1. Introduction

A study performed by the U.S. Department of Energy (DOE) concludes that for the U.S. to achieve a net-zero energy footprint by 2050 would require 550–770 GW of additional clean power generation capabilities. Further, the study indicates that advanced nuclear power solutions could provide approximately 200 GW of this requirement [

1]. To this end, the DOE is currently supporting the development and demonstration of advanced nuclear reactor concepts.

In 2020, the DOE Advanced Reactor Demonstration Program provided

$30 million to support five projects to develop advanced nuclear reactor designs to be built by private industry [

2]. This includes one small modular reactor (SMR) based on light-water technologies and four non-water-cooled advanced reactor concepts. Specifically, (1) the Hermes Reduced-Scale Test Reactor being developed by Kairos Power, a fluoride salt-cooled high temperature reactor to be built in Oak Ridge, Tennessee; (2) Westinghouse Electric Company’s eVinci concept, a heat pipe-cooled micro-reactor; (3) the BWXT Advanced Nuclear Reactor micro-reactor concept being developed by BWXT Advanced Technologies; and (4) TerraPower’s Molten Chloride Reactor Experiment, to be built at Idaho National Laboratory (INL), a 1200 MW critical fast-spectrum salt reactor design, in which the fuel is mixed with a molten salt coolant and flows through the entire primary loop of the system.

In 2021, DOE followed up with

$4.6 billion in multi-year projects to support the demonstration of three new reactor concepts: another SMR design and two advanced reactors [

3]. The advanced demonstration reactors are the TerraPower Natrium™ Demonstration reactor, to be built in Kemmerer, Wyoming, and the Xenergy Xe-100 Demonstration reactor, to be constructed in the state of Washington, likely in the vicinity of Richland.

It is important to note that in the U.S. the current commercial power reactor fleet uses low-enriched uranium (LEU) fuel. From a regulatory perspective, commercial reactors are currently limited to fuels under 5% enrichment

235U [

4]. There are a number of reasons for this limit, but the strongest is the lack of data and experience with fuels enriched over 5%. Indeed, early reactors operated with enrichments of 3% or less, and sensitivity and uncertainty methods were used to satisfy regulatory requirements for higher enrichments. Today, enrichments of 4.5% are not uncommon in the commercial reactor fleet. However, 5% remains a regulatory cap to which commercial reactors are limited. Nevertheless, there is a desire to use fuels over that cap, both to extend fuel lifetimes in the existing fleet and to use in advanced reactor designs.

The advanced reactor concepts described above, along with a number of less advanced concepts under development, are designed to use High-assay LEU (HALEU) nuclear fuel. HALEU fuel is enriched into the 5–20%

235U range. An enrichment over 20% is considered to be high enrichment; hence, LEU itself is less than 20% enrichment. HALEU is already in use in research and test reactors both domestically and internationally; this fuel is typically used in reactors that previously operated with highly enriched uranium (HEU; generally with enrichments greater than 90%

235U). The commercial nuclear power industry is currently seeking to extend fresh fuel enrichments up to 10%

235U, and the U.S. Nuclear Regulatory Commission (NRC) is evaluating its rulemaking to be able to review such requests. NRC commissioners have reviewed NRC document SECY-21-0109, “Rulemaking Plan on use of Increased Enrichment of Conventional and Accident Tolerant Fuel Designs for Light Water Reactors”, [

5] to allow NRC staff to review potential regulatory implications of increased enrichment fuels [

6]. However, in this paper we consider uranium fuel that is enriched near the 20% cutoff, as this enrichment is most relevant to many advanced reactor designs. Indeed, as we demonstrate, a valuable quantity of experimental fuel-depletion data for fuel near 20% enrichment may be available to validate depletion simulations.

At present, all worldwide commercial HALEU production is performed by Techsnabexport, also known as TENEX, a subsidiary of the Russian state-owned nuclear energy company Rosatom. And while the United States has not yet sanctioned Rosatom over the 2022 invasion of Ukraine, U.S. power plant developers, such as X-energy and TerraPower, do not want to be dependent on the Russian supply [

7]. Moreover, even before 2022, the DOE sought to develop a U.S. capacity to produce HALEU fuel to provide independence from the Russian HALEU supply chain [

8]. Initially, DOE proposed producing about 10 metric tonnes of HALEU for advanced reactor designs.

The fuel was generated decades ago in the Experimental Breeder Reactor-II at Idaho National Laboratory (INL) site west of Idaho Falls, and is stored there now. DOE proposed processing the high-assay low-enriched uranium into fuel that can be used for research and development for companies experimenting with small mobile reactors [9].

This fuel was initially enriched to 67%

235U and discharged at 65% enrichment, contaminated with about 100 parts per million transuranic contaminants [

9].

In addition, in support of both life extension and advanced reactor designs, DOE has sought to expand the current enrichment capabilities of the United States, for enrichments greater that 5%

235U. With the 2013 shutdown of the Paducah Gaseous Diffusion Plant, the only operational uranium enrichment facility in the United States is the Urenco-USA facility in southeastern New Mexico. This plant is currently licensed by the Nuclear Regulatory Commission to enrich uranium to up to 5.5% [

10] but has announced their capability to provide HALEU [

11]. In November 2022, DOE announced that it had selected American Centrifuge Operating LLC, a subsidiary of Centrus Energy, for a cost-shared contract. Under this agreement, American Centrifuge Operating LLC will produce 20 kg of 19.75% enriched HALEU by 31 December 2023 and will continue production for all of 2024 to produce an additional 900 kg of HALEU [

12].

Nevertheless, with the anticipated usage of higher enrichment fuel in advanced reactor concepts, industry is facing new challenges in expanding available data to support regulatory approval for using HALEU fuel, and in the nearer term, to support developing fuel fabrication facilities and appropriate transportation packages for fuel shipping. Certainly an important area of concern is ensuring subcriticality during fabrication and transportation [

13]. Hence, there is a need to develop an appropriate set of benchmarks to validate analysis methods for HALEU systems.

2. Regulatory Requirements

Using fuel enriched to around 20%

235U in a commercial facility under NRC oversight will require the licensee to demonstrate that the facility (reactor, enrichment facility, transportation cask, storage, etc.) will operate with a well-quantified fuel reactivity. Furthermore, for spent fuel storage, licensees will be required to demonstrate that they have the ability to validate the codes they use to predict fuel compositions as a function of burnup or to assume that the fuel is in its most reactive state. To this end, the DOE Office of Nuclear Energy has been directed to develop benchmark data to assist the NRC in the licensing and regulation of special nuclear materials for HALEU applications [

14].

Power plant licensees are required to only use methods that have been specifically approved by the NRC for use at the respective licensee facility [

15]. For the last 25 years, most licensees have adopted the “Kopp 5%” approach [

16] in lieu of a formal, and potentially computationally intensive, depletion code validation. In [

16], the author states:

A reactivity uncertainty due to uncertainty in the fuel depletion calculations should be developed and combined with other calculational uncertainties. In the absence of any other determination of the depletion uncertainty, an uncertainty equal to 5% of the reactivity decrement to the burn up of interest is an acceptable assumption.

This approach, as applied to spent fuel pools, is described further in NRC internal staff guidance [

17]. Using NRC-approved codes for reactor core and cycle design generally results in criticality calculations well within 5% of measured values. Hence, most commercially licensed light-water reactor (LWR) licensees use the Kopp 5% approach rather than performing validation calculations for their depletion methods [

15]. This approach is very conservative and is based on thousands of reactor years of operation within the United States. Nonetheless, outside the LWR domain, no such operational experience is available. Spent fuel storage and transportation applications have historically been licensed assuming fuel elements are fresh and in their most reactive state for criticality calculations (i.e., no credit for burnable poisons present in the fuel)—the so-called fresh fuel assumption [

18,

19]. This approach is highly conservative and severely limits the amount of fuel that can be stored in pools or casks. The NRC has more recently allowed consideration for partial credit for spent fuel isotopics, using burnup credit [

17,

20], based on validation for depletion calculations and other considerations [

21]. In support of burnup credit applications, biases and uncertainties in predicting isotopic compositions must be determined using measured data, typically in the form of radiochemical assay (RCA) data from well-characterized spent fuel pins [

22].

Because there is little to no historical operating experience for HALEU-fueled reactors, whether in an LWR or advanced reactor concept, the NRC will most certainly require the validation of criticality and depletion methods using HALEU data, as has been required for applying burnup credit [

23].

Several test reactors have been converted to operate using HALEU worldwide [

24], but at this time very few benchmarks have been produced with their data. Such test reactors are rarely refueled, and when they are, RCAs are not performed. Hence, there is a clear need to increase the amount of available qualified data to validate computational methods for HALEU fuel designs. And there is a sparcity of relevant data for these validations. For example, nuclear cross sections used for LWR operation and design and for HEU-fueled cores have been used for decades. Cross-section deficiencies (in both transport or depletion calculations) have thus been identified and have then been remeasured and/or reevaluated to improve the ability to simulate such systems. No such operational and validation experience exists for HALEU fuel, and there is no assurance that existing data will be sufficiently accurate for design and safety calculations. Regulators will want to understand biases with respect to data; validation provides the ability to evaluate and quantify such biases.

A challenge with some of the reactor conversions from HEU to HALEU is establishing a converted core with an equivalent performance to their original HEU core, as expected from modeling and simulations. For example, TRIGA (Training, Research, Isotopes, General Atomics) LWR research reactors with UZrH HALEU fuel would typically have a positive computational bias in models, effectively overpredicting total core excess reactivity [

25,

26], while simulated worth measurements suitably represented actual values within evaluated uncertainties [

27]. Comprehensive analyses indicated that the likely cause of the observed inconsistency is nuclear data deficiencies, such as for Zr and ZrH thermal scattering, which has a more pronounced impact in smaller critical systems [

28] than in larger configurations. More recent studies performed using improved nuclear data for Zr and ZrH indicate some improvement in TRIGA simulation accuracy compared to measurements; however, there were still deficiencies for systems containing Er as a burnable poison, indicating a further need to revise Er nuclear data [

29]. Similar nuclear data impacts upon the modeling and simulation of graphite-moderated and -reflected reactor systems can also be significant [

30].

The following section will discuss potential sources for validating the analysis methods applied to HALEU-based systems. There are a number of reactor physics benchmarks based on fresh HALEU fuel that will help support validating criticality calculations for core designs, but benchmarks that can validate the prediction of isotopes generated during operation do not exist. Qualified benchmark data relevant for validating both criticality and depletion calculations will be essential to satisfy regulatory review [

31,

32].

3. Data for HALEU Validation

The amount of data available for validating fresh or burned HALEU systems is somewhat limited. Nine well-documented reactor physics benchmark evaluations are available within the International Reactor Physics Experiment Evaluation Project (IRPhE) Handbook [

33] and are described in detail below. A number of experiments with HALEU fuel are available or will be in the near future. However, while collections of RCA measurement data and associated measurement and irradiation reports characterizing the measured fuel have been developed to support validating depletion methods and are provided in the Spent Fuel Isotopic Composition database (SFCOMPO) [

34] and elsewhere, none of these provide measured data or benchmark specifications for validating depletion methods for HALEU fuel [

35]. The SFCOMPO database, the world’s largest resource of RCA experimental data for spent nuclear fuel, includes data for 750 samples selected from fuel irradiated in 44 reactors, including UOX and MOX fuel, for more than 90 isotopes important to a large variety of spent fuel applications. However, no RCA measurement data are available in the database for UO

2 fuel with an initial enrichment over 5%

235U.

Section 3.1 describes data that may be used for validating criticality calculations for fresh HALEU fuel. There is a limited set of benchmarks and other data that could be used, but its applicability to specific applications remains to be determined. For example, it is unclear if any of these benchmarks would be applicable for a molten-salt reactor with HALEU fuel. The IRPhE Handbook contains only one molten-salt reactor benchmark [

36]; although, the evaluation has a very large uncertainty, and while relevant at a 33% enrichment, it is not technically HALEU fueled.

The following subsections describe evaluated data sets along with data that have not been converted to an evaluated benchmark format.

Section 3.2 then describes other sources of data for validating fresh fuel measurements.

Table 1 provides a summary of these data, each of which is described in more detail in the following subsections.

Finally,

Section 3.3 describes a set of experiments in which HALEU fuel was irradiated in the INL Advanced Test Reactor (ATR). Although spent fuel characterization was not the intent of those experiments, RCA data exist that may permit developing quality benchmarks for validation.

3.1. Existing Benchmarks for Criticality and Fresh Fuel HALEU Validation

A number of research and test reactors have been converted to run using HALEU fuel (typically a silicide-based fuel with uranium enriched to 19.8% 235U). These facilities do not operate continuously nor at a high power level and thus the fuel depletion rate is very slow. Few, if any, high-burnup HALEU elements are available from these sources. The available fuel elements do, however, provide the opportunity to validate criticality methods for fresh fuel.

As mentioned above, the IRPhE Handbook contains a number of benchmarks for HALEU fuel that can be used to validate criticality and reactor physics measurements. The following subsections describe nine IRPhE evaluations.

Section 3.2 describes facilities that could provide potential future benchmark evaluations for validating fresh fuel criticality calculations.

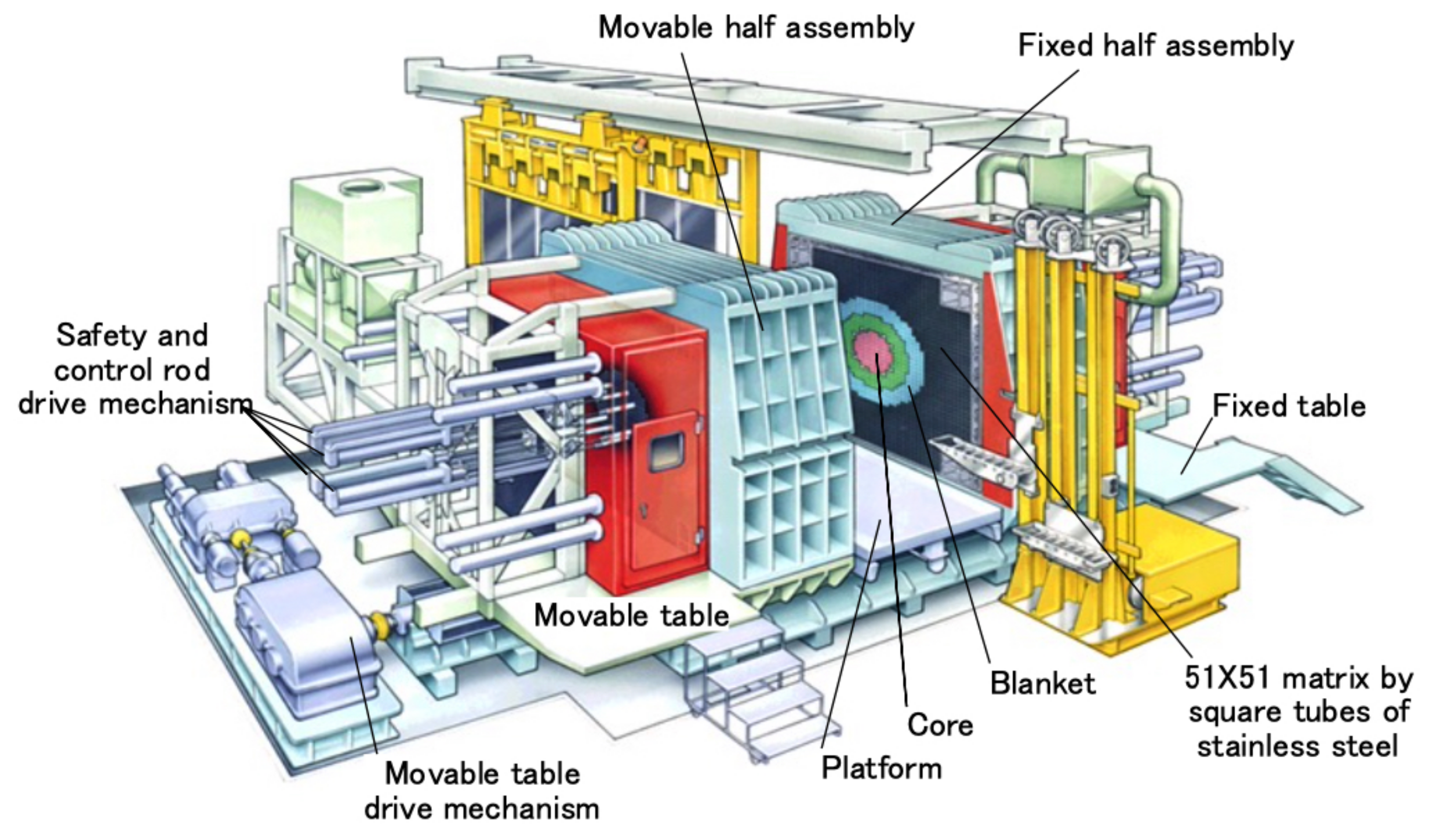

3.1.1. 20% Enriched Uranium Metal with a Depleted Uranium Blanket

The IRPhE evaluation, “FCA IX-7 Assembly Experiments: 20% Enriched Uranium Metal Core Surrounded by Depleted Uranium Metal Blanket”, FCA-FUND-EXP-001, contains measurements from Japan Atomic Energy Agency’s Fast Critical Assembly (FCA) facility. It is a critical assembly very similar to the Zero Power Reactor at INL. The FCA IX-7 critical experiment was a demonstration of a fast core with 20 wt% enriched uranium metal surrounded by a depleted uranium metal blanket. The critical assembly was a simple system, with axial and radial blankets of depleted uranium metal.

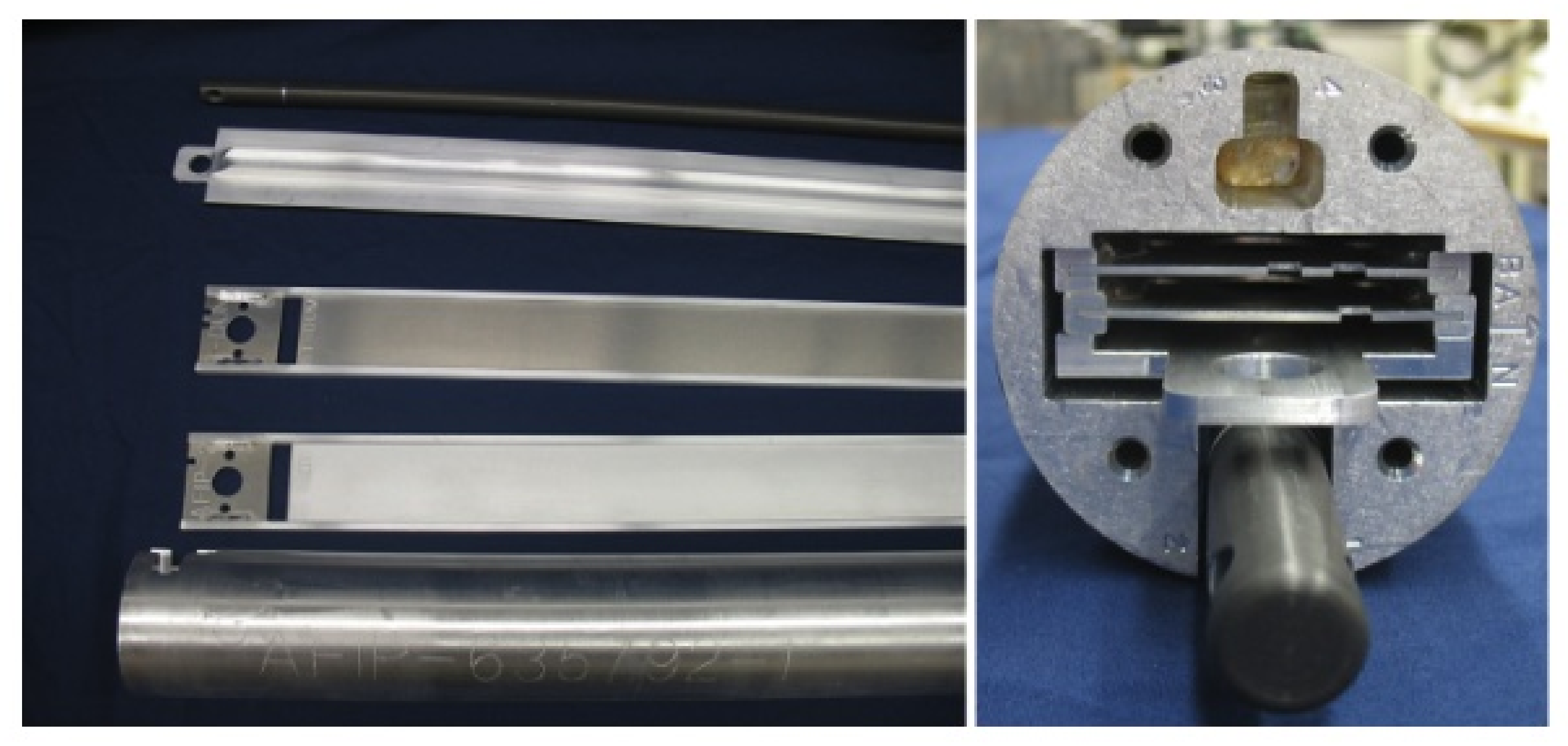

Figure 1 provides a schematic illustration of the FCA facility.

3.1.2. 20% Enriched Uranium Metal Cylinders with Various Reflectors

This is a series of IRPhE evaluations from the FR0 (Fast Reactor 0) fast-spectrum zero-power reactor in Studsvik, Sweden. Three evaluations are included in the IRPhE Handbook:

The FR0 Series 1: Copper-Reflected “Cylindrical” Uranium (20 wt% 235U) Metal (ID FR0-FUND-RESR-001)

The FR0 Series 4: 20%-Enriched “Cylindrical” Uranium Metal Reflected by Natural Uranium (ID FR0-FUND-RESR-002)

The FR0 Experiments with Diluted 20%-Enriched “Cylindrical” Uranium Metal Reflected by Copper (ID FR0-FUND-RESR-003)

FR0 was a split-table machine with vertical fuel and reflector elements. A quantity of approximately 600 kg of enriched uranium was available for performing critical experiments. The uranium metal, with more than 3000 20 wt%

235U plates with varying dimensions, allowed for a flexible fuel geometry. For the above experiments, fuel plate placement approximated a real cylinder, hence the quotations in the titles. The core configuration is illustrated in

Figure 2.

3.1.3. NRAD with 20% Enriched U-ZrH-Er Fuel

This represents a set of two IRPhE evaluations from the Neutron Radiography (NRAD) Reactor located at INL:

Fresh-Core Reload of the Neutron Radiography (NRAD) Reactor with Uranium(20)-Erbium-Zirconium-Hydrid Fuel (ID NRAD-FUND-RESR-001)

Neutron Radiography Reactor 64-Element Core Upgrade (ID NRAD-FUND-RESR-002)

The NRAD core is a square-lattice TRIGA Mark II core designed for steady-state operation with or without in-core or in-tank experiments. It was converted to the current 19.75 wt% U-Er-ZrH fuel in 2010. The original 56-element critical loading and a second 60-element loading are provided in NRAD-FUND-RESR-001. However, because the core’s excess reactivity was lower than predicted and would not allow for extended operations, NRAD was upgraded with the addition of four fuel elements and four graphite elements in 2013. Measurements reported in NRAD-FUND-RESR-002 include a 62-element initial critical and standard 64-element configuration.

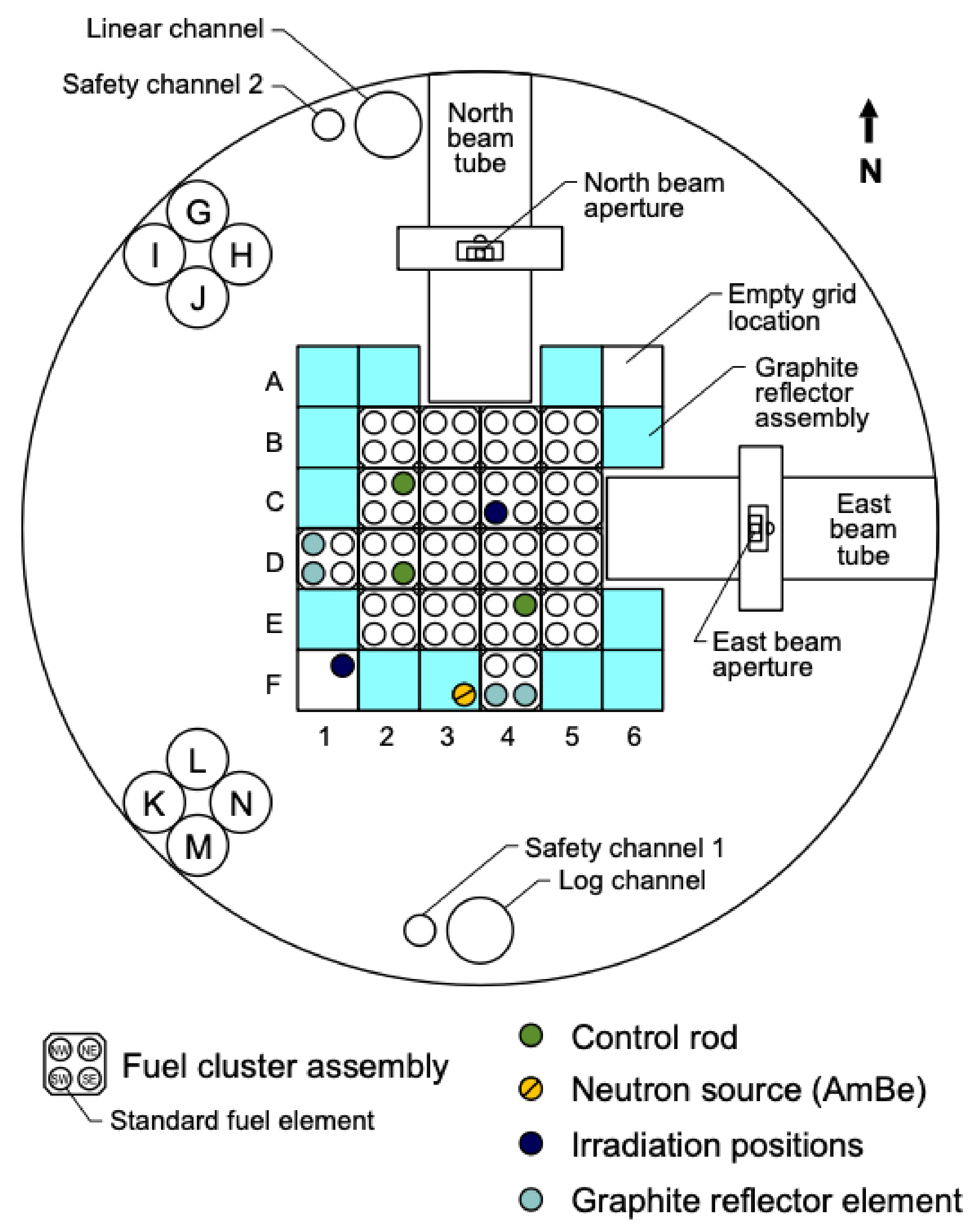

Figure 3 shows NRAD’s current 64-element configuration.

3.1.4. TRIGA Mark II Reactor with 20% Enriched U-ZrH Fuel in Water with a Graphite Reflector

This also represents two IRPhE evaluations from the Jozef Stefan Institute (JSI) TRIGA Mark II reactor in Ljubljana, Slovenia:

TRIGA Mark II Reactor: U(20)—Zirconium Hydride Fuel Rods in Water with Graphite Reflector (ID TRIGA-FUND-RESR-001)

Reaction Rate Distribution Experiments at the Slovenian JSI TRIGA Mark II Research Reactor (ID TRIGA-FUND-RESR-002)

The core uses standard commercial TRIGA fuel elements arranged in a cylindrical configuration; hence, it does not have a periodic structure. TRIGA-FUND-RESR-001 provides the results of two critical measurements made in the core after a 1991 upgrade with all fresh fuel. In October 2011 and July 2012, a series of absolute fission rate distribution measurements was performed at the JSI reactor; the idea behind the experimental calibration method was to record multiple axial reaction-rate profiles along the active height of the reactor core with in-core detectors to create a detailed map of the neutron flux distribution. These measurements were made in a core with burned fuel present; burnup values were calculated based on the core’s operating history.

Figure 4 shows the core layout and configuration for the first critical measurement in TRIGA-FUND-RESR-001.

3.1.5. 18% Enriched Fuel Rods in Water

The IRPhE evaluation “Power Burst Facility: U(18)O

2-CaO-ZrO

2 Fuel Rods in Water”, PBF-FUND-RESR-001, contains two startup critical measurements from the Power Burst Facility (PBF). This reactor operated from 1972 to 1985 on INL’s Special Power Excursion Reactor Test Area I, then known as the Nuclear Reactor Test Station. This evaluation focuses on two similar operational loading tests, differing only in the number of fuel rods and position of the control rods, published in a startup-test report in 1974. The fuel was enriched to 18.31%

235U.

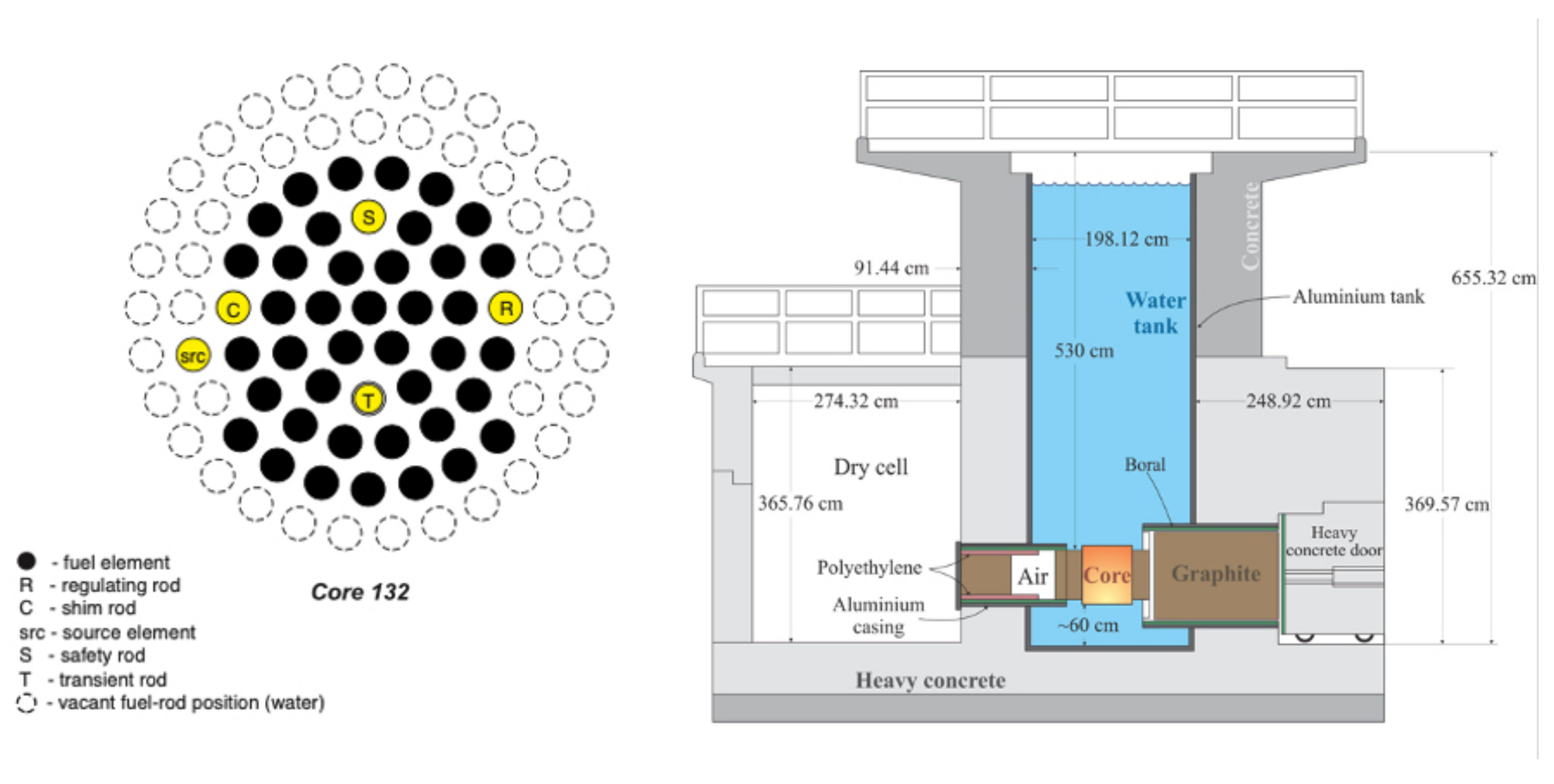

Figure 5 provides a cross-cut illustration of the PBF core configuration for the first critical evaluation.

3.1.6. 20% Enriched Water-Reflected and -Moderated Fuel Plates

The IRPhE evaluation “RA-6 Reactor: Water Reflected, Water Moderated U(19.77)

3Si

2-Al Fuel plates”, RA6-FUND-RESR-001, contains an evaluation of a measurement performed as part of a startup test program after its conversion to LEU silicide fuel. The RA-6 (Reactor Argentino, Número 6) is an open-pool research reactor, built to support the nuclear engineering and reactor physics training and research activities in the Argentinian Atomic Energy Commission. Initially operated with HEU fuel, the core was converted to a silicide fuel enriched to 19.77%

235U in 2008. The fuel elements are Materials Test Reactor (MTR)-type, composed of rectangular fuel plates attached to two aluminum side plates that hold the fuel plates and burnable poisons in place.

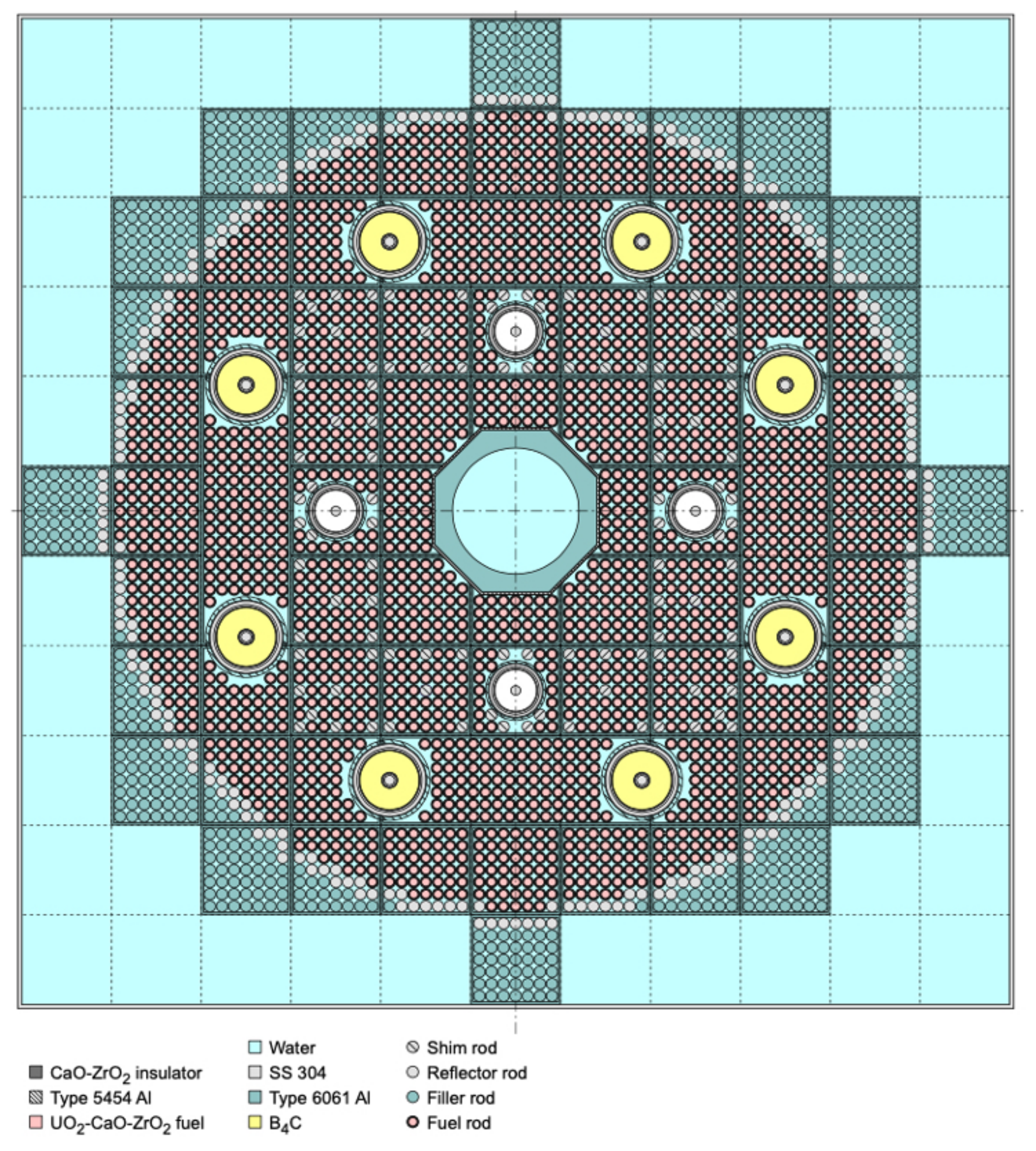

Figure 6 provides a picture of the core with its first HALEU critical loading.

3.1.7. Fuel and Moderator Pebbles with 16.7% Enriched UO2 in TRISO Fuel Form

PROTEUS was a zero-power research reactor at the Paul Scherrer Institute in Switzerland and was a large cylindrical graphite annulus with a central cylindrical cavity. From 1992 to 1996 it was configured as a pebble-bed reactor critical facility and was given the designation HTR-PROTEUS. It provided experimental benchmark data to support the computational assessment of high-temperature gas-cooled reactors (HTGRs). The HTR-PROTEUS experimental program, conducted within the scope of an International Atomic Energy Agency (IAEA) coordinated research program, performed eleven experiments, with both random and ordered pebble arrangements, different moderator ratios employing different loading ratios for fuel and moderator pebbles, and other experimental parameters [

37]. All eleven of these are available in the IRPhE Handbook within four evaluations [

33]:

PROTEUS-GCR-EXP-001: HTR-PROTEUS Pebble Bed Experimental Program Cores 1, 1A, 2, and 3: Hexagonal Close Packing with a 1:2 Moderator-To-Fuel Pebble Ratio

PROTEUS-GCR-EXP-002: HTR-PROTEUS Pebble Bed Experimental Program Core 4: Random Packing with a 1:1 Moderator-To-Fuel Pebble Ratio

PROTEUS-GCR-EXP-003: HTR-PROTEUS Pebble Bed Experimental Program Cores 5, 6, 7, & 8: Columnar Hexagonal Point-On-Point Packing with a 1:2 Moderator-To-Fuel Pebble Ratio

PROTEUS-GCR-EXP-004: HTR-PROTEUS Pebble Bed Experimental Program Cores 9 & 10: Columnar Hexagonal Point-On-Point Packing with a 1:1 Moderator-To-Fuel Pebble Ratio

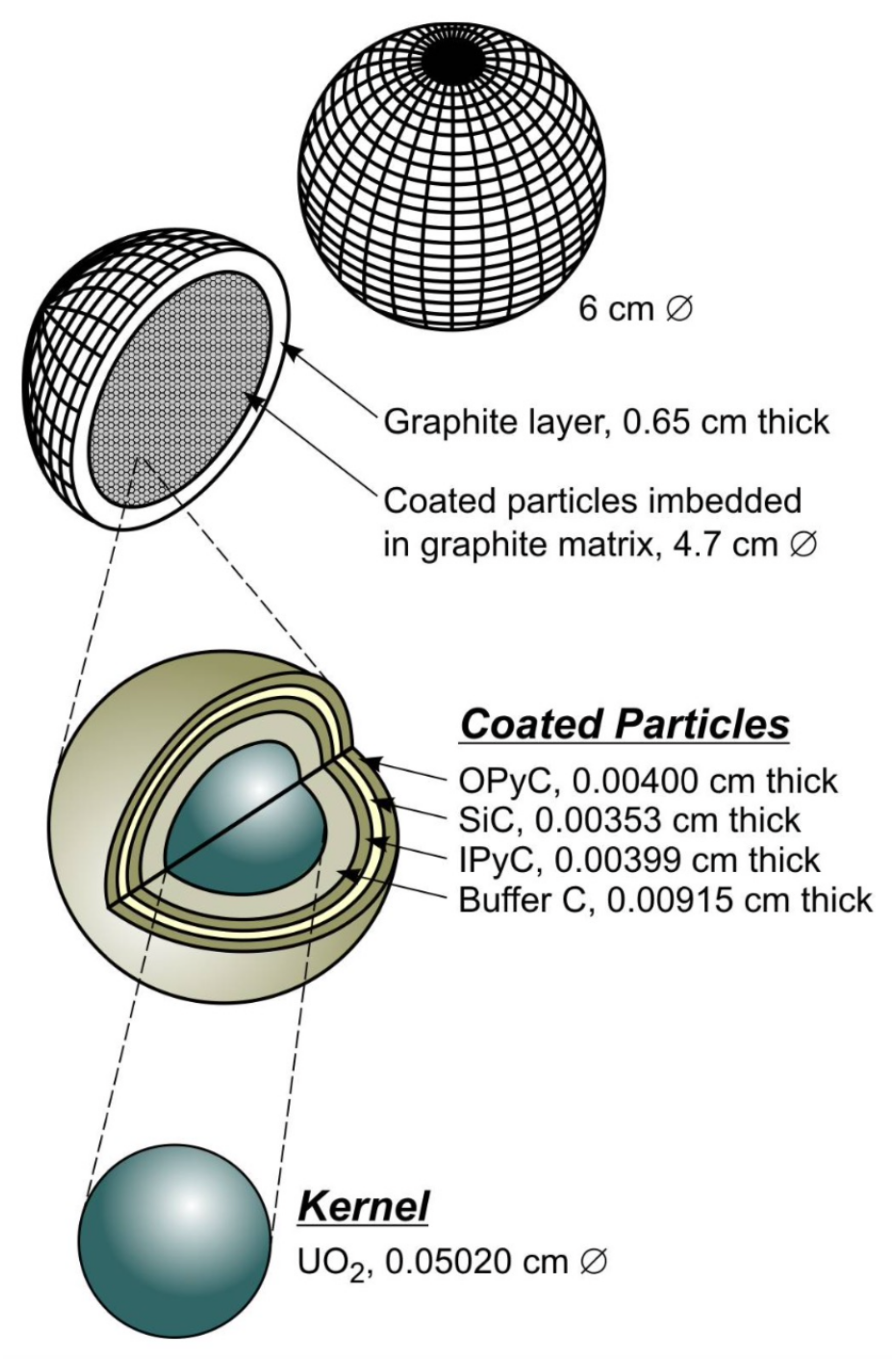

Figure 7 shows the dimensions and composition of the fuel pebbles used in the experiment series. Moderator pebbles had the same 6 cm radius but only contains graphite. While there are many components of the PROTEUS core that remained unchanged throughout the course of the HTR-PROTEUS experiments, many parameters did change between experiments, such as the use of graphite filler pieces, control rod types and locations, the presence of polyethylene rods to simulate water ingress, core pebble packing, and conditions at criticality [

38].

3.1.8. Pebble Bed Test Reactor with 17% Enriched UO2 in TRISO Fuel Form

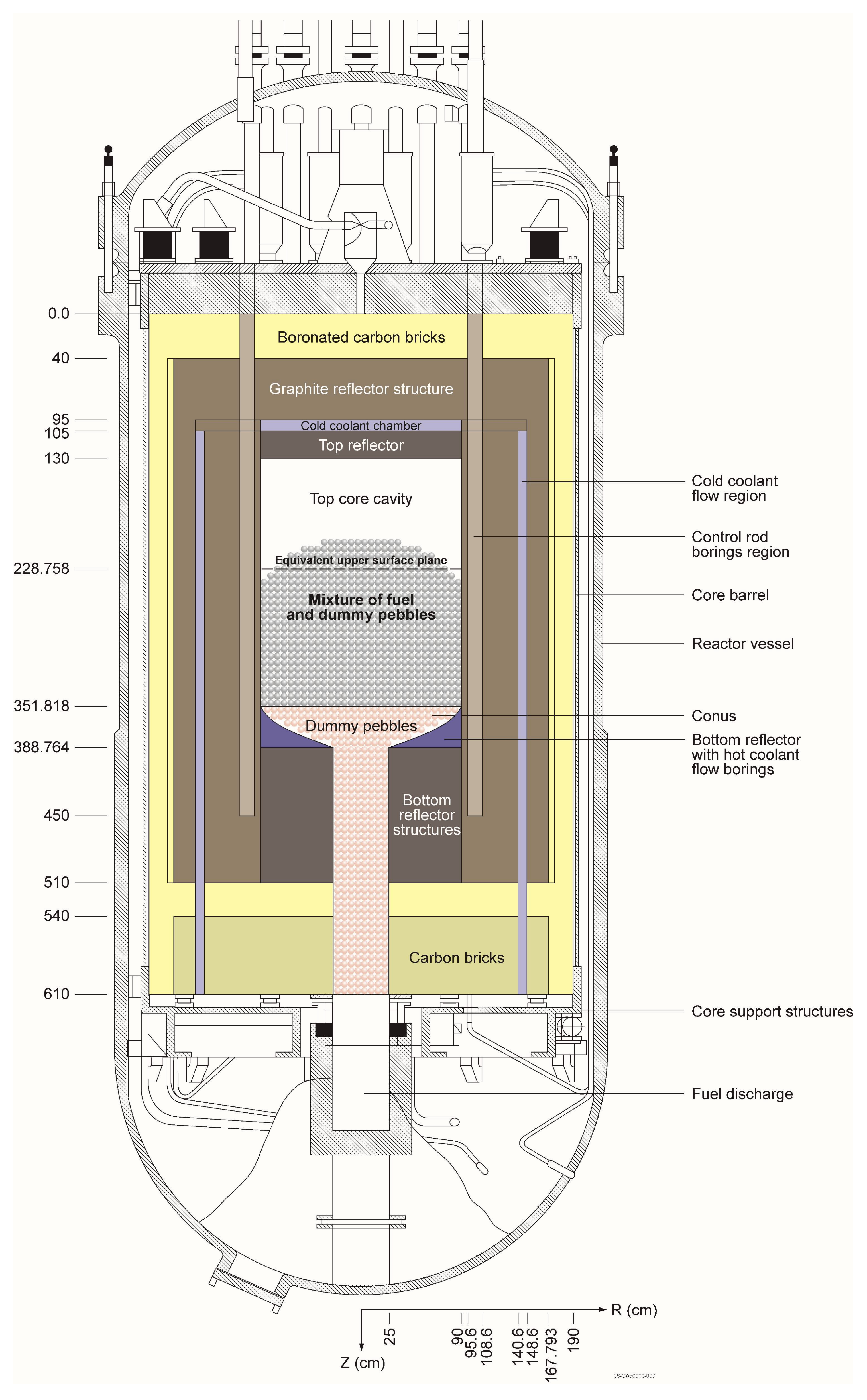

The HTR-10 benchmark is provided in the IRPhE Handbook as evaluation HTR10-GCR-RESR-001. The information on which the evaluation is based comes primarily from the IAEA publication IAEA-TECDOC-1382, as the outcome of an IAEA Coordinated Research Project, “Evaluation of HTGR Performance”. Dr. Yuliang Sun of the Institute of Nuclear and New Energy Technology (INET) is the principal author of the chapters in IAEA-TECDOC-1382 on the HTR-10 core physics calculation performed by INET. The core configuration is illustrated in

Figure 8.

INET designed, built, and operates the HTR-10 test reactor in China. The reactor is a small, 10 MW

th high-temperature gas-cooled, pebble-bed test reactor intended to aid in the development of pebble-bed reactor technology in China. The core was fueled with TRISO fuel encased in 6-cm-diameter graphite pebbles, mixed with unfueled graphite pebbles for moderation and reactivity control. In the initial critical condition provided in the benchmark, all control rods were withdrawn; control rod worth measurements were also made on the cold clean core [

33].

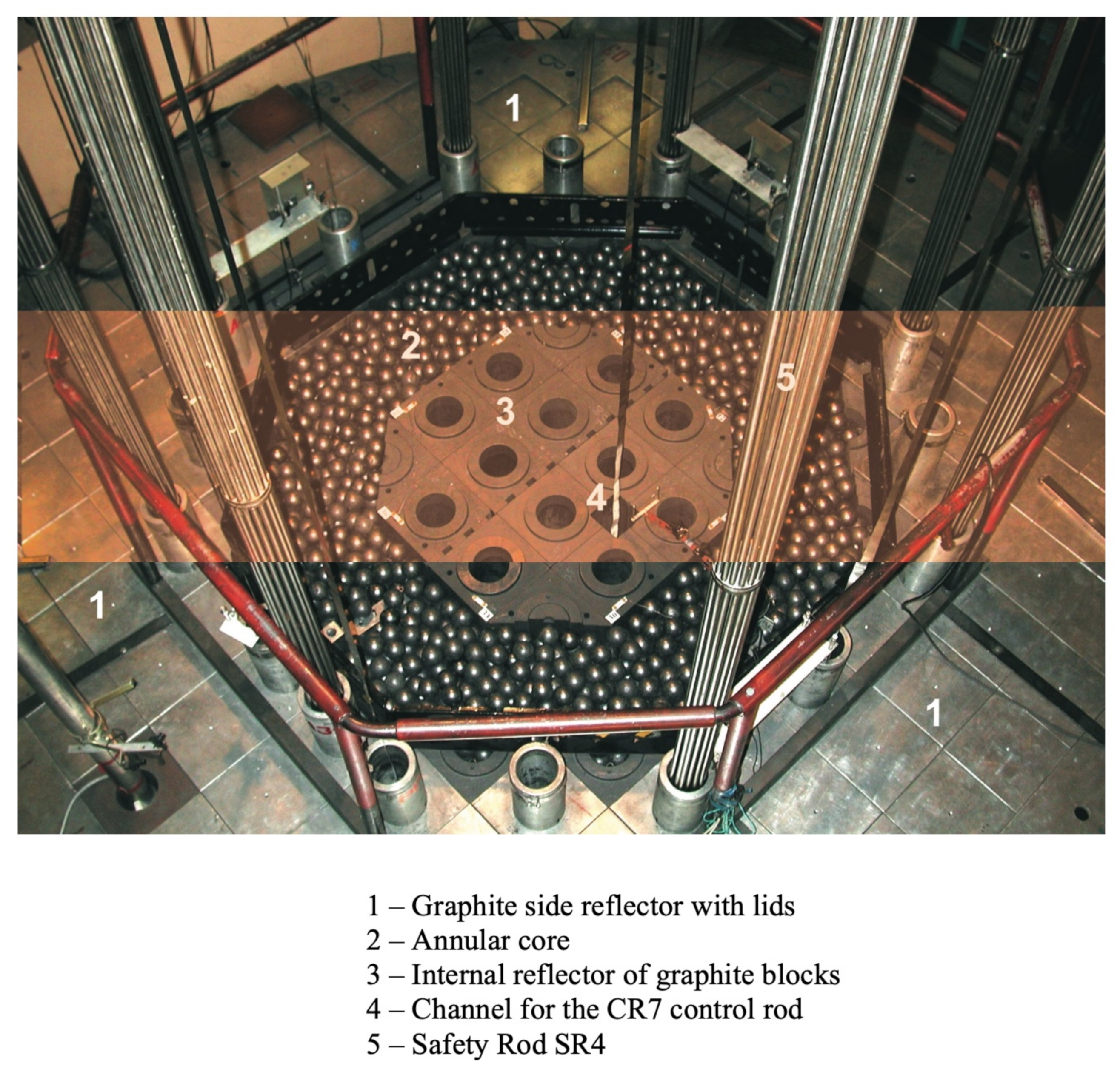

3.1.9. Annular Pebble Core with Coated 21% Enriched UO2 in Fuel Particles

The ASTRA critical facility was put into operation at the Russian Kurchatov Institute in 1980. It was designed for the experimental investigation of neutron physics parameters of a thermal spectrum helium-cooled graphite-moderated high-temperature reactor. ASTRA critical experiments use uranium dioxide fuel of about 21% enrichment in

235U in the form of coated fuel particles distributed throughout the graphite matrix of spherical fuel elements. Each fuel particle consists of a spherical uranium dioxide kernel with four layers of coating around it.

Figure 9 shows a picture of the core configuration.

IRPhE evaluation ASTRA-GCR-EXP-001 provides results of critical experiments performed between 2003 and 2004 at room temperature (19.5–21.5 °C) for five critical experimental assembly configurations.

3.2. Potential Future Benchmarks for Criticality and Fresh Fuel Validation

The IPEN/MB-01 reactor, for which 21 IRPhE evaluations have been completed, was converted from UO

2 rod-type fuel, enriched to 4.3% enriched in

235U, to U

3Si

2-Al plate-type fuel elements, enriched to 19.75%

235U [

39]. Although not yet evaluated as a benchmark, such an evaluation is likely forthcoming. The National Academy of Science of Belarus has performed criticality measurements for a number of higher enrichments (21, 36, and 45%); these measurements have not been developed into IRPhE benchmarks at this time, and it is unclear if the higher enrichments over 21% are relevant in validating HALEU applications [

40]. Finally, the Microreactor Applications Research Validation and Evaluation (MARVEL) reactor to be built and brought critical by December 2024 should provide additional data relevant for HALEU and advanced reactor concepts. These and other potential benchmarks are described below.

3.2.1. 19.75% Enriched U3Si2-Al Plate Fuel in a Water-Moderated Lattice

The new IPEN/MB-01 plate-type core is a tank-type research reactor. The core configuration is disposed in a 4 × 5 configuration, with 19 fuel elements (U

3Si

2-Al, 2.8 g U/cm

3, and 19.75% enriched in

235U), plus one aluminum block providing an internal irradiation position. Cadmium wires are used as a burnable poison to control the power density and the excess reactivity during operation. The core is reflected by four boxes of heavy water, with four hafnium control plates, and has a maximum nominal power of 100 W [

39]. Although a number of such test reactors exist worldwide, measurements from the IPEN facility are typically prepared in the IRPhE-prescribed format used for development of benchmark evaluations [

41].

Figure 10 shows the IPEN/MB-01 core operating prior to its conversion to plate fuel.

3.2.2. 21% Enriched UO2 in Water-Moderated Hexagonal Lattices

The Joint Institute for Power and Nuclear Research at Sosny of the Belarus National Academy of Science reported on measurements performed for four hexagonal lattices of fuel rods in water; each lattice differed by the pitch of the rods. The fuel rods are completely flooded with water, and the number of rods was adjusted to reach criticality [

40]. Details of the four experiments are provided in

Table 2.

3.2.3. Microreactor Applications Research Validation and Evaluation Reactor

Although not yet available, the MARVEL project at INL may provide additional data in the near future. Under the auspices of the DOE Microreactor Program, INL is developing a nuclear microreactor applications test bed to perform research and development on various microreactor operational features and enable an improved integration of microreactors into end-user applications. The MARVEL reactor design is a sodium-potassium-cooled thermal microreactor fueled with standard commercial TRIGA uranium zirconium hydride fuel pins using HALEU. It will be a 100 kW

th reactor capable of generating about 20 kW

e using Stirling engines over a core life of about 2 years [

42]. MARVEL development will provide an opportunity to perform an additional criticality validation in the near future and perhaps HALEU depletion data at the core’s end of life.

3.3. Potential Data for Validating Depletion Methods Using Irradiated Fuel

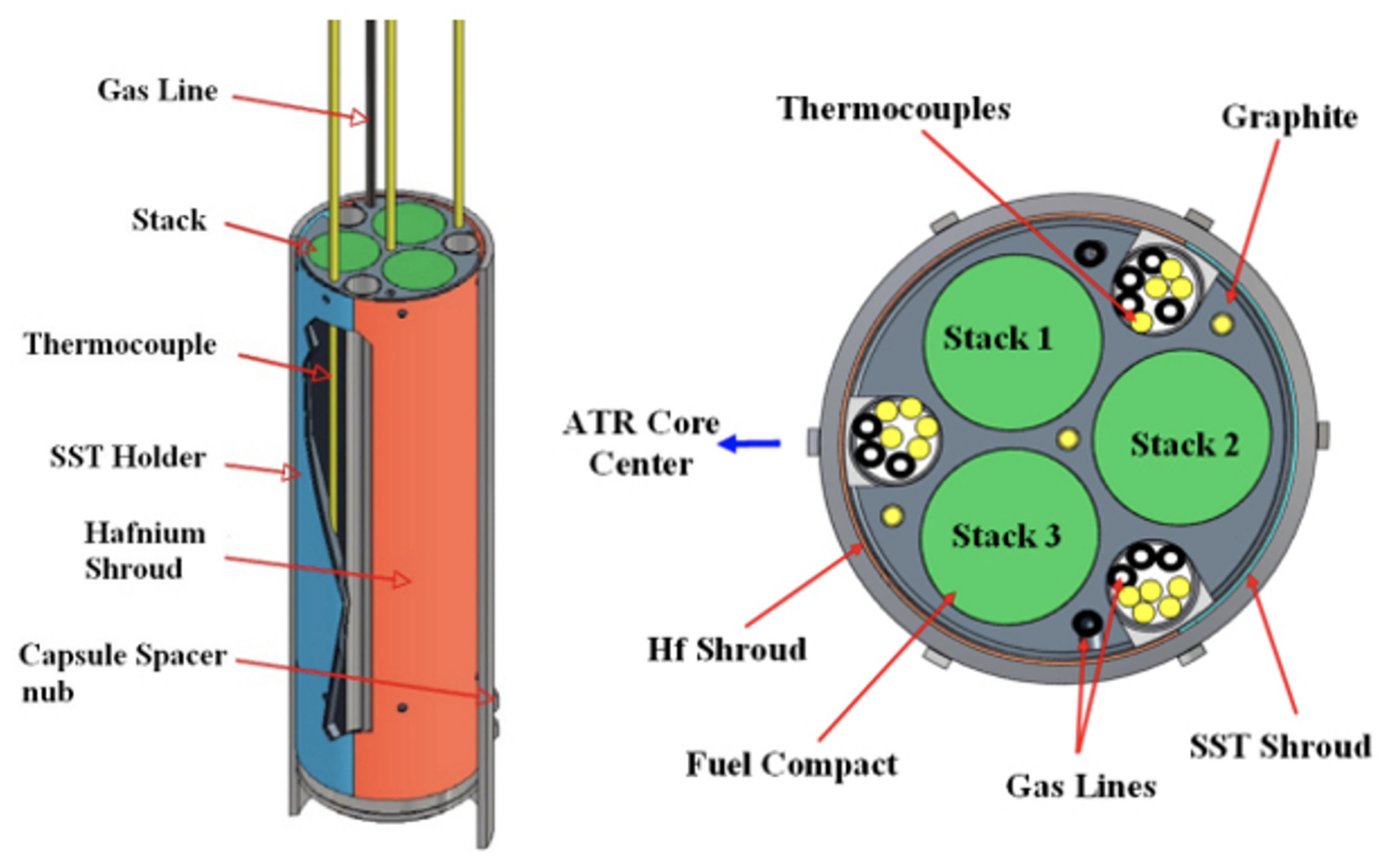

In terms of irradiated or spent fuel for validating depletion methods, a number of experiment series irradiated within ATR have used HALEU fuels of varying enrichments. For a number of these irradiations, RCA data are available from destructive post-irradiation examination (PIE). Specifically, these data were obtained from:

The evaluation of LEU fuel concepts based on uranium-molybdenum alloys being evaluated for high-performance research reactors with 19.8%

235U fuel [

43];

The Advanced Gas Reactor (AGR) Fuel Development and Qualification program, pursuing the qualification of TRISO particle fuel for HTGRs, with enrichments of 9.6, 14, and 19.8%

235U [

44].

Although not prototypical of intended applications for advanced reactor concepts, these measurements do provide data that may be used, at least in part, to validate depletion capabilities. While certainly not exhaustive, a survey of potential HALEU data at INL has found several potential sources, described in the following subsections:

3.3.1. AGR Series

The objectives of the AGR experiments were to perform a shakedown irradiation, safety testing, and post-irradiation evaluation of candidate fuel designs. At the start of the program, because no specific design concept was favored, the AGR program chose to qualify fuel samples in an operating envelop that would include both pebble-bed and prismatic fuel options, with a peak time-averaged temperature of 1250 °C. Studies performed under these programs examined the release of specific fission products from fuel grains; however, assay data for selected isotopes are available from a number of these experiments [

45].

AGR-1

The AGR-1 experiment [

46] tested TRISO fuel under HTGR irradiation conditions. This experiment was irradiated for 620 effective full power days over 13 ATR cycles and approximately three calendar years. The AGR-1 fuel consisted of TRISO-coated particles comprised of a mixture of UO

2 and UCO (uranium oxycarbide) with a 19.75%

235U enrichment pressed into cylindrical fuel compacts; 72 such compacts were irradiated for up to 20% fissions per initial heavy metal atom (FIMA) without a measurable indication of a single particle failure. Four of these compacts were selected for destructive examination across a burnup range of approximately 10–20% FIMA. Although these experiments were performed for other reasons, the data were also used to validate the approach used in the physics simulation of the AGR-1 experiment [

46,

47,

48].

Figure 11 shows the configuration of a capsule in the AGR-1 experiment. The experiment train contained a stack of six experiment capsules.

AGR-2

The AGR-2 experiment was the second of the planned irradiations for the AGR Program. The objectives of the AGR-2 experiment included irradiating both UCO and UO

2 fuel to provide irradiated fuel samples for PIE. For this experiment, 14% enriched HALEU was used in the UCO fuel, while the uranium in the UO

2 fuel was 9.6% enriched [

50]. Estimates of the fuel burn range from 9.26 to 12.55% FIMA [

51], with later measurements determining burnups ranging from 9.8 ± 0.15 to 12.68 ± 0.19 based on the fission production of

148Nd [

52]. Fuel compact burnup measurements and selected fission product inventories were performed, but the focus of the experiment was to evaluate the release-rate-to-birth-rate ratio, a measure of the ability of fuel kernels, particle coating layers, and compact matrix material to retain fission gas species [

53]. However, an RCA was performed for a number of nuclides, listed in

Table 3. The capsule configuration for the AGR-2 is nearly identical to that of AGR-1 and is not shown here.

AGR-3/4

AGR-3/4 was the combined third and fourth planned irradiation for the AGR Program. The AGR-3/4 experiment was designed as a fission product transport experiment with the following objectives [

54]:

Irradiate fuel containing UCO designed to fail (DTF) fuel particles that would provide a fixed source of fission products for subsequent transport through compact matrix and structural graphite materials

Assess the effects of sweep gas impurities, such as CO, H2O, and H2 typically found in the primary coolant circuit of HTGRs, on fuel performance and fission product transport

Provide irradiated fuel and material samples for PIE and safety testing

Support the refinement of fuel performance and fission product transport models with real time and PIE data

The AGR-3/4 test train was irradiated in ATR for 369 effective full-power days, from December 2011 to April 2014. The experiment achieved its goals in terms of burnup and fast fluence levels reached at the end of irradiation and fuel temperature levels maintained throughout irradiation [

55]:

Peak compact burnup ranged from 4.85 to 15.27% FIMA;

Peak compact fast fluence ranged from 1.19 to 5.32 × 1025 n/m2 (E > 0.18 MeV);

Time-average volume-average temperatures of the compacts ranged from 854 to 1345 °C;

Fission product release-to-birth ratios reached 10−4–10−3 early during irradiation as the DTF particles started to fail.

Assays were performed for a number of actinides and fission products, listed in

Table 4.

However, the AGR-3/4 compact PIE was not performed by dissolution of the entire fuel sample. Because this experiment used DTF fuel specimens, PIE included the radial deconsolidation of individual compacts to segment the compacts into separate collections of particles and matrix debris from concentric cylindrical volumes, each of which was subjected to a leach-burn-leach analysis to quantify the actinides and fission products released by the driver fuel and DTF particles [

56]. This experiment configuration was significantly different from that of the AGR-1 and AGR-2 tests and is illustrated in

Figure 12.

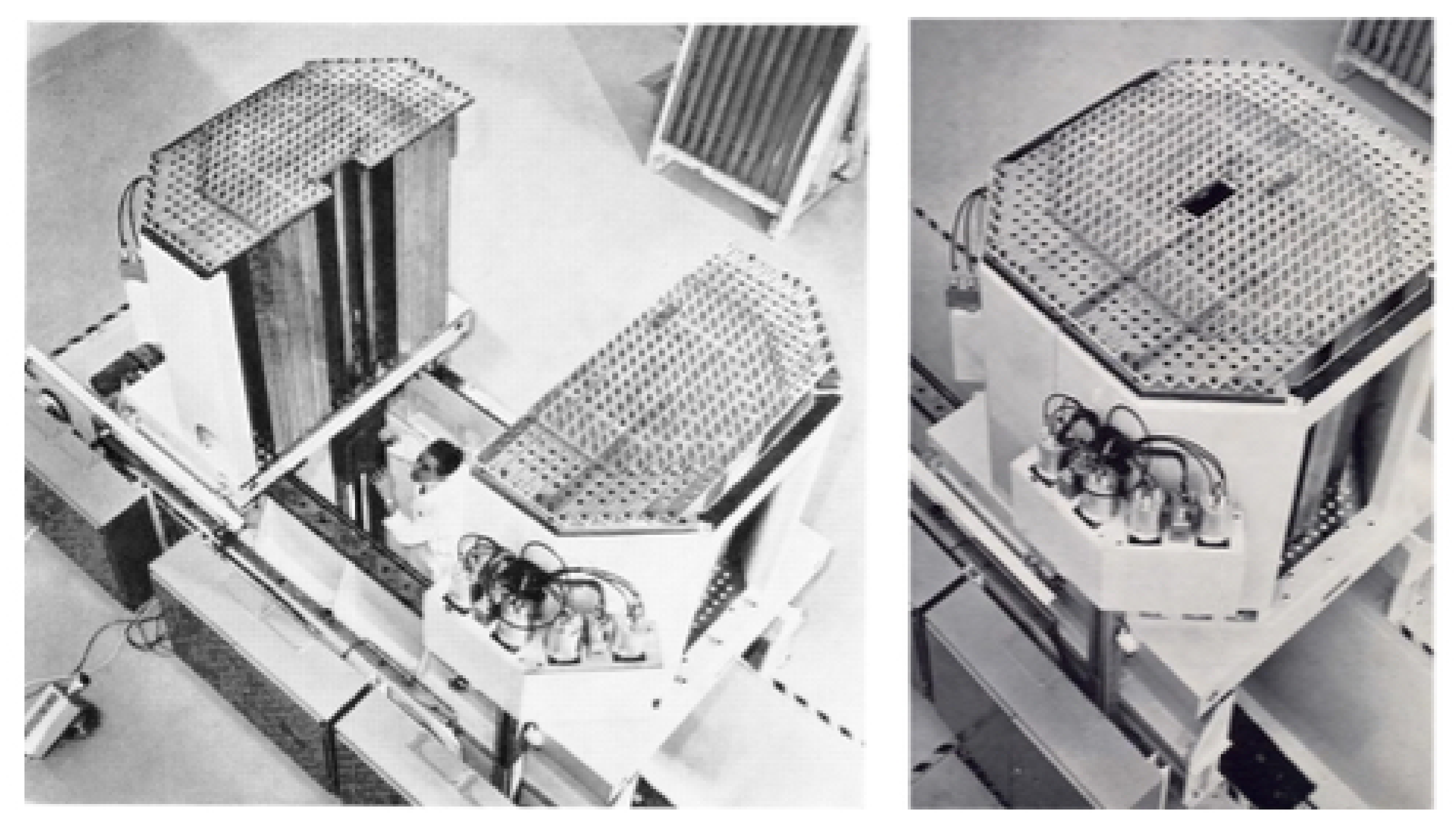

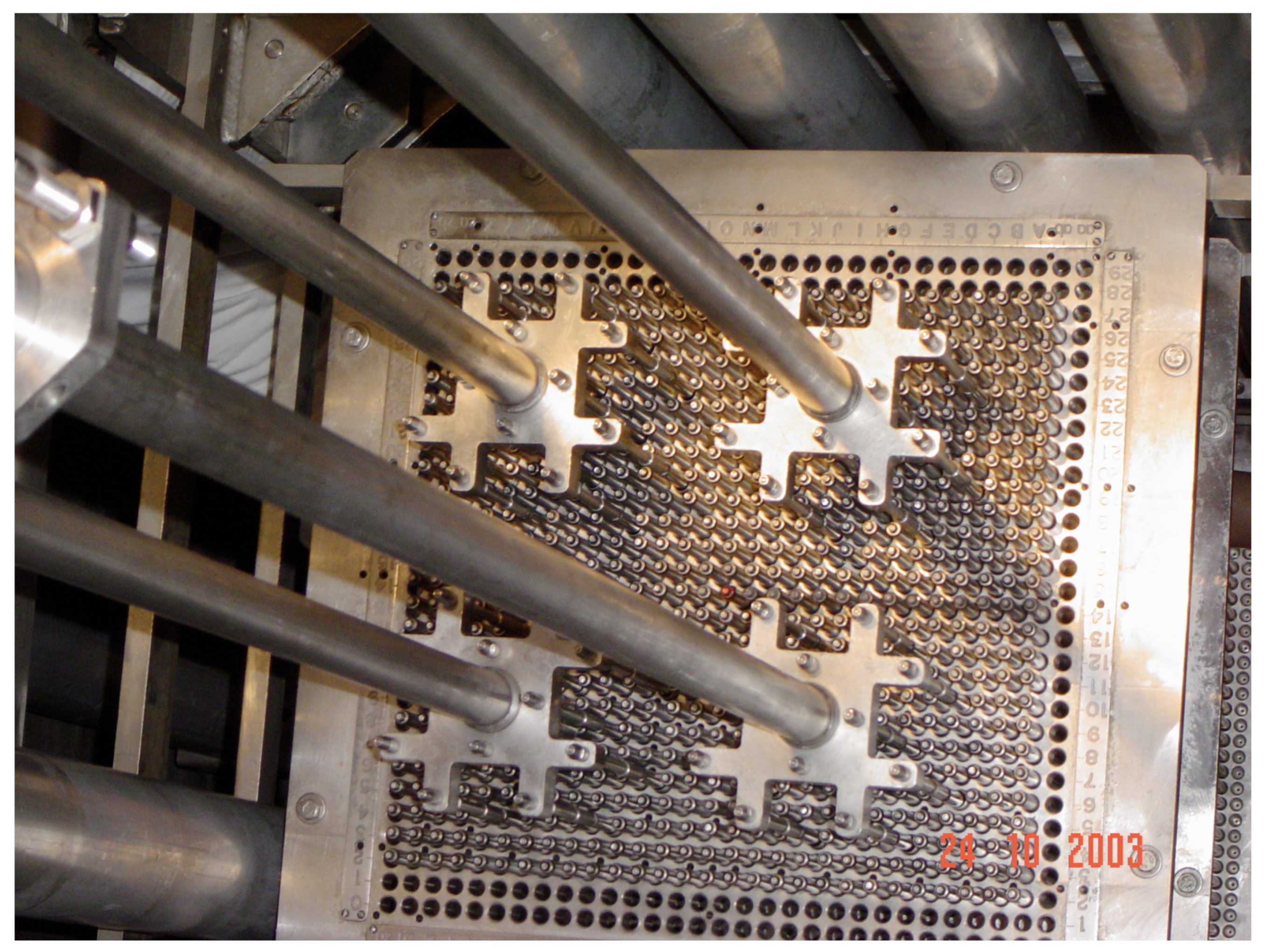

3.3.2. AFIP Series

A number of HALEU irradiations have been performed under the ATR full-size-plate in center flux trap position (AFIP) series of experiments. These experiments evaluated the performance of uranium-molybdenum alloy fuels at a scale prototypic of research reactor fuel plates. For a number of the experiments, post-irradiation destructive assays were performed for selected isotopes, primarily to determine fissile depletion and burnup. Early measurements (AFIP-1, AFIP-2, AFIP-3, and AFIP-4) were performed using 19.75% fuel because this was the anticipated enrichment for high-performance research reactor fuels. However, later experiments (AFIP-5 and later) in the series used enrichments around 40% to obtain power densities at a desired level. Those measurements are thus less relevant for HALEU validation efforts. However, the first three sets of measurements provide useful data; isotopic data are not available from the AFIP-4 experiment.

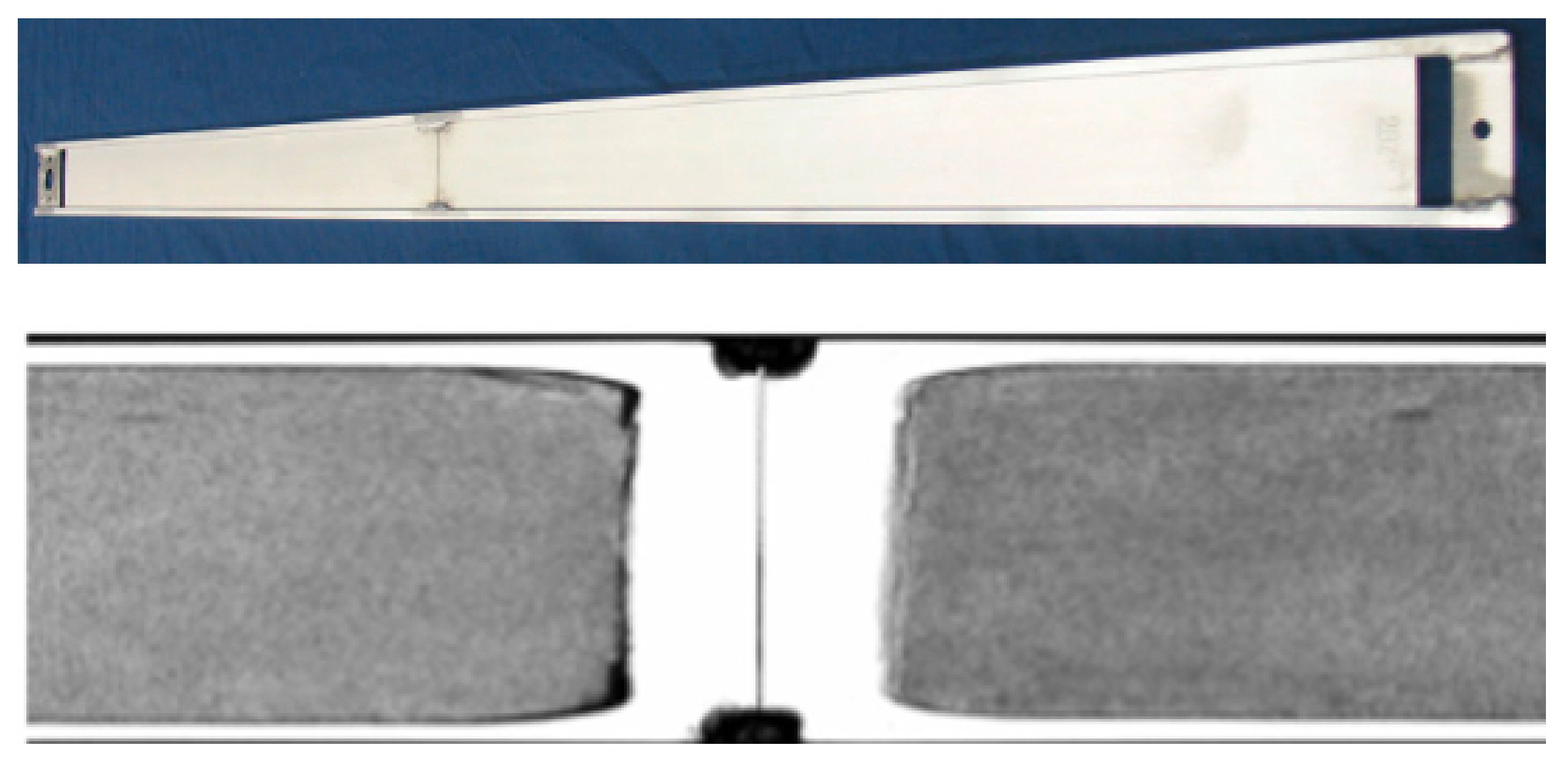

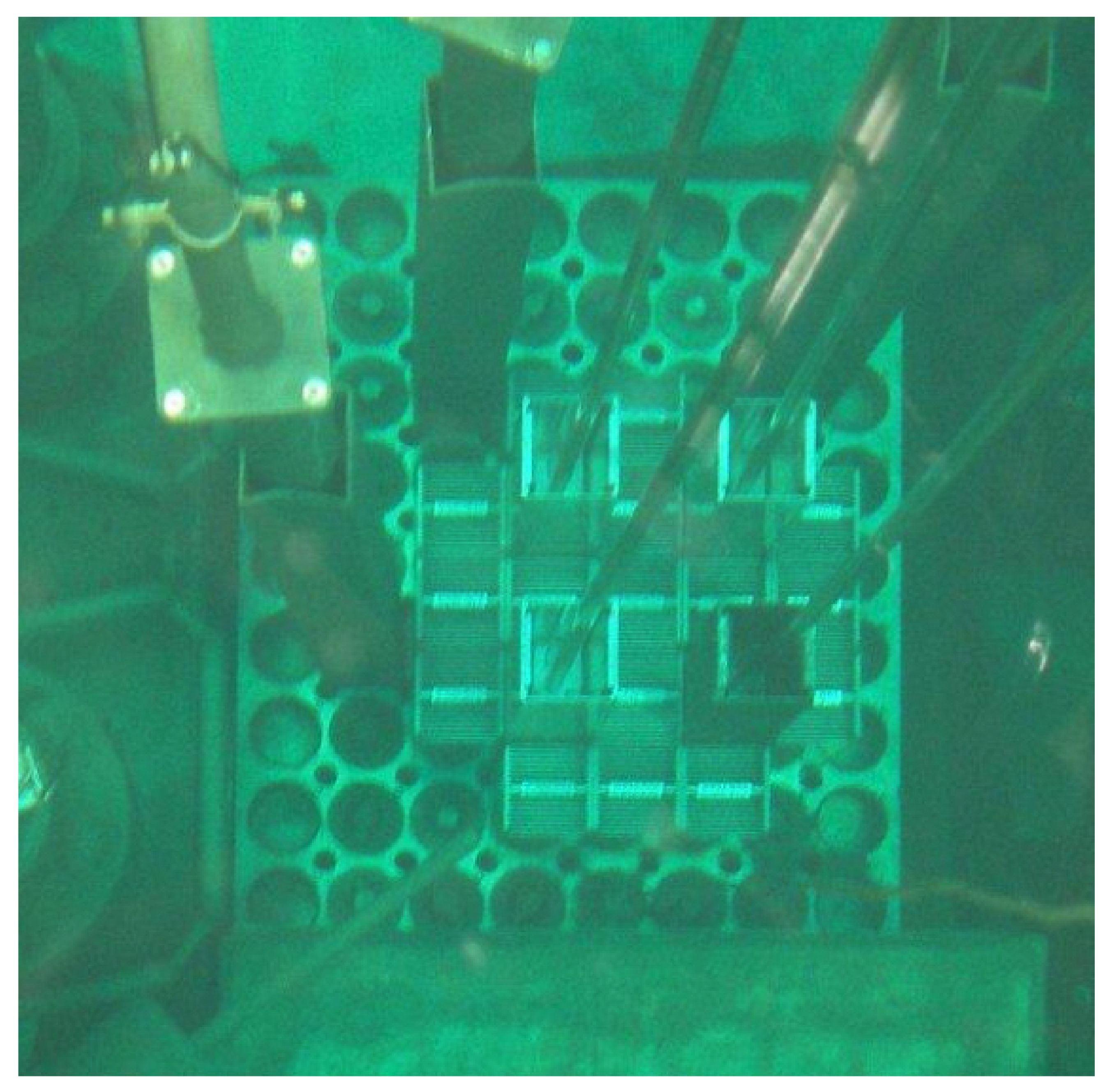

Photographs of the flat-plate AFIP experiment configuration for the first three AFIP experiments are shown in

Figure 13. Each experiment element contained two approximately half-height fuel plates;

Figure 14 shows the top and bottom sections. The AFIP capsule is capable of holding two fuel plate assemblies and can be disassembled and reconfigured in the ATR fuel handling canal between ATR irradiation cycles. The various AFIP test plate assemblies were inserted into this test rig. Depending on the cycle, the capsule could contain four different test plates in two elements or two test plates in one element and a dummy aluminum plate.

In these experiments, gamma spectrometry was used to measure the activity of

243Am and a number of fission products. Inductively coupled plasma mass spectrometry was performed for five fission products. To support burnup analyses, samples were extracted from two locations in each fuel plate, dissolved in nitric acid, and analyzed with mass spectroscopy to determine the isotopic composition for plutonium and uranium nuclides.

Table 5 lists the nuclides for which inventories were measured. At this time, PIE details for the AFIP series have not been reviewed nor cleared for external release, but no sensitivity to release of the data is known.

AFIP-1

The AFIP-1 fuel element contained two half-length fuel plates and was irradiated for three successive cycles. The two fuel meats consisted of a U-7Mo fuel phase dispersed in either an aluminum-2 wt% silicon alloy matrix or Al4043 alloy matrix. The estimated peak fission density on the fuel was 3.4 × 10

21 fissions/cm

3. The AFIP-1 experiment was irradiated for three full ATR cycles in the central position (Position 1) of the irradiation vehicle. Position 2 of the irradiation vehicle was occupied by the AFIP-2 fueled test plate assembly, an aluminum dummy plate assembly, and the AFIP-3 fueled test plate assembly, respectively, during each successive irradiation cycle. The complete AFIP-1 irradiation history is summarized in

Table 6.

Table 6.

AFIP-1 experiment irradiation history [

57].

Table 6.

AFIP-1 experiment irradiation history [

57].

| ATR Cycle | Cycle Dates | Cycle Effective Full-Power Days |

|---|

| 142B | 4 July 2008–30 August 2008 | 52 |

| 143A | 24 September 2008–6 December 2008 | 48.9 |

| 143B | 23 December 2008–20 February 2009 | 57.3 |

Figure 13.

AFIP capsule configuration used for all AFIP experiments [

58].

Figure 13.

AFIP capsule configuration used for all AFIP experiments [

58].

Figure 14.

AFIP element showing top and bottom regions (

top) and an ultrasonic imaging picture showing two plates with the element (

bottom) [

58].

Figure 14.

AFIP element showing top and bottom regions (

top) and an ultrasonic imaging picture showing two plates with the element (

bottom) [

58].

AFIP-2

As with AFIP-1, two half-length research reactor fuel plates were used in the top and bottom halves of the AFIP-2 assembly. In this experiment, two 14 mil (360

m) monolithic metallic foils of U-10Mo were used, sealed inside Al-6061 cladding. The two plates used different bonding agents, a 1 mil (25.4

m) silicon thermal spray layer on each side of the foil and a 1 mil zirconium layer co-rolled on both sides of the fuel. A peak fission density of 6.13 × 10

21 fissions/cm

3 was obtained. The three-cycle AFIP-2 irradiation history is summarized in

Table 7.

AFIP-3

Again, AFIP-3 used two prototypic-sized research reactor fuel plates, with the same silicon and zirconium layers each used for one plate. The foils had a nominal thickness of 16 mil (400

m). A peak fission density of 4.17 × 10

21 fissions/cm

3 was obtained in the Zr-bonded fuel, and 3.22 × 10

21 fissions/cm

3 in the Si-bonded fuel. AFIP-3 was irradiated in two sequential ATR cycles, as described in

Table 8 [

60].

4. Conclusions

There is a pressing need to develop a set of well-documented measurements for HALEU fuels to validate analysis methods for criticality and depletion, a requirement for the NRC licensing of HALEU facilities. The IRPhE Handbook only provides nine evaluations for reactor applications with HALEU fresh fuel. A number of other potential benchmarks exist or are forthcoming, but there are no efforts underway to formally develop quality benchmarks that have undergone the strict IRPhE review process and publication. It is hoped that this review will help to justify new programs that could be used to perform complete experiment evaluations and, if data located are complete, then preparation, review, and publication of these valuable benchmarks. Certainly IRPhE should work to solicit work for these experiments.

Results from relevant irradiation experiments performed at INL provide such data that can support depletion calculations. However, these data have not been curated and assembled into either a single document or set of documents with an adequate level of content granularity and detail, as would be necessary for validation. Indeed, much of the data are contained in internal or limited-distribution documents not readily available to external parties. An effort should be initiated to collect these available data and prepare a document that could be publicly released to benefit the nuclear science and engineering community. At the same time, these data could ultimately be added to the SFCOMPO 2.0 database.

For the set of depletion experiments performed at ATR, a curated, publicly available document is needed to provide sufficient information on core design and operation for enabling fuel depletion modeling within the core. Although ATR is a complex configuration, three-dimensional models of the core are available for a number of Monte Carlo codes, and a detailed description of the core is available from [

61]. Similarly, descriptions of experimental apparati used in the irradiation experiments must also be compiled, along with power history data and other core operations that would potentially influence the experiment irradiation environment. Finally, measured data must be compiled and presented in a consistent format, along with any available reported experimental uncertainties.

Developing a reference set of documents for validating methods applied to HALEU fuels will certainly be necessary before the NRC is able to accept the results of core design calculations from a plant licensee, or even for fuel processing at enrichment and fabrication facilities. No doubt more data will become available as HALEU fuel continues to be produced and used in ongoing and future measurement programs to support fresh and depleted fuel validation. Until such specific data become available in the future, the advanced reactor community can clearly benefit from the existing INL irradiation data. These existing data can establish the first benchmarks in the first volume of evaluated benchmarks for HALEU fuel depletion to serve the stringent needs for analysis method validation by future potential licensees.