Abstract

Continuous monitoring of body movements or physicochemical health indicators by various wearable devices with intriguing geometries has attracted increasing research attention. Among them, fiber-based wearable devices have been intensively investigated due to the ease of fabrication, excellent flexibility and adaptability, and abundant applicable working mechanisms. Although various spinning methods can prepare composite fibers, obtaining highly conductive fibers at high filler-loading fractions has always been difficult. In addition, most synthetic fibers are designed only for specific applications, exhibiting narrow applicability. This work proposed a dual-functional smart fiber-based sensor that could work based on either piezoresistive or electrochemical mechanisms. Through the wet spinning of dopes containing nanosized carbon black and thermoplastic polyurethane, nanocomposite fibers with decent electrical conductivities (2.10 × 102 S m−1 or 4.77 × 10−3 Ω·m), high mechanical stretch abilities and toughness (εmax~2400%, KIC = 61.44 MJ m−3), as well as excellent self-heal abilities (η ≥ 64.8%), could be obtained. Such coupled electromechanical properties endowed the as-synthesized fibers with strain-sensing or biomarker monitoring capabilities based on piezoresistive or electrochemical mechanisms. The proposed novel dual-functional smart fibers demonstrated potential for multifunctional wearable health monitoring devices.

1. Introduction

Clothes and textiles, mainly weaved from various fibers, have been worn every day for centuries. And thus, fibers are some of the most frequently applied materials that come into contact with the human body [1]. As a result, fibers have also become an ideal platform for wearable electronics [2,3,4,5]. In recent years, fiber-based electronics have received tremendous attention from academics and industries due to their intriguing material and mechanical and physical properties, such as being source-abundant, having excellent flexibility and adaptability, good processability, and stimuli responsiveness [6,7,8,9]. As a result, smart functional fibers made of conductive thermoplastics have found critical applications in energy storage, power generation, flexible displays, wearable sensors, human-machine interfaces, etc. [10,11,12,13,14,15,16,17,18]. For example, by incorporating rGO flakes into porous polyurethane, a pressure sensor with tunable sensitivity ranging from 0.146 to 3.05 kPa−1 could be obtained [18]. Such works demonstrated the successful fusion of tradition and modern technologies.

Fibers can be fabricated by various spinning and drawing methods, including wet spinning, dry spinning, thermal drawing, electrospinning, and so on [18,19,20,21,22,23,24,25]. Among them, wet spinning as a potent synthetic fiber method exhibits unique advantages for scalability, convenience, and cost-effectiveness. Indeed, wet spinning has been proven effective for continuous fiber fabrication, with materials ranging from polymers and macromolecules, carbon nanotubes (CNTs), two-dimensional materials (e.g., graphene, MXene, etc.), to their composites [26,27,28,29,30,31]. For example, Sun et al. prepared polyacrylonitrile (PAN) fibers by wet spinning, and they found that the draw ratio had an essential effect on the crystallite orientation and the crystallinity of the fibers [26]. Chang et al. wet spun starch-grafted poly(butylacrylate/styrene) (St-g-PBAS) copolymer fibers with a mechanical strength as high as 2.11 cN·dtex−1 and a moderate elasticity of 88.2% [27]. Such fibers also exhibited a thermochromic effect, switching color from purple to pink when the temperature changed. Since most polymeric materials are non-conductive, electrically conductive fibers made of CNTs and conductive 2D materials were fabricated. For example, Tang et al. wet spun tough and strong graphene fibers from graphene oxide with fewer terminal groups and structural defects in 80 wt% acetic acid solution. Such graphene fibers exhibited high tensile strength (~875.9 MPa) and toughness (~13.3 MJ m−3), as well as an electrical conductivity of 1.06 × 105 S m−1, respectively [28]. In addition, Ti3C2Tx MXene fibers were fabricated by wet spinning in an aqueous solution containing NH4+, Cl−, and OH−, achieving a superior electrical conductivity of 7713 S cm−1 [30]. Although high conductivities were achieved in inorganic wet-spun fibers, the weak macroscopic strength and low extensibility (~5–10%) greatly limit their applications in wearable scenarios (at least 20% stretchability). Fabricating electrically conductive fibers based on conductive nanocomposites may balance the conflict. For example, Seyedin et al. wet-spun MXene/polyurethane fibers in either acetic acid or isopropyl alcohol coagulation baths as a wearable strain sensor, achieving a superhigh gauge factor of 12,900 at 152% strain [31].

Despite the efforts made on the wet spinning for electrically conductive nanocomposite fibers, several essential issues still need to be solved. (1) Firstly, achieving good electrical conductivities at high filler loading fractions is challenging. The high viscose dope dramatically increases the difficulties in blending and extrusion resistance. This becomes especially prominent for fillers with high aspect ratios, impeding fiber uniformity and stretchability [32]. (2) Secondly, to accelerate the solvent exchange or the gelation process catering to continuous fiber spinning, it is inevitable to use hazardous organic solvents or corrosive inorganic salts as coagulants [28,30,31]. This will lead to environmental and health issues. (3) Thirdly, most synthetic fibers are designed to function only for a single scenario, which is detrimental to fulfilling the potential and integration of the fiber. It would make more sense for the fibers to work based on multiple mechanisms for different targeted applications or scenarios, especially in wearable health monitoring devices where multiple health indicators are studied [33,34]. (4) Last, but not least, developing fibers with good stretchability and self-healing, along with high electrical conductivities, is desirable for bioelectronics, electronic skins, and human-machine interface applications. Particularly, self-healable electrically or thermally conductive polymeric nanocomposites have found important applications in various scenarios and are crucial for wearable electronics [35,36].

Concerning the abovementioned issues, conductive nanocomposite fibers were fabricated and proposed as novel dual-functional wearable sensors that could work based on either piezoresistive or electrochemical mechanisms. Such nanocomposite fibers consisting of nanosized conductive carbon black (CB) and highly resilient thermoplastic polyurethane (TPU) could be smoothly and continuously produced in an eco-friendly deionized (DI) water coagulation bath. Nanosized low aspect ratio CB facilitates the fabrication of the fiber at high filler loading fractions (50 wt%) while still preserving the mechanical compliance of TPU material. This endows the fiber with good electrical conductivity as high as 2.10 × 102 S m−1 (or 4.77 × 10−3 Ω·m), adjustable stretchability from 62 to 2400%, and decent self-healing capability (efficiency η > 65%). Furthermore, benefiting from the high electrical conductivity of such fibers, strain sensing or electrochemical detection of biomarkers could be achieved, exhibiting good application potential for monitoring either human motions or physicochemical health indicators, respectively. This kind of dual-functional smart fiber may be one of the potential candidates for the next-generation of fiber electronics.

2. Experimental Sections

2.1. Materials

All the materials and chemicals were used as received without further purification. Nanosized conductive carbon black (CB) was purchased from Alfa Aesar. Thermoplastic polyurethane (TPU 65a) was purchased from BASF (Shanghai, China) Co., Ltd. N,N-dimethylformamide (DMF) was obtained from General-reagent. The D(+)-glucose anhydrous, maltose, L-ascorbic acid, sodium chloride (NaCl), DL-lactic acid, and artificial saliva were purchased from Sinopharm Chemical Reagent Co., Ltd. (Shanghai, China). Uric acid (>98%) was obtained from TCI Co., Ltd. (Shanghai, China). The glucose oxidase from Aspergillus (>100 U/mg) was obtained from Sangon Biotech. Conductive carbon paste with Prussian Blue (PB) mediator was purchased from SunChemical Co. Ltd. (Parsippany, NJ, USA).

2.2. Fabrication of the Conductive Fibers

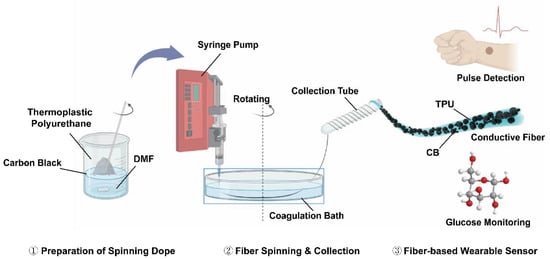

The fabrication flow of the fiber is shown in Figure 1. Firstly, the spinning dope was prepared by mixing TPU and nanosized CB, of which the formulation can be found in Table S1. In a typical preparation process, 2.0 g of TPU was fully dissolved in 12.75 mL DMF under vigorous magnetic stirring at 60 °C in a water bath until a uniform solution was obtained. After that, specific amounts of nanosized CB were added into the above solution with final filler loading fractions of 10–50 wt%, respectively. The mixture was continuously stirred until a uniform dope was obtained.

Figure 1.

Schematics illustrate the dual-functional fiber synthesized by wet spinning and its potential applications in human motion and health indicator monitoring.

Next, the as-prepared dope was utilized for the wet spinning of TPU/CB-based fibers. A 20 mL syringe was typically used to load the spinning dope attached with blunt-type nozzles (19, 21, 24 G), as shown in Table S2. Then, the plastic syringe was loaded onto a syringe pump (New Era Pump System, NE1000, Farmingdale, NY, USA) and the dope was injected into a DI water coagulation bath placed above a rotation stage at 0.05–0.15 mL min−1 (Table S3). The spinning dope was continuously injected into the coagulation bath and quickly coagulated into solid fibers, which could then be collected by a plastic tube and dried in the air before use.

2.3. Fabrication of the Dual-Functional Fiber Sensors

The as-fabricated fibers were then applied to fabricate various types of sensory devices. As for the strain sensor, the fiber was adhered to conductive copper tape fixed by silver paste and then attached to various parts of the human body, such as the wrist, throat, or finger, with gloves. The electrical response of the fiber sensor was recorded along with the body movements.

The fiber-based electrochemical sensor was fabricated using layer-by-layer coating methods. The as-fabricated fiber was first sputtered with a gold layer using a desktop sputter coater (GSL-1100X-SPC-16, Shenyang Kejing, Shenyang, China) for 300 s. After that, the Au-coated TPU/CB fiber was dip-coated with the PB-containing carbon paste and dried at 60 °C for 20 min before use. Then, glucose oxidase (GOx) was immobilized following previously reported methods. Briefly, the glucose oxidase was dissolved in phosphate-buffered saline (PBS) solution at 50 mg mL−1 under magnetic stirring, denoted as solution A. Multiwalled carbon nanotubes (MWCNTs) were added into chitosan/acetic acid solution at 2 mg mL−1 and mixed in an ultrasonic bath followed by magnetic stirring for 1 h at room temperature, denoted as solution B. Then, solutions A and B were mixed at 1:2 volume ratio under magnetic stirring. The PB-coated fiber was dip coated in the mixed solution for 10 s and dried in the open environment prior to the test.

2.4. Characterizations

Various methods were used to characterize the as-fabricated fibers. The surface morphology and cross-sectional information of the fibers were observed by scanning electron microscopy (SEM, ZEISS GeminiSEM 300, Jena, Germany). Energy dispersive spectroscopy (EDS) was used to study the elemental distribution of the fiber materials. Attenuated total reflectance (ATR)-Fourier transferred infrared (FTIR) spectroscopy (PerkinElmer Spectrum 3 Mid-IR FTIR Spectrometer, Shanghai, China) was used to study the chemical bonding information of the composite fiber at wavenumbers of 4000–650 cm−1. The mechanical performances of the original and the bifurcated-healed fibers (n = 5) were investigated using the tensile test on a custom-built linear stretching system (Newmark System Inc., Santa Margarita, CA, USA) coupled with a digital force gauge (Mark-10 M5i, Copiague, NY, USA) after calibration at a strain rate of 200 μm min−1 until fracture according to ASTM standard D3379-75 [37,38,39]. The electrical sensory response of the fibers with different CB loading fractions was measured (n = 5) by the digital multimeter (Keithley, Cleveland, OH, USA, DMM 6500) coupled with the aforementioned custom-built testing interface. The resistivity of the fiber sensor was calculated according to Equation (1) shown below:

where ρ is the resistivity, S and l are the cross-sectional area and length of the fiber, respectively, and R is the measured resistance. In addition, the glucose sensing capability of the fiber was tested using electrochemical cyclic voltammetry (CV) and amperometric I-t methods.

ρ = RS⁄l

3. Results and Discussion

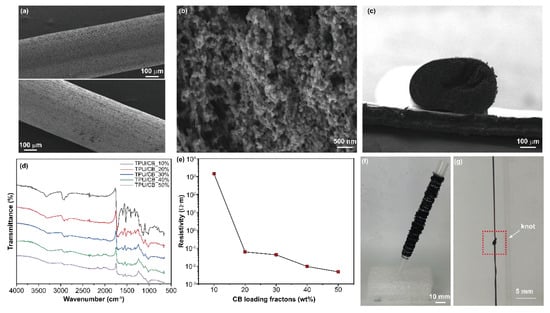

The synthesis started from optimization of the spinning parameters, including the injection rates and the nozzles. The injection rate will affect the phase separation and the solvent exchange process of the solid materials in the coagulation bath, whereas the nozzle diameter affects the diameter of the as-synthesized fiber [40]. After optimization, an injection rate of 0.1 mL min−1 using a 21 G nozzle was applied. Such parameters could generate strong continuous fibers with good electrical conductivity and mechanical flexibility, as compared with other parameters tested. Figure 2a shows the SEM images of the pristine TPU/CB fiber (top) and the Au-coated TPU/CB fiber (bottom), respectively. Both images exhibited holistically smooth but microscopically rough cylindrical fiber morphologies. This could be observed more clearly in the localized SEM image of the TPU/CB nanocomposite, as shown in Figure 2b, in which the nanosized CB with sizes of about 50 nm are uniformly distributed within the TPU matrix. In contrast, the holistic morphology of the pure TPU fiber synthesized by the same wet spinning method appeared to be much rougher and wrinkled (Figure S1a) due to the solvent exchange process in the coagulation bath, whereas its localized morphology appeared to be smoother (Figure S1b).

Figure 2.

Characterization of the TPU/CB nanocomposite fibers. (a) SEM images showing the TPU/CB and Au-coated TPU/CB fibers. (b) Localized SEM image of the fiber materials, showing the distribution of the nanosized CB in the TPU matrix. (c) Cross-sectional SEM image of the TPU/CB fiber. (d) ATR-FTIR characterization of TPU/CB fibers with different CB loading fractions. (e) Electrical resistivities of the as-synthesized TPU/CB fiber at different CB loading fractions. (f) Digital image showing a bundle of collected TPU/CB fibers. (g) TPU/CB fiber with a knot in the middle, indicating its high mechanical robustness.

Consequently, introducing the nanosized CB changes the morphology and structure of the pure TPU material, reflecting the excellent interfacial adhesiveness between the two materials. In addition, compared with the pristine TPU/CB fiber, the Au-coated TPU/CB fiber appeared smooth due to the gold deposition. The successful deposition of the Au layer can be further verified by the elemental mapping from EDS characterization (Figure S2). Figure 2c shows the cross-sectional image of the fiber. Although there is a slight shrinking of the fiber from the vertical direction, the cylindrical shape of the fiber could be greatly preserved during the storage, preparation, and characterization processes. This indicates the outstanding mechanical robustness of the nanocomposite fiber, in which the addition of nanosized CB particles dramatically enhances the mechanical strength.

The chemical bonding information of the as-fabricated TPU/CB nanocomposite fibers with incrementing CB loading fractions was studied by FTIR spectroscopy [41,42,43,44]. The tested specimen with 10–50% nanosized CB loading fractions showed the fading bands at around 3330–3250 cm−1 that refer to –OH groups with increasing CB contents (Figure 2d). C–H stretching corresponding to CH2 and CH3 could be evidenced by the peaks at around 2950–2850 cm−1 and 1415 cm−1, respectively. The characteristic peaks of N=C=O at around 2250 cm−1 were hardly observable with all the measured specimens, indicating low residual isocyanate groups. The strong peaks at around 1735–1700 cm−1 associated with the C=O in the urethane groups weaken with the introduction of CB. The vibration of C–O–C groups could be found at around 1280–1100 cm−1, respectively. All the measurements confirmed the characteristics of TPU polymer, whereas the incorporation of nanosized CB slightly suppressed the bonding movement.

The electrical conductivities of the as-fabricated TPU/CB fibers are one of the most critical parameters in this study. The electrical resistance values of the fibers were measured, and the fiber resistivities were calculated based on the length and the cross-sectional area obtained from the SEM characterization. Figure 2e shows the evolution of resistivities as a function of nanosized CB loading fractions. The pure TPU fiber was insulative. At 10 wt% CB loading fractions, the resistivity of the TPU/CB fiber reached 1.43 × 103 Ω·m, corresponding to a conductivity of 2.10 × 102 S m−1. A further increase in the CB loadings drastically decreased the resistivities to 6.15 × 10−2, 4.24 × 10−2, 9.42 × 10−3, and 4.77 × 10−3 Ω·m at 20–50 wt%, respectively. This indicated that the nanosized CB fillers reached the percolation threshold leading to significantly enhanced electrical conductivity, which will benefit the sensory performances. Such electrical performance of the TPU/CB fibers exhibited superior environmental stability over temperature and humidity changes. As shown in Figure S3, the electrical resistance of the TPU/CB50 fiber exhibited excellent stability when environmental temperature changes from 20 to 70 °C, and relative humidity changes from 30 to 90%. The maximum resistance variations for temperature and relative humidity are 3.5% and 4.7%, respectively. Based on the optimized process, the extruded spinning dope coagulated quickly in the eco-friendly DI water coagulation bath through liquid phase separation, forming solid primary fibers. The rotation introduced shear force that further enhanced the strength of the primary fiber, which led to the scalable formation of a conductive fiber with high mechanical performances. It can be observed in Figure 2f that a bundle of conductive fibers could be continuously produced and collected, reaching an approximate speed of 30.6 m h−1. Due to its good mechanical strength and flexibility, the as-synthesized fiber could be knotted without fracture, as shown in Figure 2g.

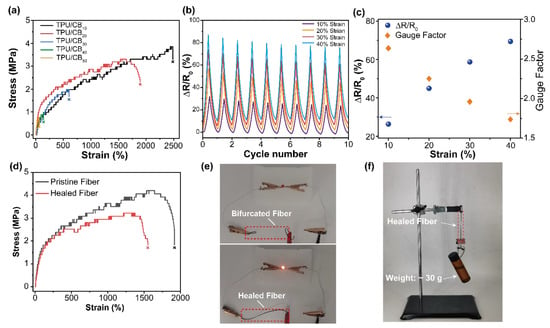

Next, the electromechanical properties of the as-synthesized TPU/CB fibers were systematically investigated. The mechanical performances of the TPU/CB fibers with different CB loading fractions ranging from 10 to 50 wt% were studied by the tensile test at a constant rate of 200 μm min−1. It can be observed in Figure 3a that the TPU/CB fibers exhibited a highly stretchable nature with a maximum stretchability of over 2400%. The stretchability of the fibers decreased to 1900%, 600%, 140%, and 62% gradually with incrementing CB loading fractions from 20 wt% to 50 wt%, respectively. This indicated that the increasing content of CB fillers impedes the TPU polymer chain mobility, leading to decreased mechanical extensibility. Then, the electrical responses of the TPU/CB50 fiber were studied by cyclically stretching the fiber to different strains ranging from 10 to 40%, while recording the resistance change. As shown in Figure 3b, the electrical responses of the fiber exhibited highly symmetrical characteristics along with the loading–unloading cycles at different strain values. Initially, the change of resistance at different strain values decreased slightly as the cycle number increased and then gradually stabilized. This is probably due to the ageing effect that the conductive fillers are gradually aligned to the strain direction. According to Figure 3c, the average relative change in resistance correlates linearly with the applied strain values. At 10% strain value, the average ∆R/R0 value was 26.35%, which then increased to 45.01%, 58.80%, and 69.49% as the strain values increased to 40%, respectively. The gauge factor (GF) as a measure of the sensitivity for the fiber-based strain sensor was calculated to be varied from 1.74 to 2.63.

Figure 3.

Mechanical and electrical characterizations of the TPU/CB fibers. (a) Stress–strain curve of TPU/CB fibers with different CB loading fractions. (b) The relative change of resistance for TPU/CB50 fiber as a function of strains. (c) The correlation between strain and ΔR/R0, and the calculated gauge factor. (d) Stress–strain correlation of pristine and bifurcated TPU/CB fiber healed for 14 days at room temperature. (e) When lighting up an LED bulb, a digital image shows the electrical conduction of the bifurcated (top) and the healed TPU/CB50 fiber (bottom). (f) Digital image showing the mechanical strength of the healed TPU/CB50 fiber when hanging a 30.0 g weight without breaking.

Apart from stretchability and electrical responses, the self-healing performance of the TPU/CB-based fibers was also studied. TPU obtained an intrinsic self-healing ability due to abundant intramolecular H-bonding, which will be favorable for restoring the mechanical and electrical properties once fractured. Figure 3d displays the mechanical stretchability of the pristine TPU/CB20 fiber and the bifurcated TPU/CB20 fiber after 14 days of healing at room temperature. It can be observed that the healed fiber can be stretched to 1550%, corresponding to 80.94% of the original stretchability. The fracture toughness as a measure of the energy absorbed by the fiber during the test until breakage was calculated by integrating each stress–strain curve. As shown in Figure S4, the fracture toughness of the pristine TPU/CB fiber was 61.44 kJ m−3, whereas that of the 14-day healed fiber was 39.84 kJ m−3, corresponding to a healing efficiency of 64.8%. This demonstrated a good self-healing performance of the TPU/CB fiber from the mechanical aspect. In addition, the electrically conductive nature of the bifurcated fiber could also be restored after healing, as shown by the digital images in Figure 3e. The bifurcated TPU/CB50 fiber could be used to light up an LED bulb after the 14-day healing. Such a healed fiber obtained high strength and electrical conductivity and could lift a 30 g weight without breaking. This favorable feature could find promising applications in wearable electronics.

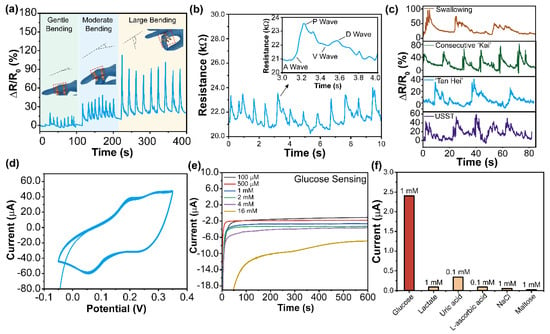

By virtue of the excellent electro-mechanical performances, the TPU/CB50 fiber with high conductivity and moderate stretchability was applied in dual-functional wearable sensors. Strain sensing is one of the critical applications for wearable sensors for revealing body movements and health-related information. Figure 4a–c show that the as-synthesized TPU/CB50 fiber was assembled with conductive copper tape as wearable strain sensors. Such a device could be attached to different parts of the human body, including fingers, wrist, and throat, to monitor motions from high amplitude to low amplitude. By adhering to lab gloves, the fiber-based strain sensor could effectively detect finger movement from gentle bending to heavy bending, as evidenced by different signal amplitudes shown in Figure 4a. In addition, by attaching it to the wrist, the fiber-based sensor could sense the arterial pulse wave. As shown in Figure 4b, the pulse wave detected by the fiber-based strain sensor exhibited good consistency with a healthy adult volunteer’s average pulse rate (~72 bpm). Moreover, the typical wave pattern of the pulse wave could be resolved, evidenced by the demonstrated A, P, V, and D waves, which stand for the base point, the percussion wave, the valley, and the dicrotic wave, respectively [37]. Therefore, detecting pulse waves could be critical in diagnosing and monitoring cardiovascular diseases, such as arteriosclerosis, hypertension, coronary artery disease, etc. Figure 4c shows the fiber-based sensor’s swallowing and voice detection capabilities when attached to the throat. The swallowing process causes the movement of the throat, which leads to changes in the fiber shape, which is then reflected in the resistance change. As a result, the three primary peaks were recorded concerning the swallowing process three times. The pronunciation could also cause throat movement, leading to the same detection process. As a proof of concept, the pronounced ‘Kai’, ‘Tan Hei’, and ‘USST’ recorded different signal patterns, demonstrating the good sensory performance of our fiber-based wearable strain sensor.

Figure 4.

Application of the TPU/CB fiber as dual-functional wearable sensors for human motion and health indicator monitoring. (a) TPU/CB fiber-based strain sensor attached to gloves for finger movement detection. (b) TPU/CB fiber-based strain sensor for monitoring pulse at the wrist. Inset shows that the sensor can show the phases in one pulse wave. (c) TPU/CB fiber-based strain sensor attached to throat for recognizing swallowing and pronunciations, e.g., ‘Kai’, ‘Tan Hei’, and “USST’, respectively. (d) Cyclic voltammetry study for Au-coated TPU/CB fiber sensor in a solution containing FeCl3, KCl, K3Fe(CN)6, and HCl at 50 mV s−1. (e) Amperometric I-t responses of the Au-coated TPU/CB fiber in various glucose/PBS solutions with concentrations ranging from 0 to 16.0 mM, respectively. (f) Selectivity of the fiber-based glucose sensor in different concentrations of analytes, showing the highest response current to glucose.

In medical diagnostics, non-invasive detection of various disease-related biomarkers through electrochemical, enzymatic, or fluorescent techniques is an essential research category. In this regard, the fiber-based sensor proposed by this study also exhibited potential in the electrochemical detection of key disease-related biomarkers. As a proof-of-concept, a fiber-based glucose electrochemical sensor was fabricated using the layer-by-layer coating of the conductive electrode composed of Au and a PB mediator and then immobilized with GOx as the glucose-sensing electrode. Figure 4d shows the CV scanning of the Au-coated TPU/CB50 fiber in Fe(CN)63− containing solution at 50 mV s−1 in an electrochemical window of −0.05–0.35 V. A pair of redox peaks at 0.05 V and 0.2 V, respectively, were clearly observed, indicating the successful electrochemical reduction–oxidation process of Fe(CN)63−. Later, the GOx-immobilized fiber glucose sensor was tested by the amperometric I-t method in solutions containing incrementing glucose concentrations from 0 to 16 mM, which covers the glucose levels in both the sweat and plasma. In the detection process, glucose molecules were enzymatically oxidized to gluconolactone in the presence of GOx, while the PB mediator could catalytically detect the by-product H2O2. As a result, the electrode captured the electrons transferred in the reaction and reflected as the negative current flow. It can be observed in Figure 4e that the amplitude of the negative current increases with the increasing glucose concentrations within 600 s. The sensitivity of the fiber-based sensor could be indicated by the slope of the calibration curve shown in Figure S5, which was 0.336 ± 0.04 μA mM−1 with an R2 of 0.938. The selectivity of the fiber-based glucose sensor was tested in solutions containing different concentrations of analytes, such as lactic acid, uric acid, L-ascorbic acid, NaCl, and maltose. It could be observed in Figure 4f and Figure S6 that the fiber-based glucose sensor exhibited the highest responses to 1 mM glucose or different concentrations of interferants in the presence of glucose (1 mM) compared with other analytes alone, including lactate (1 mM), uric acid (0.1 mM), L-ascorbic acid (0.1 mM), NaCl (1 mM), and maltose (1 mM). This demonstrates good selectivity and anti-interference capabilities of the proposed fiber-based electrochemical glucose sensor. In addition, we further applied our fiber-based sensor to monitor glucose level in biological fluid (e.g., sweat, saliva, and tears etc.) for non-invasive diagnostics. As a proof-of-concept, we applied artificial saliva containing different concentrations of glucose to demonstrate the performance of the proposed device (Figure S7). It was found that the fiber-based sensor can effectively distinguish different concentrations of glucose in artificial saliva that contains various biomolecules with good linearity (R2 = 0.9708). This result suggested that the proposed fiber-based glucose sensor exhibited the capability for continuous glucose monitoring towards diabetes management, which also holds the potential for other disease-related biomarker monitoring.

4. Conclusions

In this work, a novel type of stretchable and conductive TPU/CB-based fiber was obtained by continuous wet spinning and proposed as dual-functional wearable sensors for monitoring body movements and health indicators. By virtue of the high conductivity of the nanosized CB filler, the as-fabricated TPU/CB fibers achieved high filler loading fractions from 10 to 50 wt%, leading to the favorable low electrical resistivity of 2.10 × 102 S m−1 or 4.77 × 10−3 Ω·m. The fiber-based material exhibited good stretchability with a maximum strain of over 2400% while preserving the good self-healing capabilities of the TPU materials. The TPU/CB20 fiber restored more than 80% of the original stretchability and around 65% of the fracture toughness. In addition, the as-fabricated nanocomposite fiber exhibited good application potential as either a strain sensor or electrochemical glucose sensor for detecting body movements or health indicators. Such results demonstrate its promise as a next-generation smart fiber for wearable electronics.

Supplementary Materials

The following supporting information can be downloaded at: https://www.mdpi.com/article/10.3390/analytica4030025/s1, Table S1: Composition of the spinning dope; Table S2: Optimization of the nozzles in wet-spinning process; Table S3: Optimization of the injection rates in wet-spinning process; Figure S1: SEM image showing the morphologies of the pure TPU fiber prepared by the same wet spinning method; Figure S2: Elemental mapping of the key elements in the pristine TPU/CB fiber and the Au-TPU/CB fiber through EDS, respectively; Figure S3: Temperature and humidity stabilities of the electrical resistance of the as-synthesized TPU/CB50 fibers, respectively; Figure S4: Fracture toughness of the TPU/CB fiber obtained from stress-strain curves; Figure S5: Calibration curve of the current responses as a function of glucose concentrations; Figure S6: Localized amperometric curves of the interference studies in different solutions either containing or without 1 mM glucose; Figure S7: Application of the proposed fiber-based electrochemical sensor to monitor glucose concentrations in the artificial saliva.

Author Contributions

Z.W. conceived the project idea and draft of the manuscript. X.W. and J.C. performed the experiments and analyzed the data. Z.S. and F.Y. performed the experiments. Y.H. and Z.L. revised the paper. Z.Z. supervised the project, reviewed and finalized the manuscript, and acquired the funding. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by University of Shanghai for Science and Technology and the University Capacity Building Project of the Shanghai Science and Technology Commission grant number [21010502800] and the APC was funded by [21010502800].

Data Availability Statement

Not applicable.

Acknowledgments

The authors gratefully acknowledge financial support from the University of Shanghai for Science and Technology and the University Capacity Building Project of the Shanghai Science and Technology Commission (21010502800).

Conflicts of Interest

The authors declare no conflict of interest.

References

- Heo, J.S.; Eom, J.; Kim, Y.H.; Park, S.K. Recent Progress of Textile-Based Wearable Electronics: A Comprehensive Review of Materials, Devices, and Applications. Small 2018, 14, 1703034. [Google Scholar] [CrossRef] [PubMed]

- Shi, X.L.; Chen, W.Y.; Zhang, T.; Zou, J.; Chen, Z.G. Fiber-Based Thermoelectrics for Solid, Portable, and Wearable Electronics. Energy Environ. Sci. 2021, 14, 729–764. [Google Scholar] [CrossRef]

- Liu, Z.; Zhu, T.; Wang, J.; Zheng, Z.; Li, Y.; Li, J.; Lai, Y. Functionalized Fiber-Based Strain Sensors: Pathway to Next-Generation Wearable Electronics. Nano-Micro Lett. 2022, 14, 61. [Google Scholar] [CrossRef] [PubMed]

- Tian, Y.; Shao, H.; Liu, X.; Chen, F.; Li, Y.; Tang, C.; Zheng, Y. Superhydrophobic and Recyclable Cellulose-Fiber-Based Composites for High-Efficiency Passive Radiative Cooling. ACS Appl. Mater. Interfaces 2021, 13, 22521–22530. [Google Scholar] [CrossRef] [PubMed]

- Luo, G.; Xie, L.; He, M.; Jaisutti, R.; Zhu, Z. Flexible Fabric Gas Sensors Based on Reduced Graphene-Polyaniline Nanocomposite for Highly Sensitive NH3 Detection at Room Temperature. Nanotechnology 2021, 32, 305501. [Google Scholar] [CrossRef] [PubMed]

- Tao, X. Study of Fiber-Based Wearable Energy Systems. Acc. Chem. Res. 2019, 52, 307–315. [Google Scholar] [CrossRef]

- Chen, X.; Rogers, J.A.; Lacour, S.P.; Hu, W.; Kim, D.H. Materials Chemistry in Flexible Electronics. Chem. Soc. Rev. 2019, 48, 1431–1433. [Google Scholar] [CrossRef]

- Lee, J.; Jeon, S.; Seo, H.; Lee, J.T.; Park, S. Fiber-Based Sensors and Energy Systems for Wearable Electronics. Appl. Sci. 2021, 11, 531. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, Z.; Wang, Z.; He, B.; Chen, M.; Qi, M.; Liu, Y.; Xin, J.; Wei, L. Recent Progress of Fiber-Based Transistors: Materials, Structures and Applications. Front. Optoelectron. 2022, 15, 2. [Google Scholar] [CrossRef]

- Li, H.; Zhang, X.; Zhao, Z.; Hu, Z.; Liu, X.; Yu, G. Flexible Sodium-Ion Based Energy Storage Devices: Recent Progress and Challenges. Energy Storage Mater. 2020, 26, 83–104. [Google Scholar] [CrossRef]

- Huang, L.; Lin, S.; Xu, Z.; Zhou, H.; Duan, J.; Hu, B.; Zhou, J. Fiber-Based Energy Conversion Devices for Human-Body Energy Harvesting. Adv. Mater. 2020, 32, 1902034. [Google Scholar] [CrossRef] [PubMed]

- Rafique, A.; Ferreira, I.; Abbas, G.; Baptista, A.C. Recent Advances and Challenges toward Application of Fibers and Textiles in Integrated Photovoltaic Energy Storage Devices. Nano-Micro Lett. 2023, 15, 40. [Google Scholar] [CrossRef] [PubMed]

- He, J.; Lu, C.; Jiang, H.; Han, F.; Shi, X.; Wu, J.; Wang, L.; Chen, T.; Wang, J.; Zhang, Y.; et al. Scalable Production of High-Performing Woven Lithium-Ion Fibre Batteries. Nature 2021, 597, 57–63. [Google Scholar] [CrossRef] [PubMed]

- Shi, X.; Zuo, Y.; Zhai, P.; Shen, J.; Yang, Y.; Gao, Z.; Liao, M.; Wu, J.; Wang, J.; Xu, X.; et al. Large-Area Display Textiles Integrated with Functional Systems. Nature 2021, 591, 240–245. [Google Scholar] [CrossRef]

- Wang, T.; Meng, J.; Zhou, X.; Liu, Y.; He, Z.; Han, Q.; Li, Q.; Yu, J.; Li, Z.; Liu, Y.; et al. Reconfigurable Neuromorphic Memristor Network for Ultralow-Power Smart Textile Electronics. Nat. Commun. 2022, 13, 7432. [Google Scholar] [CrossRef]

- Li, T.; Su, Y.; Chen, F.; Zheng, H.; Meng, W.; Liu, Z.; Ai, Q.; Liu, Q.; Tan, Y.; Zhou, Z. Bioinspired Stretchable Fiber-Based Sensor toward Intelligent Human–Machine Interactions. ACS Appl. Mater. Interfaces 2022, 14, 22666–22677. [Google Scholar] [CrossRef]

- He, M.; Xie, L.; Luo, G.; Li, Z.; Wright, J.; Zhu, Z. Flexible Fabric Gas Sensors Based on Pani/WO3 p−n Heterojunction for High Performance NH3 Detection at Room Temperature. Sci. China Mater. 2020, 63, 2028–2039. [Google Scholar] [CrossRef]

- Cho, H.; Lee, H.; Lee, S.; Kim, S. Reduced Graphene Oxide-Based Wearable and Bio-Electrolyte Triggered Pressure Sensor with Tunable Sensitivity. Ceram. Int. 2021, 47, 17702–17710. [Google Scholar] [CrossRef]

- Gao, T.; Yan, G.; Yang, X.; Yan, Q.; Tian, Y.; Song, J.; Li, F.; Wang, X.; Yu, J.; Li, Y.; et al. Wet Spinning of Fiber-Shaped Flexible Zn-Ion Batteries toward Wearable Energy Storage. J. Energy Chem. 2022, 71, 192–200. [Google Scholar] [CrossRef]

- Tang, Z.; Jia, S.; Wang, F.; Bian, C.; Chen, Y.; Wang, Y.; Li, B. Highly Stretchable Core–Sheath Fibers Via Wet-Spinning for Wearable Strain Sensors. ACS Appl. Mater. Interfaces 2018, 10, 6624–6635. [Google Scholar] [CrossRef]

- Zhao, Y.; Dong, D.; Gong, S.; Brassart, L.; Wang, Y.; An, T.; Cheng, W. A Moss-Inspired Electroless Gold-Coating Strategy toward Stretchable Fiber Conductors by Dry Spinning. Adv. Electron. Mater. 2019, 5, 1800462. [Google Scholar] [CrossRef]

- Feng, L.; Chang, Y.; Zhong, J.; Jia, D.C. Dry Spin Graphene Oxide Fibers: Mechanical/Electrical Properties and Microstructure Evolution. Sci. Rep. 2018, 8, 10803. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; Wu, T.; Wang, Z.; Zhang, T.; Chen, M.; Zhang, J.; Liu, L.; Qi, M.; Zhang, Q.; Yang, J.; et al. Designer Patterned Functional Fibers Via Direct Imprinting in Thermal Drawing. Nat. Commun. 2020, 11, 3842. [Google Scholar] [CrossRef] [PubMed]

- Chen, M.; Wang, Z.; Zhang, Q.; Wang, Z.; Liu, W.; Chen, M.; Wei, L. Self-Powered Multifunctional Sensing Based on Super-Elastic Fibers by Soluble-Core Thermal Drawing. Nat. Commun. 2021, 12, 1416. [Google Scholar] [CrossRef]

- Azimi, B.; Milazzo, M.; Lazzeri, A.; Berrettini, S.; Uddin, M.J.; Qin, Z.; Buehler, M.J.; Danti, S. Electrospinning Piezoelectric Fibers for Biocompatible Devices. Adv. Healthc. Mater. 2020, 9, 1901287. [Google Scholar] [CrossRef]

- Parham, S.; Kharazi, A.Z.; Bakhsheshi-Rad, H.R.; Ghayour, H.; Ismail, A.F.; Nur, H.; Berto, F. Electrospun Nano-Fibers for Biomedical and Tissue Engineering Applications: A Comprehensive Review. Materials 2020, 13, 2153. [Google Scholar] [CrossRef]

- Sun, L.; Shang, L.; Xiao, L.; Zhang, M.; Li, M.; Ao, Y. Structural Changes of Polyacrylonitrile Fibers in the Process of Wet Spinning. J. Appl. Polym. Sci. 2020, 137, 48905. [Google Scholar] [CrossRef]

- Chang, L.; Wang, F.; Guo, Y.; Li, J.; Gong, Y.; Shi, Q. Green Preparation of Thermochromic Starch-Based Fibers through a Wet-Spinning Process. ACS Appl. Polym. Mater. 2021, 3, 436–444. [Google Scholar] [CrossRef]

- Tang, P.; Deng, Z.; Zhang, Y.; Liu, L.X.; Wang, Z.; Yu, Z.Z.; Zhang, H.B. Tough, Strong, and Conductive Graphene Fibers by Optimizing Surface Chemistry of Graphene Oxide Precursor. Adv. Funct. Mater. 2022, 32, 2112156. [Google Scholar] [CrossRef]

- Lee, D.; Kim, S.G.; Hong, S.; Madrona, C.; Oh, Y.; Park, M.; Komatsu, N.; Taylor, L.W.; Chung, B.; Kim, J.; et al. Ultrahigh Strength, Modulus, and Conductivity of Graphitic Fibers by Macromolecular Coalescence. Sci. Adv. 2022, 8, eabn0939. [Google Scholar] [CrossRef]

- Eom, W.; Shin, H.; Ambade, R.B.; Lee, S.H.; Lee, K.H.; Kang, D.J.; Han, T.H. Large-Scale Wet-Spinning of Highly Electroconductive Mxene Fibers. Nat. Commun. 2020, 11, 2825. [Google Scholar] [CrossRef] [PubMed]

- Seyedin, S.; Uzun, S.; Levitt, A.; Anasori, B.; Dion, G.; Gogotsi, Y.; Razal, J.M. MXene Composite and Coaxial Fibers with High Stretchability and Conductivity for Wearable Strain Sensing Textiles. Adv. Funct. Mater. 2020, 30, 1910504. [Google Scholar] [CrossRef]

- Seyedin, S.; Razal, J.M.; Innis, P.C.; Wallace, G.G. A Facile Approach to Spinning Multifunctional Conductive Elastomer Fibres with Nanocarbon Fillers. Smart Mater. Struct. 2016, 25, 35015. [Google Scholar] [CrossRef]

- Wang, Z.; Jiang, R.; Li, G.; Chen, Y.; Tang, Z.; Wang, Y.; Liu, Z.; Jiang, H.; Zhi, C. Flexible Dual-Mode Tactile Sensor Derived from Three-Dimensional Porous Carbon Architecture. ACS Appl. Mater. Interfaces 2017, 9, 22685–22693. [Google Scholar] [CrossRef] [PubMed]

- Yu, H.; Chen, C.; Sun, J.; Zhang, H.; Feng, Y.; Qin, M.; Feng, W. Highly Thermally Conductive Polymer/Graphene Composites with Rapid Room-Temperature Self-Healing Capacity. Nano-Micro Lett. 2022, 14, 135. [Google Scholar] [CrossRef]

- Zhou, X.; Rajeev, A.; Subramanian, A.; Li, Y.; Rossetti, N.; Natale, G.; Lodygensky, G.A.; Cicoira, F. Self-Healing, Stretchable, and Highly Adhesive Hydrogels for Epidermal Patch Electrodes. Acta Biomater. 2022, 139, 296–306. [Google Scholar] [CrossRef] [PubMed]

- Adusumalli, R.B.; Venkateshan, K.C.; Kunchi, C.; Vadlamani, S.R. Tensile Testing of Single Fibres. Procedia Struct. Integr. 2019, 14, 150–157. [Google Scholar] [CrossRef]

- Ilankeeran, P.K.; Mohite, P.M.; Kamle, S. Axial Tensile Testing of Single Fibres. Mod. Mech. Eng. 2012, 2, 151–156. [Google Scholar] [CrossRef]

- Liu, Y.; Lu, F.; Yang, L.; Wang, B.; Huang, Y.; Hu, Z. Closed-Loop Recycling of Carbon Fiber-Reinforced Composites Enabled by a Dual-Dynamic Cross-Linked Epoxy Network. ACS Sustain. Chem. Eng. 2023, 11, 1527–1539. [Google Scholar] [CrossRef]

- Shirvan, A.R.; Nouri, A.; Sutti, A. A Perspective on the Wet Spinning Process and Its Advancements in Biomedical Sciences. Eur. Polym. J. 2022, 181, 111681. [Google Scholar] [CrossRef]

- He, Z.; Cao, Q.; Jing, B.; Wang, X.; Deng, Y. Gel Electrolytes Based on Poly(Vinylidenefluoride-Co-Hexafluoropropylene)/Thermoplastic Polyurethane/Poly(Methyl Methacrylate) with in Situ SiO2 for Polymer Lithium Batteries. RSC Adv. 2017, 7, 3240–3248. [Google Scholar] [CrossRef]

- Lopes, G.H.; Junges, J.; Fiorio, R.; Zeni, M.; Zattera, A.J. Thermoplastic Polyurethane Synthesis Using Poss as a Chain Modifier. Mater. Res. 2012, 15, 698–704. [Google Scholar] [CrossRef]

- Jiang, Y.; Li, F.; Mei, Y.; Ding, Y.; Pang, H.; Zhang, P. Gel Polymer Electrolyte Based on Hydrophilic–Lipophilic TiO2-Modified Thermoplastic Polyurethane for High-Performance Li-Ion Batteries. J. Mater. Sci. 2021, 56, 2474–2485. [Google Scholar] [CrossRef]

- Chang, S. The Meridian System and Mechanism of Acupuncture—A Comparative Review. Part 2: Mechanism of Acupuncture Analgesia. Taiwan J. Obstet. Gynecol. 2013, 52, 14–24. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).