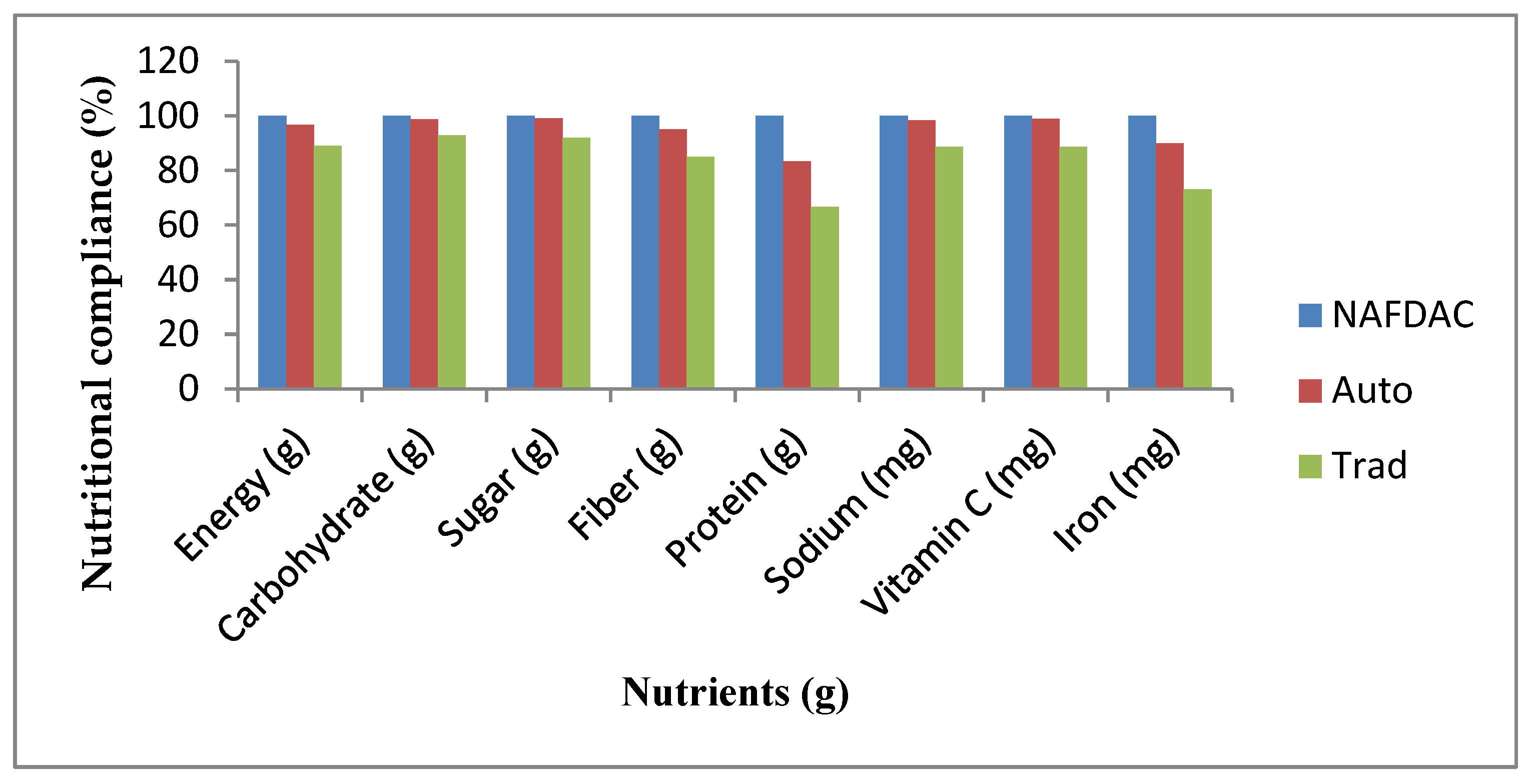

Table 4 compares the average nutritional values of zobo juice produced using the Automated Zobo Processing Machine and the traditional method against the NAFDAC-nutritional requirements compliance.

The automated method consistently achieved nutrient values closer to the NAFDAC nutritional requirements compliance, with deviations mostly within 0–5%, except for protein (16.7%) and iron (10%). The traditional method showed higher and more erratic deviations, with significant deficiencies in protein, iron, and fiber, likely due to uncontrolled heating and a lower nutrients extraction capacity compared to the automated method. Vitamin C retention was better preserved in the automated method, due to its smart temperature control and rapid cooling, which minimized thermal degradation of nutrients.

3.2. ANOVA Analysis

The Python 3.11 via panda v2.x ANOVA analysis was conducted to compare the nutrient compositions of zobo juice produced through the automated and traditional methods against the NAFDAC nutritional compliance requirements as indicated in

Table 5.

The automated method shows high consistency and partial conformity with NAFDAC standards, with about 62.5% of nutrients showing statistically significant deviation, but with relatively small magnitudes. The traditional method exhibits statistically significant deviations from the NAFDAC nutritional compliance requirements in 100% of tested parameters, indicating lower conformity and greater variability.

The automated process aligns more closely with NAFDAC nutritional compliance requirements than the traditional method. This is evidenced by fewer statistically significant deviations and higher p-values in certain nutrients, especially those susceptible to manual measurement errors (e.g., sodium and vitamin C). Therefore, the automated method is more nutritionally reliable and consistent for NAFDAC zobo nutritional compliance requirements productions.

3.3. Batch Performance Analysis

Figure 1 shows the compliance with the NAFDAC nutritional requirements for the automated and traditional methods batches. Automated batches demonstrated higher convergence toward NAFDAC nutritional compliance requirements, while traditional batches fluctuated due to uncontrolled manual operations. This indicated the close alignment of the Auto to NAFDAC nutritional compliance requirements.

3.4. Sensory Evaluation and Shelf Life

Sensory evaluations were conducted over six days.

Table 6 summarizes the panel’s assessment.

The automated zobo maintained high acceptability for up to six days, with minor sensory degradation. The traditional zobo showed rapid spoilage by day four, losing all acceptability by day five, due to lack of pasteurization and microbial control. This confirms that automated thermal regulation and hygienic filtration significantly increase shelf life and consumer acceptance.

3.5. Process Accuracy and Stability

Ingredient measurement accuracy in the automated system was ±2% compared to higher subjective variation in manual processing. Temperature stability was maintained within ±1 °C in the automated system, promoting uniform nutrient extraction and microbial safety. Stirring and mixing mechanisms ensured homogeneous blending, reducing nutrient stratification and improving taste.

3.6. Environmental and Operational Impact

Energy use in the automated system was optimized through smart heating cycles and insulated tanks, unlike the traditional method’s open-flame heating, which incurs higher heat losses. By replacing traditional firewood-based heating with an electric system, the automated plant reduces reliance on biomass, thereby lowering deforestation and associated emissions. Although the initial capital cost of automation is high, it is offset by improved yield, labor savings, and scalability for commercial applications.

3.7. Production Cost Analysis

Table 7 gives the monthly cost analysis of the production of zobo juice by the traditional and automated processes with a total batch production of 1500 L and 13,500 L per month for the traditional and automated processes, respectively. The cost analysis indicated that the cost per L at one month of operation significantly reduces by 42.35% to the larger scale production capacity of the automated method in spite of its large initial equipment cost. The automated method is capable of three batch production per day due to the shorter production cycle of about one hour thirty minutes, whereas the traditional method is capable of two batch productions due to a longer production cycle of three hours.

4. Conclusions

This study demonstrated that automation significantly enhances the quality and consistency of zobo beverage production. The automated method produced outputs that aligned more closely with NAFDAC nutritional compliance requirements compared to the traditional method. Based on ANOVA results, the automated method showed statistically insignificant differences (p > 0.05) for three out of eight assessed nutrients (fiber, sodium, and vitamin C), indicating better compliance. In contrast, the traditional method significantly deviated (p < 0.05) in all eight nutrient categories. These findings underscore the limitations of manual processing, particularly its inability to consistently control critical factors like temperature and filtration, which affect nutrient retention and product safety.

The integration of smart controls in the automated system enabled precise temperature regulation and hygienic filtration, which contributed to better nutrient preservation and microbial safety. Given these advantages, along with potential scalability and reduced dependency on labor skill level, the automated system presents a superior alternative for commercial zobo production. The cost–benefit analysis and sensory evaluation further strengthen the case for automation, highlighting long-term economic and quality assurance gains over the traditional methods.