Design and Experimental Study of Full-Process Automatic Anti-Corrosion Joint-Coating Equipment

Abstract

1. Introduction

2. Design of Equipment Structure

2.1. Design of the Universal Chassis

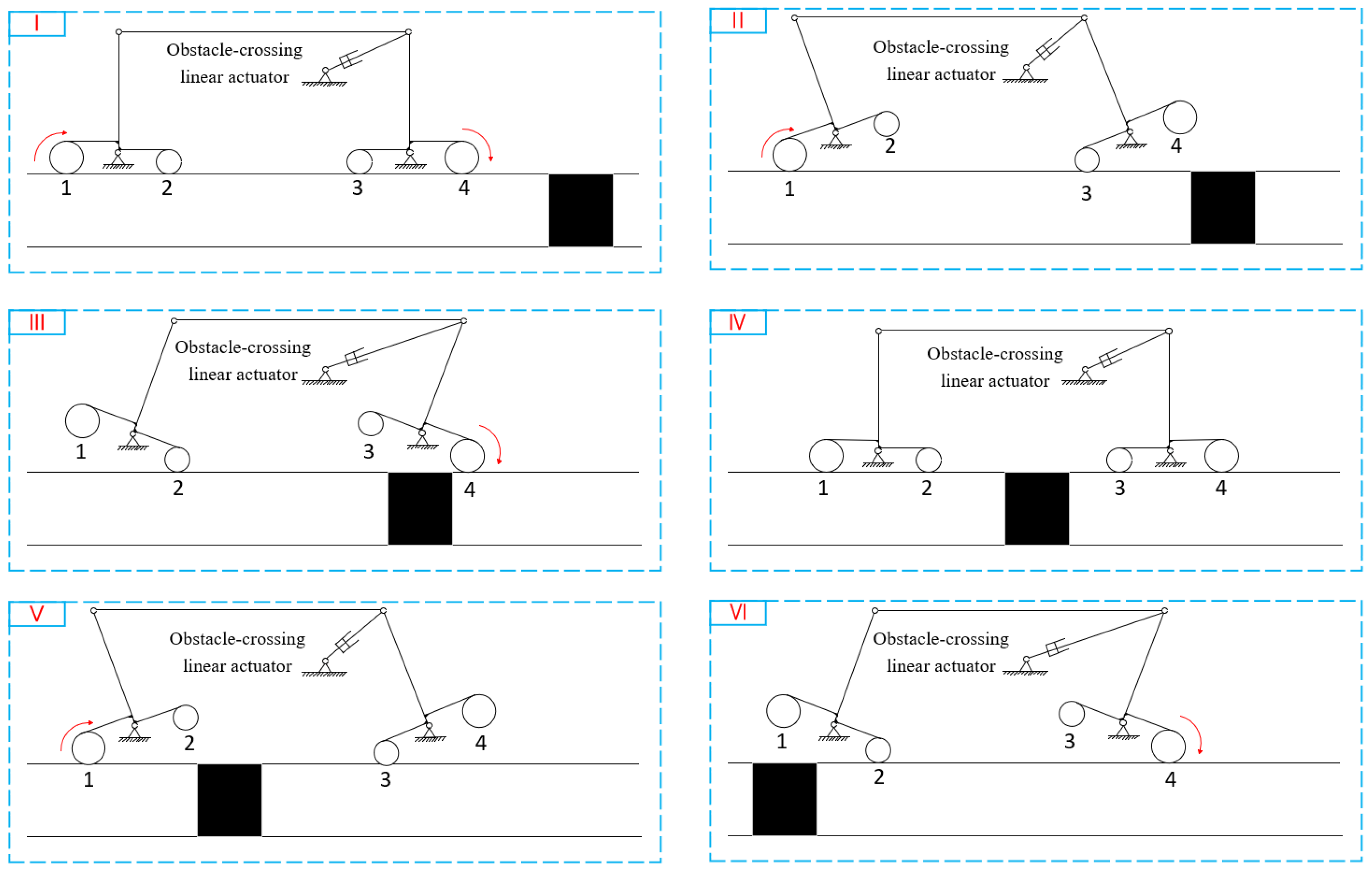

2.1.1. Axial Obstacle Traversal Walking System

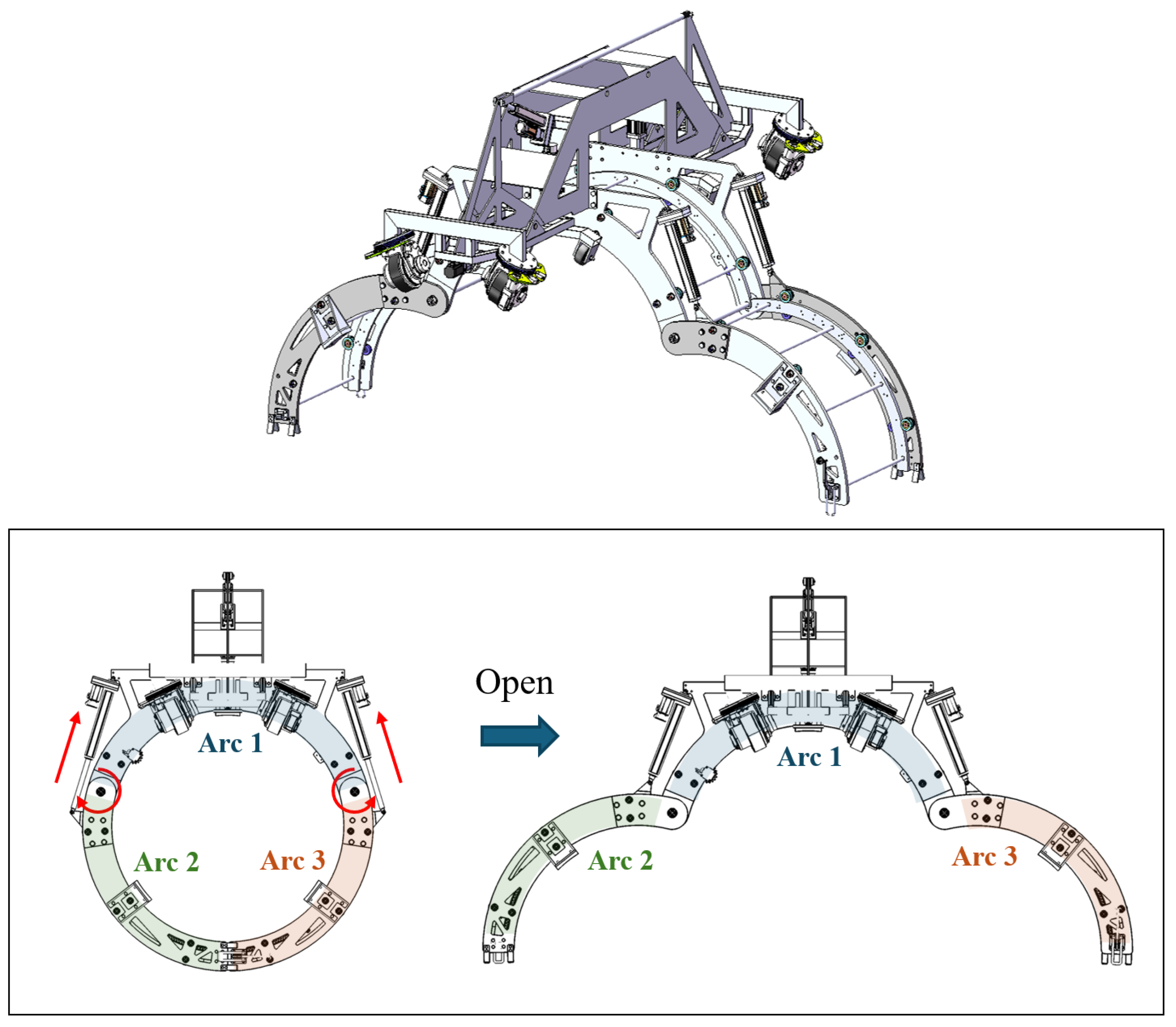

2.1.2. Design of the Equipment’s Opening and Closing Mechanism

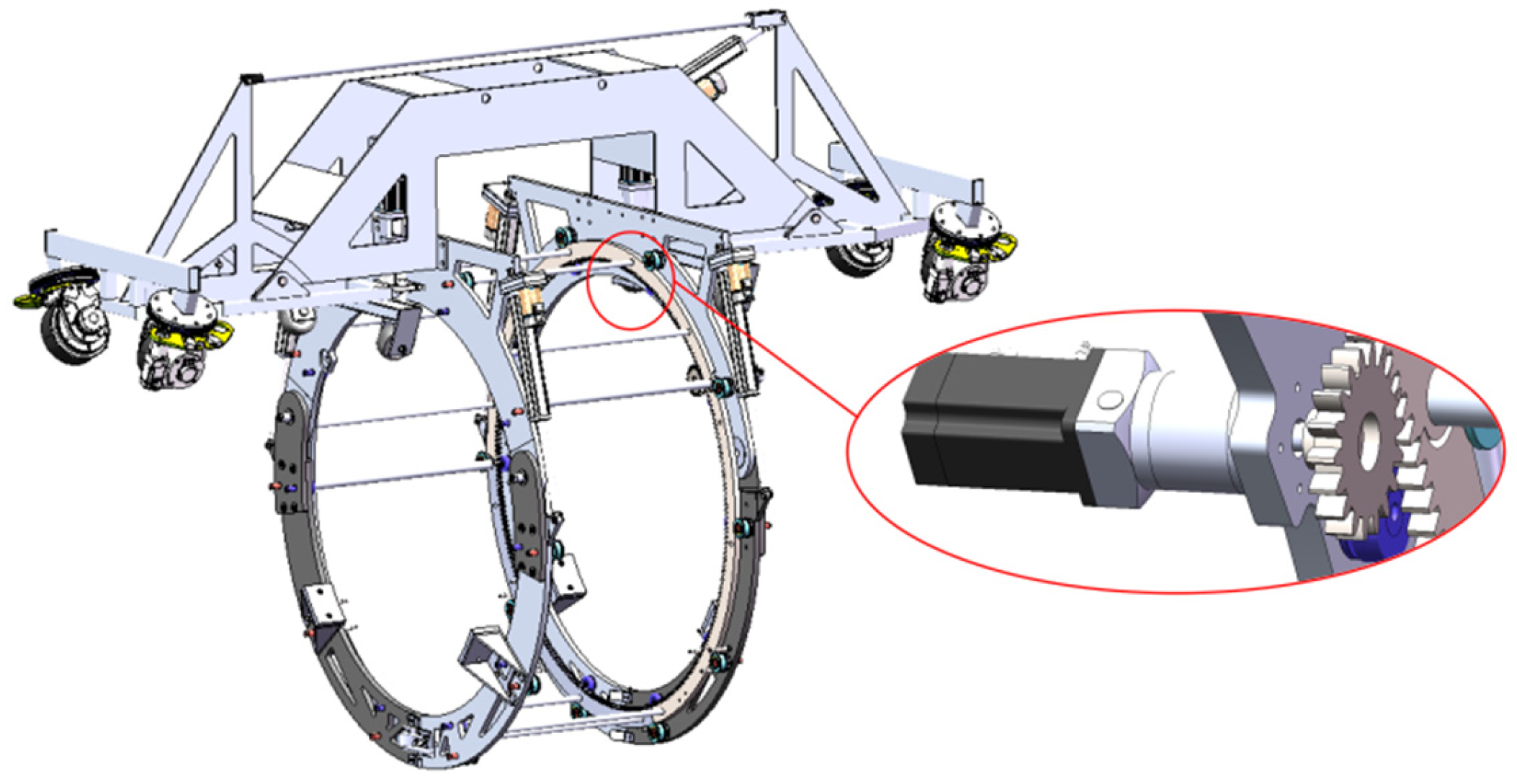

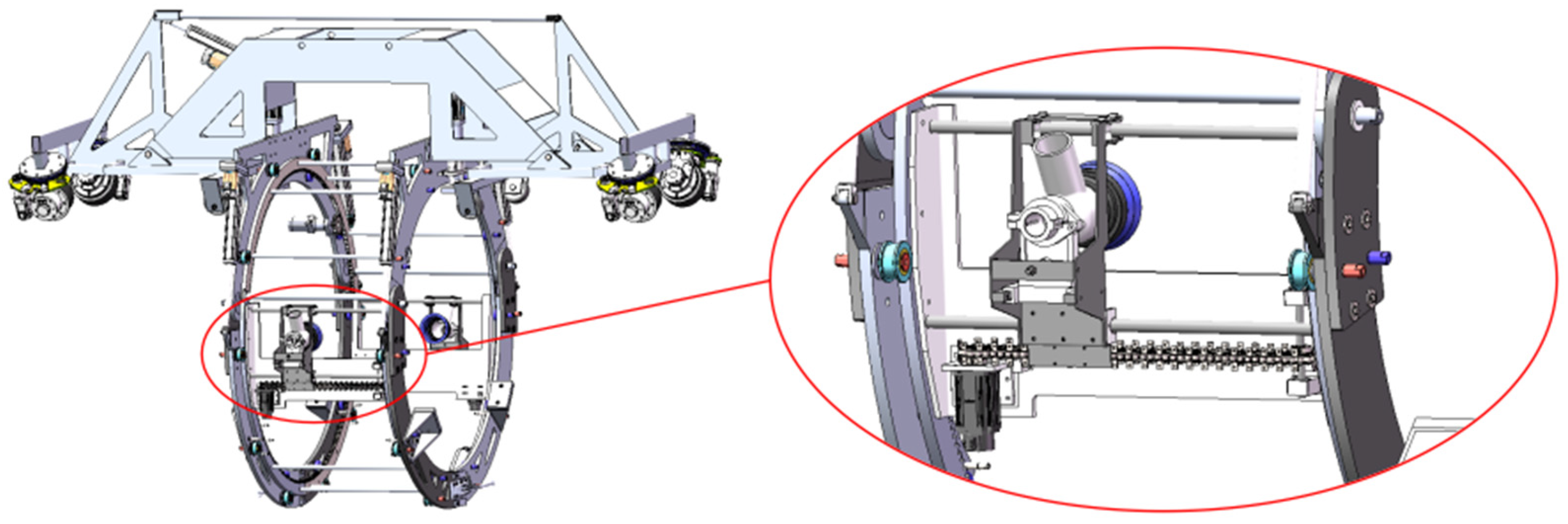

2.1.3. Design of the Circumferential Rotation Mechanism

2.2. Structural Design of Functional Modules

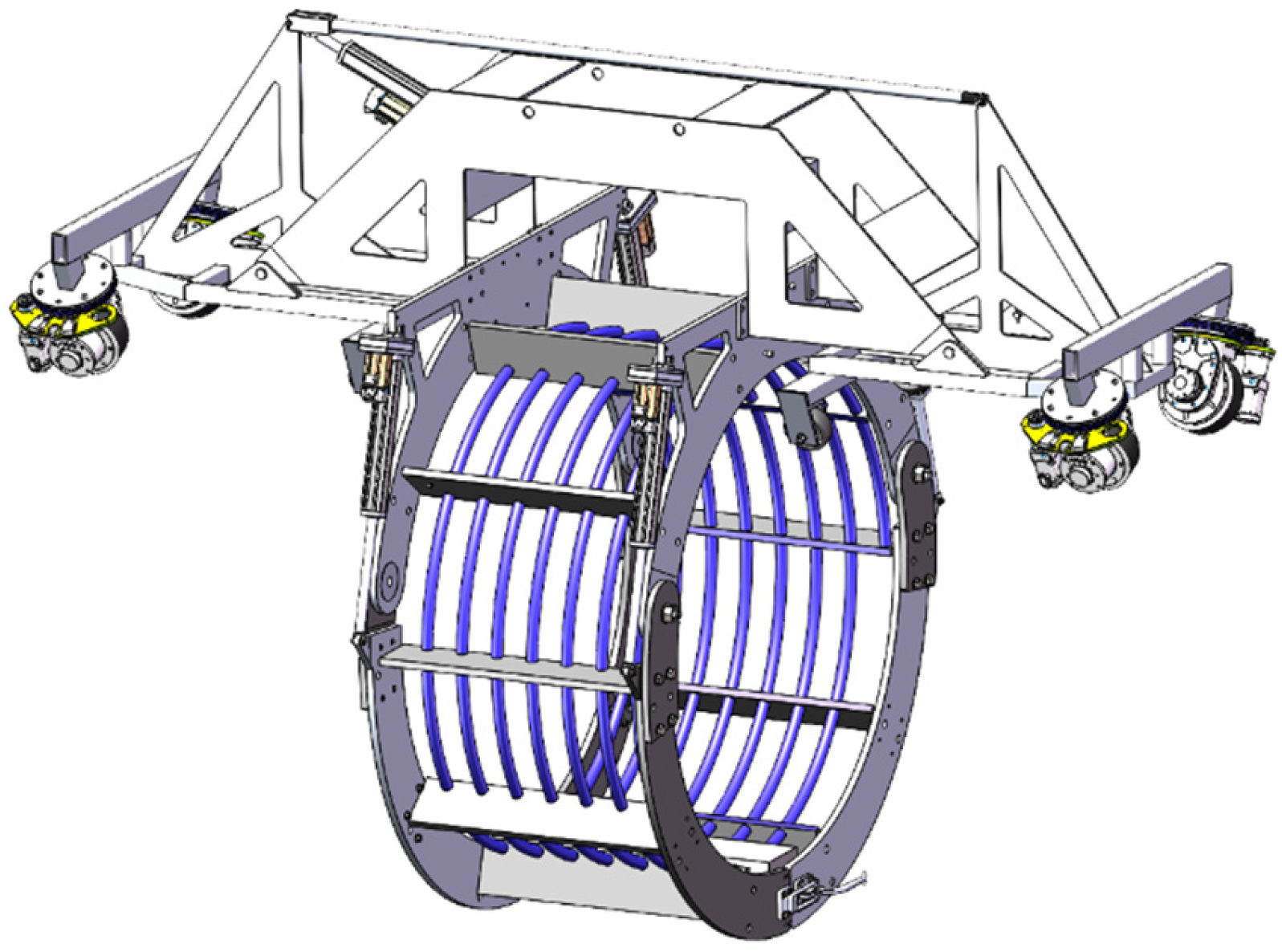

2.2.1. Design of the Sandblasting and Rust Removal Module

2.2.2. Design of the Mid-Frequency Heating Module

- (1)

- The pipe wall thickness is much greater than the skin depth (i.e., the thin-wall approximation holds).

- (2)

- The pipe radius R is sufficiently larger than δ, so the local surface can be regarded as planar (curvature effects neglected).

- (3)

- The magnetic permeability μ is a linear constant, independent of magnetic field strength or temperature variation.

- (4)

- The electrical conductivity σ is uniform, and temperature-induced changes in conductivity are neglected during steady-state analysis

- (5)

- The induction heating coil and pipe wall geometry, as well as the spatial distribution of coil turns n, are idealized as uniform; there is no strong coupling at the coil edges, and end effects are assumed negligible.

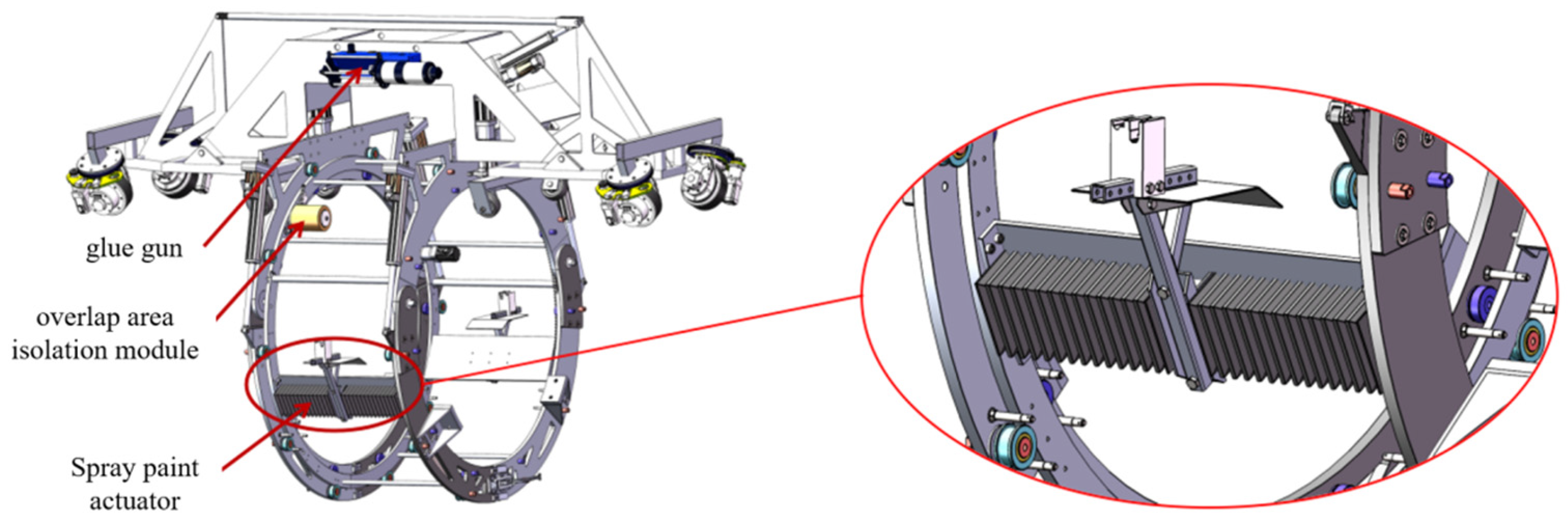

2.2.3. Design of the Primer Spray Module

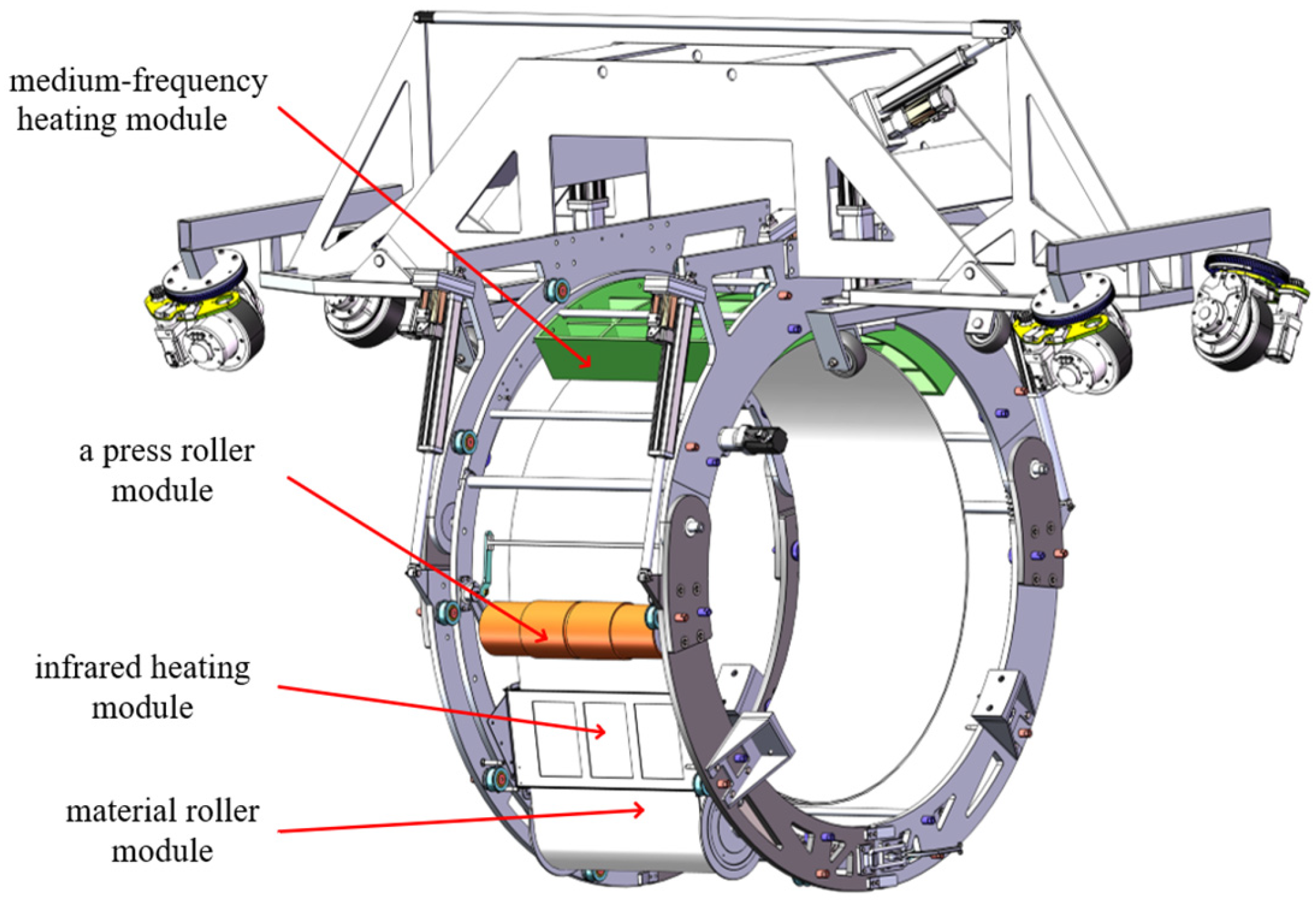

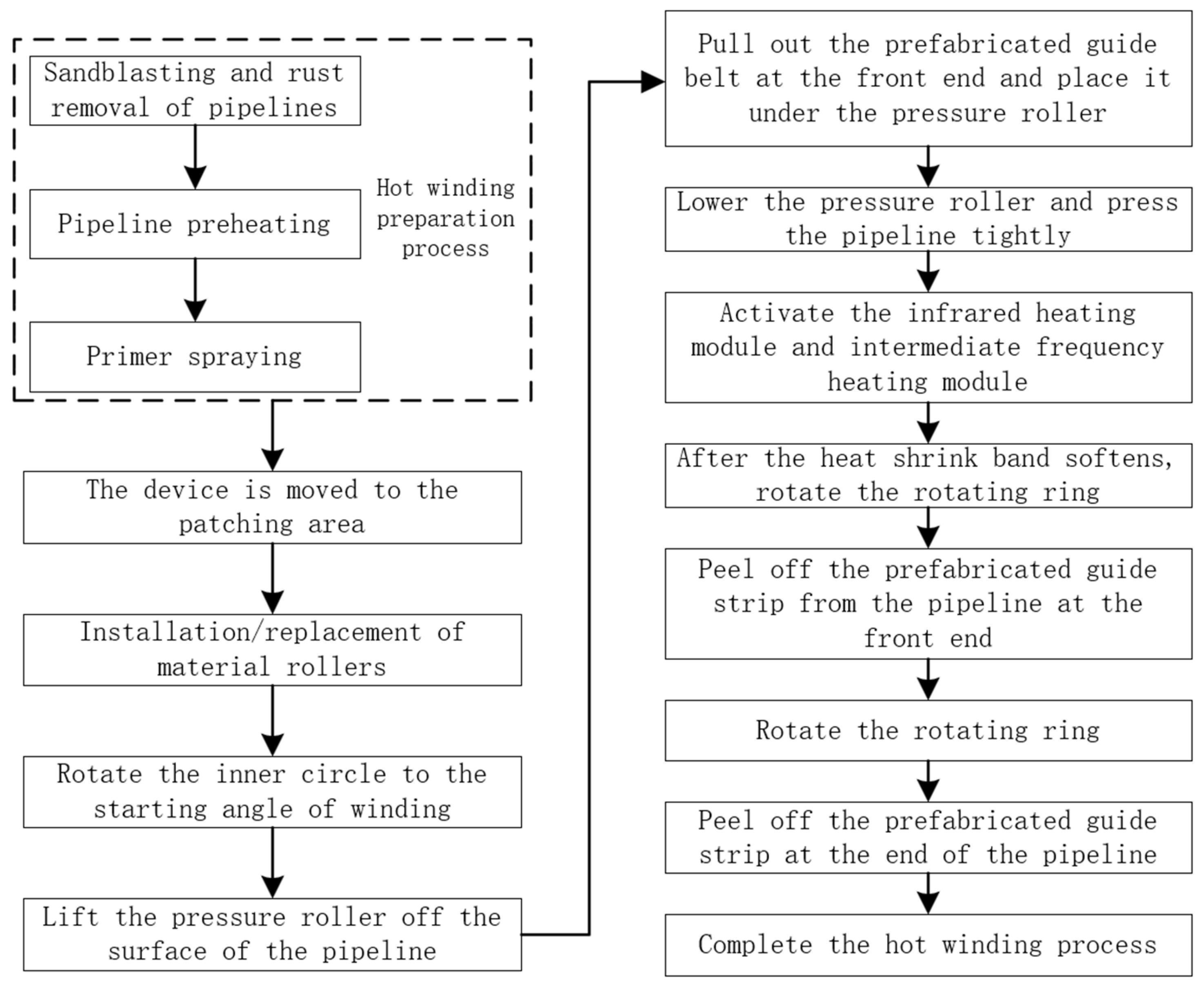

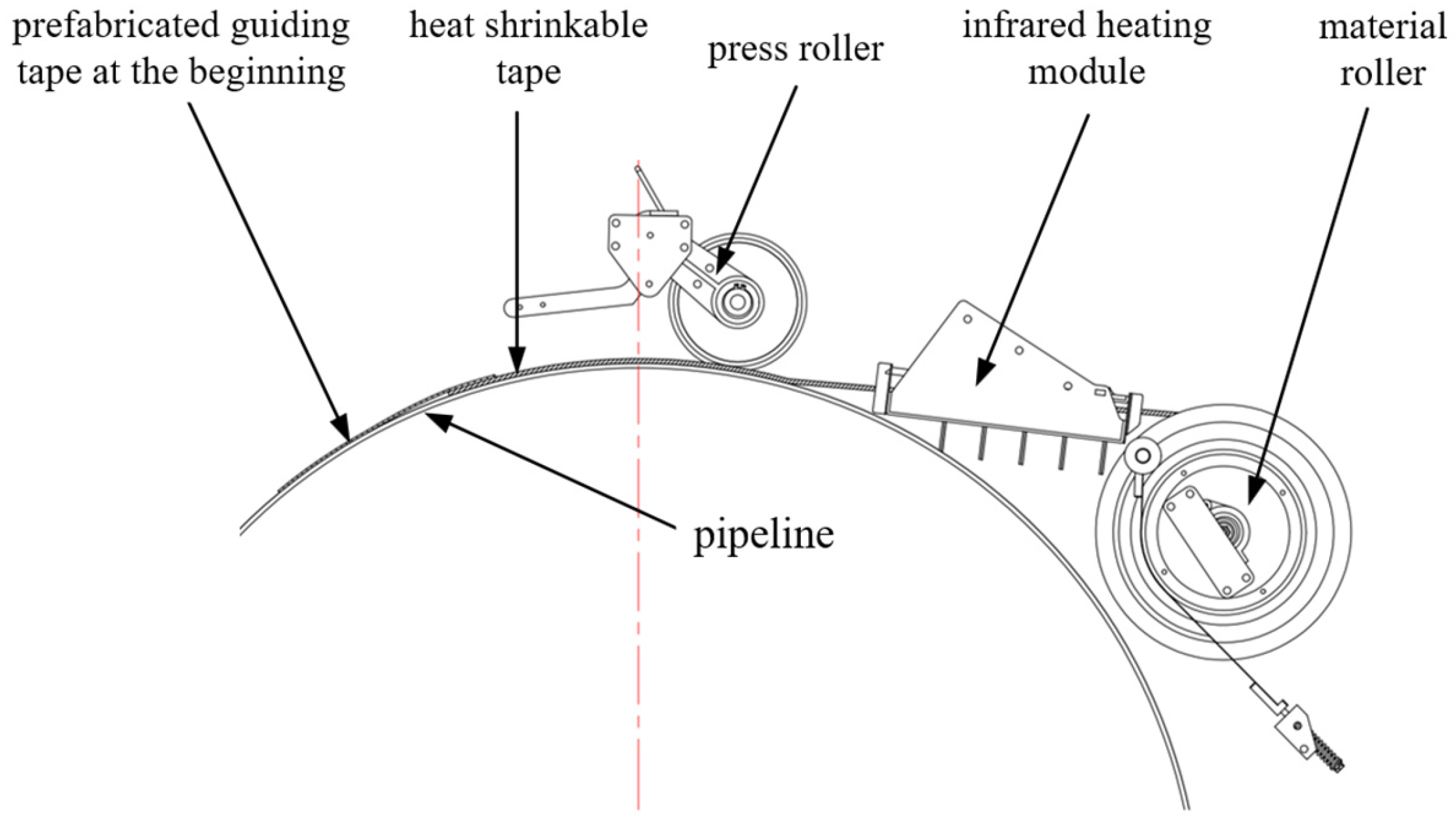

2.2.4. Design of the Heat-Shrink-Tape Wrapping Module

3. Simulation Analysis of Key Structural Components

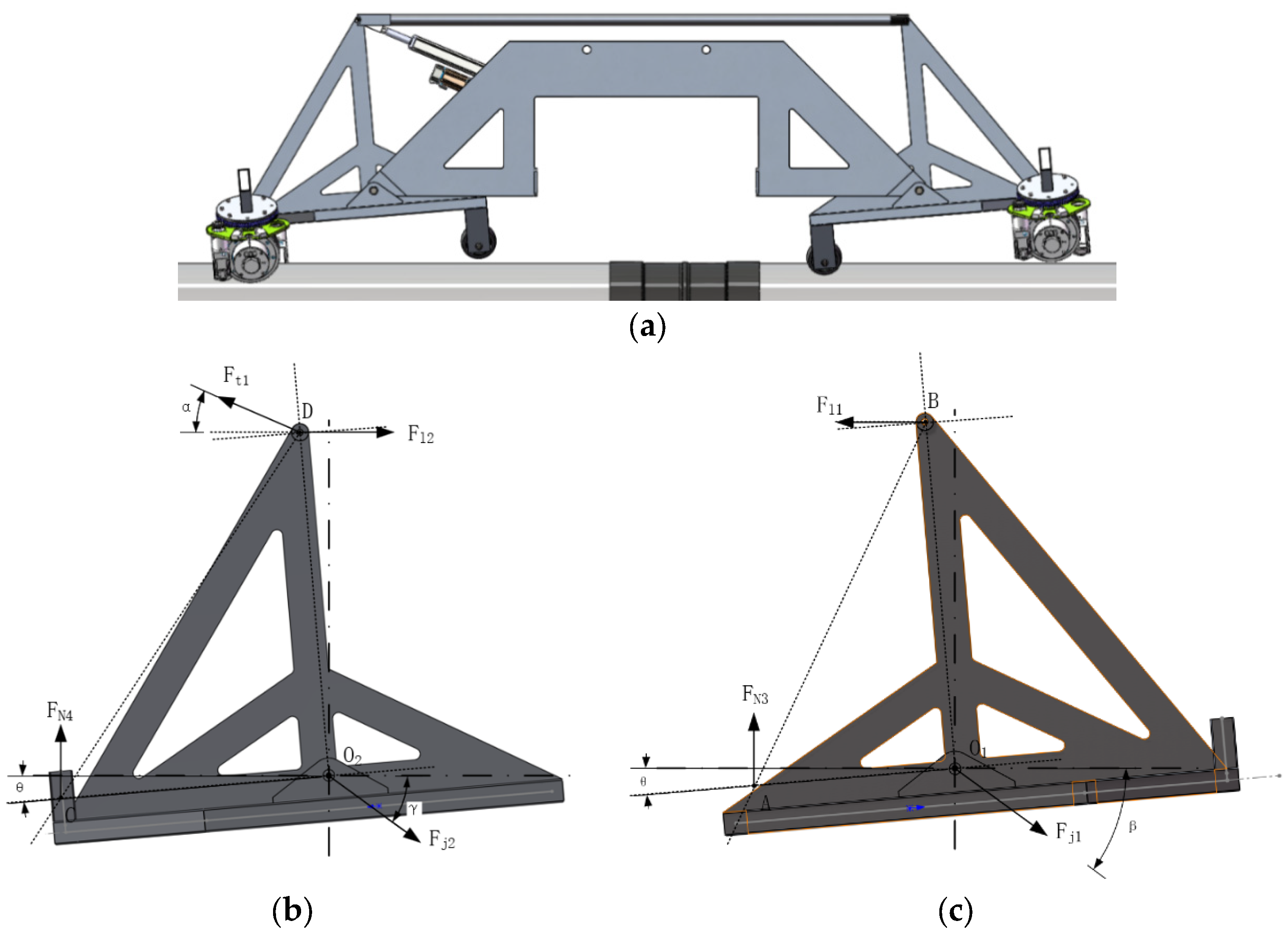

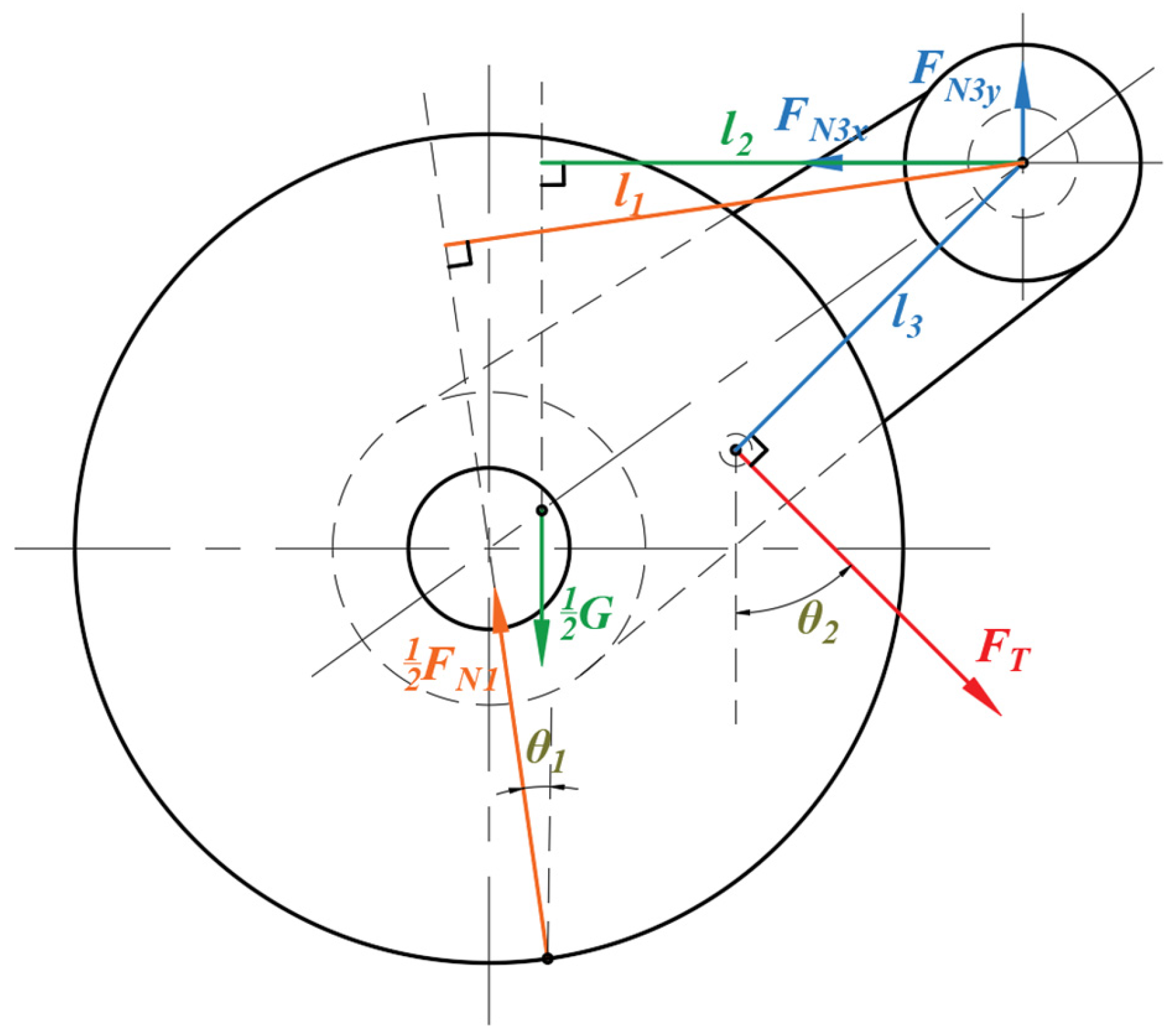

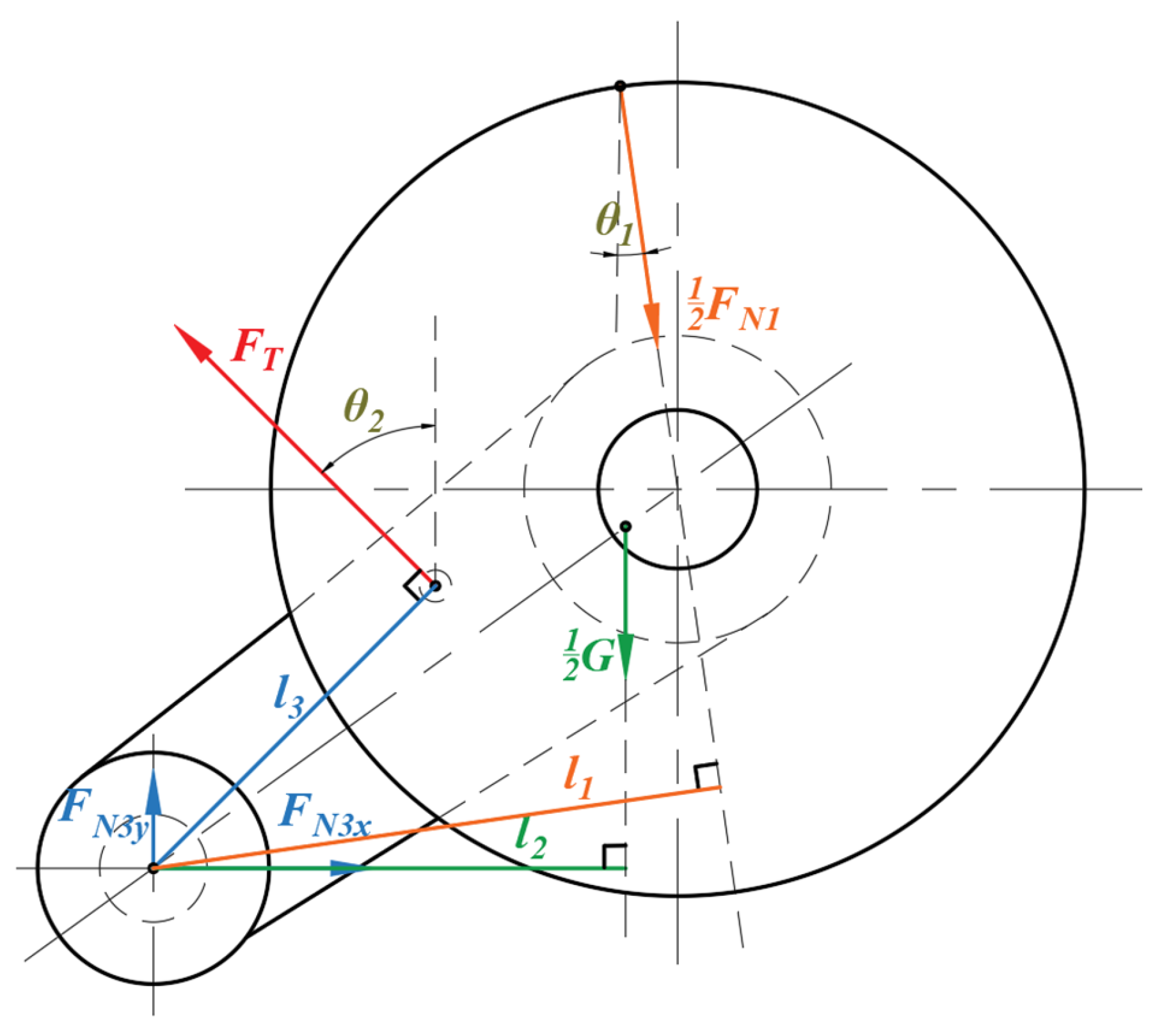

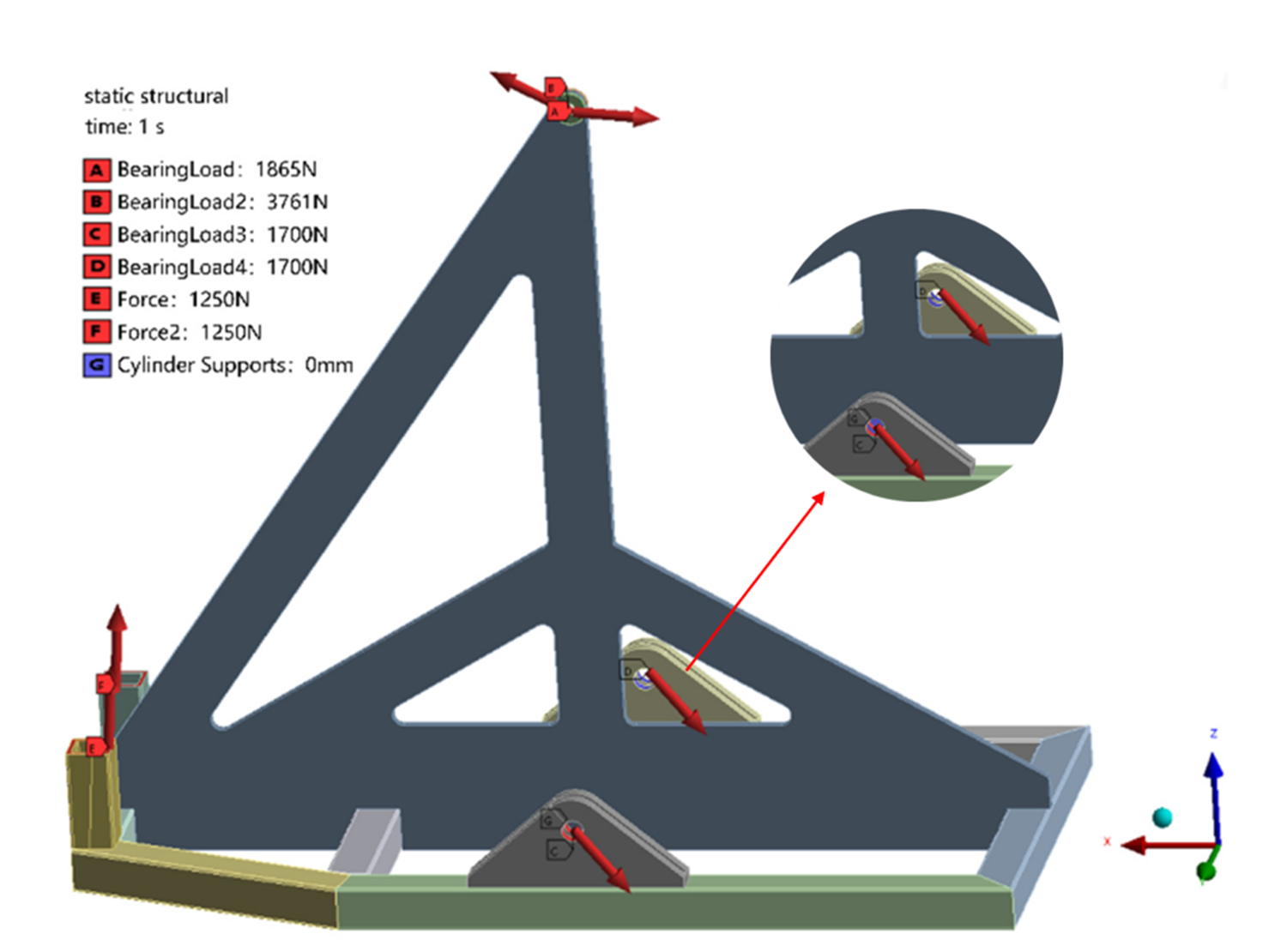

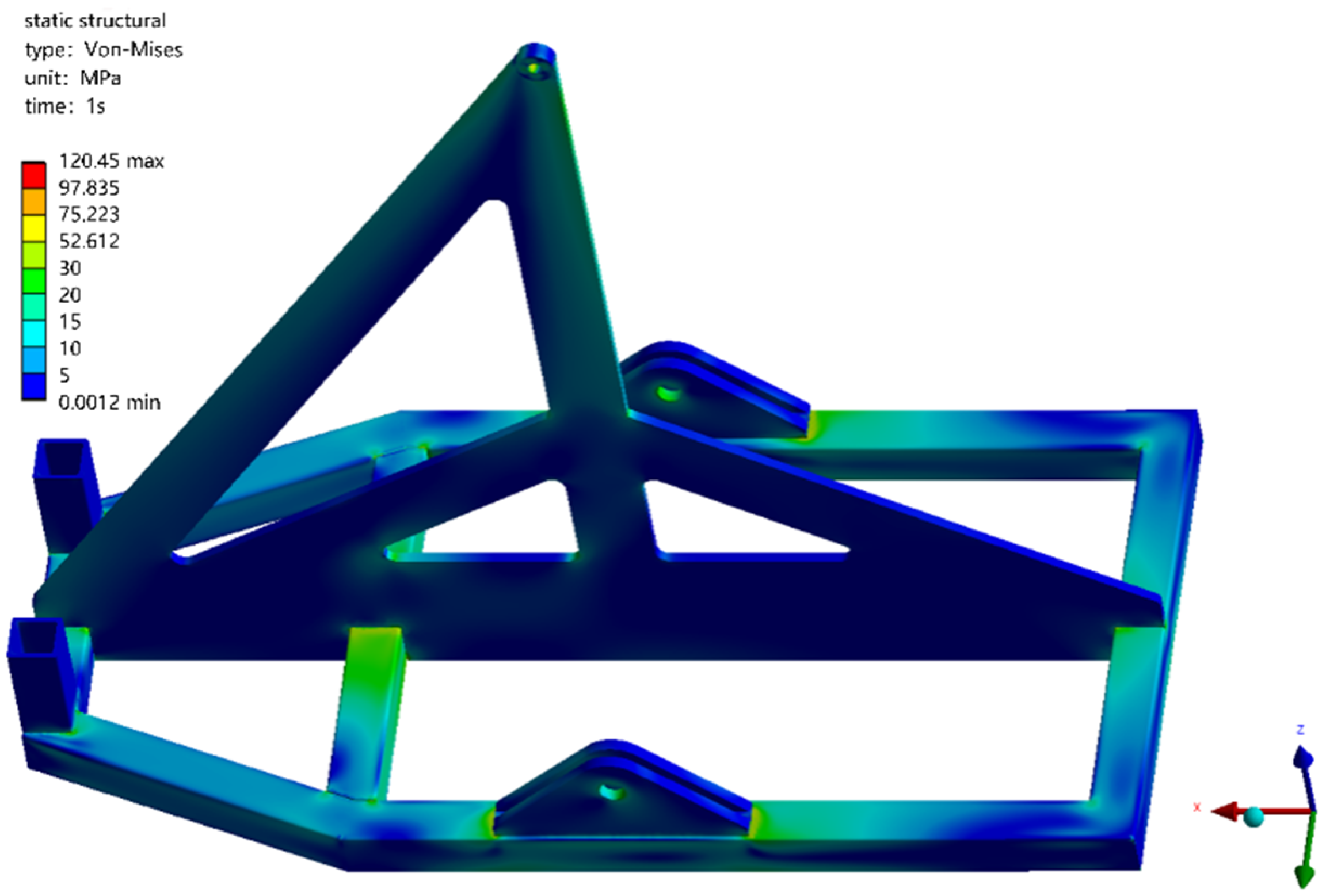

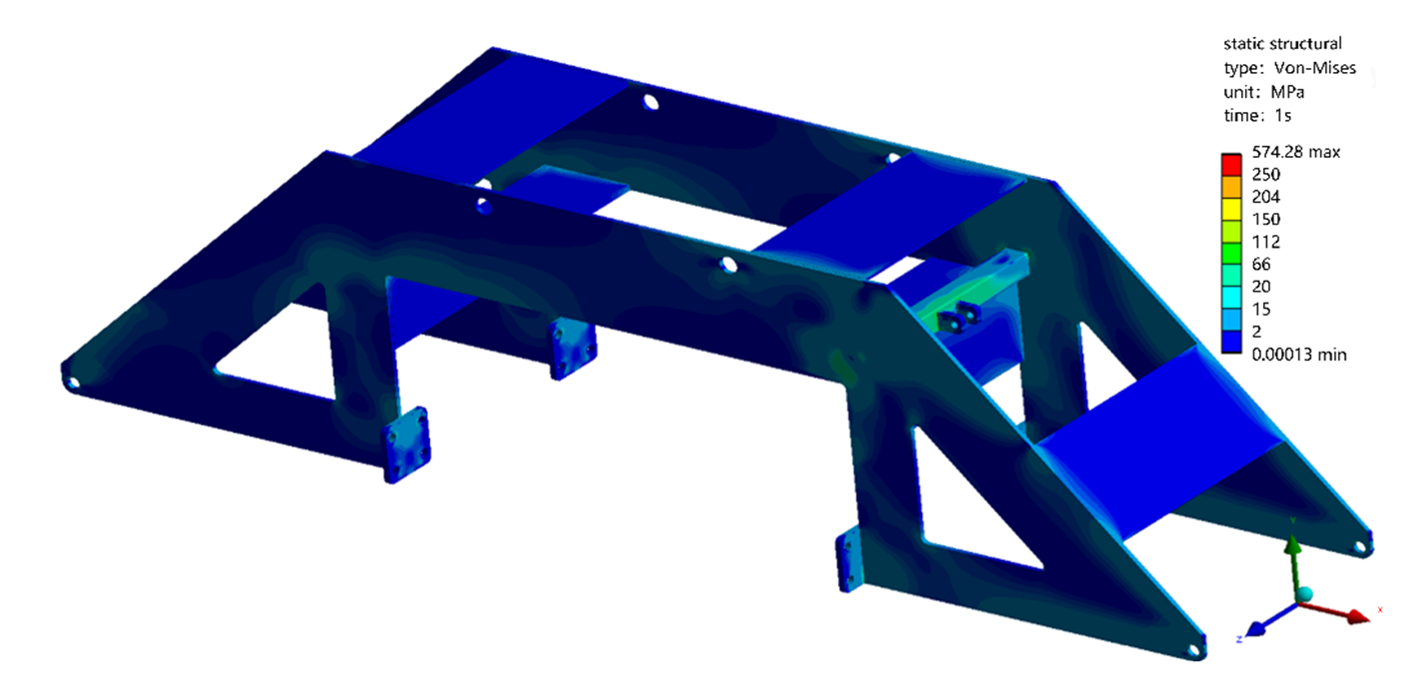

3.1. Simulation Analysis of the Drive-Wheel Support Frame

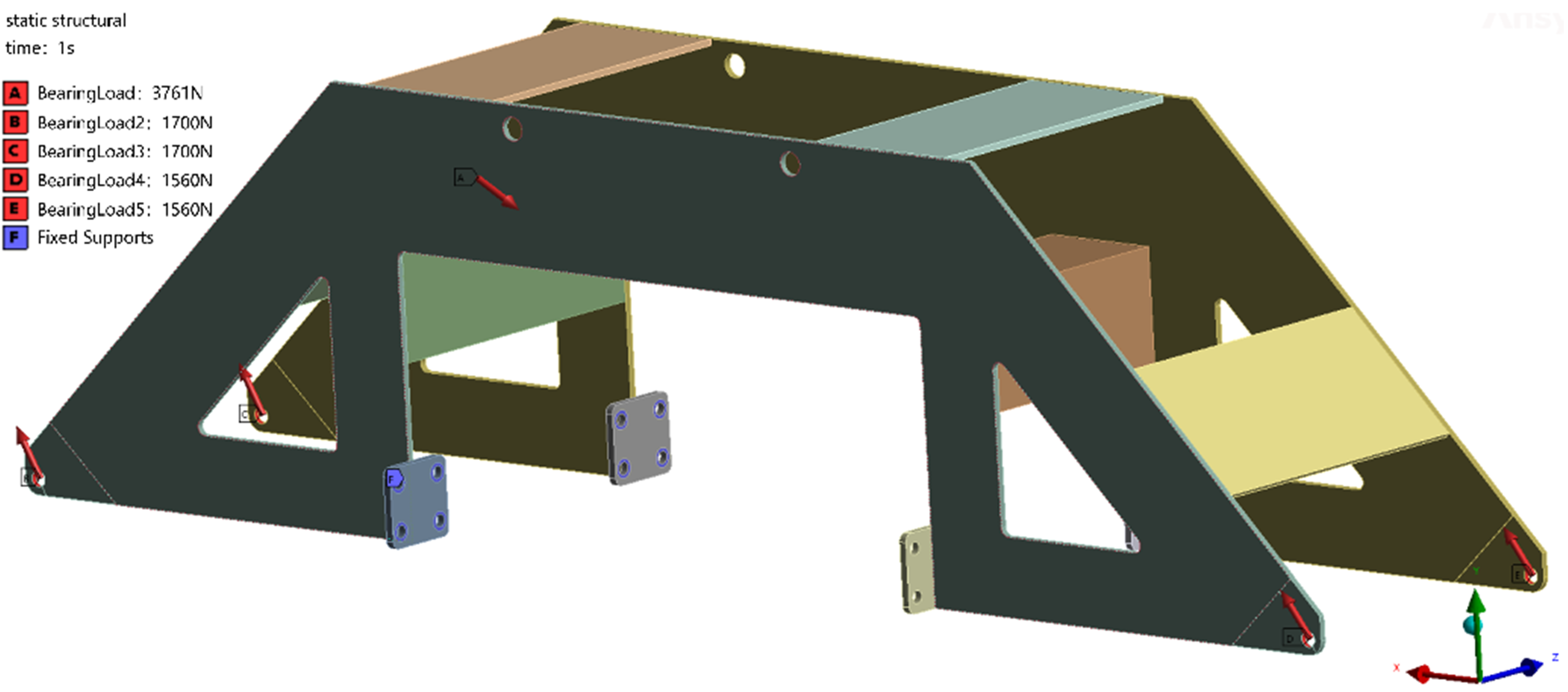

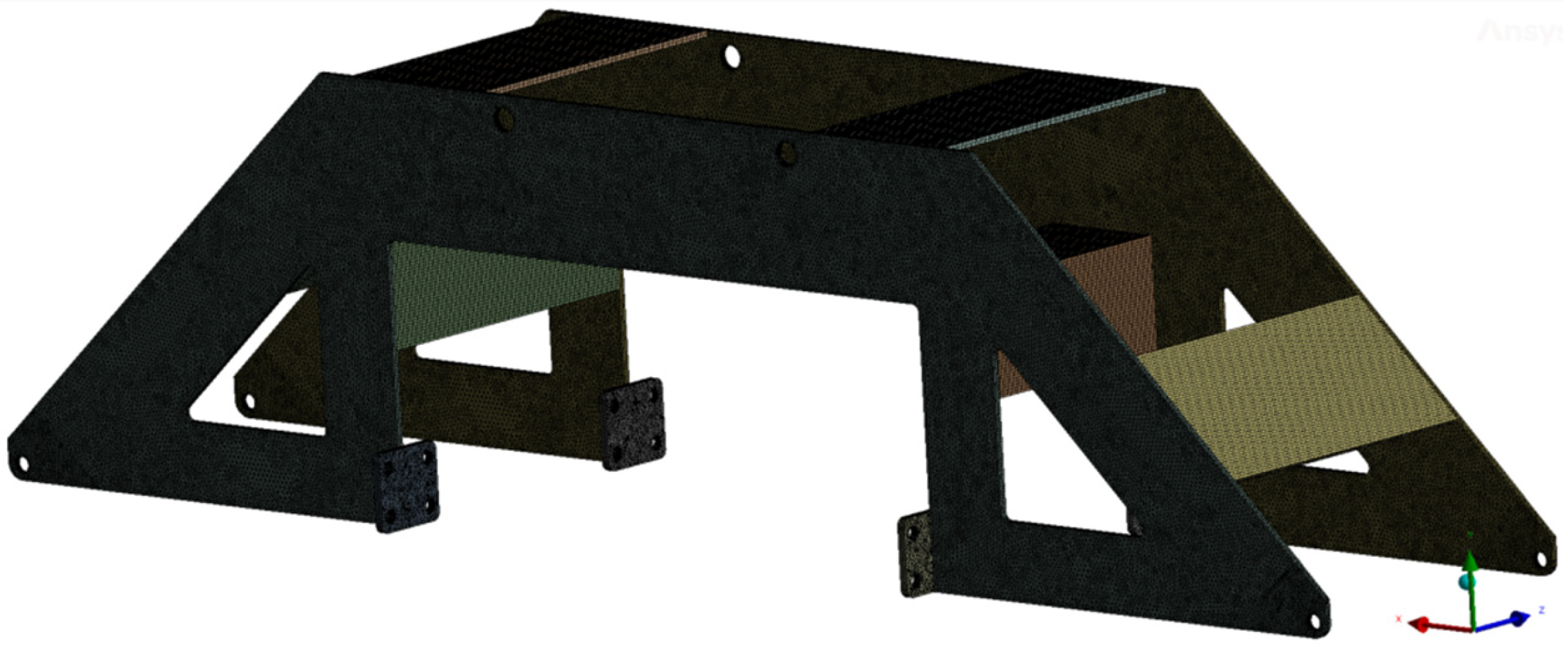

3.2. Simulation Analysis of the Obstacle-Crossing Frame

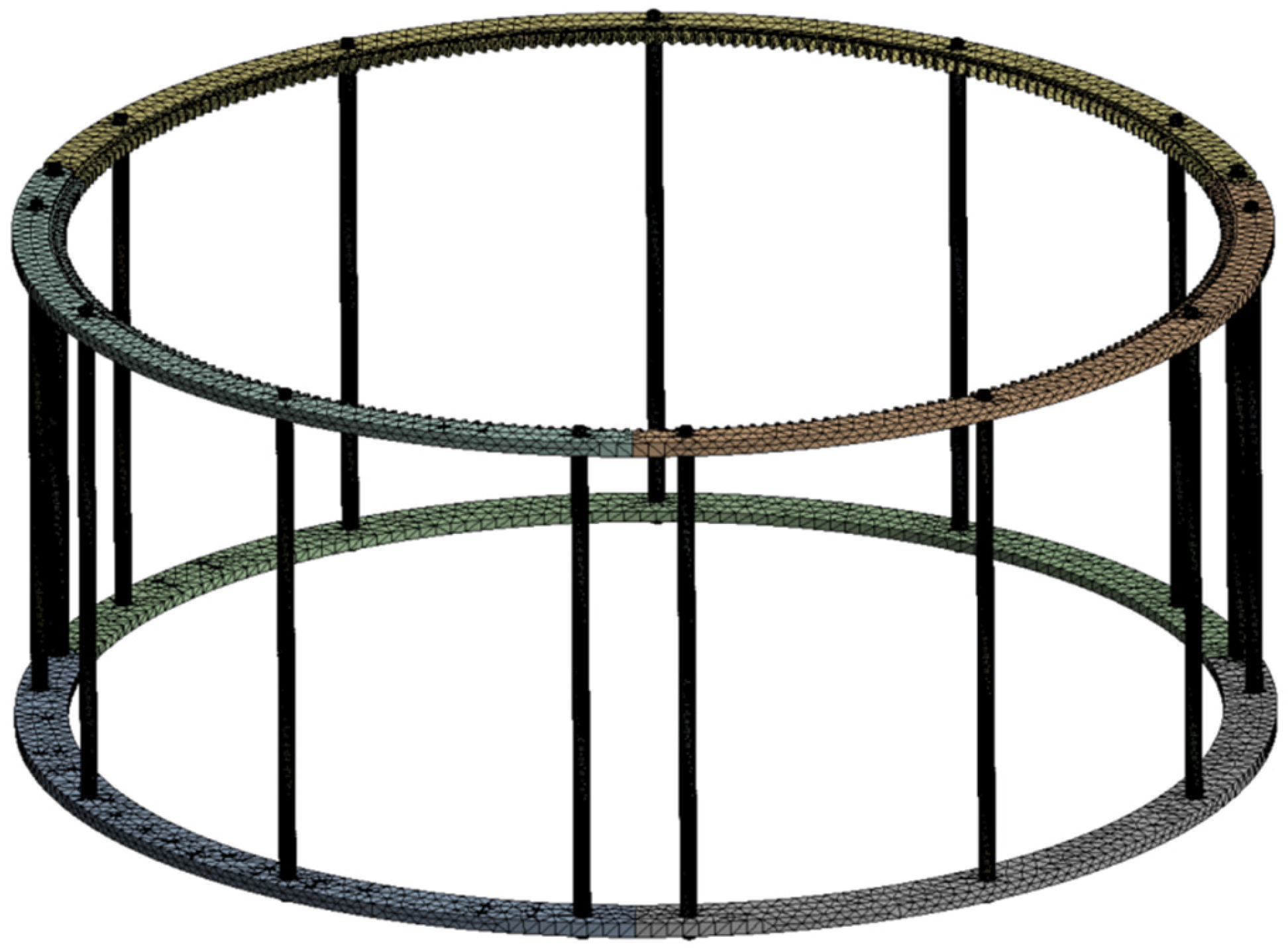

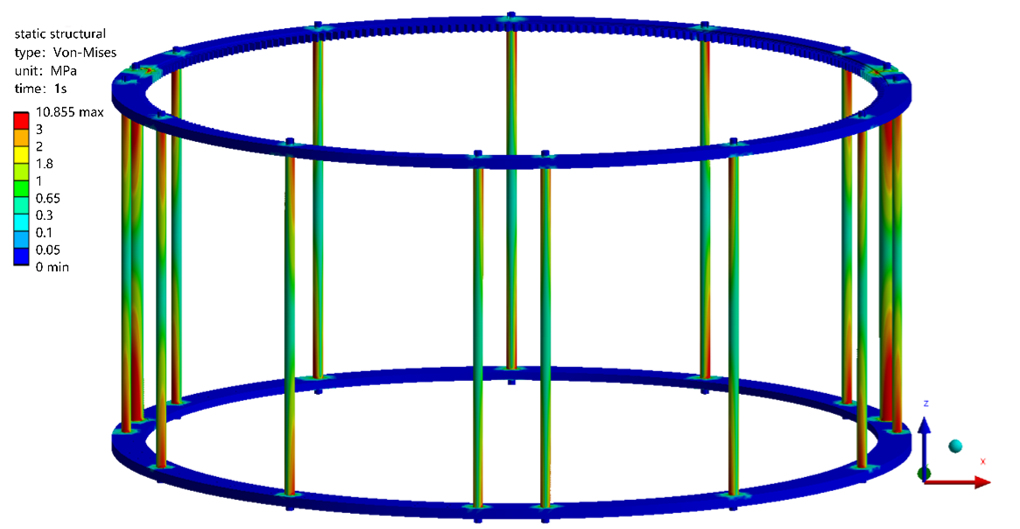

3.3. Simulation Analysis of the Rotary Frame

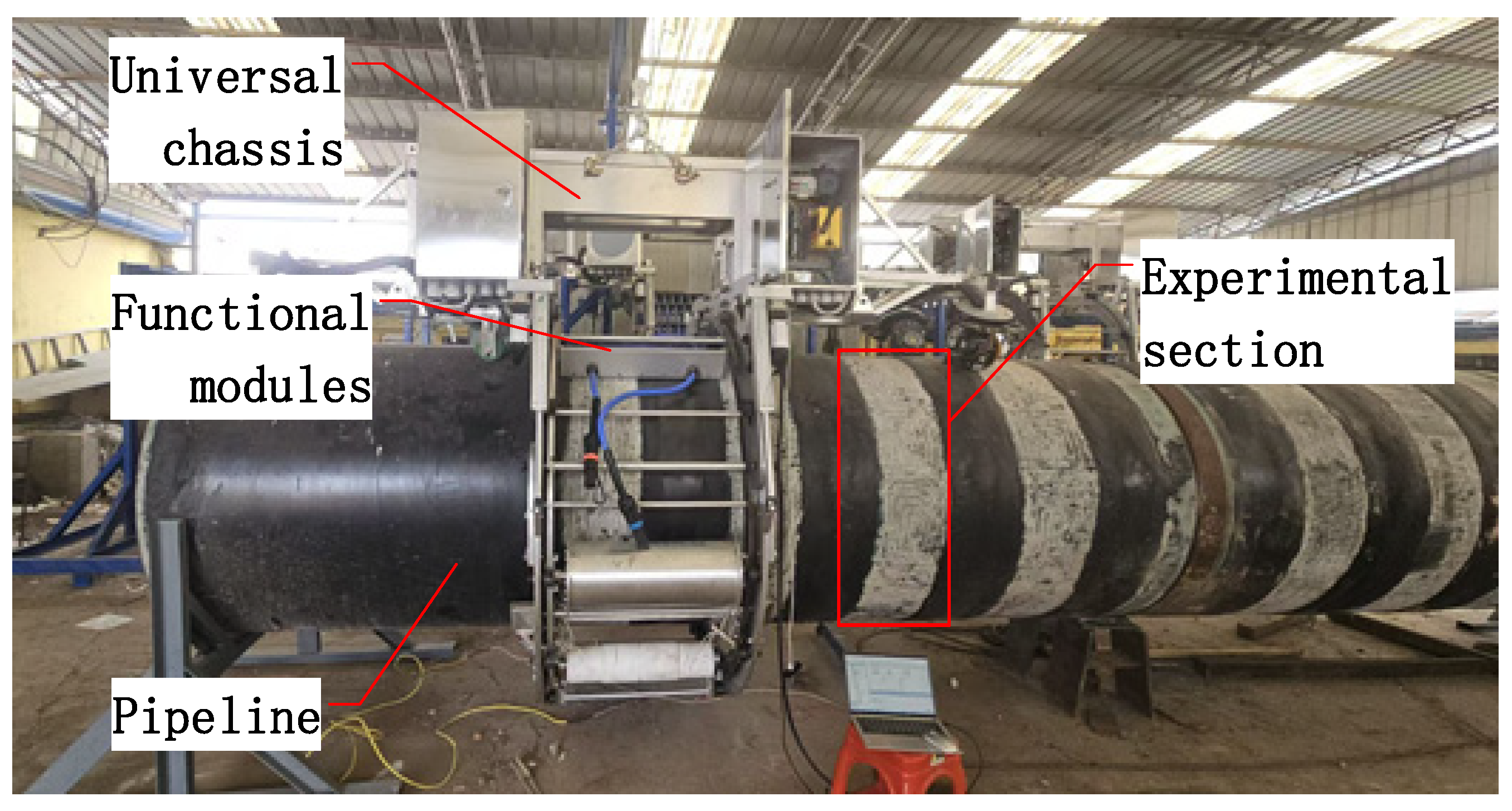

4. Experimental Validation of the Joint-Coating Equipment

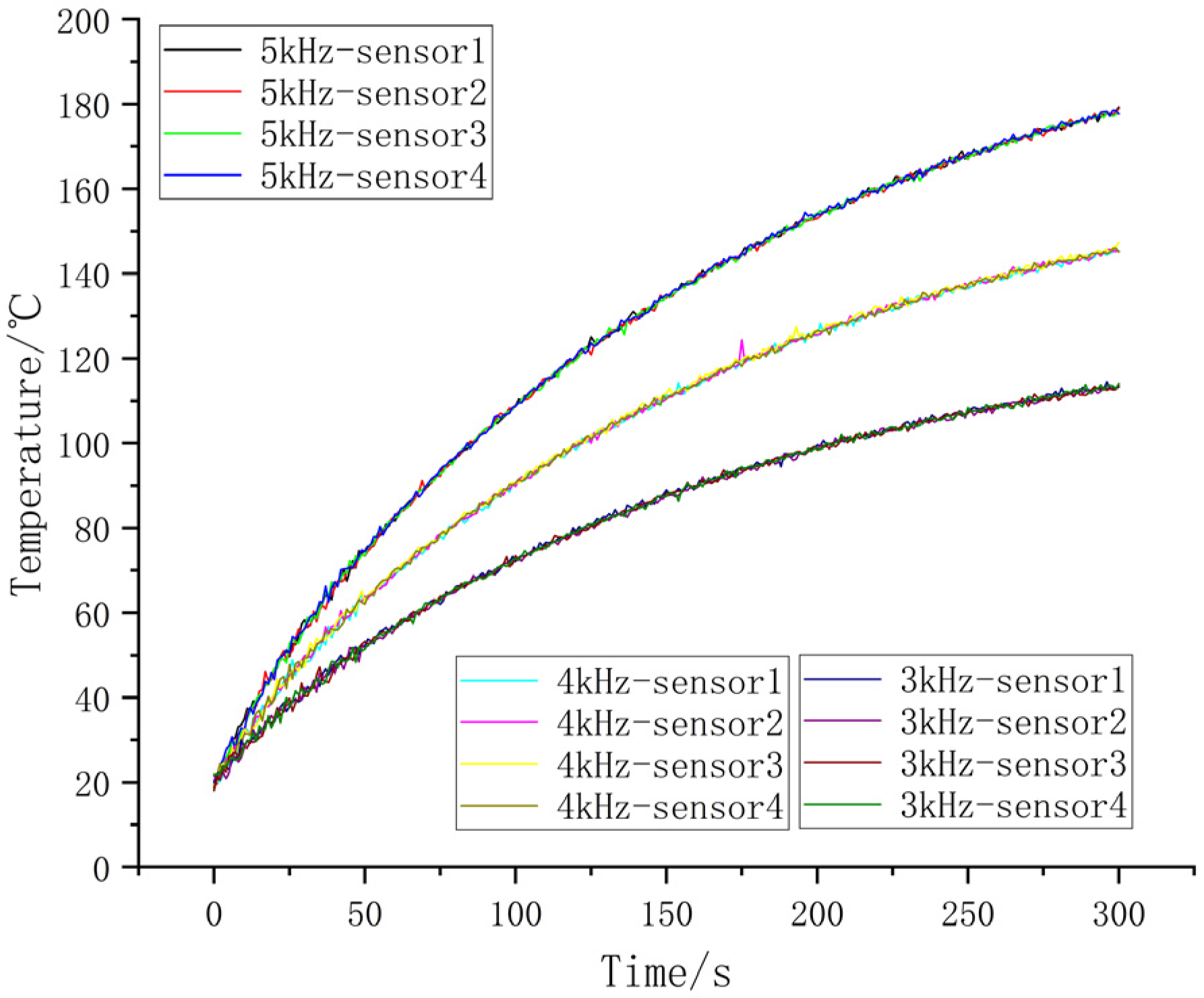

4.1. Experiment of Mid-Frequency Heating Modules

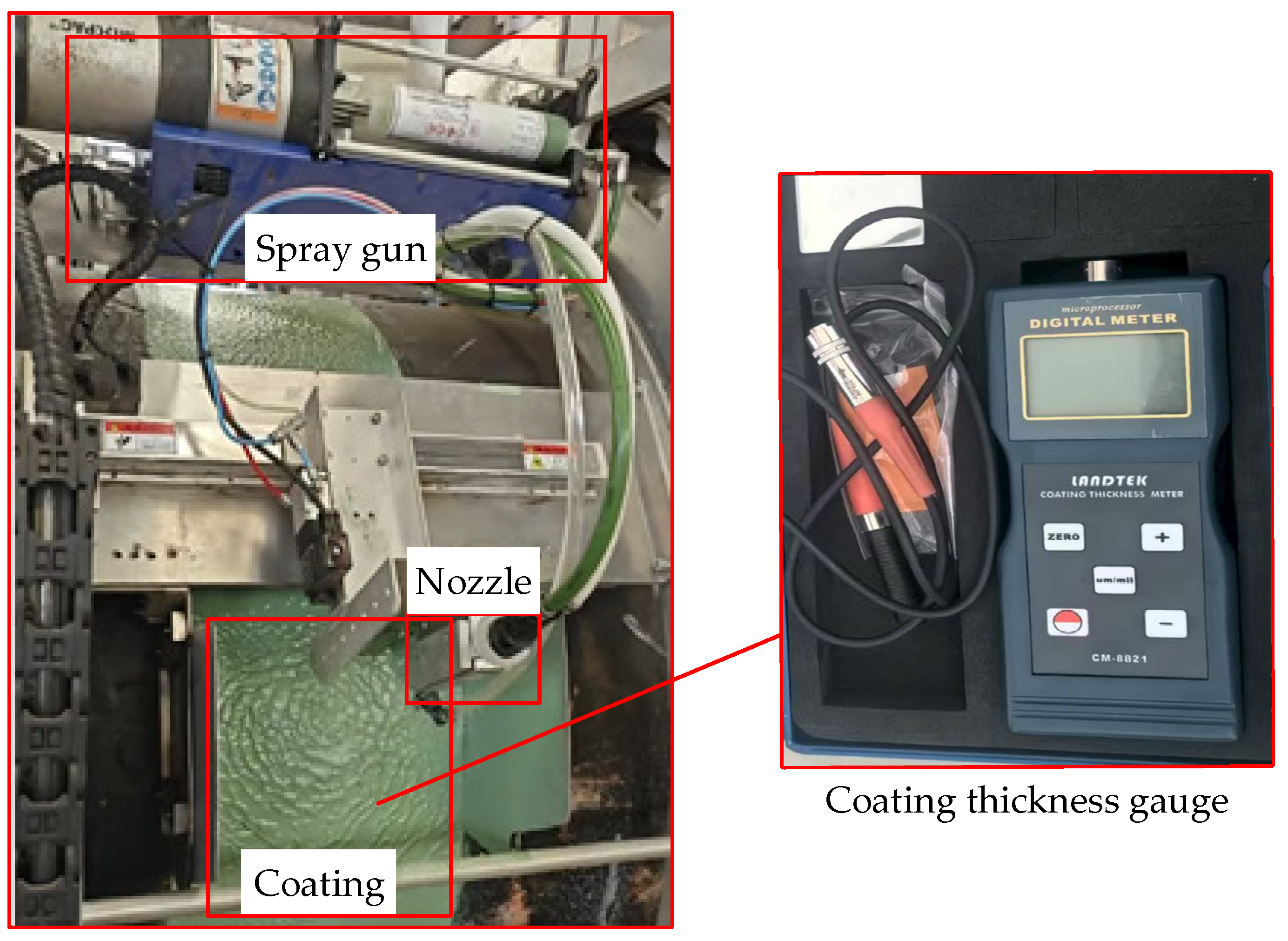

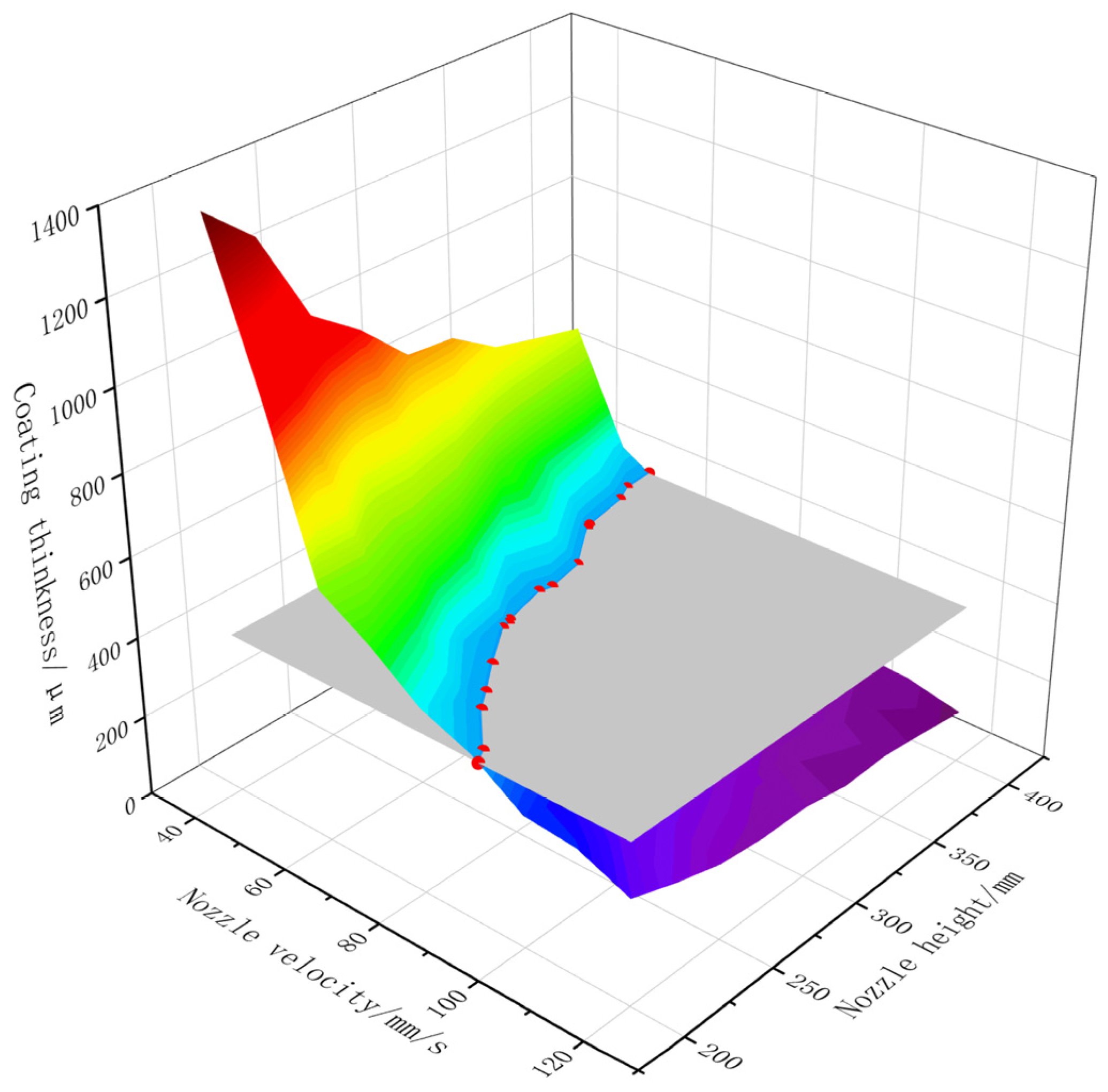

4.2. Experiment of Primer Spraying Modules

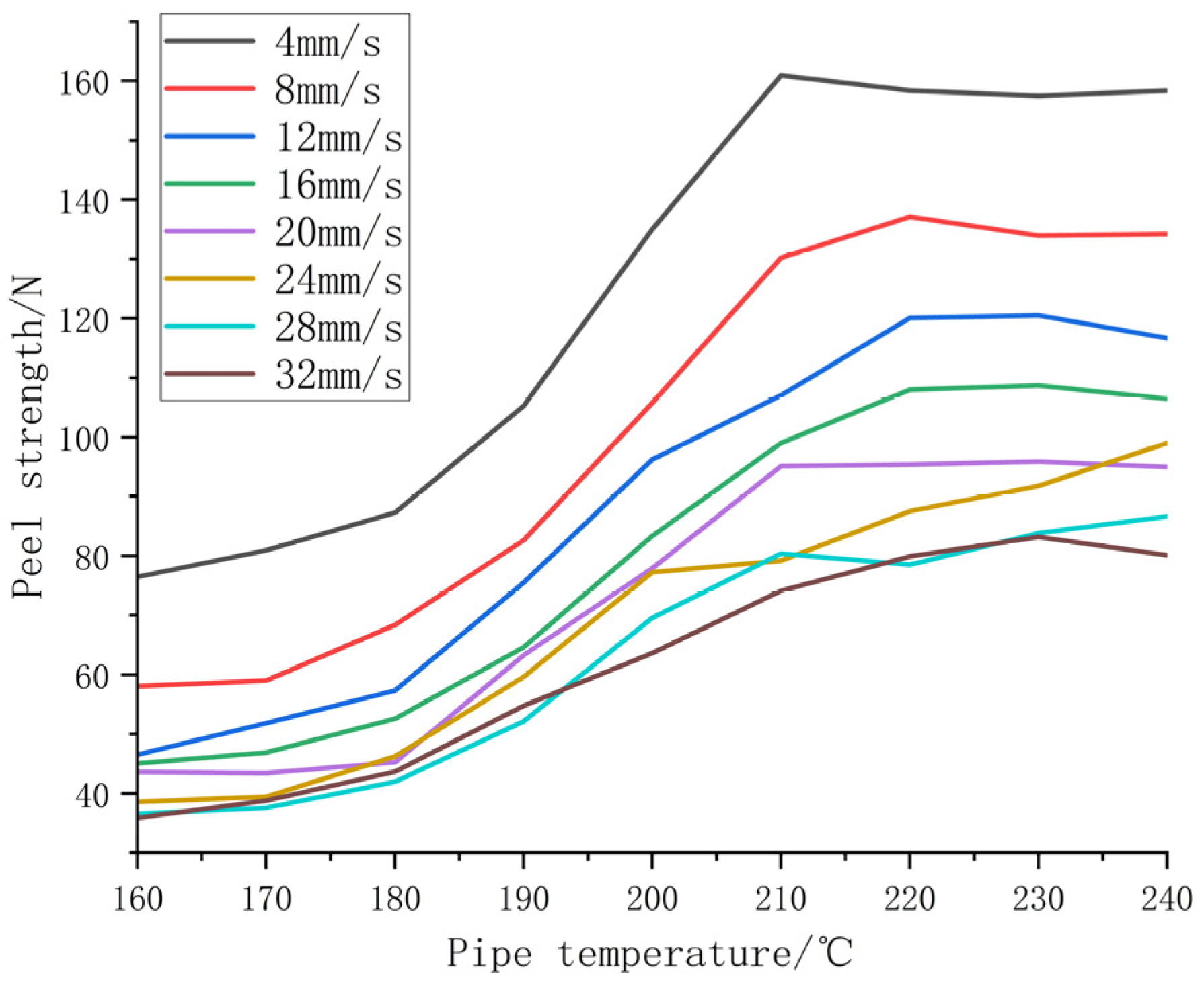

4.3. Experiment of the Heat-Shrink-Tape Wrapping Module

5. Conclusions

- (1)

- A modular design integrating a universal chassis with interchangeable functional modules was proposed. The universal chassis incorporates axial obstacle-crossing, automated opening–closing, and circumferential rotation mechanisms, while the functional modules perform abrasive blasting, medium-frequency heating, primer spraying, and heat-shrink-tape wrapping. This design enables semi-automatic to near-automatic operation of the joint-coating process, significantly reducing manual intervention.

- (2)

- The structural integrity of critical components—including the rotating frame, sliding support, and cam rocker—was verified through finite element analysis. The results confirm that the system satisfies strength and safety requirements under operational conditions while maintaining a lightweight and robust configuration.

- (3)

- The experiments demonstrated that the system achieves uniform heating, controlled coating thickness, and adequate adhesion strength. For pipelines up to 1219 mm in diameter, the system meets industrial performance requirements and can be adapted for other sizes, such as 813 mm, ensuring broad applicability.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhao, Y. CPP to Enhance China’s Pipeline Construction Powered by Technological Innovation and Supporting Important Projects. Pet. Sci. Technol. Forum 2011, 30, 17–19+68. [Google Scholar]

- Xie, Y.; Chu, X.; Ouyang, P.; Jiang, L.; Xing, J.; Yao, H.; Zayed, T. A mini review on coated pipes: Materials, manufacturing and anti-corrosion protection. Corros. Eng. Sci. Technol. 2025, 60, 217–230. [Google Scholar] [CrossRef]

- Shah, B.A.; Muthalif, A.G.A. A comprehensive review on corrosion management in oil and gas pipeline: Methods and technologies for corrosion prevention, inspection and monitoring. Anti-Corros. Methods Mater. 2025, 72, 681–701. [Google Scholar] [CrossRef]

- Yan, L.; Deng, W.; Wang, N.; Xue, X.; Hua, J.; Chen, Z. Anti-corrosion reinforcements using coating technologies—A review. Polymers 2022, 14, 4782. [Google Scholar] [CrossRef]

- Cheng, S.; Yuan, W. Corrosion mechanism and anticorrosion technology of oil and gas gathering and transportation pipeline. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2021; Volume 859, p. 012115. [Google Scholar]

- Yang, Z.; Yu, J.; Wang, J.; Zhang, S. Lightweight Design of Cable Detection Climbing Device and Dynamic Performance Analysis. Mach. Des. Manuf. 2021, 10, 57–61. [Google Scholar]

- Yu, J.; Zhang, S.; Xiao, Q.; Luo, H.; Zhang, H. Design and Stability Analysis of Cable Inspection Robot’s Climbing Device. Mach. Des. Res. 2017, 33, 45–49. [Google Scholar]

- Zhang, S. The Design of Bridge Cable Inspection Robot's Climbing Device. Master’s Thesis, Hunan University, Changsha, China, 2014. [Google Scholar]

- Zhang, D. Structural Design of the High Voltage Transmission Line Tower Climbing Robots. J. Mech. Transm. 2015, 39, 93–96. [Google Scholar]

- Zhang, Z. The Research on The Mechanism of PGR-II Pipe Climbing Robot. Master’s Thesis, Northeast Petroleum University, Daqing, China, 2015. [Google Scholar]

- Zhang, Z.; He, F. Modeling and Simulation of PGR-II Pipe Climbing Robot. China Pet. Mach. 2016, 44, 106–110. [Google Scholar]

- Zhang, X. Research on Wall—Climbing Robot of Wheel—shaped Suspended Magnetic Adsorption. Master’s Thesis, Harbin Institute of Technology, Harbin, China, 2012. [Google Scholar]

- Zhou, H.; Liu, Q.; Liu, Y.; Jiang, Y.; Zhao, H.; Zhang, G.; Zhou, G. Application of Mobile Medium Frequency Heating Equipment in Field Joint Coating of Pipeline by Using Heat-shrinkable Tapes. Pet. Eng. Constr. 2015, 41, 75–78. [Google Scholar]

- Lu, Y.; An, Z.; Liu, Q.; Guo, M. Large-diameter Pipe Medium-Frequency Heating Equipment. Pipeline Tech. Equip. 2015, 6, 13–15. [Google Scholar] [CrossRef]

- Wang, C.; Zeng, H.; Zhao, Y.; Liu, R. Automatic Sand-Blasting Equipment Applied to 3rd West-East Natural Gas Pipeline Project. Fluid Mach. 2014, 42, 53–56. [Google Scholar]

- Jia, C. Design and Realization of Automatic Rust Removal Equipment for In-Service Pipeline Maintenance. Welded Pipe Tube 2020, 43, 53–56. [Google Scholar]

- Wang, C.; Zhang, F.; Zhang, H.; Liu, R.; Xu, M. Research on Integration of Joint Coating Equipment for Oil and Gas Pipelines. China Pet. Mach. 2022, 50, 142–149. [Google Scholar]

- GB/T 51241-2017; Ministry of Housing and Urban-Rural Development of the People’s Republic of China. Technical Code fer Field Joint Coatings of Pipeline. China Planning Press: Beijing, China, 2017.

- GB/T 8923.1-2011; Preparation of steel substrates before application of paints and related products—Visual assessment of surface cleanliness—Part 1: Rust grades and preparation grades of uncoated steel substrates and of steel substrates after overall removal of previous coatings. China Planning Press: Beijing, China, 2011.

- ISO 8501-1:2007; Preparation of steel substrates before application of paints and related products—Visual assessment of surface cleanliness—Part 1: Rust grades and preparation grades of uncoated steel substrates and of steel substrates after overall removal of previous coatings. International Organization for Standardization: Vernier, Switzerland, 2007.

- ASTM D4417-2003; Standard Test Methods for Field Measurement of Surface Profile of Blast Cleaned Steel. ASTM International: West Conshohocken, PA, USA, 2003.

- Wang, Z. 7075 The Approach to Holding Area Prediction of 7075 Aluminum Alloy Thick Plate for Pre-Stretching Processes. Master’s Thesis, Nanchang HangKong University, Nanchang, China, 2017. [Google Scholar]

| Case No. | Node Count | Element Count | Peak Stress (MPa) |

|---|---|---|---|

| Case 1 | 1,264,348 | 936,453 | 0.62 |

| Case 2 | 2,994,145 | 2,328,482 | 0.46 |

| Case 3 | 4,784,597 | 3,650,450 | 0.45 |

| Case 4 | 8,454,980 | 6,236,670 | 0.45 |

| Case 5 | 15,153,125 | 11,513,981 | 0.44 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, C.; Yang, J.; Wang, H.; Ji, G.; Zhang, S. Design and Experimental Study of Full-Process Automatic Anti-Corrosion Joint-Coating Equipment. Eng 2025, 6, 331. https://doi.org/10.3390/eng6110331

Wang C, Yang J, Wang H, Ji G, Zhang S. Design and Experimental Study of Full-Process Automatic Anti-Corrosion Joint-Coating Equipment. Eng. 2025; 6(11):331. https://doi.org/10.3390/eng6110331

Chicago/Turabian StyleWang, Changjiang, Jianxin Yang, Hehe Wang, Guangpeng Ji, and Shimin Zhang. 2025. "Design and Experimental Study of Full-Process Automatic Anti-Corrosion Joint-Coating Equipment" Eng 6, no. 11: 331. https://doi.org/10.3390/eng6110331

APA StyleWang, C., Yang, J., Wang, H., Ji, G., & Zhang, S. (2025). Design and Experimental Study of Full-Process Automatic Anti-Corrosion Joint-Coating Equipment. Eng, 6(11), 331. https://doi.org/10.3390/eng6110331