Optical Coatings: Applications and Metrology †

Abstract

:1. Introduction

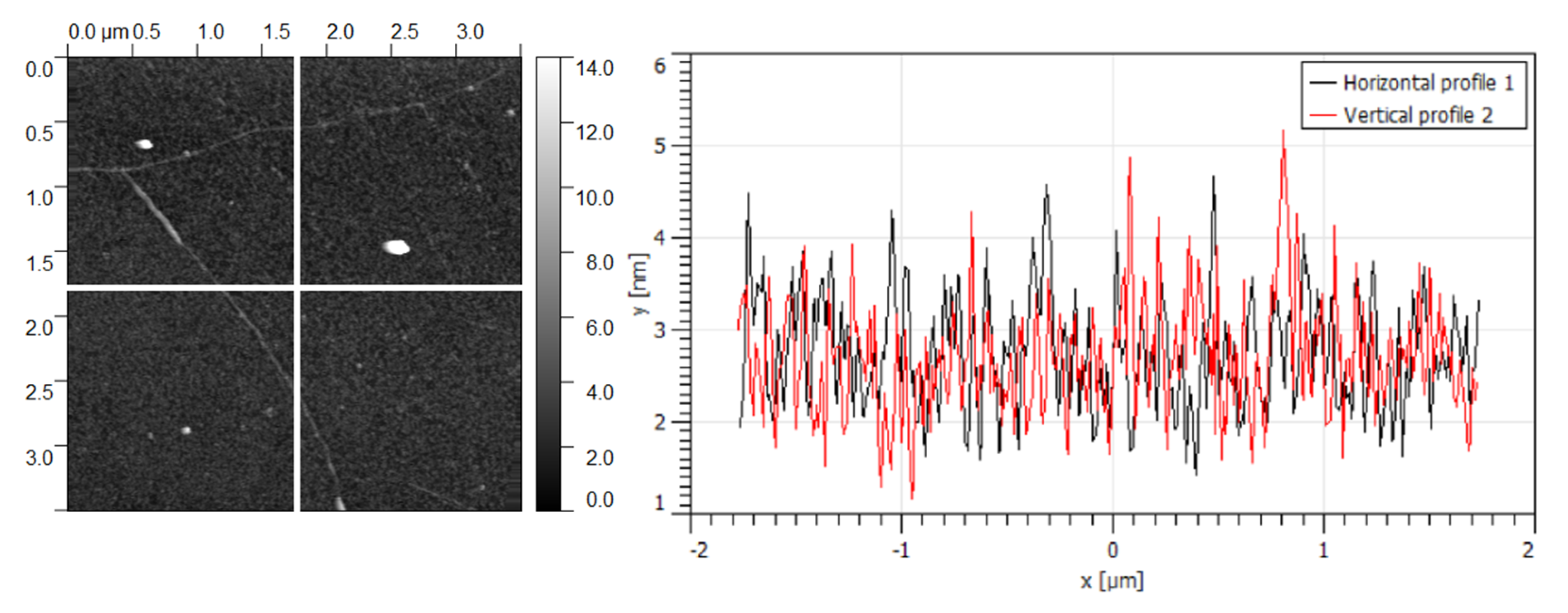

2. Experimental Arrangement and Samples

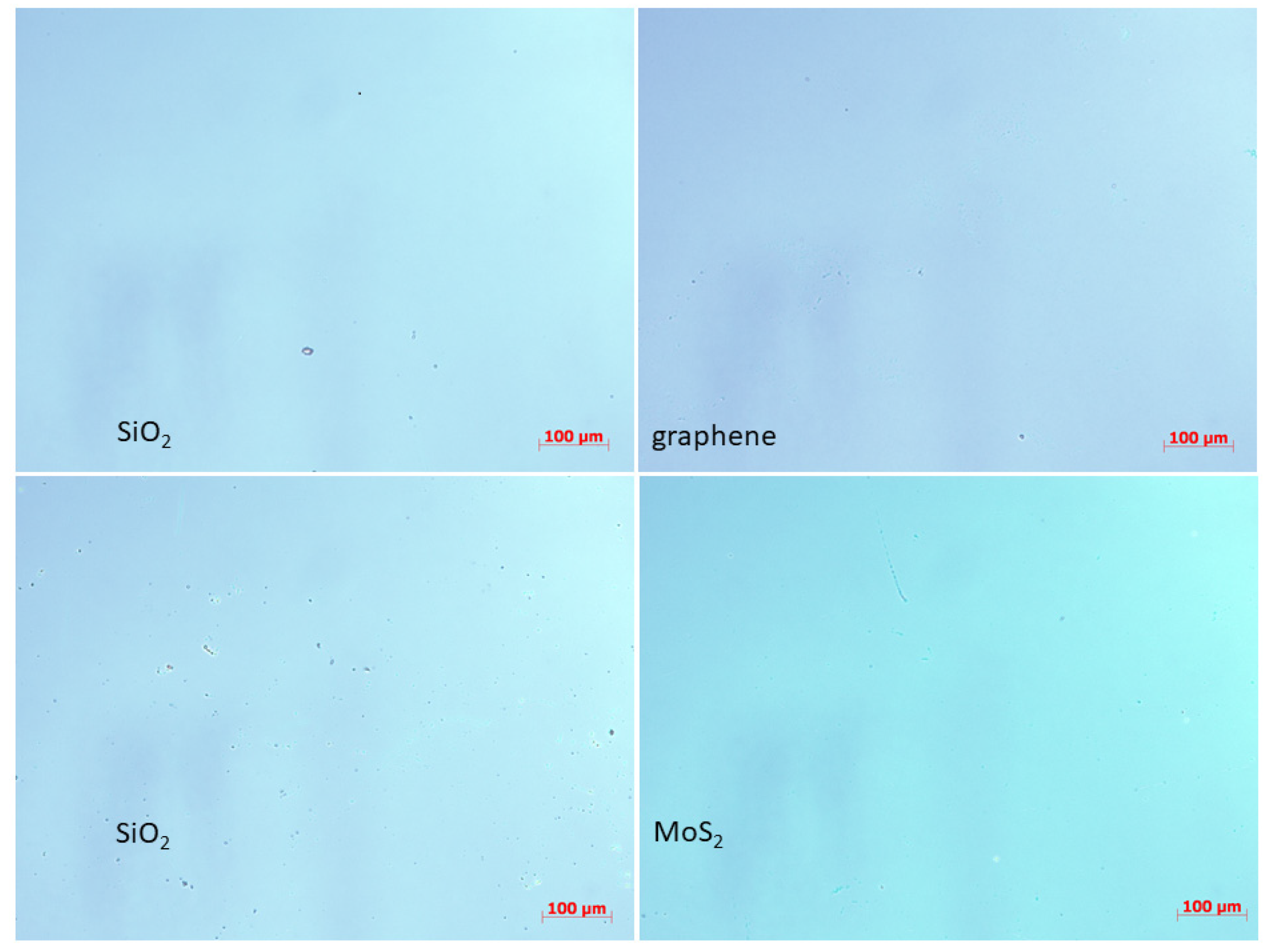

- Monolayer graphene onto SiO2 (300 nm)/Si and the corresponding bare sample of SiO2 (300 nm)/Si (named “SiO2 [R-G), both provided by Graphenea, Inc.;

- Monolayer of MoS2 onto SiO2 (300 nm)/Si and the corresponding bare sample of SiO2 (300 nm)/Si, (named “MoS2 [R-MoS2]”), both provided by 2D semiconductors.

3. Results

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Available online: http://www.pd.ifn.cnr.it (accessed on 1 April 2022).

- Yesudasu, V.; Shekhar Pradhan, H.; Jasvanthbhai Pandyab, R. Recent progress in surface plasmon resonance based sensors: A comprehensive review. Heliyon 2021, 7, e06321. [Google Scholar] [CrossRef] [PubMed]

- Zeng, Y.; Zhou, J.; Sang, W.; Kong, W.; Qu, J.; Ho, H.P.; Zhou, K.; Zhi Gao, B.; Chen, J.; Shao, Y. High-Sensitive Surface Plasmon Resonance Imaging Biosensor Based on Dual-Wavelength Differential Method. Front. Chem. 2021, 9, 801355. [Google Scholar] [CrossRef] [PubMed]

- Cai, H.; Shan, S.; Wang, X. High Sensitivity Surface Plasmon Resonance Sensor Based on Periodic Multilayer Thin Films. Nanomaterials 2021, 11, 3399. [Google Scholar] [CrossRef]

- Zhu, J.; Li, N. Novel high sensitivity SPR sensor based on surface plasmon resonance technology and IMI waveguide structure. Results Phys. 2020, 17, 103049. [Google Scholar] [CrossRef]

- Garoli, D.; Rodriguez De Marcos, L.V.; Larruquert, J.I.; Corso, A.J.; Proietti Zaccaria, R.; Pelizzo, M.G. Mirrors for Space Telescopes: Degradation Issues. Appl. Sci. 2020, 10, 7538. [Google Scholar] [CrossRef]

- Slaughter, J.M.; Schulze, D.W. Structure and performance of Si/Mo multilayer mirrors for the extreme ultraviolet. J. Appl. Phys. 1994, 76, 2144. [Google Scholar] [CrossRef]

- Zuppella, P.; Pasqualotto, E.; Zuccon, S.; Gerlin, F.; Corso, A.J.; Scaramuzza, M.; De Toni, A.; Paccagnella, A.; Pelizzo, M.G. Palladium on Plastic Substrates for Plasmonic Devices. Sensors 2015, 15, 1138–1147. [Google Scholar] [CrossRef] [Green Version]

- Cennamo, N.; Zuppella, P.; Bacco, D.; Corso, A.J.; Pelizzo, M.G.; Zeni, L. SPR Sensor Platform Based on a Novel Metal Bilayer Applied on D–Shaped Plastic Optical Fibers for Refractive Index Measurements in the Range 1.38–1.42. IEEE Sens. J. 2016, 16, 4822–4827. [Google Scholar] [CrossRef]

- Zuppella, P.; Monaco, G.; Corso, A.J.; Nicolosi, P.; Windt, D.L.; Bello, V.; Mattei, G.; Pelizzo, M.G. Iridium/silicon multilayers for extreme ultraviolet applications in the 20–35 nm wavelength range. Opt. Lett. 2011, 36, 1203–1205. [Google Scholar] [CrossRef]

- Gaballah, A.E.H.; Nicolosi, P.; Ahmed, N.; Jimenez, K.; Pettinari, G.; Gerardino, A.; Zuppella, P. Vacuum ultraviolet quarter wave plates based on SnTe/Al bilayer: Design, fabrication, optical and ellipsometric characterization. App. Surf. Sci. 2019, 463, 75–81. [Google Scholar] [CrossRef]

- Gaballah, A.E.H.; Nicolosi, P.; Ahmed, N.; Jimenez, K.; Pettinari, G.; Gerardino, A.; Zuppella, P. EUV polarimetry for thin film and surface characterization and EUV phase retarder reflector development. Rev. Sci. Instrum. 2018, 89, 015108. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Malik, N.A.; Nicolosi, P.; Jimenez, K.; Gaballah, A.; Giglia, A.; Lazzarino, M.; Zuppella, P. Experimental Study of Few-Layer Graphene: Optical Anisotropy and Pseudo-Brewster Angle Shift in Vacuum Ultraviolet Spectral Range. Adv. Photonics Res. 2021, 2, 2000207. [Google Scholar] [CrossRef]

- Geim, A.K.; Novoselov, K.S. The rise of graphene. Nat. Mater. 2007, 6, 183–191. [Google Scholar] [CrossRef] [PubMed]

- Galashev, A.; Rakhmanova, O. Mechanical and thermal stability of graphene and graphene-based materials. Phys. Uspekhi 2014, 57, 970–989. [Google Scholar] [CrossRef]

- Su, Y.; Kravets, V.G.; Wong, S.L.; Waters, J.; Geim, A.K.; Nair, R.R. Impermeable barrier films and protective coatings based on reduced graphene oxide. Nat. Commun. 2014, 5, 5843. [Google Scholar] [CrossRef]

- Zhang, W.; Zhang, P.; Su, Z.; Wei, G. Synthesis and sensor applications of MoS2-based nanocomposites. Nanoscale 2015, 7, 18364–18378. [Google Scholar] [CrossRef]

- Zhao, L.; Kong, D.; Wu, Z.; Liu, G.; Yan, X.; Liu, F.; Liu, X.; Wang, C.; Cui, J.; Lu, G. Interface interaction of MoS2 nanosheets with DNA based aptameric biosensor for carbohydrate antigen 15–3 detection. Microchem. J. 2020, 15, 104675. [Google Scholar] [CrossRef]

- Gitlin, D.; Karp, J.; Moyzhes, B. Graded tunnelling barrier and oxygen concentration in thermally grown ultrathin SiOx gate oxide. J. Phys. D Appl. Phys. 2007, 40, 2143–2149. [Google Scholar] [CrossRef]

- Gravalidis, C.; Gioti, M.; Laskarakis, A.; Logothetidis, S. Real-time monitoring of silicon oxide deposition processes. Surf. Coat. Technol. 2004, 180−181, 655–658. [Google Scholar] [CrossRef]

- Aharonovich, I.; Lifshitz, Y.; Tamir, S. Growth mechanisms of amorphous SiO[sub x] nanowires. Appl. Phys. Lett. 2007, 90, 263109. [Google Scholar] [CrossRef]

- Blake, P.; Hill, E.W. Making graphene visible. Appl. Phys. Lett. 2007, 91, 063124. [Google Scholar] [CrossRef] [Green Version]

- Zhang, X.; Kawai, H.; Yang, J.; Goh, K.E.J. Detecting MoS2 and MoSe2 with optical contrast simulation. Prog. Nat.Sci. Mater. Int. 2019, 29, 667–671. [Google Scholar] [CrossRef]

- Stubrov, Y.; Nikolenko, A.; Strelchuk, V.; Nedilko, S.; Chornii, V. Structural Modification of Single-Layer Graphene Under Laser Irradiation Featured. Nanoscale Res. Lett. 2017, 12, 297. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Xu, H.; Zhou, W.; Zheng, X.; Huang, J.; Feng, X.; Ye, L.; Xu, G.; Lin, F. Control of the Nucleation Density of Molybdenum Disulfide in Large-Scale Synthesis Using Chemical Vapor Deposition. Materials 2018, 11, 870. [Google Scholar] [CrossRef] [Green Version]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zuppella, P.; Chioetto, P.; Casini, C.; Nordera, S.; Cennamo, N.; Zeni, L.; Deppo, V.D. Optical Coatings: Applications and Metrology. Eng. Proc. 2021, 11, 50. https://doi.org/10.3390/ASEC2021-11137

Zuppella P, Chioetto P, Casini C, Nordera S, Cennamo N, Zeni L, Deppo VD. Optical Coatings: Applications and Metrology. Engineering Proceedings. 2021; 11(1):50. https://doi.org/10.3390/ASEC2021-11137

Chicago/Turabian StyleZuppella, Paola, Paolo Chioetto, Chiara Casini, Simone Nordera, Nunzio Cennamo, Luigi Zeni, and Vania Da Deppo. 2021. "Optical Coatings: Applications and Metrology" Engineering Proceedings 11, no. 1: 50. https://doi.org/10.3390/ASEC2021-11137

APA StyleZuppella, P., Chioetto, P., Casini, C., Nordera, S., Cennamo, N., Zeni, L., & Deppo, V. D. (2021). Optical Coatings: Applications and Metrology. Engineering Proceedings, 11(1), 50. https://doi.org/10.3390/ASEC2021-11137