Numerical Analysis for Hydrogen Flame Acceleration during a Severe Accident Initiated by SBLOCA in the APR1400 Containment

Abstract

1. Introduction

2. Multi-Dimensional Hydrogen Analysis System

2.1. Calculation Method of the Multi-Dimensional Hydrogen Analysis System

2.2. Established Analysis Methodology for the Hydrogen Flame Acceleration

3. The MHAS Analysis for the SBLOCA

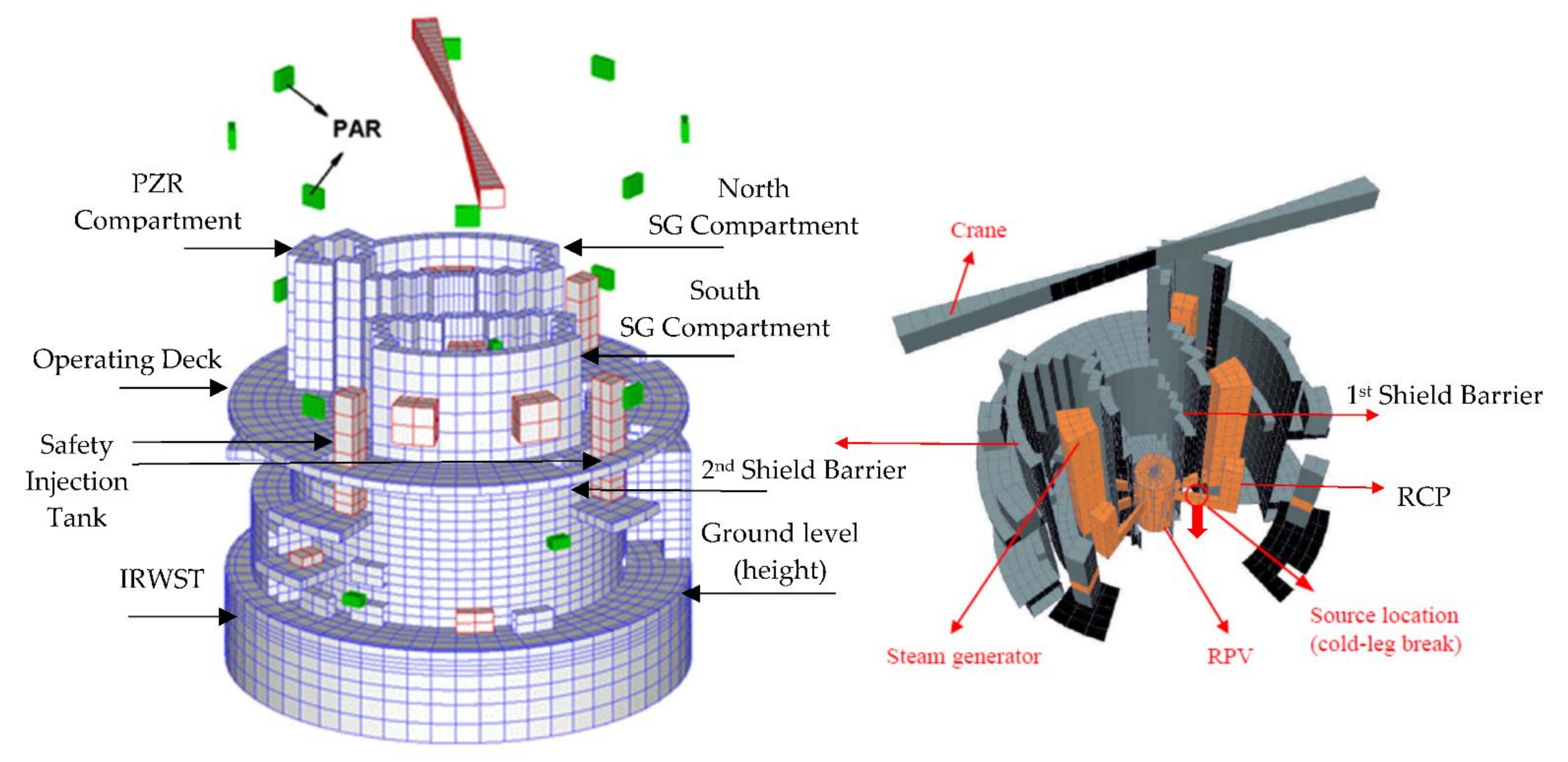

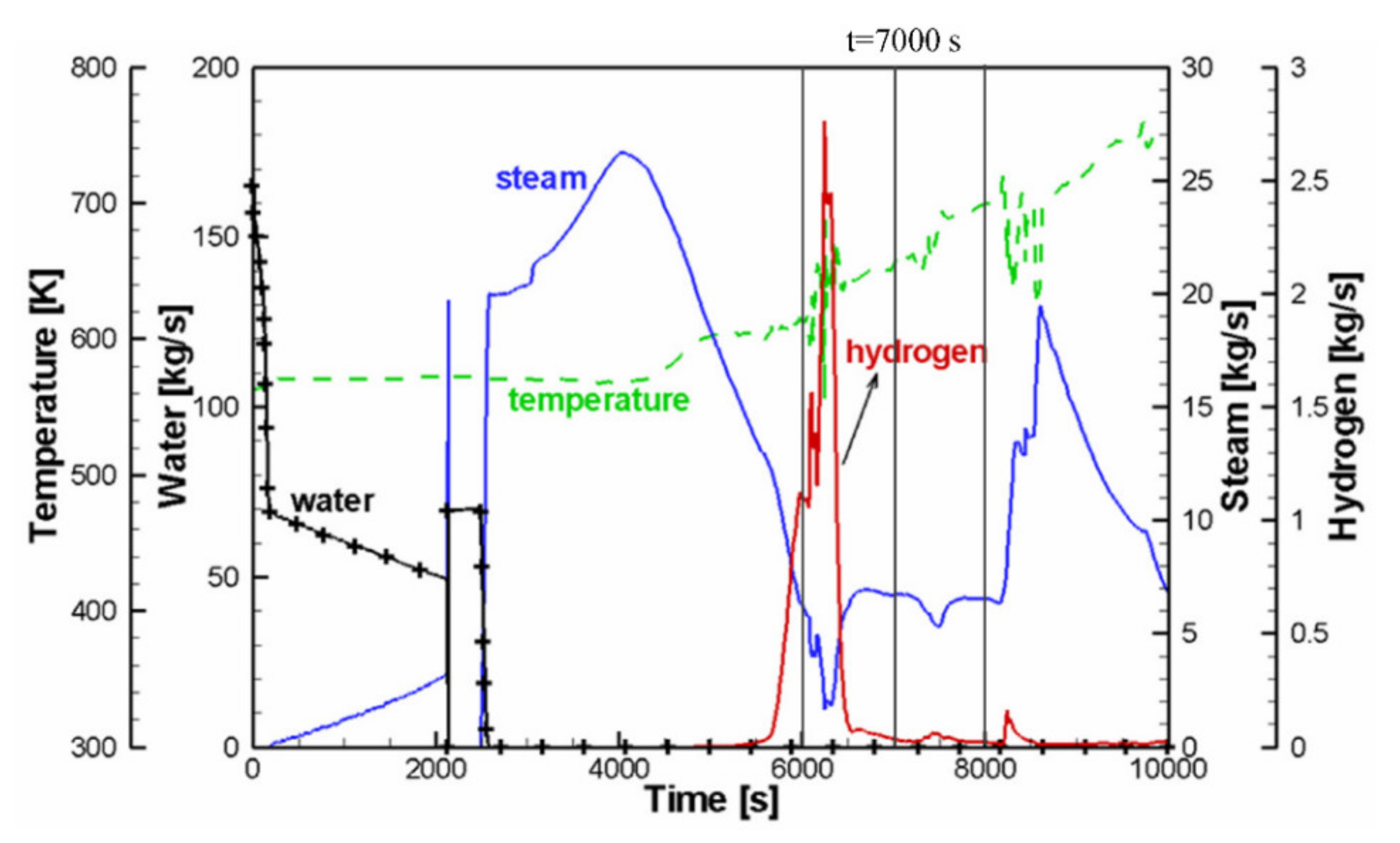

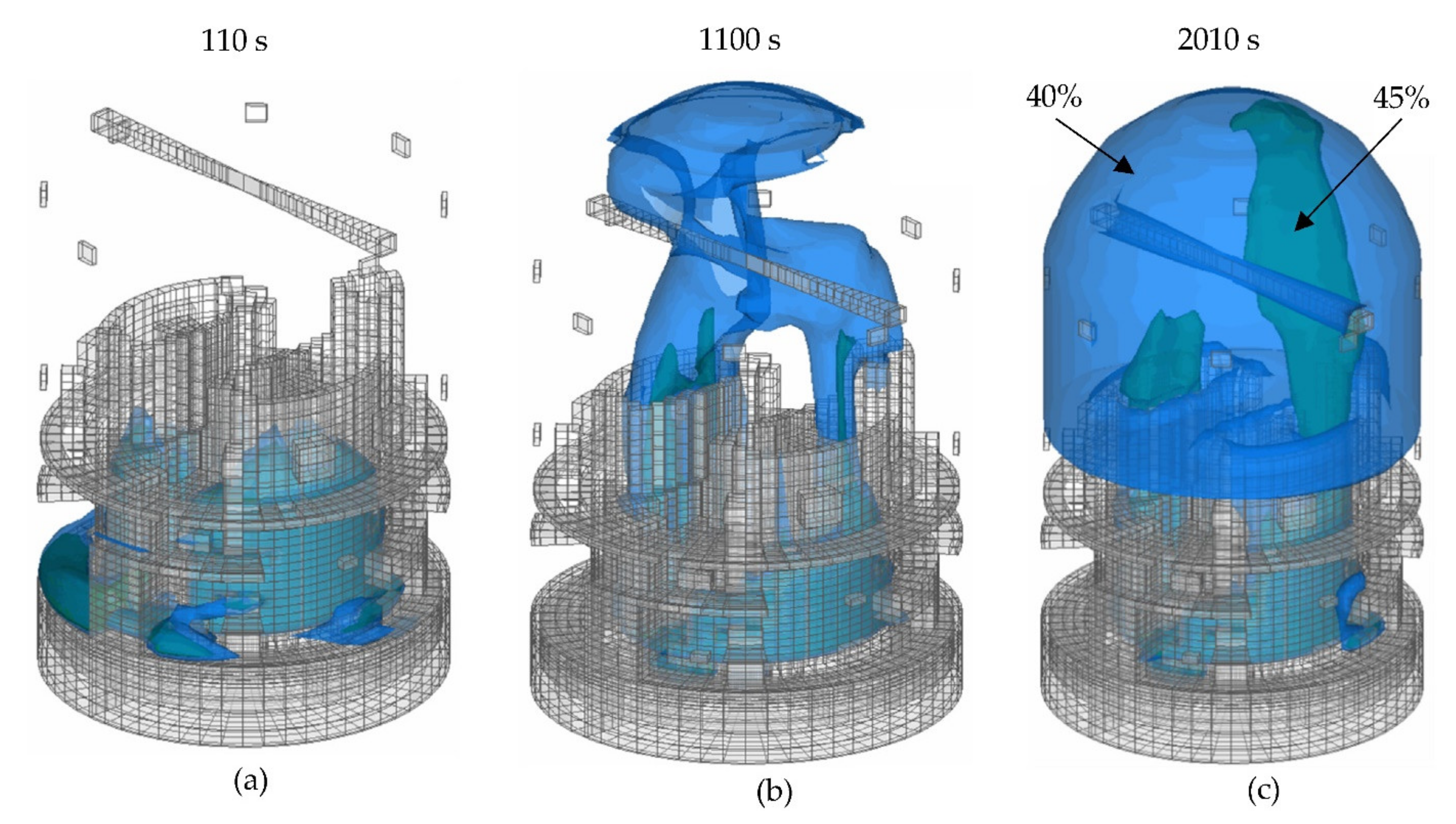

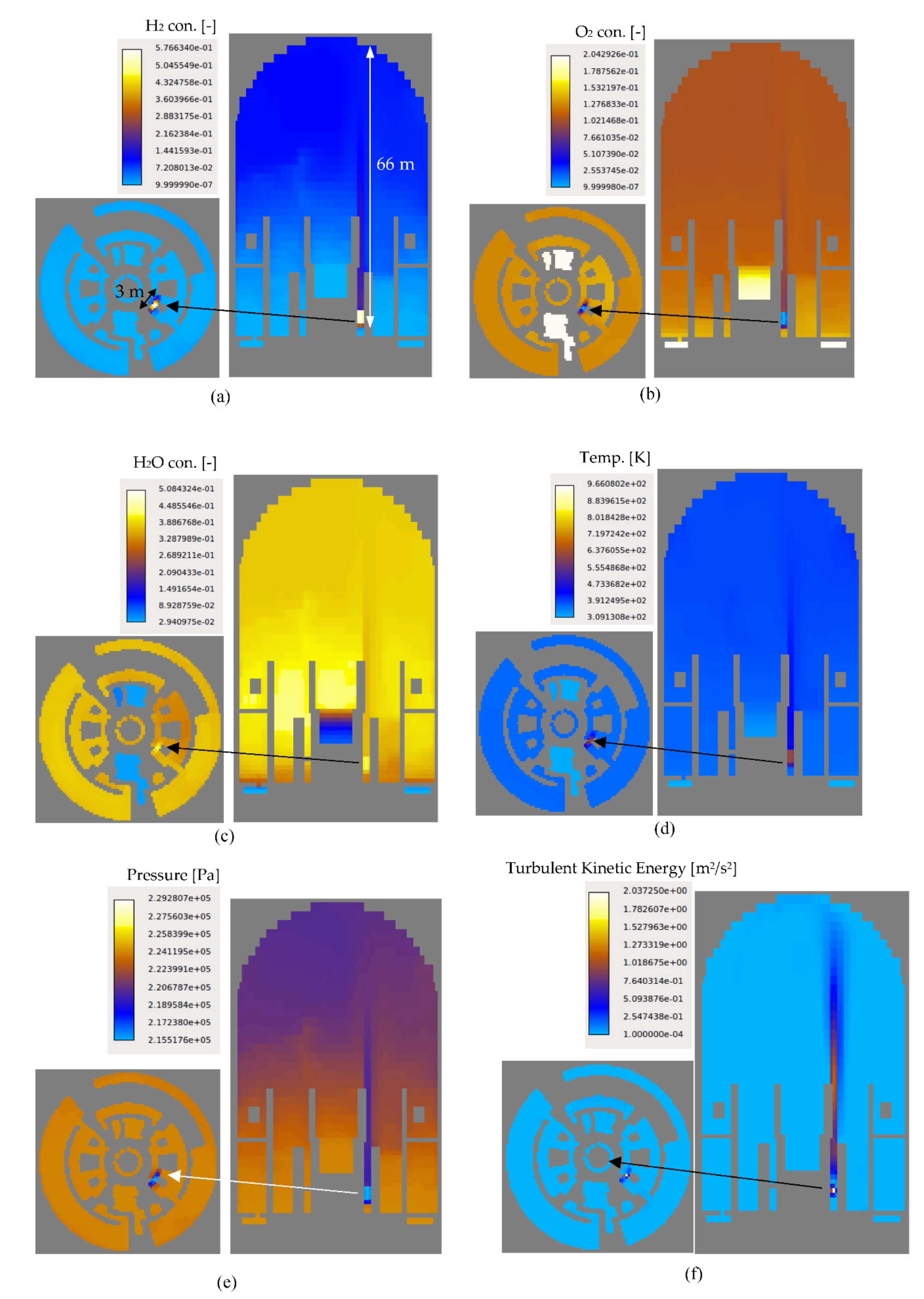

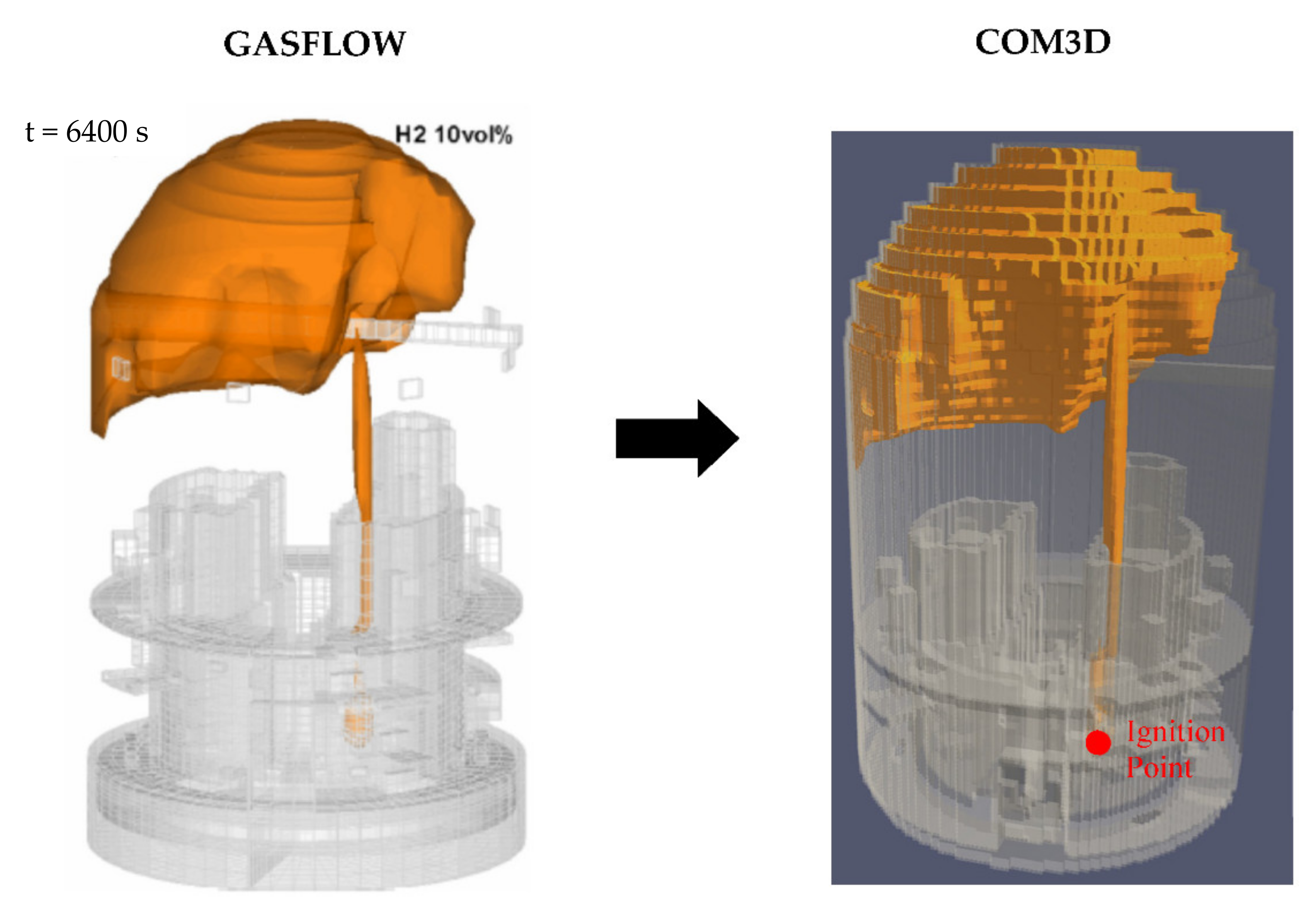

3.1. Calculation of the Hydrogen Distribution by GASFLOW and MAAP

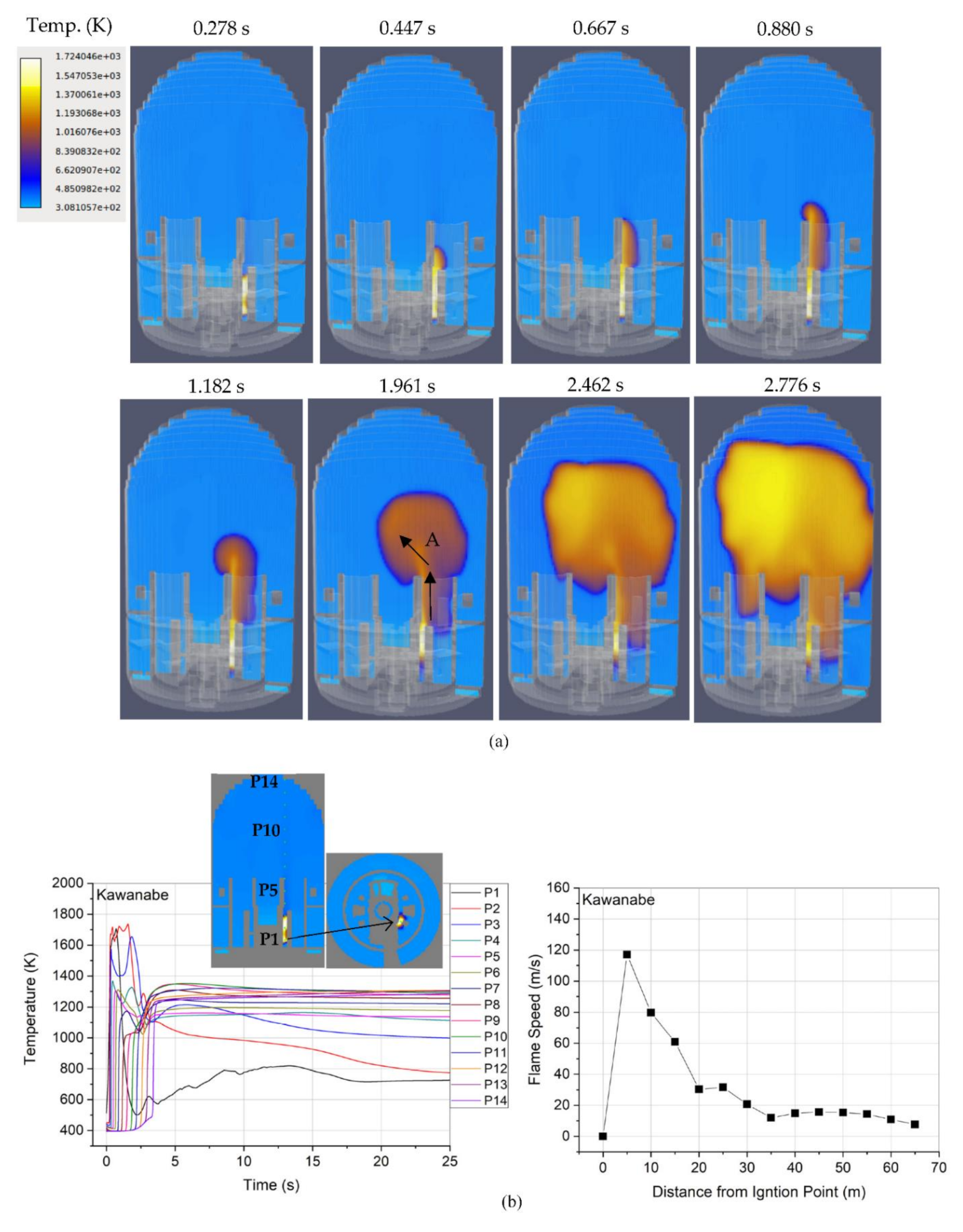

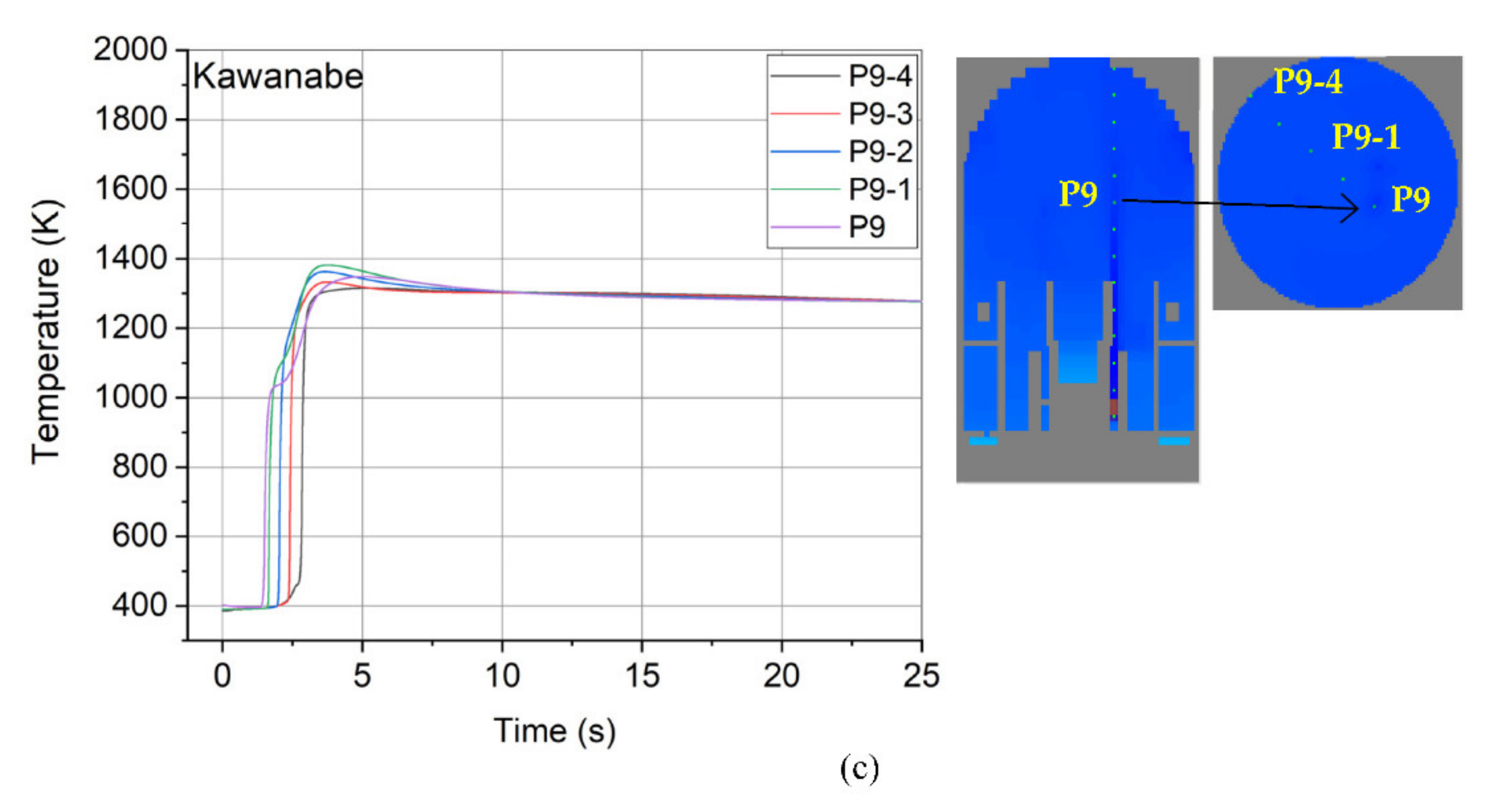

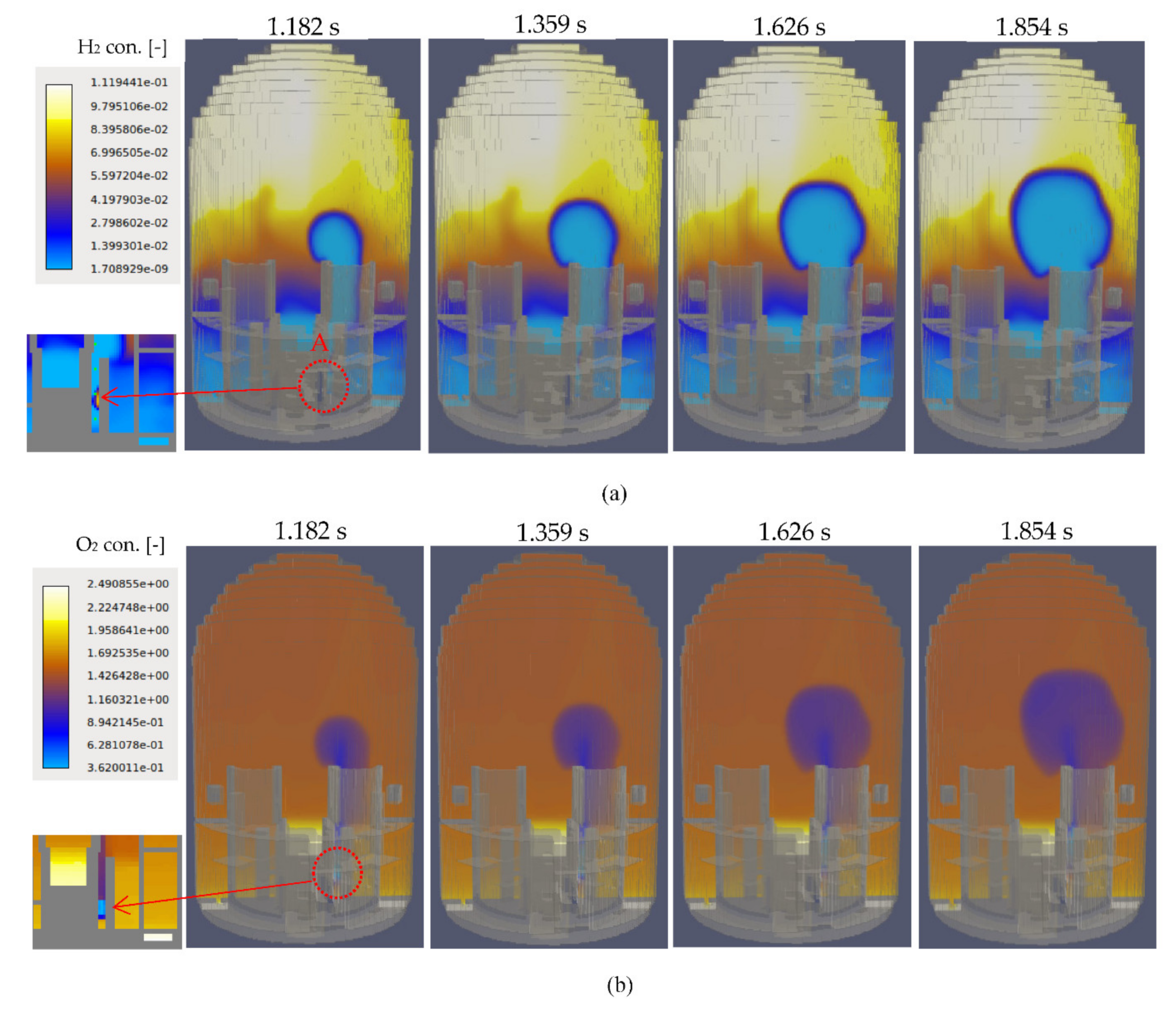

3.2. Calculation of the Hydrogen Flame Acceleration by the COM3D Code

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| Dt | turbulent diffusion coefficient [m2/s] |

| f | progressive variable [-] |

| k | turbulent kinetic energy [m2/s2] |

| P | pressure [Pa] |

| SL | laminar flame speed [m/s] |

| St | turbulent flame speed [m/s] |

| T | temperature [K] |

| u’ | turbulence fluctuation velocity [m/s] |

| Ui | velocity component [m/s] |

| Greek Letters | |

| α,β | correlation constant [-] |

| ε | turbulent eddy dissipation [m/s2] |

| μ | viscosity [kg/ms] |

| ρ | density [kg/m3] |

| σ | gas expansion coefficient [-] |

| Subscripts | |

| L | laminar |

| tur | turbulence |

| t | turbulence |

References

- International Atomic Energy Agency (IAEA). The Fukushima Daiichi Accident, Vol.1, Description and Context of the Accident; International Atomic Energy Agency (IAEA): Vienna, Austria, 2015. [Google Scholar]

- Kang, H.S.; Kim, J.; Kim, S.B.; Hong, S.W. Numerical analysis for H2 combustion in the APR1400 containment using a multi-dimensional H2 analysis system. In Proceedings of the 11th International Topical Meeting on Nuclear Reactor Thermal Hydraulics, Operational and Safety (UTHOS-11), Gyeongju, Korea, 9–13 October 2016. [Google Scholar]

- Kang, H.S.; Kim, J.; Hong, S.W.; Kim, S.B. Numerical Analysis for Hydrogen Flame Acceleration during a Severe Accident in the APR1400 Containment Using a Multi-Dimensional Hydrogen Analysis System. Energies 2020, 13, 6151. [Google Scholar] [CrossRef]

- Henry, R.E.; Paik, C.Y.; Plys, M.G. MAAP4-Modular Accident Analysis Program for LWR Plants; Fauske and Associates Inc.: Burr Ridge, IL, USA, 1994. [Google Scholar]

- Travis, J.R.; Royal, P.; Xiao, J.; Necker, G.A.; Reflinger, R.; Spore, J.W.; Lam, K.L.; Wilson, T.L.; Muller, C.; Nichols, B.D. GASFLOW: A Computational Fluid Dynamics Code for Gases, Aerosols, and Combustion; Karlsruhe Institute of Technology (KIT): Karlsruhe, Germany, 2011. [Google Scholar]

- Kotchourko, A.; Lelyakin, J.; Yanez, J.; Halmer, G.; Svishchev, Z.; Xu, Z.; Ren, K. COM3D User/Tutorial Guide, Version 4.10; Karlsruhe Institute of Technology (KIT): Karlsruhe, Germany, 2015. [Google Scholar]

- Bentaib, A.; Cataldo, C.; Chaumont, B.; Chevalier-Jabet, K. Evaluation of the impact PARs have on the hydrogen risk in the reactor containment: Methodology and application to PSA level 2. Sci. Technol. Nuclear Install. 2010, 2010, 320396. [Google Scholar] [CrossRef]

- Kim, H.C.; Suh, N.D.; Park, J.H. Hydrogen Behavior in the IRWST of APR1400 following a Station Blackout. Nucl. Eng. Technol. 2006, 38, 195–200. [Google Scholar]

- Kim, J.; Hong, S.W.; Kim, S.B.; Kim, H.D. Three-Dimensional Behaviors of the Hydrogen and Steam in the APR1400 Containment during a Hypothetical Loss of Feed Water Accident. Ann. Nucl. Energy 2007, 34, 992–1001. [Google Scholar] [CrossRef]

- Kim, J.; Hong, S.W.; Kim, S.B.; Kim, H.D.; Lee, U.J.; Royal, P.; Travis, J.R. Analysis of hydrogen behavior in the APR1400 containment with GASFLOW II. In Proceedings of the Tenth International Topical Meeting on Nuclear Reactor Thermal Hydraulics (NURETH-10), Seoul, Korea, 5–9 October 2003. [Google Scholar]

- Royal, P.; Rochholz, H.; Breitung, W.; Travis, J.R.; Necker, G. Analysis of Steam and Hydrogen Distributions with PAR Mitigation in NPP Containments. Nucl. Eng. Des. 2000, 202, 231–248. [Google Scholar] [CrossRef]

- Kudriakov, S.; Dabbene, F.; Studer, E.; Beccantini, A.; Magnaud, J.P.; Paillere, H.; Bentaib, A.; Bleyer, A.; Malet, J.; Porcheron, E.; et al. The TONUS CFD Code for Hydrogen Risk Analysis: Physical Models, Numerical Schemes and Validation Matrix. Nucl. Eng. Des. 2008, 238, 551–565. [Google Scholar] [CrossRef]

- Heitsch, M.; Huhtanen, R.; Techy, Z.; Fry, C.; Kostka, P.; Niemi, J.; Schramm, B. CFD Evaluation of Hydrogen Risk Mitigation Meaures in a VVER-440/213 Containment. Nucl. Eng. Des. 2010, 240, 385–396. [Google Scholar] [CrossRef]

- Bentaib, A.; Bleyer, A.; Meynet, N.; Chaumeix, N.; Schramm, B.; Höhne, M.; Kostka, P.; Movahed, M.; Worapittayaporn, S.; Brähler, T.; et al. SARNET Hydrogen Deflagration Benchmark: Main Outcomes and Conclusions. Ann. Nucl. Energy 2014, 74, 143–152. [Google Scholar] [CrossRef]

- Sathiah, P.; Komen, E.; Roekaerts, D. The Role of CFD Combustion Modeling in Hydrogen Safety-Part I: Validation Based on Small Scale Experiment. Nucl. Eng. Des. 2012, 248, 93–107. [Google Scholar] [CrossRef]

- Hong, S.W.; Kim, J.; Kang, H.S.; Na, Y.S.; Song, J. Research Effort for the Resolution of Hydrogen Risk. Nucl. Eng. Technol. 2015, 47, 33–46. [Google Scholar] [CrossRef]

- Xiao, J.; Travis, J.R.; Royl, P.; Necker, G.; Svishchev, A.; Jordan, T. Three-Dimensional All-Speed CFD Code for Safety Analysis of Nuclear Reactor Containment: Status of GASFLOW Parallelization, Model Development, Validation and Application. Nucl. Eng. Des. 2016, 301, 290–310. [Google Scholar] [CrossRef]

- Yanez, J.; Kuznetsov, M.; Souto-Iglesias, A. An Analysis of the Hydrogen Explosion in the Fukushima-Daiichi Accident. Int. J. Hydrog. Energy 2015, 40, 8261–8280. [Google Scholar] [CrossRef]

- Korea Hydro & Nuclear Power (KHNP). Final Safety Analysis Report of Shin-Kori 1&2; Korea Hydro & Nuclear Power (KHNP): Gyeongju-si, Korea, 2012. [Google Scholar]

- U.S.NRC. Regulation, 10CFR50.34(f), Additional TMI-Related Requirements; U.S.NRC: Rockville, MD, USA, 2015.

- Safety Review Guidelines for Light Water Reactors, Rev.6, KINS/GE-001; Korea Institute of Nuclear Safety (KINS): Daejeon, Korea, 2014.

- KEPCO & KHNP. Small Break Loss of Coolant Accident Evaluation Model, Rev.0, APR1400-F-A-NR-14001-NP, Rev.0; KEPCO & KHNP: Naju-si/Gyeongju-si, Korea, 2014. [Google Scholar]

- Kang, H.S.; NO, H.C.; Kim, S.B.; Kim, M.H. Methodology of CFD Analysis for Evaluating H2 Explosion Accidents in an Open Space. Int. J. Hydrogen Energy 2015, 40, 3075–3090. [Google Scholar] [CrossRef]

- Kang, H.S.; NO, H.C.; Kim, S.B. Application of the Developed CFD Analysis Methodology to H2 Explosion Accidents in an Open Space. Int. J. Hydrogen Energy 2017, 42, 1306–1317. [Google Scholar] [CrossRef]

- Hong, S.W.; Kim, J.; Kim, S.B.; Kang, H.S.; Na, Y.S.; Min, B.T.; Hong, S.H.; Son, D.G.; Song, J.H.; Jung, J.H.; et al. Development of Containment Long-Term Integrity Establishment Technology; Research Report, Report No. 4172/2016; KAERI: Daejeon, Korea, 2017. [Google Scholar]

- Peterson, R.J.; Grewal, S.S.; El-Wakil, M.M. Investigation of Liquid Flashing and Evaporation due to Sudden Depressurization. Int. J. Heat Mass Transf. 1984, 27, 301–310. [Google Scholar] [CrossRef]

- Bejan, A. Convection Heat Transfer, 2nd ed.; John Wiley and Sons Inc.: New York, NY, USA, 1995. [Google Scholar]

- Movahed-Shariat-Panahi, M.A. Recommendation for Maximum Allowable Mesh Size for Plant Combustion Analyses with CFD codes. Nucl. Eng. Design 2012, 253, 360–366. [Google Scholar] [CrossRef]

- Kotchourko, A.; Lelyakin, J.; (KIT, Karlsruhe, Land Baden-Württemberg, Germany). Personal communication, 2016.

- Dorofeev, S.B. Hydrogen Flames in Tubes: Critical Run-Up Distances. Int. J. Hydrogen Energy 2009, 34, 5832–5837. [Google Scholar] [CrossRef]

- Kang, H.S.; Kim, J.; Kim, S.B.; Hong, S.W. Preliminary Hydrogen Combustion Analysis for the APR1400 Containment Using the COM3D Code; Technical Report, Report No. 5312/2014; KAERI: Daejeon, Korea, 2016. [Google Scholar]

| Parameter | Model |

|---|---|

| 2nd order Total Variation Diminishing |

| KYLCOM+ |

| Kawanabe |

| Low Re number |

| <0.9 |

| <0.4 |

| Velocity slip/Temp. constant |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kang, H.-S.; Kim, J.; Hong, S.-W. Numerical Analysis for Hydrogen Flame Acceleration during a Severe Accident Initiated by SBLOCA in the APR1400 Containment. Hydrogen 2022, 3, 28-42. https://doi.org/10.3390/hydrogen3010002

Kang H-S, Kim J, Hong S-W. Numerical Analysis for Hydrogen Flame Acceleration during a Severe Accident Initiated by SBLOCA in the APR1400 Containment. Hydrogen. 2022; 3(1):28-42. https://doi.org/10.3390/hydrogen3010002

Chicago/Turabian StyleKang, Hyung-Seok, Jongtae Kim, and Seong-Wan Hong. 2022. "Numerical Analysis for Hydrogen Flame Acceleration during a Severe Accident Initiated by SBLOCA in the APR1400 Containment" Hydrogen 3, no. 1: 28-42. https://doi.org/10.3390/hydrogen3010002

APA StyleKang, H.-S., Kim, J., & Hong, S.-W. (2022). Numerical Analysis for Hydrogen Flame Acceleration during a Severe Accident Initiated by SBLOCA in the APR1400 Containment. Hydrogen, 3(1), 28-42. https://doi.org/10.3390/hydrogen3010002