HyPLANT100: Industrialization from Assembly to the Construction Site for Gigawatt Electrolysis

Abstract

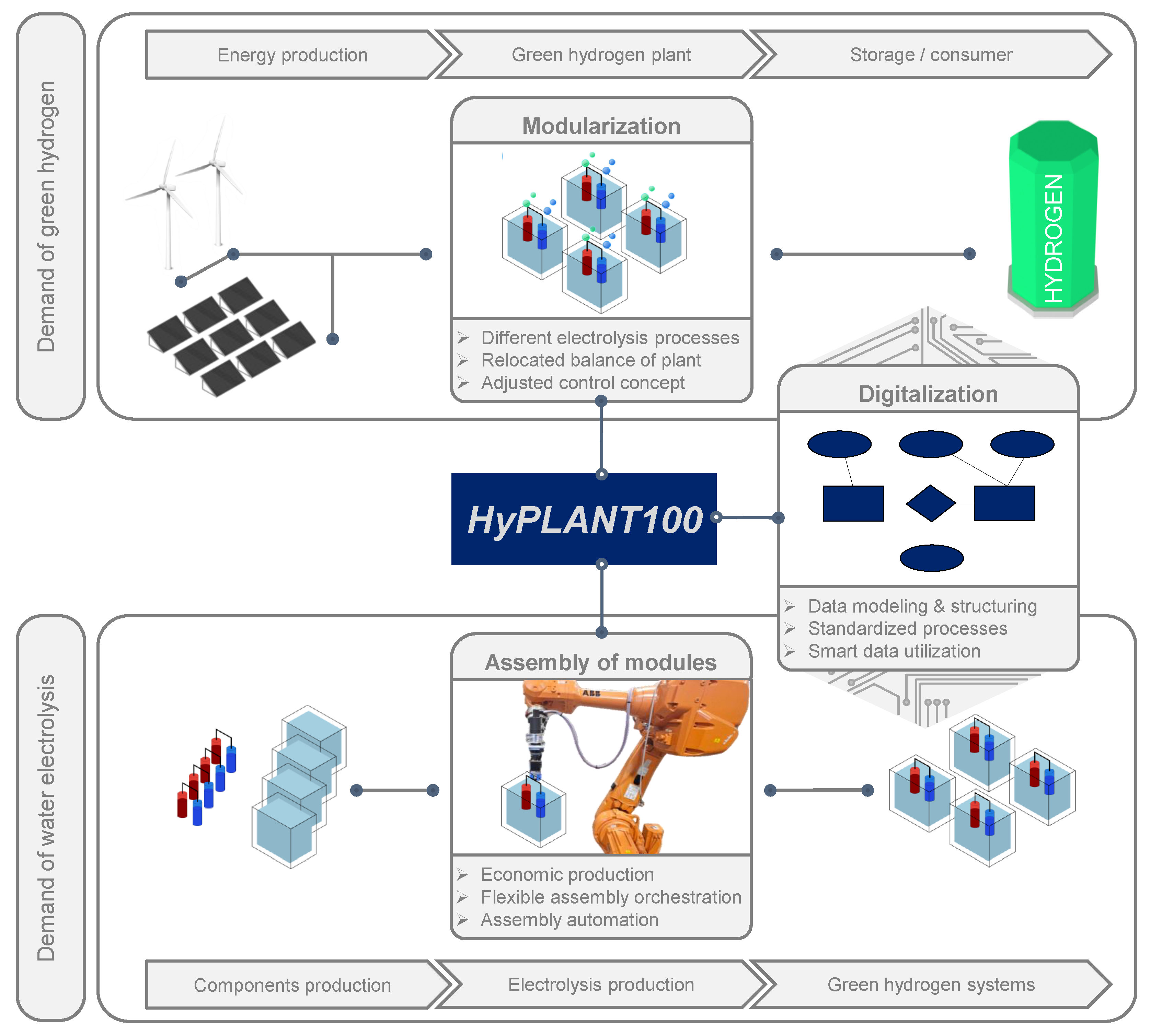

1. Introduction

- 1.

- The development and design of suitable modules;

- 2.

- The identification and development of (partial) automation;

- 3.

- Increasing efficiency through digitalization with the help of standardized data modeling.

2. Related Work

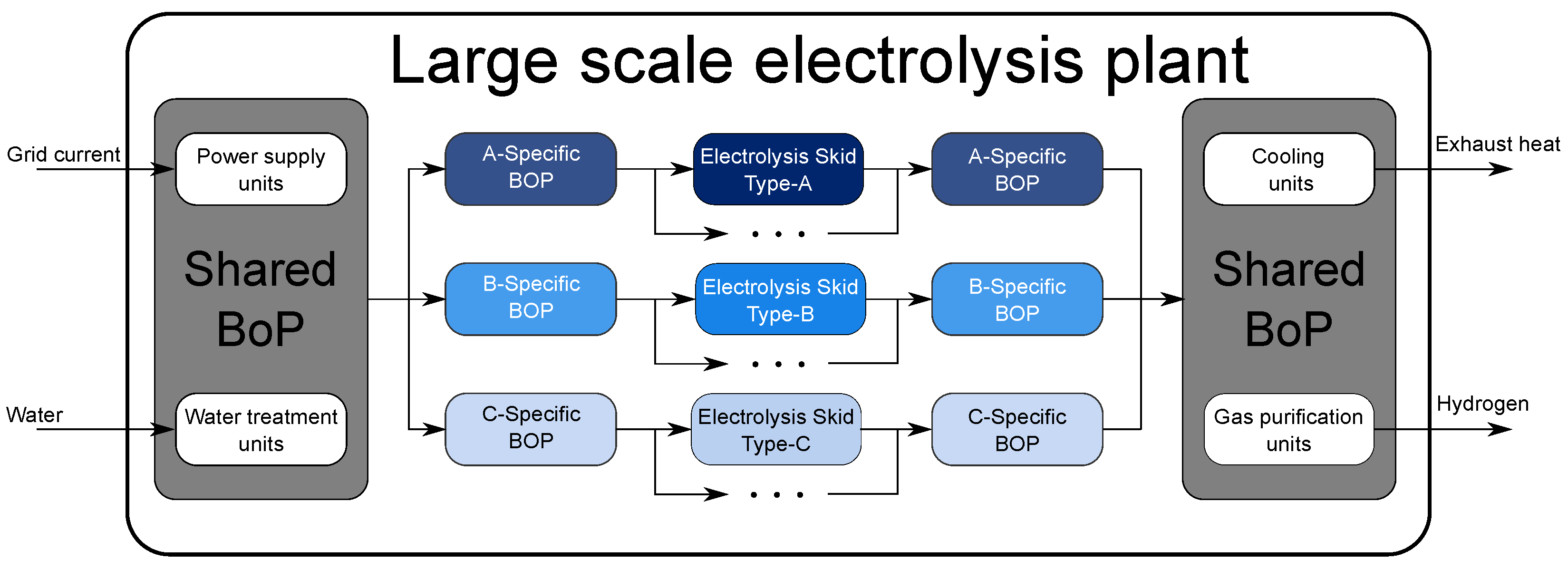

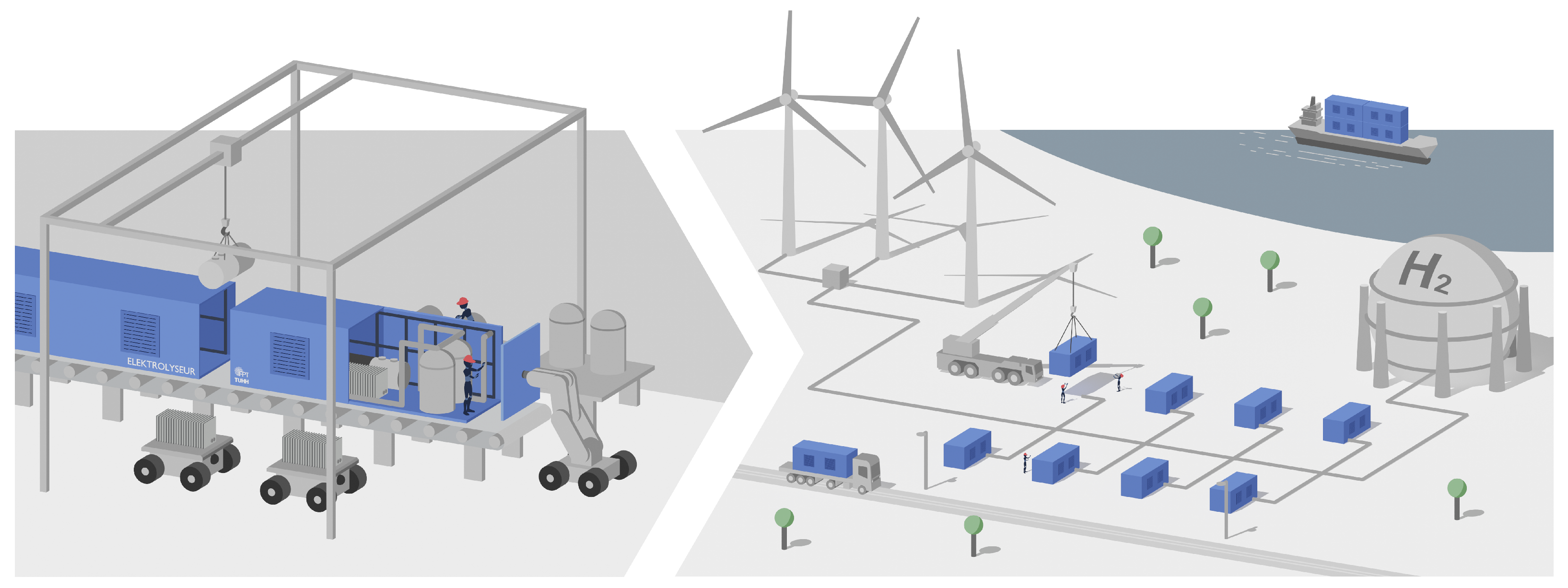

3. Modularization of Electrolysis Systems

3.1. Electrolysis Technologies and Their Respective Balance of Plant

- Water Purification System: Furnish the electrolyzer with ultrapure water. Components include deionization units, filters, reverse osmosis units, and storage tanks

- Gas Purification System: Purify and analyze hydrogen and oxygen gases produced during the electrolysis process. Components include separators, reactors, dryers, and gas analyzer systems

- Heat Exchanger Network: Ensure optimal temperature range. Components include heat exchangers, pumps, and temperature sensors.

- Power Supply and Conversion: Channel the requisite electrical power to the electrolyzer. Components include rectifiers, transformers, and power factor correction.

- Utilities: Supply compressed air and nitrogen. Components include compressors, air separators, and a nitrogen trailer station.

- Control and Monitoring: Evaluate and control the electrolyzer operation. Components include sensors and programmable logic controllers.

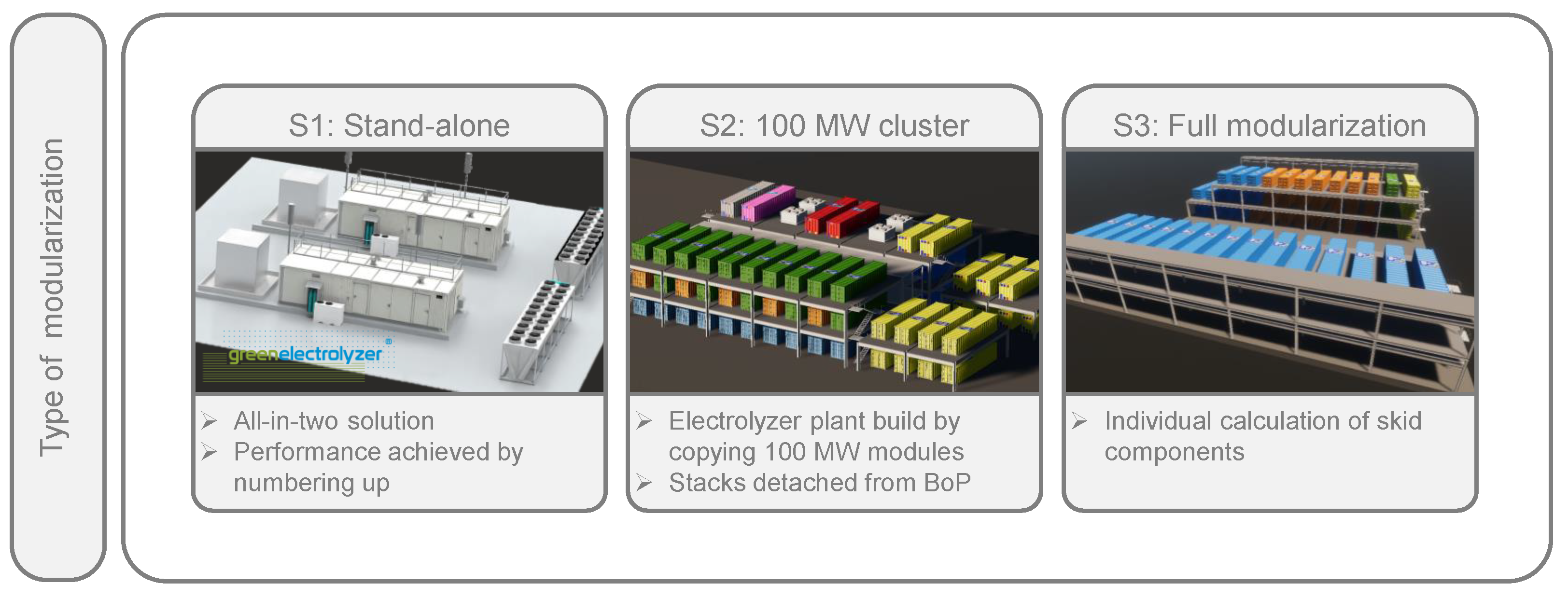

3.2. Modularization of Water Electrolysis

3.3. Operation of Modularized Electrolyzers

3.4. Investigation of the Degree of Modularization

- Water availability;

- Availability of space and topology;

- Availability of renewable energy.

4. Production

4.1. Pre-Assembly on the Shop Floor

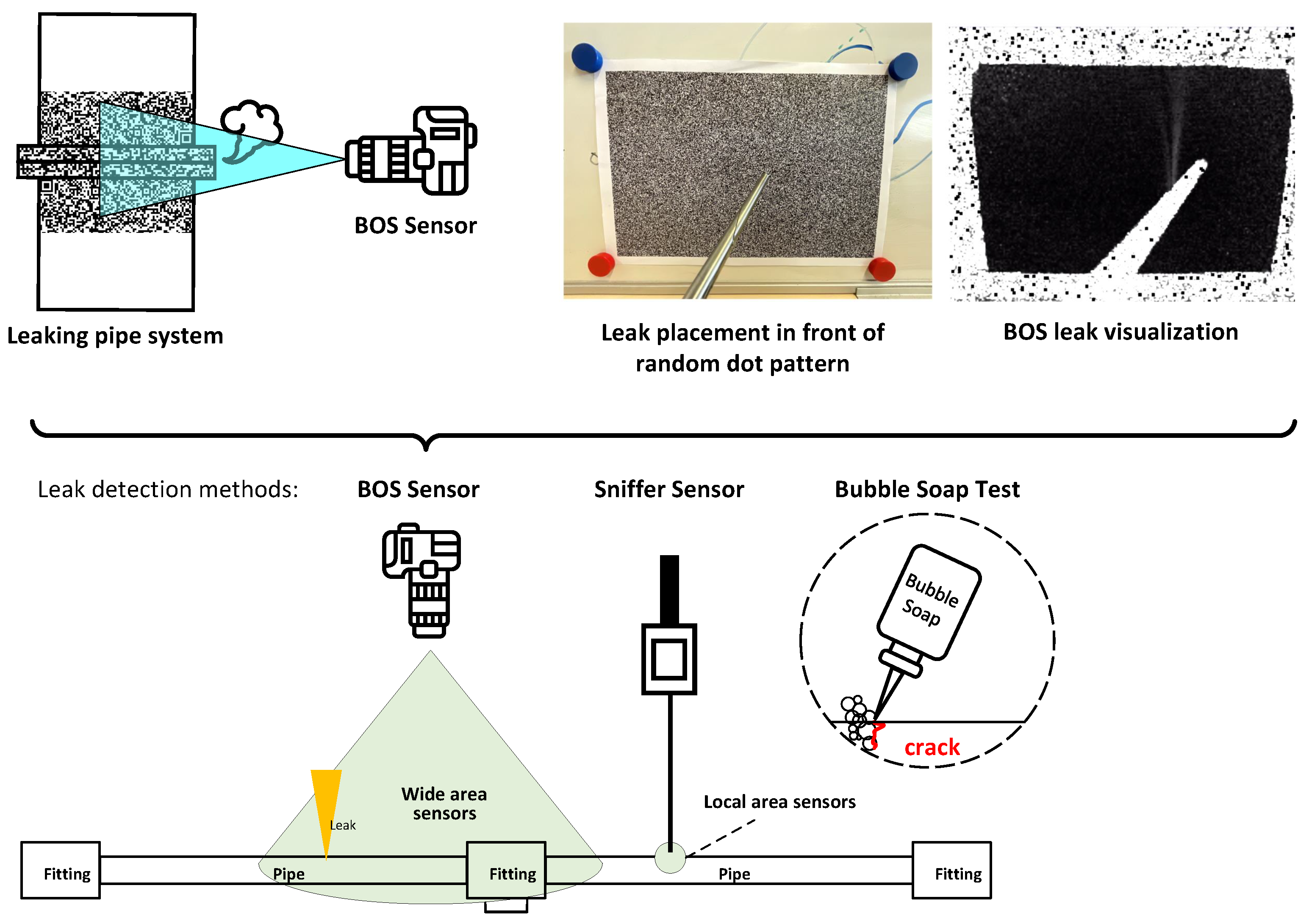

4.2. Quality Assurance

4.3. Assembly at the Construction Site

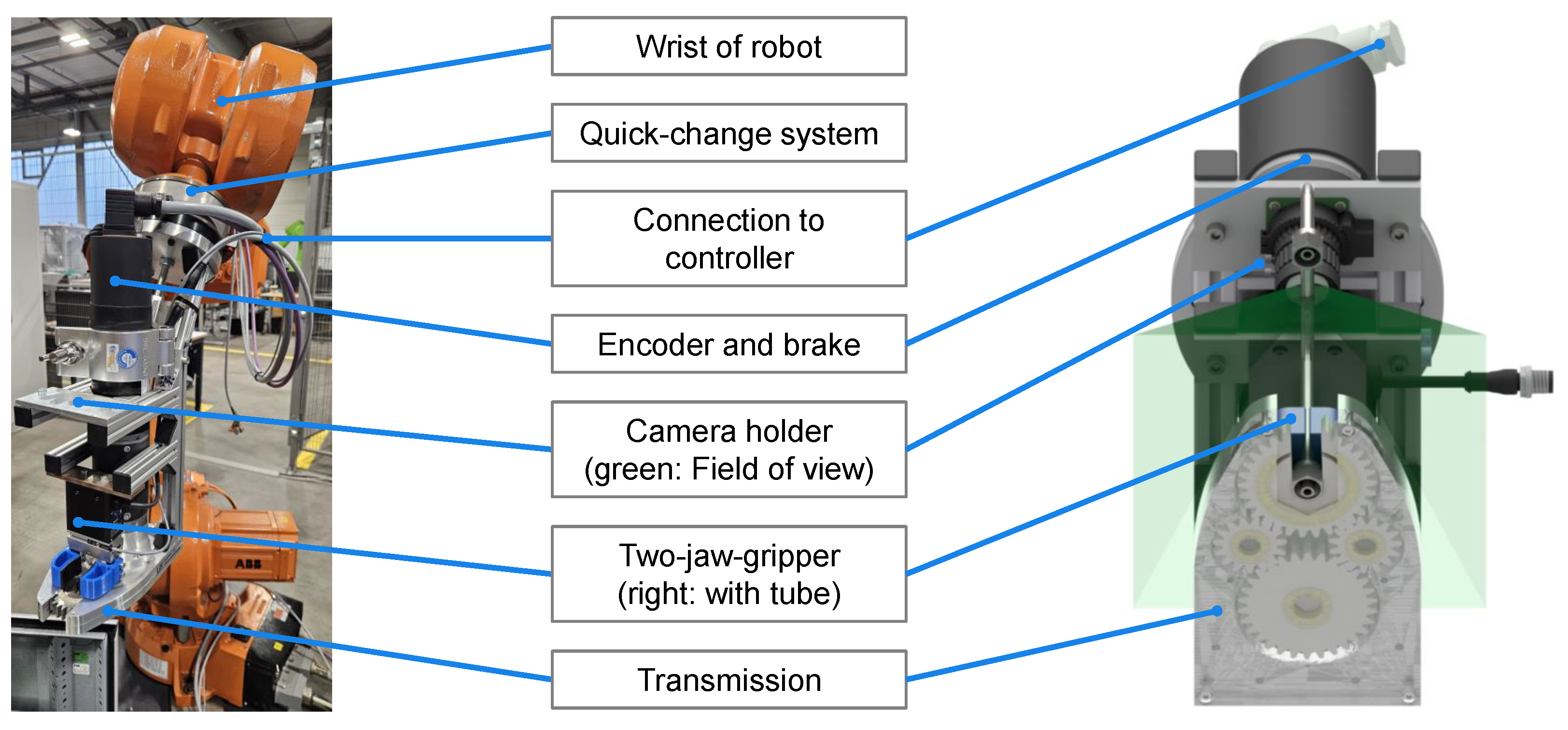

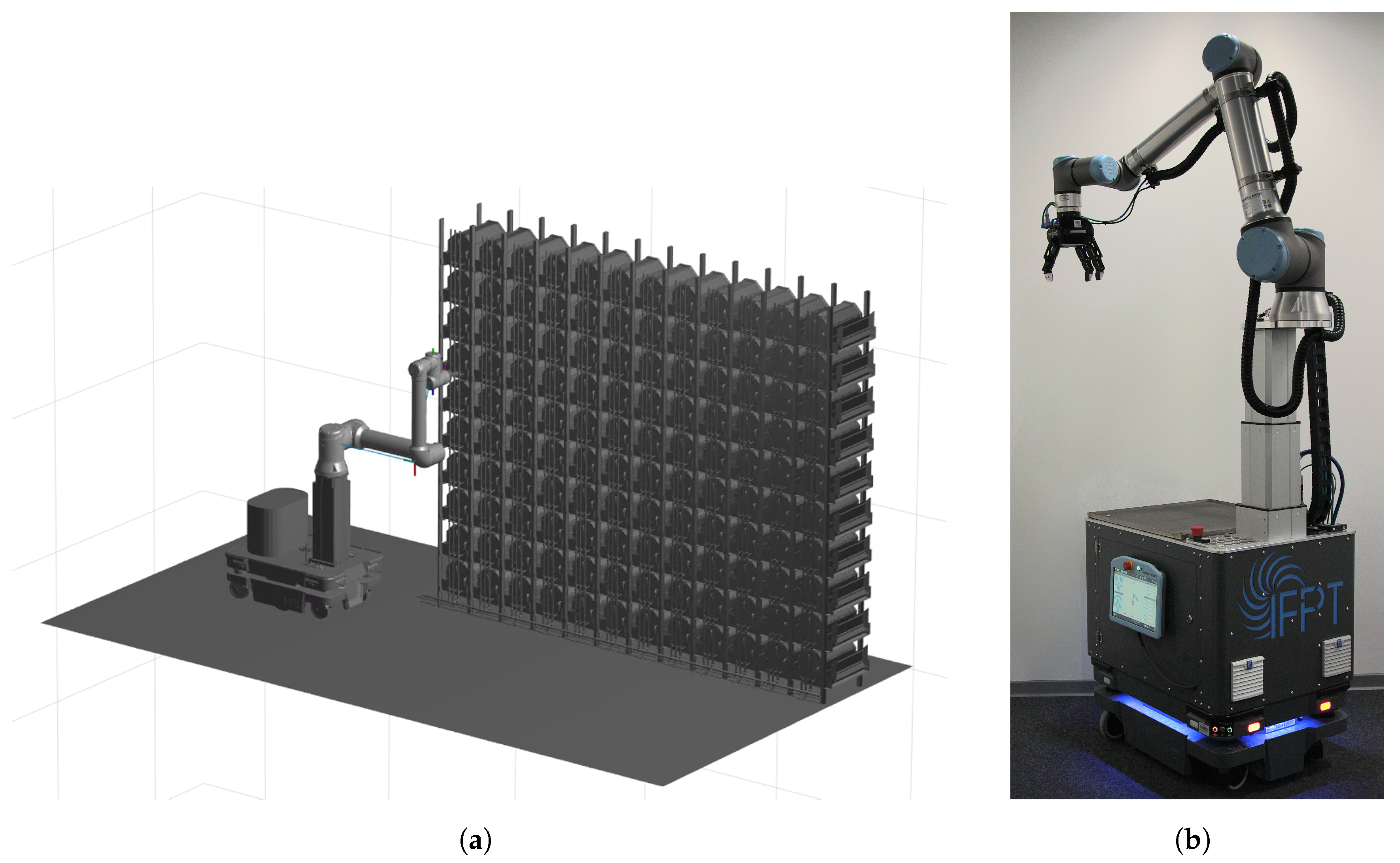

4.4. Further Automation Potential

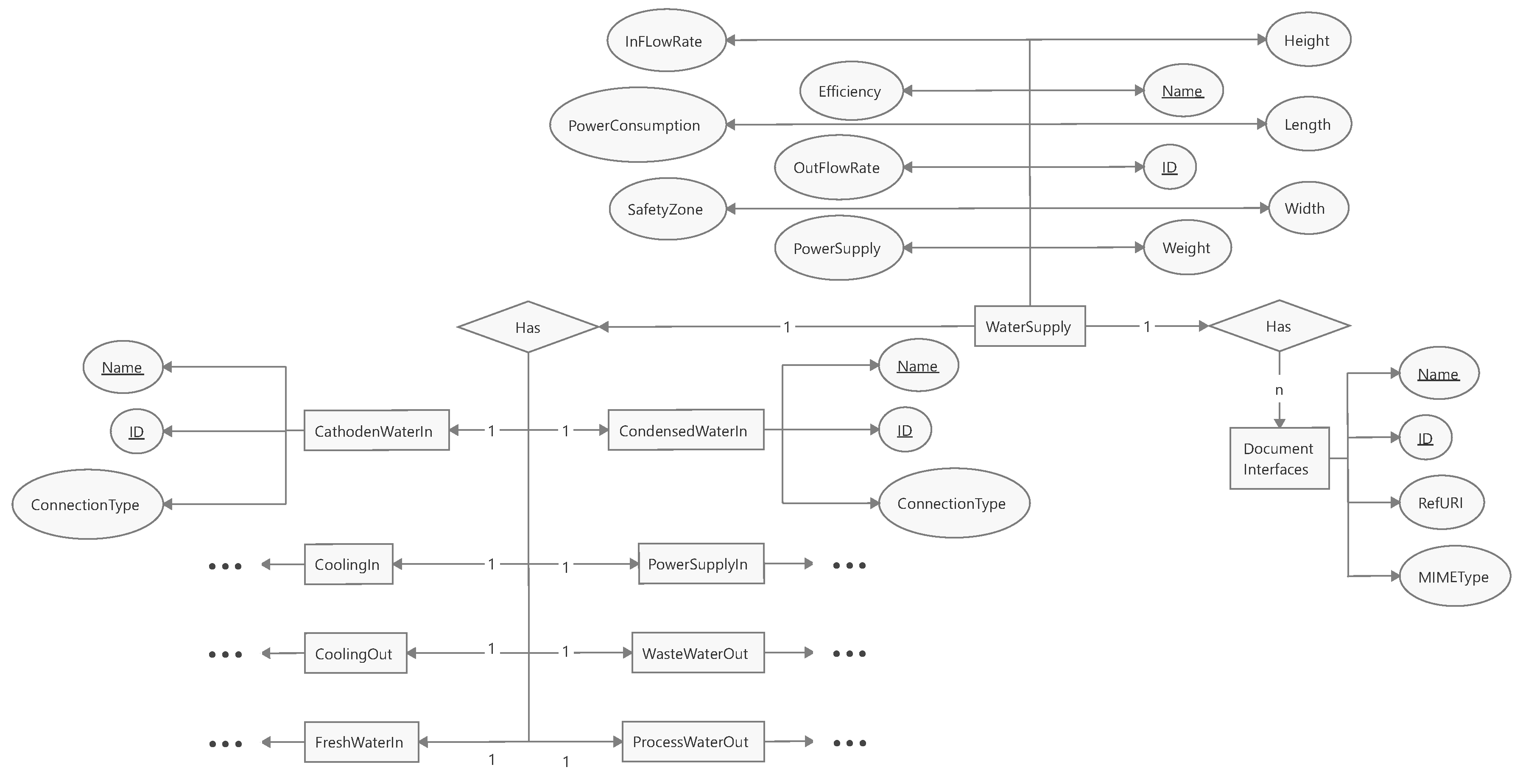

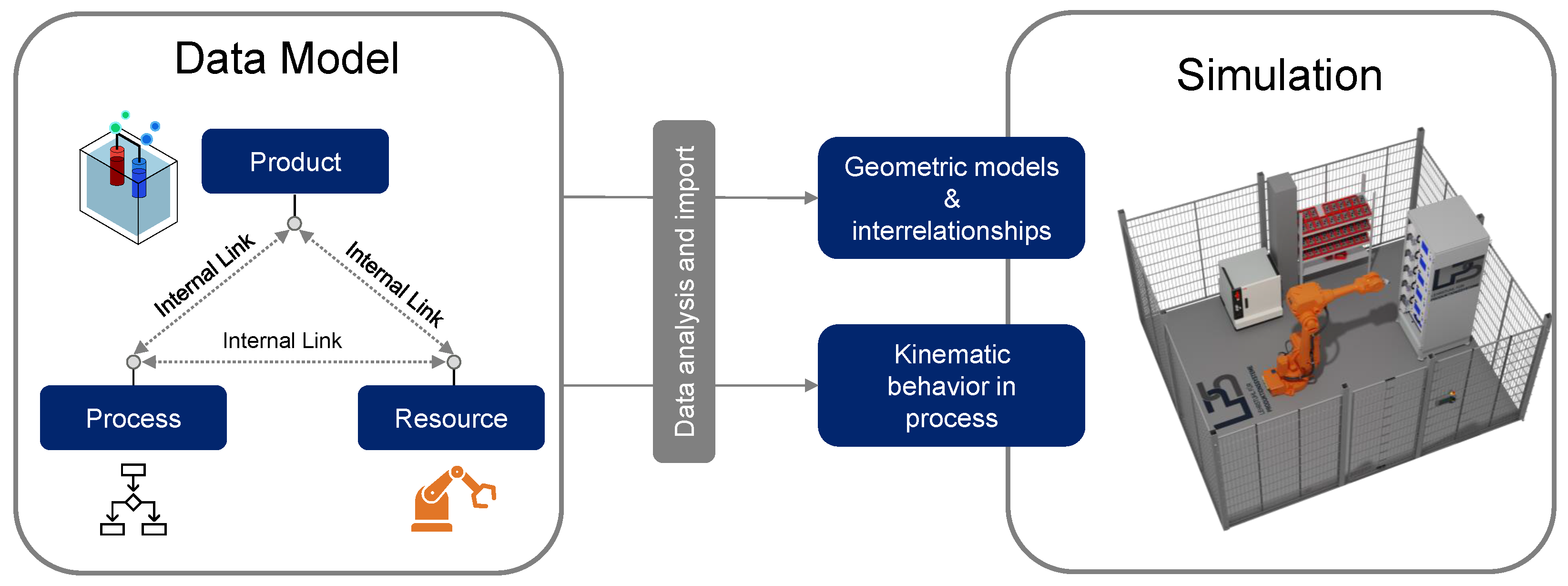

5. Digitalization

5.1. Layout Planning in the Context of Modularization

5.2. Derived Simulation for Production Automation

5.3. AI-Based Error Compensation

6. Conclusions and Outlook

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| AAS | Asset Administration Shell; |

| AEM | Anion Exchange Membrane; |

| AI | Artificial Intelligence; |

| AR | Augmented Reality; |

| AutomationML | Automation Markup Language; |

| AWE | Alkaline Water Electrolysis; |

| BoP | Balance of Plant; |

| BOS | Background-Oriented Schlieren; |

| CapEx | Capital Expenditures; |

| CMMS | Computerized Maintenance Management System; |

| DCS | Distributed Control System; |

| ERD | Entity Relation Diagram; |

| MTM | Methods-Time Measurement; |

| OPC UA | Open Platform Communications Unified Architecture; |

| OpEx | Operational Expenditures; |

| PEM | Proton Exchange Membrane; |

| PLC | Programmable Logic Controllers; |

| PPR | Product–Process–Resource; |

| SOWE | Solid Oxide Water Electrolysis; |

| WE | Water Electrolyzer. |

References

- Fit for 55. Available online: https://www.consilium.europa.eu/en/policies/green-deal/fit-for-55-the-eu-plan-for-a-green-transition/ (accessed on 8 February 2024).

- Ishaq, H.; Dincer, I.; Crawford, C. A review on hydrogen production and utilization: Challenges and opportunities. Int. J. Hydrogen Energy 2022, 47, 26238–26264. [Google Scholar] [CrossRef]

- Ueckerdt, F.; Verpoort, P.C.; Anantharaman, R.; Bauer, C.; Beck, F.; Longden, T.; Roussanaly, S. On the cost competitiveness of blue and green hydrogen. Joule 2024, 8, 104–128. [Google Scholar] [CrossRef]

- Wappler, M.; Unguder, D.; Lu, X.; Ohlmeyer, H.; Teschke, H.; Lueke, W. Building the green hydrogen market—Current state and outlook on green hydrogen demand and electrolyzer manufacturing. Int. J. Hydrogen Energy 2022, 47, 33551–33570. [Google Scholar] [CrossRef]

- Neugebauer, R. (Ed.) Wasserstofftechnologien; Springer eBook Collection; Springer: Berlin/Heidelberg, Germany, 2022. [Google Scholar] [CrossRef]

- Fonseca, J.; Durdevic, D.; Muron, M.; Pawelec, G.; Yovchev, I.P.; Bellomo, N.; Muse, K.; Kuhn, M.; Fraile, D.; Waciega, K. Clean Hydrogen Monitor. 2023. Available online: https://hydrogeneurope.eu/wp-content/uploads/2023/10/Clean_Hydrogen_Monitor_11-2023_DIGITAL.pdf (accessed on 14 February 2024).

- H2Giga: Serial Production. Available online: https://www.wasserstoff-leitprojekte.de/leitprojekte/h2giga (accessed on 14 February 2024).

- HyPLANT100. Available online: https://www.region-heide.de/projekte/hyplant100.html (accessed on 14 February 2024).

- Yates, J.; Daiyan, R.; Patterson, R.; Egan, R.; Amal, R.; Ho-Baille, A.; Chang, N.L. Techno-economic Analysis of Hydrogen Electrolysis from Off-Grid Stand-Alone Photovoltaics Incorporating Uncertainty Analysis. Cell Rep. Phys. Sci. 2020, 1, 100209. [Google Scholar] [CrossRef]

- Reksten, A.H.; Thomassen, M.S.; Møller-Holst, S.; Sundseth, K. Projecting the future cost of PEM and alkaline water electrolysers; a CAPEX model including electrolyser plant size and technology development. Int. J. Hydrogen Energy 2022, 47, 38106–38113. [Google Scholar] [CrossRef]

- Ginsberg, M.J.; Venkatraman, M.; Esposito, D.V.; Fthenakis, V.M. Minimizing the cost of hydrogen production through dynamic polymer electrolyte membrane electrolyzer operation. Cell Rep. Phys. Sci. 2022, 3, 100935. [Google Scholar] [CrossRef]

- Van ’t Noordende, H.; Ripson, P. Baseline Design and Total Installed Costs of a GW Green Hydrogen Plant: State-of-the-Art Design and Total Installed Capital Costs. Available online: https://ispt.eu/media/ISPT-public-report-gigawatt-green-hydrogen-plant.pdf (accessed on 7 February 2024).

- Exascale-Supercomputer Jupiter Entsteht Aus Containern. Available online: https://www.heise.de/news/Exascale-Supercomputer-Jupiter-entsteht-aus-Containern-9606417.html (accessed on 15 February 2024).

- Iberdrola Commissions the Largest Green Hydrogen Plant for Industrial Use in Europe. Available online: https://www.iberdrola.com/about-us/what-we-do/green-hydrogen/puertollano-green-hydrogen-plant (accessed on 15 February 2024).

- Hamburg Green Hydrogen Hub. Available online: https://www.hghh.eu/en (accessed on 15 February 2024).

- Northern German Living Lab (NRL). Available online: https://en.norddeutsches-reallabor.de/ (accessed on 15 February 2024).

- The AEM NEXUS 1000. Available online: https://www.h2coresystems.com/en/h2c_product/aem-nexus-1000/ (accessed on 8 February 2024).

- Green Electrolyzer: The State-of-the-Art Integrated Electrolysis System for On-Site Production of Hydrogen. Available online: https://www.fest-group.de/en/hydrogen-technology/electrolysis-systems/ (accessed on 8 February 2024).

- Lange, H.; Klose, A.; Beisswenger, L.; Erdmann, D.; Urbas, L. Modularization approach for large-scale electrolysis systems: A review. Sustain. Energy Fuels 2024, 8, 1208–1224. [Google Scholar] [CrossRef]

- Pitschak, B.; Mergel, J.; Müller, M. Elektrolyse-Verfahren. In Wasserstoff und Brennstoffzelle; Töpler, J., Lehmann, J., Eds.; Springer: Berlin/Heidelberg, Germany, 2017; pp. 207–227. [Google Scholar] [CrossRef]

- Shiva Kumar, S.; Lim, H. An overview of water electrolysis technologies for green hydrogen production. Energy Rep. 2022, 8, 13793–13813. [Google Scholar] [CrossRef]

- van Pham, C.; Escalera-López, D.; Mayrhofer, K.; Cherevko, S.; Thiele, S. Essentials of High Performance Water Electrolyzers—From Catalyst Layer Materials to Electrode Engineering. Adv. Energy Mater. 2021, 11, 2101998. [Google Scholar] [CrossRef]

- Vincent, I.; Bessarabov, D. Low cost hydrogen production by anion exchange membrane electrolysis: A review. Renew. Sustain. Energy Rev. 2018, 81, 1690–1704. [Google Scholar] [CrossRef]

- The AEM Nexus: Produce Megawatt-Scale Green Hydrogen. Available online: https://www.enapter.com/de/aem-electrolysers/aem-nexus (accessed on 15 February 2024).

- Simoes, S.G.; Catarino, J.; Picado, A.; Lopes, T.F.; Di Berardino, S.; Amorim, F.; Gírio, F.; Rangel, C.M.; Ponce de Leão, T. Water availability and water usage solutions for electrolysis in hydrogen production. J. Clean. Prod. 2021, 315, 128124. [Google Scholar] [CrossRef]

- Birth, T.; Jentsch, S.; Hayen, S.; Scheffler, M. Water as a critical resource for hydrogen production. gwf Wasser Abwasser 2022, 162, 73–88. [Google Scholar] [CrossRef]

- Hofrichter, A.; Rank, D.; Heberl, M.; Sterner, M. Determination of the optimal power ratio between electrolysis and renewable energy to investigate the effects on the hydrogen production costs. Int. J. Hydrogen Energy 2023, 48, 1651–1663. [Google Scholar] [CrossRef]

- Büsch, L.; Koch, J.; Schüppstuhl, T. Development of a multi-sensor concept for progress detection in the site assembly of electrolysis units. Procedia CIRP 2023, 120, 1363–1368. [Google Scholar] [CrossRef]

- Masuhr, C.; Büsch, L. Grünen Wasserstoff schnell produzieren. Ind. Prod. 2022, 6, 46–47. [Google Scholar]

- Ausg. Deutsch/Englisch. (Ed.) VDI 2221 Blatt 1, Entwicklung Technischer Produkte und Systeme—Modell der Produktentwicklung: = Design of Technical Products and Systems—Model of Product Design; VDI-Richtlinien; Beuth Verlag GmbH: Berlin, Germany, 2019. [Google Scholar]

- Ausg. Deutsch/Englisch. (Ed.) VDI 2221 Blatt 2, Entwicklung Technischer Produkte und Systeme—Gestaltung Individueller Produktentwicklungsprozesse: = Design of Technical Products and Systems—Configuration of Individual Product Design Processes; VDI-Richtlinien; Beuth Verlag GmbH: Berlin, Germany, 2019. [Google Scholar]

- Ausg. Deutsch/Englisch. (Ed.) VDI/VDE 2206, Entwicklung Cyber-Physischer Mechatronischer Systeme (CPMS): = Development of Cyber-Physical Mechatronic Systems (CPMS); VDI/VDE-Richtlinien; Beuth Verlag GmbH: Berlin, Germany, 2021. [Google Scholar]

- Ausg. Deutsch/Englisch. (Ed.) VDI 3633 Blatt 1, Simulation von Logistik- Materialfluss- und Produktionssystemen—Grundlagen: = Simulation of Systems in Materials Handling, Logistics and Production—Fundamentals; VDI-Richtlinien; Beuth Verlag GmbH: Berlin, Germany, 2014. [Google Scholar]

- Adler, P.; Syniawa, D.; Christ, L.; Kuhlenkoetter, B. Robot-Based Assembly of Hydrogen Tube Fittings for Large-Scale Electrolyzers; Ruhr-University Bochum, Chair of Production Systems (LPS): Bochum, Germany, 2023. [Google Scholar] [CrossRef]

- Adler, P.; Christ, L.; Weckendrup, C.; Kuhlenkötter, B. Smart production system for the process-reliable assembly of hydrogen tube fittings. Procedia CIRP 2023, 120, 440–444. [Google Scholar] [CrossRef]

- Xue, J.; Hou, X.; Zeng, Y. Review of Image-Based 3D Reconstruction of Building for Automated Construction Progress Monitoring. Appl. Sci. 2021, 11, 7840. [Google Scholar] [CrossRef]

- Koch, J.; Büsch, L.; Gomse, M.; Schüppstuhl, T. A Methods-Time-Measurement based Approach to enable Action Recognition for Multi-Variant Assembly in Human-Robot Collaboration. Procedia CIRP 2022, 106, 233–238. [Google Scholar] [CrossRef]

- Büsch, L.; Koch, J.; Schoepflin, D.; Schulze, M.; Schüppstuhl, T. Towards Recognition of Human Actions in Collaborative Tasks with Robots: Extending Action Recognition with Tool Recognition Methods. Sensors 2023, 23, 5718. [Google Scholar] [CrossRef]

- Rosen, P.A. Beitrag zur Optimierung von Wasserstoffdruckbehältern. PhD Thesis, Technische Universität Chemnitz, Chemnitz, Germany, 2018. [Google Scholar]

- Mirza, N.R.; Degenkolbe, S.; Witt, W. Analysis of hydrogen incidents to support risk assessment. Int. J. Hydrogen Energy 2011, 36, 12068–12077. [Google Scholar] [CrossRef]

- Bundesanstalt für Materialforschung und -Prüfung. Wasserstoff: Unser Beitrag zur Sicherheit/Hydrogen: Our Contribution to Safety; Bundesanstalt für Materialforschung und -Prüfung: Berlin, Germany, 2020. [Google Scholar]

- Masuhr, C.; Büsch, L.; Schüppstuhl, T. Leakage Inspection for the Scale-Up of Hydrogen Electrolyzers: A Case Study and Comparative Analysis of Technologies. In International Conference on Flexible Automation and Intelligent Manufacturing; Springer: Cham, Switzerland, 2023; pp. 496–508. [Google Scholar] [CrossRef]

- Hayasaka, K.; Tagawa, Y. Mobile visualization of density fields using smartphone background-oriented schlieren. Exp. Fluids 2019, 60, 171. [Google Scholar] [CrossRef]

- Kousi, N.; Gkournelos, C.; Aivaliotis, S.; Lotsaris, K.; Bavelos, A.C.; Baris, P.; Michalos, G.; Makris, S. Digital Twin for Designing and Reconfiguring Human–Robot Collaborative Assembly Lines. Appl. Sci. 2021, 11, 4620. [Google Scholar] [CrossRef]

- Adler, P.; Syniawa, D.; Jakschik, M.; Christ, L.; Hypki, A.; Kuhlenkötter, B. Automatisierte Montage großskaliger Wasser-Elektrolyseure: Digitale Montageplanung für eine nachhaltige Wasserstoffwirtschaft auf Grundlage von Produkt, Prozess und Ressource. Proz. Ressour. I40M 2022, 2022, 12–16. [Google Scholar] [CrossRef]

- Saadat, M.; Nan, P. Industrial applications of automatic manipulation of flexible materials. Ind. Robot. Int. J. 2002, 29, 434–442. [Google Scholar] [CrossRef]

- Patil, S.; van den, J.; Alterovitz, B.R. Motion Planning Under Uncertainty in Highly Deformable Environments. In Robotics Science and Systems: Online Proceedings; University of North Carolina: Chapel Hill, NC, USA, 2011. [Google Scholar] [CrossRef]

- Drath, R.; Mosch, C.; Hoppe, S.; Faath, A.; Barnstedt, E.; Fiebiger, B.; Schlögl, W. Diskussionspapier—Interoperabilität Mit der Verwaltungsschale, OPC UA und AutomationML: Zielbild und Handlungsempfehlungen für Industrielle Interoperabilität: Zielbild und Handlungsempfehlungen für Industrielle Interoperabilität. Available online: https://opcfoundation.org/wp-content/uploads/2023/04/Diskussionspapier-Zielbild-und-Handlungsempfehlungen-fur-industrielle-Interoperabilitat-5.3-protected.pdf (accessed on 15 February 2024).

- IEC/PAS 63088*CEI/PAS 63088; Smart Manufacturing—Reference Architecture Model Industry 4.0 (RAMI4.0). IEC International Electrotechnical Commission: Geneva, Switzerland, 2017.

- Syniawa, D.; Jakschik, M.; Hypki, A.; Kuhlenkötter, B. Automated data-driven dimensioning and planning of modular large-scale electrolysis plants. In Proceedings of the 17th CIRP Conference on Intelligent Computation in Manufacturing Engineering, Ischia, Italy, 12–14 July 2023; Elsevier: Amsterdam, The Netherlands, 2023. [Google Scholar]

- Jakschik, M.; Syniawa, D.; Hypki, A.; Kuhlenkötter, B. Automated pipe routing in context of large-scale electrolyzer plants. In Proceedings of the 17th CIRP Conference on Intelligent Computation in Manufacturing Engineering, Ischia, Italy, 12–14 July 2023; Elsevier: Amsterdam, The Netherlands, 2023. [Google Scholar]

- Schleipen, M.; Drath, R. Three-view-concept for modeling process or manufacturing plants with AutomationML. In Proceedings of the 2009 IEEE Conference on Emerging Technologies & Factory Automation, Palma de Mallorca, Spain, 22–25 September 2009; IEEE: Piscataway, NJ, USA, 2009; pp. 1–4. [Google Scholar] [CrossRef]

- Jakschik, M.; Hypki, A.; Kuhlenkötter, B. Roboterprogrammierung mithilfe von AutomationML. Atp Mag. 2022, 64, 52–58. [Google Scholar] [CrossRef]

- Lüder, A.; Hundt, L.; Keibel, A. Description of manufacturing processes using AutomationML. In Proceedings of the 2010 IEEE 15th Conference on Emerging Technologies & Factory Automation (ETFA 2010), Bilbao, Spain, 13–16 September 2010; IEEE: Piscataway, NJ, USA, 2010; pp. 1–8. [Google Scholar] [CrossRef]

- Christ, L.; Adler, P.; Schulte, L.; Kuhlenkötter, B. Synthetic data derived from a digital twin for an error compensation algorithm of hydrogen tube fitting assembly. Procedia CIRP 2023, 120, 445–450. [Google Scholar] [CrossRef]

| Electrolyzer Type | Half Cell Reactions | Process Conditions | Electrode, Electrolyte, and Separator Materials |

|---|---|---|---|

| AWE | Ox: Red: | pH: 13–14 T: 60–80 °C pH2: 0.5 barg/30 barg | Ni. aqu. KOH-solution, - |

| PEM | Ox: Red: | pH: acidic T: 50–80 °C pH2: 40 barg | Pt,C and Ir oxides, Nafion membrane, - |

| AEM | Ox: Red: | pH: basic T: 50–80 °C pH2: 35 barg | Ni, aqu. KOH-solution, AEM membrane |

| SOWE | Ox: Red: | T: 700–850 °C pH2: 0 barg | Ceramic materials; Zirconium-based solid electrolyte |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Büsch, L.; Jakschik, M.; Syniawa, D.; Masuhr, C.; Christ, L.; Schachtsiek, J.; Haalck, K.; Nerlich, L.; Frömsdorf, E.; Schirmack, N.; et al. HyPLANT100: Industrialization from Assembly to the Construction Site for Gigawatt Electrolysis. Hydrogen 2024, 5, 185-208. https://doi.org/10.3390/hydrogen5020012

Büsch L, Jakschik M, Syniawa D, Masuhr C, Christ L, Schachtsiek J, Haalck K, Nerlich L, Frömsdorf E, Schirmack N, et al. HyPLANT100: Industrialization from Assembly to the Construction Site for Gigawatt Electrolysis. Hydrogen. 2024; 5(2):185-208. https://doi.org/10.3390/hydrogen5020012

Chicago/Turabian StyleBüsch, Lukas, Malte Jakschik, Daniel Syniawa, Christian Masuhr, Lukas Christ, Jan Schachtsiek, Kay Haalck, Leon Nerlich, Elisabeth Frömsdorf, Nadine Schirmack, and et al. 2024. "HyPLANT100: Industrialization from Assembly to the Construction Site for Gigawatt Electrolysis" Hydrogen 5, no. 2: 185-208. https://doi.org/10.3390/hydrogen5020012

APA StyleBüsch, L., Jakschik, M., Syniawa, D., Masuhr, C., Christ, L., Schachtsiek, J., Haalck, K., Nerlich, L., Frömsdorf, E., Schirmack, N., Ebert, B., Kirty, C., Adler, P., Schüppstuhl, T., & Kuhlenkötter, B. (2024). HyPLANT100: Industrialization from Assembly to the Construction Site for Gigawatt Electrolysis. Hydrogen, 5(2), 185-208. https://doi.org/10.3390/hydrogen5020012