1. Introduction

Nowadays, global food security is at risk. This is compared to 2019 when almost one in three people did not have access to adequate food, in 2020, due to to the effects of the COVID-19 pandemic [

1]. In this scenery, it is vital to seek mechanisms for efficient and optimal management of irrigation systems.

On one hand, the designing or optimizing of the management of distribution networks, the usage of algorithms, or optimization processes that provide a set of feasible solutions for areas of interest are considered [

2]. The economic factor is an important element in the design and implementation of distribution systems, which is the reason for seeking designs that involve the minimum cost. As a first alternative, analytical optimization algorithms are considered. These have been used to obtain optimal designs for irrigation networks operating on-demand [

3], and supplying pipes with the Economic Series Method (ESM) by selecting piping diameters with an increasing pressure gradient per unit of maximum cost to meet all pressure requirements [

4], obtaining good results [

5,

6,

7,

8,

9,

10]. González and Aliod [

11] improved the MSE by using different materials and pipe sizes in the design of irrigation networks. García et al. [

12], used the MSEM method to optimize the design of shift irrigation networks. Planells et al. [

3], evaluated the energy cost during an irrigation campaign using Integer Non-linear Programming; Theocharis et al. [

13] dimensioned the network with the simplified Non-Linear Programming technique using independent linear equations for pipe design. Kale et al. [

14] used Linear Programming for the optimal design of lateral pipes of a parcel irrigation system. Lamaddalena et al. [

15] used Labye’s discontinuous iterative method and evaluate the variability of pressure in the hydrants of on-demand pressure irrigation systems.

On another hand, another type of algorithm employed for this purpose is an evolutionary algorithm, such as the Genetic Algorithm (GA); it is inspired by the natural evolution of populations, as is Darwin’s theory of natural selection and Mendel’s theory of the transfer of genetic material [

16]. These algorithms evaluate thousands of solutions to determine the most feasible or real solution closest to the optimal design [

17,

18,

19]. The GA does not use integer variables results in high computational efficiency [

20], and is suitable for application to the analysis of real-size networks. Such is the case of Farmani, Abadia & Savic [

21] that assign shifts to hydrants in irrigation systems, as well as the pipe diameters, resulting in an increase in the size of the decision variables, and therefore, in the resolution time.

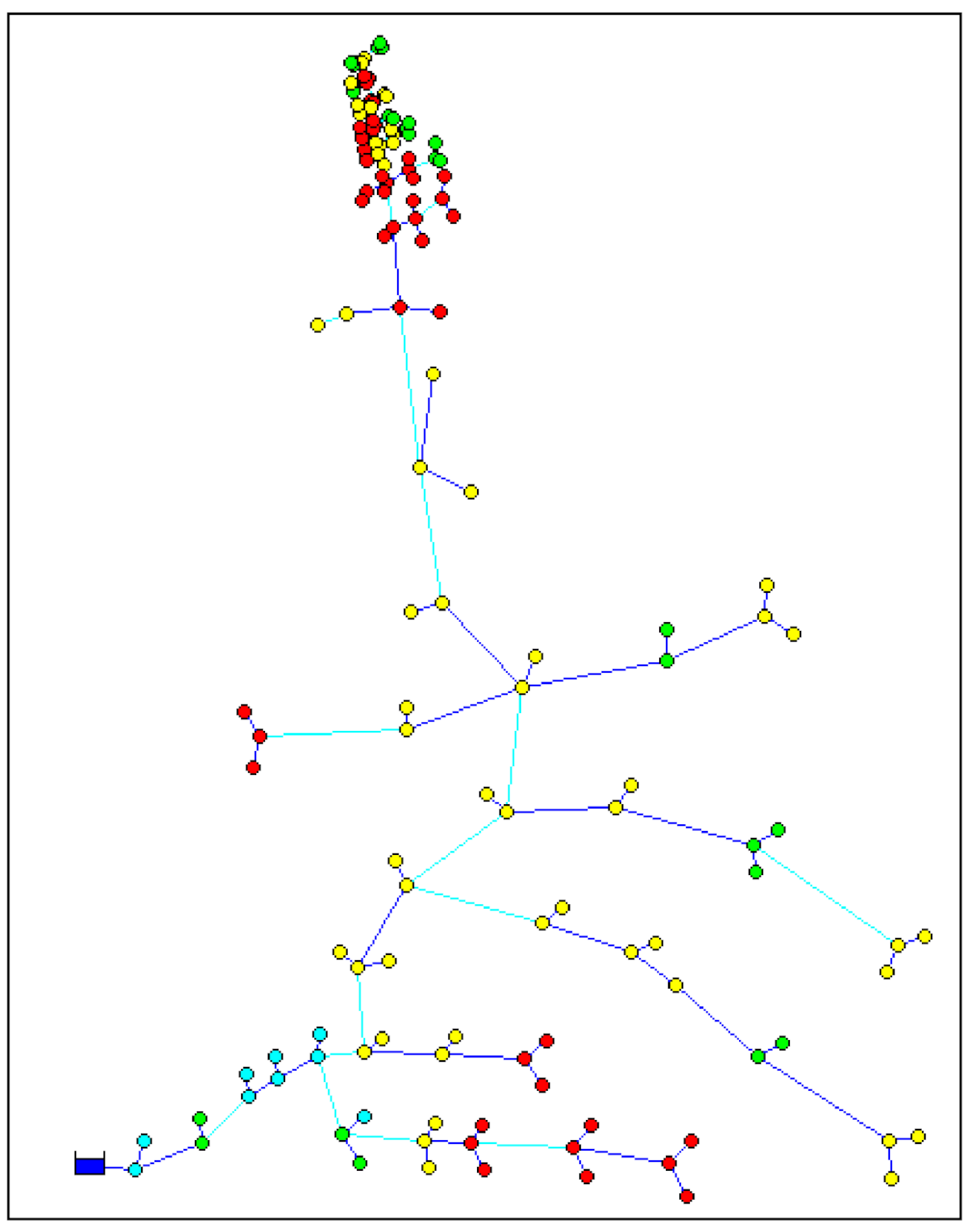

A distribution network allows water to reach from the collection point to the user for human consumption or irrigation needs [

22]. A pressurized irrigation system has components, such as collection, distribution lines, hydrants, etc.; which together with pressure and flow control devices facilitate good operation [

23]. Pressurized irrigation networks can be operated in two modalities: in shifts (they have certain restrictions during the irrigation day and the useful life of the system) and on-demand (they operate without hourly restrictions, although this means higher economic costs) [

24,

25].

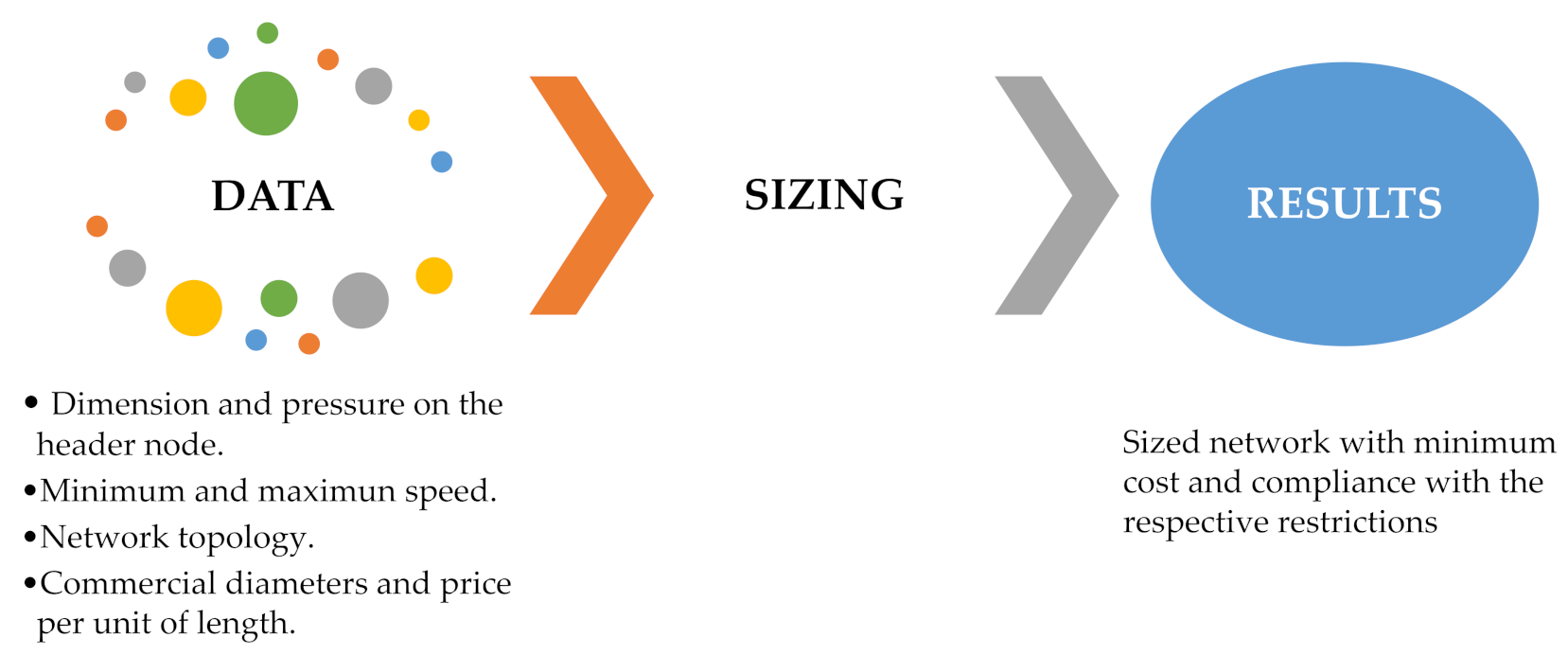

In the current research, we propose to compare and evaluate the design results obtained using an analytical method, the Method of the Improved Economic Series (MSEM) and the genetic algorithm (GA), which have been applied to four pressurized irrigation networks operating in the shift mode.

3. Results and Discussion

3.1. Results

The combination of shifts in the hydrants of the study networks selected for this research is obtained from the distribution of a head-end flow where it is verified that the pressure and velocity values at the nodes of known demand are within the technical design specifications.

Table 4 presents the irrigation time and the flow rate allocated for each shift in the different irrigation networks used.

Table 5 provides a summary of the resulting design after optimization with MSEM. The reference design budget amounts to a total of

$28274.62 excluding the cost of installation, accessories, and transport.

The design of the Tuncarta network by using the Genetic Algorithm is provided in

Table 6, the cost of which amounts to a total of

$32836.25 of pipe, and does not include its installation, fittings, and transport.

The design of the Tuncarta network under similar design criteria with the two optimization methods leads to a cost that is 13.89% lower with MSEM compared to its design cost with AG. In order to perform the design using AG, around 40 simulations are made with each of the study networks, from which the design cost of the network of the iteration with the lowest cost value is adopted. The design costs of the Inferior Callén and Cenicero networks are lower with the application of the Genetic Algorithm compared to the design resulting from the MSEM optimization method.

The design costs of the study networks with the two optimization methods are presented in

Table 7; column 4 (MSEM and AG network graph) indicates the method with the higher cost.

3.2. Discussion

The design of the Callén Inferior and Cenicero networks with the Genetic Algorithm presented a cost reduction of 0.97% and 18.04%, respectively, in relation to the design cost with the MSEM. The resulting design cost for the Tuncarta and Cariyacu networks with the MSEM was 14% and 15% lower than the design cost with the Genetic Algorithm, respectively.

In the four network designs, the set point pressures at each of the hydrants in the different shifts, as well as the flow velocity ranges were found to be within the design parameters.