1. Introduction

In the oil and gas extraction process, formation water is extracted, which is retained during subsurface formations. This water has a composition similar to seawater, but with some compounds in concentrations that can reach a toxic level to the environment [

1].

Along with the formation water, there is injected water, which is seawater with additives used for the oil extraction process, and together, they are called production water [

2].

Production water is destined for reuse in injection into the oil well for extraction or is sent for treatment and consequent disposal in the environment.

The Brazilian Resolution established the maximum dissolved manganese content of 1 mg L−1. However, it did not define the methodologies to be used, accepting that the competent environmental body must define the test methods to be used.

Scientific studies have shown that excessive manganese intake can lead to cognitive disorders such as learning disabilities and memory problems. Additionally, high concentrations of manganese in water can also have an effect on the central nervous system, leading to symptoms like Parkinson’s disease [

3,

4]. Furthermore, the health problems that most affect employees exposed to a considerable amount of manganese impact the nervous system. Such health effects include behavioral changes, and mainly those related to movements that appear slower and clumsier [

5,

6].

As there is no definition of a specific methodology for the determination of dissolved manganese, the choice being optional, within the various forms of determination presented by the authorities, each laboratory in the Petrobras System carries out the analysis using a methodology chosen with consideration of the physical structure of the laboratory, people, and budget. Recent studies analyzing manganese in produced water use the analytical techniques of optical emission spectrometry with inductively coupled plasma [

7,

8,

9], and mass spectrometry with inductively coupled plasma [

10,

11]. More attention has been paid to the analytical assessment of oil fields using water treatment technologies [

12,

13].

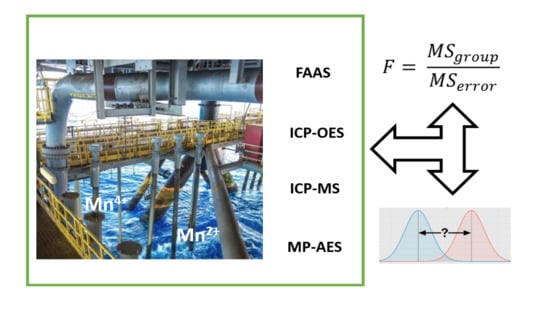

This study aimed to evaluate the compatibility between the methodologies used in the Petrobras System for determining dissolved manganese content in production water, from sample preparation to its effective analysis.

2. Test Methods

Spectroscopic methods for elemental analysis are based on the interaction between light (at wavelengths ranging from ultraviolet to infrared, in an approximate range between 180 nm and 800 nm) and matter (more specifically, in the specific electronic configuration of each element at its atomic level) [

14].

For water samples, the techniques of FAAS (Flame Atomic Absorption Spectrometry) and ICP-OES (inductively coupled plasma–optical emission spectrometry) are commonly used in the laboratory for the analysis of metals (and some semimetals such as silicon) [

15]. Both techniques can quantify concentrations as low as micrograms of the element of interest per gram of sample tested, “µg/g”. It is widespread to refer to the equivalent units “µg/g” or “mg/kg” with the expression “ppm” (parts per million), but this notation can cause confusion with the units “µg/mL” or “mg/L”.

Different methodologies are established for analyzing metals in water using these two analytical techniques. In the Standard Methods for the Examination of Water and Wastewater, a reference for water analysis, there are procedures described for both techniques: 3111 Metals by Flame Atomic Absorption Spectrometry [

16] and 3120 Metals by Plasma Emission Spectroscopy [

17].

It is widely accepted that the results obtained by the two techniques are equivalent. Thus, for example, we have an indication of procedures in the “Standard Methods for Examination of Water and Wastewater” for analyees of metals and other elements described by the FAAS (STD 3111) and ICP-OES (STD 3120) techniques without distinguishing between the results obtained. The same can be observed with methods from the ASTM International, known before as “American Society for Testing and Materials” (ASTM), the examples being methods D5184 (2022) “Standard Test Methods for Determination of Aluminum and Silicon in Fuel Oils by Ashing, Fusion, Inductively Coupled Plasma Atomic Emission Spectrometry, and Atomic Absorption Spectrometry” [

18], D5863 (2022) “Standard Test Methods for Determination of Nickel, Vanadium, Iron, and Sodium in Crude Oils and Residual Fuels by Flame Atomic Absorption Spectrometry” [

19] and D5708 (2020) “Standard Test Methods for Determination of Nickel, Vanadium, and Iron in Crude Oils and Residual Fuels by Inductively Coupled Plasma (ICP) Atomic Emission Spectrometry” [

20]. Other examples like this can be found in procedures “International Organization for Standardization” (ISO), Universal Oil Products (UOP) and Brazilian Association of Technical Standards (ABNT).

2.1. FAAS

In flame atomic absorption spectrophotometry (FAAS), a standard solution or sample is drawn as a fine mist into a flame, where it is converted into an atomic vapor consisting of ground atoms. A characteristic monochromatic radiation (normally generated using a hollow cathode lamp consisting of the element of interest) is directed towards the flame. The fraction of light absorbed by the analyte is quantified by comparing the light transmitted through the flame during the nebulization of a known concentration of the analyte with the light transmitted during the nebulization of a solution that does not contain any measurable concentration of the analyte.

The detection limits of this approach can vary in the order of 0.5 to 300 µg L

−1. Its main advantages are simplicity and lower costs than plasma-based techniques (the gases most used by FAAS are acetylene, nitrous oxide, and air, which are much cheaper than argon), and sometimes, for metrological control purposes, the analytical blank must be considered [

21].

Recent studies have used FAAS to measure the concentration of several heavy metals, including Mn, in wastewater [

22,

23,

24].

2.2. ICP-OES

Inductively coupled plasma–optical emission spectroscopy (ICP-OES) is an analytical technique that consists of injecting the sample (usually in liquid form) into the spectrometer through a sample introduction system, where the liquid is nebulized into small drops, which are classified in a nebulization chamber so that only the smallest droplets follow, forward to an argon plasma, where the components are atomized and excited. The energy issued is specific to each element and can be quantified by establishing a relationship between the concentration of known standards and the emission signal.

The detection limits of this approach can vary in the order of 0.1 to 100 µg L−1, and its main advantages are the capacity for multi-element analysis, good sensitivity for many elements (almost 30 elements), few and well-documented interferences and linear calibration over a wide dynamic concentration range (from 4 to 6 orders of magnitude).

The risk to human health of manganese contamination from wastewater discharge into rivers without any treatment can be assessed by ICP-OES [

25,

26,

27].

2.3. ICP-MS

Inductively coupled plasma–mass spectrometry (ICP-MS) is an analytical technique that uses as an ionization source a high-energy argon plasma, a detector, and a mass spectrophotometer, which presents great sensitivity for determining large numbers of elements from the periodic table to be quantified, without major problems caused by spectral interference caused by isobaric overlap.

The detection limits can vary in the order of 0.001 to 0.1 µg L−1, and its main advantage is the possibility of rapid sequential multi-element analysis combined with high sensitivity. It is important to highlight that the ICP-MS technique is a widespread and widely used technique due to the corrections and attenuations of spectral interferences.

The pollution control caused by manganese and other heavy metals in untreated industrial and domestic wastewater has been evaluated by ICP-MS [

28,

29,

30].

2.4. MP-AES

Microwave Plasma Atomic Emission Spectroscopy (MP-AES) is an analytical technique that uses plasma generated through microwave energy with nitrogen as a fuel source, unlike ICP-OES, which is also an optical/atomic emission technique and uses argon [

1]. As it is a relatively recent technique, methodological standards for water analysis using this technique are not found in the literature, the most widespread being ICP-OES.

MP-AES is a multi-element, spectroscopic technique based on the emission of characteristic light from excited atoms present in a sample. The process begins with introducing the sample in an aerosol format using a nebulizer and a nebulization chamber. This aerosol is introduced into the center of microwaves’ high-temperature (5000 K) plasma. This plasma, composed of highly energetic atoms, ions, and electrons, induces the transition of electrons to excited states in the sample atoms. When these electrons return to their ground state, they emit photons of characteristic light (wavelength), whose intensity is proportional to the concentration of the measurand present. The wavelengths generated are directed to a monochromator that selects the wavelength of the desired element and sent to a spectrometer that is used to measure and quantify these spectral emissions, allowing the determination of the elements in the sample. The instrument’s detection limits reach values in the ppb range. This limit is calculated by analyzing seven blanks and applying a factor of 3.14 times the standard deviation to the results. In contrast, the method’s limit of quantification (MLOQ) was defined as ten times the standard deviation of 7 blank measurements multiplied by the dilution factor. Lorençatto et al.’s study indicates agreement between the results obtained by the MP-AES and ICP-OES methodologies for analysis in effluents [

31].

The heavy metal pollution index of water quality has recently been evaluated by MP-AES [

32,

33].

3. Experimental

Eight laboratories, using different analytical techniques, participated in this study: Lab 1—FAAS, model SpectrAA 280, Agilent, 279.5 nm, slit 0.2 nm, air–acetylene flame and oxidizing stoichiometry, undiluted samples, APHA Method 3111; Lab 2—ICP-OES, model 5800, Agilent, argon plasma, wavelength of 257.610 nm, ASTM D1976; Lab 3—ICP-OES, model iCAP 6300 Duo, argon plasma, 257.610 nm, EPA Method 6010D; Lab 4—ICP-OES, model AA240FS, Varian/AA240FS, sample digestion with PA nitric acid, wavelength of 279.5 nm, APHA Method 3120; Lab 5—ICP-OES, model Optima 8300, Perkin Elmer, APHA Method 3120; Lab 6—ICP-MS, model 7700, Agilent wet acid digestion in open system, APHA Method 3120; Lab 7—ICP-OES, model 5800, Agilent, two views (radial and axial) and with the sample without dilution and with one-, two- and three-fold dilutions (for evaluating the effects of the saline matrices), and wavelengths of 257.610, 259.372 and 260.568 nm; and Lab 8—MP-AES, model 4200, Agilent, wavelength 403.076 nm, argon gas used for ignition and nitrogen during analysis.

All reagents used in these labs were of analytical grade. All equipment and the volumetric glassware were given by an accredited body within their expiration dates.

Labs 2 and 5 are accredited by ISO/IEC 17025, while the others have proper quality control procedures such as control charts, and they use validated procedures with participation in interlaboratory comparisons for this measurand.

Firstly, to map whether all laboratories have metrological compatibility, Lab 3 prepared five real test samples, which were collected, filtered, and subsequently acidified: sample A, 1 mg L−1 Mn; sample B, 0.5 mg L−1 Mn; sample C, 0.2 mg L−1 Mn; sample D, 1 mg L−1 Mn doped with 1 mg L−1 Mn standard; and sample E, 0.2 mg L−1 Mn doped with 1 mg L−1 Mn standard. We did not use certified reference materials (CRM) because our objective was to compare metrological compatibility between laboratories and different test methods, and not evaluate the accuracy. These five samples were refrigerated and sent to six different laboratories, labeled as Labs 1 to 6, action (i).

The concentrations were determined by Lab 1, which was considered a reference for the initial phase of the study. The samples were diluted on demand using the SIPS automatic diluter, and the calibration curve was carried out with 0, 0.1, 0.2, 0.3, 0.4 and 0.5 mg L

−1. For all equipment, an unweighted linear regression was considered appropriate [

34].

Next, actions were defined based on the results of the methodological compatibility study, action (i): (ii) visit to Lab 7, as its analyses were temporarily being carried out by a contracted laboratory, Lab 2; (iii) methodological compatibility study between Labs 1 and 7; and (iv) methodological compatibility study between Lab 1 and a new laboratory, Lab 8, to implement and validate the latter’s analytical methodology.

4. Results and Discussion

4.1. Initial Methodological Compatibility Study

Each laboratory received five samples and Labs 1, 2, 3 and 6 performed the test with five replicates, while Lab 4 performed it with three, four or five replicates and lab 5 used three replicates.

Table 1 presents the results obtained by each laboratory.

To evaluate metrological compatibility between the six laboratories, the single-factor (or one-way) Analysis of Variance test was applied [

35] (

Table 2) after guaranteeing homogeneity and stability conditions [

36].

Since the critical values, F critical, for a 95% confidence level, are smaller than the calculated values, F calculated, there are significant differences; that is, systematic errors arose among the six laboratories for samples A, B, C, D and E. Furthermore, it was possible to observe that the Lab 2 values (

Figure 1) were wildly divergent in magnitude compared to the other laboratories with low results (approximately by half) and those observed in the routine results of the contracted external laboratory. Furthermore, it is easy to see that there is a bias among laboratories.

Then, Lab 2’s results were discarded, and the single-factor Analysis of Variance [

35] test was applied again (

Table 3).

Even excluding Lab 2, the critical values, F critical, for a 95% confidence level are lower than the calculated values, F calculated; there are significant differences, that is, systematic errors, between the five laboratories for samples A, B, C, D and E. Although the results from these five laboratories are in the same order of magnitude, fine adjustments are still necessary to guarantee metrological compatibility between them.

4.2. Visit to Lab 7

Lab 7 was performing these tests routinely, and they claimed that the results were the same as they had observed in the results issued by Lab 2, whom they hired. Since Lab 2 took on routine analysis and participated in the initial stage of this study (

Section 3), it was necessary to evaluate what happened. Therefore, it was possible to infer, but not affirm, that Lab 2 could commit the same operational errors as Lab 7. Its operational conditions were: (i) axial view, wavelengths 257.610, 259.372 and 260.568 nm, indicated dilution, internal standard Y; and (ii) radial view, wavelengths 257.610, 259.372 and 260.568 nm, indicated dilution, without internal standard.

In this part of the study, possible reasons were addressed to explain why the results obtained by one of the laboratories carrying out the Mn test in water using the ICP-OES technique differed from those of the others. During a technical visit after the comparison test, new samples were taken and analyzed in comparison with pre-established results at Lab 1 based on FAAS analysis. With the observations from this visit, new experiments were proposed in Lab 7 that used ICP-OES, and the results of these experiments confirm the influences of the sample matrix and indicate that with some adjustments, the methodology used in this laboratory will derive results equivalent to the others. During the technical visit, experiments were carried out, as described below.

Firstly, Lab 1’s Mn standard was analyzed (

Table 4). If divergent results were obtained, this would indicate problems in one of the standards (Lab 1 or Lab 7). Two different dilutions were analyzed, one for a final concentration of 1 mg L

−1 and the other for 5 mg L

−1. No significant difference was observed in the reading of the 1 mg L

−1 dilution. At the 5 mg L

−1 dilution, the constructed curve was extrapolated to lower concentrations, but still, only the axial reading exceeded the maximum difference of 5%. Problems with standards can be ruled out.

It is worth an additional explanation that in the case of ICP-OES, the “vision” is the relative position from which the radiant energy coming from the emission of the analyzed elements (in this case Mn) is captured by the instrument, whether above the axis of the argon torch (axial) or perpendicular to the argon torch (radial). The axial view captures more energy and is, in theory, more sensitive. On the other hand, it is more susceptible to interference than radial vision.

Afterwards, samples taken from Lab 1, recently analyzed using the FAAS technique, were analyzed. The results obtained are summarized in

Table 5.

Evaluating qualitatively, even because there are not many data available, it is observed that the final results of diluted samples are greater than those of undiluted samples (already considering the dilution factors). It is also clear that the results in the radial view were closer to those obtained in Lab 1.

It was then suggested that the visited laboratory carry out new experiments measuring in radial and axial views and using at least two different dilutions per sample.

4.2.1. Additional Testing for Mn in Two Samples

A series of experiments were carried out by the laboratory team involving the analysis of two different real test samples of produced water (here called P and S) at the three most sensitive wavelengths for Mn (257.610, 259.372 and 260.568 nm), in the two views (radial and axial) and with the sample without dilution and with one-, two- and three-fold dilutions (

Table 6).

The results were sent to Lab 1 for evaluation. In general, it is possible to observe the following in the eighteen results for each sample.

The wavelength has no significant influence on the results;

Table 7 presents the results for sample P and S, both with six replicates.

The results of the more diluted samples converge to slightly higher values;

Table 8 presents the results of samples P and S with six replicates.

The results of the axial view differ systematically from the radial view with lower values;

Table 9 presents the results of samples P and S with nine replicates.

Higher dilutions show less matrix influence. Suppose one considers only the read values without multiplying the dilution factor. In that case, the difference between the views becomes less than 100 µg/L (0.1 mg L

−1) from the two-fold dilution and less than 50 µg/L (0.05 mg L

−1) with dilutions starting from three-fold,

Table 10.

In the samples in question, no differences were observed between the results of different wavelengths, reinforcing the hypothesis that the observed interferences are related to the salt matrix (it is unlikely that a specific interferent, such as any element, will cause changes in more than one wavelength).

As expected, the results from the radial view tend to be less susceptible to interference than those obtained from the axial view. It was also observed that sample dilution reduces potentially unwanted effects of the saline matrices under study, including on the axial view.

4.2.2. Additional Testing for Mn in Three Samples

After adjustments were made following Lab 1 guidance, additional tests were carried out on three samples. The data sent were evaluated using the same model referred to in

Section 4.2.1.

It is worth highlighting that tests were carried out using the resources and time available in a laboratory with different demands and routines.

Three real test samples of produced water (66, 68 and 69) were analyzed at three different wavelengths (

Table 11) in three different dilutions (without dilution, twice diluted, and three times diluted)—

Table 12 and in two views

Table 13.

Table 12 includes the Ba results analyzed under wavelength 233.527 nm and from the radial view.

The results from Lab 7 and Lab 1 agree within a range below +/−0.10 mg L

−1 (100 µg L

−1) (

Table 14).

In the tested samples, no relevant difference was observed between the results of the different wavelengths. As expected, the results from the radial view tend to be less susceptible to interference than those obtained from the axial view. The results obtained in two different laboratories using different techniques and conditions converged, with differences of less than +/−100 µg/L (+/−0.1 mg L−1).

As in the previous test (

Section 4.2.1), the observed interferences seem to be related to the saline matrix. Therefore, it was observed that, for both Mn and Ba, sample dilution reduces the potentially unwanted effects of the saline matrices that constitute the samples.

4.2.3. Test for Mn in Six Samples with Pre-Established Analysis Conditions

Six real test samples of produced water were analyzed by Lab 7 and then sent to Lab 1.

It is worth highlighting that tests were carried out using the resources and time available in a laboratory with different demands and routines.

The results obtained are shown in

Table 15.

Paired

t-tests [

35] were performed, with the results shown in

Table 16.

As “t Critical two-tail” (critical or tabulated value) is greater than the t-Stat (calculated value), there is metrological comparability between Lab 1 and Lab 7 for a confidence level of 95%.

The conditions established in the tests must be maintained for other samples to be analyzed by them:

- (i)

Lab 7—Mn element, ICPOES technique, wavelength 257.610 nm, radial view, 3× and 5× dilutions (or 5× and 10× depending on the range). Suggested calibration curve—0, 0.1, 0.2, 0.5 and 1.0 mg L−1 (as the samples are at least three times diluted, the working range would be 0.3 to 3 mg L−1);

- (ii)

Lab 1—Mn element, FAAS technique, 279.5 nm, slit 0.2 nm, air–acetylene flame, oxidizing stoichiometry. Samples were diluted on demand using the SIPS automatic diluter. Calibration curve—0, 0.1, 0.2, 0.3, 0.4 and 0.5 mg L−1.

4.3. Phase 3—Methodological Compatibility between Lab 1 versus Lab 8

After technicians from Lab 8, using MP-AES, gained experience in carrying out this test method, 14 real test samples of produced water were analyzed by this laboratory and Lab 1 (

Table 17).

The operational conditions for Lab 8 were a wavelength of 403.076 nm, with argon gas used for ignition and nitrogen during analysis.

To evaluate the metrological compatibility between the two laboratories, the

t-test was applied, with two samples in pairs for means (

Table 18).

As t-Stat is smaller than t Critical two-tail, there is metrological comparability between Lab 1 and Lab 8 with a confidence level of 95%.

5. Conclusions

The methodological compatibility study initially indicated systematic errors among the six laboratories for samples A, B, C, D, and E. Lab 1’s results were wildly divergent in magnitude compared to the other five laboratories. Even excluding the results from Lab 1, we observed that there were still significant differences between the results from the group of five laboratories, indicating that there were still systematic errors.

Next, after the visit to Lab 7, recommendations were presented, which, as is worth highlighting, do not constitute a final diagnosis and should be considered only as one of the steps in improving the Mn quantification test methods in produced water. As a simplification of the procedure adopted in the tests, the wavelength 257.610 nm in the radial view can be used as a reference for the results, with a dilution of at least three times the original sample being used for the dilution of the acidified solution (as has already been done). However, maintaining the other wavelengths, especially the axial view, would help us acquire more data for a more consistent future decision. Adopting an alternative dilution is helpful when carrying out tests as it constitutes an actual duplicate of the sample, making more data available for evaluation.

Finally, the study shows that the results between Lab 1 and Lab 7 were compatible within the 95% confidence interval, and therefore, Lab 7 could carry out the tests, allowing it to include Mn analyses in its analytical routine now.

As regards future work, although the results from other laboratories were of the same order of magnitude, this study recommends that fine adjustments be made to ensure metrological compatibility between them.

Author Contributions

Conceptualization, G.K.B.M., V.B.F., R.E.J. and E.C.d.O.; methodology, G.K.B.M., V.B.F., R.E.J. and E.C.d.O.; software, G.K.B.M., V.B.F., R.E.J. and E.C.d.O.; validation, G.K.B.M., V.B.F., R.E.J. and E.C.d.O.; formal analysis, G.K.B.M., V.B.F., R.E.J. and E.C.d.O.; investigation, G.K.B.M., V.B.F., R.E.J. and E.C.d.O.; resources, G.K.B.M., V.B.F., R.E.J. and E.C.d.O.; data curation, G.K.B.M., V.B.F., R.E.J. and E.C.d.O.; writing—original draft preparation, G.K.B.M., V.B.F., R.E.J. and E.C.d.O.; writing—review and editing, G.K.B.M., V.B.F., R.E.J. and E.C.d.O.; visualization, G.K.B.M., V.B.F., R.E.J. and E.C.d.O.; supervision, G.K.B.M., V.B.F., R.E.J. and E.C.d.O.; project administration, G.K.B.M., V.B.F., R.E.J. and E.C.d.O.; funding acquisition G.K.B.M., V.B.F., R.E.J. and E.C.d.O. All authors have read and agreed to the published version of the manuscript.

Funding

The authors thank the Brazilian agency CNPq for the financial support provided through the scholarship (305479/2021-0). This study was financed in part by the Coordenação de Aperfeiçoamento de Pessoal de Nível Superior—Brasil (CAPES)—Finance Code 001.

Data Availability Statement

Data are contained within the article.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Pascoal, M.S.D.; Klemz, A.C.; Weschenfelder, S.E.; Júnior, A.E.O.; Cunha, M.d.F.R.d.; Costa, B.R.d.S.; González, S.Y.G.; dos Santos, E.; Marinho, B.A.; Mazur, L.P.; et al. Intensification of naphthenic acids removal by liquid-liquid extraction of synthetic offshore produced water using onboard fuel. Process. Saf. Environ. Prot. 2024, 182, 11–19. [Google Scholar] [CrossRef]

- De Oliveira, E.C.; Biazon, C.L.; Moreira, R.M.; Filho, P.L.S. Uncertainty evaluation in the determination of oil and grease content in produced water by colorimetric method using Monte Carlo Simulation. Pet. Sci. Technol. 2019, 37, 436–442. [Google Scholar] [CrossRef]

- Balachandran, R.C.; Mukhopadhyay, S.; McBride, D.; Veevers, J.; Harrison, F.E.; Aschner, M.; Haynes, E.N.; Bowman, A.B. Brain manganese and the balance between essential roles and neurotoxicity. J. Biol. Chem. 2020, 295, 6312–6329. [Google Scholar] [CrossRef]

- Baj, J.; Flieger, W.; Barbachowska, A.; Kowalska, B.; Flieger, M.; Forma, A.; Teresińnski, G.; Portincasa, P.; Buszewicz, G.; Radzikowska-Büchner, E.; et al. Consequences of Disturbing Manganese Homeostasis. Int. J. Mol. Sci. 2023, 24, 14959. [Google Scholar] [CrossRef]

- Markiv, B.; Expósito, A.; Ruiz-Azcona, L.; Santibáñez, M.; Fernández-Olmo, I. Environmental exposure to manganese and health risk assessment from personal sampling near an industrial source of airborne manganese. Environ. Res. 2023, 224, 115478. [Google Scholar] [CrossRef]

- Wong, M.M.H.; Chan, K.Y.; Lo, K. Manganese Exposure and Metabolic Syndrome: A Systematic Review and Meta-Analysis. Nutrients 2022, 14, 825. [Google Scholar] [CrossRef] [PubMed]

- Hu, L.; Wang, H.; Xu, P.; Zhang, Y. Biomineralization of hypersaline produced water using microbially induced calcite precipitation. Water Res. 2021, 190, 116753. [Google Scholar] [CrossRef] [PubMed]

- Joseph, A.; Udofia, U.; Ajang, R. Evaluation of the water quality of borehole water from a partially remediated oil spill site in Ikot Ada Udo, Akwa Ibom State, South–South Nigeria. Environ. Technol. Innov. 2021, 24, 101967. [Google Scholar] [CrossRef]

- Al Dawery, S.K.; Al-Sawai, M.K.; Al Muzami, G.M.S.; Annamareddy, S.H.K.; Al Dawari, M.S.; Harharah, R.H.; Harharah, H.N.; Amari, A. Treatment of Produced Water Using Prepared Activated Carbon-Based Sewage Sludge. Separations 2023, 10, 519. [Google Scholar] [CrossRef]

- Xiao, F. Characterization, and treatment of Bakken oilfield produced water as a potential source of value-added elements. Sci. Total Environ. 2021, 770, 145283. [Google Scholar] [CrossRef] [PubMed]

- Zhou, S.; Peng, S.; Li, Z.; Zhang, D.; Zhu, Y.; Li, X.; Hong, M.; Li, W.; Lu, P. Risk assessment of pollutants in flowback and produced waters and sludge in impoundments. Sci. Total Environ. 2022, 811, 152250. [Google Scholar] [CrossRef]

- Tamunokuro, K.; Ramirez, A.; Molinari, M. Review of Oilfield Produced Water Treatment Technologies. Chemosphere 2022, 298, 134064. [Google Scholar] [CrossRef]

- Hardi, M.; Siregar, Y.I.; Anita, S.; Ilza, M. Determination of Heavy Metals Concentration in Produced Water of Oil Field Exploration in Siak Regency. J. Phys. Conf. Ser. 2019, 1156, 012009. [Google Scholar] [CrossRef]

- Skoog, D.A.; West, D.M.; Holler, F.J.; Crouch, S.R. Fundamentals of Analytical Chemistry, 9th ed.; Brooks/Cole Cengage Learning: Boston, MA, USA, 2014. [Google Scholar]

- Sohrabi-Gilani, N.; Ghayournezhad, A.; Mansour, S.R. Determination of Ultratrace Levels of Cobalt (II) and Chromium (III) by Magnetic Dispersive Solid-Phase Extraction (SPE) Using Urea-Formaldehyde Polymer/Magnetite Nanoparticles with Flame Atomic Absorption Spectrometry (FAAS). Anal. Lett. 2022, 55, 2650–2667. [Google Scholar] [CrossRef]

- Rice, E.W.; Baird, R.B.; Eaton, A.D.; Clesceri, L.S. 3111 Metals by flame atomic absorption spectometry. In Standard Methods for the Examination of Water and Wastewater; American Public Health Association: Washington, DC, USA; American Waterworks Association: Denver, CO, USA; Water Environment Federation: Alexandria, VA, USA, 2012; p. 10. [Google Scholar]

- American Public Health Association. APHA/AWWA/WEF Method 3120B. In Standard Methods for the Examination of Water and Wastewater, 20th ed.; American Public Health Association: Washington, DC, USA, 1999. [Google Scholar]

- ASTM D5184-12(2017); Standard Test Methods for Determination of Aluminum and Silicon in Fuel Oils by Ashing, Fusion, Inductively Coupled Plasma Atomic Emission Spectrometry, and Atomic Absorption Spectrometry. ASTM International: West Conshohocken, PA, USA, 2017.

- ASTM D5863-00a(2016); Standard Test Methods for Determination of Nickel, Vanadium, Iron, and Sodium in Crude Oils and Residual Fuels by Flame Atomic Absorption Spectrometry. ASTM International: West Conshohocken, PA, USA, 2016.

- ASTM D5708-15(2020)e1; Standard Test Methods for Determination of Nickel, Vanadium, and Iron in Crude Oils and Residual Fuels by Inductively Coupled Plasma (ICP) Atomic Emission Spectrometry. ASTM International: West Conshohocken, PA, USA, 2020.

- De Oliveira, E.C.; Monteiro, M.I.; Pontes, F.V.; de Almeida, M.D.; Carneiro, M.C.; Da Silva, L.I.; Neto, A.A. Impact of the analytical blank in the uncertainty evaluation of the copper content in waters by flame atomic absorption spectrometry. J. AOAC Int. 2012, 95, 560–565. [Google Scholar] [CrossRef] [PubMed]

- Tokalıoğlu, Ş.; Moghaddam, S.T.H.; Yılmaz, Y.; Patat, Ş. NiCo2O4@ZnCo2O4 nanomaterial for selective and fast dispersive solid phase micro-extraction of manganese and lead in water, tea and cinnamon samples followed by FAAS determination. Microchem. J. 2023, 195, 109515. [Google Scholar] [CrossRef]

- Aydın, E.S.; Zaman, B.T.; Bozyiğit, G.D.; Bakırdere, S. Analytical application of flower-shaped nickel nanomaterial for the preconcentration of manganese in domestic wastewater samples. Environ. Monit. Assess. 2023, 195, 1358. [Google Scholar] [CrossRef]

- Ahmad, F.; Hafeez, S.; Anjum, F.; Munawar, T. Comparative Assessment of Heavy Metals in Water, Sediment and Adjacent Soil of Hudiara Drain. Proc. Pak. Acad. Sci. B Life Environ. Sci. 2019, 56, 67–75. [Google Scholar]

- Iqbal, Z.; Abbas, F.; Mahmood, A.; Ibrahim, M.; Gul, M.; Yamin, M.; Aslam, B.; Imtiaz, M.; Elahi, N.N.; Qureshi, T.I.; et al. Human health risk of heavy metal contamination in groundwater and source apportionment. Int. J. Environ. Sci. Technol. 2022, 19, 7251–7260. [Google Scholar] [CrossRef]

- Iqbal, Z.; Abbas, F.; Ibrahim, M.; Qureshi, T.I.; Gul, M.; Mahmood, A. Assessment of heavy metal pollution in Brassica plants and their impact on animal health in Punjab, Pakistan. Environ. Sci. Pollut. Res. 2021, 28, 22768–22778. [Google Scholar] [CrossRef]

- Addo-Bediako, A.; Rasifudi, L. Spatial distribution of heavy metals in the Ga-Selati River of the Olifants River System, South Africa. Chem. Ecol. 2021, 37, 450–463. [Google Scholar] [CrossRef]

- Jin, L.; Rampley, C.; Abebe, Y.; Bussi, G.; To, T.Q.; Ager, D.; Whitehead, P.G. Assessing Heavy Metal Contamination Using Biosensors and a Multi-Branch Integrated Catchment Model in the Awash River Basin, Ethiopia. Water 2023, 15, 4073. [Google Scholar] [CrossRef]

- Kumar, N.; Chandan, N.K.; Bhushan, S.; Singh, D.K.; Kumar, S. Health risk assessment and metal contamination in fish, water and soil sediments in the East Kolkata Wetlands, India, Ramsar site. Sci. Rep. 2023, 13, 1546. [Google Scholar] [CrossRef] [PubMed]

- Khan, K.; Younas, M.; Khan, M.S.; Li, X.; Fawad, M.; Shah, N.S.; Ali, J.; Ullah, S.; Ayaz, M.; Maryam, A.; et al. Heavy Metal Occurrence, Pathways, and Associated Socio-ecological Risks in Riverine Water: Application of Geographic Information System, Multivariate Statistics, and Risk Assessment Models. Water Air Soil Pollut. 2023, 234, 449. [Google Scholar] [CrossRef]

- Lorençatto, R.; Monção, D.N.; Silva, R.A. High Throughput, Multi-Element Analysis of Effluents by MP-AES; Agilent Technologies, Inc.: Santa Clara, CA, USA, 2020. [Google Scholar]

- Hasimuna, O.J.; Chibesa, M.; Mumbula, I.; Mphande, J.; Jere, W.W.L.; Phiri, D.; Nawanzi, K.; Siavwapa, S.; Maseko, A.F.; Munganga, B.P.; et al. Contamination of selected heavy metals in Limnothrissa miodon (Boulenger, 1906) in the four strata of Lake Kariba Zambia: Are the consumers at risk? J. Environ. Sci. Health B 2023, 58, 521–529. [Google Scholar] [CrossRef]

- Amala, O.; Vara, L.K.; Dadhich, A.S.; Ramesh, M. Water Quality Index and Heavy Metal Pollution Index of Groundwater Quality: A case Study in Visakhapatnam District, AP. Res. J. Chem. Environ. 2022, 26, 61–76. [Google Scholar] [CrossRef]

- De Oliveira, E.C.; De Aguiar, P.F. Methodology validation for evaluation of the uncertainty in the calibration curves better adjusted for second-degree polynomials. Quim. Nova 2009, 32, 1571–1575. [Google Scholar] [CrossRef]

- Miller, J.N.; Miller, J.C.; Miller, R.D. Statistics and Chemometrics for Analytical Chemistry, 7th ed.; Pearson: Harlow, UK, 2018. [Google Scholar]

- de Camargo, M.A.C.; Manea, G.K.B.; de Oliveira, E.C. A Comparative Study of Fuel Density Precision Data Using Digital Densimeter Meters at Two Different Temperatures. Energies 2024, 17, 23. [Google Scholar] [CrossRef]

Figure 1.

Samples versus laboratories.

Figure 1.

Samples versus laboratories.

Table 1.

Results of dissolved manganese content mg L−1.

Table 1.

Results of dissolved manganese content mg L−1.

| | | Lab 1 | Lab 2 | Lab 3 | Lab 4 | Lab 5 | Lab 6 |

|---|

| | | FAAS | ICP-OES | ICP-OES | ICP-OES | ICP-OES | ICP-MS |

| Sample A | 1st | 0.61 | 0.35 | 0.60 | 0.66 | 0.79 | 0.70 |

| 2nd | 0.61 | 0.35 | 0.60 | 0.67 | 0.79 | 0.70 |

| 3rd | 0.63 | 0.36 | 0.60 | 0.68 | 0.80 | 0.70 |

| 4th | 0.62 | 0.35 | 0.60 | 0.66 | | 0.70 |

| 5th | 0.63 | 0.36 | 0.60 | | | 0.70 |

| Sample B | 1st | 1.1 | 0.64 | 1.5 | 1.2 | 1.5 | 1.3 |

| 2nd | 1.1 | 0.64 | 1.4 | 1.2 | 1.4 | 1.3 |

| 3rd | 1.1 | 0.63 | 1.4 | 1.2 | 1.4 | 1.3 |

| 4th | 1.1 | 0.64 | 1.4 | 1.1 | | 1.4 |

| 5th | 1.1 | 0.65 | 1.4 | 1.2 | | 1.3 |

| Sample C | 1st | 1.9 | 1.1 | 2.3 | 2.0 | 2.4 | 2.3 |

| 2nd | 1.9 | 1.1 | 2.5 | 2.0 | 2.4 | 2.3 |

| 3rd | 1.9 | 1.1 | 2.3 | 1.9 | 2.4 | 2.3 |

| 4th | 1.9 | 1.1 | 2.3 | 2.0 | | 2.2 |

| 5th | 1.9 | 1.1 | 2.5 | 2.0 | | 2.3 |

| Sample D | 1st | 0.83 | 0.48 | 0.95 | 0.85 | 1.0 | 1.0 |

| 2nd | 0.83 | 0.47 | 0.93 | 0.85 | 1.0 | 1.1 |

| 3rd | 0.84 | 0.47 | 0.90 | 0.86 | 1.1 | 1.0 |

| 4th | 0.85 | 0.47 | 0.89 | | | 0.9 |

| 5th | 0.84 | 0.48 | 0.94 | | | 1.1 |

| Sample E | 1st | 1.6 | 0.92 | 1.8 | 1.7 | 2.0 | 1.9 |

| 2nd | 1.6 | 0.89 | 1.8 | 1.7 | 2.0 | 1.8 |

| 3rd | 1.6 | 0.89 | 1.8 | 1.7 | 2.0 | 1.8 |

| 4th | 1.6 | 0.91 | 2.0 | 1.7 | | 1.8 |

| 5th | 1.6 | 0.91 | 2.0 | 1.7 | | 1.8 |

Table 2.

One-way ANOVA between the six laboratories.

Table 2.

One-way ANOVA between the six laboratories.

| Source of Variation | F Calculated | F Critical |

|---|

| Sample A | 2816.06 | 2.68 |

| Sample B | 469.30 | 2.66 |

| Sample C | 577.68 | 2.66 |

| Sample D | 114.26 | 2.71 |

| Sample E | 255.94 | 2.66 |

Table 3.

Single-factor ANOVA between the five laboratories, without Lab 2.

Table 3.

Single-factor ANOVA between the five laboratories, without Lab 2.

| Source of Variation | F Calculated | F Critical |

|---|

| Sample A | 608.28 | 2.96 |

| Sample B | 86.43 | 2.93 |

| Sample C | 114.00 | 2.93 |

| Sample D | 16.78 | 3.01 |

| Sample E | 31.87 | 2.93 |

Table 4.

Result of the standards analyzed at Lab 1, mg L−1.

Table 4.

Result of the standards analyzed at Lab 1, mg L−1.

| Description | Diluted to | Axial View | Radial View |

|---|

| Monoelement standard 1000 mg L−1 (Lab 1) | 1.00 mg L−1 | 1.00 | 1.01 |

| 5.00 mg L−1 | 5.29 | 5.15 |

Table 5.

Samples analyzed at Lab 1 and Lab 2, in mg L−1, with detector in axial and radial view.

Table 5.

Samples analyzed at Lab 1 and Lab 2, in mg L−1, with detector in axial and radial view.

| | Lab 1 | Lab 7, Axial View | Lab 7, Radial View |

|---|

| Samples | | No Dilution | Diluted Twice | No Dilution | Diluted Twice |

|---|

| A | 1.63 | 1.11 | 1.35 | 1.50 | 1.72 |

| B | 1.25 | 0.82 | 1.03 | 1.16 | 1.31 |

| C | 0.94 | 0.71 | 0.90 | 1.05 | 1.24 |

| D | 1.21 | 0.78 | 0.99 | 1.12 | 1.31 |

| E | 0.31 | 0.24 | 0.26 | 0.35 | 0.39 |

Table 6.

Analysis of samples at different dilutions and detector positions, mg L−1.

Table 6.

Analysis of samples at different dilutions and detector positions, mg L−1.

| Sample | Dilution | Mn (nm) | Axial | Radial |

|---|

| P | 1× | 257.610 | 0.91 | 1.17 |

| P | 1× | 259.372 | 0.95 | 1.21 |

| P | 1× | 260.568 | 0.87 | 1.18 |

| P | 2× | 257.610 | 1.07 | 1.26 |

| P | 2× | 259.372 | 1.10 | 1.20 |

| P | 2× | 260.568 | 1.03 | 1.27 |

| P | 3× | 257.610 | 1.12 | 1.26 |

| P | 3× | 259.372 | 1.14 | 1.29 |

| P | 3× | 260.568 | 1.08 | 1.27 |

| S | 1× | 257.610 | 0.69 | 0.87 |

| S | 1× | 259.372 | 0.71 | 0.90 |

| S | 1× | 260.568 | 0.66 | 0.88 |

| S | 2× | 257.610 | 0.81 | 0.94 |

| S | 2× | 259.372 | 0.82 | 0.96 |

| S | 2× | 260.568 | 0.77 | 0.94 |

| S | 3× | 257.610 | 0.85 | 0.93 |

| S | 3× | 259.372 | 0.86 | 0.95 |

| S | 3× | 260.568 | 0.82 | 0.95 |

Table 7.

Different wavelengths, samples P and S.

Table 7.

Different wavelengths, samples P and S.

| Wavelength | Sample | Mn, Average (mg L−1) | Standard Deviation (mg L−1) |

|---|

| 257.610 nm | P | 1.13 | 0.13 |

| S | 0.85 | 0.09 |

| 259.372 nm | P | 1.15 | 0.12 |

| S | 0.87 | 0.09 |

| 260.568 nm | P | 1.12 | 0.16 |

| S | 0.84 | 0.11 |

Table 8.

Different dilutions, samples P and S.

Table 8.

Different dilutions, samples P and S.

| Dilution | Sample | Mn, Average (mg L−1) | Standard Deviation (mg L−1) |

|---|

| No dilution | P | 1.05 | 0.15 |

| S | 0.79 | 0.11 |

| Two times | P | 1.16 | 0.10 |

| S | 0.87 | 0.08 |

| Three times | P | 1.19 | 0.09 |

| S | 0.89 | 0.06 |

Table 9.

Detectors in different positions, samples P and S.

Table 9.

Detectors in different positions, samples P and S.

| Configuration | Sample | Mn, Average (mg L−1) | Standard Deviation (mg L−1) |

|---|

| Axial | P | 1.03 | 0.10 |

| S | 0.78 | 0.07 |

| Radial | P | 1.23 | 0.04 |

| S | 0.92 | 0.03 |

Table 10.

Samples P and S (read values, without considering dilution factor, mg L−1).

Table 10.

Samples P and S (read values, without considering dilution factor, mg L−1).

| Dilution | Axial | Radial | Difference |

|---|

| No dilution | 0.91 | 1.19 | 0.28 |

| 0.69 | 0.88 | 0.19 |

| Two times | 0.53 | 0.62 | 0.09 |

| 0.40 | 0.47 | 0.07 |

| Three times | 0.37 | 0.42 | 0.05 |

| 0.28 | 0.31 | 0.03 |

Table 11.

Samples 66, 68 and 69, at three different wavelengths, with six replicates.

Table 11.

Samples 66, 68 and 69, at three different wavelengths, with six replicates.

| Sample | Wavelength | Mn, Average (mg L−1) | Standard Deviation (mg L−1) |

|---|

| 66 | 257.610 nm | 0.17 | 0.03 |

| 259.372 nm | 0.18 | 0.03 |

| 260.568 nm | 0.17 | 0.03 |

| 68 | 257.610 nm | 0.05 | 0.01 |

| 259.372 nm | 0.06 | 0.01 |

| 260.568 nm | 0.05 | 0.01 |

| 69 | 257.610 nm | 0.33 | 0.10 |

| 259.372 nm | 0.37 | 0.09 |

| 260.568 nm | 0.32 | 0.10 |

Table 12.

Samples 66, 68 and 69, in three different dilutions, with six replicates, mg L−1.

Table 12.

Samples 66, 68 and 69, in three different dilutions, with six replicates, mg L−1.

| Sample | Dilution | Mn, Average | Standard Deviation | Ba, Average |

|---|

| 66 | No dilution | 0.16 | 0.03 | 0.97 |

| Two times | 0.18 | 0.02 | 1.07 |

| Three times | 0.19 | 0.02 | 1.18 |

| 68 | No dilution | 0.05 | 0.01 | 5.15 |

| Two times | 0.06 | 0.01 | 5.65 |

| Three times | 0.06 | 0.01 | 6.15 |

| 69 | No dilution | 0.30 | 0.10 | - |

| Two times | 0.33 | 0.09 | - |

| Three times | 0.37 | 0.09 | 1.66 |

Table 13.

Samples 66, 68 and 69, in two views (radial and axial), with nine replicates.

Table 13.

Samples 66, 68 and 69, in two views (radial and axial), with nine replicates.

| Sample | Wavelength | Mn, Average (mg L−1) | Standard Deviation (mg L−1) |

|---|

| 66 | axial | 0.15 | 0.02 |

| radial | 0.19 | 0.01 |

| 68 | axial | 0.05 | 0.01 |

| radial | 0.06 | 0.01 |

| 69 | axial | 0.25 | 0.04 |

| radial | 0.42 | 0.03 |

Table 14.

Analyses carried out at Lab 7 versus Lab 1, mg L−1.

Table 14.

Analyses carried out at Lab 7 versus Lab 1, mg L−1.

| Samples | Lab 7 (ICPOES) * (A) | Lab 1 (FAAS) ** (B) | Difference (AB) |

|---|

| 66 | 0.20 | 0.24 | −0.04 |

| 68 | 0.06 | 0.13 | −0.07 |

| 69 | 0.44 | 0.37 | +0.07 |

Table 15.

Analyses carried out at Lab 7 versus Lab 1, with pre-established analysis conditions, mg L−1.

Table 15.

Analyses carried out at Lab 7 versus Lab 1, with pre-established analysis conditions, mg L−1.

| Identification | Lab 7 | Lab 1 |

|---|

| Sample 1 | 0.38 | 0.32 |

| Sample 2 | 0.08 | 0.12 |

| Sample 3 | 0.11 | 0.14 |

| Sample 4 | 0.90 | 0.85 |

| Sample 5 | 0.99 | 0.85 |

| Sample 6 | 0.51 | 0.48 |

Table 16.

t-test: paired two samples for means, Lab 7 versus Lab 1.

Table 16.

t-test: paired two samples for means, Lab 7 versus Lab 1.

| | Lab 7 | Lab 1 |

|---|

| Mean | 0.495 | 0.46 |

| Variance | 0.14859 | 0.10844 |

| Observations | 6 | 6 |

| Pearson Correlation | 0.995294 | |

| Hypothesized Mean Difference | 0 | |

| Degrees of freedom | 5 | |

| t-Stat | 1.299867 | |

| P(T ≤ t) one-tail | 0.125171 | |

| t Critical one-tail | 2.015048 | |

| P(T ≤ t) two-tail | 0.250343 | |

| t Critical two-tail | 2.570582 | |

Table 17.

Results of the dissolved manganese content given by Lab 1 versus Lab 8, mg L−1.

Table 17.

Results of the dissolved manganese content given by Lab 1 versus Lab 8, mg L−1.

| Date | Sample Identification | Lab 1 | Lab 8 |

|---|

| 26 May 2023 | TP-3239 | 1.1 | 1.08 |

| 26 May 2023 | TP-3235 | 1.4 | 1.3 |

| 5 April 2023 | TP-3237 | 1.5 | 1.53 |

| 5 April 2023 | TP-3238 | 0.95 | 1.04 |

| 24 March 2023 | TEDUT-34242 Bottom | 1.4 | 1.4 |

| 24 March 2023 | TEDUT-34246 Superior | 1.4 | 1.4 |

| 13 February 2023 | TP-3235 Background | 1.0 | 0.96 |

| 13 February 2023 | TP-3237 Background | 0.72 | 0.79 |

| 13 February 2023 | TP-3238 Background | 1.6 | 1.5 |

| 13 February 2023 | TP-ETE B44 LINE | 1.1 | 0.96 |

| 24 January 2023 | TP ENTRY ETE ACID | 0.97 | 1.0 |

| 24 January 2023 | TP 1BB, 1BE, 4BB | 0.55 | 0.60 |

| 24 January 2023 | TP WATER 3235 | 0.93 | 0.96 |

| 24 January 2023 | TP WATER 3238 | 1.5 | 1.5 |

Table 18.

t-test: paired two samples for means, Lab 1 versus Lab 8.

Table 18.

t-test: paired two samples for means, Lab 1 versus Lab 8.

| | Lab 1 | Lab 8 |

|---|

| Mean | 1.155385 | 1.149231 |

| Variance | 0.110444 | 0.092658 |

| Observations | 13 | 13 |

| Pearson Correlation | 0.979593 | |

| Hypothesized Mean Difference | 0 | |

| Degrees of Freedom | 12 | |

| t-Stat | 0.316682 | |

| P(T ≤ t) one-tail | 0.378463 | |

| t Critical one-tail | 1.782288 | |

| P(T ≤ t) two-tail | 0.756926 | |

| t Critical two-tail | 2.178813 | |

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).