New Heavy-Duty Sampling System for Hydrogen Refuelling Stations—Comparison of Impact of Light-Duty Versus Heavy-Duty Sampling Techniques on Hydrogen Fuel Quality

Abstract

1. Introduction

2. Materials and Methods

2.1. Sampling System Description

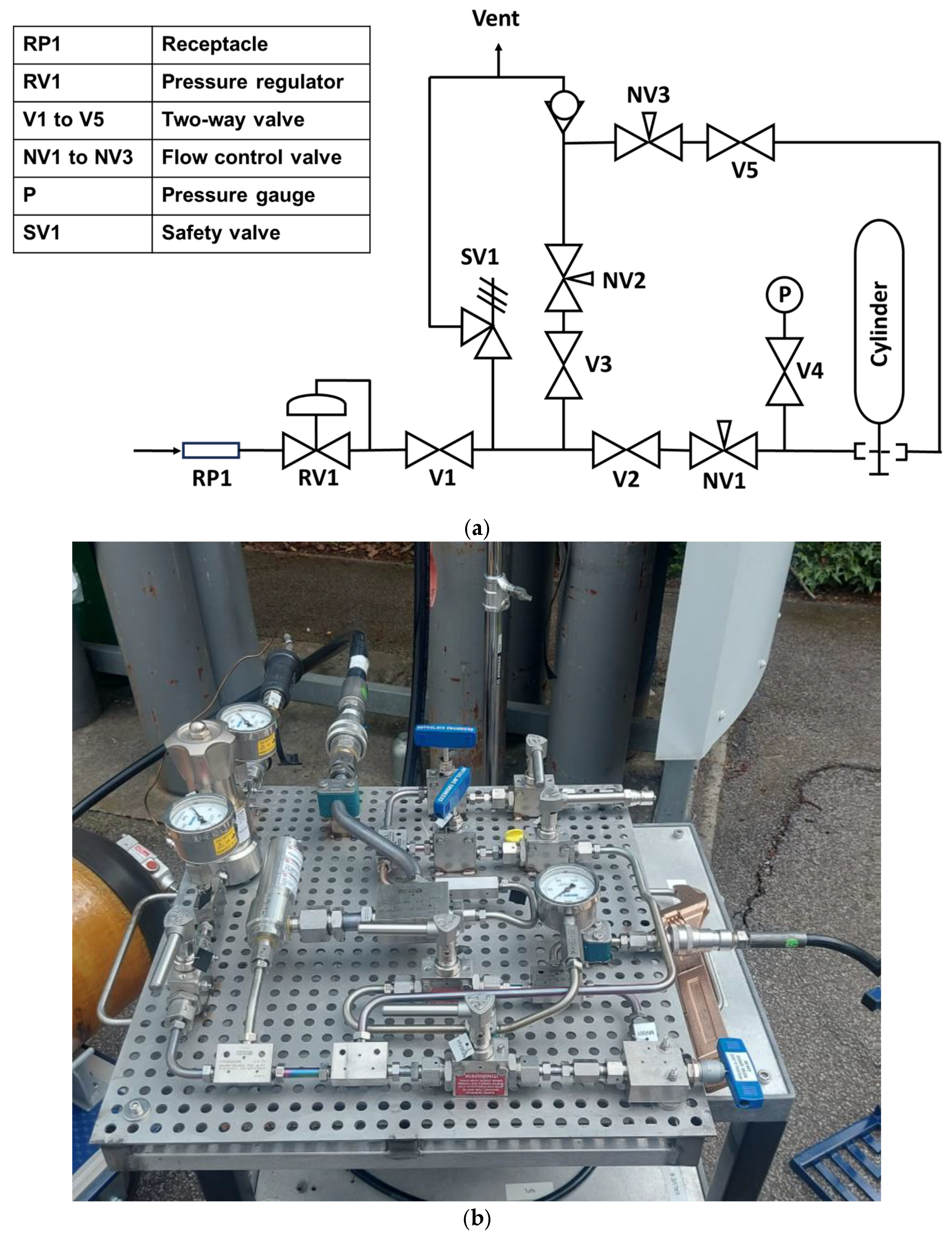

2.1.1. NPL Hydrogen Direct Sampling Apparatus (NPL DirSAM)

2.1.2. H2 Qualitizer

2.2. Hydrogen Refuelling Station Sampling Study

2.3. Analytical Methods

3. Results and Discussion

3.1. Heavy-Duty Sampling Realisation

3.2. Hydrogen Fuel Quality Results

3.3. Implications for Hydrogen for Transport Fuelling Infrastructure

4. Conclusions

- Formic acid, ammonia, formaldehyde, and total halogenated compounds show agreement between the two sampling systems (below the limit of detection).

- Sulphur compounds, non-methane hydrocarbons, and carbon dioxide show significantly lower amounts in the DirSAM sampling compared to the H2 Qualitizer. The agreement in terms of oxygen and carbon monoxide suggests the differences may not be due to the sampling systems but are likely related to the HD and LD processes in the HRS.

- A significant difference in the water concentration was observed, likely due to the precooling of hydrogen for LD refuelling, which removes water, unlike the ambient temperature used in HD fuelling.

- HD HRS sampling without requiring an FCEV or mock-up tank.

- It demands a more complex setup and station downtime.

- In contrast, the H2 Qualitizer offers a simpler and more efficient solution for LD HRS sampling but cannot be used for HD sampling.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| FCEV | Fuel cell electric vehicle |

| NPL DirSAM | National Physical Laboratory hydrogen direct sampling |

| HD | Heavy duty |

| LD | Light duty |

| HRS | Hydrogen refuelling station |

| PEMFC | Proton-exchange membrane fuel cell |

| GC | Gas chromatography |

| MS | Mass spectrometry (MS) |

| RP | Receptacle |

| PRM | Primary reference material |

References

- Chakraborty, S.; Dash, S.K.; Elavarasan, R.M.; Kaur, A.; Elangovan, D.; Meraj, S.T.; Kasinathan, P.; Said, Z. Hydrogen energy as future of sustainable mobility. Front. Energy Res. 2022, 10, 893475. [Google Scholar] [CrossRef]

- Guilbert, D.; Vitale, G. Hydrogen as a clean and sustainable energy vector for global transition from fossil-based to zero-carbon. Clean Technol. 2021, 3, 881–909. [Google Scholar] [CrossRef]

- Ampah, J.D.; Jin, C.; Afrane, S.; Yusuf, A.A.; Liu, H.; Yao, M. Race towards net zero emissions (NZE) by 2050: Reviewing a decade of research on hydrogen-fuelled internal combustion engines (ICE). Green Chem. 2024, 26, 9025–9047. [Google Scholar] [CrossRef]

- Agyekum, E.B.; Odoi-Yorke, F.; Abbey, A.A.; Ayetor, G.K. A review of the trends, evolution, and future research prospects of hydrogen fuel cells–A focus on vehicles. Int. J. Hydrogen Energy 2024, 72, 918–939. [Google Scholar] [CrossRef]

- Rahman, M.M.; Omeiza, L.A.; Subramanian, Y.; Azad, A.K. Role of Hydrogen in Polymer Electrolyte Membrane Fuel Cells. In Hydrogen Utilization in Fuel Cells, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2024; pp. 240–252. [Google Scholar]

- Borup, R.; Meyers, J.; Pivovar, B.; Kim, Y.S.; Mukundan, R.; Garland, N.; Myers, D.; Wilson, M.; Garzon, F.; Wood, D.; et al. Scientific aspects of polymer electrolyte fuel cell durability and degradation. Chem. Rev. 2007, 107, 3904–3951. [Google Scholar] [CrossRef] [PubMed]

- ISO 14687:2019; Hydrogen Fuel Quality—Product Specification. International Organization for Standardization: Geneva, Switzerland, 2019.

- Beurey, C.; Gozlan, B.; Carré, M.; Bacquart, T.; Morris, A.; Moore, N.; Arrhenius, K.; Meuzelaar, H.; Persijn, S.; Rojo, A.; et al. Review and survey of methods for analysis of impurities in hydrogen for fuel cell vehicles according to ISO 14687:2019. Front. Energy Res. 2021, 8, 615149. [Google Scholar] [CrossRef]

- Sorensen, B. Hydrogen and Fuel Cells: Emerging Technologies and Applications; Elsevier: Amsterdam, The Netherlands, 2011. [Google Scholar]

- Hassan, Q.; Azzawi, I.D.J.; Sameen, A.Z.; Salman, H.M. Hydrogen fuel cell vehicles: Opportunities and challenges. Sustainability 2023, 15, 11501. [Google Scholar] [CrossRef]

- Bender, G.; Angelo, M.; Bethune, K.; Rocheleau, R. Quantitative analysis of the performance impact of low-level carbon monoxide exposure in proton exchange membrane fuel cells. J. Power Sources 2013, 228, 159–169. [Google Scholar] [CrossRef]

- Cheng, X.; Shi, Z.; Glass, N.; Zhang, L.; Zhang, J.; Song, D.; Liu, Z.-S.; Wang, H.; Shen, J. A review of PEM hydrogen fuel cell contamination: Impacts, mechanisms, and mitigation. J. Power Sources 2007, 165, 739–756. [Google Scholar] [CrossRef]

- Shi, W.; Yi, B.; Hou, M.; Shao, Z. The effect of H2S and CO mixtures on PEMFC performance. Int. J. Hydrogen Energy 2007, 32, 4412–4417. [Google Scholar] [CrossRef]

- Matsuda, Y.; Shimizu, T.; Mitsushima, S. Adsorption behavior of low concentration carbon monoxide on polymer electrolyte fuel cell anodes for automotive applications. J. Power Sources 2016, 318, 1–8. [Google Scholar] [CrossRef]

- Sadeq, A.M.; Homod, R.Z.; Hussein, A.K.; Togun, H.; Mahmoodi, A.; Isleem, H.F.; Patil, A.R.; Moghaddam, A.H. Hydrogen energy systems: Technologies; trends; future prospects. Sci. Total Environ. 2024, 939, 173622. [Google Scholar] [CrossRef] [PubMed]

- Arrhenius, K.; Aarhaug, T.; Bacquart, T.; Morris, A.; Bartlett, S.; Wagner, L.; Blondeel, C.; Gozlan, B.; Lescornez, Y.; Chramosta, N.; et al. Strategies for the sampling of hydrogen at refuelling stations for purity assessment. Int. J. Hydrogen Energy 2021, 46, 34839–34853. [Google Scholar] [CrossRef]

- Bacquart, T.; Moore, N.; Storms, W.; Chramosta, N.; Morris, A.; Murugan, A.; Gozlan, B.; Lescornez, Y.; Férat, S.; Pinte, G.; et al. Hydrogen fuel quality for transport–First sampling and analysis comparison in Europe on hydrogen refuelling station (70 MPa) according to ISO 14687 and EN 17124. Fuel Commun. 2021, 6, 100008. [Google Scholar] [CrossRef]

- Murugan, A.; de Huu, M.; Bacquart, T.; van Wijk, J.; Arrhenius, K.; te Ronde, I.; Hemfrey, D. Measurement challenges for hydrogen vehicles. Int. J. Hydrogen Energy 2019, 44, 19326–19333. [Google Scholar] [CrossRef]

- Brown, A.S.; Murugan, A.; Brown, R.J.C. Measurement of ‘total halogenated compounds’ in hydrogen: Is the ISO 14687 specification achievable? Accredit. Qual. Assur. 2015, 20, 223–227. [Google Scholar] [CrossRef]

- Fernicola, V.C. Review of Sampling Strategy and Requirements for Hydrogen Quality Analysis. Available online: https://met4h2.eu/wp-content/uploads/2024/12/NPL-report-Sampling-requirements-for-hydrogen-sampling-A3.1.1-and-A3.1.2_rev1.pdf (accessed on 2 May 2025).

- Bacquart, T.; Moore, N.; Hart, N.; Morris, A.; Aarhaug, T.A.; Kjos, O.; Aupretre, F.; Colas, T.; Haloua, F.; Gozlan, B.; et al. Hydrogen quality sampling at the hydrogen refuelling station—Lessons learnt on sampling at the production and at the nozzle. Int. J. Hydrogen Energy 2020, 45, 5565–5576. [Google Scholar] [CrossRef]

- Smith, I.M. Software for Determining Polynomial Calibration Functions by Generalised Least Squares: User Manual, Developed by the National Physical Laboratory (NPL); National Physical Laboratory (NPL): Teddington, UK, December 2010. Available online: https://eprintspublications.npl.co.uk/4830/1/ms11.pdf (accessed on 12 March 2025).

- Linsinger, T. Comparison of a measurement result with the certified value. Eur. Ref. Mater. 2005, 7, 1–2. [Google Scholar]

- ISO/DIS 19880-2; Gaseous Hydrogen—Fuelling Stations Part 2: Dispensers and Dispensing Systems. International Organization for Standardization: Geneva, Switzerland, 2025. Available online: https://www.iso.org/obp/ui/#iso:std:iso:19880:-2:dis:ed-1:v1:en (accessed on 27 March 2025).

- ISO 19880-9:2024; Gaseous Hydrogen—Fuelling Stations Part 9: Sampling for Fuel Quality Analysis. International Organization for Standardization: Geneva, Switzerland, 2024. Available online: https://www.iso.org/obp/ui/es/#iso:std:iso:19880:-9:en (accessed on 27 March 2025).

- Spitta, C.; Optenhostert, T.; Aarhaug, T. Impurities Beyond the Scope of ISO 14687. 2019. Available online: https://www.sintef.no/globalassets/projectweb/metrohyve-2/3-4-metrohydraite-impurities_zbt_hydraite.pdf (accessed on 24 March 2025).

- Hsu, J.P. Recommended pre-operation cleanup procedures for hydrogen fueling station. Int. J. Hydrogen Energy 2012, 37, 1770–1780. [Google Scholar] [CrossRef]

| Component | Analytical Instrument Used | Limit of Detection [µmol/mol] |

|---|---|---|

| Nitrogen | Gas chromatography pulsed discharge helium ionization detector (GC-PDHID) | 0.16 |

| Argon | 0.16 | |

| Helium | Micro gas chromatography with thermal conductivity detector (micro-GC-TCD) | 3.65 |

| Oxygen | Gas chromatography thermal conductivity detector (GC-TCD) | 2.10 |

| Water | Cavity ring-down spectroscopy (CRDS) | 0.015 |

| Carbon dioxide | Gas chromatography flame ionization detector methanizer (GC-FID-Methanizer) | 0.002 |

| Methane | 0.005 | |

| Non-methane hydrocarbons | 0.010 | |

| Carbon monoxide | Gas chromatography pulsed discharge helium ionization detector (GC-PDHID) | 0.006 |

| Formic acid | Optical feedback cavity-enhanced absorption spectroscopy (OFCEAS) | 0.007 |

| Ammonia | 0.002 | |

| Formaldehyde | 0.005 | |

| Halogenated compounds | Thermal desorption gas chromatography mass spectrometry flame ionization detector (TD-GC-MS-FID) | 0.00012 |

| Total sulphur compounds | Gas chromatography sulphur chemiluminescence detector (GC-SCD) | 0.018 |

| Component | Sampling Type | NPL DirSAM | Qualitizer | Difference | Uncertainty of Difference | Significance |

|---|---|---|---|---|---|---|

| Cylinder Reference | D923893 | D258908 | ||||

| ISO 14687:2019 Grade D (µmol/mol) | Measured Amount Fraction and Uncertainty (k = 2) [µmol/mol] | |||||

| Nitrogen | 300 | 1.94 ± 0.11 | 1.50 ± 0.08 | 0.44 | 0.136 | Significant |

| Argon | 300 | <0.16 | <0.16 | n.a. | n.a | |

| Helium | 300 | <5 | <5 | n.a. | n.a | |

| Oxygen | 5 | 188.2 ± 3.7 | 188.1 ± 3.1 | 0.1 | 4.8 | Not significant |

| Water | 5 | 13.3 ± 1.0 | 2.73 ± 0.20 | 10.57 | 1.02 | Significant |

| Carbon dioxide | 2 | 0.075 ± 0.008 | 0.134 ± 0.013 | 0.059 | 0.015 | Significant |

| Methane | 100 | <0.010 | <0.010 | n.a. | n.a | |

| Non-methane hydrocarbons | 2 | <0.02 | 0.155 ± 0.019 | n.a. | n.a | |

| Carbon monoxide | 0.2 | 0.0095 ± 0.0024 | 0.0128 ± 0.0027 | 0.0033 | 0.0036 | Not significant |

| Formic acid | 0.2 | <0.007 | <0.007 | n.a. | n.a | |

| Ammonia | 0.1 | <0.010 | <0.010 | n.a. | n.a | |

| Formaldehyde | 0.2 | <0.005 | <0.005 | n.a. | n.a | |

| Halogenated compounds | 0.05 | <0.018 | <0.018 | n.a. | n.a | |

| Total sulphur compounds | 0.004 | <0.0007 | 0.00219 ± 0.00037 | n.a. | n.a | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Enakonda, L.R.; Bacquart, T.; Khaki, S.; Zhang, F.; Kerr, H.; Longhurst, B.; Morris, A.S.O. New Heavy-Duty Sampling System for Hydrogen Refuelling Stations—Comparison of Impact of Light-Duty Versus Heavy-Duty Sampling Techniques on Hydrogen Fuel Quality. Hydrogen 2025, 6, 35. https://doi.org/10.3390/hydrogen6020035

Enakonda LR, Bacquart T, Khaki S, Zhang F, Kerr H, Longhurst B, Morris ASO. New Heavy-Duty Sampling System for Hydrogen Refuelling Stations—Comparison of Impact of Light-Duty Versus Heavy-Duty Sampling Techniques on Hydrogen Fuel Quality. Hydrogen. 2025; 6(2):35. https://doi.org/10.3390/hydrogen6020035

Chicago/Turabian StyleEnakonda, Linga Reddy, Thomas Bacquart, Shirin Khaki, Fangyu Zhang, Hannah Kerr, Benjamin Longhurst, and Abigail S. O. Morris. 2025. "New Heavy-Duty Sampling System for Hydrogen Refuelling Stations—Comparison of Impact of Light-Duty Versus Heavy-Duty Sampling Techniques on Hydrogen Fuel Quality" Hydrogen 6, no. 2: 35. https://doi.org/10.3390/hydrogen6020035

APA StyleEnakonda, L. R., Bacquart, T., Khaki, S., Zhang, F., Kerr, H., Longhurst, B., & Morris, A. S. O. (2025). New Heavy-Duty Sampling System for Hydrogen Refuelling Stations—Comparison of Impact of Light-Duty Versus Heavy-Duty Sampling Techniques on Hydrogen Fuel Quality. Hydrogen, 6(2), 35. https://doi.org/10.3390/hydrogen6020035