As-Built Simulation of the High Flux Isotope Reactor †

Abstract

1. Introduction

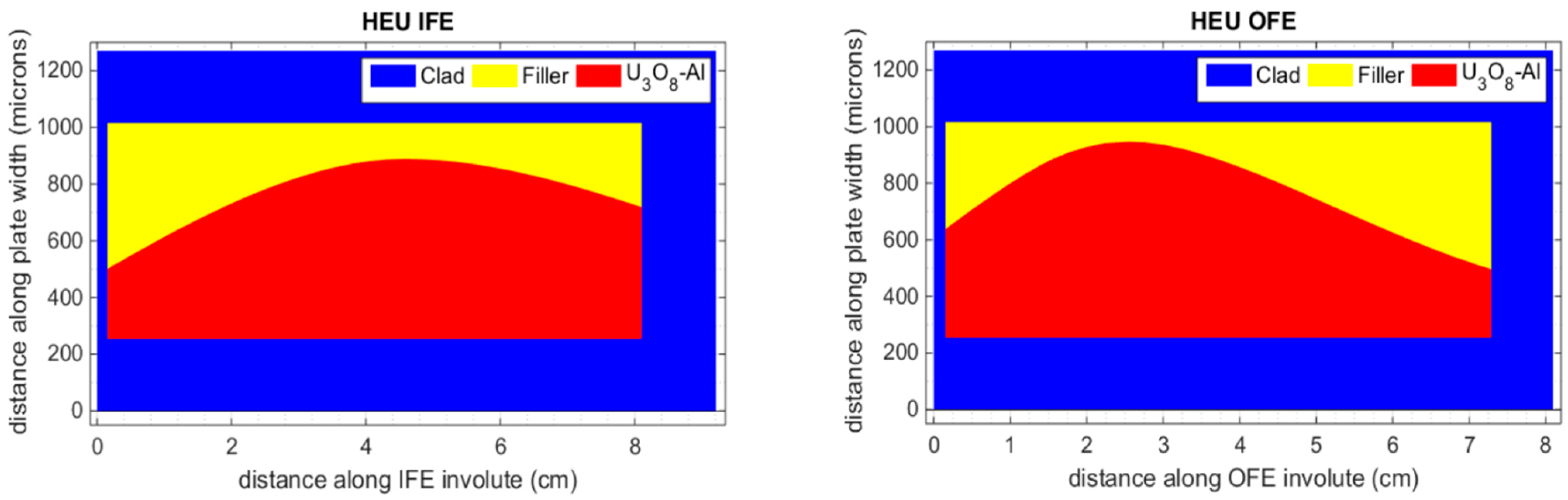

2. Modeling Tools

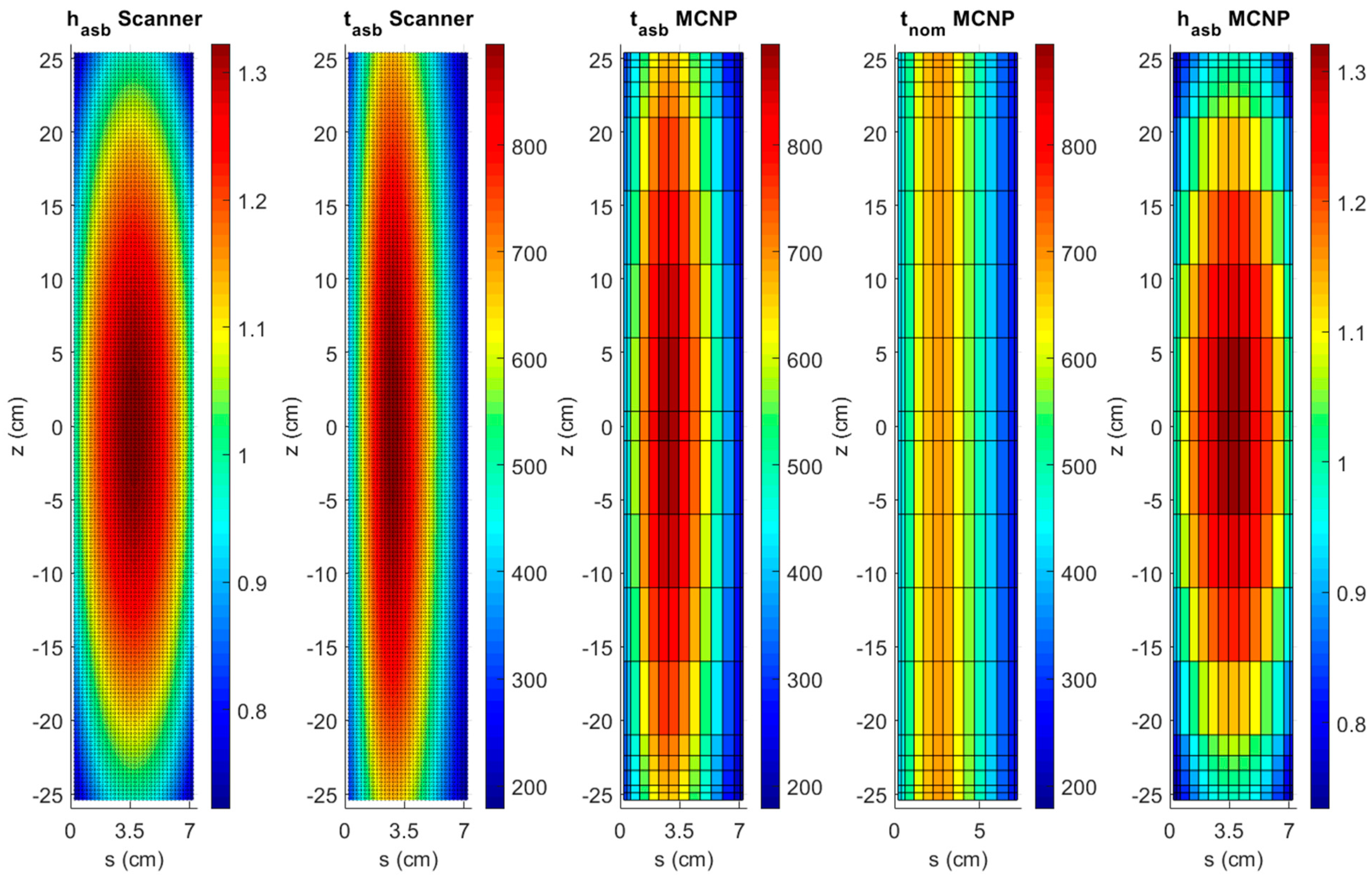

3. As-Built Data

4. Results and Discussion

5. Discussion

Author Contributions

Funding

Conflicts of Interest

References

- Cheverton, R.D.; Sims, T.M. HFIR Core Nuclear Design; ORNL-4621; Oak Ridge National Laboratory: Oak Ridge, TN, USA, 1971. [Google Scholar]

- Chandler, D.; Betzler, B.; Cook, D.; Ilas, G.; Renfro, D. Neutronic and thermal-hydraulic feasibility studies for high flux isotope reactor conversion to low-enriched uranium silicide dispersion fuel. Ann. Nucl. Energy 2019, 130, 277–292. [Google Scholar] [CrossRef]

- Chandler, D.; Betzler, B.R.; Davidson, E.E.; Ilas, G. Modeling and Simulation of a High Flux Isotope Reactor Representative Core Model for Updated Performance and Safety Basis Assessments. Nucl. Eng. Des. 2020, 366, 110752. [Google Scholar] [CrossRef]

- Pandya, T.M.; Johnson, S.R.; Evans, T.M.; Davidson, G.G.; Hamilton, S.P.; Godfrey, A.T. Implementation, capabilities, and benchmarking of shift, a massively parallel Monte Carlo radiation transport code. J. Comput. Phys. 2016, 308, 239–272. [Google Scholar] [CrossRef]

- Davidson, G.G.; Pandya, T.M.; Johnson, S.R.; Evans, T.M.; Isotalo, A.E.; Gentry, C.A.; Wieselquist, W.A. Nuclide depletion capabilities in the shift Monte Carlo code. Ann. Nucl. Energy 2018, 114, 259–276. [Google Scholar] [CrossRef]

- Pandya, T.M.; Johnson, S.R.; Davidson, G.G.; Evans, T.M.; Hamilton, S.P. Shift: A massively parallel monte carlo radiation transport package. In Proceedings of the M&C 2015, Nashville, TN, USA, 19–23 April 2015. [Google Scholar]

- Betzler, B.R.; Ade, B.; Chandler, D.; Ilas, G.; Sunny, E. Optimization of depletion modeling and simulation for the high flux isotope reactor. In Proceedings of the ANS Mathematics & Computation Topical Meeting, Nashville, TN, USA, 19–23 April 2015. [Google Scholar]

- X-5 Monte Carlo Team. MCNP—A General N-Particle Transport Code; Version 5; LA-UR-03-1987; Los Alamos National Laboratory: Los Alamos, NM, USA, 2003.

- Mosher, S.W.; Wilson, S.C. Algorithmic Improvements to MCNP5 for High-Resolution Fusion Neutronics Analyses. Fusion Sci. Technol. 2018, 74, 263–276. [Google Scholar] [CrossRef]

- Rearden, B.T.; Jessee, M.A. (Eds.) SCALE Code System; Version 6.2; ORNL/TM-2005/39; Oak Ridge National Laboratory: Oak Ridge, TN, USA, 2016; Available from Radiation Safety Information Computational Center at Oak Ridge National Laboratory as CCC-834. [Google Scholar]

- Betzler, B.R.; Chandler, D.; Davidson, E.E.; Ilas, G. Optimized Design Performance Analysis Tools for a High Flux Isotope Reactor Low-Enriched Uranium Core; Oak Ridge National Laboratory: Oak Ridge, TN, USA, 2018; Volume 119. [Google Scholar]

- Betzler, B.R.; Chandler, D.; Cook, D.H.; Davidson, E.E.; Ilas, G. High flux isotope reactor low-enriched uranium core designs and challenges. In Proceedings of the ANTPC 2018—Advances in Nuclear Nonproliferation Technology and Policy Conference, Wilmington, NC, USA, 23–27 September 2018. [Google Scholar]

- Chandler, D.; Betzler, B.R.; Ilas, G.; Cook, D.H.; Renfro, D.G. Neutronic and thermal-hydraulic feasibility studies for high flux isotope reactor conversion to low-enriched uranium U3Si2-Al fuel. In Proceedings of the PHYSOR 2018—Reactor Physics Paving the Way Towards More Efficient Systems, Cancun, Mexico, 22–26 April 2018. [Google Scholar]

- Betzler, B.R.; Chandler, D.; Cook, D.H.; Davidson, E.E.; Ilas, G. High flux isotope reactor low-enriched uranium core design optimization studies. In Proceedings of the PHYSOR 2018—Reactor Physics Paving the Way Towards More Efficient Systems, Cancun, Mexico, 22–26 April 2018. [Google Scholar]

- Betzler, B.R.; Chandler, D.; Davidson, E.E.; Ilas, G. Design Optimization Studies for a High Flux Isotope Reactor Low-Enriched Uranium Core; Oak Ridge National Laboratory: Oak Ridge, TN, USA, 2017; Volume 117. [Google Scholar]

- Betzler, B.R.; Chandler, D.; Davidson, E.E.; Ilas, G. High fidelity modeling and simulation for a high flux isotope reactor low-enriched uranium core design. Nucl. Sci. Eng. 2017, 187, 81–99. [Google Scholar] [CrossRef]

- Davidson, E.E.; Betzler, B.R.; Chandler, D.; Ilas, G. Heat deposition analysis for the high flux isotope reactor’s HEU and LEU core models. Nucl. Eng. Des. 2017, 322, 563–576. [Google Scholar] [CrossRef]

- Davidson, E.E.; Betzler, B.R.; Chandler, D.; Ilas, G. High-fidelity heat deposition analysis for the high flux isotope reactor. In Proceedings of the PHYSOR 2016—Unifying Theory and Experiments in the 21st Century, Sun Valley, ID, USA, 1–5 May 2016. [Google Scholar]

- Ilas, G.; Betzler, B.R.; Chandler, D.; Davidson, E.E. High flux isotope reactor core analysis—Challenges and recent enhancements in modeling and simulation. In Proceedings of the PHYSOR 2016—Unifying Theory and Experiments in the 21st Century, Sun Valley, ID, USA, 1–5 May 2016. [Google Scholar]

- Ilas, G.; Chandler, D.; Ade, B.J.; Sunny, E.E.; Betzler, B.R.; Pinkston, D. Modeling and Simulations for the High Flux Isotope Reactor Cycle 400; Oak Ridge National Laboratory Report ORNL/TM-2015/36; Oak Ridge National Laboratory: Oak Ridge, TN, USA, 2015. [Google Scholar]

- Bergeron, A. Review of the Oak Ridge National Laboratory Neutronic Calculations Regarding the Conversion of the High Flux Isotope Reactor to the Use of LEU Fuel; ANL/RERTR/TM-12/49; Argonne National Laboratory: Argonne, IL, USA, 2012. [Google Scholar]

- Oak Ridge Leadership Computing Facility. Titan Cray XK7; Oak Ridge Leadership Computing Facility: Oak Ridge, TN, USA, 2015.

| Model | Nodes (Processors per Node) | Real-Time (Hours) |

|---|---|---|

| One-plate as-designed | 1280 (16) | 1.17 |

| 369-plate as-designed | 5120 (16) | 2.67 |

| 369-plate as-built | 5120 (16) | 3.53 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Betzler, B.R.; Chandler, D.; Evans, T.M.; Davidson, G.G.; Daily, C.R.; Wilson, S.C.; Mosher, S.W. As-Built Simulation of the High Flux Isotope Reactor. J. Nucl. Eng. 2021, 2, 28-34. https://doi.org/10.3390/jne2010003

Betzler BR, Chandler D, Evans TM, Davidson GG, Daily CR, Wilson SC, Mosher SW. As-Built Simulation of the High Flux Isotope Reactor. Journal of Nuclear Engineering. 2021; 2(1):28-34. https://doi.org/10.3390/jne2010003

Chicago/Turabian StyleBetzler, Benjamin R., David Chandler, Thomas M. Evans, Gregory G. Davidson, Charles R. Daily, Stephen C. Wilson, and Scott W. Mosher. 2021. "As-Built Simulation of the High Flux Isotope Reactor" Journal of Nuclear Engineering 2, no. 1: 28-34. https://doi.org/10.3390/jne2010003

APA StyleBetzler, B. R., Chandler, D., Evans, T. M., Davidson, G. G., Daily, C. R., Wilson, S. C., & Mosher, S. W. (2021). As-Built Simulation of the High Flux Isotope Reactor. Journal of Nuclear Engineering, 2(1), 28-34. https://doi.org/10.3390/jne2010003