1. Introduction

Airfield pavements are one of the most important facilities of an airport, and must have sufficient load-bearing capacity to ensure the safe operation of aircraft. To achieve this goal, adequate design of pavement structures is essential. Due to the different loading conditions that occur during a complete aircraft loading cycle, there are several areas at an airport that are subject to different loads, e.g., runways, taxiways, aprons, etc. For this reason, these areas are usually built with different types of pavements. In general, concrete pavements are used, especially for areas subject to static loads, such as aprons and runway edges.

The main component of concrete pavements is concrete, which is used as the surface layer of the pavement structure. Over the past four decades, concrete has become a popular alternative to asphalt on highways due to its durability, longevity and lower maintenance requirements. However, the cost of constructing concrete pavements is generally higher than that of asphalt pavements. For this reason, extensive research has been carried out to develop concrete mixes with improved properties compared to conventional concrete mixes in order to reduce the thickness of concrete pavements and, thus, the associated costs [

1,

2,

3,

4].

In addition to reducing costs, research into alternative, more efficient concrete mixes also aims to reduce the use of cement raw materials in order to conserve natural minerals. This is particularly important as large quantities of cement are also used for the construction of numerous infrastructures such as buildings, bridges, etc. On this basis, the reuse of by-products from various industries can be implemented in the spirit of robust sustainable development that meets the needs of modern society [

5].

To improve the mechanical properties of concrete, fibers can be added to conventional concrete, and this has led to the development of Fiber Reinforced Concrete (FRC). There are different types of fiber materials that can be used for this purpose, such as steel, carbon, glass, plastic, polypropylene, nylon and cotton [

6]. The use of different types of fibers in concrete has been studied with a view to improving the compressive and flexural strength of concrete, and this can change the brittle nature of concrete [

7]. It must be emphasized that the compressive strength of concrete is considered as an index of mix composition, but one of the most important properties of concrete for the construction of concrete pavements is its flexural strength. The top layer of concrete pavements consists of a concrete slab designed to carry the load. The load creates a tensile force on the underside of the slab, which can lead to cracking as the tensile strength of concrete is only about 10% of its compressive strength. The incorporation of fibers into the concrete can, therefore, affect the flexural strength, improve the performance of the concrete and, consequently, affect the required pavement thickness. In addition to improving concrete performance, the environmental and economic benefits of FRC have also been investigated [

8,

9].

Against this background, this work aims to quantify the effect of fibers on the thickness of airfield concrete pavements. The study focuses on the use of polypropylene and steel fibers in the production of concrete. Polypropylene fibers are typically used to increase the durability of concrete by reducing the cracking that occurs during concrete curing due to hydration. They do not alter the visual appearance of the concrete and this eliminates the risk of them serving as potentially dangerous protrusions [

10]. For this reason, they are used in many industrial applications [

6] and also in pavements [

11]. On the other hand, steel fibers are increasingly used in the construction of industrial pavements, roads, parking lots and airport runways as an effective alternative to conventional reinforcement [

12]. Although there are concerns about the use of steel fibers in airfield pavements because the fibers can protrude, proper mixing techniques and proper curing can minimize the exposure of surface fibers. In addition, steel fibers can affect the workability of the concrete, but this depends on the type, size, shape and dosage of the fibers. In any case, the application of an appropriate mix design procedure that takes into account the effect of the fibers is necessary to ensure adequate workability in practice [

13,

14].

On this basis, a literature review was first carried out to collect the experiences and practices gathered by researchers worldwide on the behavior of concrete with fibrous materials. The focus of the review is on the effects of incorporating polypropylene and steel fibers on the evaluation of concrete strength, focusing on the papers that contain laboratory test data on the flexural strength of concrete. International experience on this topic is then summarized in order to select suitable weighted values for the flexural strength of concrete for further analysis. In a next step, an airfield concrete pavement for the edge of an airport runway is designed according to the US Department of Defense Unified Facility Criteria (UFC) for the design and evaluation of airfields and roads [

15,

16], and these are implemented by the Pavement Transportation Computer Assisted Structural Engineering (PCASE) software version 7.0.7 [

17]. Comparisons are made between the pavement thicknesses determined using the above method and conclusions are drawn on the effects of using steel and polypropylene fibers on the design of airfield pavements. The ultimate goal of this study is to fill the knowledge gap that exists in assessing the potential improvement in concrete strength from the addition of these fiber types in order to comparatively quantify the impact on the design of concrete pavements on airfields.

2. Experience on Fibers’ Effect on Concrete Strength

2.1. Polypropylene Fibers

Polypropylene fibers were first suggested in 1965 as a blending product to be added to concrete for the construction of blast resistant structures for the US Corps of Engineers [

7]. However, since then, several researchers have addressed the use of these fibers, with the most recent ones mentioned below.

In 2014, Ede and Ige [

6] investigated the effect of polypropylene fiber in improving concrete strength, with the main objective being to identify the optimum quantity for improving the compressive and flexural strength of concrete. For this reason, samples with 0.25%, 0.5%, 0.75% and 1% content levels of polypropylene fibers were tested in the laboratory in order to assess the concrete compressive and flexural strength after 7, 14, 21 and 28 days. Compared to the strength of a control sample without polypropylene fibers, it occurred that the optimum percentage was pinpointed as being between 0.25% and 0.5%. The maximum increase in the compressive strength was about 9%, and was observed for the 0.25% percentage, while for the same content the flexural strength was increased by 65%.

In 2017, Kumar et al. [

18] investigated the use of polypropylene fibers for road pavements in India. The experimental analysis included the construction of concrete samples with percentages of 1%, 2%, 3%, 4% and 5% by weight of cement, in order to estimate the compressive, tensile and flexural strength for 7 days and 28 days. According to the performed testing, the 3% percentage of polypropylene fibers led to the maximum increase in compressive, tensile and flexural strength.

In 2018, Rudresh and Shashank [

19] investigated the impact of polypropylene and steel fibers on the behavior of concrete pavement quality. For this reason, polypropylene fiber content levels of 0.5%, 0.75% and 1% were considered. From the analysis, it occurred that the maximum compressive strength was observed at the 1% polypropylene fiber content level.

In 2019, Hasan et al. [

20] investigated the effect of different amounts of polypropylene fibers on concrete strength and workability. For this reason, nine concrete mixes were prepared with fiber volume fractions of 0.06%, 0.12%, 0.24%, 0.48%, 0.72%, 0.96%, 1.2%, 1.44%, 1.68%, 1.92% and 2.16%. Compared to the strength of the plain concrete mix, the maximum increase in the compressive, splitting tensile and flexural strength was about 18%, 16% and 14%, respectively. This increase was obtained for a 0.36% fiber percentage.

In 2020, Hussain et al. [

21] investigated the effect of polypropylene and glass fibers in comparison to steel fibers on the thickness design of highway pavements. For this objective, three concrete samples were constructed using 1% polypropylene fiber, glass fiber and hooked steel fiber fractions for two concrete types of different strength. In order to highlight the advantages of fibers, a pavement design for a collector street was performed using the ACPA design method, which was implemented through the StreetPave software. The experimental analysis included, among others, the estimation of compressive and flexural strength. The results showed that the net gain in flexural strength due to steel fiber was almost double compared to that caused by polypropylene and glass fiber. For polypropylene fibers, a reduction of about 17% of pavement thickness was obtained, while pavement thickness was reduced by 35% due to steel fibers.

In 2021, Gupt and Dulawat [

7] investigated the impact of the addition of different percentages of polypropylene fibers on the behavior of concrete. For this reason, specimens with 0.1%, 0.2% and 0.3% by volume were constructed and lab experiments were performed in order to access the compressive strength and the flexural strength of the concrete for 7 days and 28 days. The analysis showed that fiber content of between 0.2% and 0.3% was found beneficial to use, since strength decreased after 0.2% fiber content.

In 2024, Madhukar et al. [

10] investigated the impact of the addition of polypropylene fibers on the concrete airfield pavement design of an apron of Gautam Buddha International Airport using FAARFIELD. On this basis, concrete strength parameters, including compressive strength, split tensile strength and flexural strength for 7 days and 28 days were assessed. Laboratory tests were conducted on concrete specimens incorporating varying percentages of polypropylene fibers by weight of cement, such as 0.2%, 0.4%, 0.6% and 0.8%. The estimated strengths were compared with the related parameters of plain concrete usually used in Nepal for airfield pavement construction. The analysis showed that the 0.4% polypropylene fiber percentage was the optimum since it led to the maximum strength increase. The split tensile strength at 28 days increased by 18% and the flexural strength increased by 14.05%, highlighting the impact of polypropylene fibers. Regarding the effect of the inclusion of polypropylene fibers in pavement design, a thickness reduction of 13.25% was observed, corresponding to 60 mm in terms of absolute thickness values.

Recently, Pietrak [

22] investigated the influence of the structure and length of polypropylene fibers on the properties of concrete. In this research, polypropylene fibers of different length and structure were considered and the compressive strength after 7, 28 and 56 days was measured, along with other concrete properties, such as water absorption, bulk density and frost resistance. By increasing the fiber length in the range of 6–12 mm, a slight increase of 1.2% in the compressive strength of concrete after 28 days was observed.

2.2. Steel Fibers

The incorporation of steel fibers on concrete pavement performance was investigated by researchers at least four decades ago [

23,

24,

25] by considering the field performance of concrete pavements. Since then, several researchers have assessed the use of steel fibers, while the most recent ones that include the effect of fibers based on laboratory data are mentioned below.

In 2016, Kamel [

26] investigated concrete strength parameters due to the incorporation of steel fibers in concrete mix in order to quantify the benefits of adding steel fibers for the extension of pavement life. Concrete samples with fiber content of 4% and 8% of cement weight were tested in order to assess, among other characteristics, the compressive strength, the flexural strength, the modulus of elasticity and the indirect tensile strength. The results showed that the flexural strength had improved up to 60% as compared to plain concrete. The incorporation of steel fibers resulted in a significant increase in compressive strength for different curing times, with the increase ranging from 10% to 45%.

The effect of recycled steel fibers on the mechanical properties of normal concrete and of concrete with recycled aggregates has been investigated by Ahmani et al. [

27]. Since the concrete with recycled aggregates has lower strength than the concrete with natural aggregates, using the steel fibers recovered from waste tires in the concrete improves the mechanical properties of this concrete as well as solving the environmental problem of these waste steel wires. Additionally, the effect of fibers on the reduction in concrete pavement thickness was studied, considering fiber content of 0.5% and 1% of concrete volume. According to the main findings of the research, the addition of recycled fibers at 0.5% and 1% levels could reduce concrete pavement thickness by 8% and 16%, respectively, as estimated through the implementation of the PCA method.

In 2018, Rudresh and Shashank [

19] investigated the impact of steel fibers on the behavior of concrete pavement quality. For this purpose, steel fibers with 2%, 2.5% and 3% content were considered. From the analysis, it occurred that the maximum compressive strength was observed for 3% steel fiber content.

In 2018, Jhatial et al. [

28] investigated the mechanical characteristics of concrete reinforced with steel fibers added at 1%, 2%, 3%, 4% and 5% percentages, compared with a control sample with no fibers. The effect on concrete strength was determined and it occurred that the addition of 3% fiber led to the maximum flexural and compressive strength. The addition of steel fibers was considered to impact significantly the flexural strength due to the improvement in ductility behavior of the concrete.

In 2020, Kamani et al. [

29] studied the effect of steel fiber incorporation on the mechanical properties of concrete, focusing on concrete compressive strength and water absorption. For the analysis, fiber content levels of 1%, 1.5% and 2% by volume of concrete were considered, while two types of fibers were used: hooked-end fibers and flat-crimped fibers. The addition of fibers to concrete increased the 28-days compressive strength and decreased water absorption. The maximum increase in compressive strength appeared for 1.5% steel fibers by volume. Moreover, the concrete mix with hooked-end fibers performed better than the concrete mix with flat-crimped fibers.

In 2020, Murthi et al. [

30] investigated the impact of steel fibers on granite powder-blended pavement-quality concrete. For this reason, steel fibers were added at 0.25%, 0.5%, 0.75%, 1.0%, 1.25% and 1.5% by volume of concrete. The behavior of the concrete was assessed through the determination of compressive strength and flexural strength. Compressive strength was obtained using 150 mm cube specimens, while flexural strength was obtained through testing on beam specimens for curing periods of 7 days, 14 days, 28 days and 90 days. The analysis showed that for a 28-day curing period, the addition of about 1.0% steel fibers improved the mechanical characteristics of concrete by 42%, compared to the control mix.

In 2020, Hassuna and Jung [

31] investigated the impact of steel fibers and steel slag on the improvement of concrete flexural strength for concrete pavements. For this reason, specimens with 0.5%, 1.0%, 1.5% and 2.0% steel fibers were tested in the laboratory at 7 days and 28 days in order to estimate the obtained flexural strength, while other samples were prepared with 20% steel slag. The analysis showed that using steel fibers only without adding steel slag led to a significant increase in the flexural strength for the 1.0% fibers percentage, while the increase in strength was insignificant at the 1.5% steel fiber content level.

Recently, Taher et al. [

32], investigated the effect of steel fibers on the improvement in compressive, tensile and flexural strength of concrete used in concrete pavements. For this purpose, laboratory tests were performed to evaluate the mechanical properties of concrete specimens including 1%, 3% and 5% of steel fibers after curing periods of 7 days and 28 days. The analysis showed that the addition of steel fibers into concrete significantly impacted the mechanical properties of the concrete mix. In particular, the inclusion of 5% steel fibers has led to a flexural strength increase of about 32.3% compared to the concrete mix that contained no fibers.

3. Research Methodology

In this study, the methodology shown in

Figure 1 was applied to investigate the effects of fibers on the design of airfield concrete pavements. The results of the literature review were analyzed to select representative values for concrete flexural strength that were used for further analysis.

In order to investigate the effect of the inclusion of steel and polypropylene fibers on the required concrete layer thickness, a runway edge pavement was designed using the US Department of Defense Unified Facility Criteria (UFC) for the design and evaluation of airfields and roadways [

15,

16], which is implemented through the PCASE software [

17]. It is noted that PCASE automates the pavement design and evaluation procedures outlined in the related UFC and includes procedures for rigid (concrete), flexible, unsurfaced and overlay surfaces. Especially for concrete pavement design, there are two methodologies that can be applied: (i) k/Westergaard procedure and (ii) the Linear Elastic Analysis (LEA) procedure. The k/Westergaard procedure is based on the Westergaard solution that uses medium-thick plate theory and utilizes the modulus of subgrade reaction (k) as a strength index for layers supporting the concrete slab. More details on this procedure can be found in [

16], while in the framework of the present investigation, the LEA procedure is used for pavement design.

According to UFC system [

16], the main principle of concrete pavement design is to limit the tensile stresses in the concrete slab to levels that are sufficiently below the flexural strength of the concrete, such that failure occurs only after the pavement has sustained many load repetitions. For the LEA, a subroutine computes the pavement responses that implement the performance criteria in PCASE. For the analysis, the pavement is considered to be a multilayered structure, with each individual layer being characterized by its thickness, modulus of elasticity and Poisson’s ratio. All layers are assumed to be homogeneous, isotropic and to extend infinitely in the horizontal direction.

The concrete flexural strength divided by the maximum tensile stress in a concrete slab is the design parameter and is referred to as the Design Factor (DF). DF is estimated through Equation (1):

where

R corresponds to concrete slab flexural strength and

σ corresponds to maximum tensile stress at the bottom of the slab. This parameter has been related to pavement performance through a study of test sections’ data. In the performance model, the pavement Structural Condition Index (SCI) is considered. The SCI is an index that is determined based on the load-related distresses of a pavement and corresponds to the failure criteria used for concrete pavement design. More specifically, failure is described through the conditions of SCI = 50 or SCI = 0. An SCI of 50 corresponds to the formation of one or more cracks per slab in 50 percent of the trafficked slabs (first crack failure criteria) and an SCI equal to 0 correlates approximately to a shattered-slab condition.

The

DF is related to the allowable repetitions to failure through Equation (2):

where

DF = design factor,

A = 0.2967 + 0.002267 × SCI,

B = 0.3881 + 0.000039 × SCI,

C = coverage level at selected SCI and SCI = structural condition index. Especially for SCI = 50, which corresponds to the criterion usually used for concrete pavement design, Equation (2) can be transformed to Equation (3):

At this point, it must be noted that coverage is a term that is used to define the number of maximum stress repetitions that occur in a pavement due to aircraft operations. For concrete pavements, a coverage occurs when each point in the pavement within the limits of the traffic lane has been subjected to a maximum stress by operating aircraft.

The determination of pavement layer thicknesses is based on the Cumulative Damage Factor (CDF). For each aircraft, the maximum tensile stresses in the concrete slab are computed and then the allowable coverages to failure are estimated using Equation (3). The damage caused by each aircraft is determined by dividing the number of applied load operations for the design period to the number of allowable load operations in terms of coverages. To account for mixed traffic, the cumulative damage concept is implemented, which is based on Miner’s hypothesis. Pavement thicknesses are determined when the CDF is equal to 1.

The LEA procedure was used for the investigation of the impact of the use of fibers on airfield pavement design, as is presented in the following chapters. For pavement design, characteristic values of concrete strength were selected, based on an analysis of the review data. Comparison between the pavement thicknesses obtained follows, along with the related conclusions.

4. Review Data Analysis

4.1. Selection of Characteristic Strength Values for Concrete Reinforced with Polypropylene Fibers

In order to proceed with pavement design, representative values of concrete strength were considered based on the experience gained through the literature review process. According to the UFC [

16] for pavement design, the 28-day third-point loading flexural strength is used. It is noted that some of the researchers have estimated the flexural strength based on beam testing, while others have considered the behavior of concrete based on tensile splitting strength test. For analysis purposes, in the framework of the present investigation, the research papers that had estimated the flexural strength based on beam testing were gathered for further consideration, for reasons of consistency with the followed pavement design procedure.

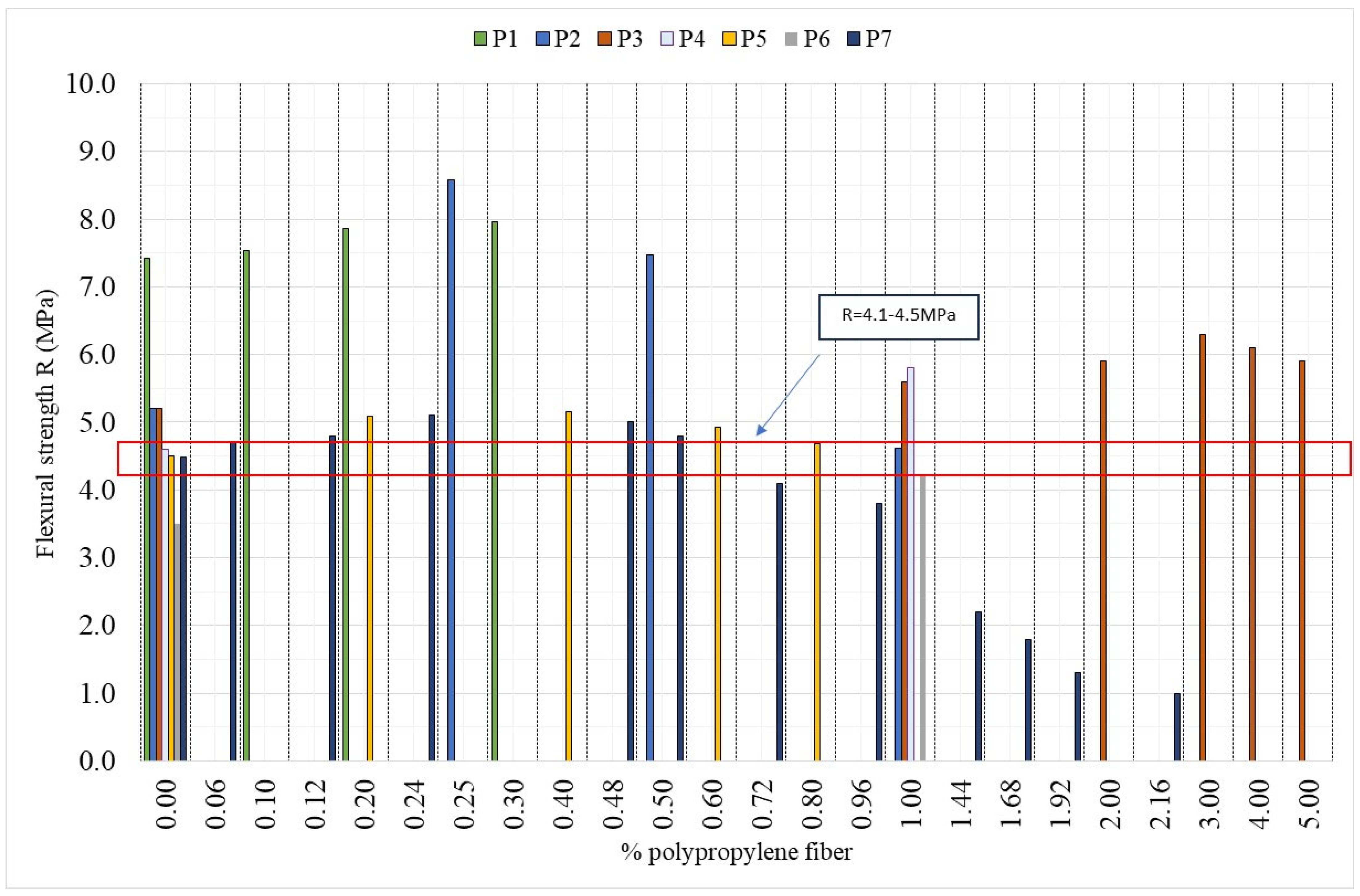

Initially, the investigations concerning the addition of polypropylene fibers were considered. The results of the concrete flexural strength tests in these investigations are presented in

Figure 2, and the designations of P1 through P7 are explained in

Table 1. It should be noted that concrete compressive strength data from laboratory tests were also available for all these investigations and are listed in

Table 2. These data are also required for the LEA since the modulus of elasticity of concrete can be estimated based on compressive strength, using related empirical equations.

Figure 2 shows the concrete flexural strength values in relation to the percentage of polypropylene fiber content, while, for all investigations, the behavior of plain concrete corresponds to polypropylene fibers percentage of 0%. It should be noted that different proportions of polypropylene fibers were studied worldwide, with the maximum increase occurring at different values of polypropylene fiber content. This may be due to the fact that the properties of the tested materials, including the concrete mix, and the type of polypropylene fibers used are different. For this reason, the maximum percentage increase in flexural strength due to the addition of polypropylene fibers was determined for each case, regardless of the particular fiber content, as shown in

Figure 3.

According to

Figure 3, the average value of the maximum increase is about 24%. This value corresponds with the results of Hussain et al. [

21] (P4 in

Table 1), which can be taken into account in the further analysis of the pavement design. However, if the outlier value of Ede et al. [

6] (P2 in

Table 1) is removed, an average increase of 17% can be considered. For this reason, the results corresponding to a maximum percentage increase of 14% could also be considered for the analysis, which corresponds to the results of Madhukar et al. [

10] and Hasan et al. [

20] (P5 and P7 in

Table 1).

It must be noted that according to the UFC for the plain concrete airfield pavement design, the design flexural strength is suggested to be as high as is practicable and economical but not less than 4.48 MPa (650 psi). In any case, it is believed that the actual mean flexural strength in the field will be greater than the design flexural strength. Moreover, it is considered that design ASTM C 78 [

33] flexural strengths of 4.14 to 4.48 MPa (600 to 650 psi) are readily achievable with most local materials, and the designer should use higher design strengths only with caution [

16]. From

Figure 2, it occurs that the flexural strength of plain concrete ranges from 3.5 MPa to 7.42 MPa. However, based on the above, the values that will be considered for further analysis will be selected in the range of about 4.1 MPa to 4.5 MPa as far as the reference concrete mix of plain concrete is concerned. Based on the above, the results of Hussain et al. [

21] (P4 of

Table 1) and Hasan et al. [

20] (P7 of

Table 1) were used for pavement thickness design. It is noted that the results of Madhukar et al. [

10] (P5 of

Table 1), initially pinpointed to present the same increase (14%) of flexural strength as the results of Hasan et al. [

20] (P7 of

Table 1) were not considered for further analysis since they concerned the same flexural strength absolute values as P7, which would generate similar results.

4.2. Selection of Characteristic Strength Values for Concrete Reinforced with Steel Fibers

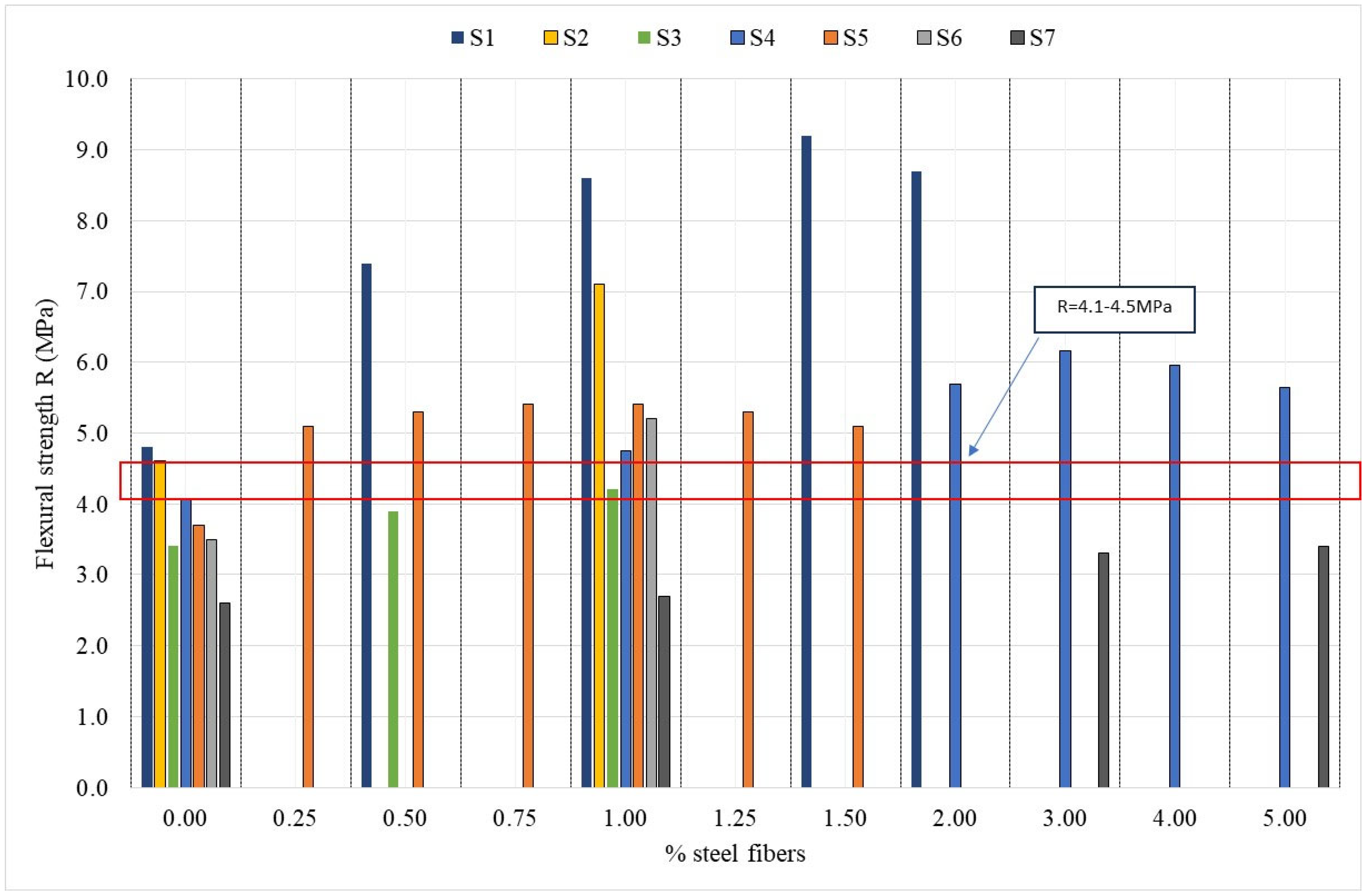

As a next step, the investigations concerning the addition of steel fibers were considered. The results of the concrete flexural strength tests performed in these investigations are presented in

Figure 4, and the designations of S1 through S7 are explained in

Table 3. It is noted that for all these investigations concrete compressive strength data were also available from laboratory tests, as presented in

Table 4.

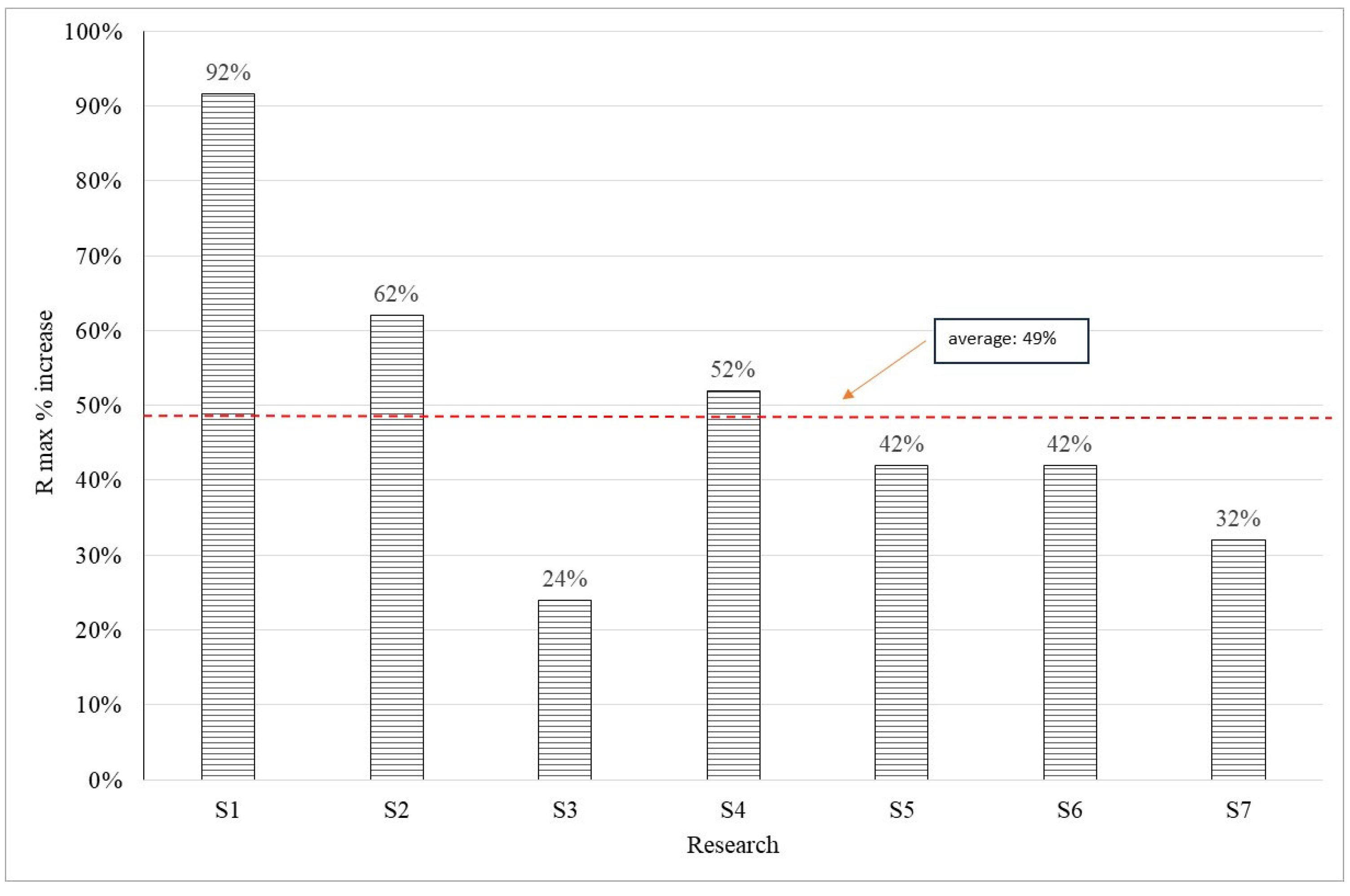

Figure 4 shows the flexural strength values of the concrete as a function of the percentage steel fiber content, and for all tests the behavior of plain concrete corresponds to a steel fiber content of 0%. It should be noted that different steel fiber content levels were investigated worldwide, with the maximum increase occurring at different values of steel fiber content. This may be due to the fact that the properties of the materials tested, including the concrete mix, and the type of steel fibers used are different. However, it should be noted that a percentage of 1% was used in all studies, which is not always optimal. For this reason, the maximum percentage increase in flexural strength due to the addition of steel fibers was determined for each case, regardless of the particular fiber content, as shown in

Figure 5. It can be seen that the average value of the maximum increase is around 49%.

The flexural strength values used for further analysis were selected to be close to the average value of the sample (49%). This value is most close to the results of Jhatial et al. [

28] (S4 of

Table 3), which can be considered for further analysis in terms of pavement design. It is noted that the flexural strength values of the plain concrete were in the range suggested by the UFC of about 4.1 MPa to 4.5 MPa.

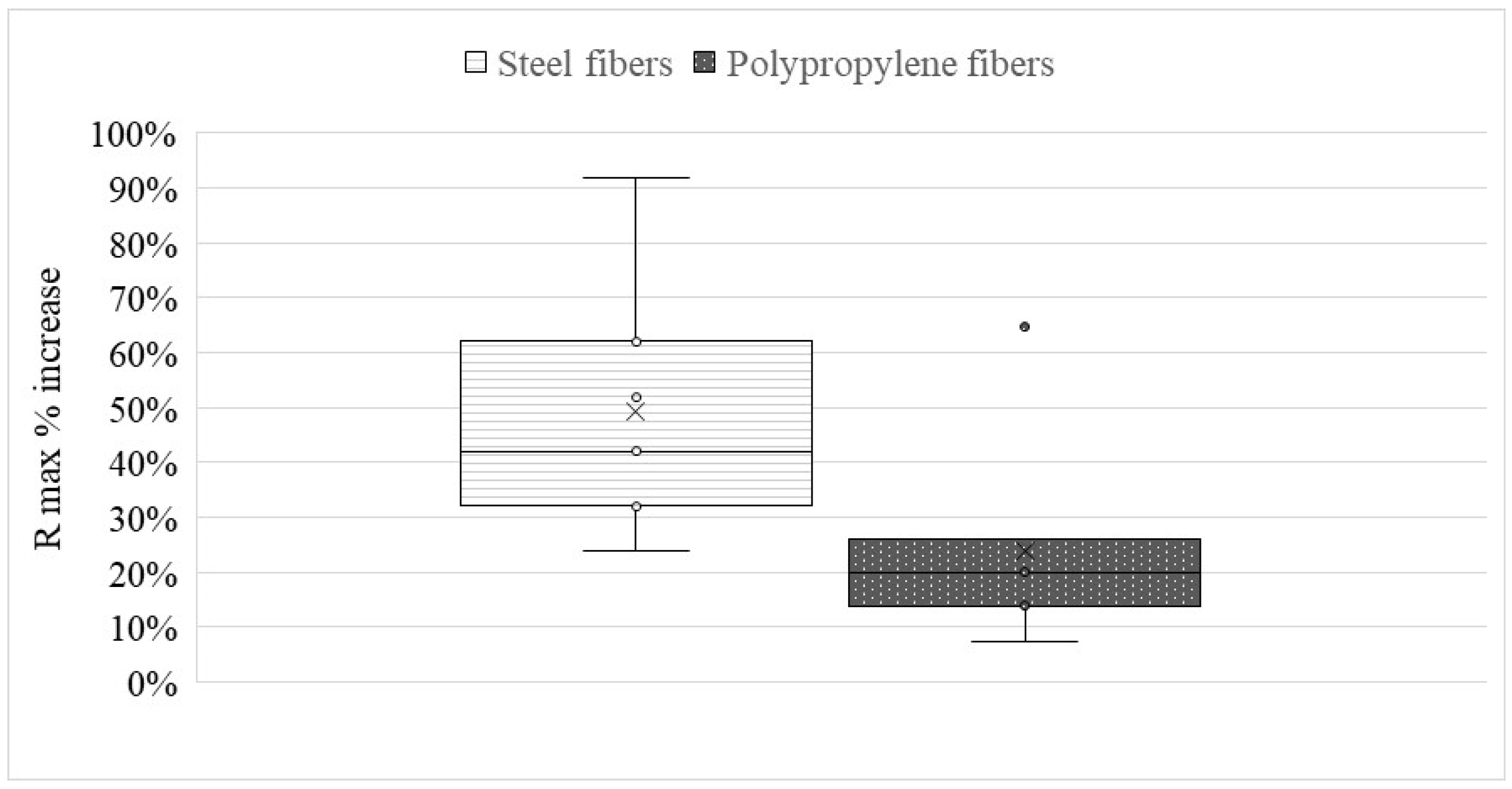

Figure 6 shows a comparison between the maximum percentage increase in flexural strength due to the addition of steel and polypropylene fibers in concrete through boxplots, where the internal line corresponds to the mean value of the samples. It can be seen that the addition of steel fibers probably has a greater influence on the increase in flexural strength than the addition of polypropylene fibers. Furthermore, the mean value of the maximum increase in flexural strength with the addition of polypropylene fibers is about half as high as with the addition of steel fibers.

Based on the above observations, the effects of increasing the flexural strength by steel and polypropylene fibers on the thickness of the pavement are investigated.

5. Concrete Pavement Design

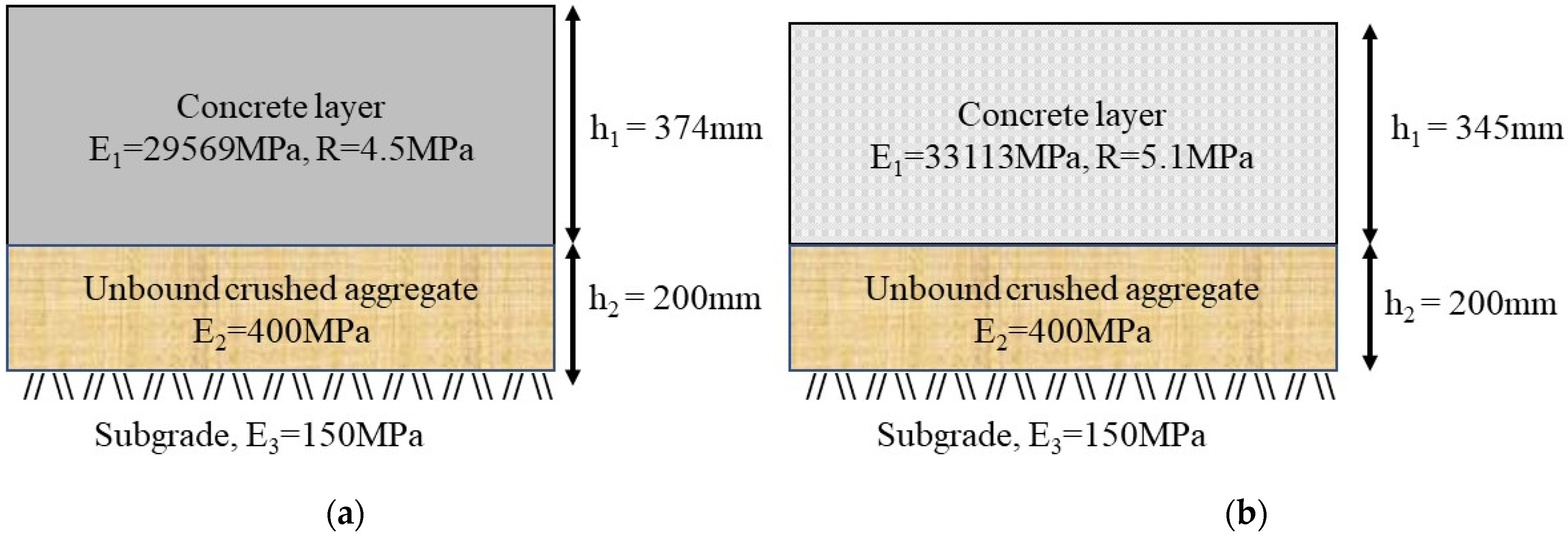

5.1. Pavement Design Assumptions

In order to investigate the impact of the use of polypropylene and steel fibers on concrete layer thickness, pavement design was performed by considering different material assumptions for the surface layer. The pavement structure consisted of the surface concrete layer, an unbound crushed aggregate layer and the subgrade layer. For design purposed, the unbound crushed aggregate layer was considered to have a modulus of elasticity of E

2 = 400 MPa and a layer thickness equal to h

2 = 200 mm, while the subgrade was considered to have a modulus of elasticity of E

3 = 150 MPa, as shown in

Figure 7. Those parameters were kept constant during the design in order to assess only the impact of concrete characteristics on concrete layer thickness.

According to the UFC method, the modulus value of the concrete can be determined in the laboratory or conservatively estimated as 27,576 MPa (4,000,000 psi). The concrete layer modulus can be estimated through the compressive strength of the concrete using Equation (4):

where

E is the modulus of elasticity (psi) and

C is the compressive strength (psi) [

15]. Equation (4) was used in the present study to estimate the modulus of elasticity of the concrete layer as this information was not available in the relevant literature.

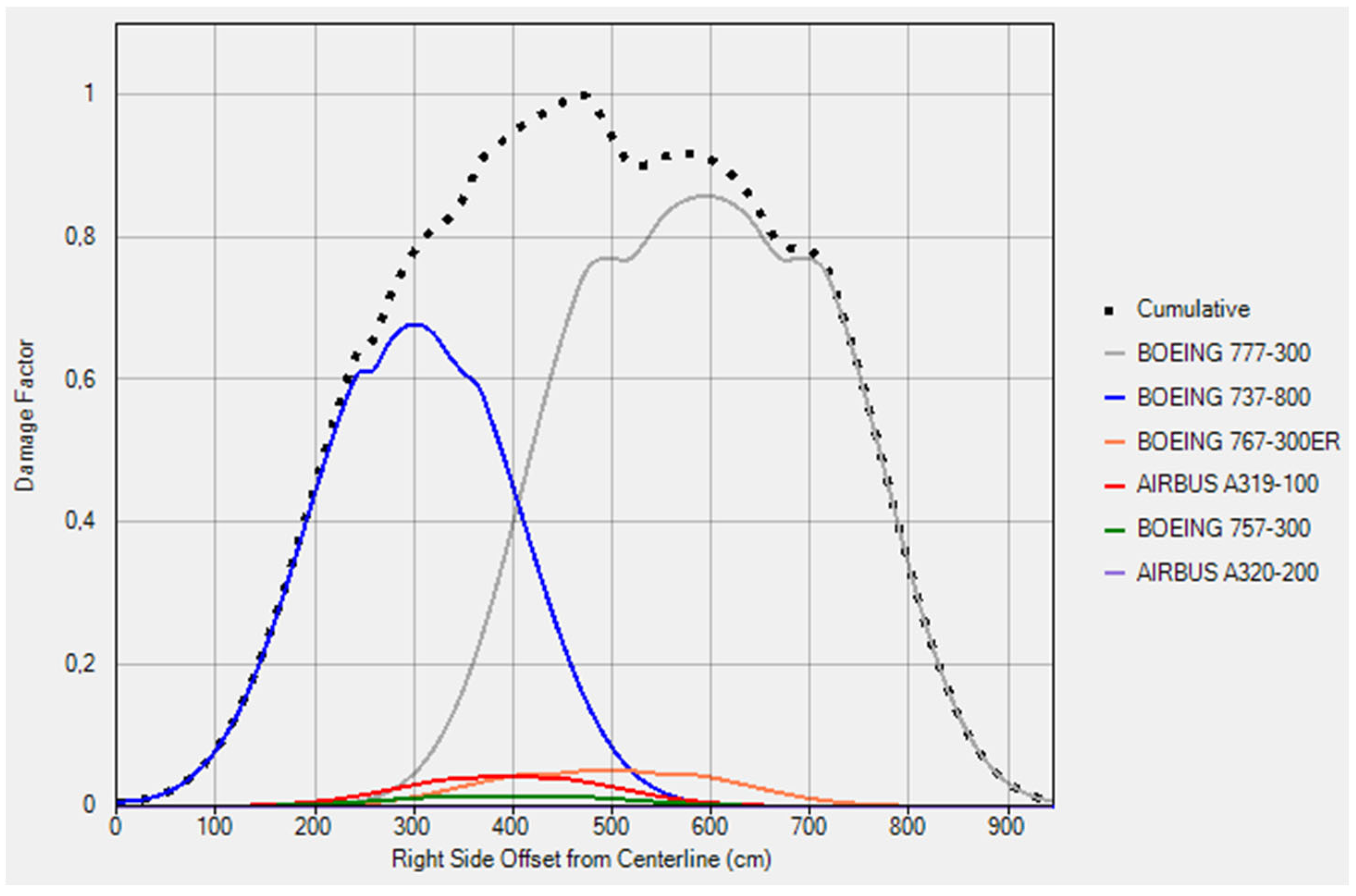

The concrete pavement design was based on the expected aircraft traffic fleet for the design period. The traffic data concerning the types of the aircraft that were expected to use the runway’s pavement for a 20-year design period and their frequency of trafficking (annual departures) are shown in

Table 5. The pavement was expected to serve movements of six different types of aircraft that have different landing gear configurations.

Table 6 shows the values for the flexural and compressive strength of the concrete that were used for the further analysis of the paving structure and determined by corresponding laboratory tests. It can be seen that the addition of fibers also leads to an increase in concrete compressive strength in all cases, although there does not appear to be a specific trend in the increase in compressive strength compared to flexural strength. It should be noted that mild climate conditions were considered for the analysis, which correspond to the non-frost design in PCASE.

5.2. Analysis Considering Concrete Reinforced with Polypropylene Fibers

To investigate the effects of using polypropylene and steel fibers, the pavement was first designed using concrete without fibers, resulting in the cross-section shown in

Figure 8a. The flexural strength was assumed to be 4.6 MPa, while the modulus of elasticity was estimated on the basis of the corresponding compressive strength according to Equation (4). The thickness of the concrete layer was estimated to be 376 mm, for which the CDF was equal to 1 (

Figure 9).

Figure 9 shows the contribution of each aircraft to the cumulative damage caused by the aircraft fleet.

Figure 9 shows that the aircrafts with the largest contribution to cumulative damage are the B737-800 and the B777-300. A pavement design was then performed considering the use of polypropylene fibers and the average increase in flexural strength of 26% (R = 5.8 MPa) according to the results presented by Hussain et al. [

21] (P4 of

Table 1). The corresponding analysis showed a thickness of the concrete layer of 316 mm (

Figure 8b), which corresponds to a reduction of 16% (60 mm) compared to normal concrete.

A more conservative approach was then adopted, and the flexural strength was increased by 14%, which corresponded with the results of Hasan et al. [

20] (P7 in

Table 1). Based on these results, a pavement design with concrete without fibers was first created, resulting in the cross-section shown in

Figure 10a. The flexural strength was assumed to be 4.5 MPa, while the modulus of elasticity was estimated on the basis of the corresponding compressive strength according to Equation (4). The thickness of the concrete layer was estimated to be 374 mm. Then, the pavement was designed considering the use of polypropylene fibers and increasing the flexural strength by 14% (R = 5.1 MPa), according to the results presented by Hasan et al. [

20] (P7 in

Table 1). From the corresponding analysis, the thickness of the concrete layer was 345 mm (

Figure 10b), which corresponds to a reduction of 8% (30 mm) compared to normal concrete.

From the above analysis, it occurred that the reduction in pavement thickness ranged from 8% to 16% with the addition of polypropylene fibers to plain concrete.

5.3. Analysis Considering Concrete Reinforced with Steel Fibers

In order to investigate the impact of the use of steel fibers, an initial pavement design was performed considering the use of concrete without fibers and the cross-section of

Figure 11a occurred. The flexural strength was set at 4.1 MPa, while the modulus of elasticity was estimated according to Equation (4) on the basis of the corresponding compressive strength. The thickness of the concrete layer was estimated to be equal to 385 mm, for which the CDF was equal to 1. Then, pavement design was performed considering the use of steel fibers and the increase in flexural strength of 52% (R = 5.8 MPa), according to the results presented in S4. From the related analysis, the thickness of the concrete layer that occurred was equal to 288 mm (

Figure 11b), which corresponds to a 25% decrease (97 mm) compared to the plain concrete.

5.4. Comparison Between Pavement Designs with Polypropylene and Steel Fibers

Figure 12 shows the thickness of the concrete layer resulting from the use of steel and polypropylene fibers and the flexural strength values used for the analysis. It should be noted that the flexural strength of plain concrete in each analysis does not correspond exactly to the absolute value as the representative values used for the analysis were selected according to the corresponding observations in the relevant references. However, it is considered that these variations have a limited effect on the thickness of the plain concrete layer, as shown in

Figure 12, so the comparison between the observed thicknesses is meaningful.

More precisely, by using polypropylene fibers with an increase in flexural strength of 14% and 26%, the thickness of the concrete layer could be reduced by about 8% and 16%, respectively. However, the use of steel fibers could lead to a greater reduction in the thickness of the concrete layer by about 25%, based on an increase in flexural strength of 52%.

6. Conclusions

In the present study, an attempt was made to quantify the effects of incorporating polypropylene and steel fibers into the surface course of airfield concrete pavements. To this end, international experience and practice in investigating the change in the flexural and compressive strength of concrete due to the addition of polypropylene and steel fibers was considered and characteristic strength values were selected for further analysis. The effects of the use of fibers on concrete were evaluated using an airfield pavement based on indicative traffic data and taking into account the principles of the UFC method.

Analysis of the literature data revealed that different proportions of polypropylene and steel fibers were tested worldwide, with the maximum increase in flexural strength occurring at different fiber proportions. This may be due to the fact that the properties of the materials tested, including the concrete mix, and the type of fibers used were different. For each case, the maximum percentage increase in flexural strength due to the addition of fibers was determined, regardless of fiber content. On this basis, significant differences were found in the maximum percentage increase in flexural strength due to the addition of fibers. For polypropylene fibers in particular, this increase is between 7% and 62%, with an average value of 24%. When steel fibers were added, a significant variation in maximum flexural strength was observed of between 24% and 92%, with an average value of 49%. It was found that the mean value of the increase in maximum flexural strength with the addition of polypropylene fibers was about half of the value with the addition of steel fibers.

The design of airfield pavements showed that the use of polypropylene fibers reduced the concrete layer thickness by 8 to 16%, while the addition of steel fibers could lead to a higher reduction in concrete layer thickness of about 25%. On this basis, the use of steel fibers appears to be more advantageous in terms of thickness reduction.

However, a cost–benefit analysis would facilitate the optimal strategy for the construction of concrete pavements in terms of a more sustainable approach. It should also be emphasized that the analysis carried out was based on mild climatic conditions. It would be interesting in the future to also investigate freeze–thaw resistance and the effects of corrosion on the concrete structure, especially in the case of steel fiber-reinforced concrete.