Effect of Lattice Structures in the Stress–Strain State for an Impeller Turbine

Abstract

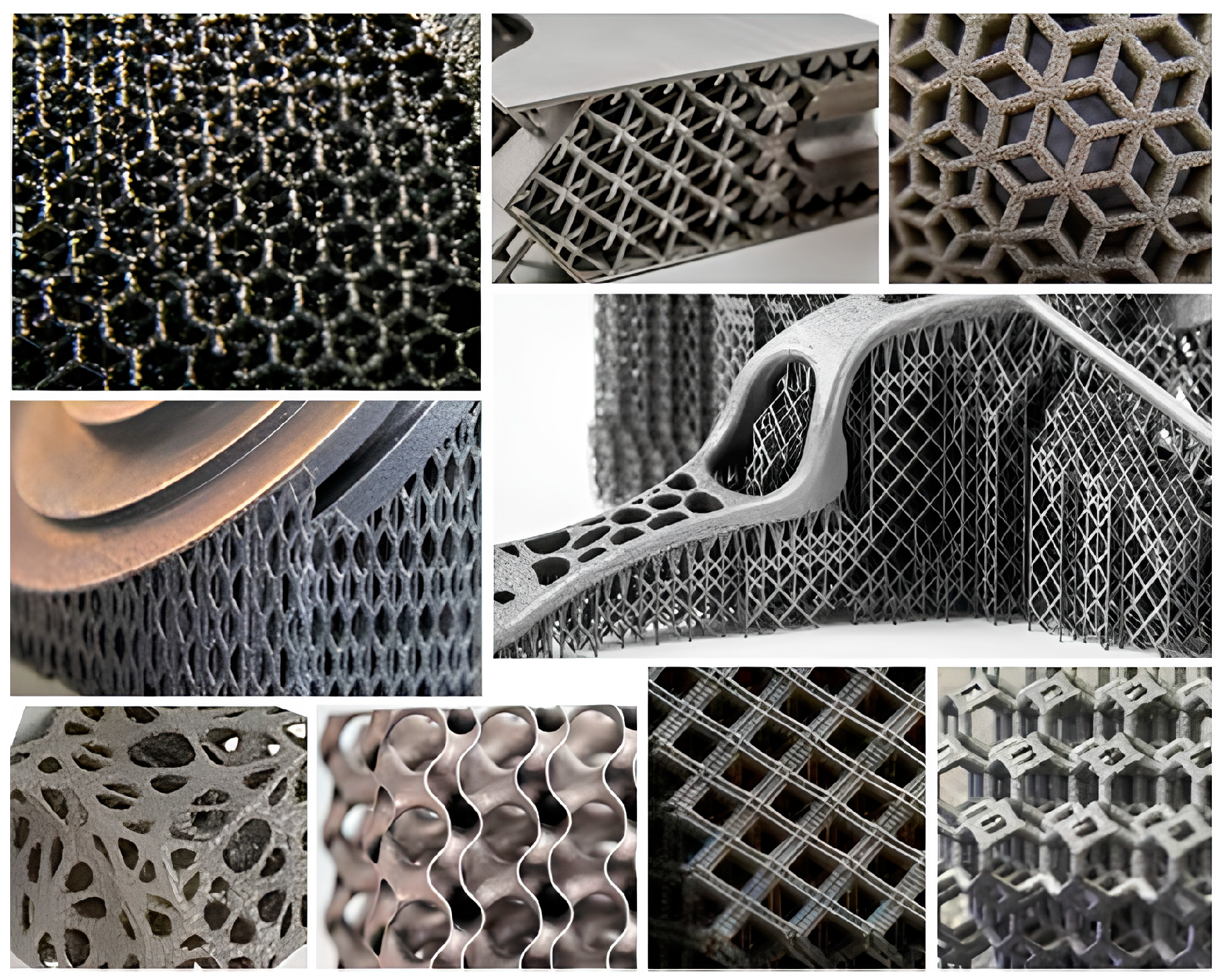

1. Introduction

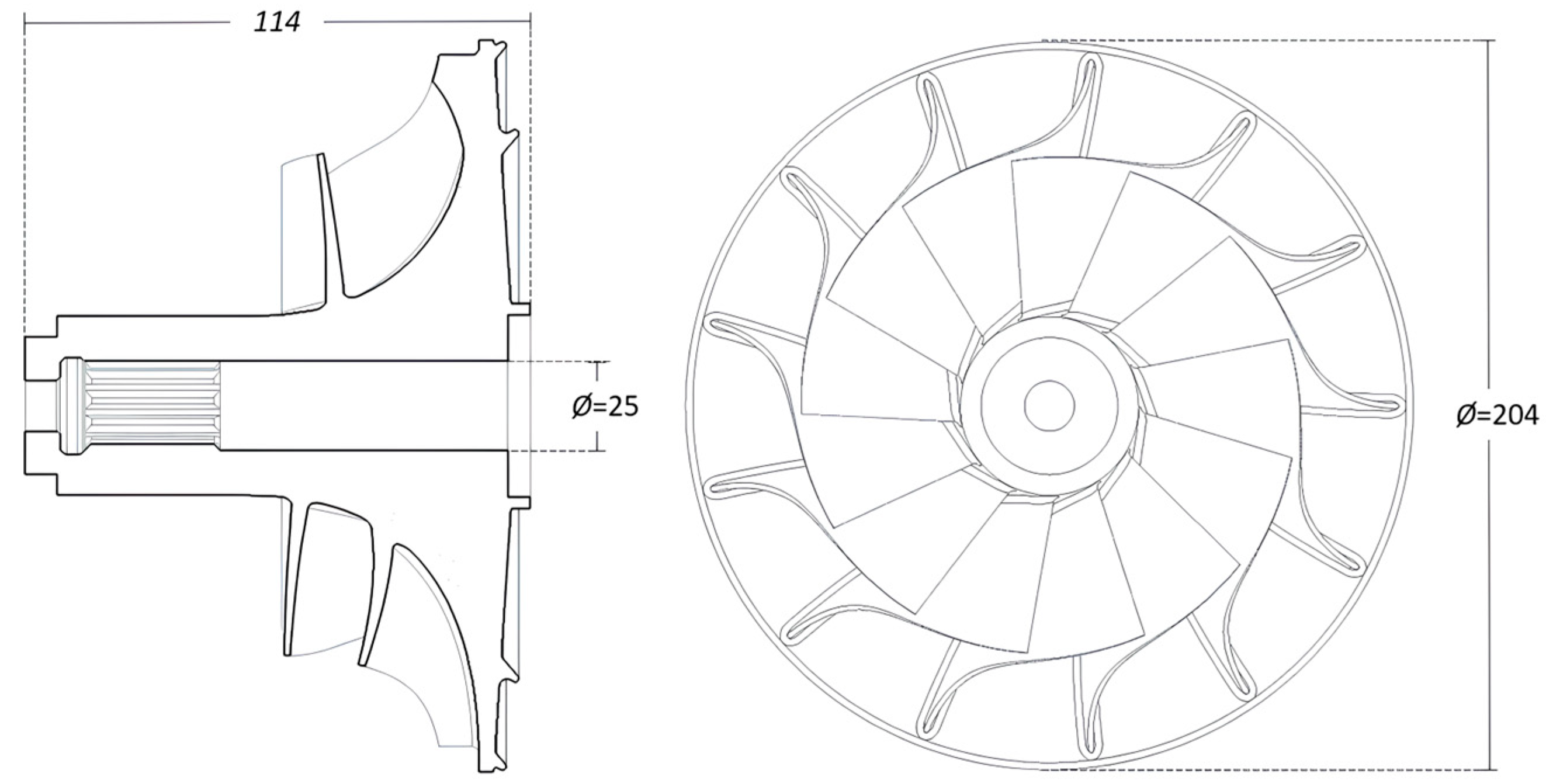

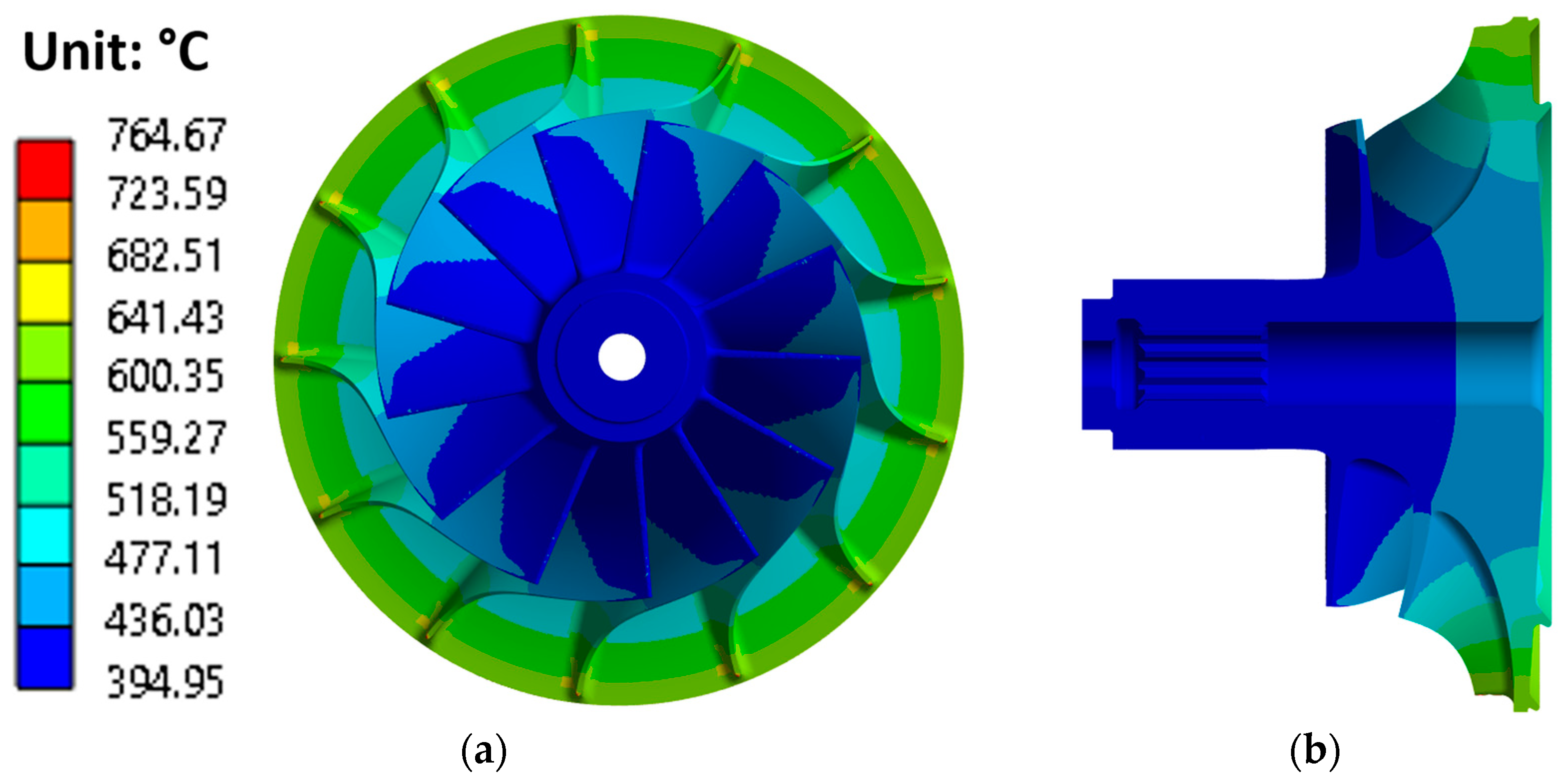

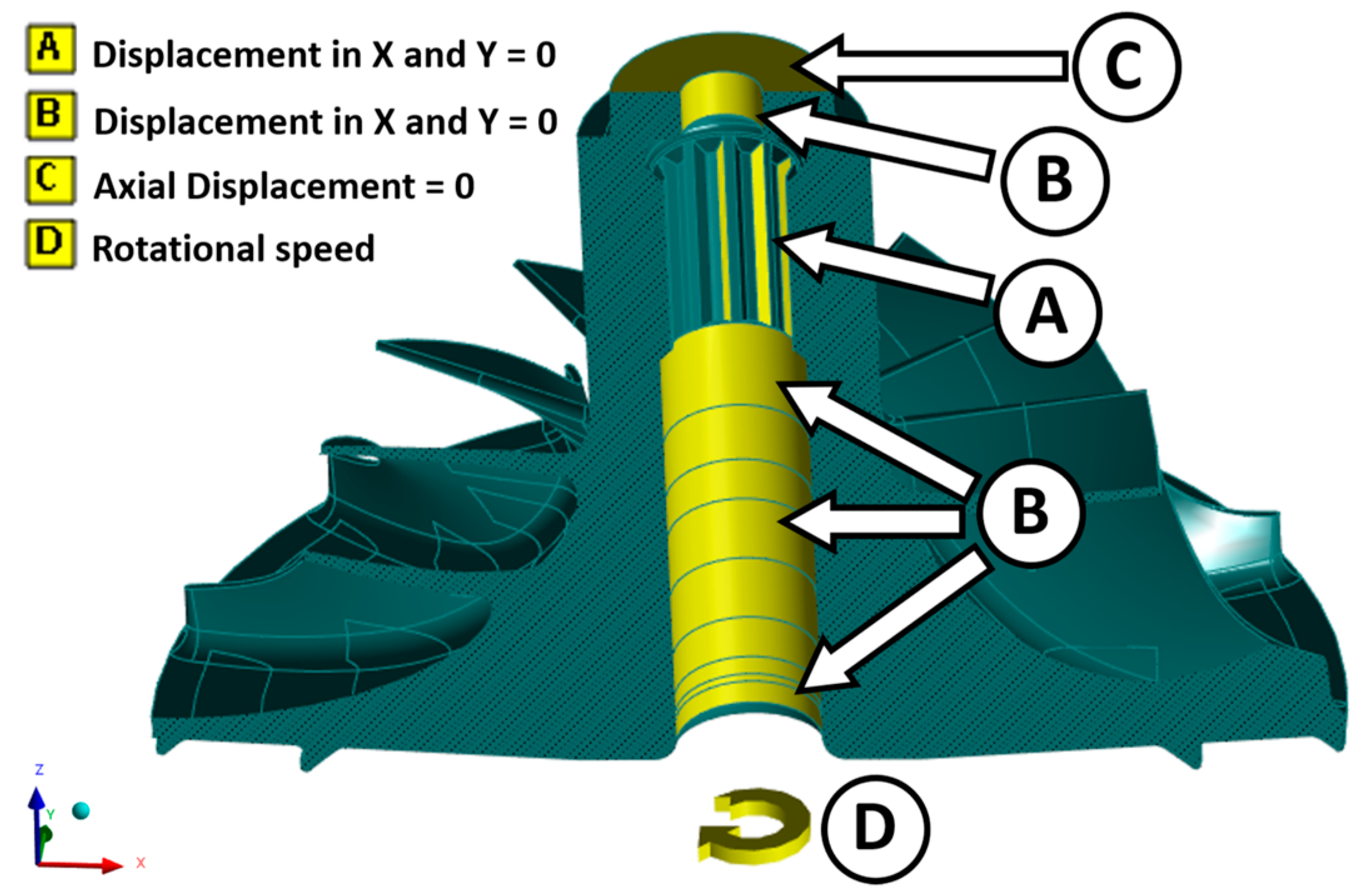

2. Materials and Methods

2.1. Boundary Conditions

2.2. Model Construction

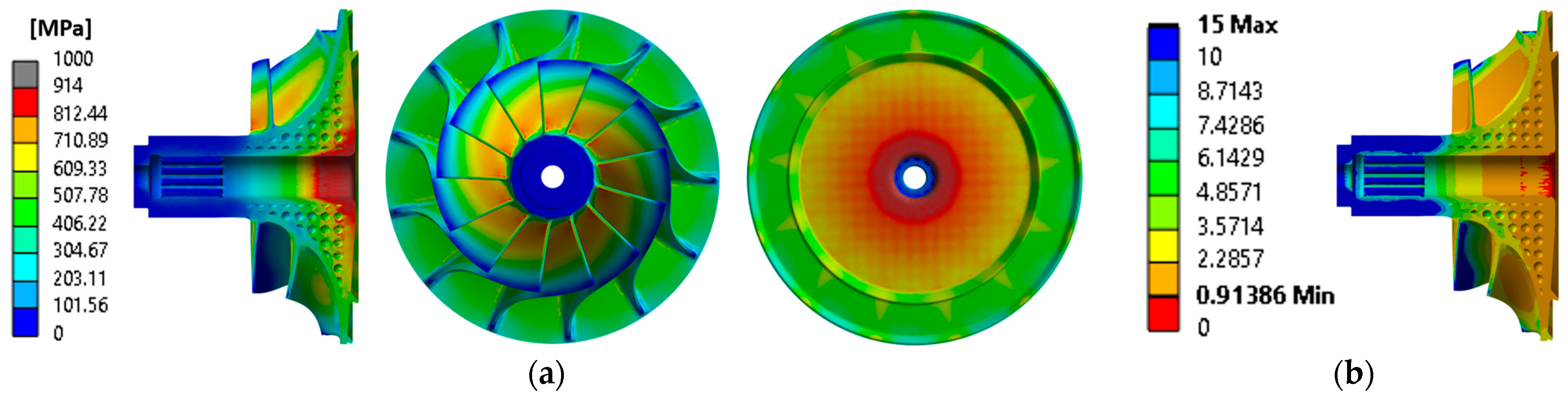

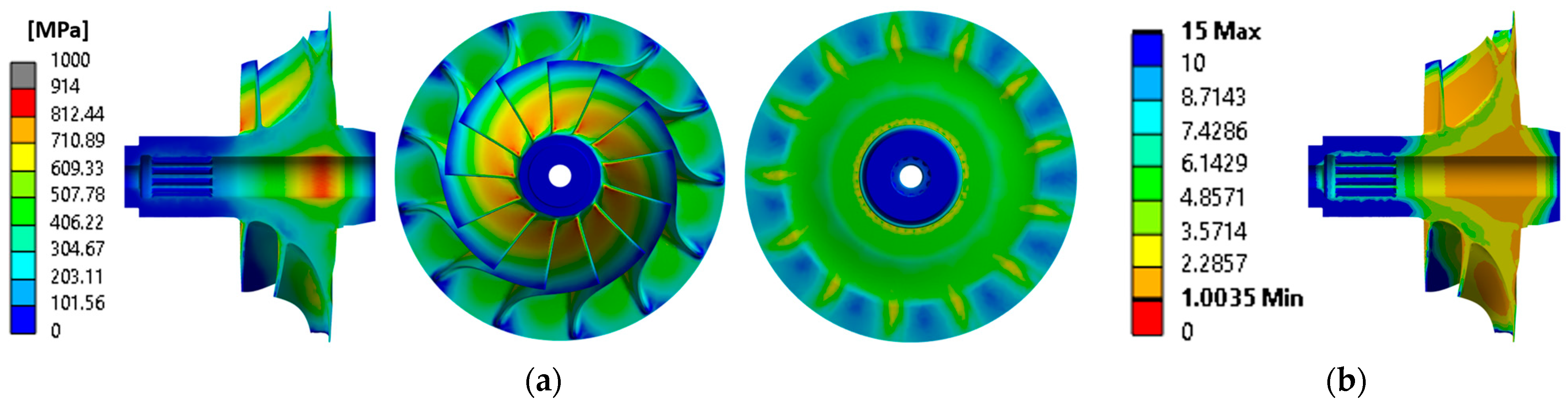

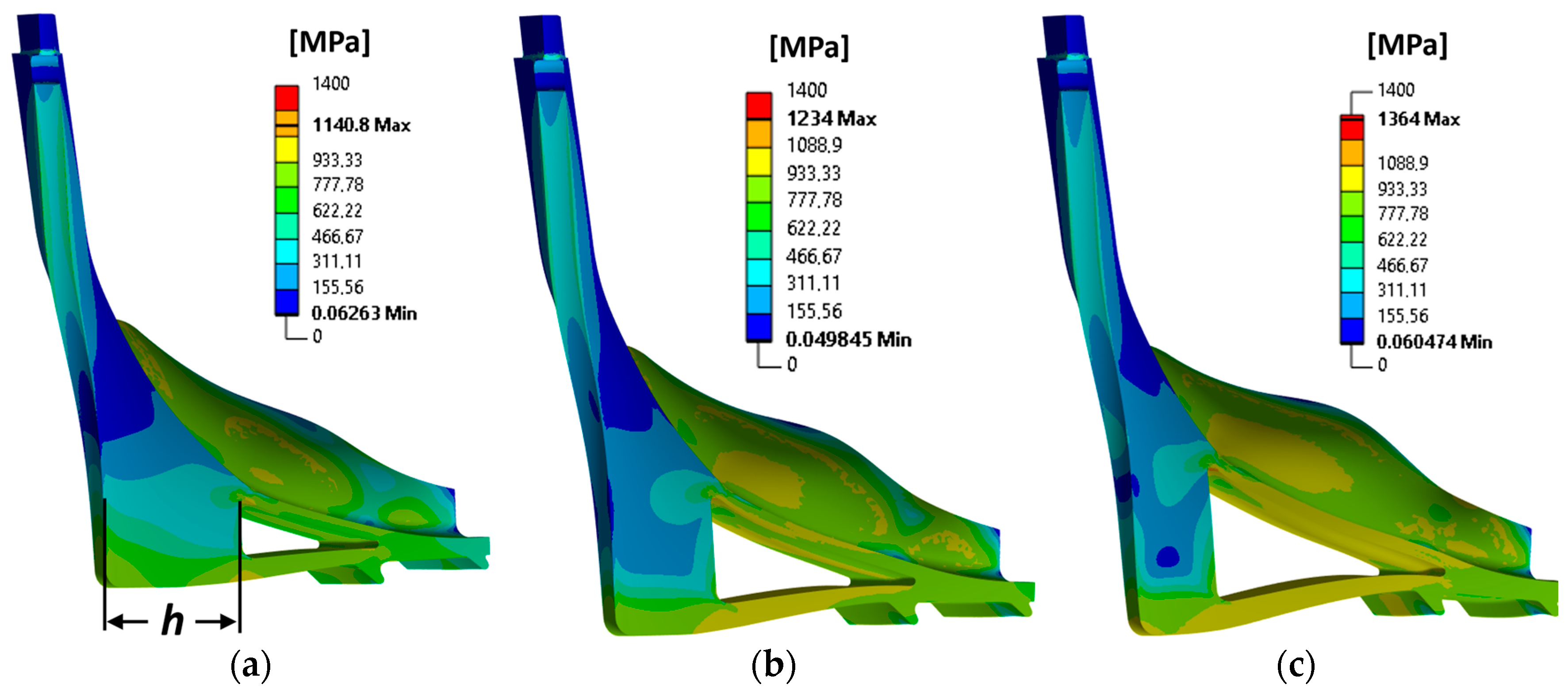

3. Results and Discussion

4. Conclusions

- •

- The better balance between mass reduction and stress reduction was achieved with the upgraded design, which resulted in a 12.5% reduction in stress and a 12.6% reduction in mass. This was performed by reinforcing the hub zone and reducing the thickness of the peripheral zones, without the incorporation of LSs.

- •

- The employment of LSs represents an effective strategy for the reduction of the mass of the impellers. Nevertheless, a reduction in the impeller mass does not result in a corresponding decrease in the induced stresses due to centrifugal forces.

- •

- The efficacy of LSs is contingent upon the geometry of the components in question.

- •

- The unloading effect is more pronounced when LSs are positioned in the peripheral regions of the impellers.

- •

- In the event that the impeller in question exhibits a relatively small periphery volume and the LSs are constrained to the hub zone, the placement of the LS will inevitably result in a pronounced surge in stresses. This is a direct consequence of the diminished strength of the hub zone, which is a result of the aforementioned constraints.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Driver, D.; Hall, D.W.; Meetham, G.W. The Gas Turbine Engine. In The Development of Gas Turbine Materials; Meetham, G.W., Ed.; Springer: Dordrecht, The Netherlands, 1981; pp. 1–30. ISBN 978-94-009-8113-3. [Google Scholar]

- Kang, H.-S.; Kim, Y.-J. Optimal Design of Impeller for Centrifugal Compressor under the Influence of One-Way Fluid-Structure Interaction. J. Mech. Sci. Technol. 2016, 30, 3953–3959. [Google Scholar] [CrossRef]

- Boyce, M.P. Gas Turbine Engineering Handbook, 4th ed.; Elsevier/Butterworth-Heinemann: Amsterdam, The Netherlands; Boston, MA, USA, 2012; pp. 361–372. ISBN 978-0-12-383842-1. [Google Scholar]

- Cesari, G.; Panella, F.W.; Pirinu, A. Stress/Strain State for Critical Components of a Jet Engine Aeronautical Compressor. Eng. Fail. Anal. 2020, 116, 104745. [Google Scholar] [CrossRef]

- Valakos, I.M.; Ntipteni, M.S.; Nikolos, I.K. Structural Optimization of a Centrifugal Impeller Using Differential Evolution in CATIA™ Environment. Oper. Res. Int. J. 2007, 7, 185–211. [Google Scholar] [CrossRef]

- Abd-El-Hussein, I.; Mäki-Iso, M.; Tiainen, J.; Teemu, T.-S.; Schuster, S.; Brillert, D. Reduction of Mechanical Stresses in Centrifugal Compressor Impellers for Hydrogen Applications. In Proceedings of the 15th European Conference on Turbomachinery Fluid dynamics & Thermodynamics (ETC15), Budapest, Hungary, 24–28 April 2023. [Google Scholar] [CrossRef]

- Lima, D.Z.; Dezan, D.J.; Gasparin, E.E.; Salviano, L.O.; Yanagihara, J.I.; Ferreira, W.G. Modal Analysis and Structural Optimization of Integrated Bladed Disks and Centrifugal Compressor Impellers. Struct. Multidisc. Optim. 2024, 67, 40. [Google Scholar] [CrossRef]

- Vivek, E.K.; Kumar, L.; Senthil Kumaran, R.; Veera Sesha Kumar, C. Improving Structural Integrity of a Centrifugal Compressor Impeller by Blading Optimization. In Proceedings of the 6th National Symposium on Rotor Dynamics; Rao, J.S., Arun Kumar, V., Jana, S., Eds.; Lecture Notes in Mechanical Engineering; Springer: Singapore, 2021; pp. 545–554. ISBN 978-981-15-5700-2. [Google Scholar]

- Chandan, A.K.; Sahoo, B.K.; Bansal, G.K.; Ghosh, M. Root Cause Analysis for the Failure of an Air Compressor Impeller. Trans. Indian Inst. Met. 2025, 78, 23. [Google Scholar] [CrossRef]

- Hearn, E.J. Mechanics of Materials: An Introduction to the Mechanics of Elastic and Plastic Deformation of Solids and Structural Materials, 3rd ed.; Butterworth-Heinemann: Oxford, UK; Boston, MA, USA, 1997; pp. 122–123. ISBN 978-0-7506-3265-2. [Google Scholar]

- Pugachuk, A.S.; Pribylov, V.G.; Volkov-Muzylev, V.V.; Konoplev, V.N. Design of Blade Joints with Turbine Impeller Disk of Low-Power Gas Turbine Engine. Chem. Petrol. Eng. 2019, 55, 3–9. [Google Scholar] [CrossRef]

- Gurianov, D.; Fortuna, S.; Nikonov, S.; Kalashnikova, T.; Chumaevskii, A.; Utyaganova, V.; Kolubaev, E.; Rubtsov, V. Assessment of Structure and Properties Homogeneity after Repairing of a Nickel-Based Superalloy Product by the Electron Beam Additive Technology. Crystals 2022, 12, 1400. [Google Scholar] [CrossRef]

- Chen, L.; Zhu, C. Rotor Strength Analysis for High Speed Permanent Magnet Machines. In Proceedings of the 2014 17th International Conference on Electrical Machines and Systems (ICEMS), Hangzhou, China, 22–25 October 2014; pp. 65–69. [Google Scholar]

- Schwarz, M.; Wirsum, M. Structural Design and Optimization of High-Speed Radial Compressor Wheels for Light Gases; ISSN-Nr: 2504-4400; GPPS: Aachen, Germany, 2024. [Google Scholar]

- Liu, S.; Mi, D.; Wen, C.; Zheng, Y. Topology Optimization Design With Addictive Manufacturing Constraints for Centrifugal Impeller. J. Phys. Conf. Ser. 2022, 2252, 012026. [Google Scholar] [CrossRef]

- Lu, X.; Xv, G.; Cong, C.; Gu, H.; Liang, S.Y. Residual Stress Prediction of Micro-Milling Inconel 718 Thin-Walled Parts. Int. J. Adv. Manuf. Technol. 2024, 133, 1305–1316. [Google Scholar] [CrossRef]

- Sujuan, W.; Tao, Z.; Wenping, D.; Zhanwen, S.; To, S. Analytical Modeling and Prediction of Cutting Forces in Orthogonal Turning: A Review. Int. J. Adv. Manuf. Technol. 2022, 119, 1407–1434. [Google Scholar] [CrossRef]

- Yaroslavcev, V.M. New Technologies for Surface Layer Quality Improvement in Cutting Fibrous Polymer Composite Materials. HoBMSTU.SME 2017, 6, 79–88. (In Russian) [Google Scholar] [CrossRef]

- Demirpolat, H.; Binali, R.; Patange, A.D.; Pardeshi, S.S.; Gnanasekaran, S. Comparison of Tool Wear, Surface Roughness, Cutting Forces, Tool Tip Temperature, and Chip Shape during Sustainable Turning of Bearing Steel. Materials 2023, 16, 4408. [Google Scholar] [CrossRef]

- Diniță, A.; Neacșa, A.; Portoacă, A.I.; Tănase, M.; Ilinca, C.N.; Ramadan, I.N. Additive Manufacturing Post-Processing Treatments, a Review with Emphasis on Mechanical Characteristics. Materials 2023, 16, 4610. [Google Scholar] [CrossRef] [PubMed]

- Makarov, V.F.; Meshkas, A.E.; Shirinkin, V.V. Study of the problems of mechanical processing of modern high-strength composite materials used for the production of parts for aviation and rocket and space technology. Vestnik PNIPU. Mashinostroenie Mashinovedenie 2015, 17, 30–41. (In Russian) [Google Scholar]

- Ryzhov, E.V.; Averchenkov, V.I. Optimization of Technological Processes of Mechanical Processing; Naukova dumka Publ.: Kyiv, Ukraine, 1989. (In Russian) [Google Scholar]

- Evdokimov, D.V.; Ahtam’yanov, R.M.; Aleksencev, A.A. Development of a comprehensive methodology for assessing deviations in the shape of a product and its service life depending on technological residual stresses. Vestnik MAI 2024, 31, 164–173. (In Russian) [Google Scholar]

- Al-Ketan, O.; Rowshan, R.; Abu Al-Rub, R.K. Topology-Mechanical Property Relationship of 3D Printed Strut, Skeletal, and Sheet Based Periodic Metallic Cellular Materials. Addit. Manuf. 2018, 19, 167–183. [Google Scholar] [CrossRef]

- Borikar, G.P.; Patil, A.R.; Kolekar, S.B. Additively Manufactured Lattice Structures and Materials: Present Progress and Future Scope. Int. J. Precis. Eng. Manuf. 2023, 24, 2133–2180. [Google Scholar] [CrossRef]

- Novak, N.; Vesenjak, M.; Ren, Z. High Strain Rate Hardening of Metallic Cellular Metamaterials. J. Dyn. Behav. Mater. 2024, 10, 363–377. [Google Scholar] [CrossRef]

- Kladovasilakis, N.; Tsongas, K.; Karalekas, D.; Tzetzis, D. Architected Materials for Additive Manufacturing: A Comprehensive Review. Materials 2022, 15, 5919. [Google Scholar] [CrossRef]

- Hassan, I.M.; Enab, T.A.; Fouda, N.; Eldesouky, I. Design, Fabrication, and Evaluation of Functionally Graded Triply Periodic Minimal Surface Structures Fabricated by 3D Printing. J. Braz. Soc. Mech. Sci. Eng. 2023, 45, 66. [Google Scholar] [CrossRef]

- Yan, J.; Guo, X.; Cheng, G. Multi-Scale Concurrent Material and Structural Design under Mechanical and Thermal Loads. Comput. Mech. 2016, 57, 437–446. [Google Scholar] [CrossRef]

- Adiaconitei, A.; Vintila, I.S.; Mihalache, R.; Paraschiv, A.; Frigioescu, T.; Vladut, M.; Pambaguian, L. A Study on Using the Additive Manufacturing Process for the Development of a Closed Pump Impeller for Mechanically Pumped Fluid Loop Systems. Materials 2021, 14, 967. [Google Scholar] [CrossRef] [PubMed]

- Boccini, E.; Furferi, R.; Governi, L.; Meli, E.; Ridolfi, A.; Rindi, A.; Volpe, Y. Toward the Integration of Lattice Structure-Based Topology Optimization and Additive Manufacturing for the Design of Turbomachinery Components. Adv. Mech. Eng. 2019, 11, 1687814019859789. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, F.; Jia, D. Lightweight Design and Static Analysis of Lattice Compressor Impeller. Sci. Rep. 2020, 10, 18394. [Google Scholar] [CrossRef] [PubMed]

- Jia, D.; Li, F.; Zhang, Y. 3D-Printing Process Design of Lattice Compressor Impeller Based on Residual Stress and Deformation. Sci. Rep. 2020, 10, 600. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Li, F.; Jia, D. Lattice Impeller Design and Multi-Scale Stress-Deformation Analysis Based on Conventional Cubic Lattice. Mech. Adv. Mater. Struct. 2022, 29, 2235–2249. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, F.; Jia, D. Residual Stress and Deformation Analysis of Lattice Compressor Impeller Based on 3D Printing Simulation. Mech. Adv. Mater. Struct. 2022, 29, 717–731. [Google Scholar] [CrossRef]

- Kishkin, S.; Kachanov, E.; Bulygin, I. Aviation Materials. Volume 3, Heat-Resistant Steels and Alloys; ОНТИ (Объединенное научно-техническое издательство) United Scientific and Technical Publishing House: Moscow, Russia, 1975; pp. 284–296. (In Russian) [Google Scholar]

- Hussain, S.; Ghopa, W.A.W.; Singh, S.S.K.; Azman, A.H.; Abdullah, S. Experimental and Numerical Vibration Analysis of Octet-Truss-Lattice-Based Gas Turbine Blades. Metals 2022, 12, 340. [Google Scholar] [CrossRef]

- Baturin, O.V.; Liu, C.; Sun, P.; Han, K. Educational Optimization Software for Axial Compressor Flow Path Design. In Proceedings of the 2022 IEEE 5th International Conference on Electronics Technology (ICET), Chengdu, China, 13 May 2022; pp. 381–385. [Google Scholar] [CrossRef]

- Neelambika, T.; Veerbhadrappa, T. CFD Analysis of mixed flow Impeller. Int. J. Eng. Res. Technol. 2014, 3, 601–607. [Google Scholar]

- Chen, Z.; Xia, Z.; Luo, J. Impact of Inlet Flow Angle Variation on the Performance of a Transonic Compressor Blade Using NIPC. AIP Adv. 2022, 12, 025001. [Google Scholar] [CrossRef]

- Diaz, R.B.; Tomita, J.T.; Bringhenti, C.; Silva, F.J.D.S.; Cavalca, D.F. An Evaluation of Passive Wall Treatment with Circumferential Grooves at the Casing of the First and Second Blade Rotor Rows of a High-Performance Multi-Stage Axial Compressor. Aerospace 2024, 11, 662. [Google Scholar] [CrossRef]

- Bhavik, P.; Mayur, K.; Dhruv, J. Design and Analysis of Turbocharger Impeller for Diesel Engine. Int. J. Manag. Technol. Eng. 2018, 8, 1804–1811. [Google Scholar]

- Rafi, S.; Amara, N.; Rao, N. Structure Analysis of a Turbocharger Compressor Wheel Using FEA. Int. J. Eng. Res. Appl. 2014, 4, 157–159. [Google Scholar]

- Sathishkumar, N.; Premkumar, P.; Ruskin Bruce, A.; Pravinkumar, K.; Sudharsan, P.L. Design and Analysis of an Impeller of a Turbocharger. Int. J. Res. Rev. 2020, 7, 45–51. [Google Scholar]

- Yan, C.; Zhu, J.; Shen, X.; Fan, J.; Jia, Z.; Chen, T. Structural Design and Optimization for Vent Holes of an Industrial Turbine Sealing Disk. Chin. J. Aeronaut. 2021, 34, 265–277. [Google Scholar] [CrossRef]

- Lipian, M.; Czapski, P.; Obidowski, D. Fluid–Structure Interaction Numerical Analysis of a Small, Urban Wind Turbine Blade. Energies 2020, 13, 1832. [Google Scholar] [CrossRef]

| Cr | C | Al | Ti | W | Nb |

|---|---|---|---|---|---|

| 8.0–9.5 | 0.13–0.2 | 5.1–6.0 | 2.0–2.9 | 9.5–11.0 | 0.8–1.2 |

| Mo | Co | Fe | Ni | Other (Si, S, P, Ce, Zr, B, Pb, Bi, Y) | |

| 1.2–2.4 | 9.0–10.5 | ≤1 | Base | ≤0.93 | |

| Design/Parameter | 1st Design | 2nd Design | 3rd Design | 4th Design | 5th Design | 6th Desing |

|---|---|---|---|---|---|---|

| Original | Original w Spherical LS | Original w Brick LS | Upgraded | Upgraded w Spherical LS | Upgraded w Brick LS | |

| Mass [kg] | 5.996 | 5.590 | 5.206 | 5.238 | 4.865 | 4.629 |

| Mass Variation [%] | N/A | −6.8% | −13.2% | −12.6% | −18.9% | −22.8% |

| Design/Parameter | 1st Design | 2nd Design | 3rd Design | 4th Design | 5th Design | 6th Desing |

|---|---|---|---|---|---|---|

| Original | Original w Spherical LS | Original w Brick LS | Upgraded | Upgraded w Spherical LS | Upgraded w Brick LS | |

| Von Mises stresses | 938 | 1000 | 943 | 821 | 860 | 844 |

| % Stress Variation | N/A | +6.6% | +0.5% | −12.5% | −8.3% | −10.0% |

| Design/Parameter | 1st Design | 2nd Design | 3rd Design | 4th Design | 5th Design | 6th Desing |

|---|---|---|---|---|---|---|

| Original | Original w Spherical LS | Original w Brick LS | Upgraded | Upgraded w Spherical LS | Upgraded w Brick LS | |

| Safety factor, k | 0.97 | 0.91 | 0.97 | 1.12 | 1.07 | 1.09 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Evdokimov, D.; Sangines Lezama, F.A.; Filinov, E.; Chertykovtsev, P. Effect of Lattice Structures in the Stress–Strain State for an Impeller Turbine. Eng 2025, 6, 34. https://doi.org/10.3390/eng6020034

Evdokimov D, Sangines Lezama FA, Filinov E, Chertykovtsev P. Effect of Lattice Structures in the Stress–Strain State for an Impeller Turbine. Eng. 2025; 6(2):34. https://doi.org/10.3390/eng6020034

Chicago/Turabian StyleEvdokimov, Dmitry, Fidel Agustin Sangines Lezama, Evgeny Filinov, and Pavel Chertykovtsev. 2025. "Effect of Lattice Structures in the Stress–Strain State for an Impeller Turbine" Eng 6, no. 2: 34. https://doi.org/10.3390/eng6020034

APA StyleEvdokimov, D., Sangines Lezama, F. A., Filinov, E., & Chertykovtsev, P. (2025). Effect of Lattice Structures in the Stress–Strain State for an Impeller Turbine. Eng, 6(2), 34. https://doi.org/10.3390/eng6020034