Innovative Functional Plastic Films as Cover for Stonewool Grow Blocks and Their Effect on Tomato Hydroponic Cultivation †

Abstract

:1. Introduction

2. Materials and Methods

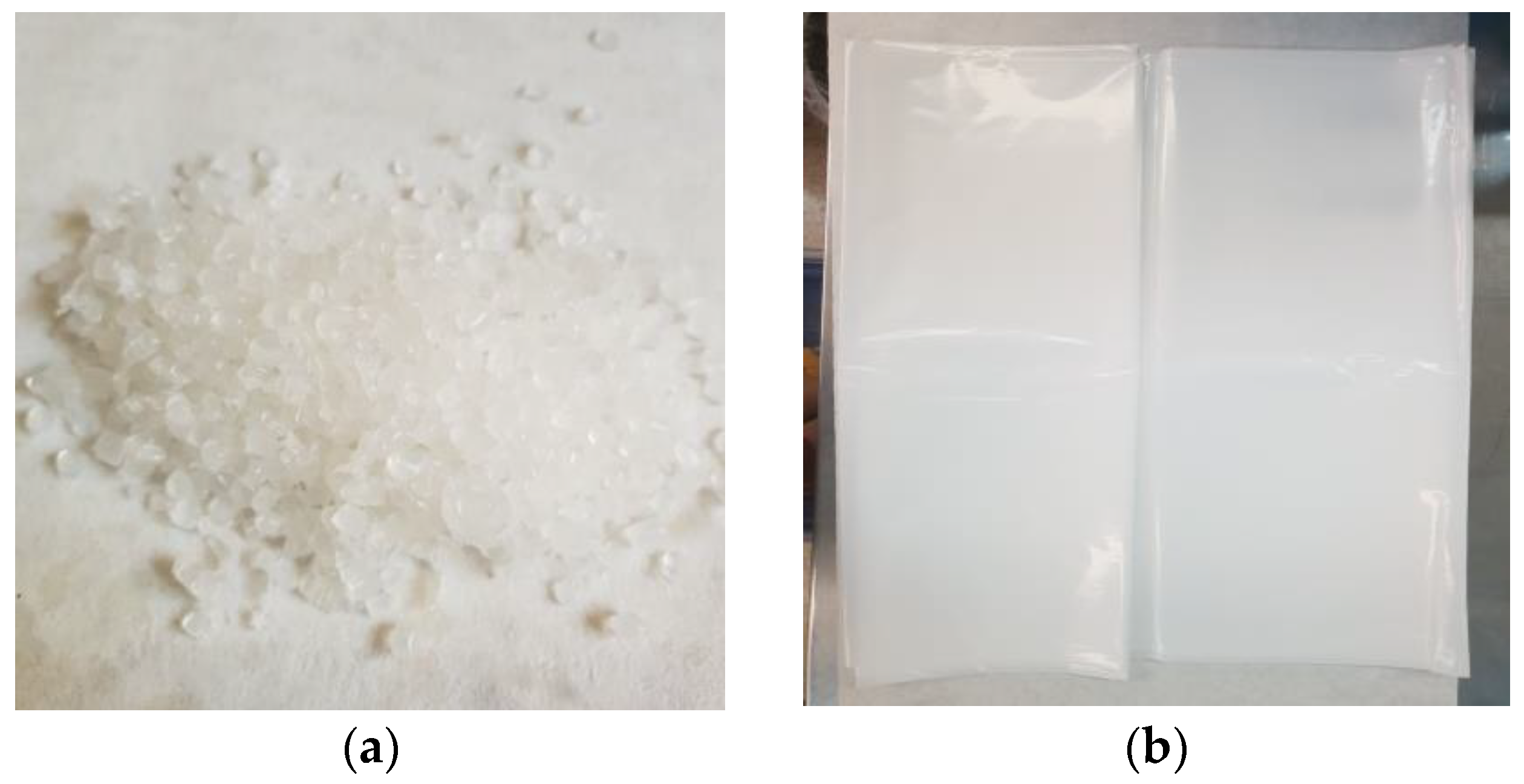

2.1. Materials

2.2. Methods

2.2.1. Extraction of Alkaloids

2.2.2. Alkaloids Detection

2.2.3. Polymeric Film Development

2.2.4. Application in the Field

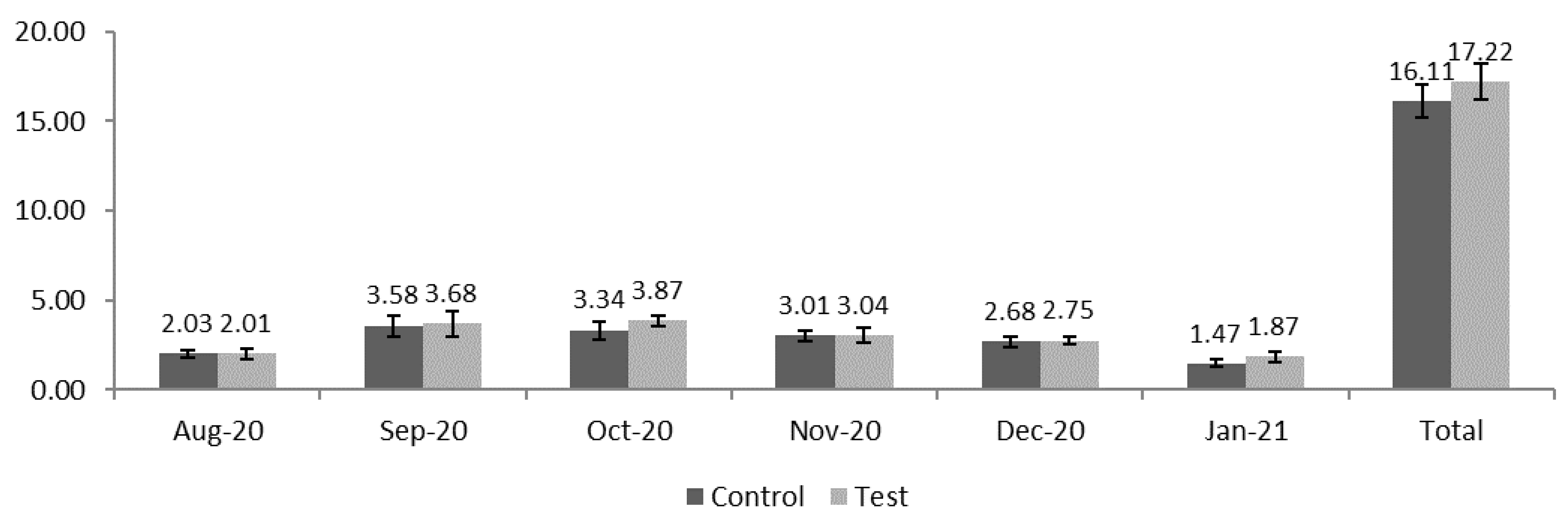

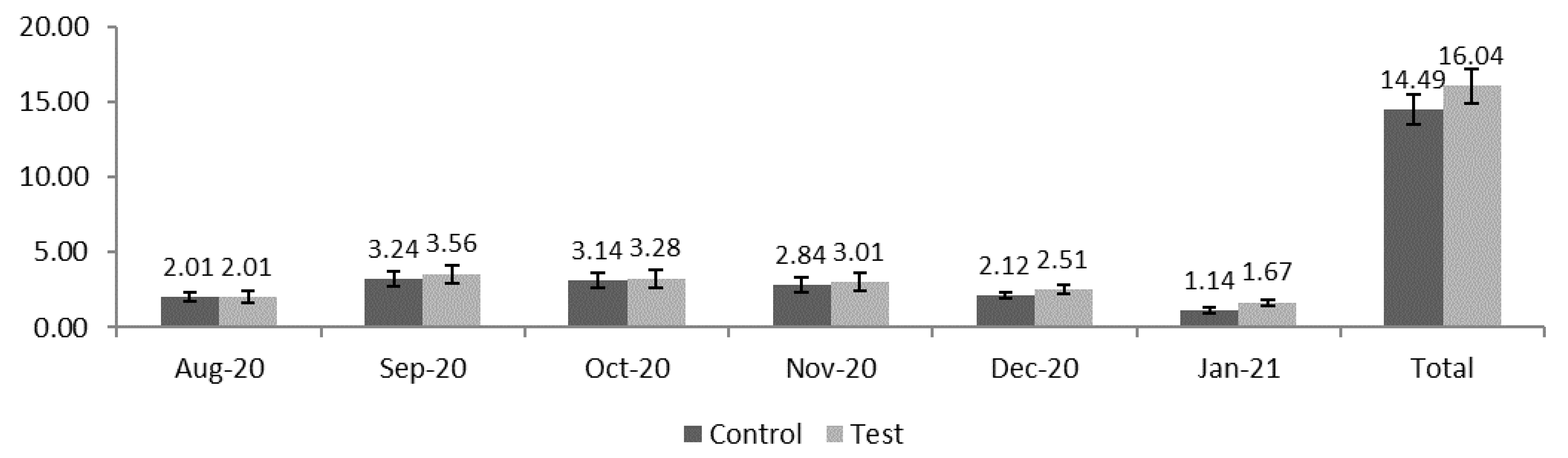

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Report from the Commission to the European Parliament and the Council on the Implementation of Regulation (EC) No 1185/2009 of the European Parliament and of the Council of 25 November 2009 Concerning Statistics on Pesticides. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A52017DC0109 (accessed on 20 November 2021).

- Kariathi, V.; Kassim, N.; Kimanya, M. Pesticide exposure from fresh tomatoes and its relationship with pesticide application practices in Meru district. Cogent Food Agric. 2016, 2, 1196808. [Google Scholar] [CrossRef]

- Kihampa, C.; Mato, R. Residues of Organochlorinated Pesticides in Soil from Tomato Fields, Ngarenanyuki, Tanzania. JASEM 2010, 4, 37–40. [Google Scholar] [CrossRef]

- Kihampa, C.; Mato, R. Levels of pesticide residues in irrigation effluent from tomato fields in Owiro Estate, Tanzania. Int. J. Biol. Chem. Sci. 2010, 4, 601–607. [Google Scholar] [CrossRef]

- Tambe, A.B.; Mbanga, B.M.R.; Nzefa, D.L.; Nama, M.G. Pesticide usage and occupational hazards among farmers working in small-scale tomato farms in Cameroon. J. Egypt. Public Health Assoc. 2019, 94, 20. [Google Scholar] [CrossRef] [PubMed]

- Dey, A.; Mukherjee, A. Chapter 6—Plant-Derived Alkaloids: A Promising Window for Neuroprotective Drug Discovery. In Discovery and Development of Neuroprotective Agents from Natural Products; Brahmachari, G., Ed.; Elsevier: Amsterdam, The Netherlands, 2018; pp. 237–320. [Google Scholar]

- Shin, M.; Umezawa, C.; Shin, T. Natural Anti-Microbial Systems|Antimicrobial Compounds in Plants. In Encyclopedia of Food Microbiology, 2nd ed.; Batt, C.A., Tortorello, M.L., Eds.; Academic Press: Oxford, UK, 2014; pp. 920–929. [Google Scholar]

- Hill, G.D. Plant Antinutritional Factors|Characteristics. In Encyclopedia of Food Sciences and Nutrition, 2nd ed.; Caballero, B., Ed.; Academic Press: Oxford, UK, 2003; pp. 4578–4587. [Google Scholar]

- Silva, N.; Ruiz-Cruz, S.; Cira, L.; Estrada, M.; Ornelas-Paz, J.; López, M.; Del Toro, L.; Ayala-Zavala, J.F.; Marquez Rios, E. Total Phenolic, Flavonoid, Tomatine, and Tomatidine Contents and Antioxidant and Antimicrobial Activities of Extracts of Tomato Plant. Int. J. Anal. Chem. 2015, 2015, 284071. [Google Scholar]

- Chiu, F.L.; Lin, J.K. Tomatidine inhibits iNOS and COX-2 through suppression of NF-κB and JNK pathways in LPS-stimulated mouse macrophages. FEBS Lett. 2008, 582, 2407–2412. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kozukue, N.; Han, J.S.; Lee, K.R.; Friedman, M. Dehydrotomatine and α-Tomatine Content in Tomato Fruits and Vegetative Plant Tissues. J. Agric. Food Chem. 2004, 52, 2079–2083. [Google Scholar] [CrossRef] [PubMed]

| Sample/Month | Aug-20 | Sep-20 | Oct-20 | Nov-20 | Dec-20 | Jan-21 |

|---|---|---|---|---|---|---|

| Control | Good * | Presence of mealybug larvae (average: 8 ± 2/leaf) | Presence of mealybug larvae (average: 5 ± 2/leaf) | Presence of mealybug larvae (average: 2 ± 1/leaf) | 2 plants infected by botrytis | Good |

| Test | Good | Presence of mealybug larvae (average: 6 ± 2/leaf) | Presence of mealybug larvae (average: 3 ± 1/leaf) | Good | 3 plants infected by botrytis | Good |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Papadaki, S.; Panagiotopoulou, M.; Pekakis, P.; Thanassoulia, I.; Krokida, M.; Symeonidou, P. Innovative Functional Plastic Films as Cover for Stonewool Grow Blocks and Their Effect on Tomato Hydroponic Cultivation. Chem. Proc. 2022, 10, 56. https://doi.org/10.3390/IOCAG2022-12328

Papadaki S, Panagiotopoulou M, Pekakis P, Thanassoulia I, Krokida M, Symeonidou P. Innovative Functional Plastic Films as Cover for Stonewool Grow Blocks and Their Effect on Tomato Hydroponic Cultivation. Chemistry Proceedings. 2022; 10(1):56. https://doi.org/10.3390/IOCAG2022-12328

Chicago/Turabian StylePapadaki, Sofia, Margarita Panagiotopoulou, Pantelis Pekakis, Ioanna Thanassoulia, Magdalini Krokida, and Polimachi Symeonidou. 2022. "Innovative Functional Plastic Films as Cover for Stonewool Grow Blocks and Their Effect on Tomato Hydroponic Cultivation" Chemistry Proceedings 10, no. 1: 56. https://doi.org/10.3390/IOCAG2022-12328

APA StylePapadaki, S., Panagiotopoulou, M., Pekakis, P., Thanassoulia, I., Krokida, M., & Symeonidou, P. (2022). Innovative Functional Plastic Films as Cover for Stonewool Grow Blocks and Their Effect on Tomato Hydroponic Cultivation. Chemistry Proceedings, 10(1), 56. https://doi.org/10.3390/IOCAG2022-12328