Impregnated Sheep Wool Fibers with an Antimicrobial Effect †

Abstract

:1. Introduction

2. Materials and Methods

2.1. Sheep Wool Washing

2.2. Preparation of Copper Particles

2.3. Determination of Dolomite Porosimetry Characteristics

2.4. Preparation of Impregnated Wool

2.5. Experimental Protocol for Testing the Antimicrobial Effect

- Sterilization of the receptacles through exposure to UV radiation for 30–40 min on each side.

- Dispensing the sterilized receptacles into sterile 50 mL bottles.

- Adding 6 mL of a nutrient culture medium composed of 10 g/L peptone, 1 g/L meat extract, 2 g/L yeast extract, and 5 g/L NaCl, at a pH of 7, to each bottle.

- Inoculating the culture medium with 30 µL of bacterial inoculum, adjusted to a turbidity equivalent to the 0.5 McFarland standard, corresponding to a bacterial density of 1...2 × 108 CFU/mL, resulting in an inoculum density of 5 × 105 CFU/mL in each sample.

- Incubating the samples at 37 °C with agitation at 140 rpm for 24 h.

- Plating 100 μL from each sample (appropriately diluted in sterile saline) onto the surface of a solid nutrient agar medium (composed of 10 g/L peptone, 1 g/L meat extract, 2 g/L yeast extract, 5 g/L NaCl, and 18 g agar; pH 7.0).

- Incubating the plated samples at 37 °C for 24 h.

- Counting the colonies and determining the number of colony forming units (CFU) per mL in the tested samples compared to a blank sample (without wool).

- The percentage of bacterial growth reduction was calculated using Formula (1).

3. Results

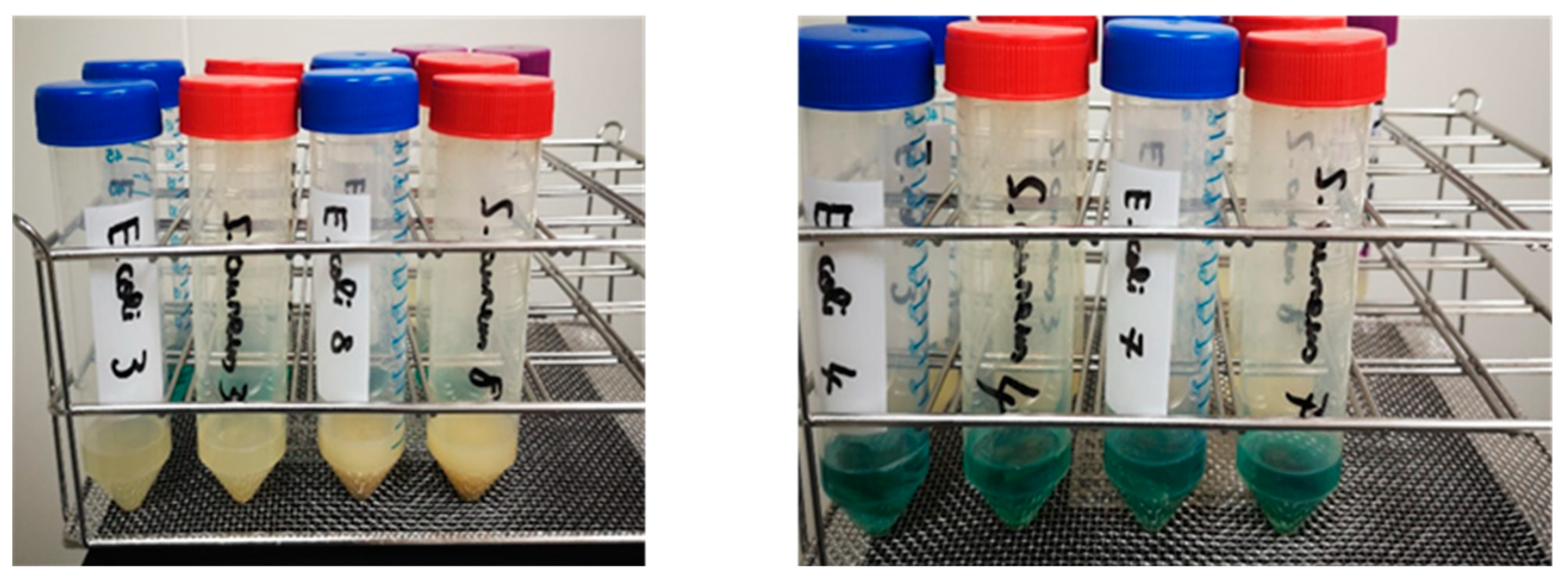

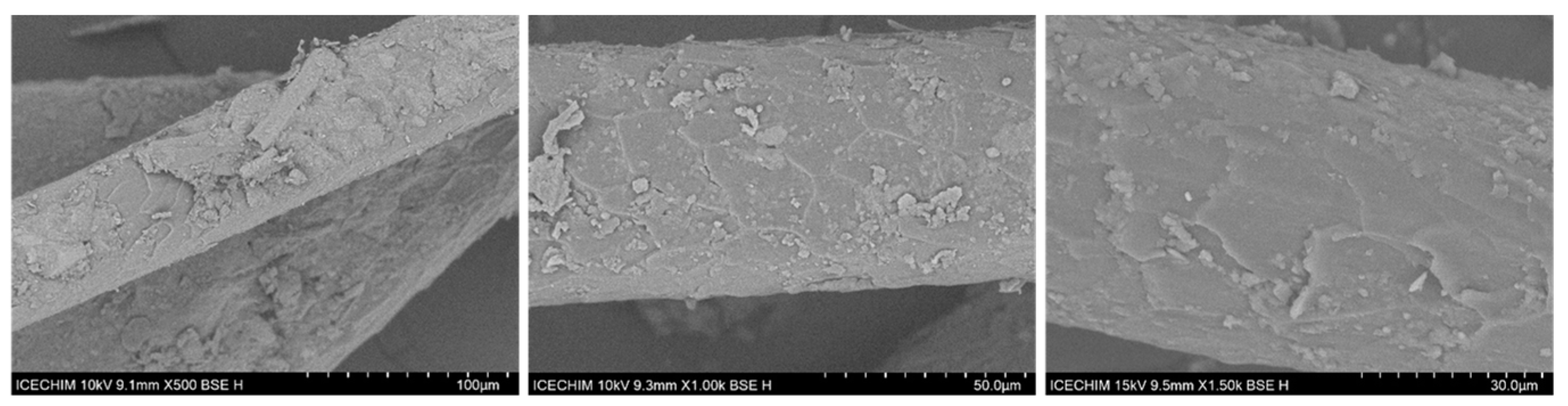

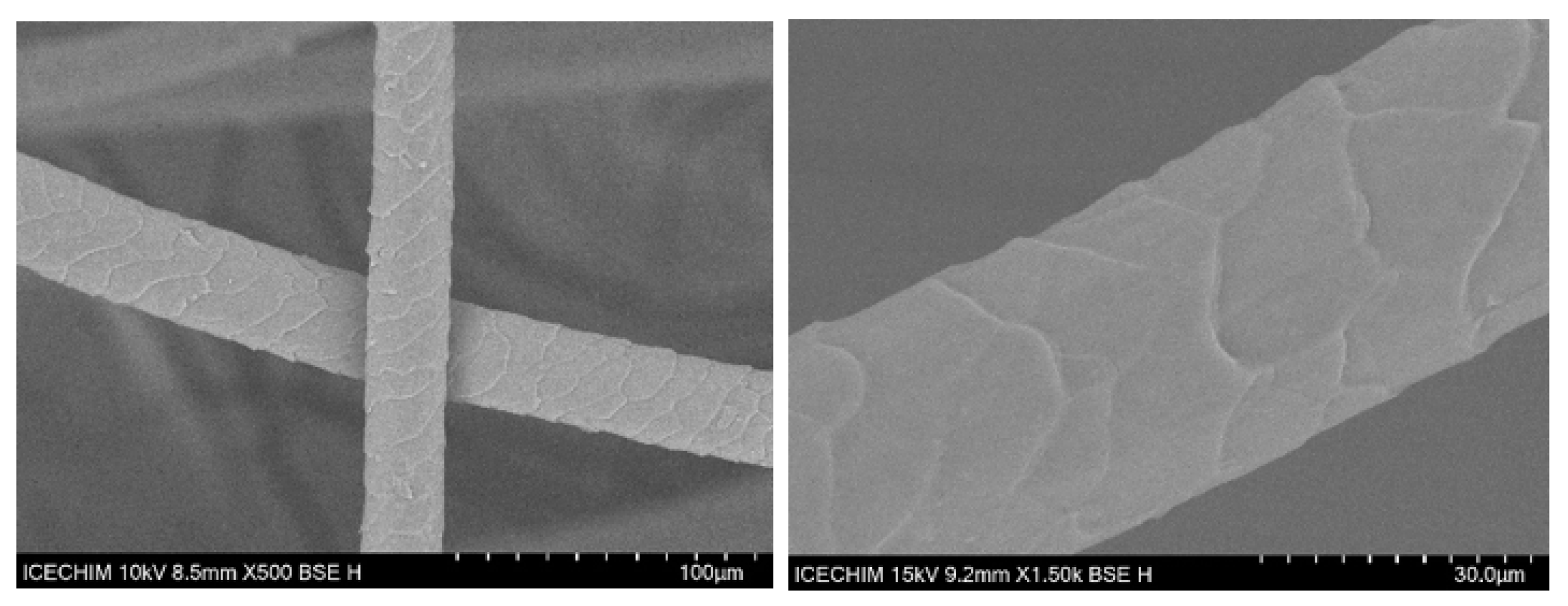

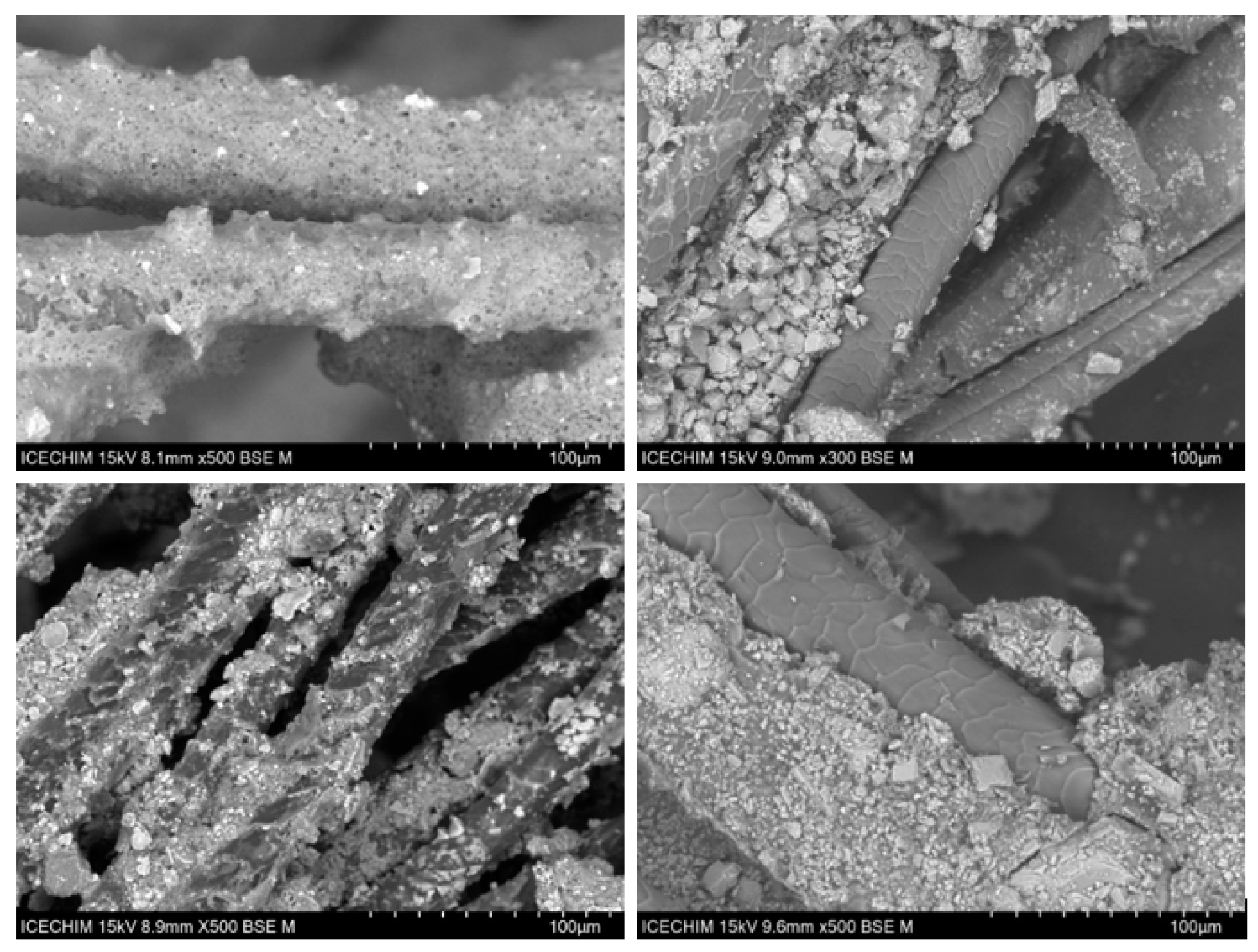

- Samples 3 and 4 completely inhibited the growth of the E. coli and S. aureus strains.

- Samples 1 and 2 had either a moderate (Sample 1—S. aureus, Sample 2—S. aureus, and Sample 1—E. coli) or absent (Sample 2—E. coli) antibacterial effect.

4. Conclusions

5. Patents

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Altin, M.; Yildirim, G.Ş. Investigation of usability of boron doped sheep wool as insulation material and comparison with existing insulation materials. Constr. Build. Mater. 2022, 331, 127303. [Google Scholar] [CrossRef]

- Valenza, A.; Fiore, V.; Nicolosi, A.; Rizzo, G.; Scaccianoce, G.; Bella, G.D. Effect of sheep wool fibres on thermal-insulation and mechanical properties of cement matrix. In Proceedings of the First International Conference on Bio-Based Building Materials, Clermont-Ferrand, France, 22–24 June 2015; Volume 33, pp. 40–45. [Google Scholar]

- Korjenic, A.; Klarić, S.; Hadžić, A.; Korjenic, S. Sheep Wool as a Construction Material for Energy Efficiency Improvement. Energies 2015, 8, 5765–5781. [Google Scholar] [CrossRef]

- Briga-Sá, A.; Gaibor, N.; Magalhães, L.; Pinto, T.; Leitão, D. Thermal performance characterization of cement-based lightweight blocks incorporating textile waste. Constr. Build. Mater. 2022, 321, 126330. [Google Scholar] [CrossRef]

- Hegyi, A.; Bulacu, C.; Szilagyi, H.; Lazarescu, A.V.; Meita, V.; Vizureanu, P.; Sandu, M. Improving Indoor Air Quality by Using Sheep Wool Thermal Insulation. Materials 2021, 14, 2443. [Google Scholar] [CrossRef] [PubMed]

- Erdogan, U.H.; Seki, Y.; Selli, F. Wool fibres. In Handbook of Natural Fibres; Woodhead Publishing: Cambridge, UK, 2020; pp. 257–278. [Google Scholar]

- Strand, E.A.; Frei, K.M.; Gleba, M.; Mannering, U.; Nosch, M.-L.; Skals, I. Old Textiles—New Possibilities. Eur. J. Archaeol. 2017, 13, 149–173. [Google Scholar] [CrossRef]

- Allafi, F.; Hossain, M.S.; Lalung, J.; Shaah, M.; Salehabadi, A.; Ahmad, M.I.; Shadi, A. Advancements in Applications of Natural Wool Fiber: Review. J. Nat. Fibers 2020, 19, 497–512. [Google Scholar] [CrossRef]

- Klinge, A.; Roswag-Klinge, E.; Ziegert, C.; Fontana, P.; Richter, M.; Hoppe, J. Naturally Ventilated Earth Timber Constructions. In Proceedings of the Sustainable Built Environment (SBE) Regional Conference, Zurich, Switzerland, 15–17 June 2016. [Google Scholar]

- Schlossman, M.L.; Mccarthy, J.P. Lanolin and its Derivatives. J. Am. Oil Chem. Soc. 1978, 55, 447–450. [Google Scholar] [CrossRef]

- Bhavsar, P.; Zoccola, M.; Dalla Fontana, G.; Pallavicini, M.; Roda, G.; Bolchi, C. Sustainable Routes for Wool Grease Removal Using Green Solvent Cyclopentyl Methyl Ether in Solvent Extraction and Biosurfactant Wool Protein Hydrolyzate in Scouring. Processes 2023, 11, 1309. [Google Scholar] [CrossRef]

- Alzaga, R.; Pascualb, E.; Errab, P.; Bayona, J.M. Development of a novel supercritical fuid extraction procedure for lanolin extraction from raw wool. Anal. Chim. Acta 1999, 381, 39–48. [Google Scholar] [CrossRef]

- Borlea Muresan, S.I.; Tiuc, A.E.; Nemes, O.; Vermesan, H.; Vasile, O. Innovative Use of Sheep Wool for Obtaining Materials with Improved Sound-Absorbing Properties. Materials 2020, 13, 694. [Google Scholar] [CrossRef] [PubMed]

- Heliopoulos, N.S.; Papageorgiou, S.K.; Galeou, A.; Favvas, E.P.; Katsaros, F.K.; Stamatakis, K. Effect of copper and copper alginate treatment on wool fabric. Study of textile and antibacterial properties. Surf. Coat. Technol. 2013, 235, 24–31. [Google Scholar] [CrossRef]

- Ma, X.; Zhou, S.; Xu, X.; Du, Q. Copper-containing nanoparticles: Mechanism of antimicrobial effect and application in dentistry-a narrative review. Front. Surg. 2022, 9, 905892. [Google Scholar] [CrossRef] [PubMed]

- Rohmawati, L.; Sholicha, S.P.; Istiqomah; Setyarsih, W. Dolomite Characteristic from Natural Material and its Application as an Antibacterial. Sci. Technol. Asia 2022, 27, 121–131. [Google Scholar]

- Longano, D.; Ditaranto, N.; Sabbatini, L.; Torsi, L.; Cioffi, N. Synthesis and Antimicrobial Activity of Copper Nanomaterials. In Nano-Antimicrobials; Springer Nature: New York, NY, USA, 2012; pp. 85–117. [Google Scholar]

- Rohmawati, L.; Sholicha, S.P.; S Holisa, S.P.; Setyarsih, W. Identification of Phase CaCO3/MgO in Bangkalan Dolomite Sand as An Antibacterial Substance. J. Phys. Conf. Ser. 2019, 1417, 012001. [Google Scholar] [CrossRef]

| Sample Code | Characteristic |

|---|---|

| 1 | Sheep wool washed and impregnated with 5% polymer and 5% dolomite |

| 2 | Sheep wool washed and impregnated with 5% polymer and 5% dolomite |

| 3 | Sheep wool washed and impregnated with 5% polymer, 5% dolomite, and 0.5% Cu microparticles |

| 4 | Sheep wool washed and impregnated with 5% polymer, 5% dolomite, and 0.5% Cu microparticles |

| Element | Wt % | |

|---|---|---|

| Sample 3 | Sample 4 | |

| O | 41.1 | 38.8 |

| O | 22.5 | 24.7 |

| Cu | 22.1 | 22.4 |

| N | 11.1 | 11.7 |

| K | 1.3 | 0.4 |

| Ca | 0.9 | 1.1 |

| S | 0.9 | 0.9 |

| Cl | 0.1 | 0.0 |

| Product Name | Specific Surface (m2/g) | Total Pore Volume (cm3/g) | Average Pore Diameter (nm) |

|---|---|---|---|

| Dolomite | 5.108 | 0.0055 | 8.508 |

| Bacterial Strain | Sample | CFU/mL | % Reduction in Bacterial Growth Compared to the Blank Sample |

|---|---|---|---|

| S. aureus | Blank | 8.75 × 1010 | - |

| 1 | 4.1 × 1010 | −53.1% | |

| 2 | 2.92 × 1010 | −66.6% | |

| 3 | 5.1 × 102 | −100% | |

| 4 | 0 | −100% | |

| E. coli | Blank | 1.06 × 1010 | - |

| 1 | 5.1 × 109 | −51.89% | |

| 2 | 3.06 × 1010 | 0% | |

| 3 | 0 | −100% | |

| 4 | 0 | −100% |

| E. coli, Dilution 10−7 | S. aureus, Dilution 10−7 | |

|---|---|---|

| Sample 1 |  |  |

| Sample 2 |  |  |

| E. coli, undiluted | S. aureus, undiluted | |

| Sample 3 |  |  |

| Sample 4 |  |  |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ghimiș, S.-B.; Mîrț, A.-L.; Vlaicu, A.; Zaharia, E.; Bomboş, M.M.; Vasilievici, G. Impregnated Sheep Wool Fibers with an Antimicrobial Effect. Chem. Proc. 2023, 13, 1. https://doi.org/10.3390/chemproc2023013001

Ghimiș S-B, Mîrț A-L, Vlaicu A, Zaharia E, Bomboş MM, Vasilievici G. Impregnated Sheep Wool Fibers with an Antimicrobial Effect. Chemistry Proceedings. 2023; 13(1):1. https://doi.org/10.3390/chemproc2023013001

Chicago/Turabian StyleGhimiș, Simona-Bianca, Andreea-Luiza Mîrț, Alexandru Vlaicu, Emilian Zaharia, Mariana Mihaela Bomboş, and Gabriel Vasilievici. 2023. "Impregnated Sheep Wool Fibers with an Antimicrobial Effect" Chemistry Proceedings 13, no. 1: 1. https://doi.org/10.3390/chemproc2023013001

APA StyleGhimiș, S.-B., Mîrț, A.-L., Vlaicu, A., Zaharia, E., Bomboş, M. M., & Vasilievici, G. (2023). Impregnated Sheep Wool Fibers with an Antimicrobial Effect. Chemistry Proceedings, 13(1), 1. https://doi.org/10.3390/chemproc2023013001