Two Realizations of the Wearable PPG Sensor Working in Reflectance Mode for Measurement in Weak Magnetic Field †

Abstract

:1. Introduction

2. Subject and Methods

PPG Signal Processing

3. Measurement Experiments

- Basic testing and verification of functionality of sensor’s structural blocks were performed including measurement of the sensor’s mean DC current with 5/3.3/3.7 V power supply for three functional states: without BT connection (NC), after established connection to the control device (CE), and during transmission of PPG signal samples to the laptop (MC)—compare values in Table 1.

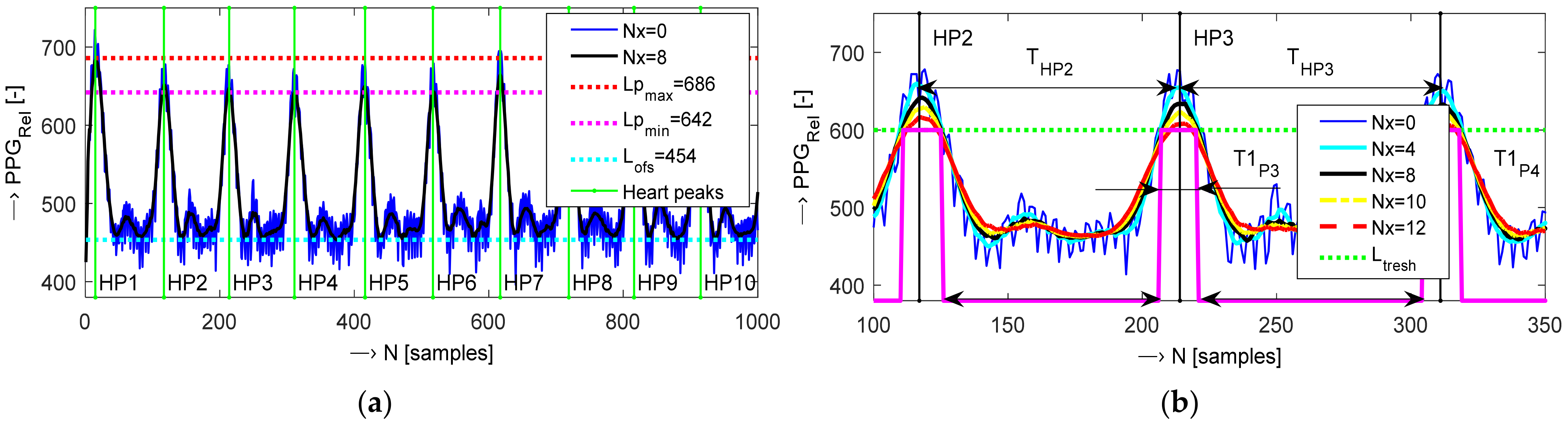

- Auxiliary analysis of the MA filtering effect on the PPG signal properties and HR determination for half a window length NX = {0, 4, 8, 10, 12}—see visualization for the PPG wave from the sensor PPG-PS1 in Figure 2 (NX = 0 means no filtering).

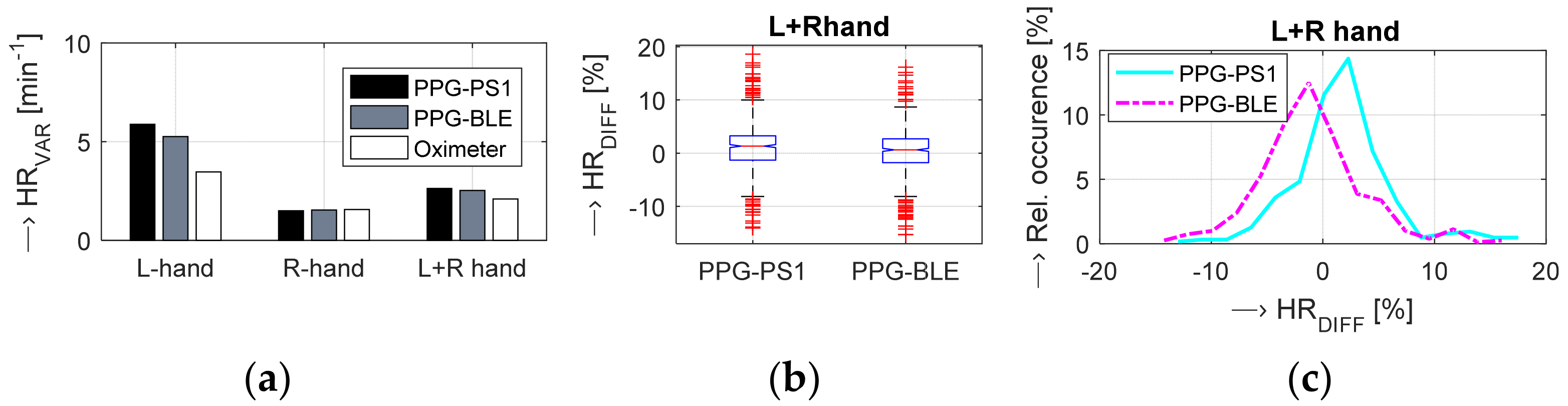

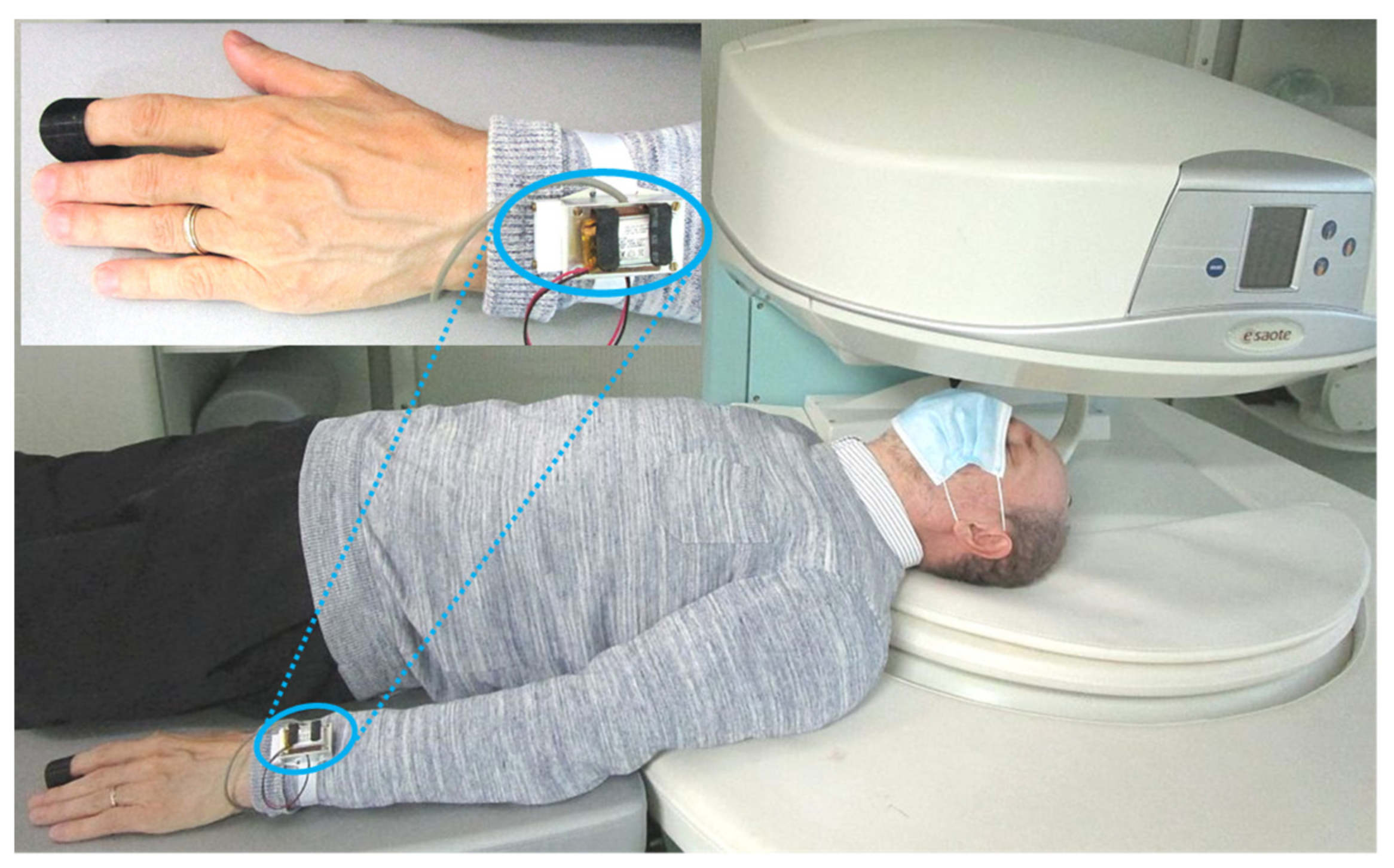

- Comparative measurement in the normal laboratory conditions—PPG signal sensing and parallel measurement with the pulse oximeter Berry BM1000C [14] by Shanghai Berry Electronic Tech Co. Ltd. for calibration of the determined HR values. This type of oximeter with an optical sensor working in a transmission mode enables also recording of blood oxygen saturation and HR values to the control device (tablet) via BT connection. PPG sensors are mounted on little fingers of both hands by an elastic ribbon, the oximeter device on the forefingers as documented in Figure 3. The recording of PPG signals as well as oximeter values lasted for 80 s. The HR values obtained in this way were subsequently processed off-line and analyzed statistically—see the results for all tested persons in Figure 4.

- Preliminary mapping of conditions for wireless connection through the shielding cage of the open-air MRI device E-scan Opera by Esaote S.p.A. [15] located at the Institute of Measurement Science in Bratislava.

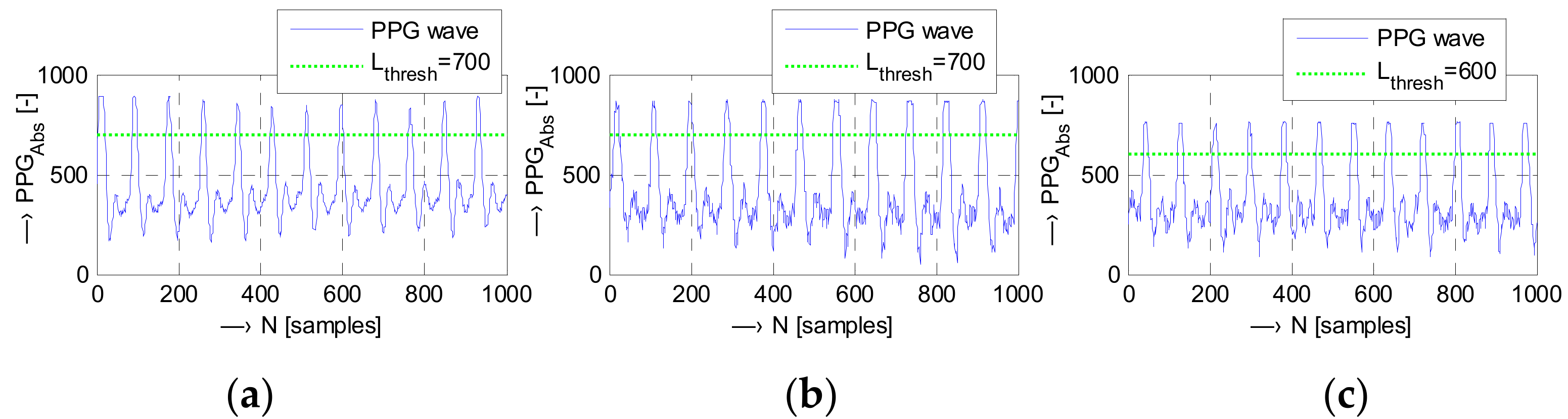

- First-step measurement of the PPG signals in a low magnetic field environment of the MRI device for two working states: the tested person lying in the MRI scanning area with no scanner activity and the 3D scan sequence running—see the measurement arrangement photo in Figure 5.

4. Discussion and Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Schickhofer, L.; Malinen, J.; Mihaescu, M. Compressible flow simulations of voiced speech using rigid vocal tract geometries acquired by MRI. J. Acoust. Soc. Am. 2019, 145, 2049–2061. [Google Scholar] [CrossRef] [PubMed]

- Steckner, M.C. A review of MRI acoustic noise and its potential impact on patient and worker health. eMagRes 2020, 9, 21–38. [Google Scholar]

- Celka, P.; Charlton, P.H.; Farukh, B.; Chowienczyk, P.; Alastruey, J. Influence of mental stress on the pulse wave features of photoplethysmograms. Healthc. Technol. Lett. 2020, 7, 7–12. [Google Scholar] [CrossRef] [PubMed]

- Blazek, V.; Venema, B.; Leonhardt, S.; Blazek, P. Customized optoelectronic in-ear sensor approaches for unobtrusive continuous monitoring of cardiorespiratory vital signs. Int. J. Ind. Eng. Manag. 2018, 9, 197–203. [Google Scholar] [CrossRef]

- Smith, A.G. Introduction to Arduino: A Piece of Cake; CreateSpace Independent Publishing Platform: Scotts Valley, CA, USA, 2011; 170p. [Google Scholar]

- Přibil, J.; Přibilová, A.; Frollo, I. Physiological impact of vibration and noise in an open-air magnetic resonance imager: Analysis of a PPG signal of an examined person. Proceedings 2020, 42, 14. [Google Scholar] [CrossRef] [Green Version]

- Přibil, J.; Přibilová, A.; Frollo, I. First-step PPG signal analysis for evaluation of stress induced during scanning in the open-air MRI device. Sensors 2020, 20, 3532. [Google Scholar] [CrossRef] [PubMed]

- Pulse Sensor Amped Product (Adafruit 1093): World Famous Electronics LLC. Ecommerce Getting Starter Guide. Available online: https://pulsesensor.com/pages/code-and-guide (accessed on 16 July 2020).

- Arduino Nano Official Store. Available online: http://arduino.cc/en/Main/ArduinoBoardNano (accessed on 21 October 2020).

- Arduino and Bluetooth Module HC-06. Available online: https://www.aranacorp.com/en/arduino-and-bluetooth-module-hc-06/ (accessed on 21 October 2020).

- Using the Arduino Pro Mini 3.3V. Available online: https://learn.sparkfun.com/tutorials/using-the-arduino-pro-mini-33v (accessed on 7 April 2021).

- MLT-BT05 4.0 Bluetooth Serial Communication Module. Available online: https://www.techonicsltd.com/product/mlt-bt05-ble4-0/ (accessed on 12 May 2021).

- Rundo, F.; Conoci, S.; Ortis, A.; Battiato, S. An advanced bio-inspired PhotoPlethysmoGraphy (PPG) and ECG pattern recognition system for medical assessment. Sensors 2018, 18, 405. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- China Berry Hospital Oxycare Pulse Oximeter for Kids. Available online: https://berrymedical.en.made-in-china.com/product/zsuQEvPLsqcJ/Ch (accessed on 12 May 2021).

- Esaote SpA. E-Scan Opera. User’s Manual; Revision A; Esaote SpA: Genoa, Italy, 2008. [Google Scholar]

| Sensor Type/Func. State | NC | CE | MC |

|---|---|---|---|

| PPG-PS1 1 | 18 mA | 26 mA | 30 mA |

| PPG-BLE 2,3 | 10.5/13.5 mA | 11/14 mA | 13/17 mA |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Přibil, J.; Přibilová, A.; Frollo, I. Two Realizations of the Wearable PPG Sensor Working in Reflectance Mode for Measurement in Weak Magnetic Field. Eng. Proc. 2021, 10, 55. https://doi.org/10.3390/ecsa-8-11252

Přibil J, Přibilová A, Frollo I. Two Realizations of the Wearable PPG Sensor Working in Reflectance Mode for Measurement in Weak Magnetic Field. Engineering Proceedings. 2021; 10(1):55. https://doi.org/10.3390/ecsa-8-11252

Chicago/Turabian StylePřibil, Jiří, Anna Přibilová, and Ivan Frollo. 2021. "Two Realizations of the Wearable PPG Sensor Working in Reflectance Mode for Measurement in Weak Magnetic Field" Engineering Proceedings 10, no. 1: 55. https://doi.org/10.3390/ecsa-8-11252

APA StylePřibil, J., Přibilová, A., & Frollo, I. (2021). Two Realizations of the Wearable PPG Sensor Working in Reflectance Mode for Measurement in Weak Magnetic Field. Engineering Proceedings, 10(1), 55. https://doi.org/10.3390/ecsa-8-11252