Having detailed these different 2D and 3D bases, we will now apply them to solve the neutron transport equation on a reactor case, the Takeda Model 4 benchmark.

3.2. Numerical Results for 2D Configuration

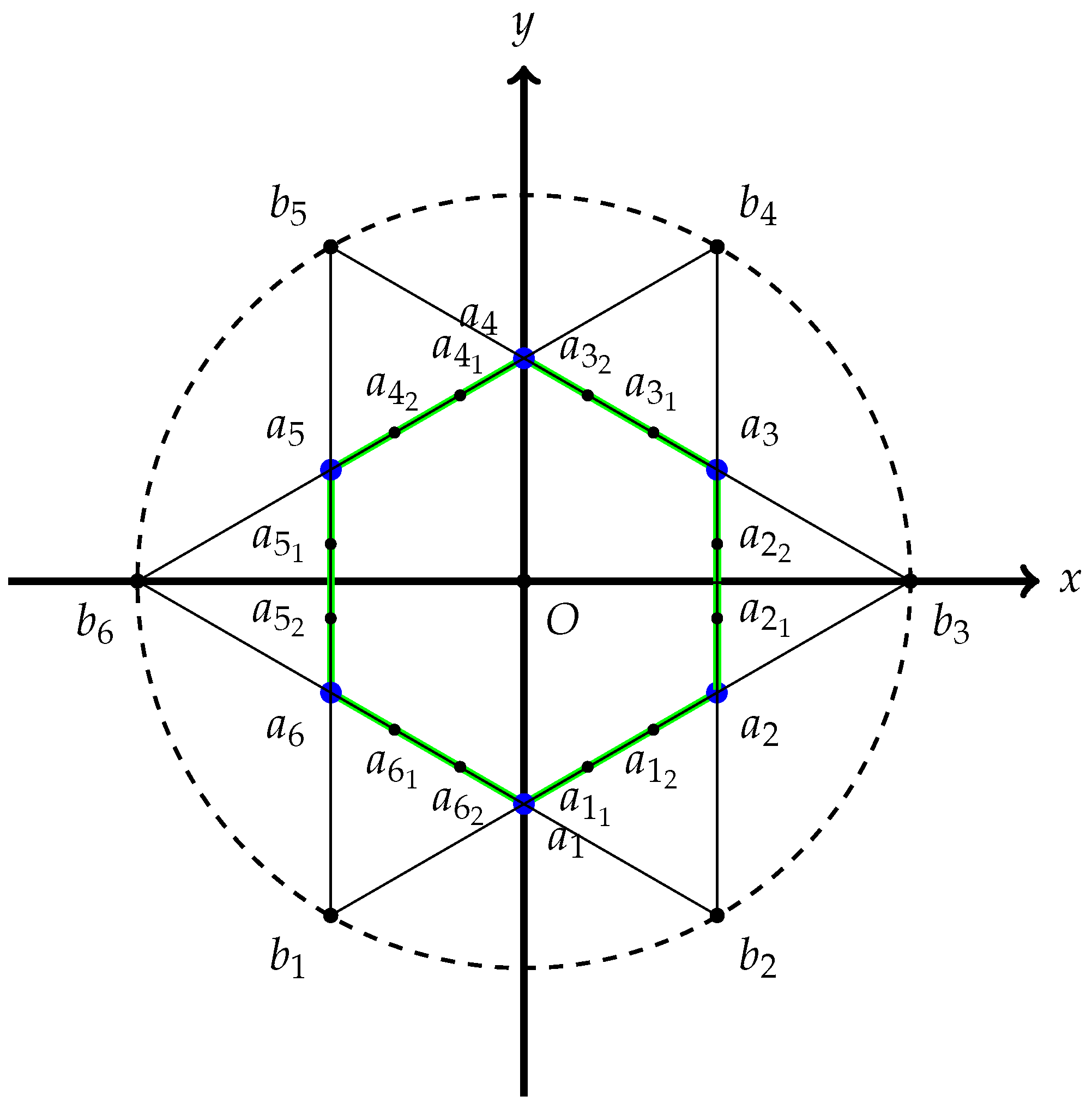

Before computing the usual 3D configuration for this benchmark, we will first consider a 2D setting, which we obtain by considering the plane lying at a height equal to 95 cm and with the control rods inserted. The reference solution is obtained using a DG-FEM code with nonconforming mesh capabilities, as described in [

5]. In this case, the regular hexagon is subdivided into 3 lozenges, which are themselves subdivided into

sublozenges and using polynomial order 5, leading to

dofs. This reference setting results in

, along with reference absorption rates.

Furthermore, the benchmark is also computed with coarse meshes where the hexagon is meshed into three lozenges (corresponding to the minimal mesh required by the code to solve the transport equation with conformal mapping of the lozenges to Cartesian elements as in [

5]) and for orders 1 to 5; this solution will be labelled

SNS1. We then compute the same 2D configuration with our methods using polygonal DG-FEM over the hexagonal mesh with high-order Wachspress functions and polynomial functions, termed

HOW and

POLY hereafter. The relative stopping criteria for all iterative loops are set to

. It should be noted that the total

dofs are given by

, with

being the number of cells (lozenges for SNS1 and hexagons for our HOW and POLY cases) in the mesh, and

the number of

dofs per cell.

Table 3 and

Table 4 present the results for the difference with the reference

in pcm and the maximum and rms values for the relative difference in the absorption rates, respectively.

From

Table 3, it can be observed that SNS1, HOW, and POLY all converge towards the reference

value as we increase order

k. Both polygonal FEM bases agree very well with the reference solution. At order 2 for HOW,

is equal to that at order 1 for SNS1 (blue labels in

Table 3), and in this case, it is very interesting to observe that the HOW solution is almost two orders of magnitude smaller than SNS1, and just a mere 20 pcm off the reference value. POLY also yields the same solution accuracy as HOW, even better at order 4 for comparable

. At order 5, it is worth noting that POLY leads to a solution with similar accuracy as SNS1 with five times fewer

dofs. The final trend of interest in that table is the comparison between HOW and POLY: although POLY starts off with worse discrepancies in

at lower orders, as

k increases, the rate at which the discrepancies diminish is much faster for POLY.

This trend is consistent with the results obtained for manufactured solutions in [

22] for very smooth functions. In reactor cases, while the global regularity of the solution is limited (see [

27]), the local regularity is not uniform, and for regions where the solution is affected locally by the discontinuities in material properties (e.g., cross sections) between two regions along the streaming direction, the regularity of the solution can be limited. This observation regarding local regularity is supported by results reported in the literature where an estimation of local regularity is made (cf. [

28], which was carried out in a logic of

-refinement).

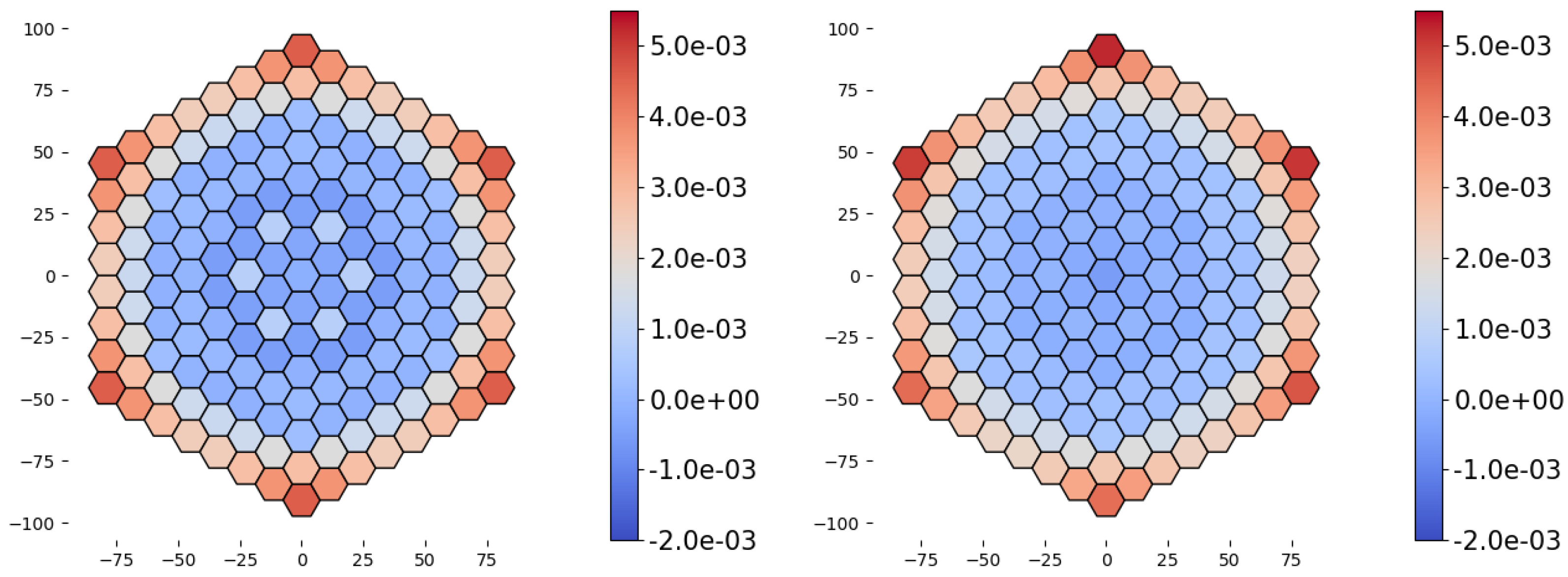

From

Table 4, SNS1, HOW, and POLY converge for both the maximum and rms relative discrepancies on the absorption rates. However, it is very clear that as of

, SNS1 performs an order of magnitude lower than its counterparts. Nonetheless, it is worth noting that for

for HOW and POLY, the discrepancies are much comparable to order 3 for SNS1. Moreover, when comparing the polygonal FEM bases, HOW leads to lower discrepancies than POLY, reversing the trend observed for the

; the HOW discrepancies are almost twice smaller compared to POLY when comparing the rms values for the absorption rates (up to

). Also, the maximum errors are of the same accuracy as the rms value, which suggests an almost flat discrepancy map, as suggested by

Figure 3 for HOW, for example. The maximum discrepancies are located on the last ring of the reactor for the reflector assemblies where scattering and streaming effects are more significant. The same type of map is also observed for SNS1 or POLY.

Finally, it can be noted that the discrepancies for SNS1 deteriorate slightly from order 4 to order 5. This observation might suggest that for this benchmark case, as from , the solution is no longer in the pre-asymptotic convergence regime with the order k. In this case, it would require h-refinement or in other terms, submeshing of the hexagon into subelements to further decrease efficiently the discrepancies. Thus, it would not be interesting to further increase the order of k for HOW and POLY to improve the accuracy for this benchmark if we maintain the hexagonal mesh only.

3.3. Numerical Results for 3D Configuration

In this part, we will now focus on the 3D case for the benchmark. The angular quadrature is a product quadrature with Gauss–Legendre for the polar angle at order 4 and Gauss–Chebyshev at order 3 for the azimuthal angle, thereby leading to 144 directions.

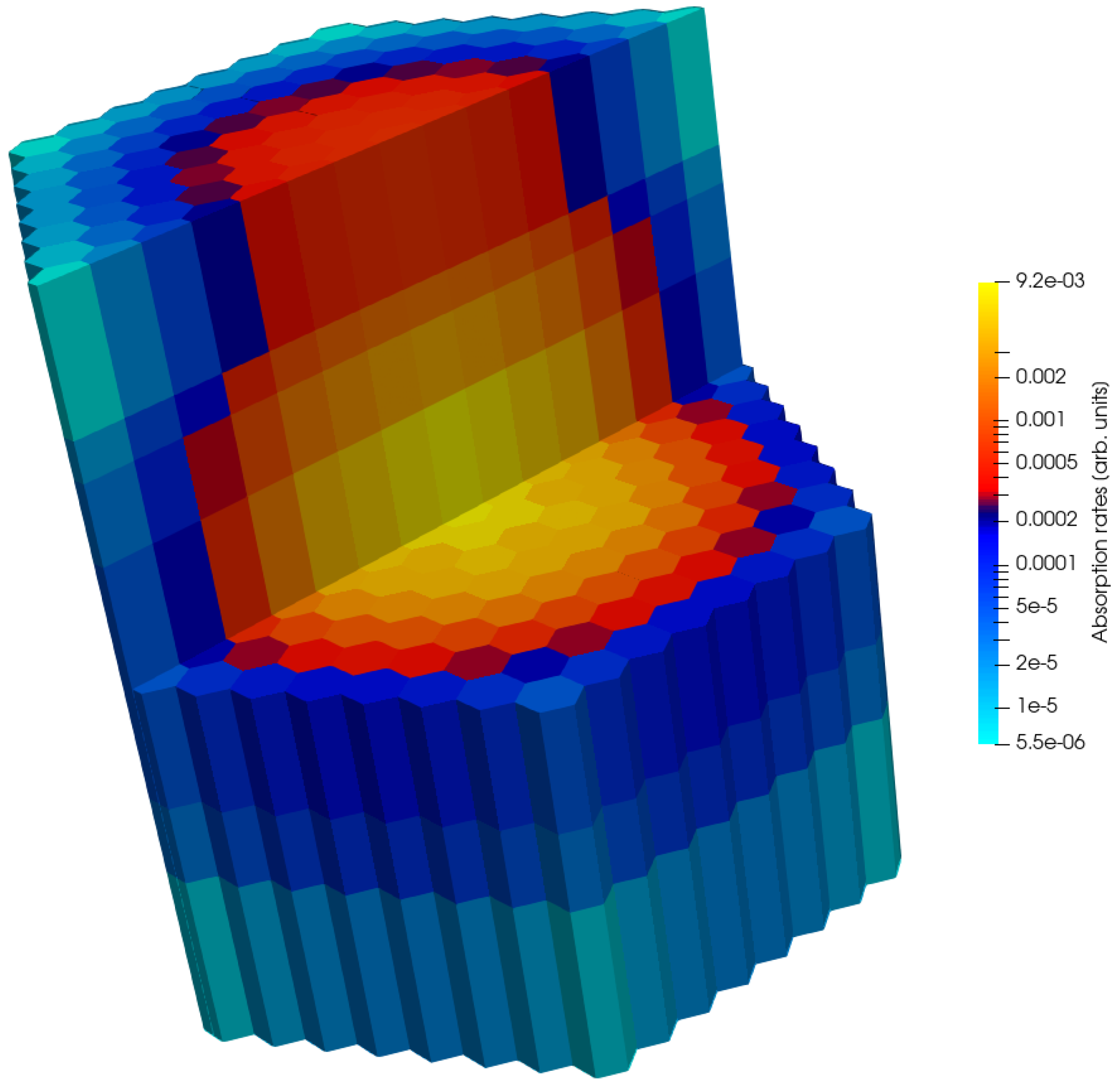

The reference solution is obtained using the same in-house solver, which refines the hexagonal cylindrical cell into parallepipeds with a lozenge base (

) and with order 5, thereby leading to

dofs. The reference

is worth 0.879836, and the reference absorption rates are computed for each hexagonal cell and are illustrated in

Figure 4.

Concerning the polygonal FEM methods, we employed high-order Wachspress (HOW) and polynomial (POLY) basis functions with the multiplicative (MP) and additive (AD) extensions to 3D. No axial submeshing has been applied, and similarly, only the polynomial degree is increased to improve the modelling for axial effects. The corresponding dofs will be recalled for these solvers in the results tables.

Furthermore, we also use the solver with subdivisions of the hexagonal cylindrical cell into simply three extruded lozenges for orders 1 to 4; we denote these solutions as SNS1, which will be used to contrast the performance of the polygonal FEM schemes. The number of dofs for this case is given as . The relative stopping criteria for all iterative loops are set to . We also recall that the total dofs are given by , , with similar definitions as in the 2D case.

The discrepancies on the

are summed up in

Table 5,

Table 6 and

Table 7 for situations that are of interest for our analysis. On the other hand,

Table 8,

Table 9 and

Table 10 illustrate the relative discrepancies for the absorption rates between the reference solution and the various cases for a subset of parameters, namely the types of basis functions and the associated radial, and axial degrees when relevant.

3.3.1. General Trends

The use of high-order polygonal FEM such as those developed in this work, and in particular the additive version HOW-AD and POLY-AD, leads to satisfactory results for this benchmark, especially in terms of computational cost vs. target accuracies on reactivity and local reaction rates. For instance, with POLY-AD at order 4, with five times fewer dofs than SNS1, the results are comparable both in terms of global indicators such as or local values such as absorption rates.

However, it should also be noted that higher accuracies can only be achieved if the hexagonal cell is submeshed, as can be observed by the red line for

in

Table 5 and

Table 7, where SNS1 produces solutions with errors almost an order of magnitude lower than HOW or POLY cases. The maximum and rms discrepancies on the absorption rates confirm the same trend as in

Table 8 and

Table 10 for both MP and AD cases. It should be noted that, just as in the previous 2D case, the maximum errors again are located on the core periphery for reflective materials where streaming and leakage effects are exacerbated. Indeed, this benchmark problem remains quite challenging on numerical discretisation methods due to its highly heterogeneous configuration, and Takeda himself noted in [

26] that some solutions obtained with an

discretisation were not sufficient, as it required more spatial meshing.

3.3.2. Remarks on HOW/POLY MP/AD Basis Functions

For the multiplicative basis functions, the radial and axial orders may be different. From

Table 6 and

Table 9, for fixed

k, the axial order

l is varied. As

l increases from 1 to 2, the results are significantly improved, e.g., for HOW-MP,

is reduced from 588 pcm for XY2-Z1 to 18.8 pcm for XY2-Z2, cf. the red line in

Table 6 for the

or

Table 9 for the absorption rates. However, the decrease in these discrepancies is far less, and even stagnates as

l is further increased (cf. the blue lines in the same tables), and we may deduce that the errors are no longer driven by the axial effects but rather by the radial discretisation order. These results are consistent with those observed from [

29], where the axial flux is approached with low-order functions. As the radial order increases from 1 to 2, HOW solutions are drastically improved compared to POLY due to more (twice)

dofs.

The same conclusions hold for the AD bases, cf.

Table 8, for instance, where HOW and POLY yield very comparable solutions.

Moreover, as in the 2D case, increasing the basis order is of interest until orders 3 or 4 in this benchmark, as is illustrated by

Table 10 whence oscillations are observed on the precision of quantities such as the maximum error.

3.3.3. MP vs. AD: Numerical Performance

The

values are higher with AD rather than MP cases, as can be observed from

Table 5 and

Table 7. Nevertheless, these differences are quite slight and very much comparable. The trend is much more favourable on the local values such as the rms discrepancies on the absorption rates, namely as from orders 3, whereby AD bases lead to more accurate results, almost twice smaller rms values, and even better considering the maximum errors. The additional

dofs contained in MP bases do not contribute significantly to the accuracy of the global solution.

This numerical accuracy coupled to the fact that AD bases are composed of much fewer dofs supports the fact that these functions are very interesting for studies in reactor applications.

Table 5.

with respect to reference values for the 3D configuration for SNS1 and the AD cases for (cf. comments in text on coloured lines).

Table 5.

with respect to reference values for the 3D configuration for SNS1 and the AD cases for (cf. comments in text on coloured lines).

| | SNS1 | HOW-AD | POLY-AD |

|---|

| | | | | | |

|---|

| 1 | 28,392 (8) | 1244 | 8281 (7) | 2780 | 4732 (4) | 3314 |

| 2 | 95,823 (27) | 16.4 | 22,477 (19) | 114 | 11,830 (10) | 296 |

| 3 | 227,136 (64) | 6.1 | 43,771 (37) | 36.4 | 23,660 (20) | 59.9 |

| 4 | 443,625 (125) | 1.7 | 72,163 (61) | −7.3 | 41,405 (35) | −5.19 |

Table 6.

with respect to reference values for the 3D configuration for the MP cases with (cf. comments in text on coloured lines).

Table 6.

with respect to reference values for the 3D configuration for the MP cases with (cf. comments in text on coloured lines).

| | HOW-MP | POLY-MP |

|---|

| | | | |

|---|

| XY1-Z1 | 14,196 (12) | 2040 | 7098 (6) | 2520 |

| XY1-Z2 | 21,294 (18) | 1490 | 10,647 (9) | 1970 |

| XY1-Z3 | 28,392 (24) | 1480 | 14,196 (12) | 1970 |

| XY1-Z4 | 35,490 (30) | 1480 | 17,745 (15) | 1970 |

| XY2-Z1 | 28,392 (24) | 588 | 14,196 (12) | 745 |

| XY2-Z2 | 42,588 (36) | 18.8 | 21,294 (18) | 179 |

| XY2-Z3 | 56,784 (48) | 14.3 | 28,392 (24) | 176 |

| XY2-Z4 | 70,980 (60) | 13.1 | 35,490 (30) | 176 |

Table 7.

with respect to reference values for the 3D configuration for the MP cases with (cf. comments in text on coloured lines).

Table 7.

with respect to reference values for the 3D configuration for the MP cases with (cf. comments in text on coloured lines).

| | HOW-MP | POLY-MP |

|---|

| | | | |

|---|

| XY1-Z1 | 14,196 (12) | 2040 | 7098 (6) | 2520 |

| XY2-Z2 | 42,588 (36) | 18.8 | 21,294 (18) | 179 |

| XY3-Z3 | 85,176 (72) | 27.5 | 47,320 (40) | 42.9 |

| XY4-Z4 | 141,960 (120) | −9.7 | 88,725 (75) | −7.3 |

Table 8.

Comparison of absorption rates with respect to reference values for the 3D configuration for SNS1 and the AD cases up to (cf. comments in text on coloured lines).

Table 8.

Comparison of absorption rates with respect to reference values for the 3D configuration for SNS1 and the AD cases up to (cf. comments in text on coloured lines).

| | SNS1 | HOW-AD | POLY-AD |

|---|

| | max [-] | rms [-] | | max [-] | rms [-] | | max [-] | rms [-] |

|---|

| 1 | 28,392 | 1.8 | 6.8 | 8281 | 2.1 | 9.0 | 4732 | 3.0 | 1.2 |

| 2 | 95,823 | 2.0 | 2.3 | 22,477 | 1.2 | 1.3 | 11,830 | 3.1 | 1.5 |

| 3 | 227,136 | 5.7 | 5.9 | 43,771 | 2.3 | 1.8 | 23,660 | 4.5 | 3.3 |

| 4 | 443,625 | 2.0 | 2.1 | 72,163 | 4.3 | 8.6 | 41,405 | 6.7 | 6.1 |

Table 9.

Comparison of absorption rates with respect to reference values for the 3D configuration for the MP cases such that (cf. comments in text on coloured lines).

Table 9.

Comparison of absorption rates with respect to reference values for the 3D configuration for the MP cases such that (cf. comments in text on coloured lines).

| | HOW-MP | POLY-MP |

|---|

| | max [-] | rms [-] | | max [-] | rms [-] |

|---|

| XY1-Z1 | 14,196 | 2.1 | 7.2 | 7098 | 2.9 | 1.0 |

| XY1-Z2 | 21,294 | 6.3 | 2.7 | 10,647 | 1.6 | 6.1 |

| XY1-Z3 | 28,392 | 6.3 | 2.7 | 14,196 | 1.6 | 6.1 |

| XY1-Z4 | 35,490 | 6.3 | 2.7 | 17,745 | 1.6 | 6.1 |

| XY2-Z1 | 28,392 | 1.7 | 7.1 | 14,196 | 1.8 | 6.9 |

| XY2-Z2 | 42,588 | 1.2 | 3.2 | 21,294 | 1.1 | 6.8 |

| XY2-Z3 | 56,784 | 1.2 | 3.1 | 28,392 | 1.0 | 6.4 |

| XY2-Z4 | 70,980 | 1.2 | 2.9 | 35,490 | 1.0 | 6.5 |

Table 10.

Comparison of absorption rates with respect to reference values for the 3D configuration for the MP cases such that (cf. comments in text on coloured lines).

Table 10.

Comparison of absorption rates with respect to reference values for the 3D configuration for the MP cases such that (cf. comments in text on coloured lines).

| | HOW-MP | POLY-MP |

|---|

| | max [-] | rms [-] | | max [-] | rms [-] |

|---|

| XY1-Z1 | 14,196 | 2.1 | 7.2 | 7098 | 2.9 | 1.0 |

| XY2-Z2 | 42,588 | 1.2 | 3.2 | 21,294 | 1.1 | 6.8 |

| XY3-Z3 | 85,176 | 1.1 | 3.0 | 47,320 | 2.0 | 4.2 |

| XY4-Z4 | 141,960 | 1.2 | 2.7 | 88,725 | 1.0 | 1.6 |