Abstract

The hydrogen fuel quality is critical to the efficiency and longevity of fuel cell electric vehicles (FCEVs), with ISO 14687:2019 grade D establishing stringent impurity limits. This study compared two different sampling techniques for assessing the hydrogen fuel quality, focusing on the National Physical Laboratory hydrogen direct sampling apparatus (NPL DirSAM) from a 35 MPa heavy-duty (HD) dispenser and qualitizer sampling from a 70 MPa light-duty (LD) nozzle, both of which were deployed on the same day at a local hydrogen refuelling station (HRS). The collected samples were analysed as per the ISO 14687:2019 contaminants using the NPL H2-quality laboratory. The NPL DirSAM was able to sample an HD HRS, demonstrating the ability to realise such sampling on an HD nozzle. The comparison of the LD (H2 Qualitizer sampling) and HD (NPL DirSAM) devices showed good agreement but significant variation, especially for sulphur compounds, non-methane hydrocarbons and carbon dioxide. These variations may be related to the HRS difference between the LD and HD devices (e.g., flow path, refuelling conditions and precooling for light duty versus no precooling for heavy duty). Further study of HD and LD H2 fuel at HRSs is needed for a better understanding.

1. Introduction

Hydrogen is increasingly regarded as a critical enabler of the transition to sustainable energy, particularly in the transportation sector, including fuel cell electric vehicles (FCEVs) [1,2,3,4]. However, its effectiveness depends on its purity, as contaminants can degrade fuel cells and shorten their lifespan. The ISO 14687:2019 standard sets strict limits on contaminants like carbon monoxide, sulphur compounds, and ammonia, which can harm fuel cell performance [5,6,7,8,9,10]. In automotive applications, even a trace amount of carbon monoxide can cause severe catalyst poisoning, and it leads to the potential failure of proton-exchange membrane fuel cells (PEMFCs). In stationary applications, such as power generation and industrial processes, ultra-pure hydrogen is essential to prevent damage and maintain the efficiency of fuel cells. Impurities can lead to carbon buildup, acidic byproducts, and reduced electrolytic efficiency, and it further increases the operational costs [11,12,13,14,15]. To ensure the reliability and economic viability, hydrogen refuelling infrastructure must include accurate sampling and analytical systems to monitor and verify the hydrogen fuel quality in real time. These monitoring systems are critical to ensuring that the hydrogen fuel supplied to vehicles and stationary systems adheres to the ISO 14687:2019 standard, which sets strict limits on the permissible impurities, thus guaranteeing the performance and longevity of fuel cell systems (ISO 14687:2019).

Hydrogen sampling at a hydrogen refuelling station (HRS) is a complex engineering realisation, as the sampling system needs to support large variations in the pressure, flow and temperature while ensuring the hydrogen fuel sampled is homogeneous and representative [16]. While a light-duty HRS may operate from 0 to 70 MPa, with a flow of up to 60 g/s and a temperature down to T40 (approximately −40 degrees Celsius), current heavy-duty HRSs refill from 0 to 35 MPa but at a much higher flow 0–120 g/s and often at an ambient temperature. The connections between the nozzle and the receptacle are not compatible to avoid safety issues. Therefore, a light-duty sampler cannot be used for heavy-duty operation without engineering modifications. Light-duty (LD) sampling has been reviewed by Arrhenius et al. [16] and studied experimentally, bringing about a good understanding of the current setup [17]. Beurey et al. [8] and Arrhenius et al. [16] reviewed the adaptation of hydrogen sampling systems to evolving HRS requirements, underscoring the importance of robust, reliable techniques for assessing particulate and gas-phase impurities in hydrogen.

Murugan and his team’s exploration of the metrological developments in terms of hydrogen quality assessment has helped shape the technical foundation for H2 quality assurance in fuel cell applications [18]. This includes the critical use of gas chromatography (GC), mass spectrometry (MS), and optical spectroscopy for analysing trace impurities in hydrogen at concentrations relevant to fuel cell operation [8,19]. These systems play a crucial role in ensuring that the hydrogen delivered to both vehicles and stationary energy systems meets the purity requirements for long-term and efficient operation.

Due to the lack of heavy-duty (HD) sampling systems for HRSs, an assumption was made concerning the possible equivalence of the hydrogen fuel quality between LD and HD nozzles. To verify the assumption, advanced sampling methods such as the novel National Physical Laboratory heavy-duty direct sampling system (NPL DirSAM) have been developed and compared to the qualitizer sampling system, which is considered a reference for light-duty HRS sampling in this study [20]. These systems provide a portable, field-based solution for monitoring the hydrogen quality in a way that meets the high standards set for both automotive and stationary applications. The NPL DirSAM sampling kit allows for the direct collection of hydrogen samples without contamination, making it ideal for use in HD or LD HRS stations, whereas the qualitizer sampling system realises parallel sampling during an FCEV refuel. It has been used as a benchmark sampling system for LD HRSs in most European projects.

This research aims to compare the effectiveness and practicality of two advanced sampling methods—the NPL DirSAM sampling kit and the qualitizer sampling system—deployed on the same day at a local hydrogen refuelling station using a heavy-duty nozzle, with the samples being analysed using ISO-14687-compliant methods. This study presents the different sampling systems, the result of the comparison and its implications for FCEV fuel quality sampling.

2. Materials and Methods

2.1. Sampling System Description

2.1.1. NPL Hydrogen Direct Sampling Apparatus (NPL DirSAM)

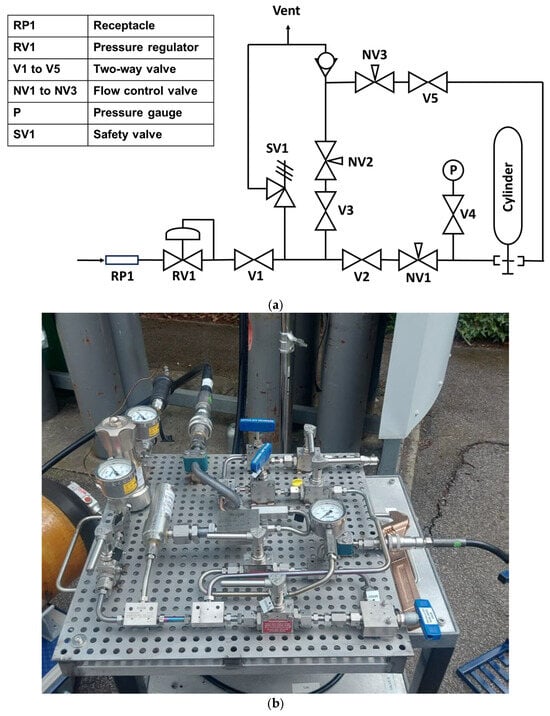

The NPL DirSAM follows the ASTM D7606 approach. This system applies a serial or direct sampling strategy in terms of the flow path. An FCEV is not required; however, the HRS needs to be in manual operation mode to realise the sampling. The NPL DirSAM is suitable for a high flow rate (up to 120 g/s). The schematic and a photo image of the system are provided in Figure 1a,b.

Figure 1.

(a) Schematic of the hydrogen fuel sampling system using a direct sampling strategy used by the National Physical Laboratory (NPL) and referred to as NPL DirSAM. (b) Image of the NPL DirSAM sampling system.

The HRS nozzle is connected to the sampler through high flow (HF) receptacle 1, indicated as RP1, with part number TN1 H2 HF (WEH, Illertissen, Bayern, Germany). The pressure of the gas is reduced from the HRS input pressure down to 100 bar by a regulator (TESCOM, Skelmersdale, UK). Then, a pressure relief valve (PRV) is present, with relief pressure of 175 bar. The gas can then be vented through a portable vent, sampled into a 10 L aluminium Luxfer SGS™ with a double-ended DIN 477 no. 1 valve (cylinder reference D923893) or flowed through the cylinder to a portable vent. The procedure involves at least 30 purges (cycling between valves V1 and V3) and the flowing of the sample gas through valves V1 and V3 for 20 s (V1, V2, V5 open). Finally, the cylinder is filled, and after the sampling, the pressure of the hydrogen gas in the cylinder is 90 barg. Additional venting and filling of the cylinder are realised to ensure a sufficient amount of gas is passed through the cylinder to obtain a representative sample (~0.5 kg). The flexible hoses from the panel to the sampling cylinder are high-pressure wire polyamide hoses (product 2440N, Parker, Coventry, United Kingdom).

2.1.2. H2 Qualitizer

For the comparative study, the qualitizer sampling followed the methodology described by Bacquart et al. [21]. The “H2 Qualitizer” sample was collected in a 10 L single-ended aluminium cylinder with a Performax passivation (EffecTech Ltd., Woking, UK) DIN 477 no. 1 valve. Prior to the sampling, the H2 Qualitizer was purged twice by pressurisation from the hydrogen in the HRS nozzle followed by depressurisation through the bleed valve. After the sampling, the pressure of the hydrogen gas in the cylinder was 60 barg, and the cylinder reference was D258908.

2.2. Hydrogen Refuelling Station Sampling Study

This study was realised at a European hydrogen refuelling station equipped with a light-duty (70 MPa nozzle, maximum flow: 60 g/s) and heavy-duty nozzle (35 MPa, maximum flow: 120 g/s) for hydrogen dispensing, which was selected to ensure representative field conditions during the sampling process. The hydrogen refuelling station was chosen based on its operational stability and the availability of a heavy-duty nozzle. Sampling was carried out during peak operational hours to ensure typical station conditions. Prior to performing the sampling using both sampling kits, the sampling cylinders were evacuated under a high vacuum (<1 × 10−6 mbar) using a custom NPL cylinder evacuation rig system, which was connected to a Leybold TMP 50 Kit vacuum pump. The NPL DirSAM and qualitizer sampling systems were deployed simultaneously at the hydrogen refuelling station, both connected to the relevant hydrogen refuelling nozzles. The NPL DirSAM was used on a heavy-duty nozzle set to nominal pressure of 35 MPa and a maximum flow of 120 g/s, and the H2 Qualitizer was used on a light-duty nozzle set to nominal pressure of 70 MPa and a maximum flow of 60 g/s.

Each system was set up in accordance with the NPL internal procedure to ensure optimal sampling conditions. The samples were taken directly from the refuelling nozzle at the dispensing point to reflect the real-time conditions. As the two samplings were realised within 1 h, the environment conditions were considered similar for both realisations. After collection, each sample was sealed and transported to the laboratory for analysis. The samples were transported in suitable containers to prevent contamination or loss of hydrogen. The cylinders were in good condition without damage on arrival at the laboratory and stored at room temperature before analysis.

2.3. Analytical Methods

The analyses were performed by the NPL’s hydrogen laboratory using NPL internal methods that were ISO-17025-accredited for N2, O2, Ar, CO, total sulphur, and H2O. All the listed analytical instruments in Table 1 were calibrated using the NPL PRMs in hydrogen matrix gas. The NPL gravimetric gas standards (NPL, Teddington, UK) and/or dynamic standards were used to generate calibration curves covering both the EN 17124 and the ISO 14687 amount fraction thresholds and the measured values from the samples. The dynamic standards were prepared by dilution of the NPL PRM with high-purity hydrogen (BIP+ quality, Air Products, Walton-on-Thames, UK) using calibrated mass flow controller systems (Bronkhorst, Veenendaal, the Netherlands). All the data were examined so that no results were discarded without a valid technical reason. The calibration curve, results of the analysis, and associated uncertainties were determined using the NPL software XLGENLINE version 2 [22]. An expanded uncertainty using a k value of 2 was used for all the results. In some cases, a more conservative uncertainty was derived from an analytical expert’s knowledge. The significant differences observed between the HD and LD nozzles were calculated at a 95% confidence level according to ERM Application Note 1 [23].

Table 1.

Analytical instruments used for the analysis of impurities in the H2 analysis and the limits of detection.

3. Results and Discussion

3.1. Heavy-Duty Sampling Realisation

Hydrogen fuel sampling systems for heavy-duty HRSs are not commercially available and have limited technical demonstration in the literature [16]. Light-duty sampling systems for HRSs are well known and have been used for several comparisons [17]. However, the geometry of the nozzle and receptacle does not allow for a system designed for sampling from a light-duty HRS to be used to sample a heavy-duty HRS [24].

The NPL DirSAM sampling system was designed using a direct sampling strategy [25]. The advantage of the NPL DirSAM is that it allows for light-duty sampling, heavy-duty sampling and other non-receptacle points of sampling through an exchangeable receptacle using a quick connection. As the system does not require an FCEV or mock-up tank, it allows the sampling of HRSs at commissioning or outside normal operations. However, it requires the station to be put in maintenance mode by the HRS operation team. The NPL DirSAM sampling system is effective and has a more involved procedure for setup, purging and sample collection, requiring additional time and expertise to ensure accurate results. This could be a potential drawback for stations with limited resources or those in need of high-frequency sampling. In comparison, the qualitizer sampling kit was found to be easier and quicker to deploy, requiring minimal training for refuelling station staff. As the H2 Qualitizer operates using a normal filling protocol, no support from the HRS operation team is required. However, it cannot perform heavy-duty HRS sampling and no engineering modification was planned to accommodate heavy-duty sampling.

This study demonstrated that the NPL DirSAM was able to realise sampling at an HD HRS under normal operation (35 MPa and flow up to 120 g/s). From a practical perspective, both sampling systems performed well in the real-world setting of a hydrogen refuelling station. For practical reasons, it may have been assumed that a light-duty HRS sampling may be representative of the fuel delivered by the heavy-duty nozzle of the same HRS. As there was a lack of HD HRS sampling systems, it was the solely available technical solution to monitor the HD HRS fuel quality. This study presents the first HD HRS sampling and its comparison with an LD HRS sampling using two hydrogen fuel sampling techniques (NPL DirSAM and H2 Qualitizer). The following section presents the results of these assessments, followed by a discussion of the implications of these findings for hydrogen fuel quality for automotive applications.

3.2. Hydrogen Fuel Quality Results

The HRS selected had a significant level of contaminants, which was extremely useful for comparing the two sampling methodologies. The actual compliance of the HRS with ISO 14687:2019 was not considered critical to this study. Even if the levels of key contaminants in the hydrogen fuel samples were mostly consistent with the stringent limits set forth by ISO 14687:2019 for FCEV fuel, several contaminants were found in measurable amounts: oxygen, sulphur compounds, nitrogen, carbon monoxide, carbon dioxide, water and non-methane hydrocarbons (see Table 2).

Table 2.

Results of the analysis of the HRS sampling system comparisons between the DirSAM and the H2 Qualitizer. The hydrogen fuel quality is presented with the values in bold when significantly different.

Some differences were observed between the two samplings, and the origin of the differences may be related to the sampling strategies or the actual HRS. The concentration of oxygen is over the 5 μmol/mol (ISO 14687 limit for oxygen). The NPL-DirSAM-sampled hydrogen fuel contains 188.2 μmol/mol oxygen, and the sample tested with the qualitizer contains 188.1 μmol/mol oxygen, and the CO levels are 0.0095 and 0.0128 μmol/mol in the hydrogen sampled with the NPL DirSAM and H2 Qualitizer, respectively. For oxygen and carbon monoxide, the two samplings agree (within the uncertainties). The amount fractions of H2O disagree, as the NPL DirSAM sample contains 13.3 μmol/mol, which is above 5 μmol/mol—the ISO 14687 threshold—whereas the sample tested with the qualitizer contains 2.73 μmol/mol (below the ISO 14687 threshold).

For reactive compounds (formic acid, ammonia, formaldehyde, halogenated), the two sampling systems agree too (below the limit of detection). For sulphur compounds, non-methane hydrocarbons or carbon dioxide, the DirSAM sampling results from the HD nozzle show a significantly lower amount fraction compared to the H2 Qualitizer from the LD nozzle. As the oxygen and carbon monoxide agreed, it is unlikely that it may be related to the sampling system but potentially to differences in the HRS HD and LD processes. The exact flow path may be different between the LD and HD devices. Some parts of the gas flow may affect the hydrogen fuel quality (valve, O-ring), which could change the amount fractions of sulphur, hydrocarbons and carbon dioxide [26,27]. Another significant difference is observed for water and may be related to the precooling of hydrogen to −33 °C to −40 °C (T40) for the light-duty refuelling while the heavy-duty fuelling is realised with hydrogen at an ambient temperature. It is expected that the precooling would act as a water removal step, which seems to agree with the results of the analysis.

This study demonstrates that the LD and HD devices are not comparable, as variation was observed on the same HRS in relation to the flow path or filling protocol (temperature difference between HD and LD fuelling). Therefore, it is not recommended to assume the equivalence of LD and HD sampling even for the same HRS at the same time.

3.3. Implications for Hydrogen for Transport Fuelling Infrastructure

The findings underscore the importance of accurate and reliable sampling techniques for ensuring the hydrogen fuel purity, especially as the adoption of fuel cell electric vehicles (FCEVs) continues to grow. As the contaminant levels, even at trace concentrations, can have significant impacts on the efficiency, durability, and overall performance of FCEVs, maintaining the hydrogen fuel purity in accordance with ISO 14687:2019 is essential for the long-term success of the FCEV sector, and therefore, the reliable sampling of hydrogen fuel at LD and HD sites is critical.

As highlighted in this study, LD and HD nozzles should be tested independently as they may present different hydrogen fuel quality. In this context, both the NPL DirSAM for an HD HRS and the H2 Qualitizer for an LD HRS sampling techniques represent valuable tools for HRS operators looking to adhere to fuel quality standards. The qualitizer system, with its ease of use and high reproducibility, is particularly well suited for routine checks, while the NPL DirSAM system may be more appropriate for heavy-duty sampling, commissioning or quality investigation (to avoid FCEV contamination) or large-scale monitoring where slightly more complexity is acceptable. Additionally, the NPL DirSAM is able to sample light-duty and heavy-duty HRSs with minimal hardware changes (exchange TN1 H2 with TN1 H2 HF).

Compared to continuous monitoring, both the NPL DirSAM and H2 Qualitizer systems offer more efficient and practical solutions for assessing the hydrogen fuel quality in accordance with ISO 14687. Cylinder sampling and laboratory analysis provide access to state-of-the-art analytical facilities with traceable standards, which are essential for comprehensive ISO 14687 analysis and investigation of unexpected events. While effective, cylinder sampling is labour-intensive and requires the transportation and storage of the collected samples, which can alter the gas composition over time and extend the operational timelines. Additionally, the type of cylinder used may influence the detection of low-level contaminants due to the potential adsorption on the cylinder surface or stability issues over time. Although continuous monitoring systems for ISO 14687 can provide real-time data, they come with higher maintenance costs and require continuous oversight, making them less practical and more expensive for full ISO 14687 compliance. However, for certain compounds, online analysis serves as a valuable tool for routine, day-to-day quality checks at hydrogen refuelling stations (HRS). Further research in this area may be beneficial.

4. Conclusions

This study highlights the importance of accurate hydrogen fuel sampling for both HD and LD HRSs. Some differences provided below were observed between the two samplings, and the origin of the differences may be related to the sampling strategies or the actual HRS.

- Formic acid, ammonia, formaldehyde, and total halogenated compounds show agreement between the two sampling systems (below the limit of detection).

- Sulphur compounds, non-methane hydrocarbons, and carbon dioxide show significantly lower amounts in the DirSAM sampling compared to the H2 Qualitizer. The agreement in terms of oxygen and carbon monoxide suggests the differences may not be due to the sampling systems but are likely related to the HD and LD processes in the HRS.

- A significant difference in the water concentration was observed, likely due to the precooling of hydrogen for LD refuelling, which removes water, unlike the ambient temperature used in HD fuelling.

It demonstrates that LD and HD samplings are not interchangeable due to the differences in the flow paths, fuelling protocols, and temperature variations.

The NPL DirSAM system effectively enables the following:

- HD HRS sampling without requiring an FCEV or mock-up tank.

- It demands a more complex setup and station downtime.

- In contrast, the H2 Qualitizer offers a simpler and more efficient solution for LD HRS sampling but cannot be used for HD sampling.

The preliminary results suggest a potential difference in the fuel quality between LD and HD hydrogen dispensed at HRSs, indicating that relying on LD fuel sampling to estimate the HD fuel quality is not reliable. These findings highlight the need for dedicated HD sampling systems. Further validation across multiple sites will be part of an upcoming broader sampling campaign using the NPL DirSAM sampler. Given the increasing adoption of FCEVs, ensuring hydrogen purity through appropriate sampling techniques is essential for maintaining fuel cell efficiency and durability

Author Contributions

Conceptualisation, T.B. and L.R.E.; methodology, T.B., L.R.E., S.K., F.Z. and A.S.O.M.; formal analysis, L.R.E., S.K., F.Z., H.K. and B.L.; investigation, T.B., L.R.E., S.K., F.Z. and A.S.O.M.; data curation, T.B., L.R.E., S.K., F.Z., H.K. and B.L.; writing—original draft preparation, L.R.E. and T.B.; writing—review and editing, L.R.E., T.B. and A.S.O.M.; supervision, T.B., L.R.E., S.K., F.Z. and A.S.O.M.; project administration, T.B.; funding acquisition, T.B. All authors have read and agreed to the published version of the manuscript.

Funding

This project was supported by the Clean Hydrogen Partnership and its members, including top-up funding from the Research Council of Norway and Innovate UK [grant number: 10072656]. The grant agreement is registered under the number 101101447. This Joint Undertaking received support from the Horizon Europe framework (Horizon JTI-CH-2022) research and innovation program and Hydrogen Europe.

Institutional Review Board Statement

Funded by the European Union. The views and opinions expressed are, however, those of the author(s) only and do not necessarily reflect those of the European Union or the Clean Hydrogen Joint Undertaking. Neither the European Union nor the granting authority can be held responsible for them.

Data Availability Statement

The original contributions presented in this study are included in the article; further inquiries can be directed to the corresponding authors.

Conflicts of Interest

The authors declare that this research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflicts of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| FCEV | Fuel cell electric vehicle |

| NPL DirSAM | National Physical Laboratory hydrogen direct sampling |

| HD | Heavy duty |

| LD | Light duty |

| HRS | Hydrogen refuelling station |

| PEMFC | Proton-exchange membrane fuel cell |

| GC | Gas chromatography |

| MS | Mass spectrometry (MS) |

| RP | Receptacle |

| PRM | Primary reference material |

References

- Chakraborty, S.; Dash, S.K.; Elavarasan, R.M.; Kaur, A.; Elangovan, D.; Meraj, S.T.; Kasinathan, P.; Said, Z. Hydrogen energy as future of sustainable mobility. Front. Energy Res. 2022, 10, 893475. [Google Scholar] [CrossRef]

- Guilbert, D.; Vitale, G. Hydrogen as a clean and sustainable energy vector for global transition from fossil-based to zero-carbon. Clean Technol. 2021, 3, 881–909. [Google Scholar] [CrossRef]

- Ampah, J.D.; Jin, C.; Afrane, S.; Yusuf, A.A.; Liu, H.; Yao, M. Race towards net zero emissions (NZE) by 2050: Reviewing a decade of research on hydrogen-fuelled internal combustion engines (ICE). Green Chem. 2024, 26, 9025–9047. [Google Scholar] [CrossRef]

- Agyekum, E.B.; Odoi-Yorke, F.; Abbey, A.A.; Ayetor, G.K. A review of the trends, evolution, and future research prospects of hydrogen fuel cells–A focus on vehicles. Int. J. Hydrogen Energy 2024, 72, 918–939. [Google Scholar] [CrossRef]

- Rahman, M.M.; Omeiza, L.A.; Subramanian, Y.; Azad, A.K. Role of Hydrogen in Polymer Electrolyte Membrane Fuel Cells. In Hydrogen Utilization in Fuel Cells, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2024; pp. 240–252. [Google Scholar]

- Borup, R.; Meyers, J.; Pivovar, B.; Kim, Y.S.; Mukundan, R.; Garland, N.; Myers, D.; Wilson, M.; Garzon, F.; Wood, D.; et al. Scientific aspects of polymer electrolyte fuel cell durability and degradation. Chem. Rev. 2007, 107, 3904–3951. [Google Scholar] [CrossRef] [PubMed]

- ISO 14687:2019; Hydrogen Fuel Quality—Product Specification. International Organization for Standardization: Geneva, Switzerland, 2019.

- Beurey, C.; Gozlan, B.; Carré, M.; Bacquart, T.; Morris, A.; Moore, N.; Arrhenius, K.; Meuzelaar, H.; Persijn, S.; Rojo, A.; et al. Review and survey of methods for analysis of impurities in hydrogen for fuel cell vehicles according to ISO 14687:2019. Front. Energy Res. 2021, 8, 615149. [Google Scholar] [CrossRef]

- Sorensen, B. Hydrogen and Fuel Cells: Emerging Technologies and Applications; Elsevier: Amsterdam, The Netherlands, 2011. [Google Scholar]

- Hassan, Q.; Azzawi, I.D.J.; Sameen, A.Z.; Salman, H.M. Hydrogen fuel cell vehicles: Opportunities and challenges. Sustainability 2023, 15, 11501. [Google Scholar] [CrossRef]

- Bender, G.; Angelo, M.; Bethune, K.; Rocheleau, R. Quantitative analysis of the performance impact of low-level carbon monoxide exposure in proton exchange membrane fuel cells. J. Power Sources 2013, 228, 159–169. [Google Scholar] [CrossRef]

- Cheng, X.; Shi, Z.; Glass, N.; Zhang, L.; Zhang, J.; Song, D.; Liu, Z.-S.; Wang, H.; Shen, J. A review of PEM hydrogen fuel cell contamination: Impacts, mechanisms, and mitigation. J. Power Sources 2007, 165, 739–756. [Google Scholar] [CrossRef]

- Shi, W.; Yi, B.; Hou, M.; Shao, Z. The effect of H2S and CO mixtures on PEMFC performance. Int. J. Hydrogen Energy 2007, 32, 4412–4417. [Google Scholar] [CrossRef]

- Matsuda, Y.; Shimizu, T.; Mitsushima, S. Adsorption behavior of low concentration carbon monoxide on polymer electrolyte fuel cell anodes for automotive applications. J. Power Sources 2016, 318, 1–8. [Google Scholar] [CrossRef]

- Sadeq, A.M.; Homod, R.Z.; Hussein, A.K.; Togun, H.; Mahmoodi, A.; Isleem, H.F.; Patil, A.R.; Moghaddam, A.H. Hydrogen energy systems: Technologies; trends; future prospects. Sci. Total Environ. 2024, 939, 173622. [Google Scholar] [CrossRef] [PubMed]

- Arrhenius, K.; Aarhaug, T.; Bacquart, T.; Morris, A.; Bartlett, S.; Wagner, L.; Blondeel, C.; Gozlan, B.; Lescornez, Y.; Chramosta, N.; et al. Strategies for the sampling of hydrogen at refuelling stations for purity assessment. Int. J. Hydrogen Energy 2021, 46, 34839–34853. [Google Scholar] [CrossRef]

- Bacquart, T.; Moore, N.; Storms, W.; Chramosta, N.; Morris, A.; Murugan, A.; Gozlan, B.; Lescornez, Y.; Férat, S.; Pinte, G.; et al. Hydrogen fuel quality for transport–First sampling and analysis comparison in Europe on hydrogen refuelling station (70 MPa) according to ISO 14687 and EN 17124. Fuel Commun. 2021, 6, 100008. [Google Scholar] [CrossRef]

- Murugan, A.; de Huu, M.; Bacquart, T.; van Wijk, J.; Arrhenius, K.; te Ronde, I.; Hemfrey, D. Measurement challenges for hydrogen vehicles. Int. J. Hydrogen Energy 2019, 44, 19326–19333. [Google Scholar] [CrossRef]

- Brown, A.S.; Murugan, A.; Brown, R.J.C. Measurement of ‘total halogenated compounds’ in hydrogen: Is the ISO 14687 specification achievable? Accredit. Qual. Assur. 2015, 20, 223–227. [Google Scholar] [CrossRef]

- Fernicola, V.C. Review of Sampling Strategy and Requirements for Hydrogen Quality Analysis. Available online: https://met4h2.eu/wp-content/uploads/2024/12/NPL-report-Sampling-requirements-for-hydrogen-sampling-A3.1.1-and-A3.1.2_rev1.pdf (accessed on 2 May 2025).

- Bacquart, T.; Moore, N.; Hart, N.; Morris, A.; Aarhaug, T.A.; Kjos, O.; Aupretre, F.; Colas, T.; Haloua, F.; Gozlan, B.; et al. Hydrogen quality sampling at the hydrogen refuelling station—Lessons learnt on sampling at the production and at the nozzle. Int. J. Hydrogen Energy 2020, 45, 5565–5576. [Google Scholar] [CrossRef]

- Smith, I.M. Software for Determining Polynomial Calibration Functions by Generalised Least Squares: User Manual, Developed by the National Physical Laboratory (NPL); National Physical Laboratory (NPL): Teddington, UK, December 2010. Available online: https://eprintspublications.npl.co.uk/4830/1/ms11.pdf (accessed on 12 March 2025).

- Linsinger, T. Comparison of a measurement result with the certified value. Eur. Ref. Mater. 2005, 7, 1–2. [Google Scholar]

- ISO/DIS 19880-2; Gaseous Hydrogen—Fuelling Stations Part 2: Dispensers and Dispensing Systems. International Organization for Standardization: Geneva, Switzerland, 2025. Available online: https://www.iso.org/obp/ui/#iso:std:iso:19880:-2:dis:ed-1:v1:en (accessed on 27 March 2025).

- ISO 19880-9:2024; Gaseous Hydrogen—Fuelling Stations Part 9: Sampling for Fuel Quality Analysis. International Organization for Standardization: Geneva, Switzerland, 2024. Available online: https://www.iso.org/obp/ui/es/#iso:std:iso:19880:-9:en (accessed on 27 March 2025).

- Spitta, C.; Optenhostert, T.; Aarhaug, T. Impurities Beyond the Scope of ISO 14687. 2019. Available online: https://www.sintef.no/globalassets/projectweb/metrohyve-2/3-4-metrohydraite-impurities_zbt_hydraite.pdf (accessed on 24 March 2025).

- Hsu, J.P. Recommended pre-operation cleanup procedures for hydrogen fueling station. Int. J. Hydrogen Energy 2012, 37, 1770–1780. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).