Stress and Temperature Monitoring of Bridge Structures Based on Data Fusion Analysis †

Abstract

1. Introduction

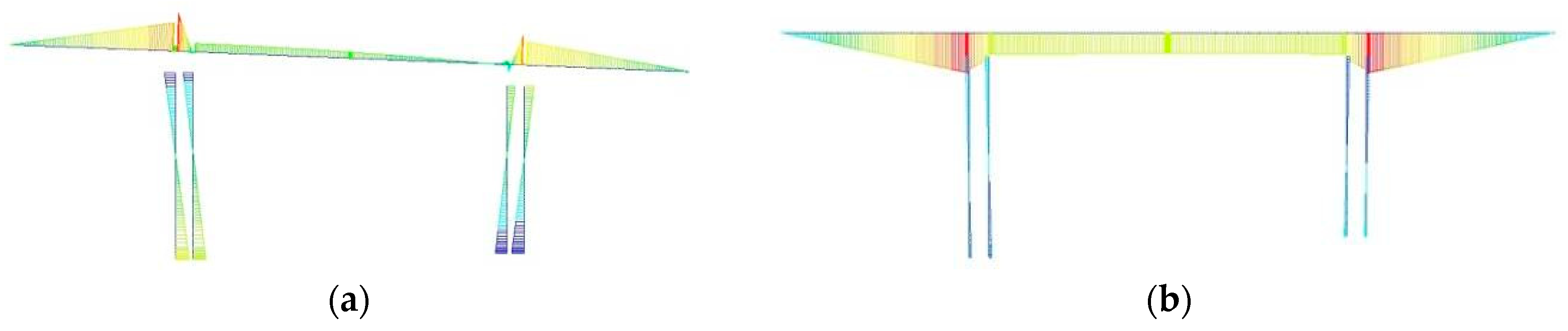

2. Data Processing and Fusion

2.1. Outlier Processing

- Independent variables must have a significant effect on the dependent variable and present a close linear correlation.

- The linear correlation between independent and dependent variables must be genuine rather than merely formal.

- Independent variables must have a certain degree of exclusivity, meaning the degree of correlation between independent variables must not be higher than that between the independent variables and the dependent variable.

- Independent variables must have complete statistical data, and their predicted values should be easily determined.

- Step 1: The characteristic quantification, data standardization, and smoothing of the extreme or of the standardized data are necessary to avoid calculation errors caused by large differences in values. According to Equation (2), if {} is close to , there are abnormal data.

- Step 2: The gross error criteria is set according to the amount of data n, probability distribution, or skewness and peak , and the number of abnormal data j.

- Step 3: Given the significance level , the two kinds of errors of discarding the true and taking the false in the gross error discrimination are identified. Generally, = 0.05 or 0.01 is used for a small number of samples. In large samples, the required confidence probability is p = 1 − .

- Step 4: The statistics of the selected gross error are obtained to assess the influence of abnormal data.

- Step 5: The critical value of the test is determined to determine the critical value of the statistics under .

- Step 6: It is inferred whether there is a gross error according to the rejection field (Re) of the inspection. If there is a gross error, the corresponding abnormal data are eliminated. Otherwise, it is considered that there is no gross error, and the suspicious data are retained.

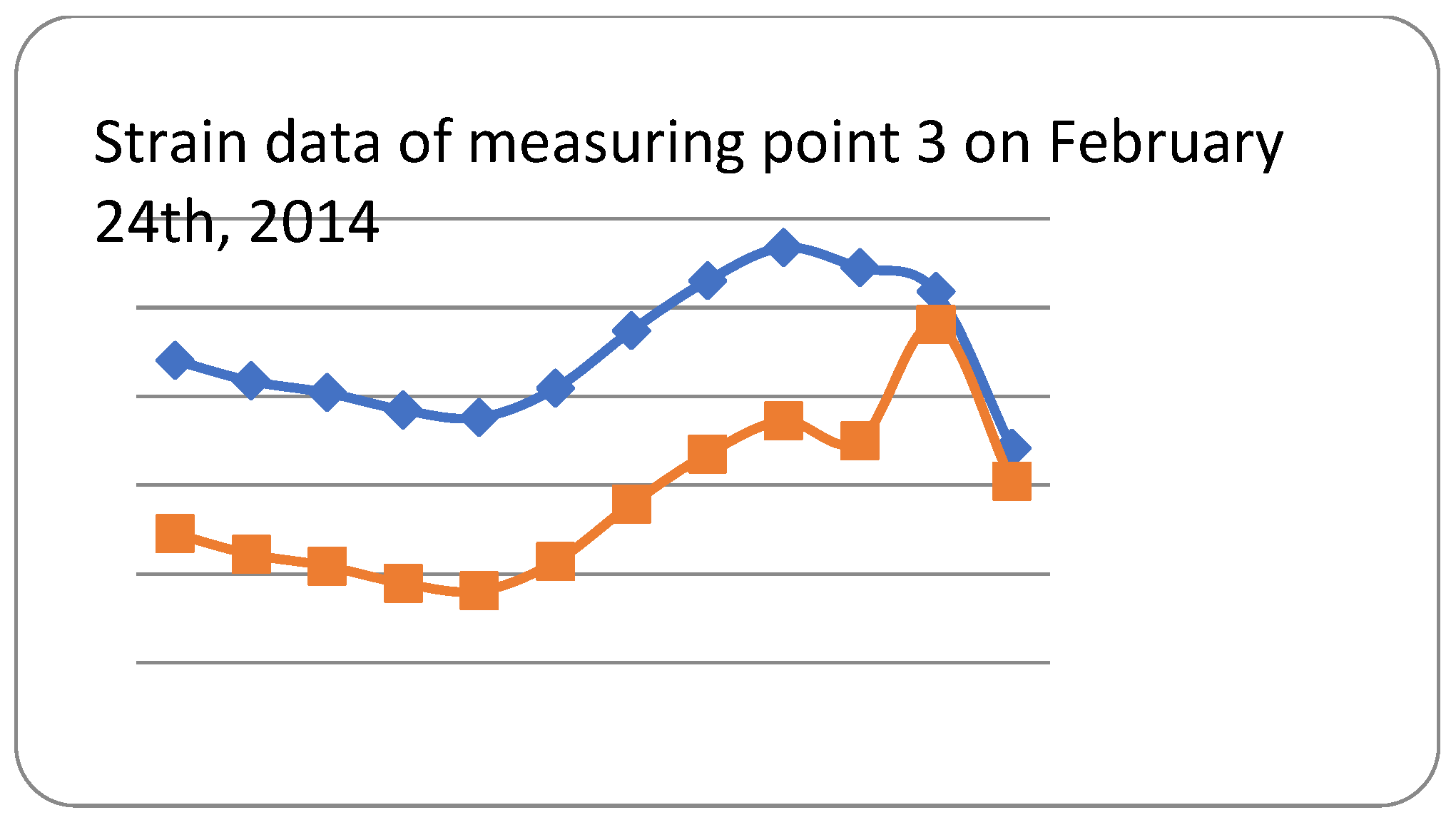

2.2. Improvement of Strain Outlier Processing Method

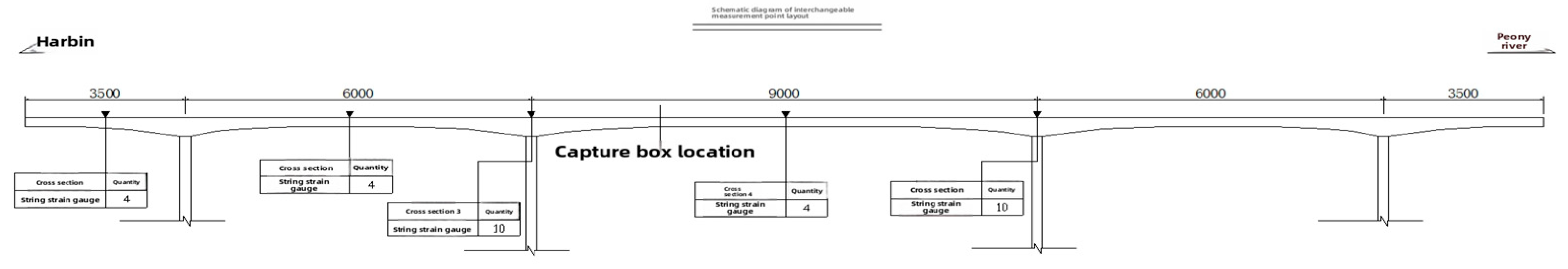

3. Monitoring Strain and Temperature

3.1. Temperature Compensation for Strain Data

3.2. Influence of Temperature on Sensors

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Järvinen, T.; Kannus, P.; Maffulli, N.; Khan, K. Achilles tendon disorders: Etiology and epidemiology. Foot Ankle Clin. 2005, 10, 255–266. [Google Scholar] [CrossRef] [PubMed]

- Rejeb, A.; Rejeb, K.; Zailani, S.; Treiblmaier, H.; Hand, K.J. Integrating the Internet of Things in the halal food supply chain: A systematic literature review and research agenda. Internet Things 2021, 13, 100361. [Google Scholar] [CrossRef]

- Sayeed, A.; Verma, C.; Kumar, N.; Koul, N.; Illés, Z. Approaches and challenges in internet of robotic things. Future Internet 2022, 14, 265. [Google Scholar] [CrossRef]

- Rodrigues, J.J.; Segundo, D.B.D.R.; Junqueira, H.A.; Sabino, M.H.; Prince, R.M.; Al-Muhtadi, J.; De Albuquerque, V.H.C. Enabling technologies for the internet of health things. IEEE Access 2018, 6, 13129–13141. [Google Scholar] [CrossRef]

- Engel, M.S.; Paas, B.; Schneider, C.; Pfaffenbach, C.; Fels, J.J.C. Perceptual studies on air quality and sound through urban walks. Cities 2018, 83, 173–185. [Google Scholar] [CrossRef]

- García, L.; Parra, L.; Jimenez, J.M.; Parra, M.; Lloret, J.; Mauri, P.V.; Lorenz, P. Deployment strategies of soil monitoring WSN for precision agriculture irrigation scheduling in rural areas. Sensors 2021, 21, 1693. [Google Scholar] [CrossRef] [PubMed]

- Millar, N.; Murrell, G.; McInnes, I. Inflammatory mechanisms in tendinopathy–towards translation. Nat. Rev. Rheumatol. 2017, 13, 110–122. [Google Scholar] [CrossRef] [PubMed]

- Ahmad, I.; Asghar, Z.; Kumar, T.; Li, G.; Manzoor, A.; Mikhaylov, K.; Shah, S.A.; Höyhtyä, M.; Reponen, J.; Huusko, J.; et al. Emerging technologies for next generation remote health care and assisted living. IEEE Access 2022, 10, 56094–56132. [Google Scholar] [CrossRef]

- Champier, D. Thermoelectric generators: A review of applications. Energy Convers. Manag. 2017, 140, 167–181. [Google Scholar] [CrossRef]

- Oswald-Tranta, B. Detection and characterisation of short fatigue cracks by inductive thermography. QIRT J. 2022, 19, 239–290. [Google Scholar] [CrossRef]

- Lee, J.-H.; Kalkan, I. Analysis of thermal environmental effects on precast, prestressed concrete bridge girders: Temperature differentials and thermal deformations. Adv. Struct. Eng. 2012, 15, 447–460. [Google Scholar] [CrossRef]

- Prastiyo, W.; Fiebig, W. Multibody simulation and statistical comparison of the linear and progressive rate double wishbone suspension dynamical behavior. Simul. Model. Pract. Theory 2021, 108, 102273. [Google Scholar] [CrossRef]

- Haghighat, E.; Raissi, M.; Moure, A.; Gomez, H.; Juanes, R. A deep learning framework for solution and discovery in solid mechanics. arXiv 2020, arXiv:2003.02751. [Google Scholar] [CrossRef]

- Devi, S.S.; Roy, A.; Singha, J.; Sheikh, S.A.; Laskar, R.H. Malaria infected erythrocyte classification based on a hybrid classifier using microscopic images of thin blood smear. Multimed. Tools Appl. 2018, 77, 631–660. [Google Scholar] [CrossRef]

- Abberley, P. The concept of oppression and the development of a social theory of disability. Disabil. Handic. Soc. 1987, 2, 5–19. [Google Scholar] [CrossRef]

- Saberironaghi, A.; Ren, J.; El-Gindy, M. Defect detection methods for industrial products using deep learning techniques: A review. Algorithms 2023, 16, 95. [Google Scholar] [CrossRef]

| Temperature (°C) | −8 | −10 | −12 | −14 | −16 | −18 | −20 |

|---|---|---|---|---|---|---|---|

| ) | −3.71325 | −19.5113 | −19.9027 | −15.5107 | −26.7253 | −25.8405 | −33.9823 |

| Temperature | 0–−5 °C | −5–30 °C | −30–40 °C |

|---|---|---|---|

| Coefficient of linear expansion | /°C | /°C | /°C |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ni, Z.; Cai, S.; Ni, C.; Lin, B.; Li, L. Stress and Temperature Monitoring of Bridge Structures Based on Data Fusion Analysis. Eng. Proc. 2025, 108, 19. https://doi.org/10.3390/engproc2025108019

Ni Z, Cai S, Ni C, Lin B, Li L. Stress and Temperature Monitoring of Bridge Structures Based on Data Fusion Analysis. Engineering Proceedings. 2025; 108(1):19. https://doi.org/10.3390/engproc2025108019

Chicago/Turabian StyleNi, Zhensong, Shuri Cai, Cairong Ni, Baojia Lin, and Liyao Li. 2025. "Stress and Temperature Monitoring of Bridge Structures Based on Data Fusion Analysis" Engineering Proceedings 108, no. 1: 19. https://doi.org/10.3390/engproc2025108019

APA StyleNi, Z., Cai, S., Ni, C., Lin, B., & Li, L. (2025). Stress and Temperature Monitoring of Bridge Structures Based on Data Fusion Analysis. Engineering Proceedings, 108(1), 19. https://doi.org/10.3390/engproc2025108019