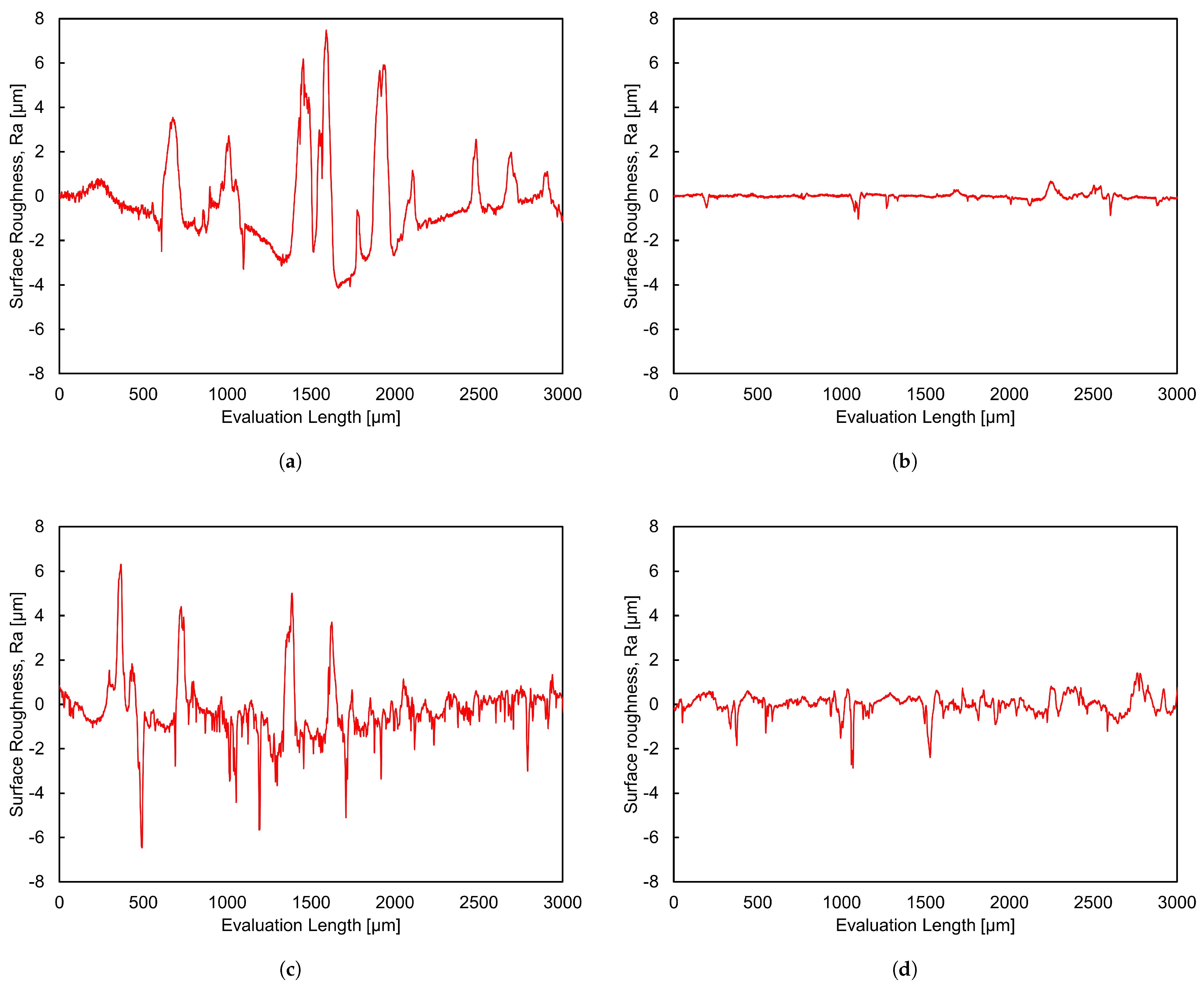

3.1. Surface Roughness of Unlaminated Specimens and Laminating Films

Table 1 presents the average surface roughness (

) values for the unlaminated neat PP and 25 wt% WP specimens, while

Table 2 presents the surface roughness values for the 0.1 mm thick PP and PET laminating films. For all materials, the coefficient of variation (CV)—expressed as a percentage of the mean—is shown in parentheses to indicate measurement variability. Representative surface roughness profiles for the specimens and films are illustrated in

Figure 6 and

Figure 7, respectively.

As shown in

Table 1 and

Figure 6, the surface roughness (

) in the transverse direction was substantially higher than in the longitudinal direction for both unlaminated neat PP and 25 wt% WP specimens. Specifically, the transverse roughness was approximately 13 times greater for neat PP and 2.8 times greater for 25 wt% WP compared to their respective longitudinal values. In the longitudinal direction, neat PP exhibited lower roughness than 25 wt% WP, whereas in the transverse direction, the opposite trend was observed. This pronounced increase in transverse roughness is likely due to scratches and flaws on the mold die surface, which were replicated on the specimen surface during fabrication. Notably, neat PP specimens appeared more sensitive to these surface imperfections.

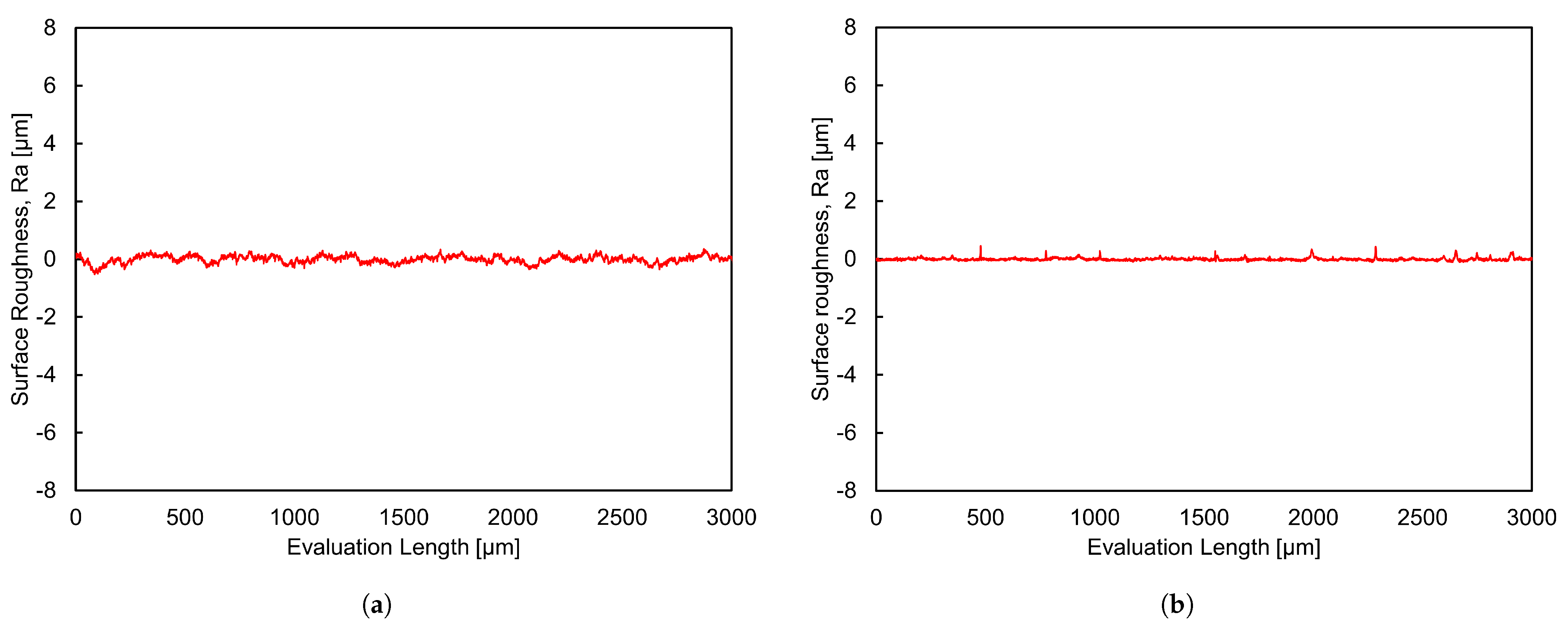

For the 0.1 mm PP and PET films (see

Table 2 and

Figure 7), surface roughness values differed significantly from those of the neat PP and 25 wt% WP specimens. The films exhibited low and uniform surface roughness, with average

values of 0.10 and 0.03 µm for the PP and PET films, respectively. In contrast, the neat PP and 25 wt% WP specimens showed higher roughness values of 1.56 and 0.86 µm, respectively, in the longitudinal direction—the direction with maximum surface roughness. The low roughness and small coefficients of variation observed in the films confirm their homogeneous surface texture, which contributed to the smoothing and homogenization of the specimen surface upon lamination. These results demonstrate that both PP and PET films are effective laminating materials for reducing surface roughness and masking surface defects in neat PP and WP specimens.

A comparison of the two laminating films (PP and PET) based on

Table 2 and

Figure 7 shows that the 0.1 mm PET film exhibits a smoother surface than the 0.1 mm PP film. The PET film recorded a lower average

value of 0.03 µm, compared to 0.10 µm for the PP film. In addition, the surface profile of the PET film (

Figure 7b) appears finer and more uniform than that of the PP film (

Figure 7a), indicating a higher degree of surface homogeneity. Although both films effectively reduced the surface roughness of the neat PP and WP specimens when applied as laminating layers, the PET film proved more effective in achieving a smoother and more uniform laminated surface. This superior performance can be attributed to the intrinsic smoothness and finer microtexture of the PET film, which likely enhanced its ability to conform to and mask surface irregularities in the substrate during lamination.

3.3. Effect of Lamination on the Tensile Properties of PP and WP Specimens

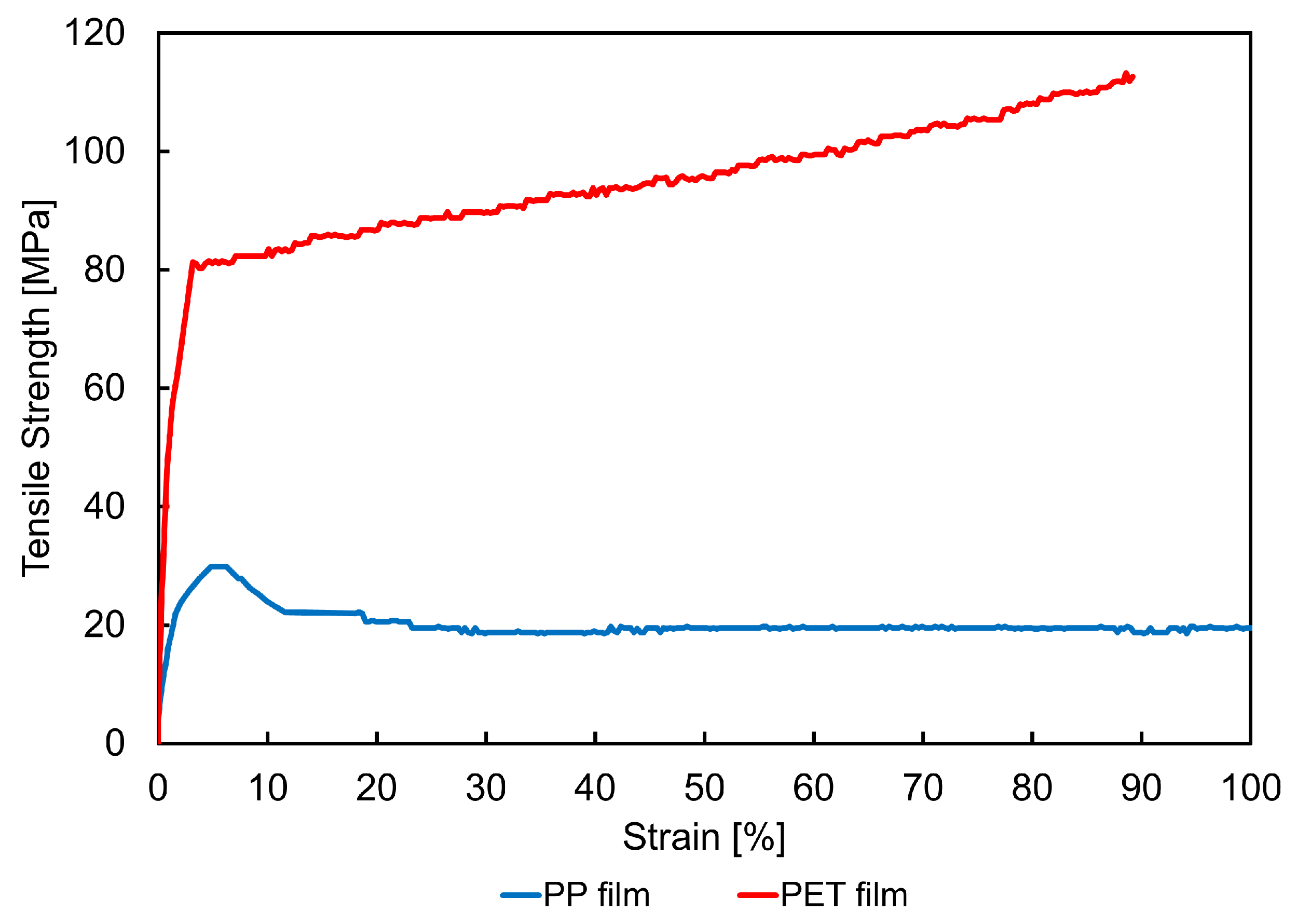

Table 3 details the tensile properties of 0.1 mm PP and PET films, while

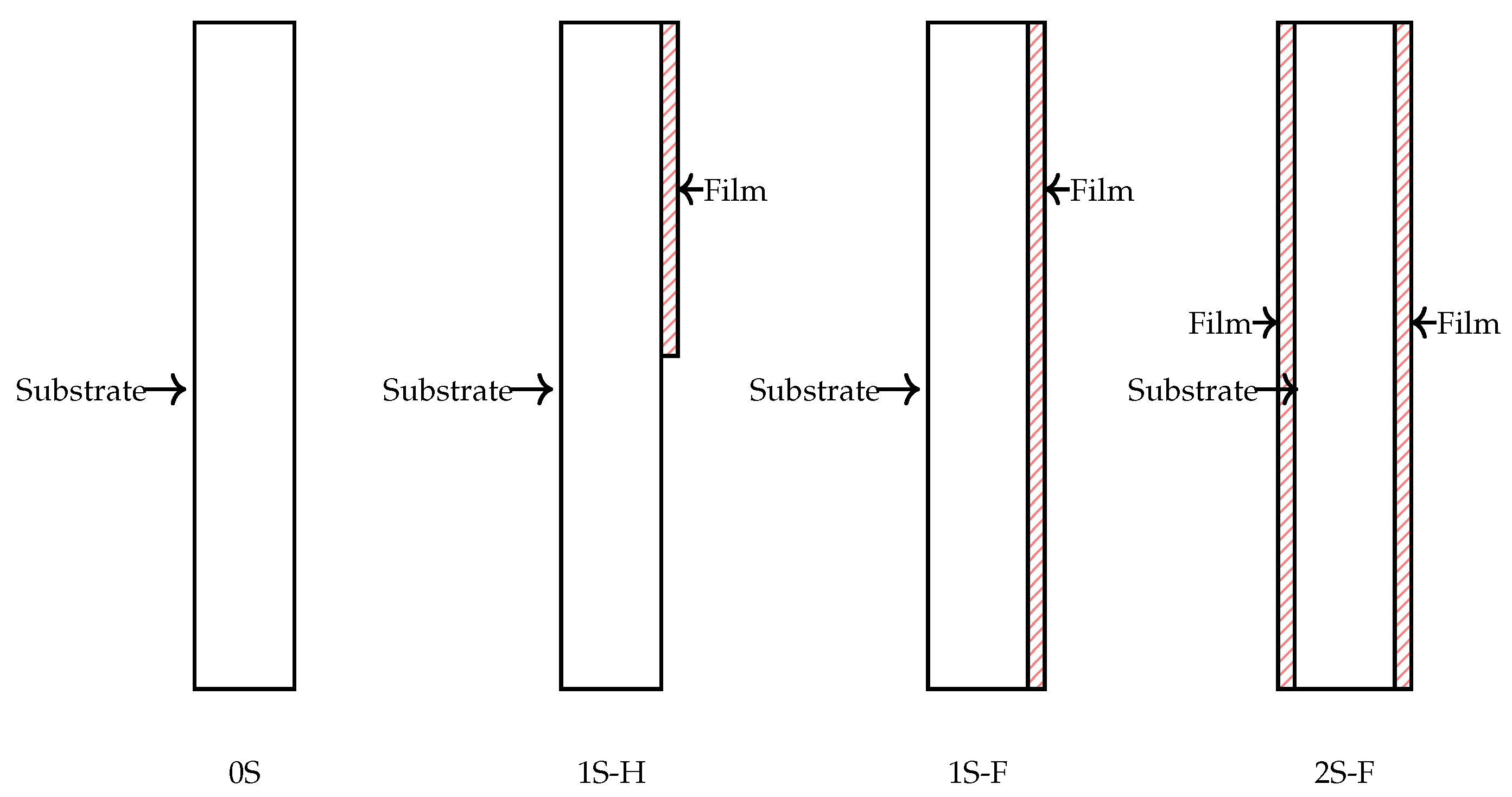

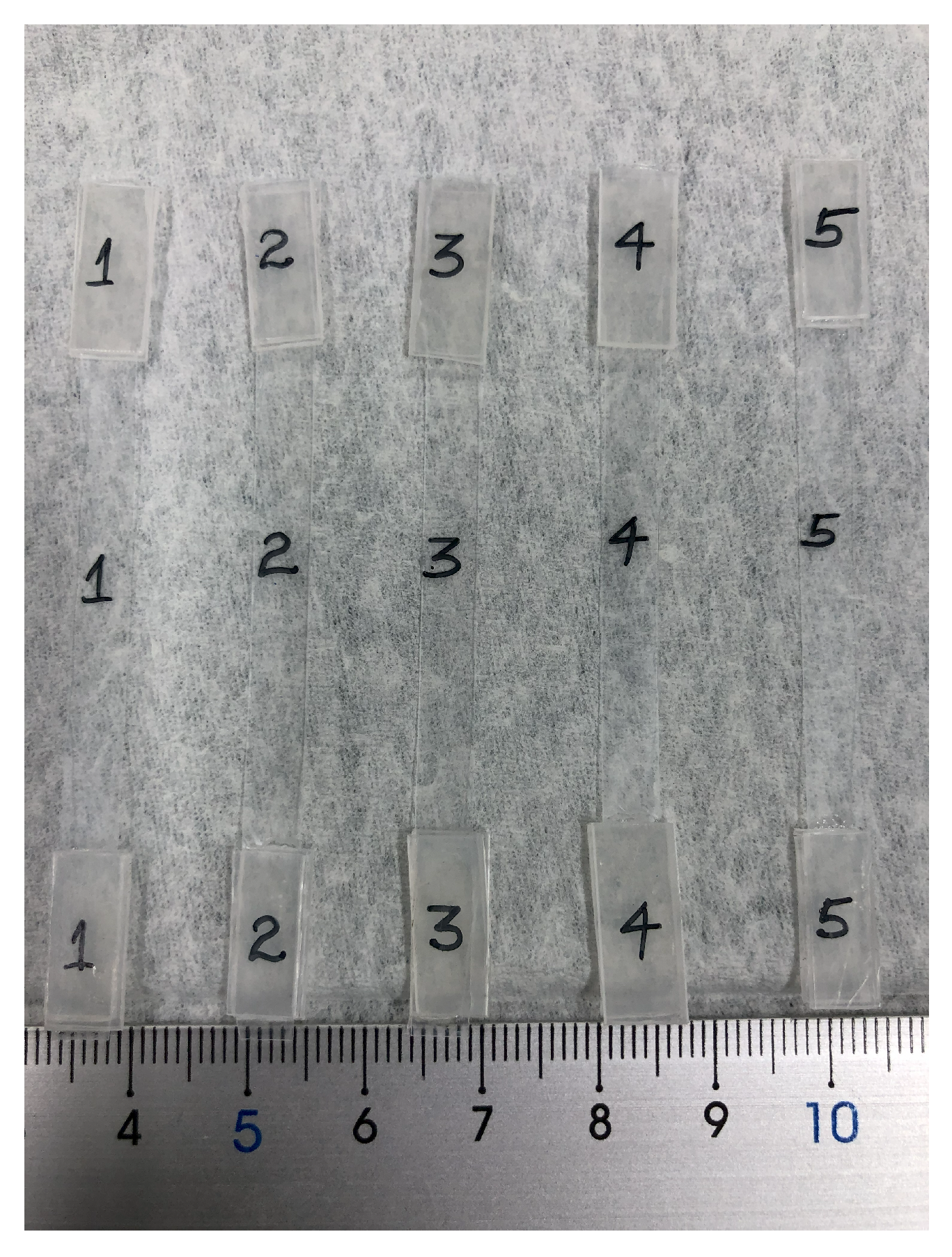

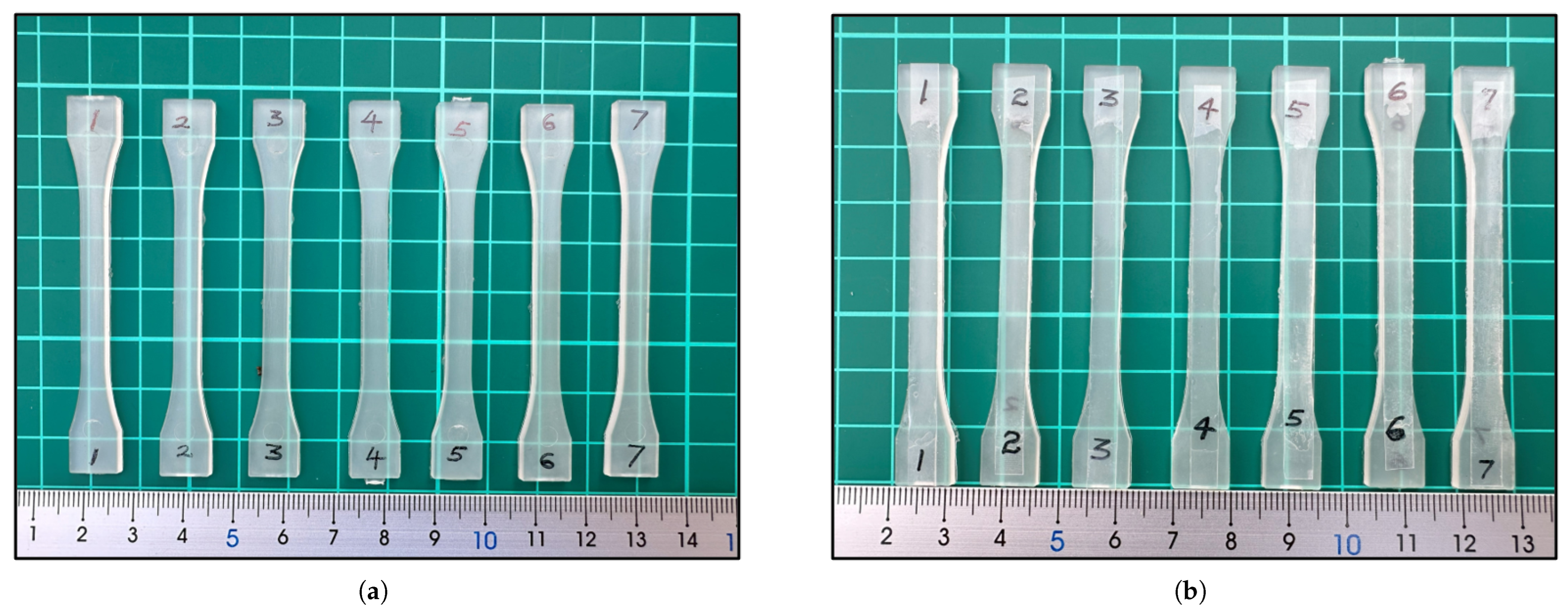

Table 4 presents those of neat PP and 25 wt% WP specimens under their various lamination configurations (0S, 1S-H, 1S-F, and 2S-F), with coefficients of variation shown in parentheses beside the respective values.

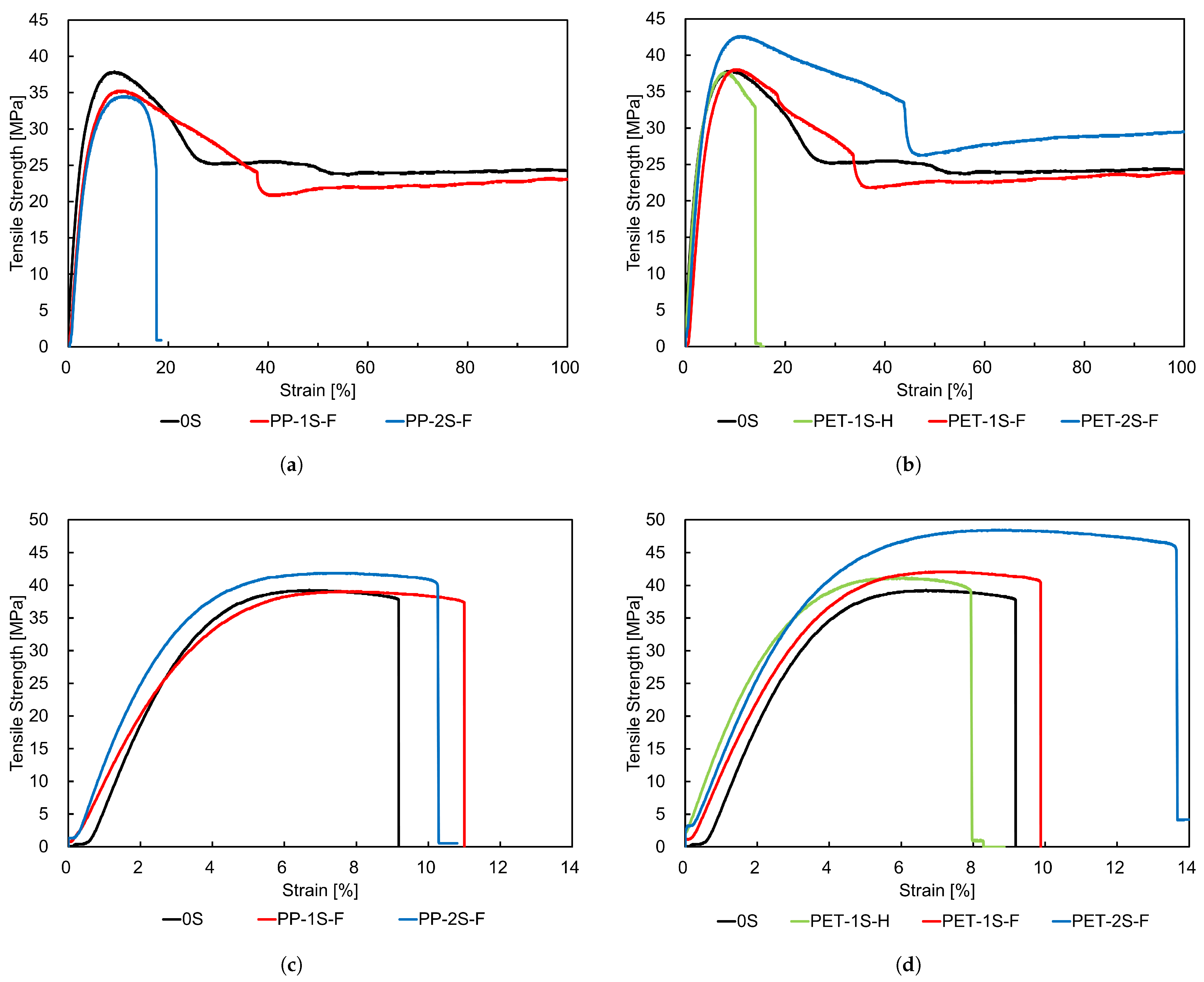

Figure 9 illustrates representative tensile stress–strain curves for the films, and

Figure 10 depicts the stress–strain behavior of neat PP and WP specimens under these different lamination conditions. Additionally, a Lamination Strength Ratio (LSR) column is provided in

Table 4. This ratio, calculated as

, represents the tensile strength of each laminated specimen (

) relative to its unlaminated reference (

). LSR values greater than one indicate enhanced tensile strength due to lamination.

As shown in

Figure 9, the tensile properties of the 0.1 mm PET and PP films reveal a marked contrast, underscoring their differing suitability for use as surface laminates in composite structures. The PET film exhibits a tensile strength of 113.2 MPa—approximately 3.8 times greater than the 29.5 MPa recorded for the PP film—attributable to the inherently higher stiffness and molecular orientation of PET. While both films display large fracture strains, the PP film is more ductile, with strains exceeding 100% of the original gauge length, compared to an average of 88.1% for PET.

These results demonstrate that PET offers superior strength, whereas PP contributes more to flexibility. Moreover, the PET film undergoes significant strain hardening after yielding, with its maximum strength approximately 42% higher than the yield point. In contrast, the PP film exhibits strain softening, characterized by a reduction in stress after peak strength, followed by stable plastic deformation. These contrasting behaviors are critical in evaluating their performance as laminating materials. The strain hardening of PET enhances its load-bearing capability and resistance to plastic deformation under tensile loading, making it more effective in reinforcing the structural integrity of laminated composites. Conversely, the higher ductility of PP may offer advantages in applications requiring flexibility but contributes less to overall stiffness and strength. Accordingly, PET is the more suitable choice for applications where mechanical reinforcement of the substrate is a primary requirement.

Turning to the stress–strain curves of the dumbbell specimens shown in

Figure 10, it is observed that lamination with the 0.1 mm PP film led to a reduction in tensile strength for the neat PP specimens, as indicated by LSR values below unity. Specifically, the 1S-F configuration exhibited a 4.0% decrease in tensile strength, while the 2S-F configuration showed a more pronounced 6.4% reduction compared to the unlaminated PP specimen. This decline is primarily attributed to the lower tensile strength of the laminated PP film relative to the bulk PP substrate, which introduced a mechanically weaker surface layer and consequently diminished the overall load-bearing capacity of the specimens. This interpretation is further reinforced by the observed trend in which tensile strength decreases progressively with increasing laminated surface area, as seen in the transition from the 0S to the 1S-F and 2S-F configurations. Thus, although PP film lamination may offer certain surface-related advantages—such as homogenization, void sealing, and improved surface smoothness—the overriding influence of its low intrinsic strength ultimately led to a net reduction in tensile performance.

Another contributing factor may be the high sensitivity of polypropylene to stress concentrations, which are often introduced by notches or microcracks that can form on the film surface due to firm adhesive bonding during lamination. Given that PP–PP adhesion is relatively strong compared to bonding with dissimilar materials, any initial crack in the adhesive layer can easily propagate through the film and into the underlying substrate. Because the adhesive bond between the film and the specimen is strong, delamination does not occur, allowing the crack to transfer directly to the specimen surface. This mechanism likely contributes to the observed reduction in tensile strength. This behavior is particularly evident in the 2S-F configuration, which unexpectedly exhibits a markedly low fracture strain. It is inferred that double-sided lamination imposes significant constraints on the specimen during tensile loading. In the absence of debonding, as previously discussed, cracks originating from the film or adhesive interface are rapidly transferred to the substrate, resulting in premature rupture and fracture. This explains the anomalous fracture behavior observed in the 2S-F configuration.

In contrast, the other configurations—namely 0S and 1S-F—exhibited normal ductile behavior, with fracture strains exceeding 200% of the original gauge length. Such extensive elongation is consistent with the well-known ductility of polypropylene and aligns with expectations for unreinforced or single-laminated PP specimens. The 1S-F configuration, in particular, retains an unlaminated surface, which allows greater deformation freedom on one side. This reduces the constraining effect associated with film bonding, thereby mitigating premature crack transfer and enabling fracture strain behavior comparable to that of the unlaminated specimen.

The lamination of neat PP specimens with the 0.1 mm PET film, however, resulted in improved tensile strength, as reflected by LSR values exceeding one. The tensile strength increased progressively with greater surface coverage—by 1.9% for the 1S-H configuration, 2.9% for 1S-F, and 12.3% for 2S-F—relative to the unlaminated specimen. This positive correlation is primarily attributed to the superior intrinsic strength and stiffness of PET, which imparts a reinforcing effect akin to that of a composite layer when firmly bonded to the PP substrate. Further evidence is provided by surface roughness measurements and SEM observations (

Figure 7 and

Figure 8), which indicate that PET lamination effectively sealed surface voids and irregularities, producing a more uniform and defect-free surface. This morphological improvement likely reduced stress concentrations and delayed the onset of crack initiation under tensile loading. The most significant enhancement was observed in the 2S-F configuration, which benefited from full surface coverage on both sides—minimizing the number of flaw sites and maximizing structural reinforcement, thereby yielding the highest tensile strength improvement among the tested configurations. Additionally, although the adhesive bond between the PET film laminate and the PP substrate is relatively weaker than that observed with PP film lamination, the reinforcement provided by the PET film’s superior intrinsic strength appears to outweigh the drawbacks associated with the weaker interfacial bonding. This indicates that the mechanical advantage conferred by the PET layer is primarily governed by its own strength and stiffness, rather than by adhesive performance alone.

With respect to fracture strain, all PET-laminated configurations—except for 1S-H—exhibited pronounced ductility, with elongation exceeding 200% prior to failure. This behavior is consistent with the inherent ductility of polypropylene, as previously discussed. In contrast, the 1S-H configuration showed a markedly reduced fracture strain. This anomaly is attributed to stress concentration localized at the specimen midspan, where the PET film coverage terminates. The abrupt interface between the laminated and unlaminated regions likely acted as a stress riser, initiating crack formation at the substrate surface. The crack then propagated rapidly through the specimen, leading to premature rupture. This explanation is supported by the observation that, in all tested specimens within the 1S-H configuration, fracture consistently occurred at the midspan—precisely at the transition point between the bonded and unbonded regions.

For the 25 wt% WP specimens, lamination with the PP film exhibited a distinct behavior compared to neat PP. Under the 1S-F configuration, tensile strength remained essentially unchanged, as reflected by an LSR value of 1.00. However, the 2S-F configuration showed a significant increase of 5.0% in tensile strength relative to the unlaminated specimen. This contrasts with the trend observed in neat PP specimens, where lamination with the same PP film consistently reduced tensile strength across all configurations. This difference suggests that, despite the intrinsically low tensile strength of the PP film, its lamination on the rougher surface of the WP specimen produced a net positive effect. The presence of wood fibers inherently increases surface roughness and introduces interfacial voids or micro-defects during molding. When laminated with PP film, these surface irregularities were effectively smoothed and sealed, resulting in enhanced surface homogeneity. This likely reduced stress concentration sites and delayed crack initiation under tensile loading.

Moreover, although the lamination introduces a relatively weaker surface layer and restricts local deformation due to the strong but brittle adhesive bond, these drawbacks appear to be outweighed in the case of WP specimens by the reduction in surface flaws and improved load distribution at the interface. Especially in the 2S-F configuration, where both surfaces are covered, the cumulative effect of void sealing and stress mitigation becomes more pronounced, resulting in a net gain in tensile performance. These results underscore that surface modification through PP film lamination can be more beneficial for composite materials—where stress concentration is a greater concern—than for homogeneous polymers.

For the WP25 specimens laminated with PET film, tensile strength improvements of approximately 4%, 6%, and 21% were observed for the 1S-H, 1S-F, and 2S-F configurations, respectively, relative to the unlaminated baseline. These results demonstrate that lamination in all configurations led to measurable enhancements in tensile strength, with the 2S-F configuration yielding the most pronounced improvement—21%, the highest observed in this study. The mechanism underlying this enhancement is consistent with that described for PET-laminated neat PP specimens. Specifically, the improvement arises from a combination of the reinforcing contribution of the PET film—whose inherent tensile strength exceeds that of the substrate—and the beneficial surface homogenization effect. The PET film effectively masks surface voids and irregularities, promoting more uniform stress distribution during loading. The superior performance of the 2S-F configuration underscores the importance of bilateral surface modification: lamination on both sides more effectively seals surface defects, mitigates premature failure by suppressing crack initiation sites, and thus yields a substantial gain in mechanical performance. This interpretation is further supported by the fractographic analysis presented in the subsequent section.

Regarding the fracture strains of the 25 wt% WP specimens, film lamination generally led to increased ductility across all configurations, as evidenced by higher fracture strains compared to the unlaminated specimen (

Table 4,

Figure 10). This enhancement is attributed to the synergistic interaction between the ductile laminating films and the brittle WP substrate, whereby the films absorbed part of the applied strain and redistributed stress more uniformly, effectively delaying fracture initiation. An exception was observed in the 1S-H configuration, which exhibited a noticeably reduced fracture strain. As discussed earlier in the case of neat PP specimens laminated with PET film, this reduction is likely due to asymmetric surface coverage—specifically, the film terminating near the specimen’s midspan—creating a localized stress concentration that served as a crack initiation site. The consistent midspan fracture location observed in this configuration supports this interpretation.

In summary, the results demonstrate that film lamination—particularly with PET—can significantly enhance the tensile strength of both PP and WP specimens, with improvements strongly influenced by the film’s mechanical properties, bonding effectiveness, and surface coverage. Notably, PP film, despite its lower intrinsic strength, offered modest benefits for WP specimens by mitigating surface flaws that act as stress concentrators.

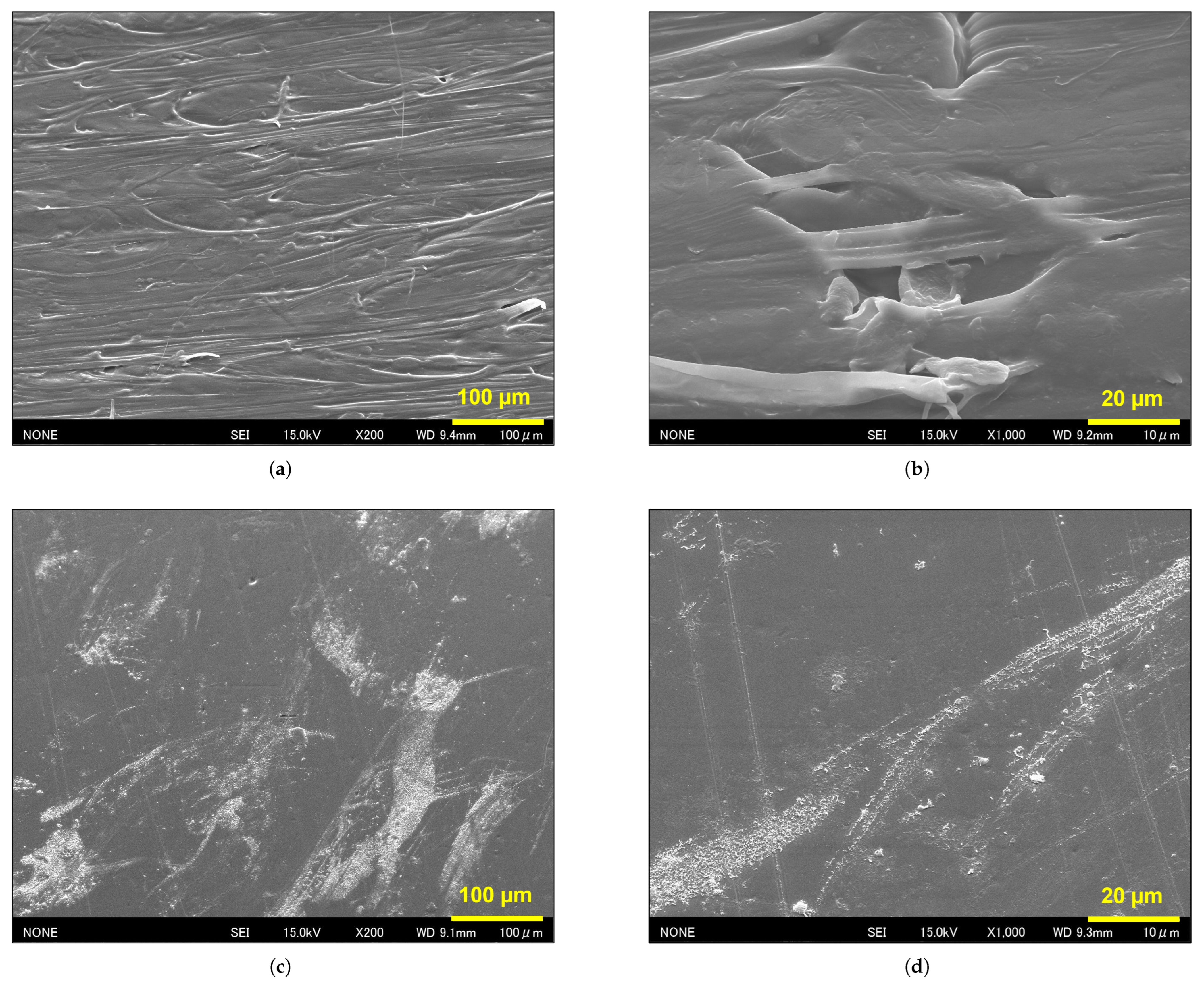

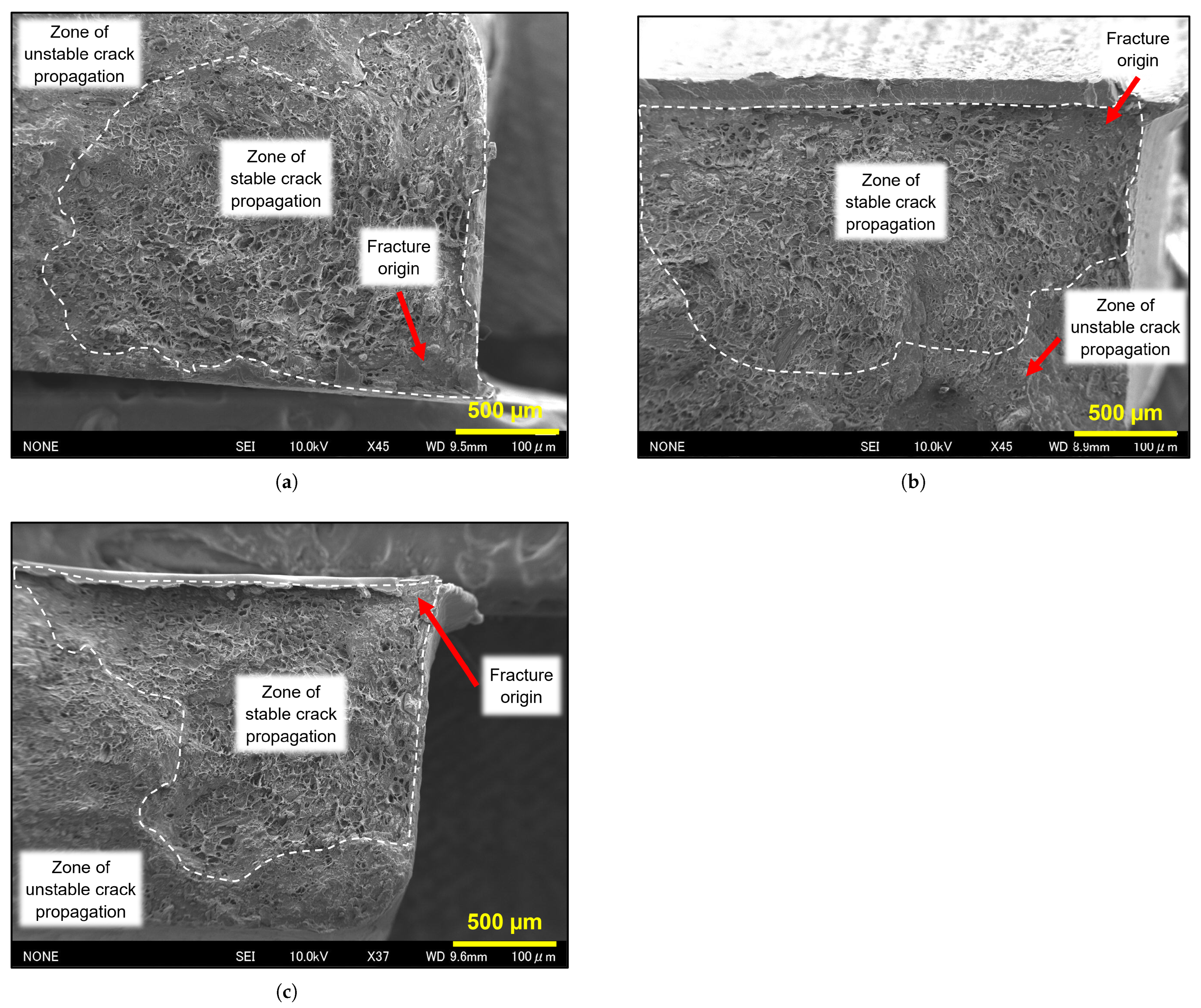

3.4. Fracture Surface Analysis of WP Specimens

Figure 11 presents the fracture morphology of 25 wt% WP specimens following tensile testing. The SEM micrographs show no observable evidence of macroscale fiber pull-out or interfacial debonding on the fracture surfaces, suggesting relatively strong interfacial adhesion between the wood fibers and the polypropylene matrix. Visual inspection revealed two distinct regions, differentiated by color: a smaller, whitened zone and a larger, brown zone. Although the color distinction was clearly visible, differences in surface texture were not discernible without magnification. Under stereoscopic microscopy, the brown region appeared rougher and more topographically irregular, whereas the white region was comparatively smoother. These morphological differences were further confirmed by SEM imaging, which—despite not capturing color—clearly revealed two distinct fracture surface textures: a rough, bumpy region covering the majority of the surface and a smoother region occupying a smaller portion. For clarity, the boundaries between these regions have been demarcated and labeled in the SEM micrographs shown in

Figure 11a–c.

This fracture pattern—comprising a larger rough, brown region and a smaller, smoother, whitened region—is consistent with the findings of Nordin et al. [

21], who observed the reverse morphology under fatigue loading conditions. The whitened zone is indicative of polypropylene fibrillation, as suggested by its characteristic appearance and previously confirmed by Nordin et al. [

21] through high-magnification SEM imaging. In addition, a distinct flat region was consistently observed near the corner edges of the fracture surface, located exclusively within the whitened area across all specimen configurations—unlaminated, PP-laminated, and PET-laminated—as illustrated in

Figure 11.

In the context of fracture mechanics, crack propagation is broadly classified into two regimes: stable and unstable. In stable crack growth, the crack advances gradually under increasing load, while in unstable crack growth, rapid and catastrophic failure occurs once a critical crack length is reached [

20,

22]. Based on the morphology and location of the distinct regions, it is inferred that the whitened area corresponds to the zone of stable crack growth, and the brown, rough region represents the zone of unstable crack propagation. The flat feature within the whitened region is considered the likely site of crack initiation, from which the fracture subsequently propagated across the cross-section of the specimen. As previously noted, Nordin et al. [

21] reported a dominant white fibrillated region and a relatively smaller brown area in fatigue-tested specimens. This discrepancy is attributed to the nature of loading: fatigue failure occurs at lower stress amplitudes but over longer durations, allowing cracks to propagate extensively before final failure. In contrast, tensile failure, as in the present study, occurs under higher stress levels where the critical crack length is reached more rapidly, resulting in a comparatively smaller stable fracture zone and a more extensive unstable region.

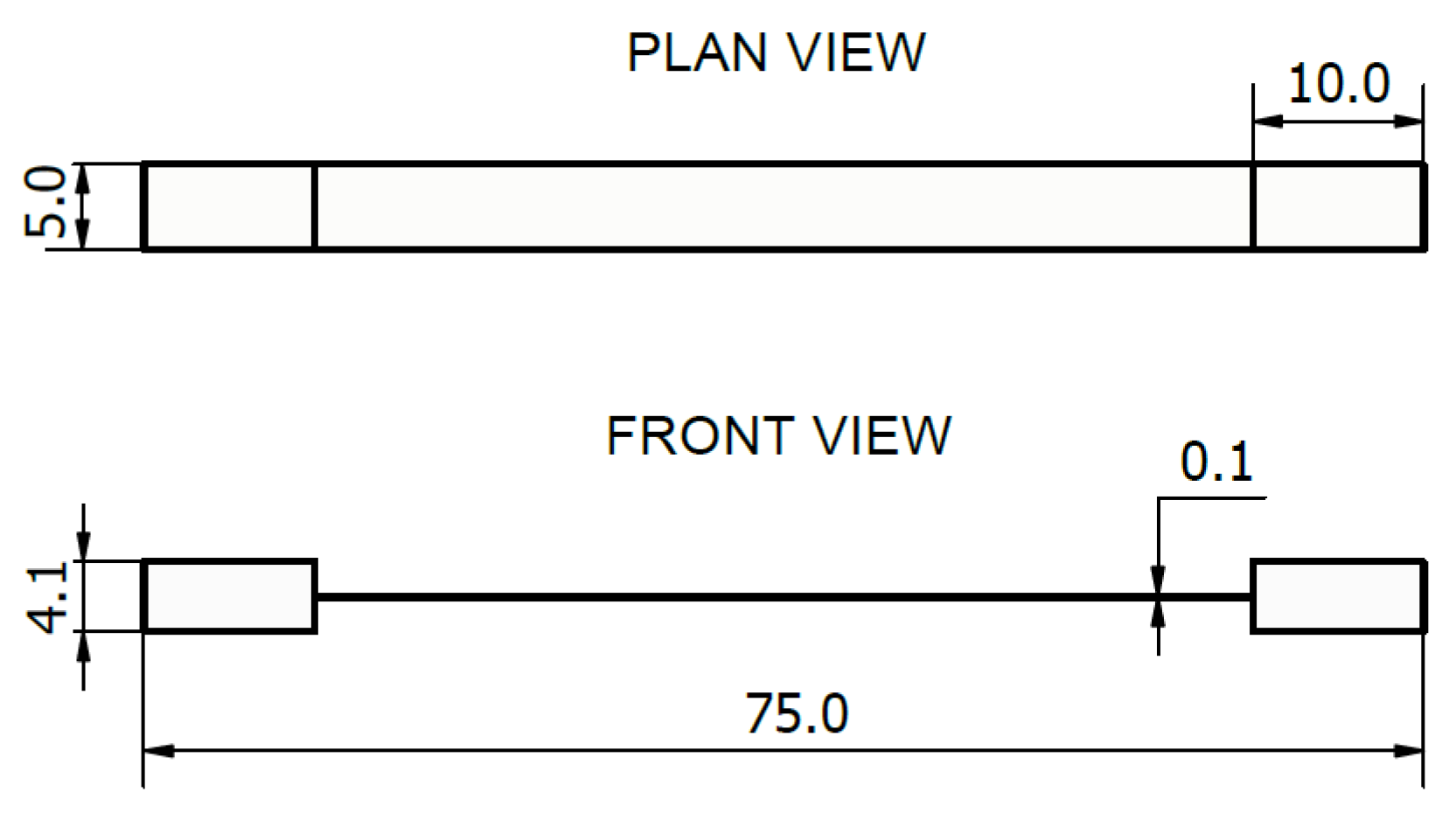

To assess the effect of film lamination on the suppression of fracture initiation, it is essential to consider the proportion of the specimen’s surface area covered by the laminate. Given that all specimens share an identical gauge length, the analysis can be normalized by considering a unit gauge length and focusing on the cross-sectional perimeter. For a specimen measuring 5 mm in width and 2 mm in thickness, the cross-sectional perimeter is 14 mm. The lamination film, also 5 mm wide, is applied to the broader (5 mm) surfaces of the specimen. Based on this configuration, the fraction of the perimeter covered by the laminate corresponds to approximately 10/14 for double-sided full-length lamination (2S-F), 5/14 for single-sided full-length lamination (1S-F), and 2.5/14 for single-sided half-length lamination (1S-H).

Among these configurations, 2S-F provides the most extensive surface coverage and correspondingly yields the greatest improvement in tensile strength. This trend indicates a clear correlation between the fraction of laminated surface and the degree of mechanical reinforcement. While this enhancement is partly attributable to the inherent stiffness and strength of the laminate, scanning electron microscopy (SEM) images of the fracture surfaces suggest a complementary mechanism: surface shielding. Lamination appears to mitigate fracture initiation by covering surface irregularities and defects—particularly at or near the corners—that typically serve as sites for crack initiation under tensile loading.

As the laminated area increases, a larger number of these critical surface features are shielded, thereby reducing the likelihood of premature failure. Although the 2 mm side faces remain unlaminated in all configurations, the 2S-F specimens still exhibit notable resistance to fracture, underscoring the effectiveness of shielding the broader 5 mm faces. This observation implies that further gains in mechanical performance could potentially be achieved by extending the film to wrap around or encapsulate the side faces. Future studies should therefore explore full-surface encapsulation strategies, including coverage of the narrow sidewalls, to assess their influence on crack suppression and overall mechanical reliability.

In summary, the SEM analyses reinforce the conclusion that surface lamination enhances fracture resistance by improving surface smoothness, uniformity, and morphological integrity. By effectively sealing topographical defects and reducing the number of accessible fracture initiation sites, lamination contributes to the observed improvements in tensile strength for both neat PP and WP specimens. These findings underscore the significance of surface engineering as a viable strategy for enhancing the mechanical reliability of polymer-based composites.

3.5. Rule of Mixtures Prediction and Experimental Comparison

To quantitatively evaluate the influence of 0.1 mm PP and PET surface laminates on the tensile properties of neat PP and 25 wt% WP specimens, theoretical predictions were made using the classical rule of mixtures. This established analytical model estimates the effective macroscopic mechanical properties of a composite system by assuming a linear relationship between the properties of its individual constituents and their respective volume fractions. In this analysis, the laminated specimens were idealized as two-phase composite systems consisting of a surface film bonded to a polymeric substrate—either neat PP or 25 wt% WP.

To enable a consistent comparison of theoretical and experimental tensile properties, the effective volume fractions of the substrate and laminating film were estimated for each configuration—1S-H, 1S-F, and 2S-F. Given the uniform film thickness of 0.1 mm, the average contributing thicknesses were considered as 0.05 mm for 1S-H (single-side half-coverage), 0.1 mm for 1S-F (single-side full-coverage), and 0.2 mm for 2S-F (double-side full-coverage). Because all specimens shared the same width and gauge length, volume fractions (

for the film and

for the substrate) were calculated using thickness as the sole variable. This approach provided a physically grounded basis for comparing predictions based on the rule of mixtures with experimental results, as summarized in

Table 5.

As shown in

Table 5, the calculated volume fractions for the laminated 25 wt% WP specimens are identical to those of the neat PP counterparts. This consistency reflects the high-dimensional precision achieved during injection molding, which yielded specimens with closely matched cross-sectional geometries across both material systems. Although slight variations in cross-sectional area were observed among individual specimens, these deviations were statistically negligible and did not warrant the differentiation of volume fraction values between the two material types. The application of uniform volume fraction assumptions is therefore justified and appropriate for the comparative analysis of tensile behavior.

The theoretical tensile strength of the laminated specimen, denoted as

, was estimated using the classical rule of mixtures:

where

and

represent the tensile strengths of the unlaminated substrate and the laminating film, respectively, and

and

denote their corresponding volume fractions.

As reported in

Section 3.3, the measured tensile strengths of the 0.1 mm PP and PET films were 29.5 MPa and 113.2 MPa, respectively. However, since all laminated specimens failed within the substrate—either neat PP or 25 wt% WP—without evidence of rupture or delamination in the bonded films, it was deemed inappropriate to use the films’ ultimate tensile strengths in the predictive model. Instead, a more representative approach was adopted by determining the stress sustained by each film at the strain corresponding to the maximum tensile stress of the respective unlaminated substrate. To implement this correction, the strain values at which the unlaminated substrates reached their tensile strength maxima were first identified from their stress–strain curves. These critical strain values were determined to be 8.2% for neat PP and 6.7% for 25 wt% WP. Given the negligible deviation in deformation behavior between laminated and unlaminated specimens—as illustrated in

Figure 10—these strain values were considered applicable to the laminated configurations as well. This refinement ensured a more accurate representation of the stress contribution of the film under actual loading conditions.

The tensile stresses corresponding to the critical strain values were then extracted directly from the stress–strain curves of the respective PP and PET films. At 8.2% strain—corresponding to the tensile strength of neat PP—the PET film sustained a stress of 80.0 MPa, while the PP film reached 26.9 MPa. Similarly, at 6.7% strain—corresponding to the tensile strength of the 25 wt% WP substrate—the PET and PP films exhibited tensile stresses of 80.0 MPa and 27.0 MPa, respectively. These nearly identical values across the two substrate types reflect the comparable deformation levels and validate the use of these adjusted film stress values in the predictive model. The refined stress values were substituted into Equation (

3) to generate more realistic theoretical estimates of the tensile strength for each lamination configuration. These predictions were then systematically compared with the experimentally obtained tensile strengths reported earlier in

Section 3.3.

Table 6 summarizes the theoretically predicted and experimentally measured tensile strengths for all configurations. To quantify the degree of enhancement achieved through surface lamination beyond what is anticipated by simple mechanical blending, the Model Strength Ratio (MSR) was calculated. The MSR is defined as the ratio of the experimentally observed tensile strength (

) to the theoretically predicted strength (

), i.e., MSR =

. Values greater than unity indicate a strengthening effect beyond rule-of-mixtures expectations, potentially attributable to interfacial effects, load redistribution, or morphological improvements induced by lamination.

For the PP film-laminated neat PP specimens, the Model Strength Ratios (MSRs) are consistently less than 1 across all lamination configurations, indicating that the experimentally measured tensile strengths fell below the values predicted by the rule of mixtures. This deviation suggests that additional factors, beyond the relatively lower tensile strength of the PP film compared to the PP substrate, may have contributed to the reduced mechanical performance. One plausible explanation involves the behavior of the adhesive layer. Although the adhesive for plastics provided a robust bond between the PP film and the PP substrate—owing to the chemical compatibility of identical materials—it may also have introduced mechanical vulnerabilities. Specifically, its inherent brittleness could have facilitated the early onset and propagation of cracks. Given the strong interfacial bonding, delamination is unlikely; instead, once the adhesive fractured, the crack may have quickly advanced through both the film and substrate, precipitating premature failure.

Another contributing factor may lie in the relatively low stiffness of the PP film. Its compliant nature makes it more susceptible to conforming to minor topographical undulations in the adhesive layer. These long-wavelength surface fluctuations, though subtle, can act as loci for stress concentration. Even without visible defects, such mechanical heterogeneity can lower the effective strength of the composite laminate. While this hypothesis remains to be experimentally validated, it presents a credible mechanism for the systematic underperformance of the PP-laminated neat PP specimens relative to theoretical predictions. Future investigations employing techniques such as digital image correlation (DIC), finite element analysis (FEA), or fracture surface microscopy could help elucidate the precise mechanisms at play and determine whether microstructural features at the interface contribute significantly to early failure.

For the PET film-laminated neat PP specimens, the MSR values for the 1S-H and 1S-F configurations were slightly below unity, at 0.99 and 0.98, respectively. These results indicate that the experimentally measured tensile strengths were marginally lower than the theoretical values predicted by the rule of mixtures. However, the deviations are minimal and fall within a range that may be considered practically consistent with theoretical expectations. In contrast, the 2S-F configuration yielded an MSR of 1.02, slightly exceeding unity but still very close to the theoretical value. Collectively, these results suggest that the tensile strength of PET-laminated neat PP specimens is largely in agreement with the rule of mixtures.

The relatively good agreement can be attributed to the high stiffness of the PET film, which likely suppresses surface undulations arising from the adhesive layer, thereby minimizing stress concentrations at the film–substrate interface. In the 1S-H and 1S-F configurations, however, part of the PP substrate remains unlaminated. Consequently, surface irregularities or defects on the exposed substrate may act as local stress concentrators, slightly reducing the overall tensile strength. This effect is expected to be minor, but it could account for the small deviations observed. In the 2S-F configuration, full lamination on both surfaces may contribute to a more uniform stress distribution, explaining the slightly higher experimental strength. On the whole, the PET film-laminated PP specimens exhibit behavior that is consistent with theoretical predictions.

For the PP film-laminated 25 wt% WP specimens, the MSR values exceeded unity across both configurations, indicating that the experimentally measured tensile strengths were higher than the theoretical values predicted by the rule of mixtures. Given the inherently low tensile strength of the PP film relative to the WP substrate, this enhancement cannot be ascribed to direct reinforcement by the film. Instead, it is more plausibly attributed to surface homogenization effects, wherein the laminated PP film may have sealed microvoids, masked surface flaws, and mitigated stress concentrations, thereby improving the overall stress distribution. This interpretation aligns with the mechanisms discussed earlier in

Section 3.3.

A closer look at the 1S-F configuration shows that while the rule of mixtures predicts a 2% increase in tensile strength relative to the unlaminated specimen, the experimental results show no significant enhancement—yielding an MSR close to 1. This suggests general agreement with the rule of mixtures, with only minor influence from the laminated film. The modest improvement can be attributed to the limited surface coverage provided by single-sided lamination, which restricts the extent of surface homogenization. In contrast, the 2S-F configuration demonstrated a 5% strength gain, compared to a theoretical prediction of 8%. This shortfall reflects the limited mechanical contribution of the PP film, which, despite improving surface integrity, lacks sufficient strength to fully realize the potential reinforcement suggested by the model.

For the PET film-laminated 25 wt% WP specimens, the MSR values consistently exceeded unity, with the highest enhancement in tensile strength observed in the 2S-F configuration—mirroring the trend seen in the PP film-laminated counterparts. This outcome suggests that surface homogenization induced by the PET film contributed to mechanical improvements beyond the predictions of the rule of mixtures, particularly when both surfaces were fully laminated. In contrast, the MSR values for the 1S-H and 1S-F configurations remained close to one, indicating a more limited effect likely due to the smaller proportion of laminated surface area and consequently reduced surface modification.

As detailed in

Table 4, a comparison of MSR and LSR values reinforces this interpretation. In the 2S-F configuration, the LSR reached 1.21, indicating a 21% experimental increase in strength over the unlaminated specimen, whereas the MSR was 1.10, reflecting a theoretical increase of only 10%. This 11% discrepancy is attributed entirely to surface homogenization effects—specifically, the PET film’s ability to seal voids, blunt surface defects, and suppress crack initiation, thereby facilitating more uniform stress transfer during loading. These beneficial surface-related contributions, which are not captured by the rule of mixtures, underscore the importance of interfacial and morphological considerations in laminated composite performance.