Oil Media on Paper: Investigating the Effect of Linseed Oils on Pure Cellulosic Paper Supports. A Research Matter of Damage Assessment

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Mock-Ups and Artificial Ageing

2.3. Methods

2.3.1. Colour

2.3.2. Opacity

2.3.3. Morphological Changes

2.3.4. Mechanical Changes

2.3.5. Chemical Changes

pH Changes

FTIR Analysis

Analysis of Volatile Organic Compounds with SPME-GC-MS

3. Results and Discussion

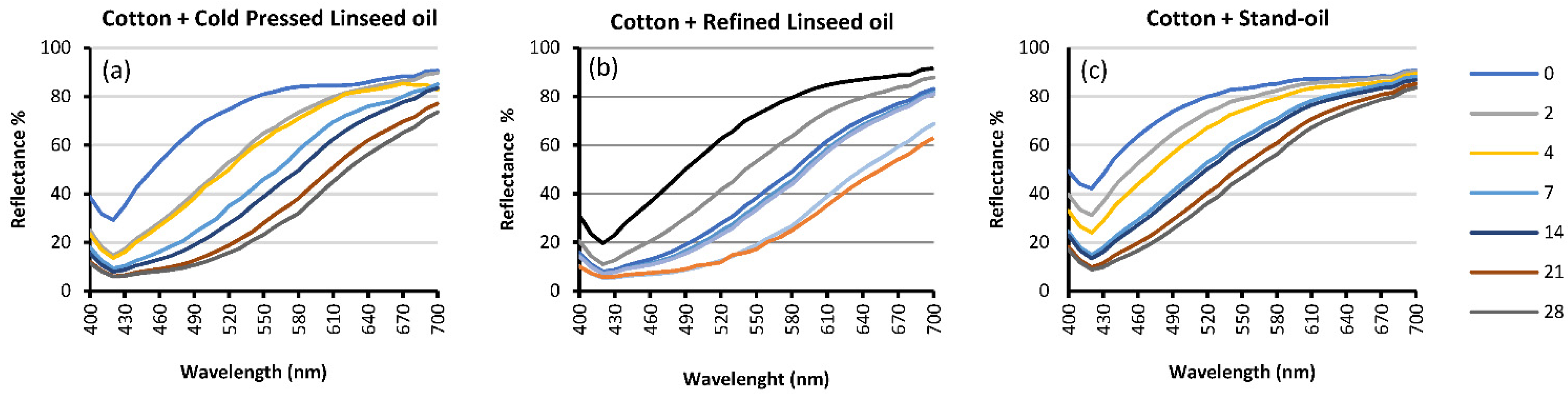

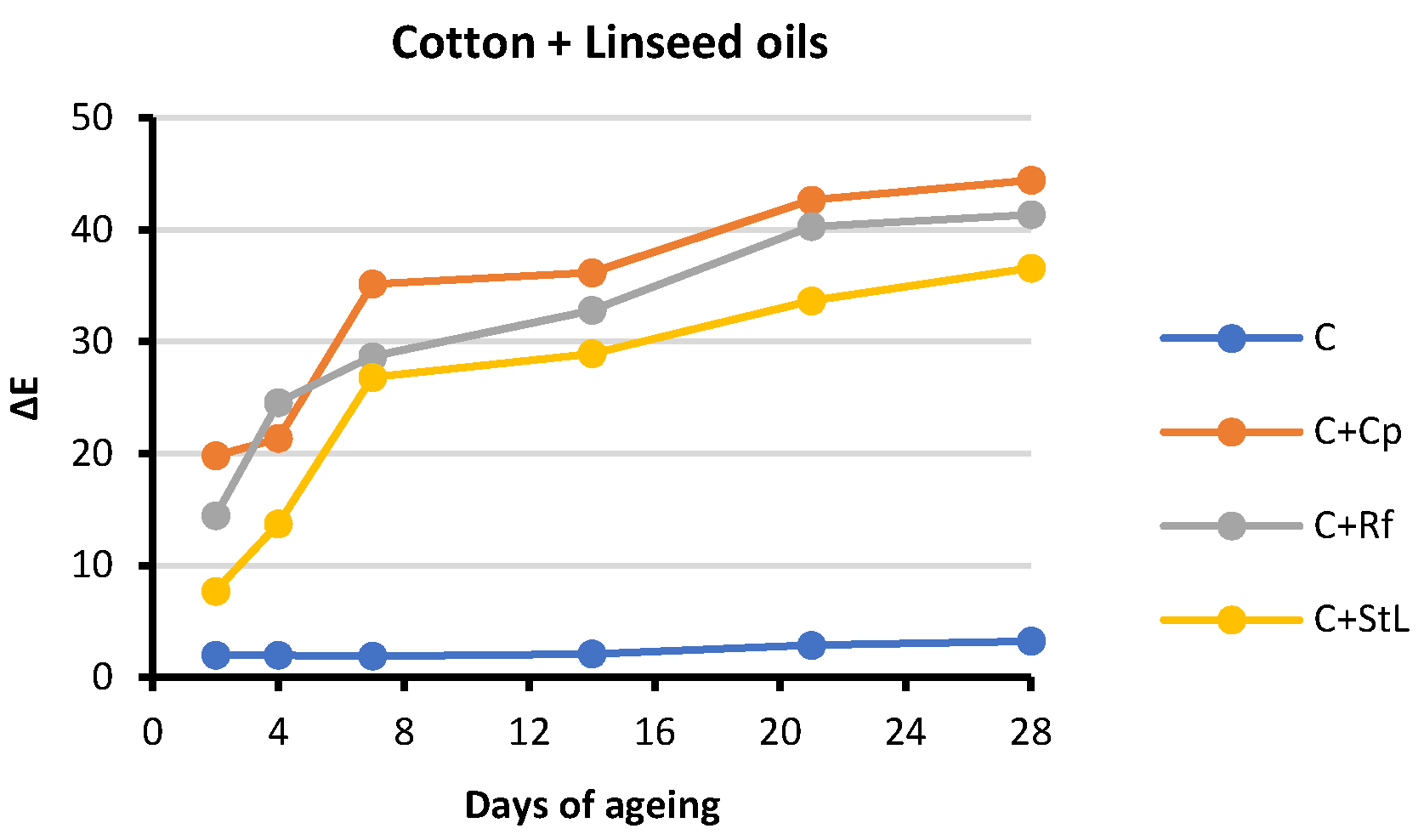

3.1. Colour Changes

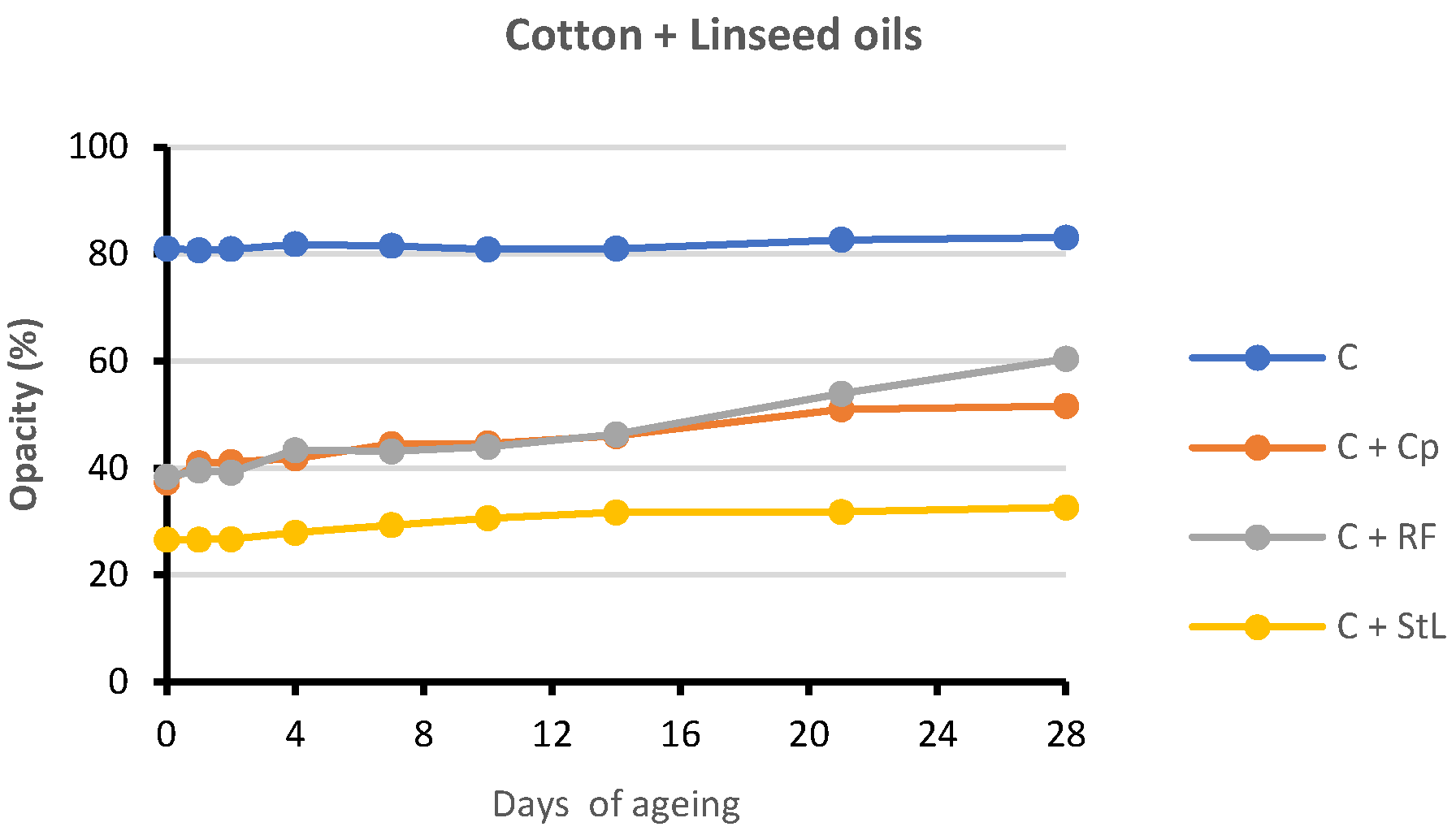

3.2. Opacity Changes

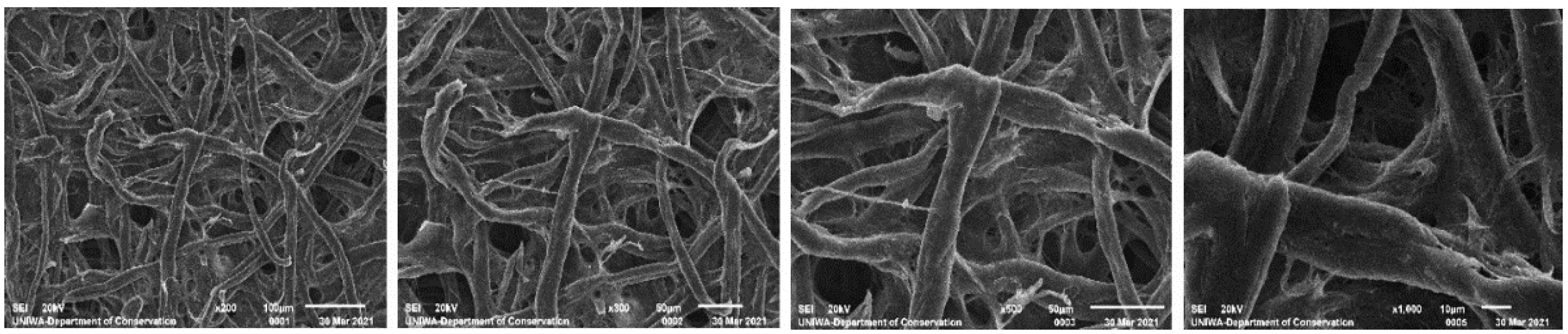

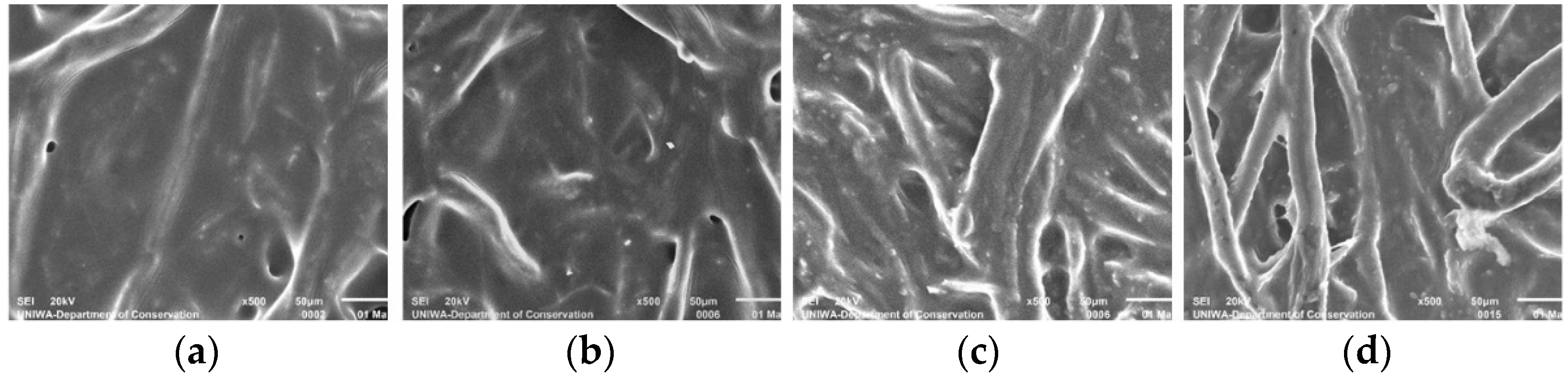

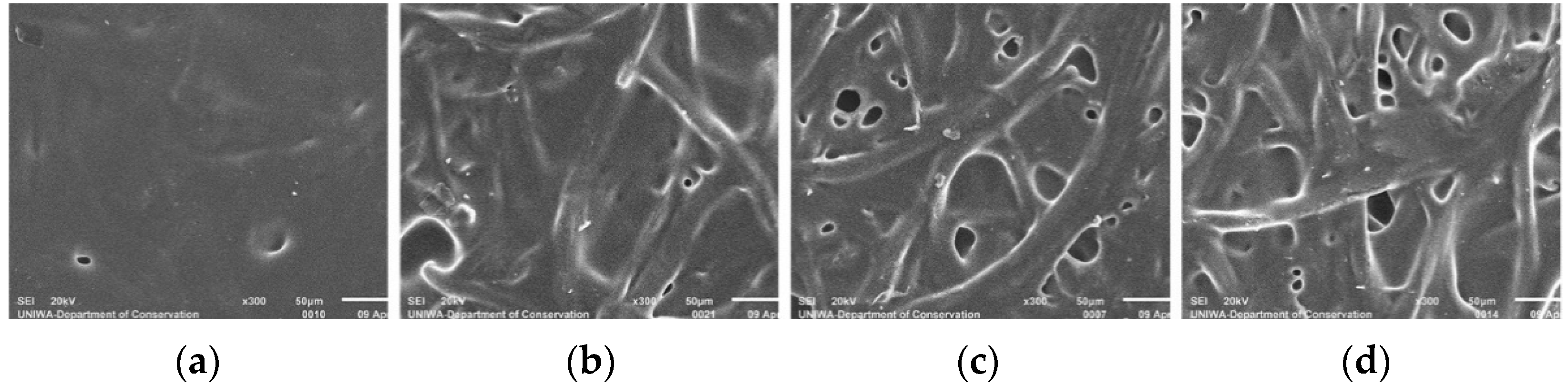

3.3. Morphological Changes

3.4. Mechanical Changes

3.5. Chemical Changes

3.5.1. pH Measurements

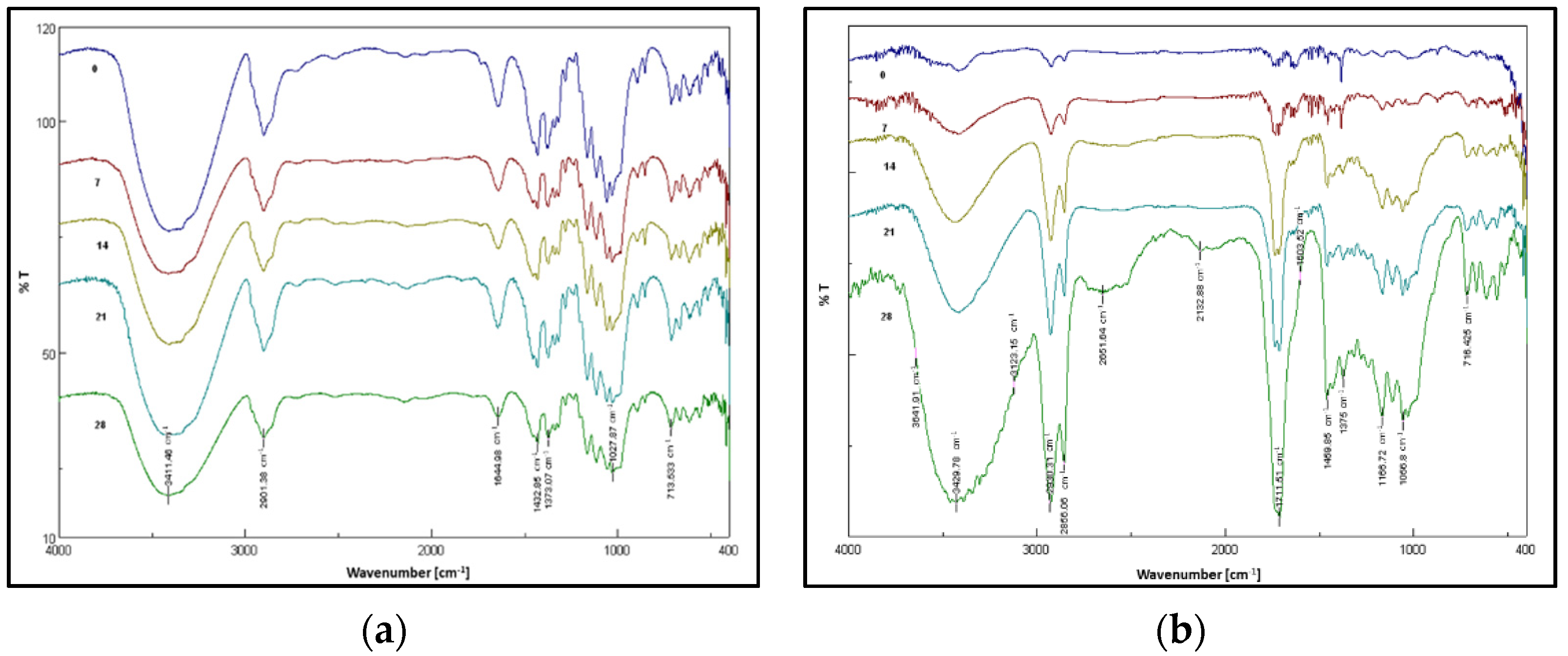

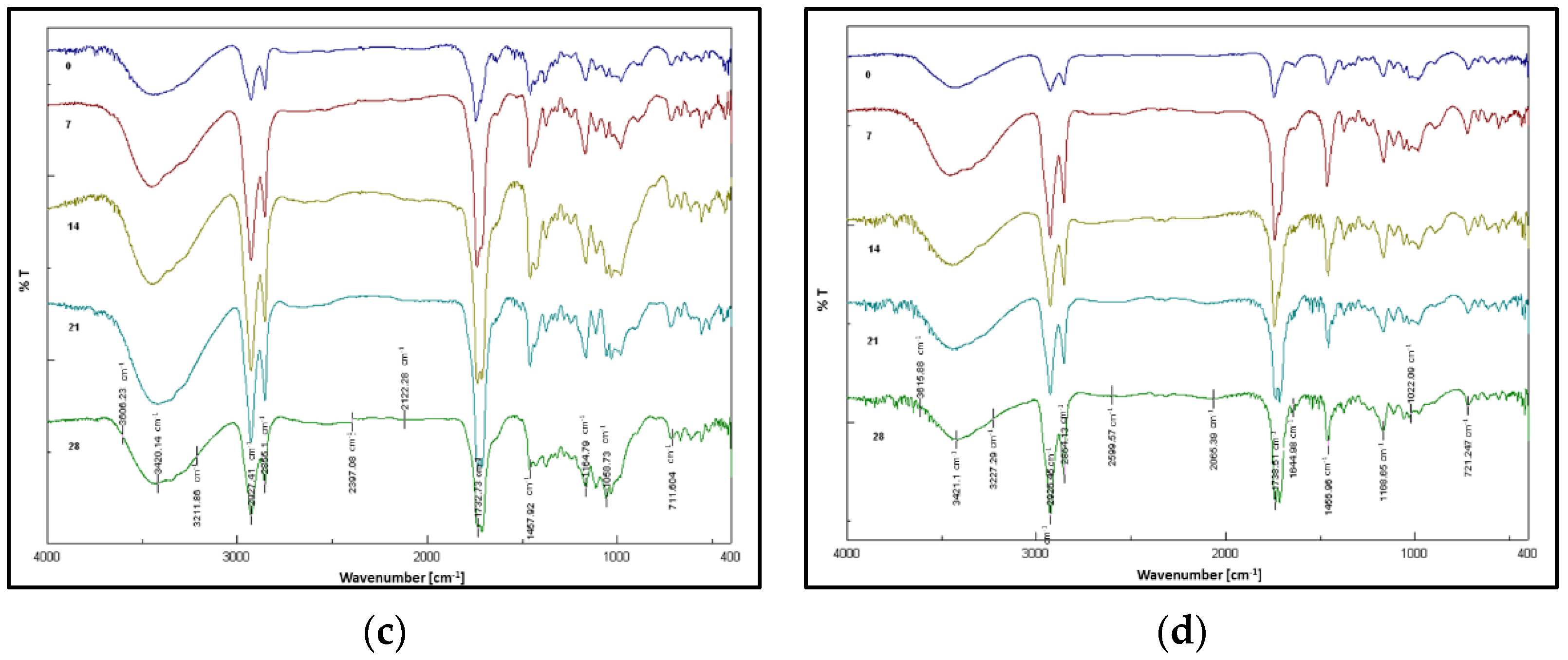

3.5.2. FTIR Analysis

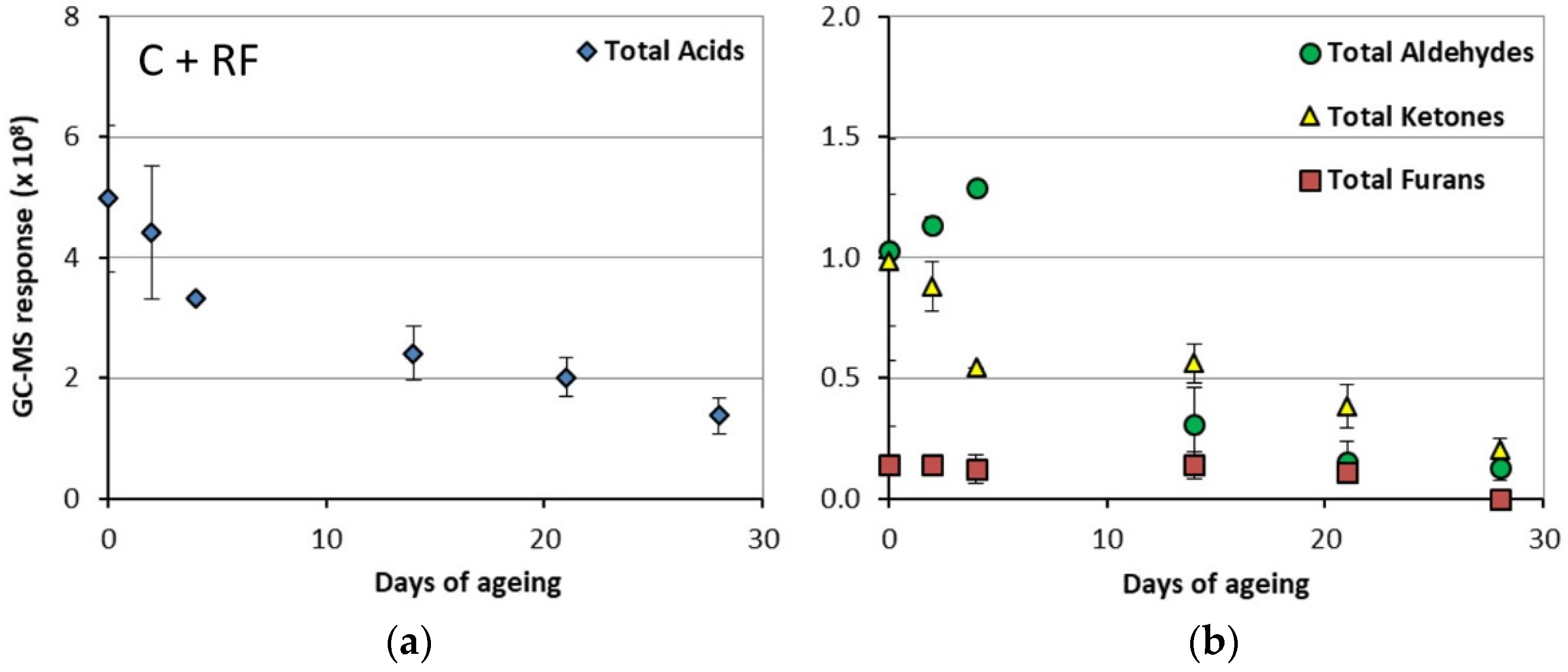

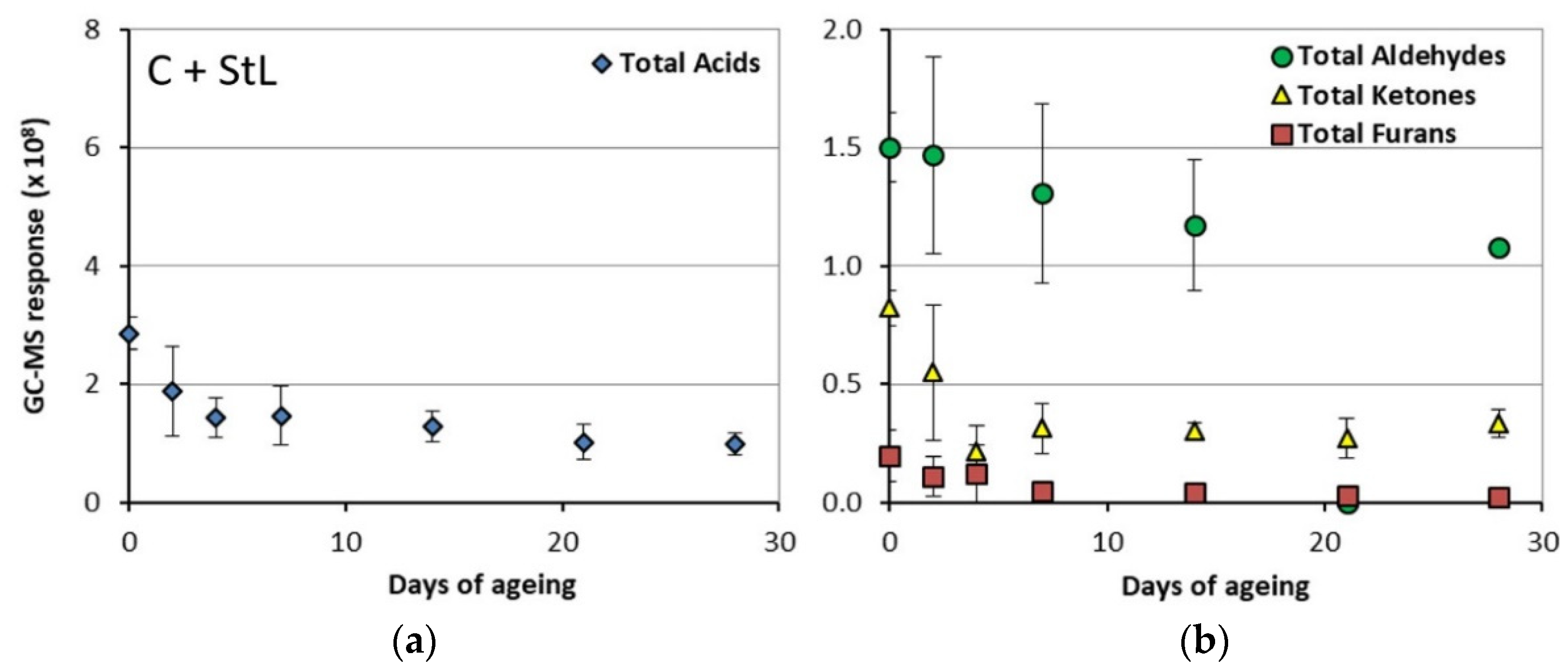

3.5.3. Analysis SPME-GC-MS

4. Conclusions

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Engram, C. Oil painting on paper and board supports. AICCM Bull. 1991, 17, 13–20. [Google Scholar] [CrossRef]

- James, C.; Corrigan, C.; Enshaian, M.C.; Greca, M.R. Old Master Prints and Drawings; University Press: Amsterdam, Holland, 1997. [Google Scholar]

- McAusland, J. Problems with works of art in oil on paper and their support: A paper conservator’s viewpoint. In General Meeting of the Association of British Picture Restorers; Kew: London, UK, 1989; pp. 1–6. [Google Scholar]

- Kosek, J.; Green, L.R. A survey of oil paintings and sketches on paper in the collection in the British Museum: An assessment of stability. In The IPC: Conference Papers Manchester; Institute of Paper Conservation: London, UK, 1992; pp. 96–102. [Google Scholar]

- Millard, T.; Le Cornu, E.; Smith, R.; Hasler, E.; Cowdy, H.; Chisholm, R.; King, E. The conservation of 830 oil paintings on paper by Marianne North. J. Inst. Conserv. 2011, 34, 159–172. [Google Scholar] [CrossRef]

- Banou, P.; Alexopoulou, A.; Singer, B.W. The Treatment of Oil Paintings on Paper Supports Considerations on the Treatment Applications Used from the Past until the Present. J. Pap. Conserv. 2015, 16, 29–36. [Google Scholar] [CrossRef]

- Daniels, V. Oxidative Damage and the Preservation of Organic Artefacts. Free. Radic. Res. Commun. 1989, 5, 213–220. [Google Scholar] [CrossRef]

- Daniels, V. The discolouration of paper on ageing. Pap. Conserv. 1988, 12, 93–100. [Google Scholar] [CrossRef]

- Banou, P.; Alexopoulou, A.; Chranioti, C.; Tsimogiannis, D.; Terlixi, A.V.; Zervos, S.; Singer, B.W. The effect of oil binders on paper supports via VOC analysis. J. Cult. Herit. 2016, 20, 589–598. [Google Scholar] [CrossRef]

- Elfecky, O.M.; Hassan, M.L. Artificial Aging and Deterioration of Oil-Painted Fabriano Paper and Cardboard Paper Supports. J. Appl. Polym. Sci. 2008, 109, 1594–1603. [Google Scholar] [CrossRef]

- Lazzari, M.; Chiantore, O. Drying and Oxidative Degradation of Linseed Oil. Polym. Degrad. Stab. 1999, 65, 303–313. [Google Scholar] [CrossRef]

- Mills, J.; White, R. Oils and fats. In Organic Chemistry of Museum Object, 2nd ed.; Routledge: London, UK, 1999; pp. 31–48. [Google Scholar]

- Gettens, R.J.; Stout, G.L. Painting Materials: A Short Encyclopaedia; Dover Publications: New York, NY, USA, 1966. [Google Scholar]

- NIIR Board. Printing ink vehicles. In The Complete Technology Book on Printing Inks; Asia Pacific Business Press Inc.: Dehli, India, 2003; pp. 11–21. [Google Scholar]

- Hunter, D. Papermaking; Dover Publications: New York, NY, USA, 1978. [Google Scholar]

- Shahani, C.J. Accelerated ageing of paper: Can it really foretell the permanence of paper. In Preservation Research and Testing Series, Report No. 9503; Library of Congress, Conservation Directorate: Washington, DC, USA, 2010. [Google Scholar]

- Lattuati-Derieux, S.; Bonnassies-Termes, B.; Lavedrine, J. Identification of volatile organic compounds emitted by a naturally aged book using solid-phase microextraction/gas chromatography/mass spectrometry. Chromatogr. A 2004, 1026, 9–18. [Google Scholar] [CrossRef]

- Lattuati-Derieux, S.; Bonnassies-Termes, B.; Lavédrine, J. Characterisation of compounds emitted during natural and artificial ageing of a book. Use of headspace-solid-phase microextraction/gas chromatography/mass spectrometry. J. Cultur. Herit. 2006, 7, 123–133. [Google Scholar] [CrossRef]

- T.A.P.P.I. Standard T 527 om-02; Color of Paper and Paperboard; Technical Association of the Pulp and Paper Industry: New York, NY, USA, 2002. [Google Scholar]

- T.A.P.P.I. Standard T 425 om-16; Opacity of Paper; Technical Association of the Pulp and Paper Industry: New York, NY, USA, 2016. [Google Scholar]

- T.A.P.P.I. Standard T 494 om-01; Tensile Properties of Paper and Paperboard; Technical Association of the Pulp and Paper Industry: New York, NY, USA, 2006. [Google Scholar]

- T.A.P.P.I. Standard T 509 om-02; Hydrogen Ion Concentration (pH) of Paper extracts (Cold Extraction Method); Technical Association of the Pulp and Paper Industry: New York, NY, USA, 2015. [Google Scholar]

- Szucs, V.; Sik Lanyi, C. 27-Online colour representation of museum artefacts. In Colour Design: Theories and Applications, 2nd ed.; Woodhead Publishing/Elsevier: Duxford, UK, 2017; pp. 641–651. [Google Scholar] [CrossRef]

- Dattner, M.; Bohn, D. 20-Characterization of Print Quality in Terms of Colorimetric Aspects. In Printing on Polymers; Izdebska, J., Thomas, S., Eds.; William Andrew Publishing/Elsevier: Waltham, MA, USA, 2016; pp. 329–345. [Google Scholar] [CrossRef]

- Oil Based Paint, USA Patents. Available online: https://patentimages.storage.googleapis.com/fe/21/c2/e877cc07bd84e3/US5326394.pdf (accessed on 20 December 2021).

- Garside, P.; Wyeth, P. Identification of cellulosic fibres by FTIR spectroscopy. Stud. Conserv. 2003, 48, 269–275. [Google Scholar] [CrossRef] [Green Version]

- Lojewski, T.; Miskowiec, P.; Proniewicz, L.M. Kinetic approach to degradation of paper. In situ FTIR transmission studies in hydrolysis and oxidation. e-Preserv. Sci. 2005, 2, 1–12. [Google Scholar]

- Gorassini, A.; Calvini, P.; Baldin, A. Fourier Transform Infrared Spectroscopy (FTIR) analysis of historic paper: Documents as a preliminary step for chemometrical analysis. In Proceedings of the Multivariate Analysis and Chemometry Applied to Environment and Cultural Heritage (2nd edition), CMA4CH 2008, Mediterraneum Meeting, Ventone Island, Italy, 1–4 June 2008. [Google Scholar]

- Ali, M.; Emsley, A.M.; Herman, H.; Heywood, R.J. Spectroscopic studies of the ageing of cellulosic paper. Polymer 2001, 42, 2892–2900. [Google Scholar] [CrossRef]

- De Viguerie, L.; Payard, P.A.; Portero, E.; Walter, P.; Cotte, M. The drying of linseed oil investigated by Fourier transform infrared spectroscopy: Historical recipes and influence of lead compounds. In Progress in Organic Coatings; Elsevier: Amsterdam, The Netherlands, 2016; pp. 46–60. [Google Scholar]

- Leclerc, D.F. Fourier Transform Infrared spectroscopy in the pulp and paper industry. In Encyclopedia of Analytical Chemistry; Meyer, R.A., Ed.; John Wiley & Sons Ltd.: Chichester, UK, 2000; pp. 8361–8388. [Google Scholar]

- Meilunas, R.J.; Bentsen, J.G.; Steinberg, A. Analysis of aged paint binders by FTIR spectroscopy. Stud. Conserv. 1990, 35, 33–51. [Google Scholar]

- Van der Weerd, J.; Van Loon, A.; Boon, J.J. FTIR studies of the effects of pigments on the aging of oil. Stud. Conserv. 2005, 50, 3–22. [Google Scholar] [CrossRef]

- Boyatzis, S.; Ioakimoglou, E.; Argitis, P. UV exposure and temperature effects on curing mechanisms in thin linseed oil films: Spectroscopic and chromatographic studies. J. Appl. Polym. Sci. 2002, 84, 936–949. [Google Scholar] [CrossRef]

- Malachowska, E.; Pawcenis, D.; Danczak, J.; Paczkowska, J.; Przybysz, K. Paper Ageing: The effect of paper chemical composition on hydrolysis and oxidation. Polymers 2021, 13, 1029. [Google Scholar] [CrossRef]

- Orlova, Y.; Harmon, R.E.; Broadbelt, L.J.; Iedema, P.D. Review of the kinetics and simulations of linseed oil autoxidation. Progress in Organic Coatings 2021, 151, 106041. [Google Scholar] [CrossRef]

- Strlic, M.; Thomas, J.; Trafela, T.; Cséfalvayová, L.; Kralj Cigic, I.; Kolar, J.; Cassar, M. Material degradomics: On the smell of old books. Anal. Chem. 2009, 81, 8617–8622. [Google Scholar] [CrossRef]

- Strlič, M.; Cigić, I.K.; Kolar, J.; De Bruin, G.; Pihlar, B. Non-Destructive Evaluation of Historical Paper Based on pH Estimation from VOC Emissions. Sensors 2007, 7, 3136–3145. [Google Scholar] [CrossRef] [Green Version]

- Clark, A.J.; Calvillo, J.L.; Roosa, M.S.; Green, D.B.; Ganske, J.A. Degradation product emission from historic and modern books by headspace SPME/GC-MS: Evaluation of lipid oxidation and cellulose hydrolysis. Anal. Bioanal. Chem. 2011, 399, 3589–3600. [Google Scholar] [CrossRef]

- Gaspar, E.M.; Santana, J.C.; Lopes, J.F.; Diniz, M.B. Volatile organic compounds in paper: An approach for identification of markers in aged books. Anal. Bioanal. Chem. 2010, 397, 369–380. [Google Scholar] [CrossRef]

- Łojewski, T.; Sawoszczuk, T.; Łagan, J.M.; Zieba, K.; Baranski, A.; Łojewska, J. Furfural as a marker of cellulose degradation. A quantitative approach. Appl. Phys. A 2010, 100, 873–884. [Google Scholar] [CrossRef]

- Dlugogorski, B.Z.; Kennedy, E.M.; Mackie, J.C. Low temperature oxidation of linseed oil: A review. Fire. Sci. Rev. 2012, 1, 3. [Google Scholar] [CrossRef] [Green Version]

- Gaca, A.; Kludská, E.; Hradecký, J.; Hajšlová, J.; Jelen, H.H. Changes in Volatile Compound Profiles in Cold-Pressed Oils Obtained from Various Seeds during Accelerated Storage. Molecules 2021, 26, 285. [Google Scholar] [CrossRef]

- Krist, S.; Stuebiger, G.; Bail, S.; Unterweger, H. Analysis of volatile compounds and triacylglycerol composition of fatty seed oil gained from flax and false flax. Eur. J. Lipid Sci. Technol. 2006, 108, 48–60. [Google Scholar] [CrossRef]

- Uriarte, P.S.; Goicoechea, E.; Guillen, M.D. Volatile components of several virgin and refined oils differing in their botanical origin. J. Sci. Food Agric. 2011, 91, 1871–1884. [Google Scholar] [CrossRef]

- Dlugogorski, B.Z.; Kennedy, E.M.; Makie, J.C. Identification and quantitation of volatile organic compounds from oxidation of linseed oil. Ind. Eng. Chem. Res. 2012, 51, 5645–5652. [Google Scholar] [CrossRef]

- Dlugogorski, B.Z.; Kennedy, E.M.; Makie, J.C. Mechanism of formation of volatile organic compounds from oxidation of linseed oil. Ind. Eng. Chem. Res. 2012, 51, 5653–5661. [Google Scholar] [CrossRef]

| Days of Ageing | C | C + Cp | C + Rf | C + StL |

|---|---|---|---|---|

| 0 | 6.8 | 4.7 | 5.0 | 4.7 |

| 1 | 6.7 | 4.4 | 4.8 | 4.5 |

| 2 | 6.4 | 4.7 | 5.4 | 4.2 |

| 4 | 6.4 | 4.7 | 4.5 | 4.2 |

| 7 | 6.3 | 4.2 | 4.5 | 4.2 |

| 10 | 6.1 | 4.0 | 4.5 | 4.2 |

| 14 | 6.2 | 4.6 | 4.3 | 4.4 |

| 21 | 6 | 4.8 | 4.5 | 4.2 |

| 28 | 6.4 | 4.3 | 4.8 | 3.9 |

| No. | Compounds | r.t. (min) | Quantification Ion (m/z) | Identification Ions (m/z) |

|---|---|---|---|---|

| 1 | methanoic acid (formic) | 1.47 | 46 | 44, 45, 43 |

| 2 | ethanoic acid (acetic) | 1.78 | 60 | 43, 45, 42 |

| 3 | propanoic acid | 3.61 | 74 | 73, 57, 45 |

| 4 | Hexanal | 4.03 | 56 | 44, 72, 82 |

| 5 | 2-hexenal | 5.36 | 55 | 69, 83, 98 |

| 6 | 2-heptanone | 6.52 | 43 | 58, 71, 114 |

| 7 | Heptanal | 6.88 | 70 | 55, 81, 96 |

| 8 | pentanoic acid | 7.56 | 60 | 73, 41, 55 |

| 9 | 2-heptenal | 8.40 | 83 | 55, 70, 112 |

| 10 | 1-octen-3-ol | 8.92 | 57 | 72, 85, 99 |

| 11 | 2-pentyl-furan | 9.04 | 81 | 53, 95, 138 |

| 12 | 2-octanone | 9.14 | 58 | 71, 128, 113 |

| 13 | Octanal | 9.38 | 84 | 69, 100, 57 |

| 14 | 5-ethyl-2-(5H)-furanone | 9.98 | 83 | 55, 112 |

| 15 | hexanoic acid | 10.10 | 60 | 73, 87,41 |

| 16 | 2-octenal | 10.30 | 83 | 55, 70, 108 |

| 17 | 4-nonanone | 10.51 | 43 | 71, 99, 142 |

| 18 | 2-nonanone | 10.80 | 58 | 71, 142 |

| 19 | Nonanal | 10.97 | 57 | 41, 70, 98 |

| 20 | heptanoic acid | 10.89 | 60 | 73, 87, 101 |

| 21 | gamma heptalactone | 11.62 | 85 | 56, 71, 110 |

| 22 | 2-nonenal | 11.68 | 41 | 70, 83, 96 |

| 23 | octanoic acid | 12.02 | 60 | 73, 101, 115 |

| 24 | 2-decanone | 12.06 | 58 | 43, 71, 156 |

| 25 | Decanal | 12.21 | 57 | 82, 112, 128 |

| 26 | 2-decenal | 12.82 | 41 | 70, 83, 98 |

| 27 | nonanoic acid | 12.97 | 60 | 73,115,129 |

| 28 | 5-pentyl-2-(5H)-furanone | 13.67 | 84 | 55, 125, 154 |

| 29 | 2-undecanal | 13.82 | 70 | 57, 83, 124 |

| 30 | gamma-nonalactone | 13.86 | 85 | 114, 128, 100 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Banou, P.; Choulis, K.; Karabotsos, T.; Tsimogiannis, D.; Tsakanika, L.-A.; Tzia, C.; Alexopoulou, A. Oil Media on Paper: Investigating the Effect of Linseed Oils on Pure Cellulosic Paper Supports. A Research Matter of Damage Assessment. Analytica 2022, 3, 120-134. https://doi.org/10.3390/analytica3010009

Banou P, Choulis K, Karabotsos T, Tsimogiannis D, Tsakanika L-A, Tzia C, Alexopoulou A. Oil Media on Paper: Investigating the Effect of Linseed Oils on Pure Cellulosic Paper Supports. A Research Matter of Damage Assessment. Analytica. 2022; 3(1):120-134. https://doi.org/10.3390/analytica3010009

Chicago/Turabian StyleBanou, Penelope, Konstantinos Choulis, Thanasis Karabotsos, Dimitris Tsimogiannis, Lamprini-Areti Tsakanika, Constantina Tzia, and Athena Alexopoulou. 2022. "Oil Media on Paper: Investigating the Effect of Linseed Oils on Pure Cellulosic Paper Supports. A Research Matter of Damage Assessment" Analytica 3, no. 1: 120-134. https://doi.org/10.3390/analytica3010009

APA StyleBanou, P., Choulis, K., Karabotsos, T., Tsimogiannis, D., Tsakanika, L.-A., Tzia, C., & Alexopoulou, A. (2022). Oil Media on Paper: Investigating the Effect of Linseed Oils on Pure Cellulosic Paper Supports. A Research Matter of Damage Assessment. Analytica, 3(1), 120-134. https://doi.org/10.3390/analytica3010009