1. Introduction

Recently, plastic food containers for delivery and takeout meals have seen a significant surge, particularly with the advent of online meal ordering and delivery services. Plastic serving containers and cutlery offer expedient and cost-effective meal-serving options that are quick and easy to use [

1]. However, these conveniences come at the price of increasing greenhouse gas emissions and plastic waste generation [

2]. In addition, plastic food containers have the potential to cause adverse effects on human health, such as congenital anomalies and immunodeficiency, because of the tendency to release toxic compounds like phthalates into food [

3]. The environmental and health concerns associated with plastic containers highlight the urgent need for sustainable alternatives.

As people seek more environmentally friendly alternatives to plastic food packaging, molded fiber and paper-based food containers have gained renewed popularity. Molded pulp products are green products that are produced by mixing recycled or neat natural fibers with water and forming the mixture into the desired shape, followed by a subsequent drying method [

4,

5,

6]. Although they offer the benefits of being biodegradable and potentially recyclable, they have several limitations, including challenges with resistance to oil and grease, recycling, and high energy consumption during manufacturing, restricting their use as food containers [

7]. Commercially, these products were treated with fluorocarbons such as per- or poly-fluoroalkyl substances (PFASs) to impart oil and grease resistance in paper-based food containers [

7]. However, these fluorocarbons are linked to life-threatening diseases in humans, such as cancers and liver problems [

8]. Though the global market of eco-friendly, grease-resistant paper products is increasing and is predicted to reach USD 1 billion by 2025 [

9], they are still not competitive with plastic-based containers, which are anticipated to have a market size of around USD 113 billion by 2025 [

10].

Research has been conducted to find alternatives to PFASs using non-toxic, biodegradable materials such as starch and montmorillonite [

11], chitin [

12], and sodium alginate [

13], among others. However, these materials often present limitations in terms of food safety, mechanical integrity, thermal stability, and barrier properties [

14,

15,

16]. In contrast, cellulose nanofibrils (CNFs) are increasingly being recognized as a superior substitute, owing to their remarkable mechanical strength, high barrier properties, and multifunctionality, making them an ideal choice for addressing the challenges associated with previous materials (PFAS) [

17]. Cellulose is one of the most plenteous organic polymers that can serve as a raw material for environmentally safe and biodegradable food containers. The development of purification processes, along with energy and cost-saving pulping technology, has made wood the primary source of cellulose [

18]. Cellulose characteristics and reaction mechanism are directed by several factors, such as interactions among the molecules, the arrangement of functional groups on the repeating units as well as across the chain structure of the polymer, but in general, the abundance of hydroxyl groups governs cellulose reactivity and physio-mechanical properties [

19].

Cellulose nanofibrils (CNFs) are generally produced by the mechanical disintegration of delignified and bleached plant cell walls. The remarkable characteristics, including their high surface area (depending on the CNF preparation method), lightweight nature, and impressive mechanical properties, make them a highly desirable form of cellulose for many applications [

20]. With more accessible hydroxyl groups on their surface, CNFs exhibit exceptional adhesion, self-assembly, and barrier properties. Due to these distinctive features, CNFs are rapidly gaining recognition as a versatile and promising raw material for a wide range of applications, including binders in composite systems, barrier coating, and oil separation [

21,

22,

23]. Compared to cellulose nanocrystals (CNCs) that are mainly produced through acid hydrolysis of cellulosic fibers, CNFs have a higher aspect ratio [

24], which also helps CNF films resist air and grease as the grammage (basis weight) increases [

21]. The hydrogen bonding between the CNFs’ hydroxyl groups is another major reason for their excellent barrier properties [

22]. For these causes, food containers made of CNFs are promising and motivate further investigations. A study by Hossain et al. (2021) found that wood flour and CNF composites coated by a layer of CNFs or lignin-containing CNFs (LCNFs) have excellent grease barrier and mechanical properties, making them a viable option for PFAS-free, oil-resistant commercial food containers compared to molded pulp products [

25]. As an alternative to using deconstructed wood flour bonded with CNFs as the substrate for a food-serving container, it can be hypothesized that a thin layer of wood veneer, a commercially available wood product, can also be used for food-serving applications, especially for shallow tray-like containers, where low flexibility of wood is not an issue. However, the wood veneer’s inherent orthotropic nature renders it weaker in the direction perpendicular to the grain and causes excessive bending and premature fracture [

26]. Moreover, the other drawback of wood veneer is its porosity, which allows the passage of oil and grease, high water absorbance, vulnerability to bacterial growth, and the possibility of extractives leaching into food, making it unsuitable for use as a food-serving container [

27].

In this study, we propose a novel design for food-serving plates made of a composite laminate system comprising CNFs (derived from bleached Kraft pulp) and yellow birch wood veneer. The use of wood veneer as the substrate for a CNF coating in 3D-formed shapes has not been previously reported in the literature. Wood veneer production technology is mature, and the infrastructure to produce it at scale is already available. If wood veneer can be laminated with CNF layers, both its mechanical and barrier properties can be improved. We used a food-grade polyamide–epichlorohydrin (PAE) to bind the layers of CNFs to the veneer. These laminates serve as a sustainable alternative to conventional paper-based and plastic food containers. A comprehensive study was designed to assess the composite’s physical, mechanical, morphological, thermal, and barrier properties as an alternative food container. Finally, a thorough analysis was performed to compare the performance of this novel food container with existing commercial food-serving containers.

2. Materials and Methods

2.1. Materials

The University of Maine’s Process Development Center (PDC) produces CNFs without significant surface charge, resulting from the absence of chemical treatment during production [

28]. CNFs from the University of Maine’s PDC were used in this study. The CNF suspension used in this work had 3 wt.% solids and 90% fine content (around 90% of fibers are shorter than 200 microns). The characteristics of the CNFs utilized for this research have been previously published [

29,

30,

31]. Yellow birch (Betula alleghaniensis) wood veneers provided by Columbia Forest Products LLC., Presque Isle, ME, USA, were used in this study. This wood species was selected for container preparation due to its durability, rigidity, and excellent shock resistance, making it easy to shape using machinery. The wood features an attractive light brown hue and a smooth grain pattern, contributing to an aesthetically pleasing appearance for food containers [

32]. Food-grade PAE (Polycup™ 9250, Solenis LLC., Wilmington, DE, USA) of 36 wt.% solids content used as a cross-linker was generously supplied by Solenis LLC., Wilmington, DE, USA.

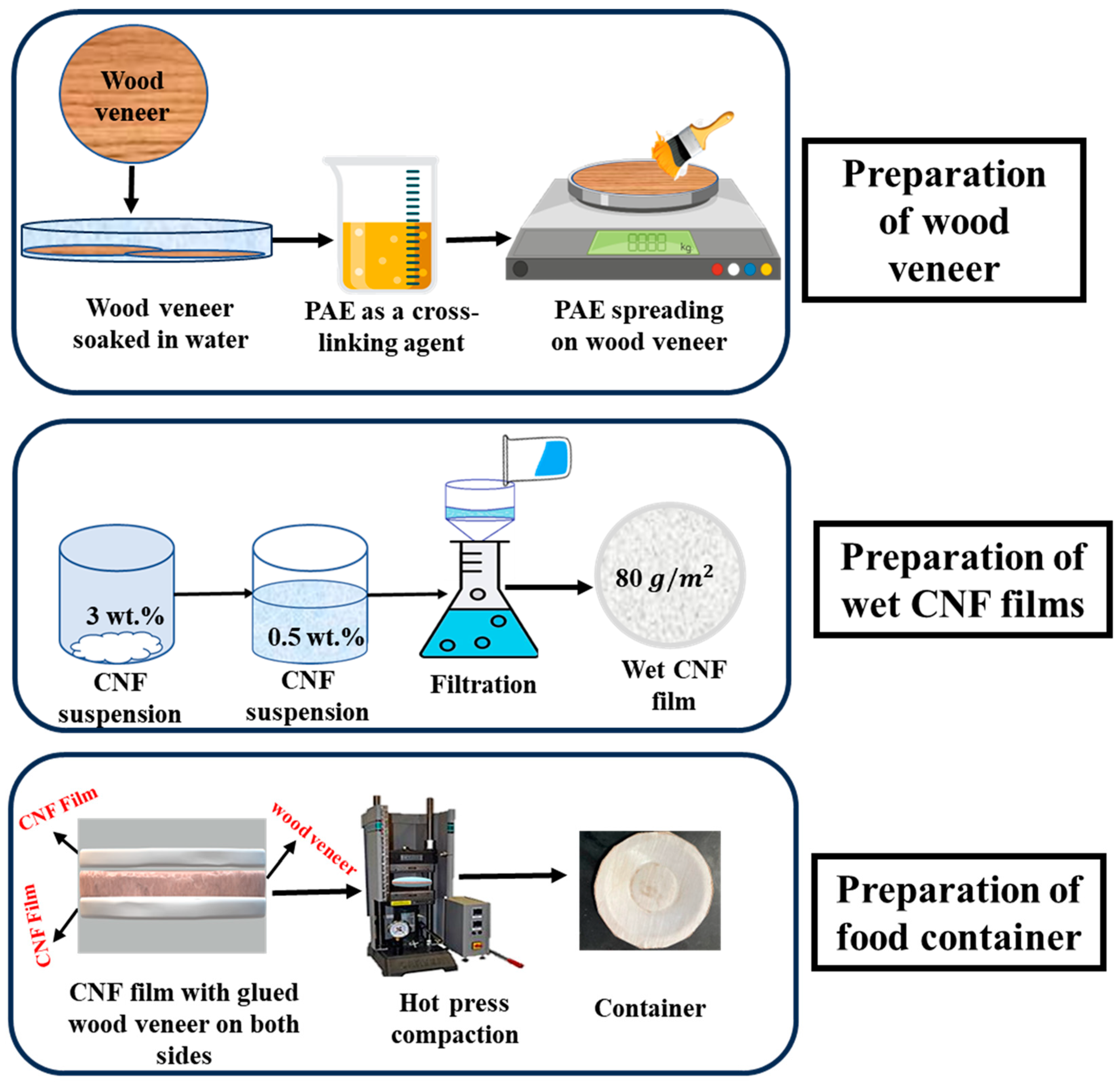

2.2. Fabrication of the Food Containers

The yellow birch wood veneer was cut into 11 cm diameter (94.98 cm2 area) circles in this experiment. The thickness and weight grammage of the wood veneers were 0.61 (±0.04) mm and 448.5 g/m2, respectively. The cut veneer was then treated in a water bath at around 25 °C for 24 h to make the veneer more flexible to form the desired shape.

In another setup, two CNF films of 80 g/m

2 were produced using a vacuum filtration process. To this end, a 0.5 wt.% CNF suspension was sonicated for 2 min at 90% amplitude using a Branson 450 Sonifier (Branson Ultrasonics Corporation, Danbury, CT, USA) and then placed in a planetary mixer (Thinky 310, Thinky Corporation, Tokyo, Japan) for 1 min to defoam for 30 s at 2000 and 2200 rpm, respectively. After that, the suspension was vacuum filtered at 381 mm Hg over a polyester mesh filter screen with an average pore size of 41 µm and a diameter of 11 cm for 7 min to form a wet CNF film with a dry thickness of 80 (±2) µm. To compare the oil, grease, and water resistance properties, the prepared food container was compared with the Chinet classic white paper lunch plates (Huhtamaki, De Soto, KS, USA).

Figure 1 presents the schematic diagram of the setup, and

Table 1 lists the conditions used to produce the composites. The formulations specify the pressing time, temperature, and pressure parameters for the hot press utilized in the production of food containers. These process variables are common hot-pressing variables and are independent of each other.

For lamination, PAE of 36 wt.% solid content was spread on each side of the wood veneer (12.28 g/m2 based on dry weight on each side) before lamination. Subsequently, the wet CNF films were placed on both sides of the wood veneer and hot pressed at 140 °C or 160 °C temperature and 1 MPa or 2 MPa pressure for 3 min or 5 min to form the container in the form of a flat sheet. These levels were selected after preliminary experiments to determine the range of these variables.

2.3. Characterizations

All samples, except those for thermal stability analysis, were conditioned at 50 ± 2% relative humidity for 24 h at 23 ± 2 °C in a conditioning chamber before testing. The solids content and density of the samples were measured by determining the mass and dimensions of the samples using an analytical scale and Vernier caliper. After dividing the conditioned mass by the calculated volume, the densities of the samples were determined, and the average density of the samples was found to be 0.95 ± 0.07 g/cm3. In addition, the containers were characterized by examining the adhesive strength between the layers, analyzing the failure’s qualitative nature, evaluating the components’ thermal degradation, and assessing oil and water barrier properties.

2.4. Mechanical Properties

The flexural strength of the food-serving container was determined by performing a three-point bending test.

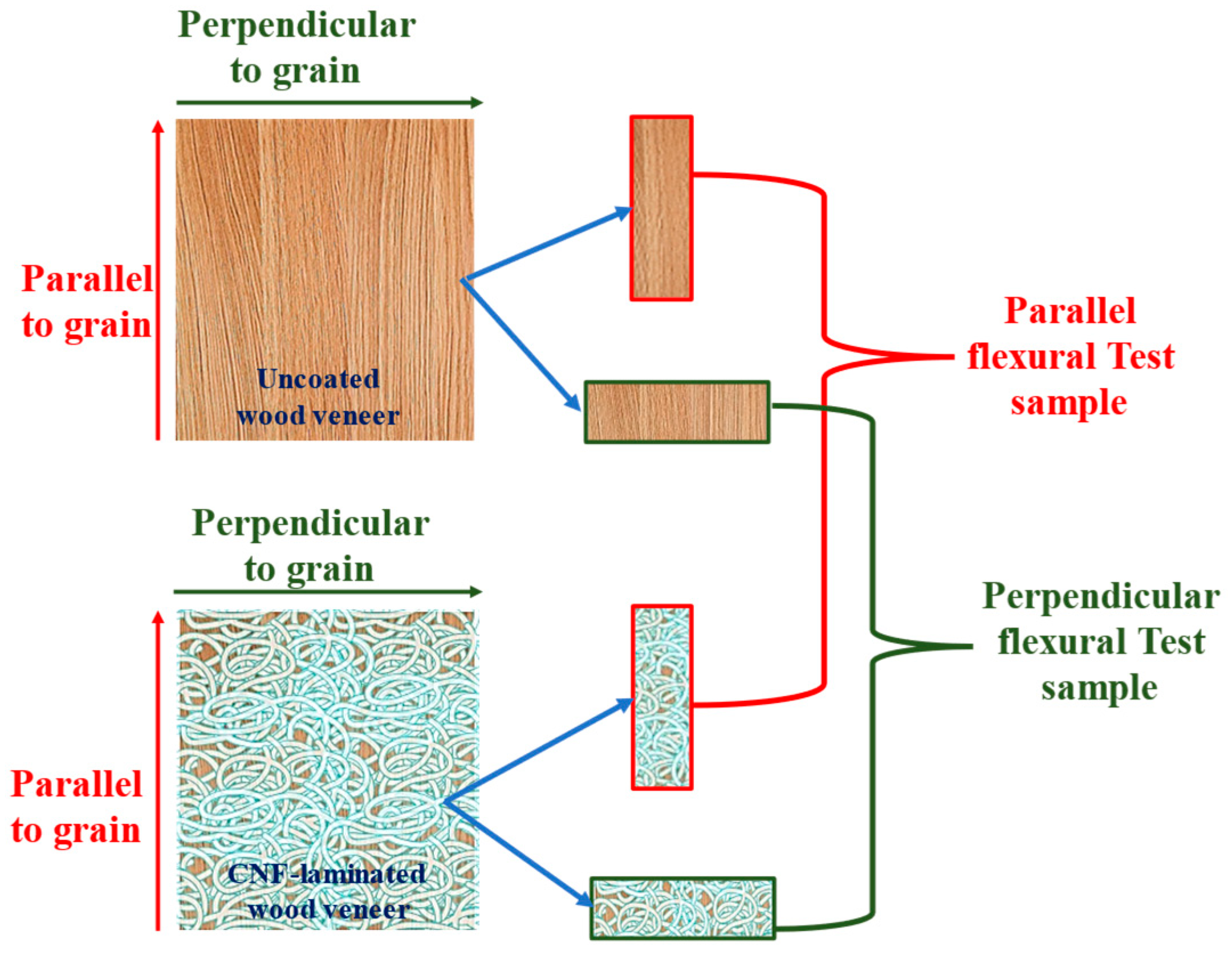

Figure 2 represents a schematic of flexural test specimens in parallel and perpendicular directions to the wood grain. An Instron mechanical testing machine with a 500 N load cell (Model 5942, Instron Instruments, Norwood, MA, USA) was used to perform the flexural testing following the ASTM standard D790 [

33] with modifications. Seven specimens, each measuring 8 cm in length and 1 cm in width, were cut using an FSL Muse Core Desktop CO

2 Laser Cutter (Sandhill Road, Las Vegas, NV, USA) from each formulation of the circular composite materials in both the parallel and perpendicular directions to the wood veneer fibers. The results were then compared with wood veneer specimens (without CNFs) of the same dimensions, hot-pressed for 5 min at a temperature of 160 °C and a pressure of 2 MPa as a control. The span length was 60 mm, and the crosshead speed of the machine was 5 mm/min during the test. The specific flexural strength, flexural strain, and specific modulus of elasticity (MOE) were determined to understand the stress–strain behavior of the composite.

A peel test was conducted to assess the relative peel resistance of the adhesive bond between the CNF film and wood veneer bond following the ASTM standard D1876 [

34]. Circular samples of each formulation were produced by applying glue to half of the wood veneer surface, which was then pressed using a hot press. At least five strips, measuring 5 cm in length and 1.5 cm in width, were cut from the circular samples, ensuring both glued and non-glued sides were included. The peel test was performed using the same Instron testing machine described above. The specimens were clamped in the machine’s grip by their unbonded ends and pulled at a 2 mm/min crosshead speed. From the test results, the specific maximum peel strength of the adhesive was determined. The equation for calculating specific maximum peel strength is given below:

2.5. Thermogravimetric Analysis (TGA)

Thermogravimetric analysis (TGA) was carried out to evaluate the thermal stability of PAE, CNFs, and CNFs with PAE to understand the thermal degradation behavior between the nanocomposite layers using a TGA Q500 (TA Instruments, New Castle, DE, USA). For each component, three specimens were used, each weighing between 5 and 15 mg. The TGA was conducted under an air atmosphere with a flow rate of 40 mL/min, and the temperature gradually increased from room temperature (~25 °C) to 600 °C at 10 °C/min. From the resulting TGA and derivative weight loss (DTG) curves, the average peak temperature and onset temperature were calculated.

2.6. Scanning Electron Microscopy (SEM)

To examine the adhesion quality between the layers of the composite, the surface morphology of the bond line between wood veneer and CNF film was assessed after failure. The bonded surfaces of these materials were compared to non-glued veneer surfaces after a peel test using a Zeiss Nvision 40 scanning electron microscope (Oberkochen, Germany). The wood veneers and CNF films were attached to aluminum stubs using conductive tape and then coated with a thin layer of gold–palladium to increase the conductivity of the samples’ surface. The coated samples were imaged under SEM at an accelerating voltage of 3 kV.

2.7. Oil and Grease Resistance

TAPPI T 559 cm-12 [

35] standard, generally known as the “kit test”, was followed to determine the oil and grease resistance of the composite food containers, and the results were compared with the commercial paper plate. The test procedure was accomplished using a series of numbered reagents (1–12) depending on their propensity to penetrate porous materials. The highest number (12) represents the most aggressive reagent that remained on the surface of the sample, while the lowest number (1) represents the least aggressive reagent. The reagents for the kit test were prepared by mixing castor oil with toluene and n-heptane.

Five conditioned specimens were tested from each formulation for oil and grease resistance using kit number 1 to 12. The reagents were dropped onto the specimen from a height of around 13 mm using an eyedropper and removed quickly after 15 s using a cotton ball. The tested area was examined immediately to detect any darkening on the test area. A sample was deemed to have passed if the highest kit number reagent did not penetrate its surface and leave a dark mark.

2.8. Water Resistance

The water absorptiveness of the food containers was measured by following the modified TAPPI 441 om-09 standard [

36]. The specimens were conditioned before the Cobb test and sized into a 77.8 cm

2 area. The preconditioned samples were then weighed on an analytical balance, and the metal ring of the Cobb tester was placed on the specimen. A soft, nonabsorbent gasket with the same internal diameter as the ring was placed between the metal ring and the specimen to prevent water leakage. The Cobb ring was then fastened firmly, and 77.8 mL of water was poured into the ring for 1200 s.

At 10 ± 2 s before the expiration of the predetermined test time, the water was removed from the ring, and the wet face of the specimen was placed on blotting paper. Another sheet of blotting paper was placed on the top of the specimen, and excess water was removed by rolling a smooth-faced stainless-steel roller with a width of 20 cm and a weight of 10 ± 0.5 kg.

The wet specimen was then reweighed to measure the weight difference between the conditioned dry specimen and the wet specimen to the nearest 0.01 g. Equation (2) was used to determine the water absorbance value (Cobb value) in grams per square meter:

2.9. Statistical Analysis

Statistical analysis was conducted using R Statistical Software (v4.4.1 for Windows, R Core Team 2024, PBC in Vienna, Austria). The flexural and peel test data were analyzed through an analysis of covariance (ANCOVA) using the “car” package, while a one-way analysis of variance (ANOVA) was used for the Cobb test data. Subsequently, Tukey’s Honestly Significant Difference (HSD) test was employed to determine any statistically significant differences between the means of different groups using the “multcomp” tool, and grouping letters were assigned using the “multcompView” package. All statistical analyses were carried out at a 95% confidence level (p < 0.05).

3. Results and Discussion

3.1. Flexural Properties

Adequate mechanical strength and stiffness can ensure a food-serving container’s durability, stackability, and safety from hot food spillage. The thickness and basis weight of the food containers were 0.63 ± 0.01 mm and 690 g/m2, respectively. The density of the samples was analyzed in both the parallel and perpendicular directions to the wood fiber alignment. To determine statistical differences in the two directions among the mechanical test data of the formulations, an analysis of variance (ANOVA) was conducted. Findings revealed that pressure caused variations in density data in parallel and perpendicular directions among the formulations. Furthermore, density differences were observed among the formulations tested in the perpendicular direction, also because of the interaction between time and temperature.

The flexural strength and modulus of elasticity (MOE) data were normalized by dividing them by the density of the specimens. Flexural strength determines the amount of applied stress a specimen is able to carry before breaking, and stiffness indicates the deformation resistance of a specimen when a load is applied for bending.

The mechanical properties of the composites were compared with a wood veneer hot pressed for 5 min at 160 °C and 2 MPa pressure. The density, specific flexural strength, flexural strain, and specific MOE values of the control sample were statistically different from the composite samples prepared under the same conditions and using the same parameters at a significance level of 0.05. This difference can be attributed to the addition of CNF layers (80 g/m

2) on both sides of the veneer.

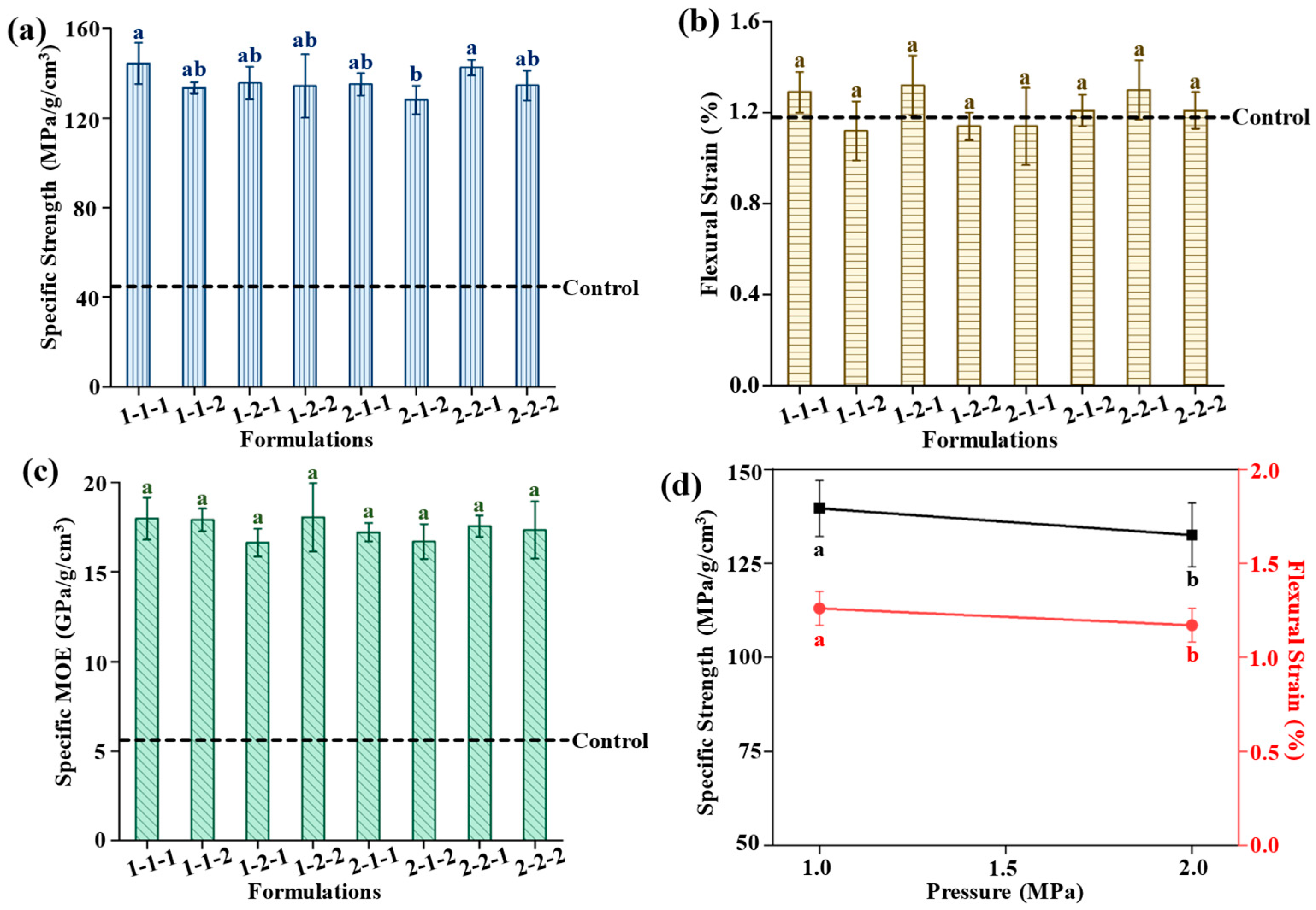

Figure 3 represents the flexural properties of the composite in the parallel-to-grain direction and compares them with the control sample.

Figure 4 illustrates the comparison of the flexural properties of the formulations with those of the control samples in the direction perpendicular to the grain.

From the bending test, formulation 1-1-1 (144.3 ± 9.2 (MPa/(g/cm

3))) and formulation 2-1-2 (128.0 ± 6.4 (MPa/(g/cm

3))) had the highest and lowest specific flexural strength, respectively, in the parallel direction (

Figure 3a). The ANCOVA of the formulations showed that pressure and the interaction of time and temperature had a significant impact on the specific strength values in the parallel direction (

Table S1). The results suggest that subjecting the samples to a pressing duration of 5 min at a temperature of 160 °C may lead to a decrease in the specific flexural strength of the samples. This reduction is likely attributable to the degradation of the CNF layer with increasing temperature during its adhesion to wood when utilizing PAE as a bonding agent. On the other hand, the specific flexural strength in the perpendicular direction was found to be the highest for the formulation 1-2-1 (80.3 ± 4.8 (MPa/g/cm

3)), and the lowest value was for the formulation 2-1-1 (69.0 ± 3.3 (MPa/g/cm

3)) (

Figure 4a). No statistical difference was found among the formulations for the specific strength values in the perpendicular direction (

Table S2).

The composite material was also found to be flexible in nature. In the parallel direction of the composite, the highest strain value was achieved for formulation 1-2-1 (1.32 ± 0.13%), while the lowest value was found for formulation 1-1-2 (1.12 ± 0.13%) (

Figure 3b). A statistically significant difference was found between the highest and the lowest strain values when ANOVA was performed between these two groups. The ANCOVA followed by a Tukey HSD analysis of the formulations demonstrated that pressure and the interaction of time and pressure have a significant effect on the flexural strain values of the formulations in the parallel-to-grain direction (

Table S3). In the perpendicular direction, no statistically significant difference was found between the highest and lowest values of the flexural strain (

Figure 4b). The specific MOE values in both parallel and perpendicular directions did not show any statistical difference among them (

Figure 3c and

Figure 4c, respectively) (

Tables S4–S6).

The specific flexural strength, strain, and specific MOE values significantly increased after adding the CNF layers to the wood veneer. Wood is inherently stronger in the growth direction (fiber alignment direction). The addition of dense CNF layers having higher mechanical properties to wood veneer provides the specimens with higher mechanical properties parallel to the grain direction. From

Figure 3d, a decreasing trend of mechanical properties is also found with increasing pressure. One possible reason could be the presence of small cracks (deep lathe checks) in between the fibers of the wood veneers cut using rotary peeling, where the depth of the lathe check could be up to 90% of the veneer thickness. Previous studies showed that these checks could open below 1 MPa pressure and affect the mechanical properties of the veneer [

37]. However, the percentages of lathe checks in the wood veneer were not measured in this study, as the veneers were laminated with CNF films.

As expected, the specific flexural strength and specific MOE values of the samples were much higher than those of the control sample. However, the control sample achieved higher flexural strain values than the composite specimens. As the strength and stiffness of the sample increased significantly, it is expected that the flexibility of the sample would be compromised. In the perpendicular direction, no significant difference was found in the overall flexural properties among the formulations due to pressure changes.

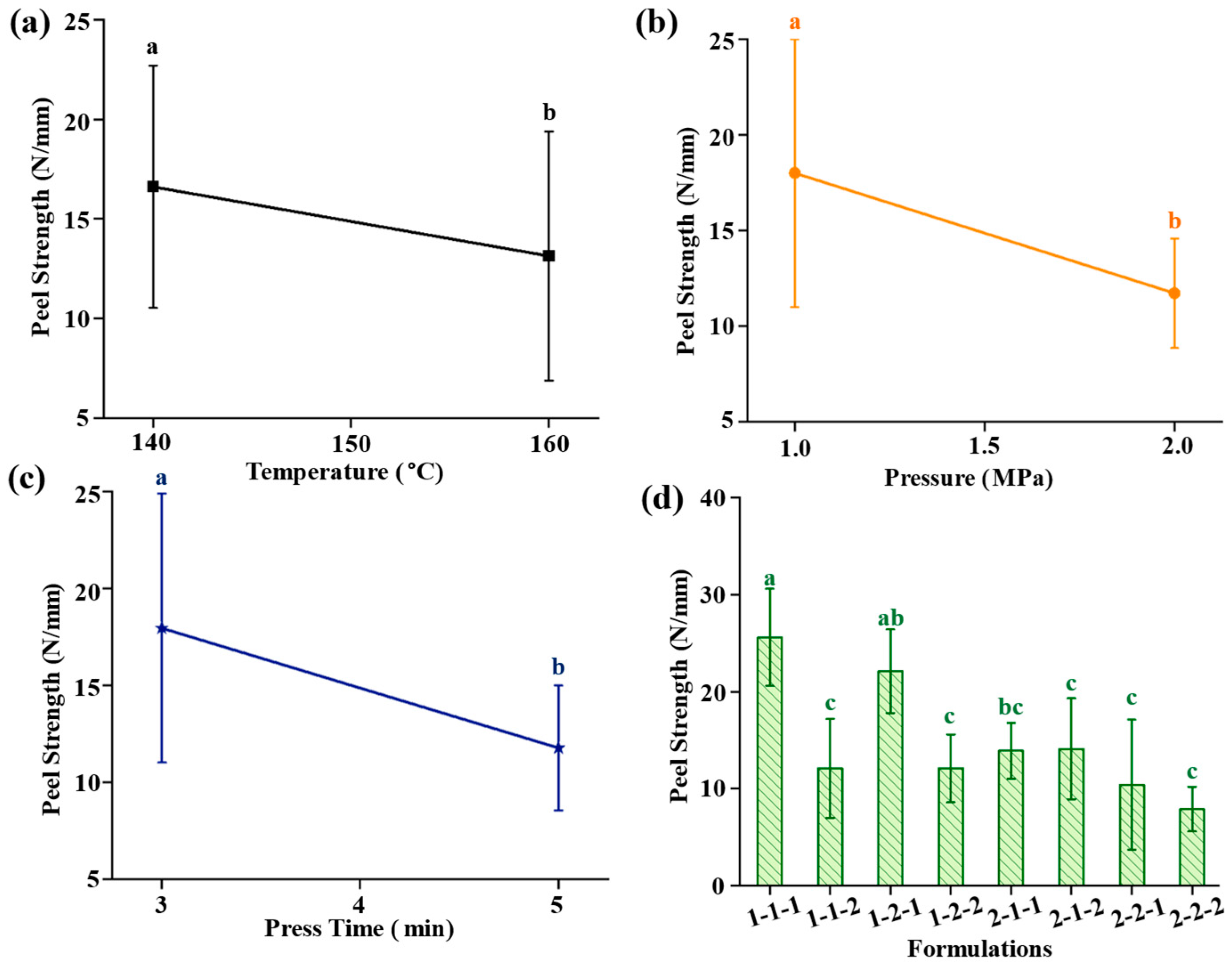

3.2. Lamination Quality

The lamination on food containers developed in this work plays a crucial role not only in mechanical and barrier properties but also in aesthetics. The adhesion properties between the laminated layers ensure hygiene and food safety and prevent detrimental food contamination. The adhesion properties of the CNF-laminated food container were characterized through the measurement of peel strength between the adherend layers.

Figure 5 presents the maximum peel strength values of the formulations. The highest peel strength value (25.6 N/mm) was achieved by formulation 1-1-1. The formulation 2-2-2 demonstrated the lowest peel strength (7.9 N/mm). The peel strength between the adhered layers also varied with the treatment factors (temperature, pressure, and press time). The interaction of time and pressure had a significant effect on the peel strength values. The results are provided in

Table S7.

An increase in treatment factors led to a decrease in peel strength. The samples pressed for 3 min at 140 °C and 1 MPa exhibited the highest peel resistance. Conversely, samples pressed for 5 min at a higher temperature of 160 °C and 2 MPa showed less resistance to peel load. The reasons for decreasing peel resistance with increasing treatment factor levels are further investigated and discussed in the later sections.

3.3. Thermal Properties

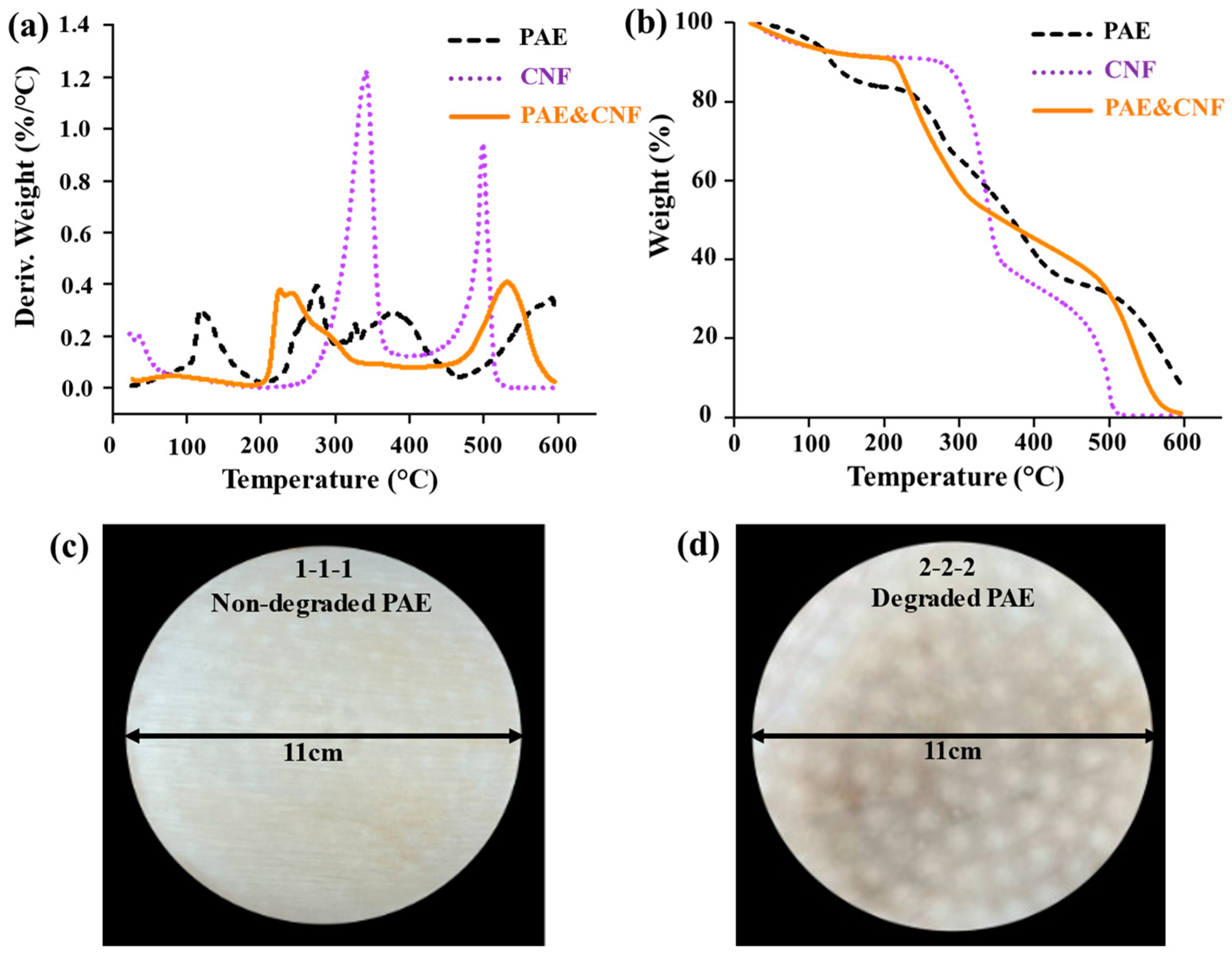

The thermal stability of food containers plays a vital role in ensuring food safety, integrity, and convenience. That is why it is important to investigate the thermal stability of the components of food containers to prevent harmful chemicals from leaching into the food when exposed to higher temperatures. The thermal degradation temperatures of pure PAE, pure CNF, and CNF with PAE were determined using thermogravimetric analysis (TGA) in air.

Figure 6a,b demonstrate the weight loss and the derivative weight loss (DTG) of the components with the increase in temperature. The main steps of thermal degradation are associated with the residual moisture evaporation and, subsequently, chemical decomposition. The onset temperature and peak temperature of pure PAE were observed at around 203 °C and 274 °C, respectively. The decomposition of pure PAE resulted in the appearance of initial and major degradation peaks at close temperature changes, indicating degradation by pyrolysis and oxidation of the PAE as testing was carried out in an air atmosphere.

In TGA, the onset temperature for thermal degradation of CNFs was found to be about 223 °C with a peak temperature of 338 °C. The CNF film used for the TGA analysis was prepared by hot pressing at 160 °C. During the thermal degradation of CNFs, processes like oxidation, depolymerization, and dehydration took place, along with the production of volatile compounds. The higher thermal degradation temperature of the CNF film can be achieved by heat treatment due to stable hydrogen bond formation [

38,

39,

40]. Additionally, CNFs can have improved crystallinity when heat-dried, as the heat-drying process can transform some portions of the amorphous and para-crystalline regions of CNF into regular crystalline structures. This increase in crystallinity contributes to the thermal stability of CNFs [

38,

41].

The cross-linked CNF with PAE showed less thermal stability than un-crosslinked CNF films. The onset temperature for cross-linked CNF film in TGA was around 186 °C, and the peak temperature was 234 °C. In

Figure 6c,d, the images for formulations 1-1-1 (at 3 min, 140 °C, and 1 MPa pressure) and 2-2-2 (at 5 min, 160 °C, and 2 MPa pressure) are represented. The low peel strength observed at higher pressure levels may be attributed to the increased interaction between CNF and PAE during hot pressing, inducing degradation of PAE even at lower temperatures. The samples also exhibited a dark brown color, indicating PAE degradation. Previous studies showed that the formation of the ester bonds between CNF and PAE is responsible for the thermal degradation of cross-linked CNF at lower temperatures [

42,

43]. Elevated temperature and pressure may undermine the integrity of adhesive interfaces through excessive thermal degradation and increased flow of the adhesive into the structure of CNF and wood layers rather than staying at the interface between them [

44].

The TGA analysis was conducted primarily to examine the alterations in color of the samples subjected to elevated temperatures and pressures. The results also suggest that the PAE-containing CNF layer is capable of withstanding temperatures up to approximately 200 °C. Consequently, it can be concluded that the food container remains safe for use at temperatures below this threshold.

3.4. Surface Morphology

SEM imaging was conducted at various magnifications to study the surface morphology of the composite’s bonded layers. Furthermore, images of unlaminated wood veneer were captured to facilitate a comparison between the laminated and unlaminated wood veneer surfaces. The images presented in

Figure 7a–c represent the microscale surface of unlaminated wood veneer, where noticeable pores at the surface act as channels for the movement of oil and water through the wood veneer.

In

Figure 7d–f,j–l, SEM images of adhesive-bonded CNF film after peeling are displayed for formulations 1-1-1 and 2-2-2, respectively. Both CNF film surfaces appear almost identical after undergoing peel tests. Upon examining the microscale SEM image, it is noticeable that the CNFs are randomly aligned on the wood veneer surface, consistent with the natural behavior of CNFs. Importantly, no wood fibers were observed to be adhered to the CNF surface, indicating an absence of wood failure during the peel test.

Images of wood veneer strips after peeling from the CNF layer are shown in

Figure 7g–i,m–o. The microscale images suggest that more CNFs remain on the veneer’s surface for formulation 2-2-2 than for formulation 1-1-1. This observation is consistent with the lower peel strength test results obtained from the composites for the formulation 2-2-2. Most of the surface of the wood veneer for all formulations remained clean, indicating that most of the CNFs remained at the surfaces of the CNF films. SEM images identified no substantial evidence of cohesive failure of the composites. It is possible that the reduced peel resistance observed in formulation 2-2-2 is due to the adhesive penetrating too high into the wood veneer at high pressure (2 MPa), resulting in a starved glue line that weakens the bonding strength between the layers. The lower peel strength can also result from the higher surface roughness of the wood.

3.5. Oil and Grease Resistance Property

Food containers require excellent oil and grease barrier properties for optimal food protection, preservation, and presentation, all while maintaining nutritional value and edibility. All formulations in this study passed kit number 12, the most aggressive reagent. This result aligns with the kit test results of CNF-coated molded pulp containers and wood flour composites [

25,

45]. The high density and internal hydrogen bonds of CNF-coated surfaces explain their excellent oil and grease barrier properties when cellulosic surfaces are dried in contact [

46]. The hydrogen bonding and van der Waals interactions between the molecules of CNFs contribute to forming denser structures with lower porosity, thus reducing air penetration. The decreased air penetration is directly related to the grease resistance of the coated CNF surface [

47,

48].

The hydrophilic nature of CNF also prevents the formation of strong bonds with oil molecules, making CNF coating an effective oil and grease barrier [

49]. The CNF networks are intricate and prevent oil and grease from penetrating between the layers [

25]. Commercial paper plates typically have porous structures on their surfaces due to their interwoven fiber arrangement, which can act as passages for oil and grease. In contrast, CNF coating provides a smoother surface finish with less porosity, resulting in a higher kit value compared to the commercial paper plate’s kit value of 4 [

7,

50]. In comparison to CNFs, alternative non-PFAS-coating materials, such as cyclic olefin copolymer (COC), demonstrated a kit value below 12. This observation underscores the growing demand for CNF as an effective biodegradable coating material as an oil and grease barrier [

51].

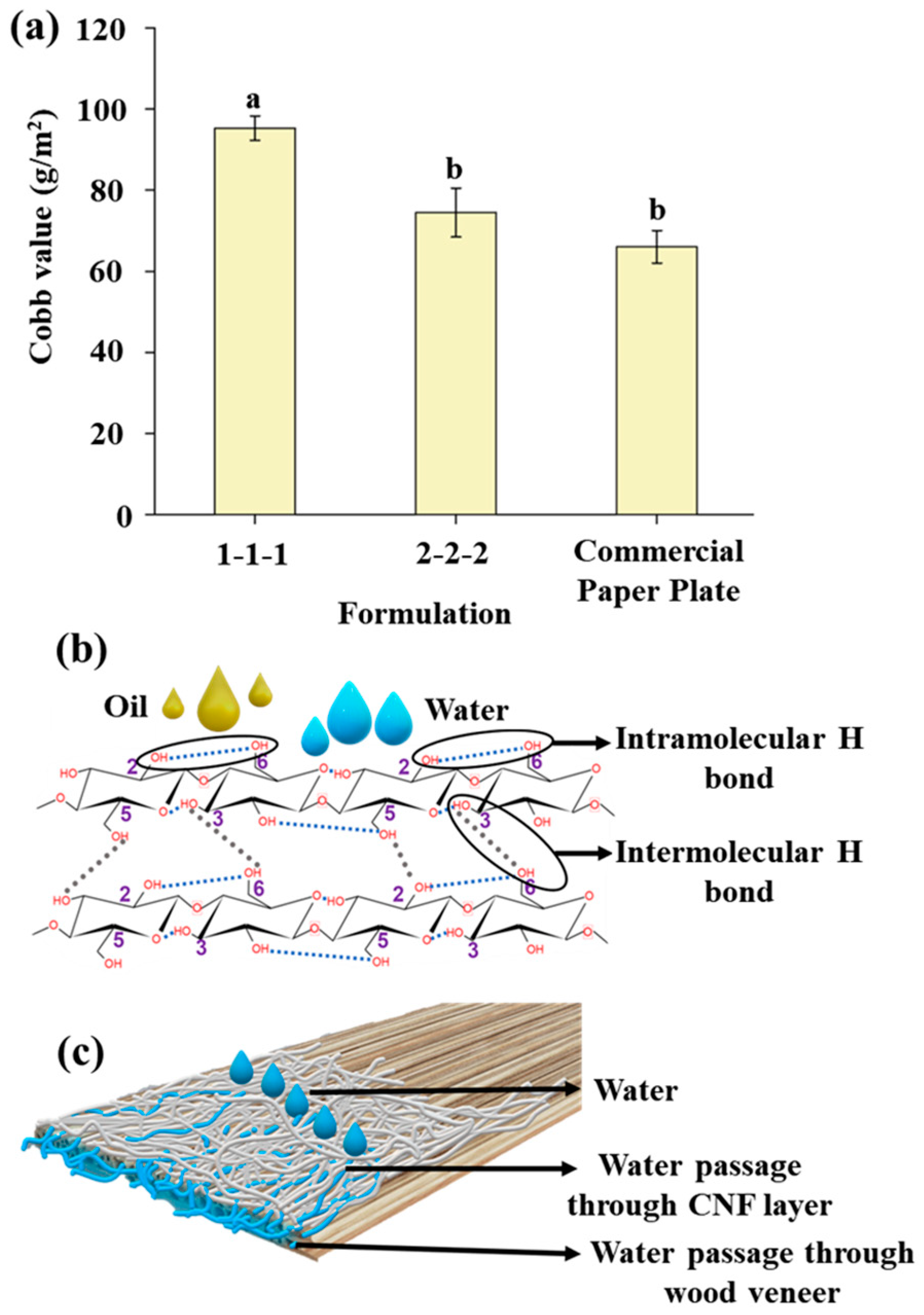

3.6. Water Resistance Property

Water absorptiveness (Cobb value) helps determine the amount of water absorbed by the food-serving container over a certain time. Cobb values of layered composites (1-1-1 and 2-2-2) and commercial paper plates are presented in

Figure 8a.

For the uncoated hot-pressed wood veneer, water absorption values were significantly higher than the commercial plates after 1200 s. A significant amount of variability was also observed in the Cobb values of pressed wood veneer. However, after adding two layers of CNF films on the top and bottom of the wood veneer, the Cobb values and variability were reduced significantly. The composite made by hot-pressing at 3 min, 140 °C, and 1 MPa (formulation 1-1-1) showed significantly higher water absorption values than commercial plates, whereas at 5 min, 160 °C, and 2 MPa hot pressing (formulation 2-2-2), the Cobb value was not statistically different from the paper-based commercial containers. CNFs exhibit strong hydrophilicity but can become less hydrophilic after reacting with substances like PAE, thereby contributing to the laminate’s water resistance. The increase in hydrophobicity with extended time, elevated temperature, and higher pressure during hot pressing may be attributed to the deep infiltration of PAE into the CNF layer, where PAE functions as a hydrophobic enhancer [

52].

As shown in

Figure 8b, semicrystalline cellulose nanofibrils form an extensive internal network by connecting through hydrogen bonds between hydroxyl and hydroxymethyl groups, which leads to a compact film structure [

53,

54]. When CNF films are made by filtration, they are more likely to have interfibrillar agglomeration. This is due to a high number of hydrogen bonds in vacuum-filtered films, rendering them highly susceptible to humidity [

55]. Water enables CNF films to plasticize, resulting in the fragmentation of hydrogen bonds between fibrils [

56].

The water contact angle of CNF films, which is smaller than 90° due to the hydrophilic nature of the hydroxyl groups on the film’s surface, facilitates water penetration through the film’s surface. Thus, it makes a way to penetrate the water through the pores of the CNF film by capillary forces. Though water can be easily absorbed by the CNF layer, the flow path of water is very tortuous (shown in

Figure 8c), which causes an elongated water passage path and a longer retention time. For these reasons, the double-sided CNF-laminated containers were found leakproof during the Cobb test when tested for 1200 s. It was also observed that the food containers generated under higher temperatures, higher pressure, and longer pressing time showed lower water absorption values and less water passage compared to those produced using lower temperature and pressure with shorter pressing time. Higher temperature and higher pressure reduce the porosity of the CNF film by densification when the film is dried by using a hot press and also promote cellulose hornification [

57]. Water can have fewer channels to pass through the film with decreasing porosity, which aligns with the Cobb test values of the composites in this study. Finally, in natural wood, trees have numerous transportation pores to pass nutrients and water. Long and plentiful micro channels are open in the thin rotary-cut wood veneer with a reduced thickness, which is suitable for water passages (also observed in the SEM image) [

58]. For this reason, it was not possible to measure the Cobb values of the unlaminated wood veneers as water seeped through them very quickly.

3.7. Overall Effects of Pressing Variables on Properties

The overall effects of hot-pressing parameters on the properties of food containers are summarized in

Table 2.

4. Conclusions

This study presented a novel food container design that utilized CNF layers on both sides of a yellow birch wood veneer and bonded together using food-grade PAE. These samples were hot-pressed at varying temperatures, pressures, and press times. The control samples were prepared by pressing wood veneer for 5 min at 160 °C and 2 MPa pressure without CNF lamination and were compared with the composite samples of identical formulation in terms of mechanical properties. All composite samples showed significant improvements in both flexural strength and MOE values. In particular, the composite sample exhibited 1.8 times greater flexural strength in the parallel direction and a remarkable 30 times higher strength in the perpendicular direction of wood fibers compared to the control samples for our best formulation. Furthermore, the addition of CNF layers to the wood veneer increased MOE values of the composite sample by 1.8 times in the parallel direction and impressively 40 times when tested in the perpendicular direction to the wood fibers alignment.

It is vital to note that the flexural strain of the container sample only slightly increased in the parallel direction (by 2%). However, it reduced in the perpendicular direction (by 30%). This outcome was expected, considering the higher increase in flexural strength observed in the perpendicular-to-grain direction. The peel strength of the formulation with lower levels of treatment factors was 2.2 times higher than the formulation with higher levels of treatment factors. To shed more light on these findings, the study used SEM to investigate the surface morphology of the peeled samples and thermogravimetric analysis to evaluate the thermal degradation of CNF and PAE. The images from the SEM did not reveal any significant CNF layer or wood veneer failure, indicating that the failure mode was largely adhesive failure. On the other hand, the TGA data showed that thermal degradation of CNF when bonded with PAE was initiated at a lower temperature, which could be due to ester bond formation during CNF–PAE cross-linking.

The CNF–wood veneer composites developed in this work outperformed commercial paper plates in their resistance to oil and grease, as demonstrated by kit number 12 versus kit number 4. When the composite was prepared by hot pressing for 5 min at 160 °C and 2 MPa pressure, it did not show any noteworthy disparity in water absorption tendency compared to commercial paper plates that contained PFASs. Future research can explore the mechanical and barrier performance by systematically assessing the effects of reducing the basis weight of CNF suspensions. Additionally, studies could focus on enhancing water resistance and minimizing moisture sensitivity, as well as evaluating the impact of storage conditions on the performance of these containers.

Overall, this work highlights the potential for CNF lamination to improve the mechanical and barrier properties of food containers made of wood veneer. This CNF-laminated wood veneer food container may provide a long-term solution to the challenges associated with conventional wood veneer-based containers. This study also presents an efficient method for readily producible and easily compostable food containers, which can be used as a safe and effective alternative to PFAS-containing containers, therefore contributing to sustainable practices. The growing emphasis on global sustainability initiatives aimed at reducing carbon footprints and addressing plastic pollution has led to a rise in regulatory restrictions concerning single-use plastics. Such innovations not only have the potential to improve food safety but also align with policy advancements promoting environmentally friendly food packaging solutions.