1. Introduction

Soil is a living system that maintains important biological, chemical, and ecological parameters and directly supports the functioning of many ecosystems, according to [

1,

2,

3]. One of the key concepts of soil testing is the ability to obtain representative soil samples to ensure the accuracy of the required data and the reliability of the results. The methodologies for collecting and processing soil samples have been thoroughly discussed by past authors [

4,

5].

A fundamental factor for precision agriculture is soil aggregate density, with profound implications for the growth and development of agricultural crops. It is a major factor for the proper planning of the future agronomic activities [

6]. Mechanical characteristics are typically assessed through methods that measure resistance. By mapping soil mechanical resistance, farmers can identify areas within their fields that may impede root growth. Both compacted soil zones and low water content can practically cause subsidence zones with high mechanical strength of the soil. Proper timing for mapping or examining the soil with a moisture sensor allows for delineation of areas requiring specific treatment.

The most popular measurement method is a standard vertical cone penetrometer, often used to measure the resistance required to penetrate a given diameter of the probe to a test depth in the soil [

7], serving as a key indicator of the degree of soil compaction. However, measurements obtained with the cone penetrometer, even when automated, are often time-consuming and yield highly variable results due to the random nature of the samples and the inherent heterogeneity of the soil composition. To overcome these issues, several prototype systems have been developed to enable the in situ measurement of soil mechanical properties.

Contact (mechanical) sensors provide precise information about the tested soil sample, yet they face limitations in accurately measuring areas with varying density across large regions, potentially resulting in the acquisition of sample data that is exclusively representative.

Any tillage equipment can be used to assess the changes in the forces acting during cutting (ploughing, cultivating, disking, etc.). The resistance during soil tillage, in the research conducted by [

8], was measured while ploughing. The study revealed the possibility of utilizing specific design maps to locate different soil types with different mechanical densities within a field.

Another approach, using a system with a set of five instruments attached to the back of a vertical straight blade, was proposed and tested in [

9]. The system is capable of estimating the mechanical soil cohesion force measured at three fixed depths. Similarly, in [

10,

11], researchers employed a comparable method by creating a sensor that measures soil density using eight separate load cells integrated within the body of a plough.

In other research conducted in ref. [

12,

13], the authors investigated the concept of using multiple horizontally positioned penetrometers to measure the mechanical resistance of the soil tested at five and six depths. The sensor they created provides discrete values for soil compaction at various depths, resulting in a comprehensive three-dimensional map of soil density.

The methods discussed so far are labour-intensive and are generally conducted independently for soil density measurements, necessitating additional resources and time. We believe that this can be accomplished during planned agronomic activities by soil tillage machines properly equipped with appropriate sensors. This approach allows for both processing of the soil and measuring its density to occur concurrently. In each of the cases examined so far, after measuring density with a mechanical sensor, this results in soil loosening without completing the necessary field processing.

1.1. Shear Stresses in Beams

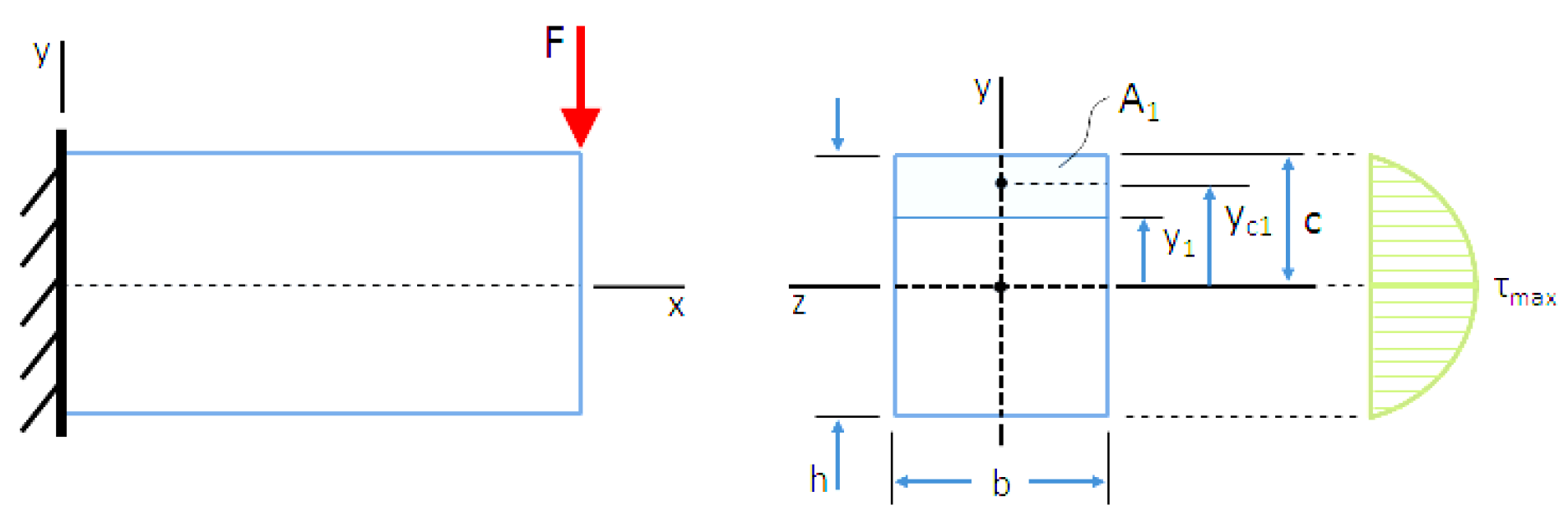

The value of the shear force

V, along the length of the beam, is quantified from the shear diagram. The shear force at any point along the beam is used to find the value of the shear stress on the cross-section of the beam at the point of study. The internal shear stress on the cross-section is obtained from the formula

Figure 1 shows the variation in shear stress, which varies with the shape of the cross-section [

14].

In the upper part (in the figure), the shear stress is equal to zero at the free surfaces and is maximum at the centroid. The equation for shear stress at any point located at a distance

y1 from the centroid of the cross-section is given by

where V is the magnitude of the shear force at the examined point of the cross-section,

is the moment of inertia in the cross-section of the area, and

b is the width of the cross-section. All concepts are assumed to be constants.

Q is the moment of the considered area limited between the end surfaces of the cross-section under consideration:

1.2. Shear Stresses in Rectangular Sections

The shear stress distribution τ in height of a rectangular cross-section is shown in

Figure 2:

The area moment at each considered point

y1, along the height of the cross-section, is calculated by

At the axis of the beam (where y

1 = 0), the maximum value of Q occurs:

The shear stress for each considered point

y1 of the cross-sectional height can be calculated by

where

Ic =

is the moment of inertia of the cross-sectional area. Maximum values for shear stress occur relative to the axes of symmetry of the beam and are calculated by

where

A = b·h is the area of the cross-section.

From the equation, it is clear that the maximum shear stress in the cross-section is 50% higher than the average stress .

The prime objective of the research is to examine and test the feasibility of measuring the mechanical properties of soil aggregates (e.g., density) by analyzing the loads and deformations in a ploughing body beam. Developed, to this effect, is a methodology using a standard strain gauge for small loads.

This study could also be beneficial for researchers in the field as well as for agricultural producers seeking to implement best practices in precision agriculture.

2. Materials and Methods

The installation of the strain gauge is carried out using the method depicted in

Figure 3 and

Figure 4, with the sensor mounted to measure the maximum shear stress.

The pulling force Ftrac generated by the movement of the agricultural machine (tractor) is responsible for pulling the reversing plough working implement. Due to the frictional forces between the soil aggregate Fs and the surface layer, a counterforce force Fr over the entire area of the working body that is in contact with the soil.

The resistance to shear caused by soil sliding, due to the frictional forces, originates from the particles in contact with the working implement. This force is dispersed over the entire area of the plough. Due to the heterogeneity of the soil aggregate, the force is unevenly distributed and is conditionally represented in

Figure 3 as a distributed load

Fs. Its correlation to its counterpart, a horizontal vector

Rfs, reveals that its point of application varies according to the soil composition and compacted zones. This force generates a tensile force in the plough shaft

Ft and a crushing force

Fp acting on the plough holder during ploughing. It is widely accepted that at the centre of this profile, these forces are equal to 0. By measuring the surface stresses from the centre to one end of the shaft profile, we can indirectly determine the magnitude of the force

Rfs, which is proportional to the soil density.

The ploughing body is attached to the beam using a stem with a cross-section of 80 × 25 mm. The stem is part of the reversible mounted ploughs “HEMUS” PLNR 4/4 L (

Figure 4), which allows for a maximum distance of 40 mm between the mounting holes of the strain gauge. To ensure stability without the need for drilling holes, the sensor is affixed securely with epoxy adhesive to create a contact surface comparable to one achieved through bolting [

15].

The strain gauge specifications are outlined in

Table 1.

To record the values accurately, the HX711 (

Figure 5) was utilized in conjunction with an Arduino STM32 and ADC module featuring a four-segment display. This setup allows for the analogue signal from the strain gauge to be displayed while maintaining communication with a computer or PLC [

16].

The installation process (involving adhesives) was carried out in such a way as to secure a 22 mm spacing between the bonding points. This is the spacing between the inner mounting holes. Thus, the strain gauge is placed at the highest point from the contact area between the plough and the soil. The reading module is strategically positioned outside the plough for easy access and optimal readability by the operator.

The system developed is designed to measure deformation on the shaft of the ploughing body, yet it is limited in its capacity to gauge the levels of the resisting force. For accurate interpretation of the results, it is necessary to perform calibration. This is achieved by attaching a scale to the plough and applying a tensile force equivalent to the resisting force of the soil.

3. Results and Discussion

A test was conducted in the experimental field using a standard penetrometer to compare the results. The findings of the test are recorded in

Table 2. The measurements were taken at discrete values with a range of 5 m in both width and length.

The calibration results, displayed in

Table 3, were obtained by affixing a weight measuring device to the centre of the ploughing body on which a pulling force was then applied, corresponding to the values listed in

Table 3.

The frontal area of the ploughing body used in the experiment was 0.11 m2. The calibration test involved applying a force on the ploughing body equal to the total resisting force.

The experimental results were differentiated over time, with measurements taken at one-second intervals while moving at the speed of 5 km/h. Assuming the speed remains constant, a continuous fertility graph for the tested area (

Figure 6) can be created. Fertility levels vary based on the soil densities, impacts from stones, and the presence of cavities. Areas with zero values occur before the movement commences and after its cessation.

A comparison was made between the results obtained from the penetrometer test and the measured values of surface stress on the shaft of the ploughing body. The collected values were assessed through linear regression analysis, and the results were analyzed via the use of Microsoft Excel from Office 365. A concise summary report is provided in

Table 4, while

Table 5 presents the ANOVA results.

The coefficient of determination, R Square = 0.906, indicates that the model explains 90.6% of the cases, demonstrating higher reliability of the obtained results when compared to those acquired from the penetrometer tests.

4. Conclusions

The model examined for measuring soil density by assessing surface deformations in the ploughing body shaft yields reliable results. The comparison between these findings and a standard penetrometer test results reveals similarity with a Multiple R = 0.95 and R Square = 0.90, even though one method examines discrete values and the other continuous values, indicating equivalence at the points of intersection.

The method, reviewed in the present paper, offers comprehensive information about the compaction zones within the soil aggregate, enabling the creation of a detailed map of the areas susceptible to compaction.

The low surface deformations of the metal in the shaft allow for the utilization of sensors with low load capacities. The elevated mounting location above the soil contact zone facilitates easy maintenance and ensures simultaneous system protection. The method measures soil density under standard agronomic practices, optimizing time and resources. Further enhancement of the system’s capabilities should include equipping it with a GPS receiver to capture the geographical coordinates of all measured points.

Author Contributions

Conceptualization, A.A.; methodology, A.A.; software, A.A. and A.B.; validation, A.B., formal analysis, A.A.; investigation, A.B.; resources, A.A.; data curation, A.A. and A.B.; writing—original draft preparation, A.B.; writing—review and editing, A.A.; visualization, A.A.; supervision, A.B.; project administration, A.A.; funding acquisition, A.B. All authors have read and agreed to the published version of the manuscript.

Funding

The current study was partially funded by the budgetary subsidies of the Technical University of Varna for research and development activities related to the scientific project “HП7/2025”.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study is available upon request from the corresponding authors.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Dominati, E.; Patterson, M.; Mackay, A. A framework for classifying and quantifying the natural capital and ecosystem services of soils. Ecol. Econ. 2010, 69, 1858–1868. [Google Scholar] [CrossRef]

- Greiner, L.; Keller, A.; Gret-Regamey, A.; Papritz, A. Soil function assessment: Review of methods for quantifying the contributions of soils to ecosystem services. Land Use Pol. 2017, 69, 224–237. [Google Scholar] [CrossRef]

- Koleva, M.; Yankova, P.; Plamenov, D.; Naskova, P. Digitalization in plant production and plant protection in bulgaria–current status and future goals. Ann. Univ. Craiova-Agric. Mont. Cadastre Ser. 2025, 54, 170–181. [Google Scholar] [CrossRef]

- Hoeft, R.G.; Peck, T.R.; Boone, L.V. Soil testing and fertility. In Illinois Agronomy Handbook 1995–1996; Circular 1333; Cooperative Extension Service, College of Agriculture, University of Illinois at Urbana-Champaign: Champaign, IL, USA, 1996; Chapter 11; pp. 70–101. [Google Scholar]

- Gelderman, R.H.; Mallarino, A.P. Soil Sample Preparation. In Recommended Chemical Soil Test Procedures for the North Central region; Brown, J.L., Ed.; North Central Regional Publ. No. 221 (Rev.). Missouri Exp. Stn. Publ. SB 1001; University of Missouri: Columbia, MO, USA, 1998; pp. 5–6. [Google Scholar]

- Upadhyaya, S.K.; Rosa, U.A.; Ehsani, M.; Koller, M.; Josiah, M.; Shikanai, T. Precision Farming in a Tomato Production System; Paper No. 99-1147; ASAE: St. Joseph, MI, USA, 1999. [Google Scholar]

- Baumgardner, M.F.; Silva, L.F.; Beihl, L.L.; Stoner, E.R. Reflectance properties of soils. Adv. Agron. 2002, 38, 1–44. [Google Scholar]

- Qin, Y.; Feng, W.; Zheng, C.; Chen, J.; Wang, Y.; Zhang, L.; Nie, T. Evaluation of Soil Quality and Balancing of Nitrogen Application Effects in Summer Direct-Seeded Cotton Fields Based on Minimum Dataset. Agronomy 2025, 15, 1763. [Google Scholar] [CrossRef]

- Adamchuk, V.I.; Morgan, M.T.; Sumali, H. Application of a strain gauge array to estimate soil mechanical impedance on-the-go. Trans. ASAE 2001, 44, 1377–1383. [Google Scholar] [CrossRef]

- Gordanić, S.V.; Radanović, D.; Rajković, M.; Lukić, M.; Dragumilo, A.; Mrđan, S.; Batinić, P.; Čutović, N.; Mikić, S.; Prijić, Ž.; et al. Influence of Mulching and Planting Density on Agronomic and Economic Traits of Melissa officinalis L. Horticulturae 2025, 11, 866. [Google Scholar] [CrossRef]

- Liao, C.; Tang, M.; Zhang, C.; Deng, M.; Li, Y.; Feng, S. Impacts of Various Straw Mulching Strategies on Soil Water, Nutrients, Thermal Regimes, and Yield in Wheat–Soybean Rotation Systems. Plants 2025, 14, 2233. [Google Scholar] [CrossRef] [PubMed]

- Kostrzewa, J.; Kaczmarek, Ł.; Bogacki, J.; Dąbska, A.; Wojtkowska, M.; Popielski, P. Potential Use of Wastewater Treatment Plant Washed Mineral Waste as Flood Embankment Materials. Materials 2025, 18, 3384. [Google Scholar] [CrossRef] [PubMed]

- Verschoore, R.; Pieters, J.G.; Seps, T.; Spriet, Y.; Vangeyte, J. Development of a sensor for continuous soil resistance measurement. In Precision Agriculture; Stafford, J., Werner, A., Eds.; Wageningen Academic Publishers: Wageningen, The Netherlands, 2003; pp. 689–695. [Google Scholar]

- Mechanicalc. 2025. Available online: https://mechanicalc.com/reference/beam-analysis#shear-stress-rectangular (accessed on 18 March 2025).

- Sz-zy. 2025. Available online: https://www.sz-zy.net. (accessed on 18 March 2025).

- Stde. 2025. Available online: http://www.stde-semiconductor.com. (accessed on 18 March 2025).

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).