Systematic Literature Review: 3D Printing Technology for Sustainable Construction Innovation †

Abstract

1. Introduction

Goal of the Review

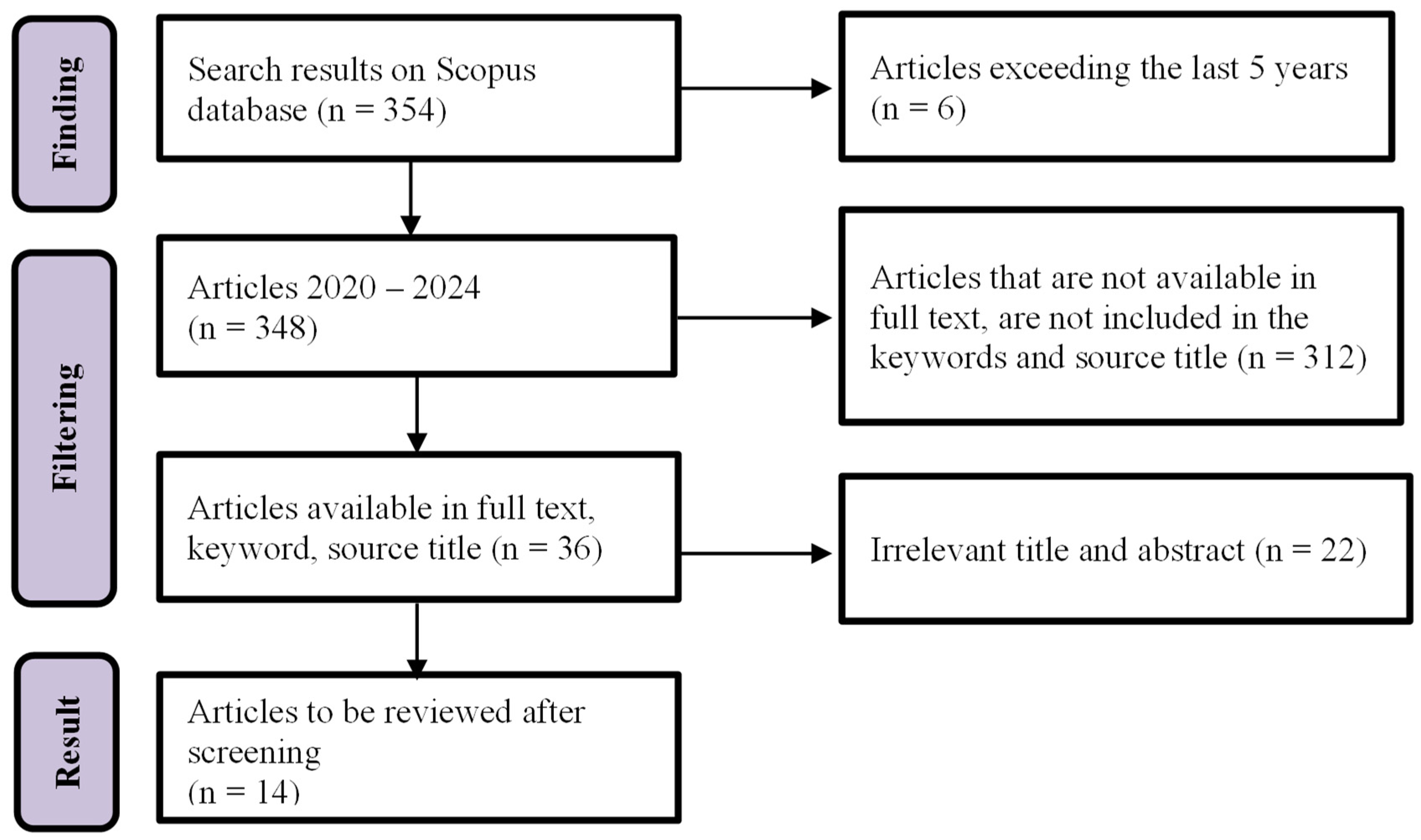

2. Methodology

2.1. Systematic Approach in Literature Review

2.2. Data Collection Process

2.3. Selection of Inclusion and Exclusion Criteria

2.4. Data Analysis

3. Result and Discussion

3.1. Three-Dimensional Printing Technology Improve Sustainable Construction Practices

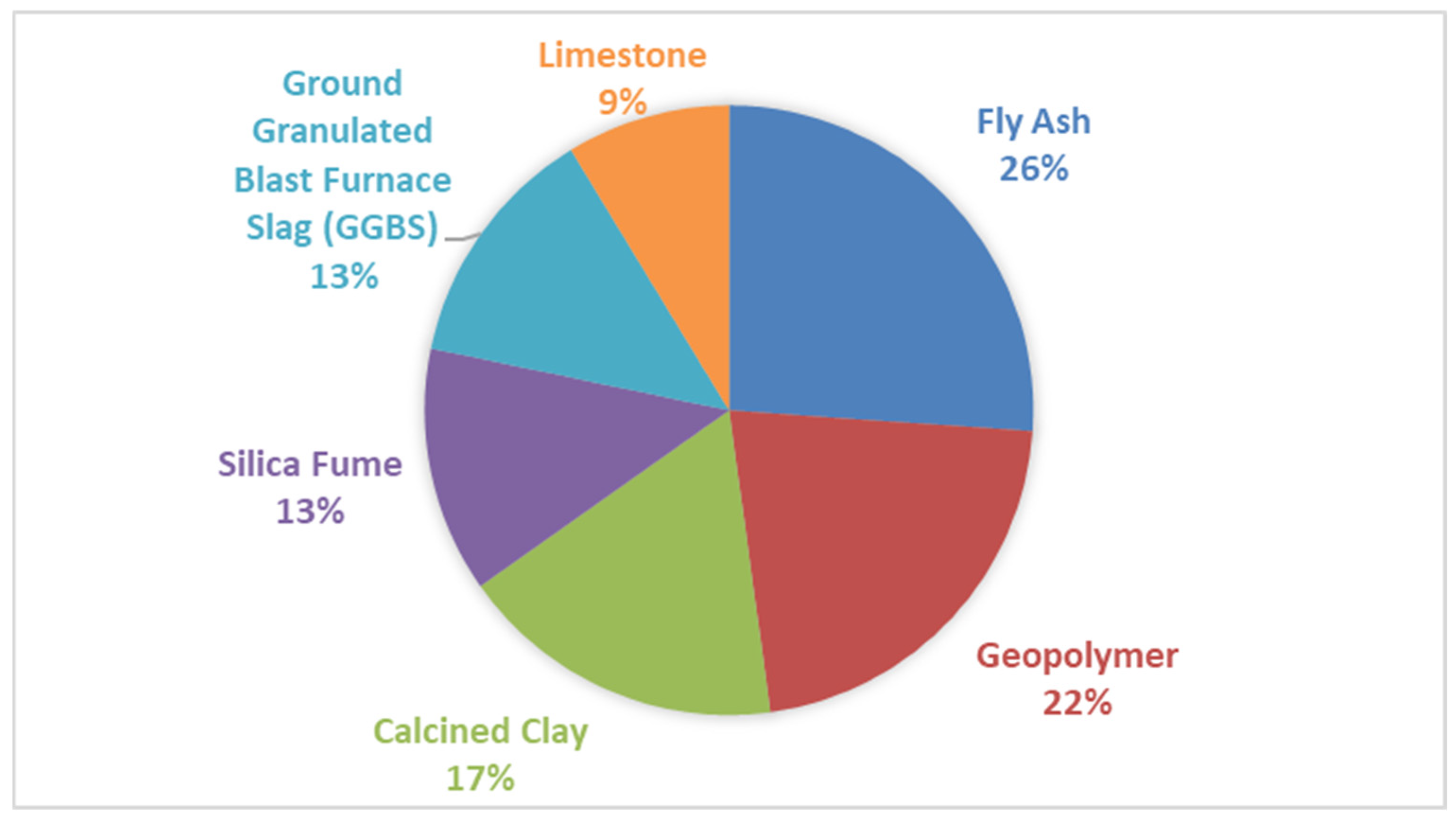

3.2. The Used Materials in 3D Printing for Sustainable Construction

3.3. The Environmental Impact of Using 3D Printing Technology Compared to Traditional Construction Methods

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Shahrubudin, N.; Lee, T.C.; Ramlan, R. An overview on 3D printing technology: Technological, materials, and applications. Procedia Manuf. 2019, 35, 1286–1296. [Google Scholar] [CrossRef]

- Scott, J.A.; Weber, C.L.; Newsome, S.; Wohlers, T.T. Additive manufacturing: Status and Opportunities. 2012. Available online: https://www.researchgate.net/publication/312153354 (accessed on 8 December 2024).

- Tay, Y.W.D.; Paul, S.C.; Mohamed, N.A.N.; Tan, M.J. 3D printing trends in building and construction industry: A review. Virtual Phys. Prototyp. 2017, 12, 261–276. [Google Scholar] [CrossRef]

- Ben Romdhane, L. 3D Printing in Construction: Benefits and Challenges. 2020. Available online: https://api.semanticscholar.org/CorpusID:233255105 (accessed on 8 December 2024).

- Yin, H.; Qu, M.; Zhang, H.; Lim, Y. 3D printing and buildings: A technology review and future outlook. Technol. Archit. Des. 2018, 2, 94–111. [Google Scholar] [CrossRef]

- Zhao, Z.; Ji, C.; Xiao, J.; Yao, L.; Lin, C.; Ding, T.; Ye, T. A critical review on reducing the environmental impact of 3D printing concrete: Material preparation, construction process and structure level. Constr. Build. Mater. 2023, 409, 133887. [Google Scholar] [CrossRef]

- Jagoda, J.A.; Diggs-McGee, B.N.; Kreiger, M.A.; Schuldt, S. The viability and simplicity of 3D-printed construction: A military case study. Infrastructures 2020, 5, 35. [Google Scholar] [CrossRef]

- Perkins, I.; Skitmore, M. Three-dimensional printing in the construction industry: A review. Int. J. Constr. Manag. 2015, 15, 1–9. [Google Scholar] [CrossRef]

- Tabassum, T.; Mir, A.A. A review of 3D printing technology: The future of sustainable construction. In Materialstoday Proceedings, Proceedings of UKIERI Concrete Congress–‘Sustainable Concrete Infrastructure’, Jalandhar, India, 14–17 March 2023; Elsevier: Amsterdam, Netherlands, 2023. [Google Scholar] [CrossRef]

- Khan, S.A.; Jassim, M.; Ilcan, H.; Şahin, O.; Bayer, I.R.; Sahmaran, M.; Koç, M. 3D printing of circular materials: Comparative environmental analysis of materials and construction techniques. CSCM 2023, 18, e02059. [Google Scholar] [CrossRef]

- Guimarães, A.S.; Delgado, J.M.P.Q.; Lucas, S.S. Thermal and environmental benefits of 3D printing on building construction. Defect Diffus. Forum 2021, 412, 99–106. [Google Scholar] [CrossRef]

- Liu, S.; Lu, B.; Li, H.; Pan, Z.; Jiang, J.; Qian, S. A comparative study on environmental performance of 3D printing and conventional casting of concrete products with industrial wastes. Chemosphere 2022, 307, 134310. [Google Scholar] [CrossRef]

- Sizirici, B.; Fseha, Y.H.; Cho, C.-S.; Yildiz, I.; Byon, Y.-J. A review of carbon footprint reduction in construction industry, from design to operation. Materials 2021, 14, 6094. [Google Scholar] [CrossRef]

- Ürge-Vorsatz, D.; Khosla, R.; Bernhardt, R.; Chatterjee, S.; Daniel, N.; Dhakal, S.; Fishman, T.; Habert, G.; Lucon, O.; Pyke, C.; et al. Advances toward a net-zero global building sector. Annu. Rev. Environ. Resour. 2020, 45, 227–269. [Google Scholar] [CrossRef]

- Kim, S. Technology and management for sustainable buildings and infrastructures. Sustainability 2021, 13, 9380. [Google Scholar] [CrossRef]

- Ma, Z.; Awan, M.B.; Lu, M.; Li, S.; Aziz, M.S. An overview of emerging and sustainable technologies for increased energy efficiency and carbon emission mitigation in buildings. Buildings 2023, 13, 2658. [Google Scholar] [CrossRef]

- Top, S.M.; Cudzik, J.; İlerisoy, Z.Y. A comprehensive review of life cycle assessment and energy efficiency in 3D printing for construction: Current state, benefits, limitations, and future outlook. J. Green Build. 2024, 19, 111–132. [Google Scholar] [CrossRef]

- Ebrahimi, M.; Mohseni, M.; Aslani, A.; Zahedi, R.M. Investigation of thermal performance and life-cycle assessment of a 3D printed building. Energy Build. 2022, 271, 112341. [Google Scholar] [CrossRef]

- Lai, Z.; Chen, Y. From wreckage to resource: Advanced 3D printing materials from construction waste for energy infrastructure. J. Renew. Sustain. Energy 2024, 16, 026103. [Google Scholar] [CrossRef]

- Raja, S.; Al-Tmimi, H.M.; Ghadir, G.K.; Mustafa, M.A.; Alani, Z.K.; Rusho, M.A.; Rajeswari, N. An analysis of polymer material selection and design optimization to improve structural integrity in 3D printed aerospace components. Appl. Chem. Eng. 2024, 7, 1875. [Google Scholar] [CrossRef]

- Dikit, M.K. 3-D printing in building construction: A literature review of opportunities and challenges of reducing life cycle energy and carbon of buildings. In Proceedings of the IOP Conference Series: Earth and Environmental Science, Proceedings of the Central Europe Towards Sustainable Building (CESB19), Prague, Czech, 2–4 July 2019; IOP Publishing: Bristol, UK, 2019; Volume 290. [Google Scholar] [CrossRef]

- Leong, W.Y.; Leong, Y.Z.; Leong, W.S. Accelerating the energy transition via 3D printing. In Proceedings of the 2023 Asia Meeting on Environment and Electrical Engineering (EEE-AM), Hanoi, Vietnam, 13–15 November 2023. [Google Scholar] [CrossRef]

- Alawneh, M. The World’s First 3D–Printed Office Building in Dubai. 2018. Available online: https://www.academia.edu/62935073/The_World_s_First_3D_PRINTED_Office_Building_in_Dubai (accessed on 9 December 2024).

- Tahmasebinia, F.; Sepasgozar, S.M.E.; Shirowzhan, S.; Niemela, M.; Tripp, A.; Nagabhyrava, S.; Mansuri, K.K.Z.; Alonso-Marroquin, F. Criteria development for sustainable construction manufacturing in Construction Industry 4.0: Theoretical and laboratory investigations. Construct. Innov. 2020, 20, 379–400. [Google Scholar] [CrossRef]

- Nadagouda, M.N.; Ginn, M.; Rastogi, V. A review of 3D printing techniques for environmental applications. Curr. Opin. Chem. Eng. 2020, 28, 173–178. [Google Scholar] [CrossRef]

- Ibrahim, I.; Eltarabishi, F.; Abdalla, H.; Abdallah, M. 3D printing in sustainable buildings: Systematic review and applications in the United Arab Emirates. Buildings 2022, 12, 1703. [Google Scholar] [CrossRef]

- Zhuang, Z.; Xu, F.; Ye, J.; Hu, N.; Jiang, L.; Weng, Y. A comprehensive review of sustainable materials and toolpath optimization in 3D concrete printing. npj Mater. Sustain. 2024, 3, 17. [Google Scholar] [CrossRef]

- Thajeel, M.M.; Balázs, G.L. 3D printing for earth construction—Review. Concr. Struct. 2022, 1, 77–89. [Google Scholar] [CrossRef]

- Tusnim, J.; Hoque, E.; Biswas, M.C. Biopolymers in building materials. In Biopolymers and Biotech Admixtures for Eco-Efficient Construction Materials; Elsevier: Amsterdam, The Netherlands, 2020; pp. 229–248. [Google Scholar] [CrossRef]

- Khan, M.; McNally, C. Recent developments on low carbon 3D printing concrete: Revolutionizing construction through innovative technology. Clean. Mater. 2024, 12, 100251. [Google Scholar] [CrossRef]

- Al-Noaimat, Y.A.; AbouRizk, S.M.; Al-Ghamdi, S.G.; Tayeh, B.A.; Abu-Dagga, A.H.; Al-Sakkaf, A.; Abu-Obeid, N. 3D printing of limestone–calcined clay cement: A review of its potential implementation in the construction industry. Results Eng. 2023, 19, 101115. [Google Scholar] [CrossRef]

- Ibrahim, K.A.; van Zijl, G.P.A.G.; Babafemi, A.J. Influence of limestone calcined clay cement on properties of 3D printed concrete for sustainable construction. SSRN 2023. [Google Scholar] [CrossRef]

- Rasulzade, J.; Maksum, Y.; Nogaibayeva, M.; Rustamov, S.; Akhmetov, B. Reduction of material usage in 3D printable structures using topology optimization accelerated with U-net convolutional neural network. Eurasian Chem. J. 2022, 24, 233–240. [Google Scholar] [CrossRef]

- Alimrani, N.; Thajeel, M.M.; Balázs, G.L. Structural aspects of topology optimization in 3D printing of concrete. Concr. Struct. 2022, 1, 45–54. [Google Scholar] [CrossRef]

- Jones, A.; Cameron, T.; Eichholz, B.; Eichers, M.; Kray, T.; Straub, J. Reducing space sensing and other mission cost with 3D printing infill optimization. In Proceedings of the SPIE Defense+Commercial Sensing 2019, Baltimore, MD, USA, 14–18 April 2019. [Google Scholar] [CrossRef]

- Pereira, G.R.; Gasi, F.; Lourenço, S.R. Review, analysis, and classification of 3D printing literature: Types of research and technology benefits. Int. J. Adv. Eng. Res. Sci. 2019, 6, 116–122. [Google Scholar] [CrossRef]

- Wankhade, P.D.; Jawarkar, S.G.; Jadhao, D.M.P. A synopsis of 3D printing technology: Materials, applications and technology. Int. J. Multidiscip. Res. 2024, 6, 1–8. [Google Scholar]

- Spicek, N.; Besklubova, S.; Skibniewski, M.J. Benchmarking critical success factors in construction projects utilizing 3D printing technology. Int. J. Appl. Sci. Eng. 2023, 20, 1–13. [Google Scholar] [CrossRef]

- Christ, J.; Leusink, S.; Koss, H. Multi-axial 3D printing of biopolymer-based concrete composites in construction. Mater. Des. 2023, 235, 112410. [Google Scholar] [CrossRef]

- Pati, D.; Lorusso, L.N. How to write a systematic review of the literature. HERD Health Environ. Res. Des. J. 2018, 11, 15–30. [Google Scholar] [CrossRef]

- Hassan, F.; Othman, S.S.; Yusoff, S.H.; Ali, K.; Omar, S.Z.; Musaddad, M.A. A systematic literature review of knowledge and awareness on terrorism. Eur. Proc. Soc. Behav. Sci. 2022, 117, 166–177. [Google Scholar] [CrossRef]

- Page, M.J.; McKenzie, J.E.; Bossuyt, P.M.; Boutron, I.; Hoffmann, T.C.; Mulrow, C.D.; Shamseer, L.; Tetzlaff, J.M.; Akl, E.A.; Brennan, S.E.; et al. The PRISMA 2020 statement: An updated guideline for reporting systematic reviews. BMJ 2021, 372, n71. [Google Scholar] [CrossRef] [PubMed]

- Ning, X.; Liu, T.; Wu, C.; Wang, C. 3D printing in construction: Current status, implementation hindrances, and development agenda. Adv. Civ. Eng. 2021, 2021, 6665333. [Google Scholar] [CrossRef]

- Žujović, M.; Obradović, R.; Rakonjac, I.; Milošević, J. 3D Printing Technologies in Architectural Design and Construction: A Systematic Literature Review. Buildings 2022, 12, 1319. [Google Scholar] [CrossRef]

- Varillas, C.J.N.; Espinoza, M.S.R.; Gamboa, A.C.G. 3D printing: An opportunity for the sustainable development of building construction. In Proceedings of the 40th International Symposium on Automation and Robotics in Construction (ISARC 2023), Chennai, India, 3–6 July 2023; pp. 692–699. [Google Scholar] [CrossRef]

- Baas, J.; Schotten, M.; Plume, A.M.; Côté, G.; Karimi, R. Scopus as a curated, high-quality bibliometric data source for academic research in quantitative science studies. Quant. Sci. Stud. 2020, 1, 377–386. [Google Scholar] [CrossRef]

- Brackett, A.; Batten, J. Ensuring the rigor in systematic reviews: Part 4, screening the results. Heart Lung J. Crit. Care 2021, 50, 182–184. [Google Scholar] [CrossRef]

- Youssef, M.A.; Abbas, L. Applying 3D printing technology in constructing sustainable houses. Archit. Plan. J. 2023, 29, 1190. [Google Scholar] [CrossRef]

- Bhusal, S.; Kshirsagar, S.B. Comparison of construction with traditional method and 3D printing technology. IRE J. 2020, 3, 93–97. [Google Scholar]

- Babbar, A.; Rai, A.; Sharma, A. Latest trend in building construction: Three-dimensional printing. J. Phys. Conf. Ser. 2021, 1950, 012007. [Google Scholar] [CrossRef]

- Oke, A.E.; Atofarati, J.O.; Folasade, S. Awareness of 3D Printing for Sustainable Construction in an Emerging Economy. Australas. J. Constr. Econ. Build. 2022, 22, 52–68. [Google Scholar] [CrossRef]

- Ebadi-jamkhaneh, M.; Kontoni, D.N.; Ebrahimi, A.H. Three-Dimensional Printing of Structural Members with Shotcrete Technique: Design, Construction, and Future Directions. E3S Web Conf. 2023, 436, 08010. [Google Scholar] [CrossRef]

- Flatt, R.J.; Wangler, T. On sustainability and digital fabrication with concrete. Cem. Concr. Res. 2022, 158, 106837. [Google Scholar] [CrossRef]

- Ambekar, R.S.; Kumar, S.; Park, J.; Kumar, A.; Kim, D.; Lee, H.; Kim, K.; Kang, M. Topologically engineered 3D printed architectures with superior mechanical strength. Mater. Today 2021, 48, 72–94. [Google Scholar] [CrossRef]

- Brüggemann, H.; Stempin, S.; Meier, J.-M. Consideration of digitalization for the purpose of resource efficiency in a learning factory. Procedia Manuf. 2020, 45, 140–145. [Google Scholar] [CrossRef]

- Nilimaa, J. Smart materials and technologies for sustainable concrete construction. Dev. Built Environ. 2023, 15, 100177. [Google Scholar] [CrossRef]

- Pasupathy, K.; Ramakrishnan, S.; Sanjayan, J. 3D concrete printing of eco-friendly geopolymer containing brick waste. Cem. Concr. Compos. 2023, 138, 104943. [Google Scholar] [CrossRef]

- Bhattacherjee, S.; Basavaraj, A.; Rahul, A.V.; Santehanam, M.; Gettu, R.; Panda, B.; Schlangen, E.; Chen, Y.; Cpuroglu, O.; Ma, G.; et al. Sustainable materials for 3D concrete printing. Cem. Concr. Compos. 2021, 122, 104156. [Google Scholar] [CrossRef]

- Asensio, J.; Josa, I.; Monserrat, A.; De Fuente, A. 3D-printed concrete footbridges: An approach to assess the sustainability performance. Struct. Concr. 2023, 24, 7705–7725. [Google Scholar] [CrossRef]

- Moscatelli, M. Preserving Tradition through Evolution: Critical Review of 3D Printing for Saudi Arabia’s Cultural Identity. Buildings 2024, 14, 697. [Google Scholar] [CrossRef]

- Soh, E.; Heng, J.; Leong, B.; Xing, T.; Le, H. 3D printing of mycelium engineered living materials using a waste-based ink and non-sterile conditions. Mater. Des. 2023, 236, 112481. [Google Scholar] [CrossRef]

- Jano, L.C.; Obregon, P.P.; Lázaro, M.; Fernandez, E.B. Enhancing sustainability in polymer 3D printing via fusion filament fabrication through integration of by-products in powder form: Mechanical and thermal characterization. Int. J. Adv. Manuf. Technol. 2024, 133, 1251–1269. [Google Scholar] [CrossRef]

- Biggerstaff, A.; Fuller, G.; Lepech, M.; Loftus, D. Determining the yield stress of a biopolymer-bound soil composite for extrusion-based 3D printing applications. Constr. Build. Mater. 2021, 305, 124730. [Google Scholar] [CrossRef]

| Title | Technology 3D Printing Application | Material | Impact of 3D Printing |

|---|---|---|---|

| Awareness of 3D Printing for Sustainable Construction in an Emerging Economy | Enables layer-by-layer control, providing design flexibility, reducing waste, and speeding up the construction process in molding concrete elements, window frames, and plumbing fittings. | Concrete, plastic, nylon, ceramic paste and photo-curative resin | Removes the need for formwork, which cuts down on construction time and expenses |

| Sustainable materials for 3D concrete printing | Printing concrete structures with special materials designed to meet the needs of extrudability, shape stability, and strength | Geopolymer, calcium sulfo-aluminate (CSA) cement, and reactive magnesium oxide cement | Reduced material waste, design flexibility for complex structures, energy efficiency, and costs |

| On sustainability and digital fabrication with concrete | Reduces the need for excess material through more efficient designs, such as complex geometric shapes and lightweight structures, and enables high-precision layer-by-layer printing to optimize materials | Concrete without coarse aggregate, fly ash, slag, and calcined clay, geopolymer, or calcium sulfo-aluminate-based mixtures | Reducing labor costs through automation and reducing construction time |

| 3D concrete printing of eco-friendly geopolymer containing brick waste | 3D printing technology is applied by utilizing environmentally friendly geopolymer materials and creating layered structures without molding. | Finely ground brick waste, geopolymer binder based on slag, fly ash, and sodium metasilicate, silica sand, nano clay | Efficiency, speeding up the construction process, and reducing production time |

| Influence of limestone calcined clay cement on properties of 3D printed concrete for sustainable construction | 3D printing technology is applied using Limestone Calcined Clay Cement (LC3) to reduce carbon emissions, increase material efficiency, and minimize material use. | Limestone Calcined Clay Cement (LC3) | Reduced costs, more environmentally friendly, and construction time is also reduced |

| Smart materials and technologies for sustainable concrete construction | This method allows reducing material waste, optimizing resources, and applying the concept of design for sustainability to concrete components with high precision and complex geometric shapes. | Fly ash, silica fume, and ground granulated blast-furnace slag (GGBS), green concrete, geopolymer binders | Reduce time and costs in production |

| 3D-printed concrete footbridges: An approach to assess the sustainability performance | 3D printing technology is applied in the construction of footbridges based on 3D-printed concrete, and this application reduces carbon emissions by up to 40%. | Cementitious composites, concrete mortar, polyethylene fiber, post-tensioned steel cables, and local aggregates to support sustainability | Reducing labor, reducing material costs |

| Multi-axial 3D printing of biopolymer-based concrete composites in construction | Printing concrete components with free geometry. | The hydrogel is based on mammalian gelatin, silica sand with a particle size of ≤0.18 mm, and water | Cost and time efficiency |

| 3D printing of mycelium engineered living materials using a waste-based ink and non-sterile conditions | Mycelium proliferation to strengthen the structure and produce features such as self-healing and natural adhesive. | Agar, coffee grounds, liquid mycelium (Pleurotus ostreatus), malt, and peptone | Cost and time efficiency |

| Preserving Tradition through Evolution: Critical Review of 3D Printing for Saudi Arabia’s Cultural Identity | 3D printing technology is applied to create structures that combine traditional and innovative elements that can reduce carbon footprints, material efficiency, and complex architectural designs. | Limestone and calcined clay, local clay, bioplastics or industrial waste (crushed glass and scrap metal), and fibers from local plants, such as mud and straw | Cost and time efficiency |

| An approach to develop set-on-demand 3D printable limestone–calcined clay-based cementitious materials using calcium nitrate | Extrusion-based 3D concrete printing (3DCP) technology is applied using limestone–calcined clay cement (LC3)-based material, enabling efficient and sustainable layer-by-layer molding. | Portland Cement (CEM I 52.5 R), limestone powder and calcined clay, calcium nitrate (Ca (NO3)2) solution, fine quartz aggregate, superplasticizer, and polycarboxylate | Cost efficiency, lower carbon footprint, time efficiency, and increase printing productivity without affecting structural stability |

| Fresh and strength properties of 3D printable concrete mixtures utilising a high volume of sustainable alternative binders | Three-dimensional printing technology is applied using extrusion-based concrete printing to produce concrete structures layer by layer without molds so as to reduce material consumption and carbon emissions. | Fly ash, silica fume, ground granulated blast furnace slag, metakaolin, kaolinite, fine aggregate, superplasticizer | Cost and time efficiency |

| Enhancing sustainability in polymer 3D printing via fusion flament fabrication through integration of by-products in powder form: mechanical and thermal characterization | Fused Filament Fabrication (FFF) technology combines shell powder, crushed car glass, and metal residue into plastic filament to reduce plastic consumption and create a more environmentally friendly filament material for 3D printing applications. | Polylactic Acid, PETg (Polyethylene Terephthalate Glycol-modified), seashells (calcium carbonate), crushed car glass, metal residue | Cost and time efficiency |

| Determining the yield stress of a Biopolymer-bound Soil Composite for extrusion-based 3D printing applications | Extrusion-based 3D printing (E3DP) technology is applied using biopolymer-bound soil composite (BSC) to produce a stable and environmentally friendly structure. | Bovine blood protein-based biopolymer, soil (lunar regolith simulant or JSC-1A), deionized water | Cost and time efficiency |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Marifah, S.L.; Saputri, U.S.; Permadi, D.D. Systematic Literature Review: 3D Printing Technology for Sustainable Construction Innovation. Eng. Proc. 2025, 107, 93. https://doi.org/10.3390/engproc2025107093

Marifah SL, Saputri US, Permadi DD. Systematic Literature Review: 3D Printing Technology for Sustainable Construction Innovation. Engineering Proceedings. 2025; 107(1):93. https://doi.org/10.3390/engproc2025107093

Chicago/Turabian StyleMarifah, Sofa Lailatul, Utamy Sukmayu Saputri, and Dio Damas Permadi. 2025. "Systematic Literature Review: 3D Printing Technology for Sustainable Construction Innovation" Engineering Proceedings 107, no. 1: 93. https://doi.org/10.3390/engproc2025107093

APA StyleMarifah, S. L., Saputri, U. S., & Permadi, D. D. (2025). Systematic Literature Review: 3D Printing Technology for Sustainable Construction Innovation. Engineering Proceedings, 107(1), 93. https://doi.org/10.3390/engproc2025107093