Numerical Simulation of Dispersion and Ventilation of Hydrogen Clouds in Case of Leakage Inside a Large-Scale Industrial Building

Abstract

1. Introduction

2. Numerical Models and Setup

2.1. The containmentFOAM Package

2.2. Solution for Unsteady Multi-Species Gas Mixture

2.3. k- SST Turbulence Model and Its Modification for Buoyancy

2.4. Computational Setup

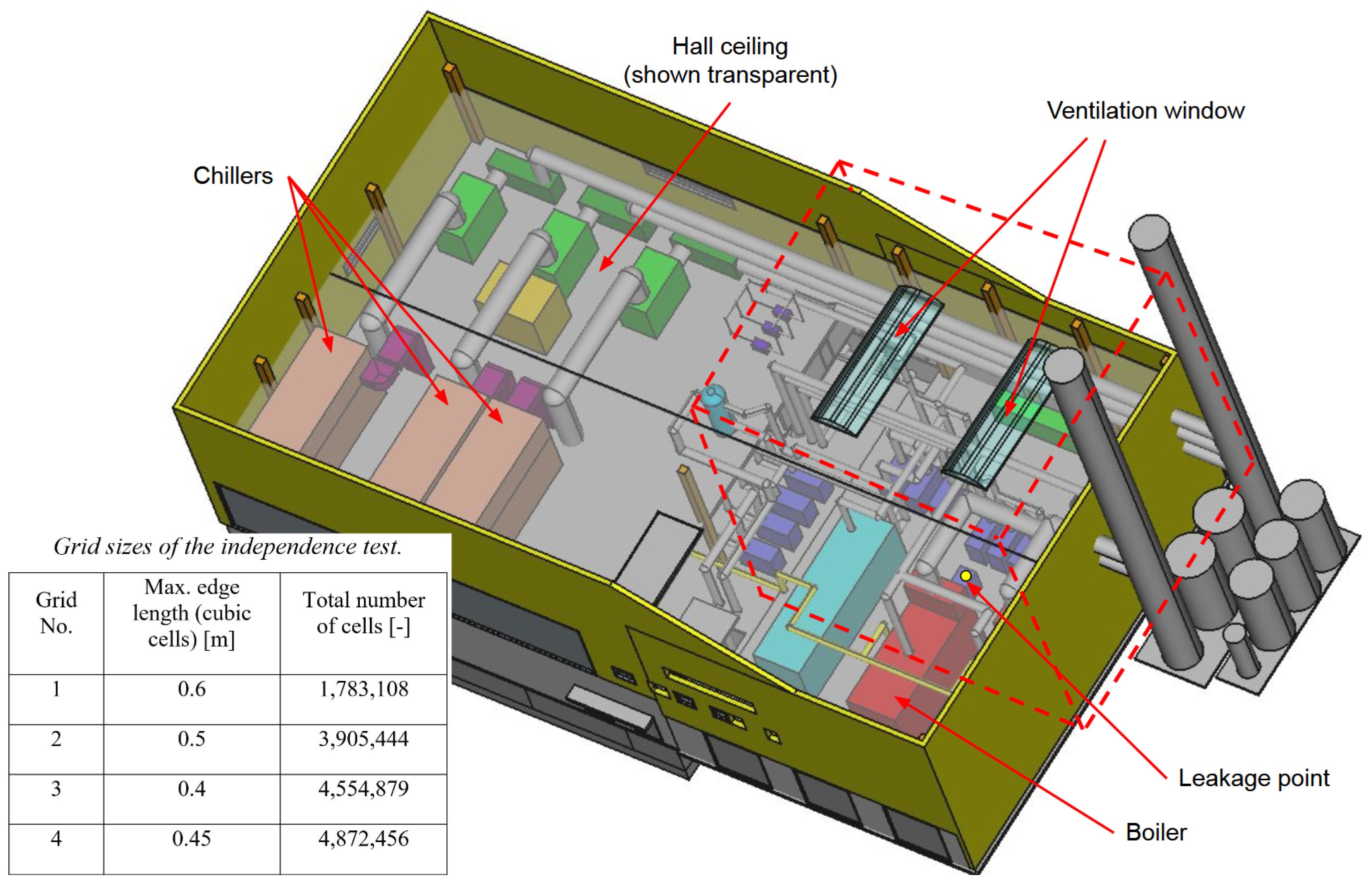

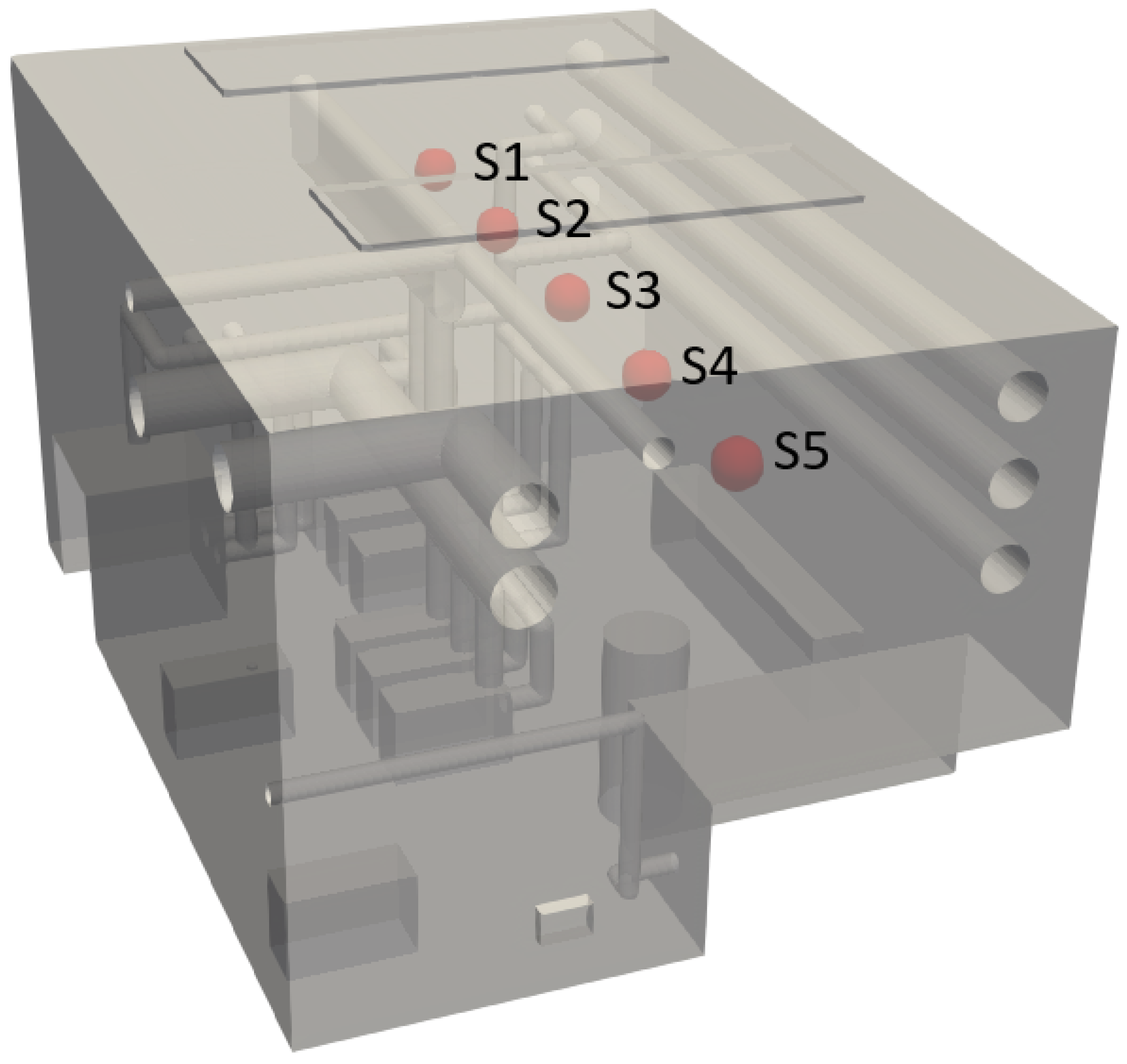

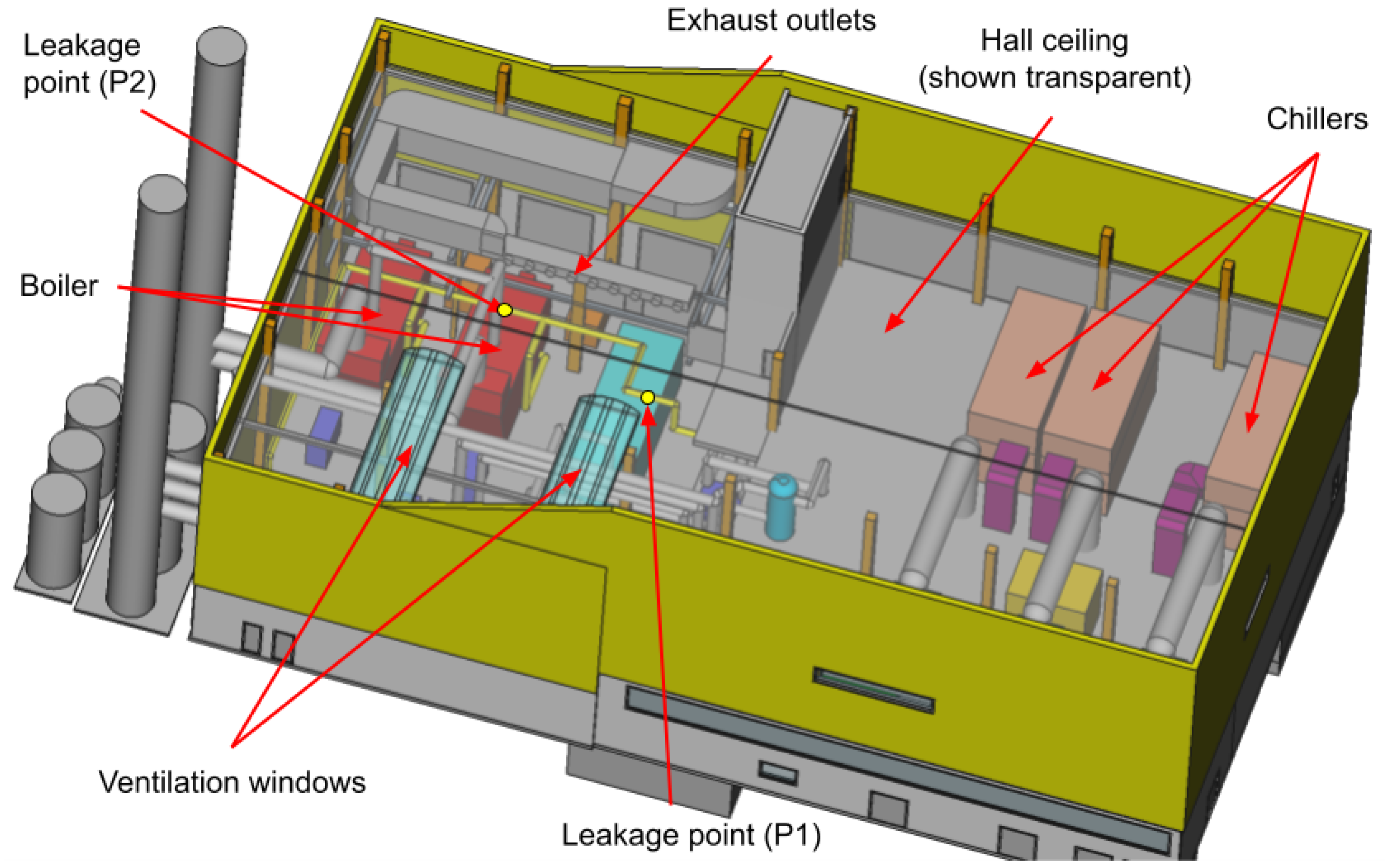

2.4.1. Numerical Grid

2.4.2. Hydrogen Leakage Parameters

2.4.3. Boundary Conditions

- There is no temperature difference between the air inside the building and the air outside the building. This means no airflow occurs between the inside and outside of the building due to temperature difference and, hence, density difference.

- There is stagnant wind around the building. Considering wind speed and direction would result in induced airflow inside the building. This requires further detailed study. However, it is not considered in the current work.

- Leakage stops after 10 s from the start of the leakage. It is assumed that the emergency shutdown system in the building takes a few seconds after being triggered by hydrogen sensors until it is fully functional, i.e., completely shuts down the hydrogen flow in the pipe. The analysis of the effects of employing different sensor technologies and optimizing their locations is not in the scope of the current study.

2.5. Studied Cases and Scenarios

- Scenario 1 (Extreme scenario): It is assumed that the hydrogen leakage from the leakage point P1 is undetected, and the hydrogen leaks inside the building without ventilation. This case is studied as a worst-case scenario (WCS) where no automatic action is taken to mitigate hydrogen leakage or accumulation.

- Scenario 2 (Natural ventilation): The hydrogen leaks from P1 and is detected and the shutdown happens 10 s after the leakage begins, as aforementioned. This results in an emergency shutdown of the hydrogen supply to the building. The roof ventilation windows are also opened to evacuate the hydrogen–air mixture from the building. The windows are assumed to be fully opened.

- Scenario 3 (Mechanical ventilation): The leakage from P1 is stopped also after 10 s, and the hydrogen evacuation outside the building is started. However, in this scenario, the existing ventilation fan and air outlets in the building are assumed to be used to evacuate the hydrogen–air mixture. Before the detection of hydrogen, i.e., after 10 s from the start of the leakage, the total volume flow rate of exhaust air is assumed to be 0.03 m3/m2/min, as recommended by the National Fire Protection Association (NFPA): Hydrogen Technology Code [30]. The total ventilation flow is calculated to be 4.371 m3/s.

- Scenario 4 (Ceiling ventilation): This scenario assumes the same parameters as in Scenario 3-a. The only difference is that the exhaust outlets are located on the ceiling of the machine room. The primary purpose of this scenario is to study the effect of the location of the exhaust outlets on the size of the hydrogen cloud in the building.

- Scenario 5 (Leakage with obstacles): This scenario assumes the same parameters as in Scenario 3-a, with the leakage point P2 indicated in Figure 1.

3. Simulations and Results

3.1. Computational Time and Effort

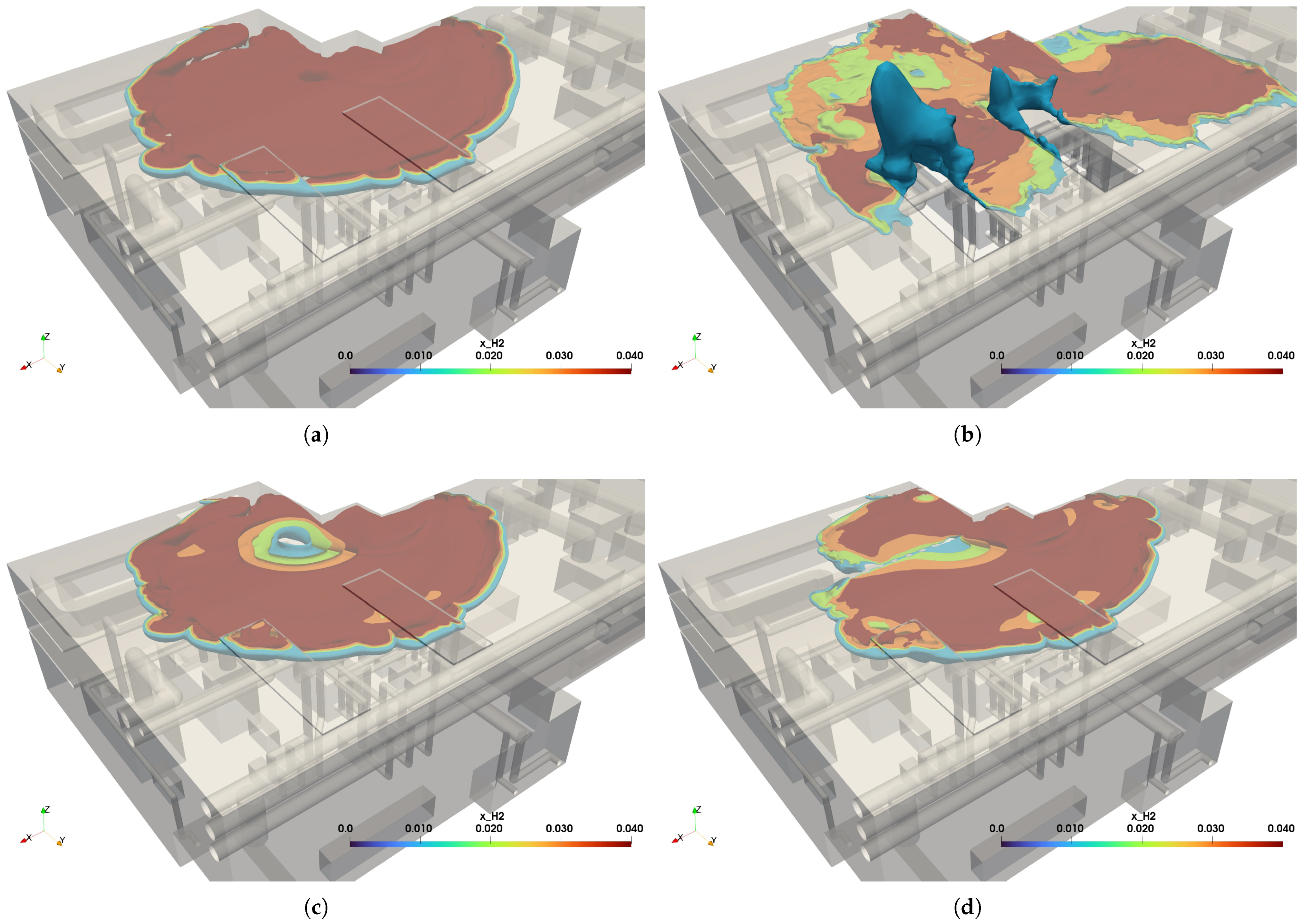

3.2. Scenario 1: No-Ventilation, No-Detection

3.3. Scenario 2: Natural Ventilation

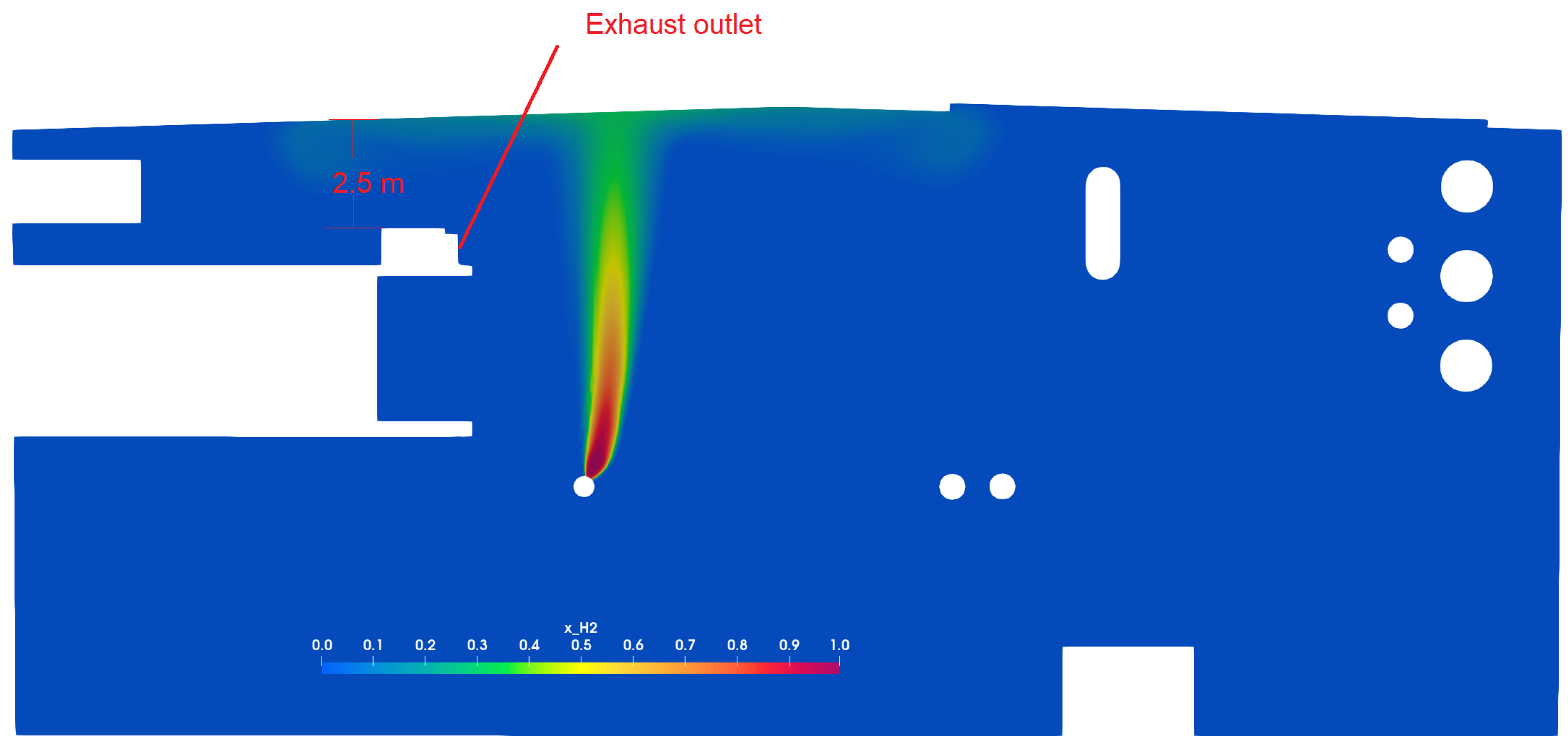

3.4. Scenario 3: Forced Ventilation

3.5. Scenario 4: Forced Ventilation from Ceiling

3.6. Scenario 5: Leakage with Obstacles

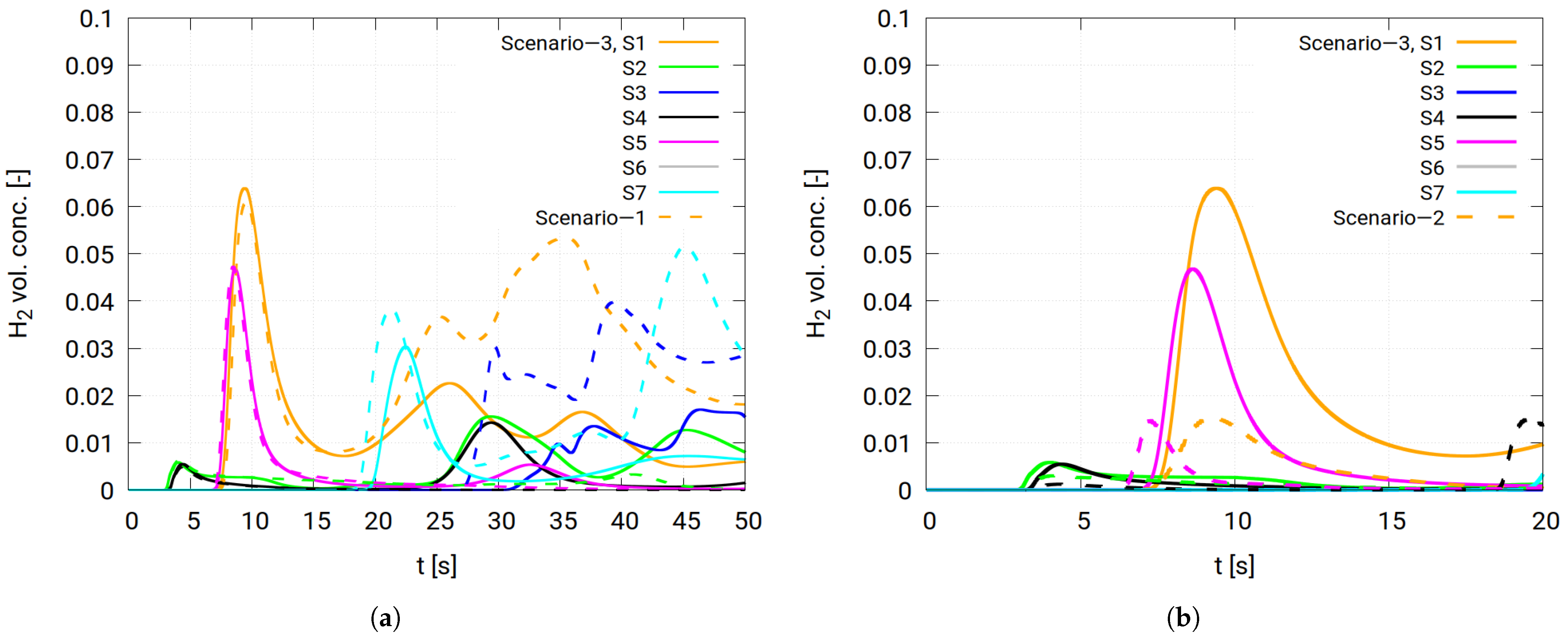

3.7. Hydrogen Concentrations

3.8. Hydrogen Combustible Cloud

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| ACH | Air Change per Hour |

| BPG | Best Practice Guidelines |

| CAD | Computer-Aided Design |

| ESDV | Emergency Shut Down Valve |

| FCV | Fuel Cell Vehicle |

| LES | Large Eddy Simulation |

| LFL | Lower Flammability Limit |

| NFPA | National Fire Protection Association |

| NZE | Net Zero Emissions |

| PAR | Passive Auto-catalytic Recombiner |

| RANS | Reynolds-Averaged Navier–Stokes |

| SGDH | Simple Gradient Diffusion Hypothesis |

| SST | Shear Stress Tensor |

| Subscripts and Superscripts | |

| i | species index |

| k | related to the turbulence kinetic energy |

| t | turbulence value |

| related to the specific rate of turbulence dissipation | |

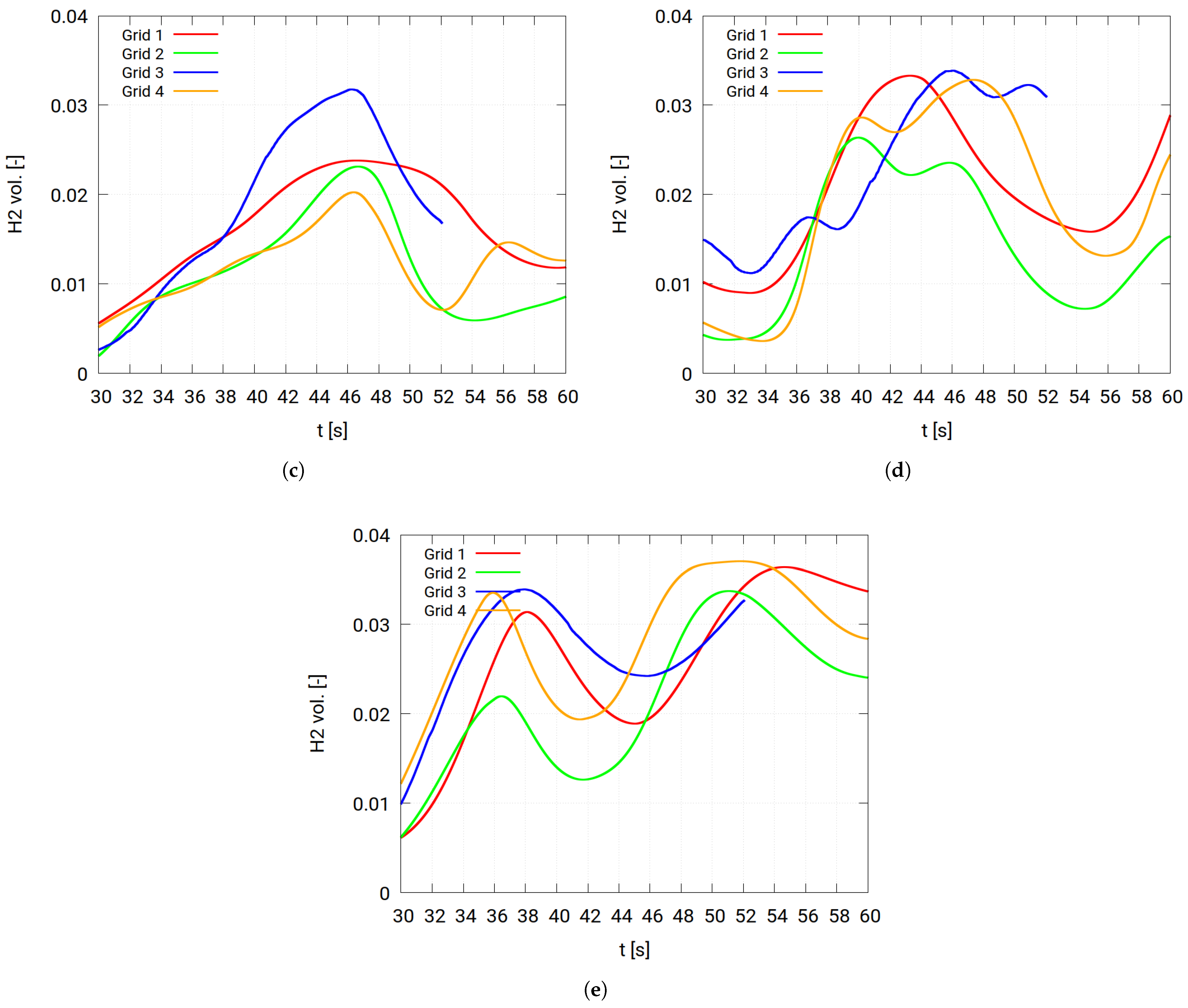

Appendix A. Grid Independence Study

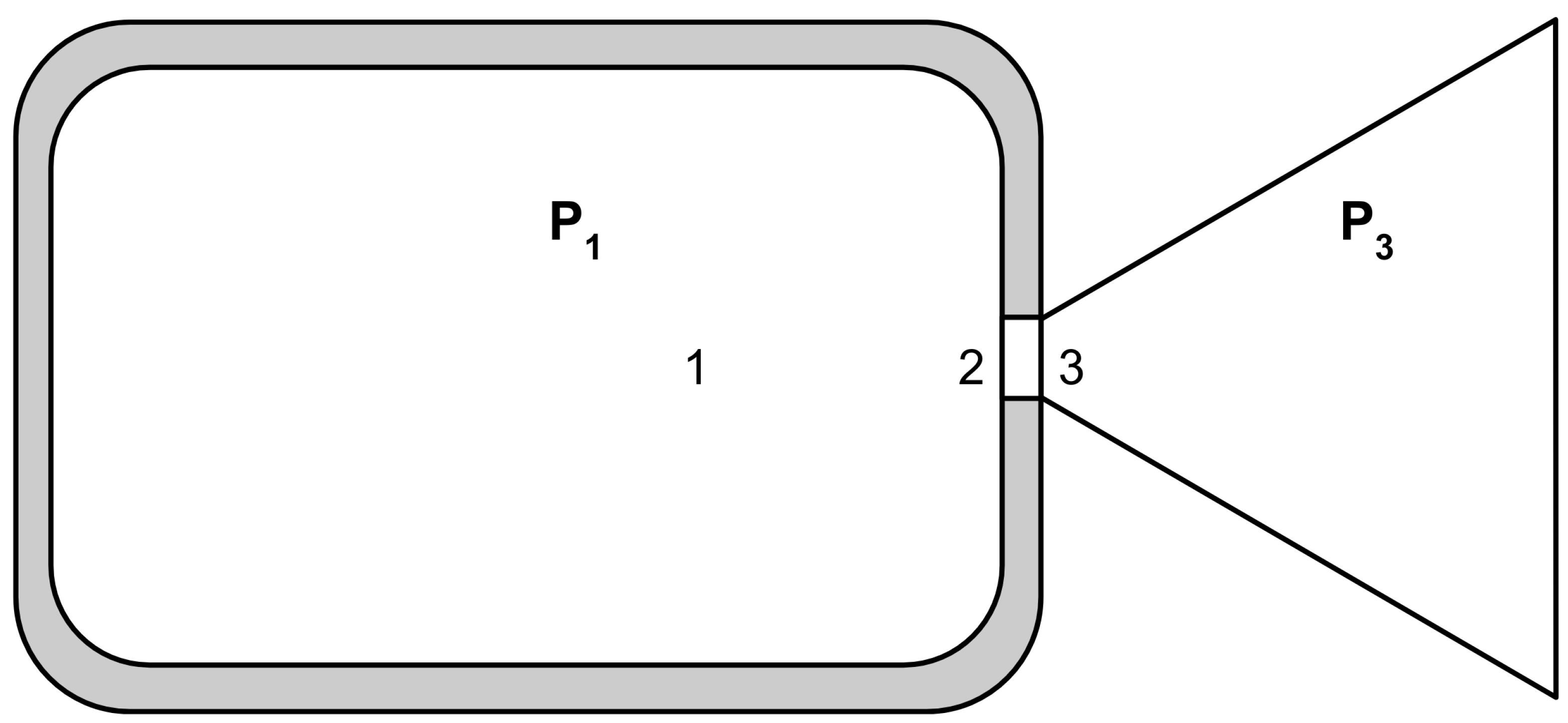

Appendix B. Under-Expanded Jet Theory

- State 1: the state of the stagnant gas inside the tank;

- State 2: the entrance of the leakage nozzle;

- State 3: the exit of the nozzle.

References

- IEA. Global Hydrogen Review 2022; OECD Publishing: Paris, France, 2022. [Google Scholar]

- Giannissi, S.G.; Tolias, I.C.; Melideo, D.; Baraldi, D.; Shentsov, V.; Makarov, D.; Molkov, V.; Venetsanos, A.G. On the CFD modelling of hydrogen dispersion at low-Reynolds number release in closed facility. Int. J. Hydrogen Energy 2021, 46, 29745–29761. [Google Scholar] [CrossRef]

- Malakhov, A.; Avdeenkov, A.; Du Toit, M.; Bessarabov, D. CFD simulation and experimental study of a hydrogen leak in a semi-closed space with the purpose of risk mitigation. Int. J. Hydrogen Energy 2020, 45, 9231–9240. [Google Scholar] [CrossRef]

- Ismail, I.; Tsukikawa, H.; Kanayama, H. Modelling Considerations in the Simulation of Hydrogen Dispersion within Tunnel Structures. J. Appl. Math. 2012, 2012, 846517. [Google Scholar] [CrossRef]

- Suzuki, J.; Oyakawa, K.; Watanabe, S.; Mukai, S.; Mitsuishi, H. CFD Simulation on Diffusion of Leaked Hydrogen Caused by Vehicle Accident in Tunnels; Technical Report; Hydrogen Knowledge Centre: Derby, UK, 2005. [Google Scholar]

- Koutsourakis, N.; Tolias, I.C.; Giannissi, S.G.; Venetsanos, A.G. Numerical Investigation of Hydrogen Jet Dispersion Below and Around a Car in a Tunnel. Energies 2023, 16, 6483. [Google Scholar] [CrossRef]

- Middha, P.; Hansen, O.R. CFD simulation study to investigate the risk from hydrogen vehicles in tunnels. Int. J. Hydrogen Energy 2009, 34, 5875–5886. [Google Scholar] [CrossRef]

- Huang, T.; Zhao, M.; Ba, Q.; Christopher, D.M.; Li, X. Modeling of hydrogen dispersion from hydrogen fuel cell vehicles in an underground parking garage. Int. J. Hydrogen Energy 2022, 47, 686–696. [Google Scholar] [CrossRef]

- Li, Y.; Jiang, J.; Yu, Y.; Zhang, Q. Numerical simulation of dispersion and distribution behaviors of hydrogen leakage in the garage with a crossbeam. Simulation 2019, 95, 1229–1238. [Google Scholar] [CrossRef]

- Hajji, Y.; Jouini, B.; Bouteraa, M.; Elcafsi, A.; Belghith, A.; Bournot, P. Numerical study of hydrogen release accidents in a residential garage. Int. J. Hydrogen Energy 2015, 40, 9747–9759. [Google Scholar] [CrossRef]

- Hajji, Y.; Bouteraa, M.; Elcafsi, A.; Bournot, P. Green hydrogen leaking accidentally from a motor vehicle in confined space: A study on the effectiveness of a ventilation system. Int. J. Energy Res. 2021, 45, 18935–18943. [Google Scholar] [CrossRef]

- IMO. Fourth IMO GHG Study 2020; International Maritime Organization: London, UK, 2020. [Google Scholar]

- Li, F.; Yuan, Y.; Yan, X.; Malekian, R.; Li, Z. A study on a numerical simulation of the leakage and diffusion of hydrogen in a fuel cell ship. Renew. Sustain. Energy Rev. 2018, 97, 177–185. [Google Scholar] [CrossRef]

- Xie, Y.; Liu, J.; Qin, J.; Xu, Z.; Zhu, J.; Liu, G.; Yuan, H. Numerical simulation of hydrogen leakage and diffusion in a ship engine room. Int. J. Hydrogen Energy 2024, 55, 42–54. [Google Scholar] [CrossRef]

- Guan, W.; Chen, J.; Chen, L.; Cao, J.; Fan, H. Safe Design of a Hydrogen-Powered Ship: CFD Simulation on Hydrogen Leakage in the Fuel Cell Room. J. Mar. Sci. Eng. 2023, 11, 651. [Google Scholar] [CrossRef]

- Greenshields, C.; Weller, H. Notes on Computational Fluid Dynamics: General Principles; CFD Direct Ltd.: Reading, UK, 2022. [Google Scholar]

- Kelm, S.; Kampili, M.; Kumar, G.V.; Sakamoto, K.; Liu, X.; Kuhr, A.; Druska, C.; Prakash, K.A.; Allelein, H. Development and first validation of the tailored CFD solver ‘containmentFoam’for analysis of containment atmosphere mixing. In Proceedings of the 18th International Topical Meeting on Nuclear Reactor Thermal Hydraulics (NURETH-18), Portland, OR, USA, 18–23 August 2019; pp. 18–23. [Google Scholar]

- Yassin, K.; Kelm, S.; Kampili, M.; Reinecke, E.A. Validation and Verification of containmentFOAM CFD Simulations in Hydrogen Safety. Energies 2023, 16, 5993. [Google Scholar] [CrossRef]

- McAllister, S.; Chen, J.Y.; Fernandez-Pello, A.C. Fundamentals of Combustion Processes; Springer: Berlin/Heidelberg, Germany, 2011; Volume 304. [Google Scholar]

- Kelm, S.; Kampili, M.; Liu, X.; George, A.; Schumacher, D.; Druska, C.; Struth, S.; Kuhr, A.; Ramacher, L.; Allelein, H.J.; et al. The Tailored CFD Package ‘containmentFOAM’ for Analysis of Containment Atmosphere Mixing, H2/CO Mitigation and Aerosol Transport. Fluids 2021, 6, 100. [Google Scholar] [CrossRef]

- Menter, F.; Esch, T. Elements of industrial heat transfer predictions. In Proceedings of the 16th Brazilian Congress of Mechanical Engineering (COBEM), Uberlândia, Brazil, 26–30 November 2001; Volume 109, p. 650. [Google Scholar]

- Abe, S.; Ishigaki, M.; Sibamoto, Y.; Yonomoto, T. RANS analyses on erosion behavior of density stratification consisted of helium–air mixture gas by a low momentum vertical buoyant jet in the PANDA test facility, the third international benchmark exercise (IBE-3). Nucl. Eng. Des. 2015, 289, 231–239. [Google Scholar] [CrossRef]

- Kampili, M.; Kumar, G.V.; Kelm, S.; Prakash, K.A.; Allelein, H.J. Validation of multicomponent species transport solver-impact of buoyancy turbulence in erosion of a stratified light gas layer. In Proceedings of the 14th OpenFOAM Workshop, Duisburg, Germany, 23–26 July 2019. [Google Scholar]

- Tolias, I.; Giannissi, S.; Venetsanos, A.; Keenan, J.; Shentsov, V.; Makarov, D.; Coldrick, S.; Kotchourko, A.; Ren, K.; Jedicke, O.; et al. Best practice guidelines in numerical simulations and CFD benchmarking for hydrogen safety applications. Int. J. Hydrogen Energy 2019, 44, 9050–9062. [Google Scholar] [CrossRef]

- Giannissi, S.; Hoyes, J.; Chernyavskiy, B.; Hooker, P.; Hall, J.; Venetsanos, A.; Molkov, V. CFD benchmark on hydrogen release and dispersion in a ventilated enclosure: Passive ventilation and the role of an external wind. Int. J. Hydrogen Energy 2015, 40, 6465–6477. [Google Scholar] [CrossRef]

- Matsuura, K.; Kanayama, H.; Tsukikawa, H.; Inoue, M. Numerical simulation of leaking hydrogen dispersion behavior in a partially open space. Int. J. Hydrogen Energy 2008, 33, 240–247. [Google Scholar] [CrossRef]

- Molkov, V.V.; Saffers, J.B. Introduction to Hydrogen Safety Engineering; Technical Report; Hydrogen Knowledge Centre: Derby, UK, 2011. [Google Scholar]

- Schefer, R.; Houf, W.; San Marchi, C.; Chernicoff, W.; Englom, L. Characterization of leaks from compressed hydrogen dispensing systems and related components. Int. J. Hydrogen Energy 2006, 31, 1247–1260. [Google Scholar] [CrossRef]

- Kotchourko, A.; Baraldi, D.; Bénard, P.; Jordan, T.; Keßler, A.; LaChance, J.; Steen, M.; Tchouvelev, A.V.; Wen, J.X. State-of-the-Art and Research Priorities in Hydrogen Safety; Technical Report; Hydrogen Knowledge Centre: Derby, UK, 2013. [Google Scholar]

- NFPA 2. NFPA 2: Hydrogen Technology Code; National Fire Protection Association: Quincy, MA, USA, 2016. [Google Scholar]

- FM Global. FM Global Property Loss Prevention Data Sheet 7–91: Hydrogen; Technical Report; FM Global: Johnston, RI, USA, 2020. [Google Scholar]

- Occupational Safety and Health Administration. 29 CFR §1910.103—Hydrogen; Safety and Health Association: Washington DC, USA, 2007. [Google Scholar]

- Jülich Supercomputing Centre. JURECA: Data Centric and Booster Modules implementing the Modular Supercomputing Architecture at Jülich Supercomputing Centre. J. Large-Scale Res. Facil. 2021, 7. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yassin, K.; Kelm, S.; Reinecke, E.-A. Numerical Simulation of Dispersion and Ventilation of Hydrogen Clouds in Case of Leakage Inside a Large-Scale Industrial Building. Hydrogen 2025, 6, 40. https://doi.org/10.3390/hydrogen6020040

Yassin K, Kelm S, Reinecke E-A. Numerical Simulation of Dispersion and Ventilation of Hydrogen Clouds in Case of Leakage Inside a Large-Scale Industrial Building. Hydrogen. 2025; 6(2):40. https://doi.org/10.3390/hydrogen6020040

Chicago/Turabian StyleYassin, Khaled, Stephan Kelm, and Ernst-Arndt Reinecke. 2025. "Numerical Simulation of Dispersion and Ventilation of Hydrogen Clouds in Case of Leakage Inside a Large-Scale Industrial Building" Hydrogen 6, no. 2: 40. https://doi.org/10.3390/hydrogen6020040

APA StyleYassin, K., Kelm, S., & Reinecke, E.-A. (2025). Numerical Simulation of Dispersion and Ventilation of Hydrogen Clouds in Case of Leakage Inside a Large-Scale Industrial Building. Hydrogen, 6(2), 40. https://doi.org/10.3390/hydrogen6020040