Development of a Microfluidic Liquid Dispensing System for Lab-on-Chips †

Abstract

1. Introduction

2. Materials and Methodology

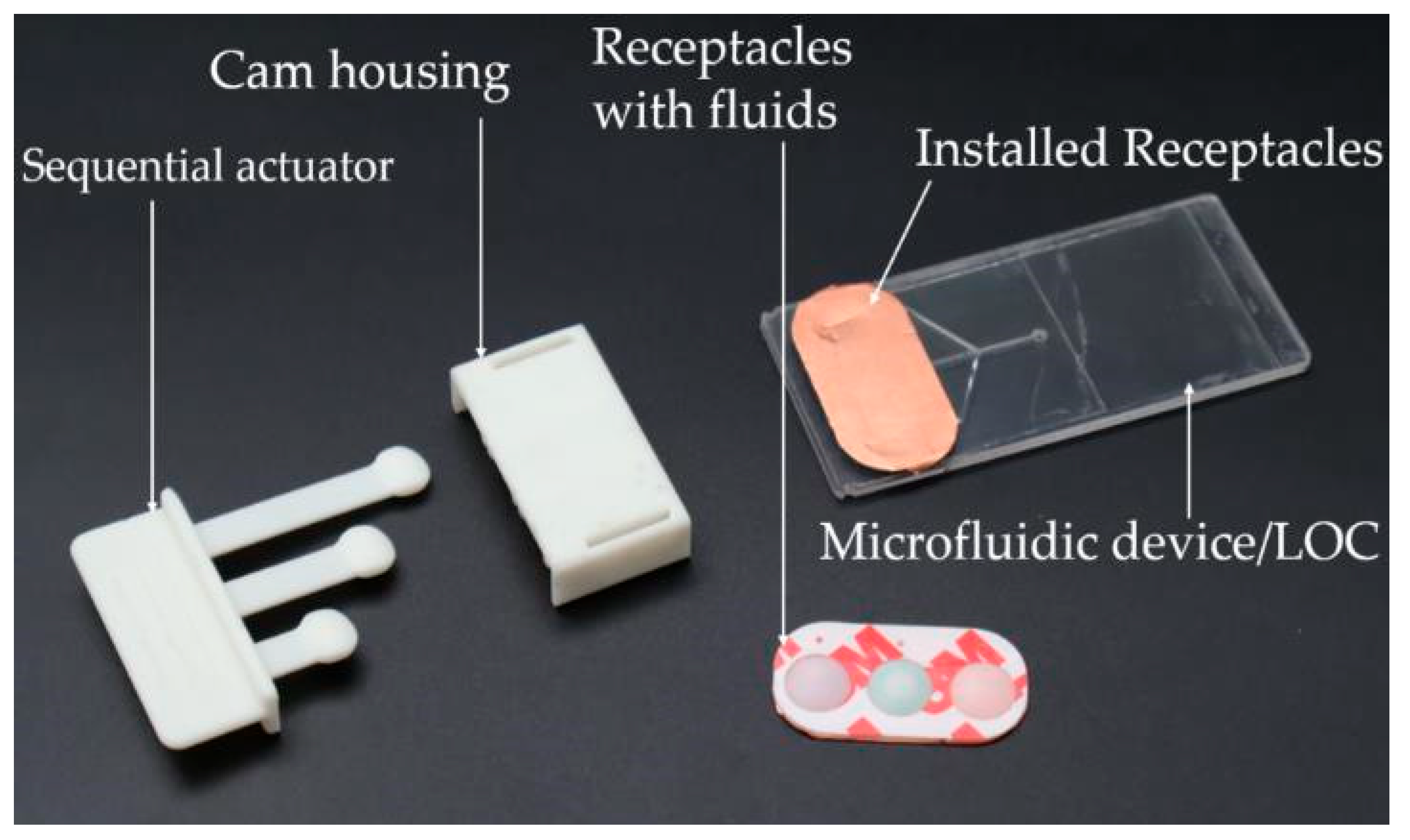

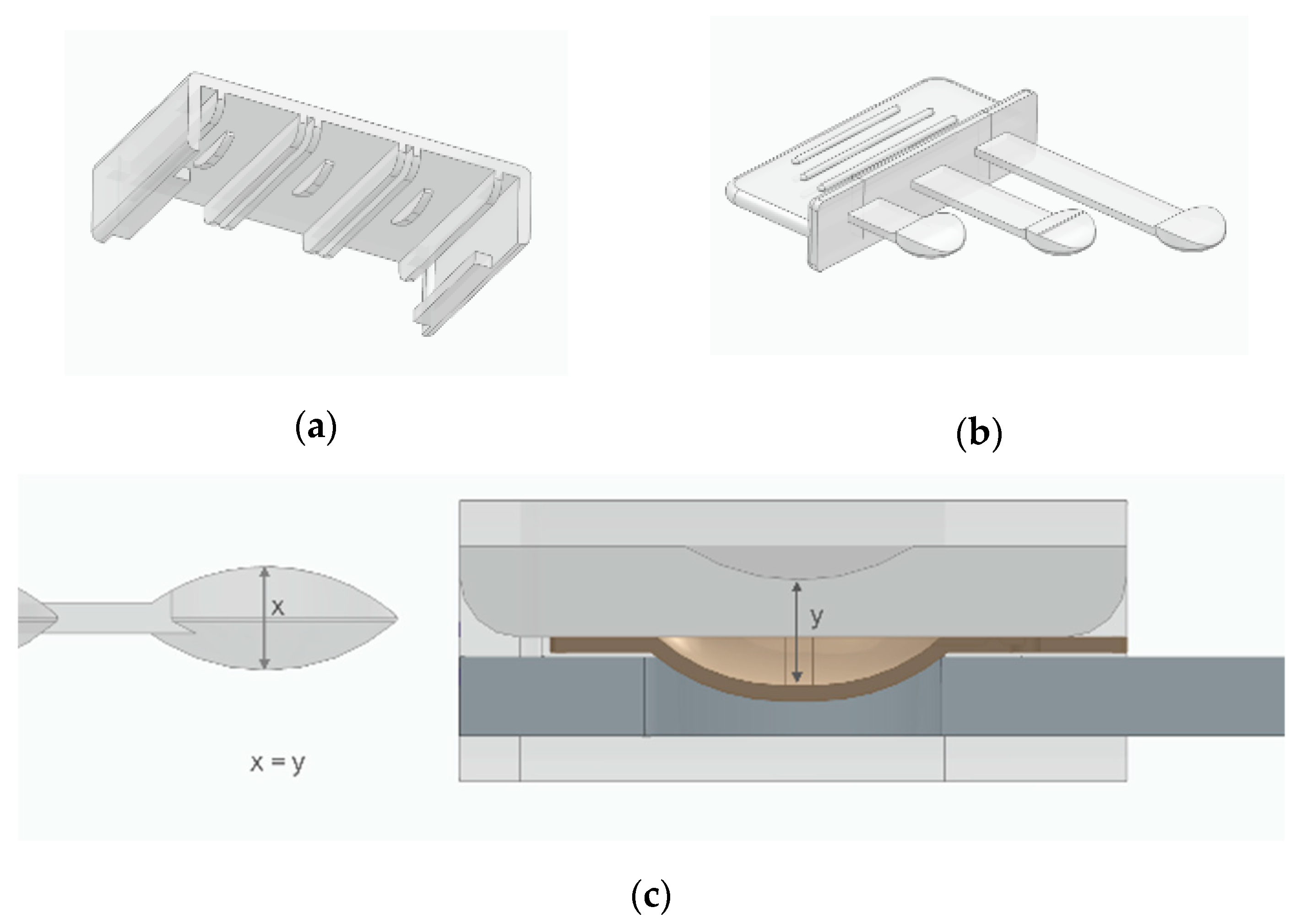

2.1. Design and Fabrication of Components

2.2. System Configuration

2.3. Control Mechanism

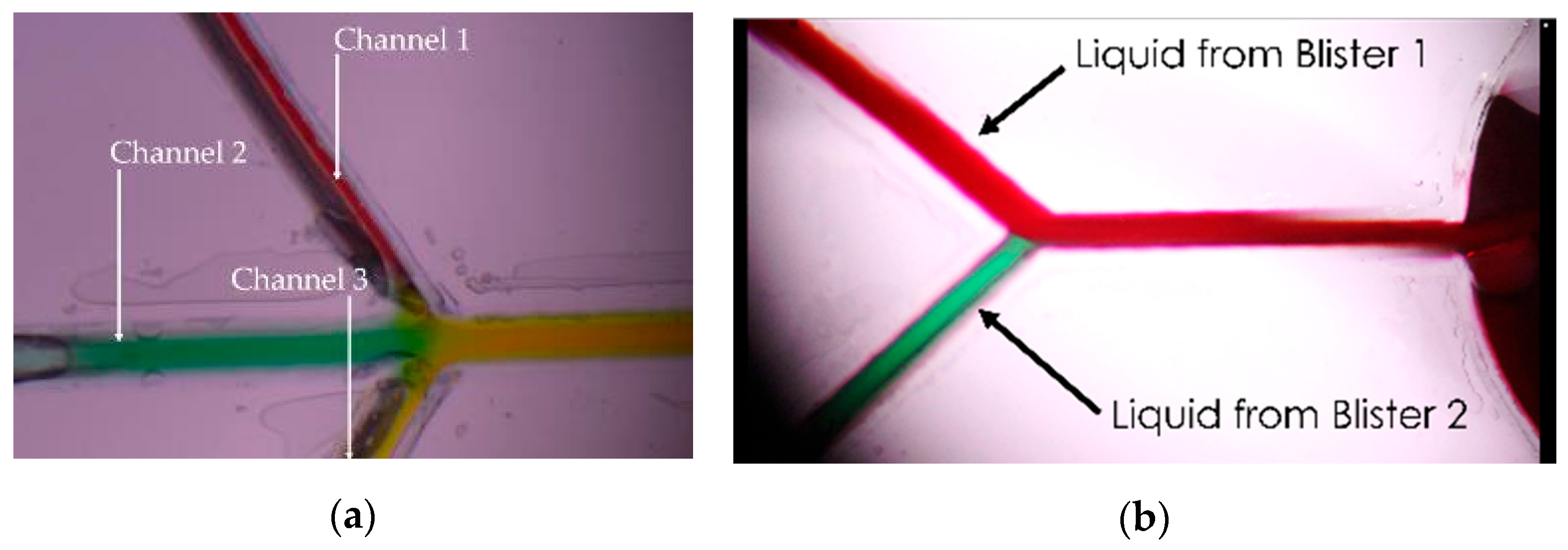

3. Results and Discussion

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Woolley, A.T.; Lao, K.; Glazer, A.N.; Mathies, R.A. Capillary Electrophoresis Chips with Integrated Electrochemical Detection. Anal. Chem. 1998, 70, 684–688. [Google Scholar] [CrossRef] [PubMed]

- Lake, J.R.; Heyde, K.C.; Ruder, W.C.; Wanunu, M. Low-cost feedback-controlled syringe pressure pumps for microfluidics applications. PLoS ONE 2017, 12, e0175089. [Google Scholar] [CrossRef] [PubMed]

- Yamada, M.; Seki, M. Nanoliter-Sized Liquid Dispenser Array for Multiple Biochemical Analysis in Microfluidic Devices. Anal. Chem. 2004, 76, 895–899. [Google Scholar] [CrossRef] [PubMed]

- Kazemzadeh, A.; Eriksson, A.; Madou, M.; Russom, A. A micro-dispenser for long-term storage and controlled release of liquids. Nat. Commun. 2019, 10, 189. [Google Scholar] [CrossRef] [PubMed]

- Castillo-León, J.; Svendsen, W.E. (Eds.) Lab-on-a-Chip Devices and Micro-Total Analysis Systems; Springer: Cham, Switzerland, 2015. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kakaza, M.T.; Scriba, M.R. Development of a Microfluidic Liquid Dispensing System for Lab-on-Chips. Eng. Proc. 2025, 109, 13. https://doi.org/10.3390/engproc2025109013

Kakaza MT, Scriba MR. Development of a Microfluidic Liquid Dispensing System for Lab-on-Chips. Engineering Proceedings. 2025; 109(1):13. https://doi.org/10.3390/engproc2025109013

Chicago/Turabian StyleKakaza, Masibulele T., and Manfred R. Scriba. 2025. "Development of a Microfluidic Liquid Dispensing System for Lab-on-Chips" Engineering Proceedings 109, no. 1: 13. https://doi.org/10.3390/engproc2025109013

APA StyleKakaza, M. T., & Scriba, M. R. (2025). Development of a Microfluidic Liquid Dispensing System for Lab-on-Chips. Engineering Proceedings, 109(1), 13. https://doi.org/10.3390/engproc2025109013