Analysis of Equipment Failures as a Contributor to Hydrogen Refuelling Stations Incidents

Abstract

1. Introduction

- This study provides a thorough analysis of key contributors to incidents at hydrogen refuelling stations, with a particular focus on the frequent equipment failures and the underlying causes of these failures.

2. Materials and Methods

- (a)

- HIAD database, incident filtering by application type (hydrogen refuelling stations), H2tool.org filtered by application type (fuelling stations).

- (b)

- Review of the incident, full description to gain an understanding of what happened, and the failed equipment.

- (c)

- Review the causes and consequences of the incident.

| Database Name | Number of Incidents Reported (HRS) | Database Administrator |

|---|---|---|

| HIAD | 716(28) Accessed 20 April 2025 | European Commission Joint Research Center, Petten, Netherland |

| H2tool.org | 67(12) | Hydrogen Safety Panel |

| Online | 5 |

3. Results

- Controlling material hardness and conducting post-weld heat treatment to reduce the hardness and temper material residual stress.

- Use dry, low-hydrogen electrodes (such as E7018-1) and pre-heating techniques for welding.

- An elevated temperature bake-out at a minimum temperature of more than 205 °C is necessary to drive out hydrogen if it diffuses into the metal during the welding or operating process.

- To stop hydrogen surface reactions, apply a weld overlay, cladding, or protective linings.

- Heavy-wall equipment handling hot hydrogen shutdown and start-up procedures must be adequately controlled to enable the pressurisation sequences as a function of temperature.

- Hardness tests and post-weld heat treatment (PWHT) are critical in the material manufacturing process, and they must not be ignored

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| CCPS | Centre for Chemical Process Safety |

| FMEA | Failure Mode Equipment Analysis |

| LHRS | Liquid Hydrogen Refuelling Stations |

| HRS | Hydrogen Refuelling Stations |

| PWHT | Post-Weld Heat Treatment |

References

- Genovese, M.; Blekhman, D.; Fragiacomo, P. An Exploration of Safety Measures in Hydrogen Refueling Stations: Delving into Hydrogen Equipment and Technical Performance. Hydrogen 2024, 5, 102–122. [Google Scholar] [CrossRef]

- Vereš, J.; Ochodek, T.; Koloničný, J. Safety Aspects of Hydrogen Fuelling Stations. Chem. Eng. Trans. 2022, 91, 49–54. [Google Scholar] [CrossRef]

- Alazemi, J.; Andrews, J. Automotive Hydrogen Fuelling Stations: An International Review. Renew. Sustain. Energy Rev. 2015, 48, 483–499. [Google Scholar] [CrossRef]

- New Report: There Are Now 1000+ Hydrogen Refuelling Stations and Counting. 2025. Available online: https://drivinghydrogen.com/2025/02/17/new-report-there-are-now-1000-hydrogen-refuelling-stations-and-counting/ (accessed on 22 June 2025).

- Halder, P.; Babaie, M.; Salek, F.; Haque, N.; Savage, R.; Stevanovic, S.; Bodisco, T.A.; Zare, A. Advancements in Hydrogen Production, Storage, Distribution and Refuelling for a Sustainable Transport Sector: Hydrogen Fuel Cell Vehicles. Int. J. Hydrogen Energy 2024, 52, 973–1004. [Google Scholar] [CrossRef]

- Nekhwevha, R.; Telukdarie, A. Analysis of Key Contributors to Process Safety Incidents in the Chemical Process Industry. In Proceedings of the 2022 Portland International Conference on Management of Engineering and Technology (PICMET), Portland, OR, USA, 7–11 August 2022. [Google Scholar]

- Mirza, N.R.; Degenkolbe, S.; Witt, W. Analysis of Hydrogen Incidents to Support Risk Assessment. Int. J. Hydrogen Energy 2011, 36, 12068–12077. [Google Scholar] [CrossRef]

- Alfasfos, R.; Sillman, J.; Soukka, R. Lessons Learned and Recommendations from Analysis of Hydrogen Incidents and Accidents to Support Risk Assessment for the Hydrogen Economy. Int. J. Hydrogen Energy 2024, 60, 1203–1214. [Google Scholar] [CrossRef]

- Sakamoto, J.; Sato, R.; Nakayama, J.; Kasai, N.; Shibutani, T.; Miyake, A. Leakage-Type-Based Analysis of Accidents Involving Hydrogen Fueling Stations in Japan and USA. Int. J. Hydrogen Energy 2016, 41, 21564–21570. [Google Scholar] [CrossRef]

- CCPS. Ccps Process Safety Glossary. Available online: https://www.aiche.org/ccps/resources/glossary (accessed on 19 April 2025).

- Cirrone, D.; Makarov, D.; Proust, C.; Molkov, V. Minimum Ignition Energy of Hydrogen-Air Mixtures at Ambient and Cryogenic Temperatures. Int. J. Hydrogen Energy 2023, 48, 16530–16544. [Google Scholar] [CrossRef]

- Arens, E.E.; Youngquist, R.C.; Starr, S.O. Intensity Calibrated Hydrogen Flame Spectrum. Int. J. Hydrogen Energy 2014, 39, 9545–9551. [Google Scholar] [CrossRef]

- Astbury, G.R.; Hawksworth, S.J. Spontaneous Ignition of Hydrogen Leaks: A Review of Postulated Mechanisms. Int. J. Hydrogen Energy 2007, 32, 2178–2185. [Google Scholar] [CrossRef]

- Zhang, T.; Uratani, J.; Huang, Y.; Xu, L.; Griffiths, S.; Ding, Y. Hydrogen Liquefaction and Storage: Recent Progress and Perspectives. Renew. Sustain. Energy Rev. 2023, 176, 113204. [Google Scholar] [CrossRef]

- Herms, E.; Olive, J.M.; Puiggali, M. Hydrogen Embrittlement of 316l Type Stainless Steel. Mater. Sci. Eng. A 1999, 272, 279–283. [Google Scholar] [CrossRef]

- Venkatasatish, R.; Dhanamjayulu, C. Reinforcement Learning Based Energy Management Systems and Hydrogen Refuelling Stations for Fuel Cell Electric Vehicles: An Overview. Int. J. Hydrogen Energy 2022, 47, 27646–27670. [Google Scholar] [CrossRef]

| Process Equipment | Injured (Rate) | Fatality (Rate) |

|---|---|---|

| Compressor (5) | 0 | 0 |

| Dispenser (15) | 0 | 0 |

| Pipelines (3) | 0 | 0 |

| Storage Tanks (18) | 12 (67%) | 3(17%) |

| Valves (4) | 0 | 0 |

| Total (45) | 27% | 7% |

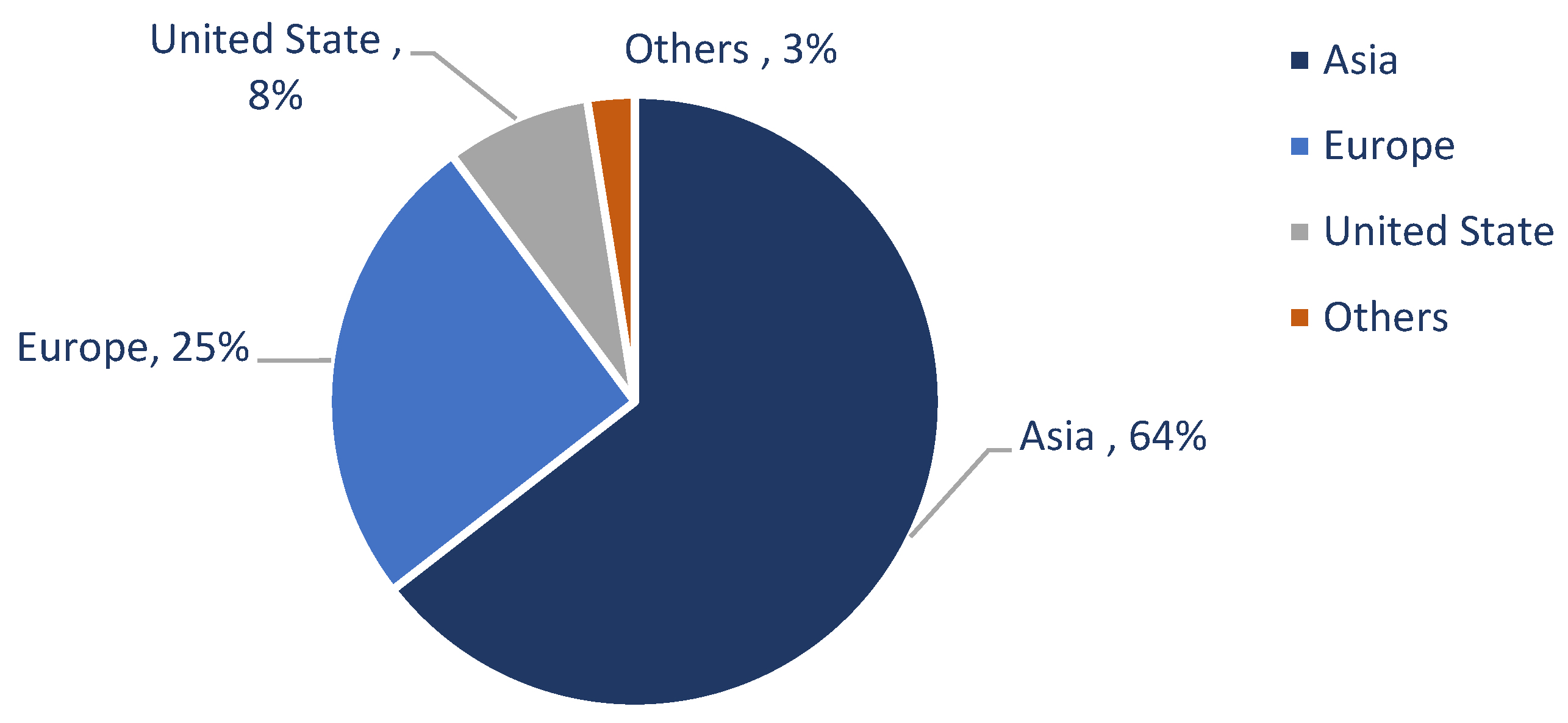

| Incident Regions | Numbers | Process Equipment |

|---|---|---|

| Asia | 5 | Storage (3); dispenser (2) |

| Europe | 19 | Dispenser (5); storage (2); other (11) |

| North America | 8 | Storage (7); dispenser (1) |

| Main Equipment Failure | Number of Incidents Reported (HRS) | Database Administrator |

|---|---|---|

| Hydrogen storage tanks (18) | Bursting disc (2) Pressure safety valve (1) Rupture disc (2) Fitting connections (1) Flange bolts (1) Plugs (2) Pressure control system (1) Welds (2) Other (5) | Procedure (human error)—38% Design deficiency (material incompatibility, manufacturing defects)—29% Inadequate management of changes—5% Poor maintenance—10% Compressor vibration—5% Stress corrosion—5% Incorrect installations—10% |

| Hydrogen dispenser (15) | Hose (7) Breakaway coupling (1) Nozzles (1) Valves (2) Other (4) | Design deficiency Poor maintenance |

| Valves (4) | Valves packings | Inadequate maintenance |

| Compressor (5) | Crankshaft bearings Pressure switches Seals and filters | Vibrations Weld failures System logic failures |

| Pipelines (2) | Pipelines | Embattlement |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nekhwevha, R.; Madyira, D.M.; Gqibani, S.L. Analysis of Equipment Failures as a Contributor to Hydrogen Refuelling Stations Incidents. Hydrogen 2025, 6, 79. https://doi.org/10.3390/hydrogen6040079

Nekhwevha R, Madyira DM, Gqibani SL. Analysis of Equipment Failures as a Contributor to Hydrogen Refuelling Stations Incidents. Hydrogen. 2025; 6(4):79. https://doi.org/10.3390/hydrogen6040079

Chicago/Turabian StyleNekhwevha, Rialivhuwa, Daniel M. Madyira, and Samuel L. Gqibani. 2025. "Analysis of Equipment Failures as a Contributor to Hydrogen Refuelling Stations Incidents" Hydrogen 6, no. 4: 79. https://doi.org/10.3390/hydrogen6040079

APA StyleNekhwevha, R., Madyira, D. M., & Gqibani, S. L. (2025). Analysis of Equipment Failures as a Contributor to Hydrogen Refuelling Stations Incidents. Hydrogen, 6(4), 79. https://doi.org/10.3390/hydrogen6040079