Effect of Hydrogen Co-Firing with Natural Gas on Thermal Efficiency and CO2 Emissions in Gas Turbine Power Plant

Abstract

1. Introduction

2. Materials and Methods

2.1. Case Description

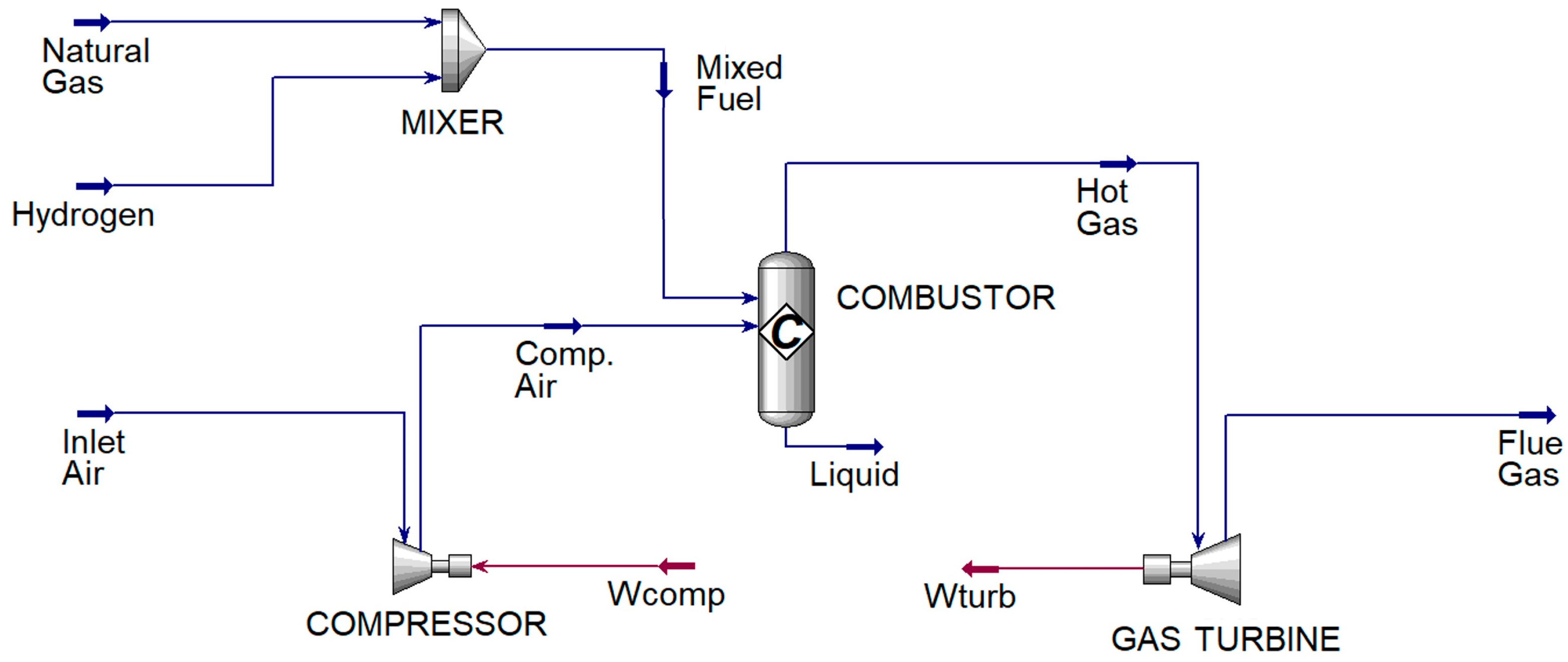

2.2. System Configuration

2.3. Software Modeling

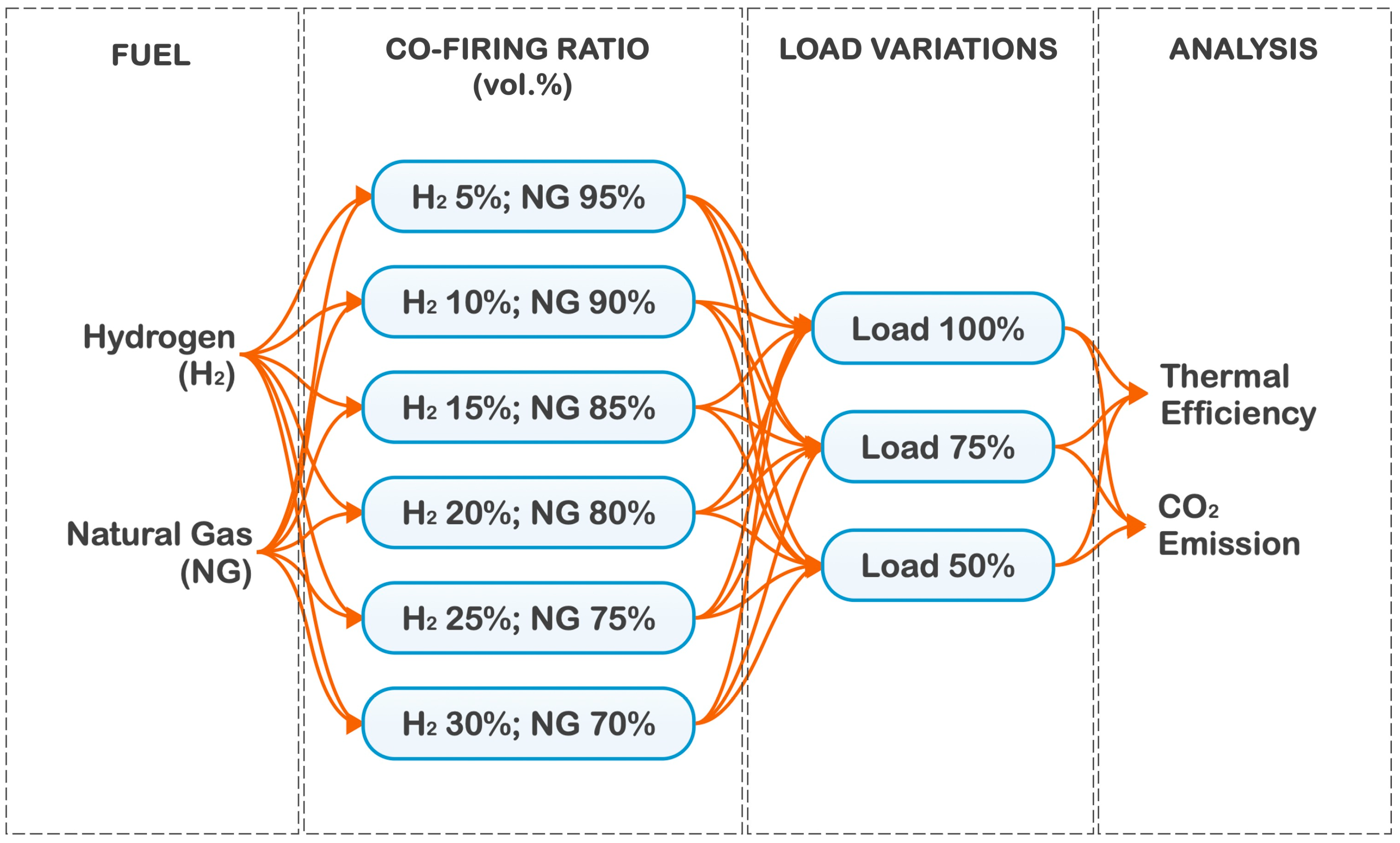

2.4. Co-Firing Parameter

2.5. Thermodynamic Analysis

2.6. Emission Analysis

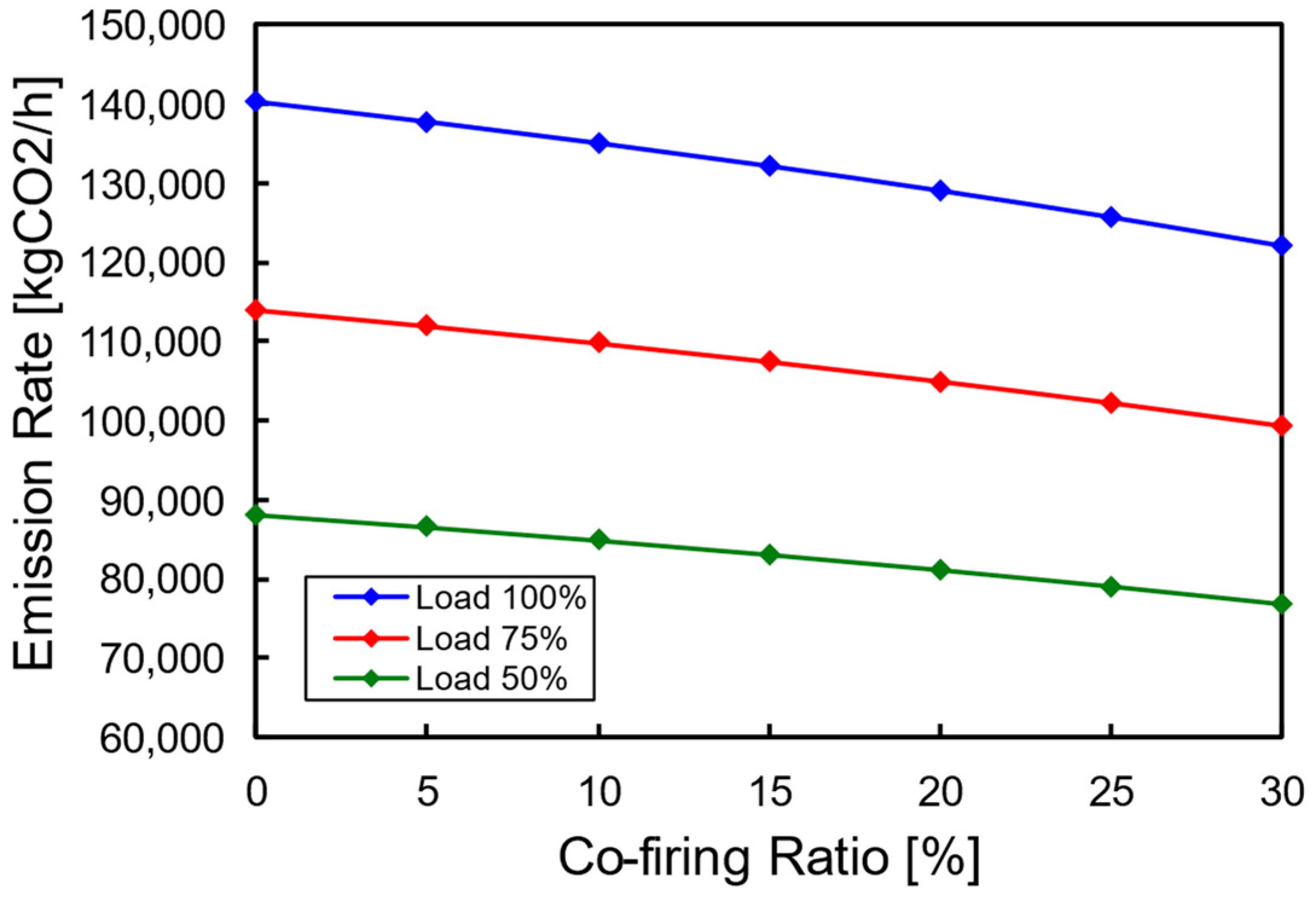

- The emission rate, which represents the total amount of CO2 emissions released over a specific period, is expressed in kg CO2/h.

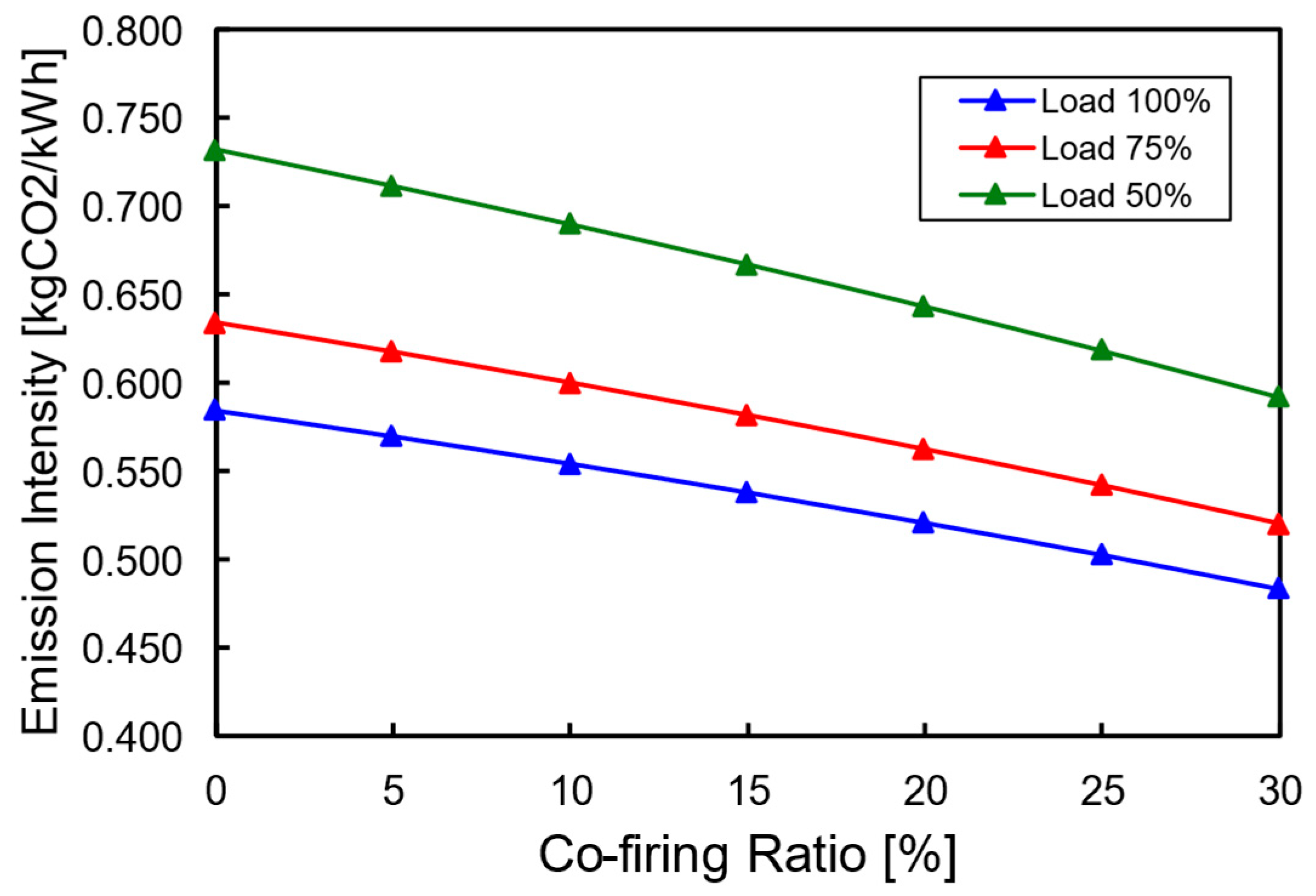

- The emission intensity, which indicates the amount of CO2 emissions per unit of electrical energy produced, is expressed in kg CO2/kWh.

3. Results and Discussion

3.1. Model Validation

3.2. Co-Firing Simulation Results

3.2.1. Effect of Hydrogen Co-Firing on the Compressor

3.2.2. Effect of Hydrogen Co-Firing on the Turbine

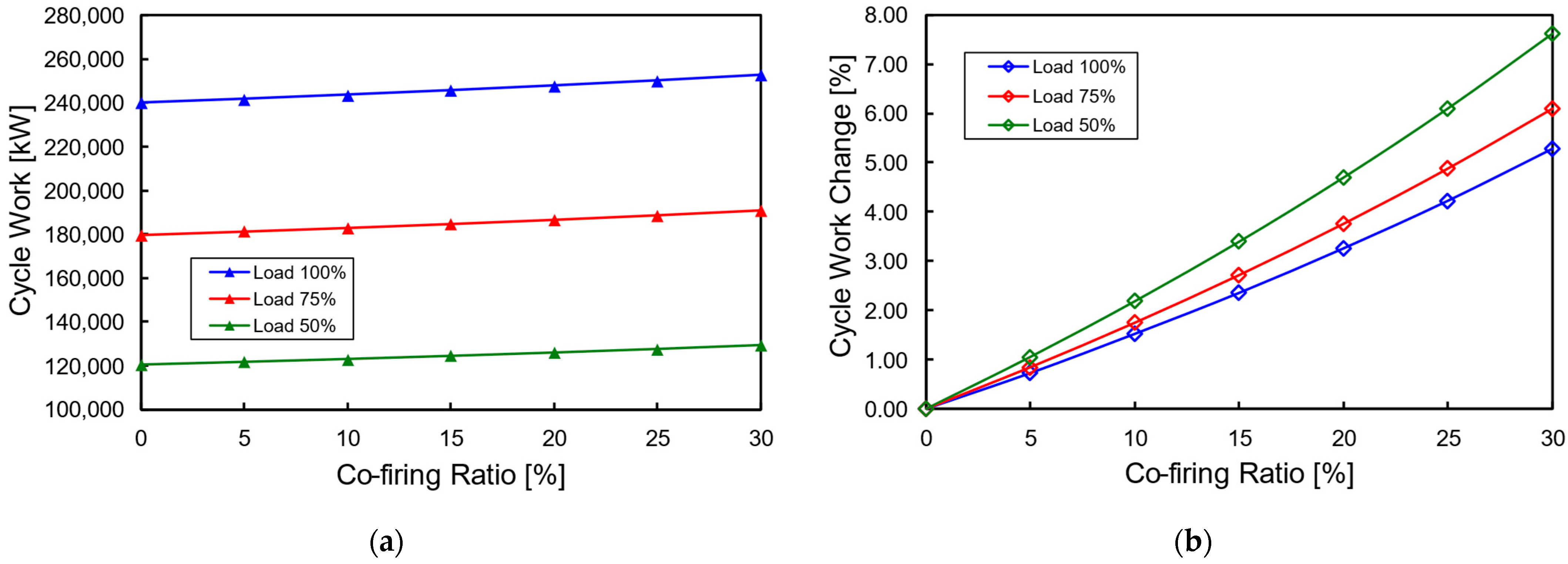

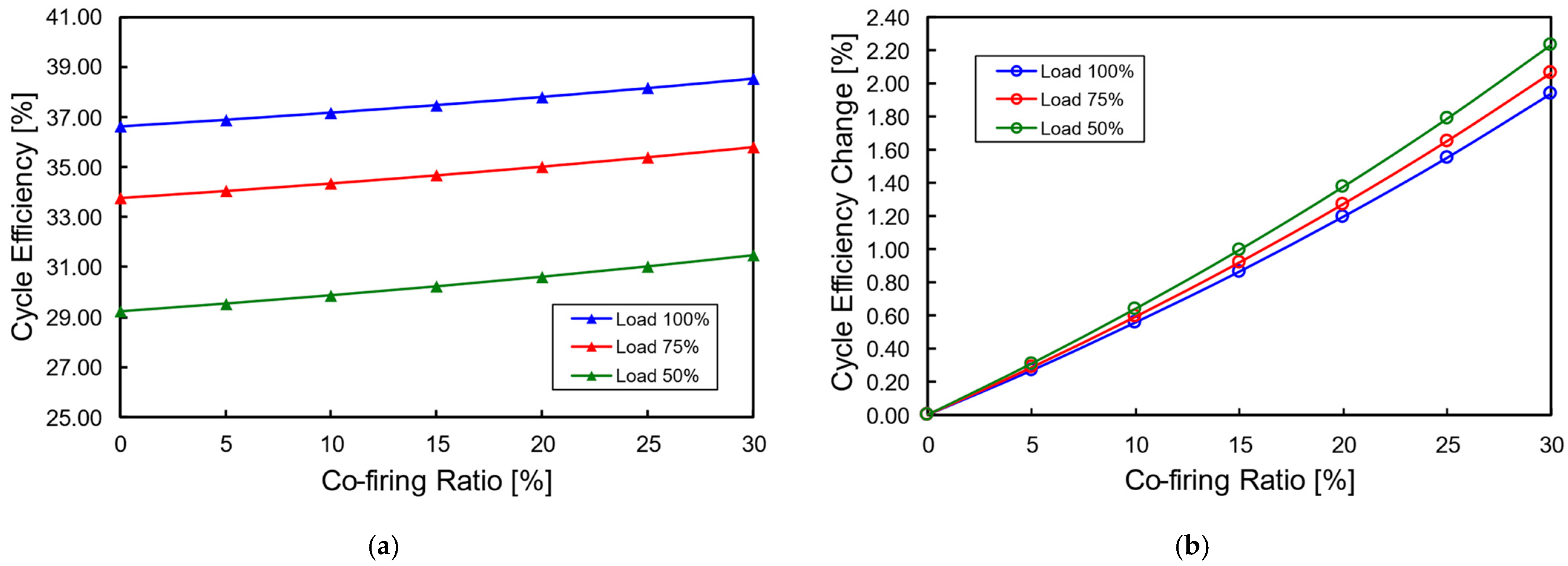

3.2.3. Effect of Hydrogen Co-Firing on the Cycle

3.2.4. Effect of Hydrogen Co-Firing on CO2 Emission

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- MEMR. Handbook of Energy & Economy Statistics of Indonesia 2022; Ministry of Energy and Mineral Resources Republic of Indonesia: Jakarta, Indonesia, 2023. [Google Scholar]

- IESR. Indonesia Energy Transition Outlook 2023: Tracking Progress of Energy Transition in Indonesia: Pursuing Energy Security in the Time of Transition; Institute for Essential Services Reform (IESR): Jakarta, Indonesia, 2022. [Google Scholar]

- Siregar, Y.I. Pathways Towards Net-Zero Emissions in Indonesia’s Energy Sector. Energy 2024, 308, 133014. [Google Scholar] [CrossRef]

- Bilgili, M.; Tumse, S.; Nar, S. Comprehensive Overview on the Present State and Evolution of Global Warming, Climate Change, Greenhouse Gasses and Renewable Energy. Arab. J. Sci. Eng. 2024, 49, 14503–14531. [Google Scholar] [CrossRef]

- Filonchyk, M.; Peterson, M.P.; Zhang, L.; Hurynovich, V.; He, Y. Greenhouse Gases Emissions and Global Climate Change: Examining the Influence of CO2, CH4, and N2O. Sci. Total Environ. 2024, 935, 173359. [Google Scholar] [CrossRef] [PubMed]

- Lamb, W.F.; Wiedmann, T.; Pongratz, J.; Andrew, R.; Crippa, M.; Olivier, J.G.J.; Wiedenhofer, D.; Mattioli, G.; Al Khourdajie, A.; House, J.; et al. A Review of Trends and Drivers of Greenhouse Gas Emissions by Sector from 1990 to 2018. Environ. Res. Lett. 2021, 16, 073005. [Google Scholar] [CrossRef]

- IPCC. 2006 IPCC Guidelines for National Greenhouse Gas Inventories; Eggleston, S., Buendia, L., Miwa, K., Ngara, T., Tanabe, K., Eds.; Institute for Global Environmental Strategies (IGES): Hayama, Japan, 2006; ISBN 4-88788-032-4. [Google Scholar]

- IESR. Climate Transparency Report 2022: Comparing G20 Climate Action; Institute for Essential Service Reform (IESR): Jakarta, Indonesia, 2022. [Google Scholar]

- MEMR. Electricity Statistics 2022, 36th ed.; Ministry of Energy and Mineral Resources Republic of Indonesia: Jakarta, Indonesia, 2023; ISBN 2829-0992. [Google Scholar]

- Karmellos, M.; Kopidou, D.; Diakoulaki, D. A Decomposition Analysis of the Driving Factors of CO2 (Carbon Dioxide) Emissions from the Power Sector in the European Union Countries. Energy 2016, 94, 680–692. [Google Scholar] [CrossRef]

- Wijayanto, T.; Hakam, D.F.; Kemala, P.N. Vision for Indonesia’s 2050 Power Generation: Scenarios of Hydrogen Integration, Nuclear Energy Prospects, and Coal Phase-Out Impact. Sustain. Futur. 2025, 9, 100438. [Google Scholar] [CrossRef]

- Febijanto, I.; Nadirah, N.; Rosmeika; Nugroho, A.S.; Guardi, A.; Yanuar, A.I.; Bahua, H.; Herdioso, R.; Sihombing, A.L.S.M.; Susila, I.M.A.D.; et al. Life Cycle Greenhouse Gas Emissions Assessment: Converting an Early Retirement Coal-Fired Power Plant to a Biomass Power Plant. Renew. Energy Focus 2024, 51, 100643. [Google Scholar] [CrossRef]

- IFHE; BRIN. Indonesia Hidrogen Roadmap; Indonesia Fuel Cell and Hydrogen Energy (IFHE): Banten, Indonesia; dan Badan Riset dan Inovasi Nasional (BRIN): Jakarta, Indonesia, 2023. [Google Scholar]

- Ahmad, A.H.; Darmanto, P.S.; Juangsa, F.B. Thermodynamic Study on Decarbonization of Combined Cycle Power Plant. J. Eng. Technol. Sci. 2023, 55, 613–626. [Google Scholar] [CrossRef]

- Jeong, J.H.; Park, H.S.; Park, Y.K.; Kim, T.S. Analysis of the Influence of Hydrogen Co-Firing on the Operation and Performance of the Gas Turbine and Combined Cycle. Case Stud. Therm. Eng. 2024, 54, 104061. [Google Scholar] [CrossRef]

- Speight, J.G. Natural Gas: A Basic Handbook, 2nd ed.; Gulf Professional Publishing: Cambridge, MA, USA, 2019; ISBN 978-0-12-809570-6. [Google Scholar]

- Boretti, A. Phased Transition from Methane to Hydrogen in Internal Combustion Engines: Utilizing Hythane and Direct Injection Jet Ignition for Enhanced Efficiency and Reduced Emissions. Int. J. Hydrogen Energy 2024, 80, 1255–1265. [Google Scholar] [CrossRef]

- Ihsan Shahid, M.; Rao, A.; Farhan, M.; Liu, Y.; Ahmad Salam, H.; Chen, T.; Ma, F. Hydrogen Production Techniques and Use of Hydrogen in Internal Combustion Engine: A Comprehensive Review. Fuel 2024, 378, 132769. [Google Scholar] [CrossRef]

- Le, O.; Loubar, K. Natural Gas: Physical Properties and Combustion Features. In Natural Gas; IntechOpen: London, UK, 2010. [Google Scholar] [CrossRef]

- Algayyim, S.J.M.; Saleh, K.; Wandel, A.P.; Fattah, I.M.R.; Yusaf, T.; Alrazen, H.A. Influence of Natural Gas and Hydrogen Properties on Internal Combustion Engine Performance, Combustion, and Emissions: A Review. Fuel 2024, 362, 130844. [Google Scholar] [CrossRef]

- Dawood, F.; Anda, M.; Shafiullah, G.M. Hydrogen Production for Energy: An Overview. Int. J. Hydrogen Energy 2020, 45, 3847–3869. [Google Scholar] [CrossRef]

- Mehra, R.K.; Duan, H.; Juknelevičius, R.; Ma, F.; Li, J. Progress in Hydrogen Enriched Compressed Natural Gas (HCNG) Internal Combustion Engines—A Comprehensive Review. Renew. Sustain. Energy Rev. 2017, 80, 1458–1498. [Google Scholar] [CrossRef]

- Zhang, W.; Wang, Y.; Long, W.; Tian, H.; Dong, P. Numerical Investigation on Knock Intensity, Combustion, and Emissions of a Heavy-Duty Natural Gas Engine with Different Hydrogen Mixing Strategies. Int. J. Hydrogen Energy 2024, 62, 551–561. [Google Scholar] [CrossRef]

- Wang, J.; Ouyang, X.; Lei, C.; Peng, S.; Wang, Z.; Wang, J. Investigation on Adaptability of Physical Property State Equation Model for Hydrogen-Blended Natural Gas. Int. J. Hydrogen Energy 2024, 81, 1256–1277. [Google Scholar] [CrossRef]

- Jayaprabakar, J.; Arunkumar, T.; Rangasamy, G.; Parthipan, J.; Anish, M.; Varshini, G.; Kiran Kumar, B. Prospectus of Hydrogen Enrichment in Internal Combustion Engines: Methodological Insights on Its Production, Injection, Properties, Performance and Emissions. Fuel 2024, 363, 131034. [Google Scholar] [CrossRef]

- Xi, Z.; Lian, T.; Shi, X.; Liu, Z.; Han, S.; Yang, X.; Zhang, J.; Li, W.; Mei, B.; Li, Y. Co-Firing Hydrogen and Dimethyl Ether in a Gas Turbine Model Combustor: Influence of Hydrogen Content and Comparison with Methane. Int. J. Hydrogen Energy 2022, 47, 38432–38444. [Google Scholar] [CrossRef]

- Inoue, K.; Miyamoto, K.; Domen, S.; Tamura, I.; Kawakami, T.; Tanimura, S. Development of Hydrogen and Natural Gas Co-firing Gas Turbine. Mitsubishi Heavy Ind. Tech. Rev. 2018, 55, 1–6. [Google Scholar]

- Nose, M.; Kawakami, T.; Araki, H.; Senba, N.; Tanimura, S. Hydrogen-Fired Gas Turbine Targeting Realization of CO2-Free Society. Mitsubishi Heavy Ind. Tech. Rev. 2018, 55, 1–7. [Google Scholar]

- Mendoza Morales, M.J.; Blondeau, J.; De Paepe, W. Assessing the Impact of CH4/H2 Blends on the Thermodynamic Performance of Aero-Derivative Gas Turbine CHP Configurations. Int. J. Hydrogen Energy 2024, 67, 159–171. [Google Scholar] [CrossRef]

- Amrouche, F.; Boudjemaa, L.; Bari, O.K. Hydrogen-Natural Gas Blending for Enhanced Performance of the MS-5002C Gas Turbine in Southern Algeria. Int. J. Hydrogen Energy 2025, 106, 1144–1157. [Google Scholar] [CrossRef]

- Normann, F.; Andersson, K.; Leckner, B.; Johnsson, F. High-Temperature Reduction of Nitrogen Oxides in Oxy-Fuel Combustion. Fuel 2008, 87, 3579–3585. [Google Scholar] [CrossRef]

- Babahammou, H.R.; Merabet, A.; Miles, A. Technical Modelling and Simulation of Integrating Hydrogen from Solar Energy into a Gas Turbine Power Plant to Reduce Emissions. Int. J. Hydrogen Energy 2024, 59, 343–353. [Google Scholar] [CrossRef]

- Alikulov, K.; Aminov, Z.; Anh, L.H.; Tran Dang, X.; Kim, W. Effect of Ammonia and Hydrogen Blends on the Performance And Emissions of an Existing Gas Turbine Unit. Int. J. Hydrogen Energy 2024, 61, 432–443. [Google Scholar] [CrossRef]

- Himmelblau, D.M.; Riggs, J.B. Basic Principles and Calculations in Chemical Engineering, 9th ed.; Pearson Education, Inc.: Upper Saddle River, NJ, USA, 2023; ISBN ISBN-13: 978-0-13-732717-1. [Google Scholar]

- Abdin, Z. Bridging the Energy Future: The Role and Potential of Hydrogen Co-Firing with Natural Gas. J. Clean. Prod. 2024, 436, 140724. [Google Scholar] [CrossRef]

- Shiva Kumar, S.; Lim, H. An Overview of Water Electrolysis Technologies for Green Hydrogen Production. Energy Rep. 2022, 8, 13793–13813. [Google Scholar] [CrossRef]

- Park, Y.; Choi, M.; Choi, G. Thermodynamic Performance Study of Large-Scale Industrial Gas Turbine with Methane/Ammonia/Hydrogen Blended Fuels. Energy 2023, 282, 128731. [Google Scholar] [CrossRef]

- MEMR. Cilegon Combine Cycle Power Plant Greenhouse Gas Emission Report. Available online: https://apple-gatrik.esdm.go.id/tingkat-fasilitas/rekap-emisi (accessed on 17 January 2025).

- Ang, B.W.; Su, B. Carbon Emission Intensity in Electricity Production: A Global Analysis. Energy Policy 2016, 94, 56–63. [Google Scholar] [CrossRef]

- Liu, Z.; Karimi, I.A. Simulation and Optimization of a Combined Cycle Gas Turbine Power Plant for Part-Load Operation. Chem. Eng. Res. Des. 2018, 131, 29–40. [Google Scholar] [CrossRef]

- MHI PT PLN (Persero). Cilegon Combined Cycle Power Plant (740 MW) Design Manual; Mitsubishi Heavy Industries, Ltd.: Takasago, Japan, 2006. [Google Scholar]

- Liu, Z.; Karimi, I.A. Simulating Combined Cycle Gas Turbine Power Plants in Aspen HYSYS. Energy Convers. Manag. 2018, 171, 1213–1225. [Google Scholar] [CrossRef]

- Ghoderao, P.N.P.; Narayan, M.; Dalvi, V.H.; Byun, H.S. Patel-Teja Cubic Equation of State—A Review of Modifications and Applications till 2022. Fluid Phase Equilib. 2023, 567, 113707. [Google Scholar] [CrossRef]

- Lopez-Echeverry, J.S.; Reif-Acherman, S.; Araujo-Lopez, E. Peng-Robinson Equation of State: 40 Years Through Cubics. Fluid Phase Equilib. 2017, 447, 39–71. [Google Scholar] [CrossRef]

- Valderrama, J.O. The State of the Cubic Equations of State. Ind. Eng. Chem. Res. 2003, 42, 1603–1618. [Google Scholar] [CrossRef]

- Moran, M.J.; Shapiro, H.N.; Boettner, D.D.; Bailey, M.B. Fundamentals of Engineering Thermodynamics, 7th ed.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2011; ISBN 13 978-0470-49590-2. [Google Scholar]

- Jiang, X.; Liu, Y.; Wei, M.; Cheng, X.; Wang, Z. A Thermodynamics-Informed Deep Learning Approach for Lightweight Modeling of Gas Turbine Performance. Eng. Appl. Artif. Intell. 2025, 143, 110022. [Google Scholar] [CrossRef]

- Cong, L.; Zhijun, S.; Yimin, L.; Zhongning, Z.; Lina, M. Experimental Study on the Performance of Micro Gas Turbines Under Different Intake Environments. Case Stud. Therm. Eng. 2024, 58, 104415. [Google Scholar] [CrossRef]

- Fatehi, M.; Campaldini, G.; Renzi, M. Micro Gas Turbine Fed by Ammonia with Steam Injection: Performance and Combustion Analysis. Appl. Therm. Eng. 2025, 264, 125428. [Google Scholar] [CrossRef]

- Kok, J.B.W.; Haselhoff, E.A. Thermodynamic Analysis of the Thermal And Exergetic Performance of a Mixed Gas-Steam Aero Derivative Gas Turbine Engine for Power Generation. Heliyon 2023, 9, e18927. [Google Scholar] [CrossRef]

- Alomar, O.R.; Ali, B.M.; Ali, O.M.; Mustafa, A.N. Impacts of Environmental Conditions on Thermal, Emissions and Economic Performance of Gas Turbine Using Different Types of Fuels: An Experimental Investigation. Results Eng. 2024, 24, 103402. [Google Scholar] [CrossRef]

- Hu, H.; Wang, T.; Ren, Y.; Zhang, F.; Zhang, B.; Li, J. A Case Study of Thermal Performance of Gas-Steam Combined Cycle with Gas Turbine Inlet Air Cooling And Condenser Deep Cooling. Case Stud. Therm. Eng. 2024, 60, 104747. [Google Scholar] [CrossRef]

- Akhtar, S.; Hui, Y.; Yu, J.; Yu, A. Heat Transfer Performance Analysis of Hydrogen-Ammonia Combustion in a Micro Gas Turbine for Sustainable Energy Solutions. Int. J. Hydrogen Energy 2025, 105, 619–631. [Google Scholar] [CrossRef]

- Harper, J.; Cloyd, S.; Pigon, T.; Thomas, B.; Wilson, J.; Johnson, E.; Noble, D.R. Hydrogen Co-Firing Demonstration at Georgia Power’s Plant McDonough: M501G Gas Turbine. In Education; Electric Power; Energy Storage; Fans and Blowers; American Society of Mechanical Engineers: New York, NY, USA, 2023; Volume 6, pp. 1–11. [Google Scholar]

- Munther, H.; Hassan, Q.; Mohammed, A.; Hanoon, T.M.; Algburi, S. Techno-Economic and Environmental Evaluation of Green Hydrogen Co-Firing in a 570 MWe Gas Turbine Combined Cycle Power Plant in Iraq. Unconv. Resour. 2025, 6, 100163. [Google Scholar] [CrossRef]

- Electric Power Research Institute (EPRI). Taking Gas Turbine Hydrogen Blending to the Next Level; EPRI: California, CA, USA, 2022. [Google Scholar]

| Parameters | Load | ||

|---|---|---|---|

| 100% | 75% | 50% | |

| Inlet air temperature [°C] | 30 | 30 | 30 |

| Inlet air pressure [bar] | 1.01325 | 1.01325 | 1.01325 |

| Inlet air mass flow [kg/h] | 2,188,000 | 1,949,720 | 1,642,430 |

| Compressed air temperature [°C] | 448 | 418 | 389 |

| Compressed air pressure [bar] | 15.80 | 13.00 | 10.40 |

| Natural gas temperature [°C] | 200 | 200 | 200 |

| Natural gas pressure [bar] | 43 | 43 | 43 |

| Natural gas mass flow [kg/h] | 54,400 | 44,220 | 34,180 |

| Natural gas LHV [kJ/kg] | 43,377 | 43,377 | 43,377 |

| Flue gas temperature [°C] | 610 | 567 | 556 |

| Flue gas pressure [bar] | 1.01883 | 1.01687 | 1.01354 |

| Cycle work [kW] | 238,500 | 178,800 | 119,200 |

| Cycle efficiency [%] | 36.39 | 33.56 | 28.94 |

| Compressor adiabatic head [m] | 36,884 | 33,244 | 29,312 |

| Compressor adiabatic efficiency [%] | 81.80 | 79.69 | 76.17 |

| Component | Composition [%mol.] | ||

|---|---|---|---|

| Inlet Air | Natural Gas | Hydrogen | |

| Oxygen (O2) | 21 | - | 0.10 |

| Carbon dioxide (CO2) | - | 5.00 | - |

| Nitrogen (N2) | 79 | 0.61 | - |

| Methane (CH4) | - | 84.49 | - |

| Ethane (C2H6) | - | 4.91 | - |

| Propane (C3H8) | - | 2.88 | - |

| i-Butane (iC4) | - | 0.79 | - |

| n-Butane (nC4) | - | 0.60 | - |

| i-Pentane (iC5) | - | 0.27 | - |

| n-Pentane (nC5) | - | 0.17 | - |

| Hexane (C6) | - | 0.15 | - |

| Heptane plus (C7+) | - | 0.12 | - |

| Hydrogen (H2) | - | - | 99.90 |

| Load 100% | |||

| Parameters | Reference | Simulation | Dev. [%] |

| Inlet air temperature [°C] | 30 | 30 | 0.000 |

| Inlet air pressure [bar] | 1.01325 | 1.01325 | 0.000 |

| Inlet air mass flow [kg/h] | 2,188,000 | 2,188,000 | 0.000 |

| Compressed air temperature [°C] | 448.00 | 448.22 | 0.049 |

| Compressed air pressure [bar] | 15.80 | 15.80 | 0.000 |

| Natural gas temperature [°C] | 200 | 200 | 0.000 |

| Natural gas pressure [bar] | 43 | 43 | 0.000 |

| Natural gas mass flow [kg/h] | 54,400 | 54,400 | 0.000 |

| Natural gas LHV [kJ/kg] | 43,377 | 43,385 | 0.018 |

| Flue gas temperature [°C] | 610 | 610 | 0.000 |

| Flue gas pressure [bar] | 1.01884 | 1.01884 | 0.000 |

| Flue gas mass flow [kg/h] | 2,242,400 | 2,242,391 | 0.000 |

| Cycle work [kW] | 238,500 | 240,003 | 0.630 |

| Cycle efficiency [%] | 36.39 | 36.61 | 0.612 |

| Load 75% | |||

| Parameters | Reference | Simulation | Dev. [%] |

| Inlet air temperature [°C] | 30 | 30 | 0.000 |

| Inlet air pressure [bar] | 1.01325 | 1.01325 | 0.000 |

| Inlet air mass flow [kg/h] | 1,949,720 | 1,949,720 | 0.000 |

| Compressed air temperature [°C] | 418.00 | 418.07 | 0.016 |

| Compressed air pressure [bar] | 13.00 | 13.00 | 0.000 |

| Natural gas temperature [°C] | 200 | 200 | 0.000 |

| Natural gas pressure [bar] | 43 | 43 | 0.000 |

| Natural gas mass flow [kg/h] | 44,220 | 44,220 | 0.000 |

| Natural gas LHV [kJ/kg] | 43,377 | 43,385 | 0.018 |

| Flue gas temperature [°C] | 567 | 567 | 0.000 |

| Flue gas pressure [bar] | 1.01688 | 1.01688 | 0.000 |

| Flue gas mass flow [kg/h] | 1,993,940 | 1,993,933 | 0.000 |

| Cycle work [kW] | 178,800 | 179,842 | 0.583 |

| Cycle efficiency [%] | 33.56 | 33.75 | 0.564 |

| Load 50% | |||

| Parameters | Reference | Simulation | Dev. [%] |

| Inlet air temperature [°C] | 30 | 30 | 0.000 |

| Inlet air pressure [bar] | 1.01325 | 1.01325 | 0.000 |

| Inlet air mass flow [kg/h] | 1,642,430 | 1,642,430 | 0.000 |

| Compressed air temperature [°C] | 389.00 | 388.80 | −0.050 |

| Compressed air pressure [bar] | 10.40 | 10.39 | −0.096 |

| Natural gas temperature [°C] | 200 | 200 | 0.000 |

| Natural gas pressure [bar] | 43 | 43 | 0.000 |

| Natural gas mass flow [kg/h] | 34,180 | 34,180 | 0.000 |

| Natural gas LHV [kJ/kg] | 43,377 | 43,385 | 0.018 |

| Flue gas temperature [°C] | 556 | 556 | 0.000 |

| Flue gas pressure [bar] | 1.01354 | 1.01354 | 0.000 |

| Flue gas mass flow [kg/h] | 1,676,610 | 1,676,604 | 0.000 |

| Cycle work [kW] | 119,200 | 120,390 | 0.998 |

| Cycle efficiency [%] | 28.94 | 29.23 | 0.980 |

| Load 100% | |||||||

| Co-firing Ratio [vol.%] | 0 | 5 | 10 | 15 | 20 | 25 | 30 |

| Natural gas mass flow [kg/h] | 54,400 | 53,425 | 52,382 | 51,263 | 50,060 | 48,764 | 47,362 |

| Hydrogen mass flow [kg/h] | 0 | 352 | 730 | 1134 | 1569 | 2037 | 2544 |

| Mixed fuel mass flow [kg/h] | 54,400 | 53,777 | 53,112 | 52,397 | 51,629 | 50,801 | 49,906 |

| Mixed fuel LHV [kJ/kg] | 43,385 | 43,885 | 44,436 | 45,039 | 45,708 | 46,450 | 47,281 |

| Mixed fuel heat input [kW] | 655,596 | 655,561 | 655,573 | 655,534 | 655,514 | 655,472 | 655,451 |

| Excess air ratio | 2.34 | 2.34 | 2.34 | 2.34 | 2.34 | 2.34 | 2.34 |

| Inlet air mass flow [kg/h] | 2,188,000 | 2,177,053 | 2,165,341 | 2,152,780 | 2,139,276 | 2,124,718 | 2,108,976 |

| Inlet air temperature [°C] | 30 | 30 | 30 | 30 | 30 | 30 | 30 |

| Compressed air temperature [°C] | 448 | 447 | 445 | 443 | 442 | 440 | 438 |

| Hot gas mass flow [kg/h] | 2,242,391 | 2,230,821 | 2,218,444 | 2,205,168 | 2,190,896 | 2,175,510 | 2,158,873 |

| Hot gas temperature [°C] | 1266 | 1268 | 1271 | 1273 | 1276 | 1279 | 1282 |

| Flue gas mass flow [kg/h] | 2,242,391 | 2,230,821 | 2,218,444 | 2,205,168 | 2,190,896 | 2,175,510 | 2,158,873 |

| Flue gas temperature [°C] | 610 | 610 | 610 | 610 | 610 | 610 | 610 |

| Load 75% | |||||||

| Co-firing Ratio [vol.%] | 0 | 5 | 10 | 15 | 20 | 25 | 30 |

| Natural gas mass flow [kg/h] | 44,220 | 43,427 | 42,580 | 41,670 | 40,692 | 39,638 | 38,499 |

| Hydrogen mass flow [kg/h] | 0 | 286 | 593 | 922 | 1275 | 1656 | 2068 |

| Mixed fuel mass flow [kg/h] | 44,220 | 43,714 | 43,173 | 42,592 | 41,968 | 41,295 | 40,567 |

| Mixed fuel LHV [kJ/kg] | 43,385 | 43,886 | 44,435 | 45,039 | 45,707 | 46,450 | 47,282 |

| Mixed fuel heat input [kW] | 532,912 | 532,896 | 532,879 | 532,861 | 532,841 | 532,820 | 532,797 |

| Excess air ratio | 2.56 | 2.56 | 2.56 | 2.56 | 2.56 | 2.56 | 2.56 |

| Inlet air mass flow [kg/h] | 1,949,720 | 1,939,965 | 1,929,528 | 1,918,336 | 1,906,302 | 1,893,329 | 1,879,302 |

| Inlet air temperature [°C] | 30 | 30 | 30 | 30 | 30 | 30 | 30 |

| Compressed air temperature [°C] | 418 | 417 | 416 | 415 | 413 | 412 | 410 |

| Hot gas mass flow [kg/h] | 1,993,933 | 1,983,672 | 1,972,694 | 1,960,921 | 1,948,263 | 1,934,617 | 1,919,862 |

| Hot gas temperature [°C] | 1158 | 1160 | 1163 | 1165 | 1168 | 1171 | 1175 |

| Flue gas mass flow [kg/h] | 1,993,933 | 1,983,672 | 1,972,694 | 1,960,921 | 1,948,263 | 1,934,617 | 1,919,862 |

| Flue gas temperature [°C] | 567 | 567 | 567 | 567 | 567 | 567 | 567 |

| Load 50% | |||||||

| Co-firing Ratio [vol.%] | 0 | 5 | 10 | 15 | 20 | 25 | 30 |

| Natural gas mass flow [kg/h] | 34,180 | 33,567 | 32,912 | 32,209 | 31,453 | 30,639 | 29,758 |

| Hydrogen mass flow [kg/h] | 0 | 221 | 458 | 712 | 986 | 1280 | 1599 |

| Mixed fuel mass flow [kg/h] | 34,180 | 33,789 | 33,370 | 32,922 | 32,439 | 31,919 | 31,356 |

| Mixed fuel LHV [kJ/kg] | 43,385 | 43,886 | 44,435 | 45,039 | 45,707 | 46,450 | 47,282 |

| Mixed fuel heat input [kW] | 411,916 | 411,904 | 411,891 | 411,877 | 411,861 | 411,845 | 411,827 |

| Excess air ratio | 2.79 | 2.79 | 2.79 | 2.79 | 2.79 | 2.79 | 2.79 |

| Inlet air mass flow [kg/h] | 1,642,430 | 1,634,213 | 1,625,421 | 1,615,992 | 1,605,855 | 1,594,927 | 1,583,111 |

| Inlet air temperature [°C] | 30 | 30 | 30 | 30 | 30 | 30 | 30 |

| Compressed air temperature [°C] | 389 | 388 | 387 | 386 | 385 | 384 | 383 |

| Hot gas mass flow [kg/h] | 1,676,604 | 1,667,996 | 1,658,786 | 1,648,908 | 1,638,289 | 1,626,840 | 1,614,462 |

| Hot gas temperature [°C] | 1073 | 1076 | 1078 | 1081 | 1084 | 1087 | 1090 |

| Flue gas mass flow [kg/h] | 1,676,604 | 1,667,996 | 1,658,786 | 1,648,908 | 1,638,289 | 1,626,840 | 1,614,462 |

| Flue gas temperature [°C] | 556 | 556 | 556 | 556 | 556 | 556 | 556 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nugraha, R.R.; Silviana, S.; Widayat, W. Effect of Hydrogen Co-Firing with Natural Gas on Thermal Efficiency and CO2 Emissions in Gas Turbine Power Plant. Hydrogen 2025, 6, 18. https://doi.org/10.3390/hydrogen6010018

Nugraha RR, Silviana S, Widayat W. Effect of Hydrogen Co-Firing with Natural Gas on Thermal Efficiency and CO2 Emissions in Gas Turbine Power Plant. Hydrogen. 2025; 6(1):18. https://doi.org/10.3390/hydrogen6010018

Chicago/Turabian StyleNugraha, Rizcky Rahadian, S. Silviana, and Widayat Widayat. 2025. "Effect of Hydrogen Co-Firing with Natural Gas on Thermal Efficiency and CO2 Emissions in Gas Turbine Power Plant" Hydrogen 6, no. 1: 18. https://doi.org/10.3390/hydrogen6010018

APA StyleNugraha, R. R., Silviana, S., & Widayat, W. (2025). Effect of Hydrogen Co-Firing with Natural Gas on Thermal Efficiency and CO2 Emissions in Gas Turbine Power Plant. Hydrogen, 6(1), 18. https://doi.org/10.3390/hydrogen6010018