Biogas Production Using “Gas Endeavour” Automatic Gas Flow System †

Abstract

:1. Introduction

2. Materials and Methods

2.1. Biomass Composition

2.2. Anaerobic Digestion of Biomass

2.2.1. Automatic Gas Flow Measuring System

2.2.2. Carbon Dioxide Absorption Unit

2.2.3. Biogas Production and Monitoring

2.2.4. Final Product Analysis

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Raja, I.A. Agriculture Residue: A Potential Source for Biogas Production. Ann. Agric. Crop Sci. 2021, 6, 1081. [Google Scholar]

- Kucher, O.; Hutsol, T.; Glowacki, S.; Andreitseva, I.; Dibrova, A.; Muzychenko, A.; Szeląg-Sikora, A.; Szparaga, A.; Kocira, S. Energy Potential of Biogas Production in Ukraine. Energies 2022, 15, 1710. [Google Scholar] [CrossRef]

- Hagos, K.; Zong, J.; Li, D.; Liu, C.; Lu, X. Anaerobic co-digestion process for biogas production: Progress, challenges and perspectives. Renew. Sust. Energy Rev. 2017, 76, 1485–1496. [Google Scholar] [CrossRef]

- Uggetti, E.; Passos, F.; Solé, M.; Garfí, M.; Ferrer, I. Recent achievements in the production of biogas from microalgae. Waste Biomass Valorization 2017, 8, 129–139. [Google Scholar] [CrossRef]

- Xie, S.; Wickham, R.; Nghiem, L.D. Synergistic effect from anaerobic co-digestion of sewage sludge and organic wastes. Int. Biodeterior. Biodegrad. 2017, 116, 191–197. [Google Scholar] [CrossRef]

- Koszel, M.; Lorencowicz, E. Agricultural use of biogas digestate as a replacement fertilizers. Agric. Agric. Sci. Procedia 2015, 7, 119–124. [Google Scholar] [CrossRef]

- Rahman, M.A.; Shahazi, R.; Nova, S.N.B.; Uddin, M.R.; Hossain, M.S.; Yousuf, A. Biogas production from anaerobic co-digestion using kitchen waste and poultry manure as substrate—Part 1: Substrate ratio and effect of temperature. Biomass Convers. Biorefin. 2023, 13, 6635–6645. [Google Scholar] [CrossRef] [PubMed]

- Xia, T.; Huang, H.; Wu, G.; Sun, E.; Xiaochen Jin, X.; Tang, W. The characteristic changes of rice straw fibers in anaerobic digestion and its effect on rice straw-reinforced composites. Ind Crops Prod. 2018, 121, 73–79. [Google Scholar] [CrossRef]

- Kafle, G.K.; Kim, S.H. Effects of chemical compositions and ensiling on the biogas productivity and degradation rates of agricultural and food processing by-products. Bioresour. Technol. 2013, 142, 553–561. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Lu, X.; Li, F.; Yang, G. Effects of temperature and carbon-nitrogen (C/N) ratio on the performance of anaerobic codigestion of dairy manure, chicken manure and rice straw: Focusing on ammonia inhibition. PLoS ONE 2014, 9, e97265. [Google Scholar]

| Experiment No. | Control (g) | Potatoes (g) | Sugar Beet (g) | Cabbage (g) | Pig Manure (g) | Dry Microalgae (g) | Liquid Digestate (Inoculum) (mL) |

|---|---|---|---|---|---|---|---|

| 1 | 3 | - | - | - | - | - | 250 |

| 2 | - | - | - | 135 | - | 15 | 250 |

| 3 | - | 75 | - | - | 75 | - | 250 |

| 4 | - | - | 41.25 | 109 | - | - | 250 |

| 5 | - | 19.8 | 6.7 | 50 | 70 | 4 | 250 |

| Experiment 1 (E1) | Experiment 2 (E2) | Experiment 3 (E3) | Experiment 4 (E4) | Experiment 5 (E5) | |

|---|---|---|---|---|---|

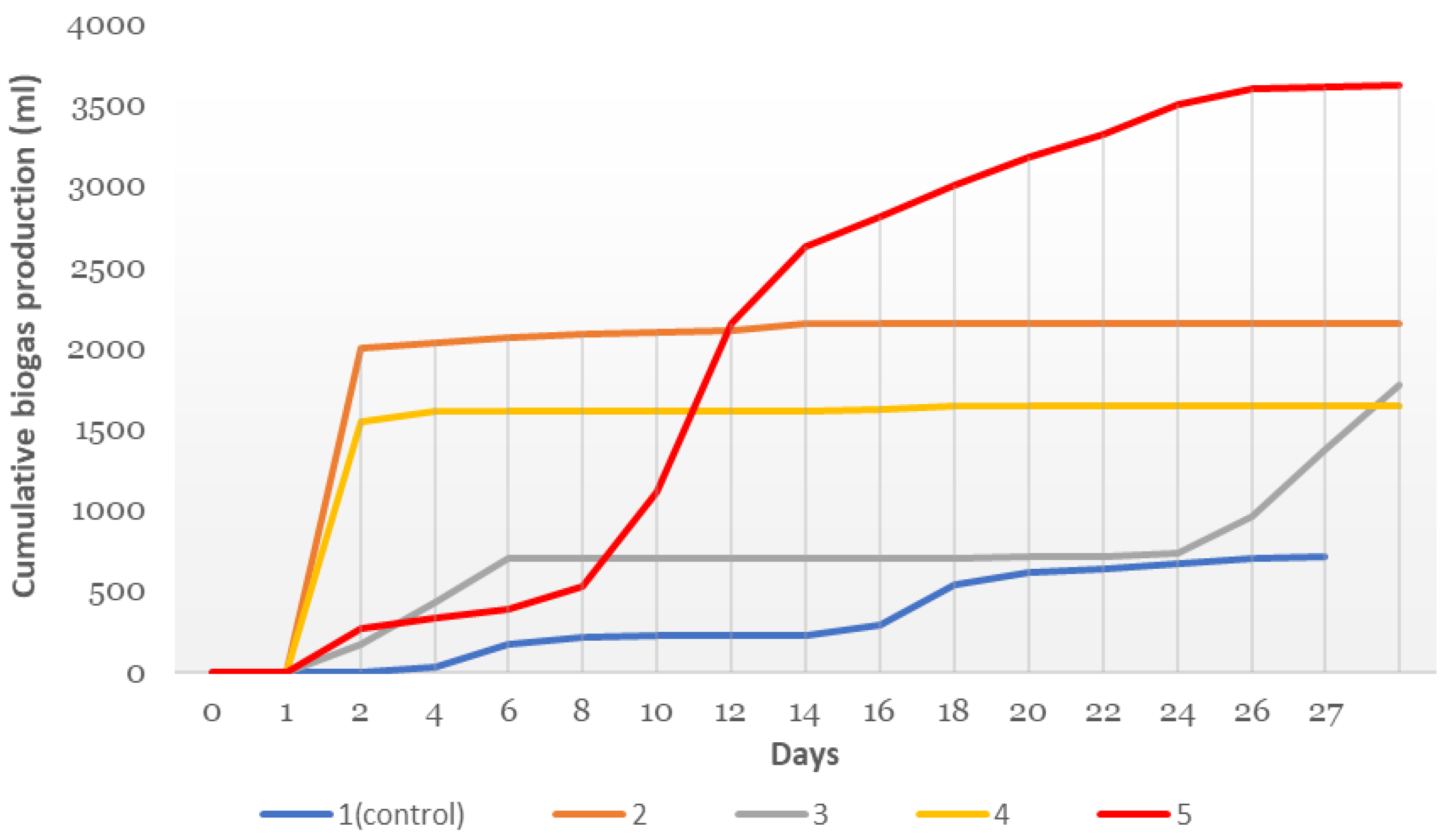

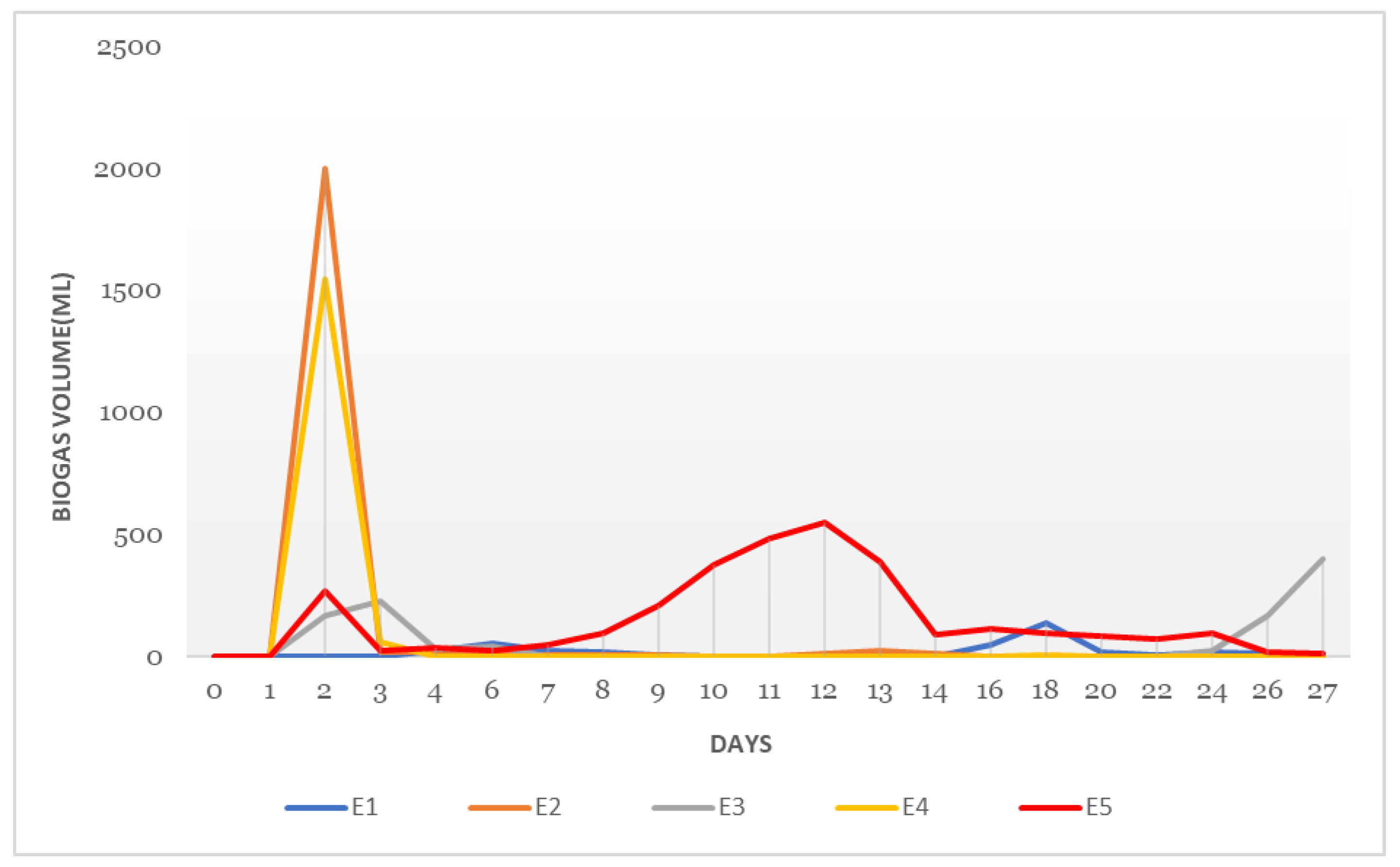

| Total Volume (mL) | 717 | 2151 | 1771 | 1642 | 3619 |

| Macroelements, % (m/m) | E1 (Liquid) | E5 (Liquid) | E1 (Solid) | E5 (Solid) |

|---|---|---|---|---|

| TN | <1.19 | <1.19 | 1.96 | 2.75 |

| P | 0.003 | 0.11 | 0.73 | 1.78 |

| K | 0.099 | 0.19 | 0.86 | 0.80 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Psenovschi, G.; Vintila, A.C.N.; Neamtu, C.; Vlaicu, A.; Capra, L.; Dumitru, M.; Enascuta, C.-E. Biogas Production Using “Gas Endeavour” Automatic Gas Flow System. Chem. Proc. 2023, 13, 17. https://doi.org/10.3390/chemproc2023013017

Psenovschi G, Vintila ACN, Neamtu C, Vlaicu A, Capra L, Dumitru M, Enascuta C-E. Biogas Production Using “Gas Endeavour” Automatic Gas Flow System. Chemistry Proceedings. 2023; 13(1):17. https://doi.org/10.3390/chemproc2023013017

Chicago/Turabian StylePsenovschi, Grigore, Alin Cristian Nicolae Vintila, Constantin Neamtu, Alexandru Vlaicu, Luiza Capra, Marinela Dumitru, and Cristina-Emanuela Enascuta. 2023. "Biogas Production Using “Gas Endeavour” Automatic Gas Flow System" Chemistry Proceedings 13, no. 1: 17. https://doi.org/10.3390/chemproc2023013017

APA StylePsenovschi, G., Vintila, A. C. N., Neamtu, C., Vlaicu, A., Capra, L., Dumitru, M., & Enascuta, C.-E. (2023). Biogas Production Using “Gas Endeavour” Automatic Gas Flow System. Chemistry Proceedings, 13(1), 17. https://doi.org/10.3390/chemproc2023013017