Performance and Uncertainty Analysis of Digital vs. Analog Pressure Scanners Under Static and Dynamic Conditions

Abstract

1. Introduction

- The ZOC17/8Px-APC Module (Scanivalve, Liberty Lake, WA, USA), analog system: This pressure scanner has 8 channels, with amplification on each channel and is representative of existing configurations on test stands.

- The MPS4264 Ethernet Miniature Pressure Scanner (Scanivalve, Liberty Lake, WA, USA), digital system: This modern pressure scanner has 64 channels with an internal 16-bit resolution, integrated analog-to-digital conversion and serial data transmission.

- A direct comparative evaluation of two distinct pressure scanner technologies (analog vs. digital) in a relevant industrial context.

- A combined analysis of signal stability, spectral content (FFT), and metrological uncertainty in both static and dynamic measurement regimes.

- The quantification of the performance difference between the two systems, supported by a detailed uncertainty budget.

- A set of clear recommendations regarding the optimal choice of pressure scanners for high-precision dynamic applications.

2. Materials and Methods

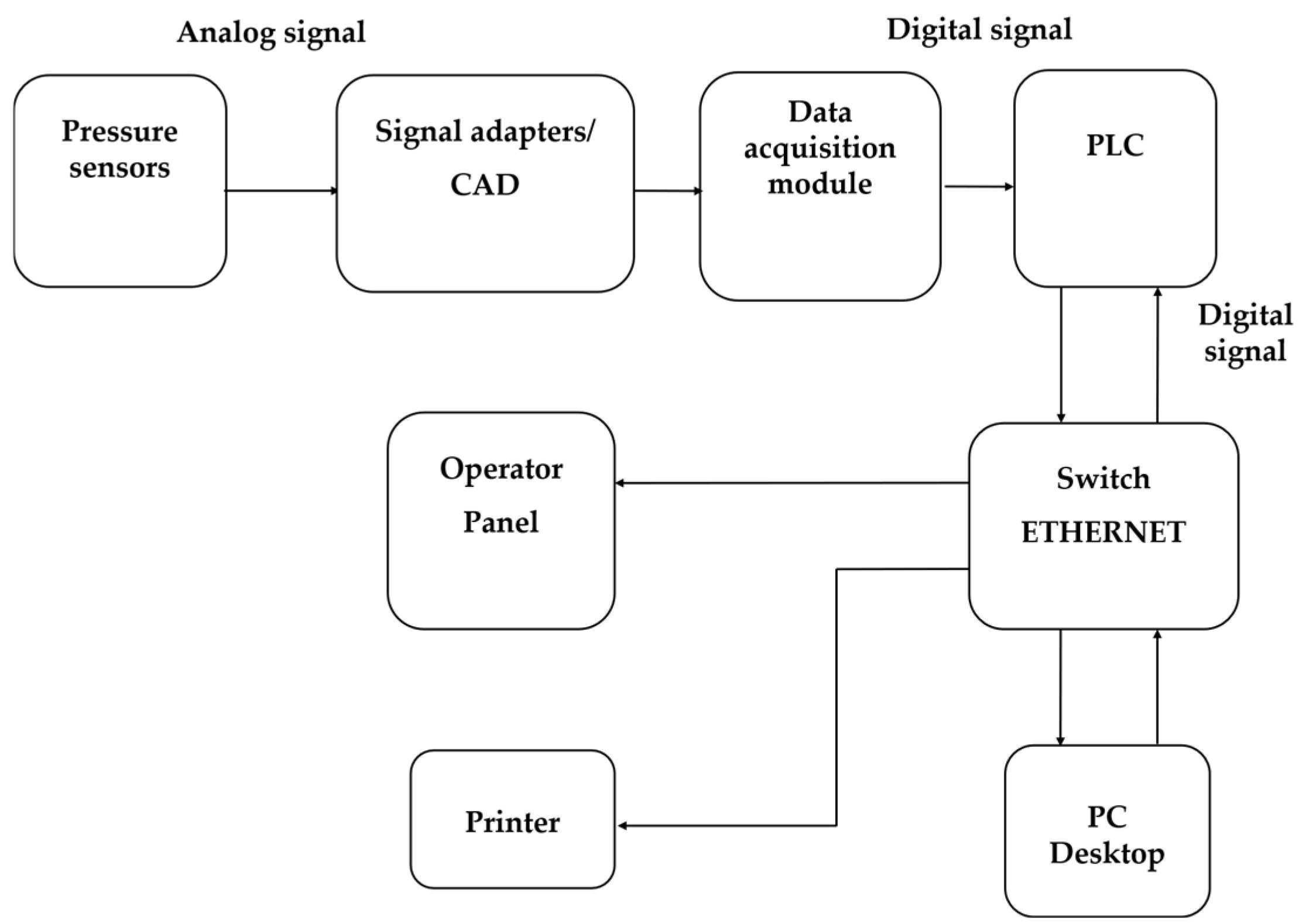

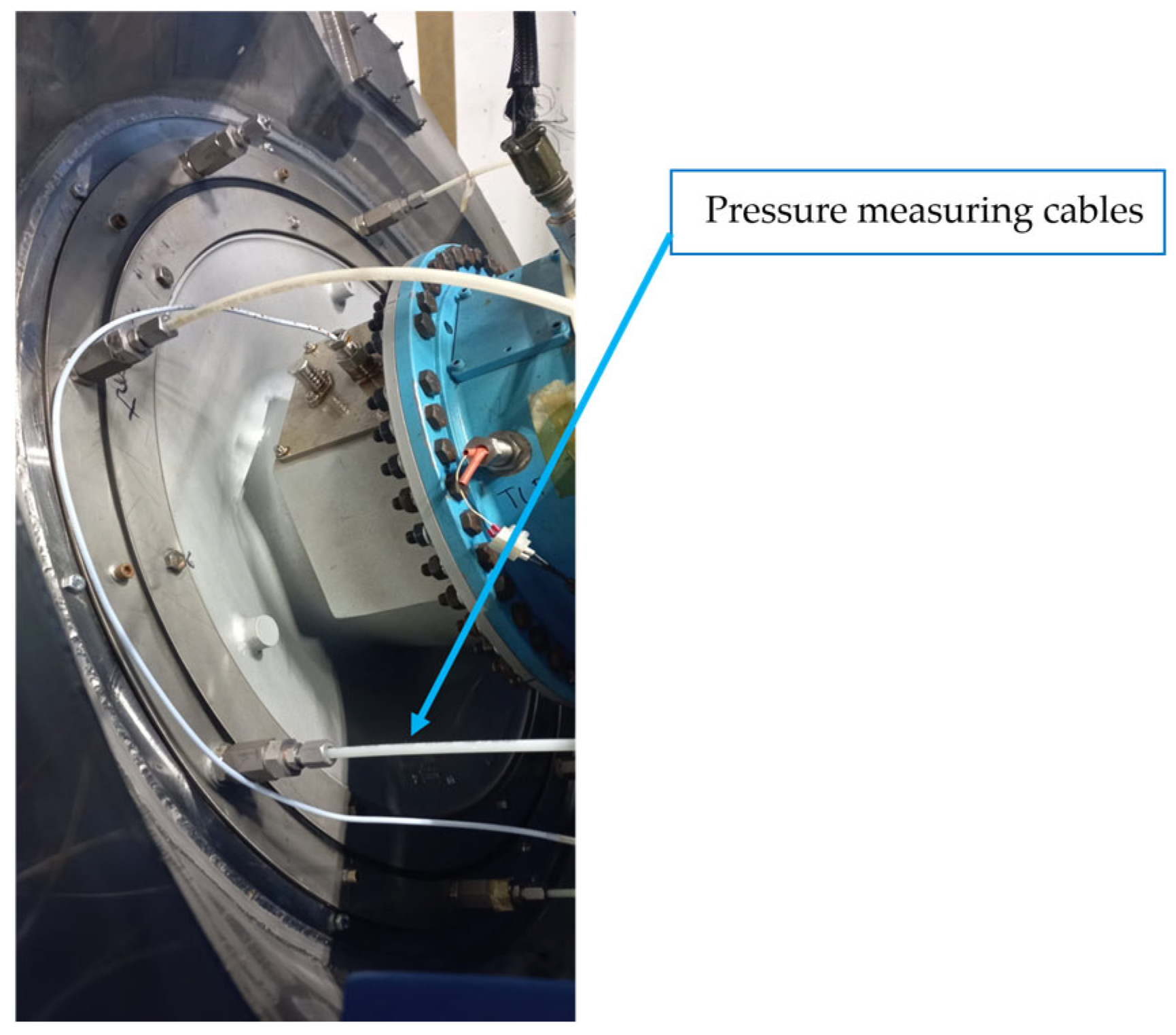

2.1. Test Stand and the Acquisition System Presentation

2.2. Testing Procedure in Dynamic Regime

- Engine preparation: The engine was mounted on a test bench, and the pressure scanners were connected to the measurement points.

- Stable dynamic conditions: The engine was started and stabilized at a constant, steady-state revolutions per minute (RPM) to ensure controlled operating conditions.

- Data acquisition: The dynamic data acquisition process was initiated, with each system (analog and digital) recording pressure signals separately, at the same measurement point.

- Data analysis: The collected time-series data were analyzed in the frequency domain using FFTs to identify noise characteristics.

- Uncertainty budget: The dynamic noise was quantified and incorporated as a component in the overall measurement uncertainty budget.

- Performance comparison: The metrological performance of the two systems was compared based on their noise levels, stability, and total uncertainty under dynamic conditions

2.3. Testing Procedure in Static Regime

- System Preparation: The pressure scanners were installed on the test bench and connected to the Fluke pressure standard, which was used as the calibration reference.

- Environmental Stabilization: The temperature and pressure were allowed to stabilize to ensure consistent measurement conditions.

- Calibration Cycles: Three complete calibration cycles were performed, with pressure being gradually increased (ascending cycle) and then decreased (descending cycle) back to zero.

- Data Acquisition: Pressure readings from the two systems were recorded at specific, predetermined calibration points.

- Data Analysis: The collected data were analyzed to determine the metrological characteristics of each scanner, including repeatability and hysteresis.

- Uncertainty Calculation: The measurement uncertainty was evaluated based on the GUM guidelines, integrating both Type A uncertainties (from repeatability) and various Type B uncertainties (from manufacturer specifications and other known sources).

- Performance Assessment: A comprehensive performance evaluation was conducted based on the calculated metrological characteristics and the total measurement uncertainty.

2.4. Data Analysis Methods for Dynamic Regime

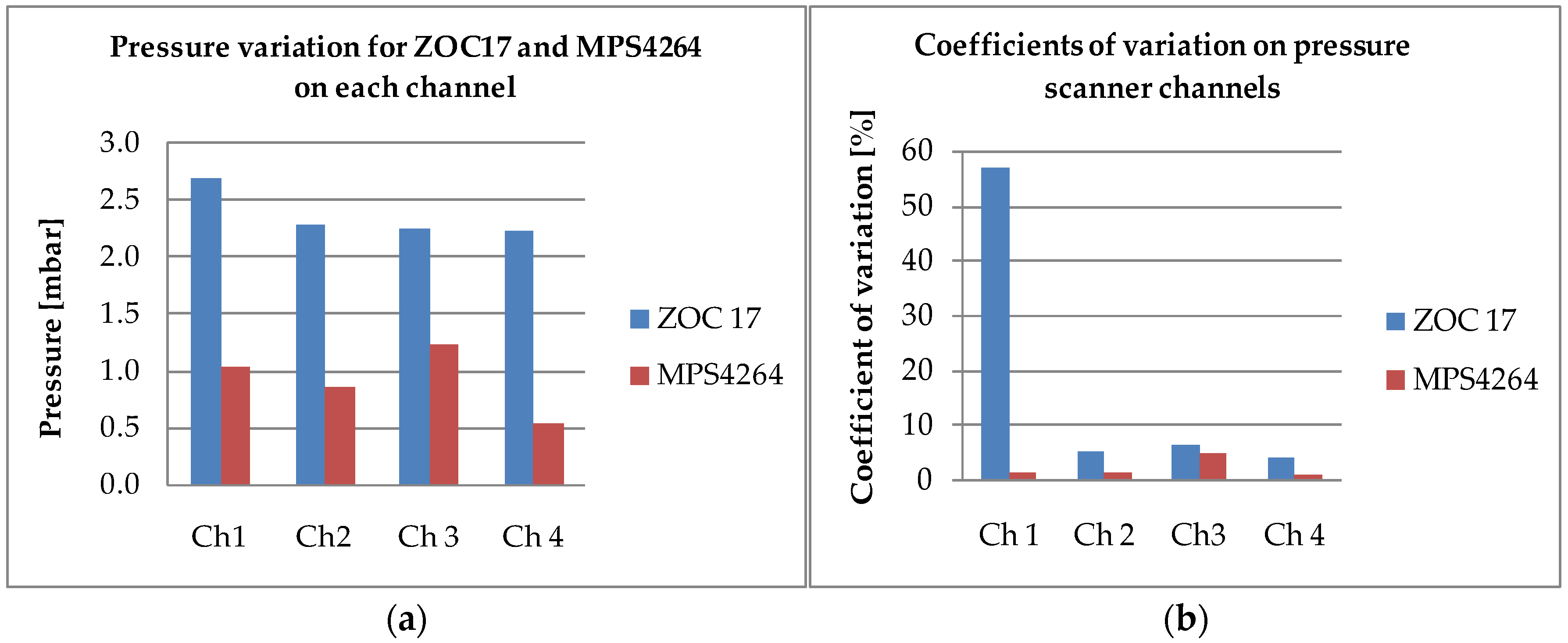

2.4.1. Coefficient of Variation (CV)

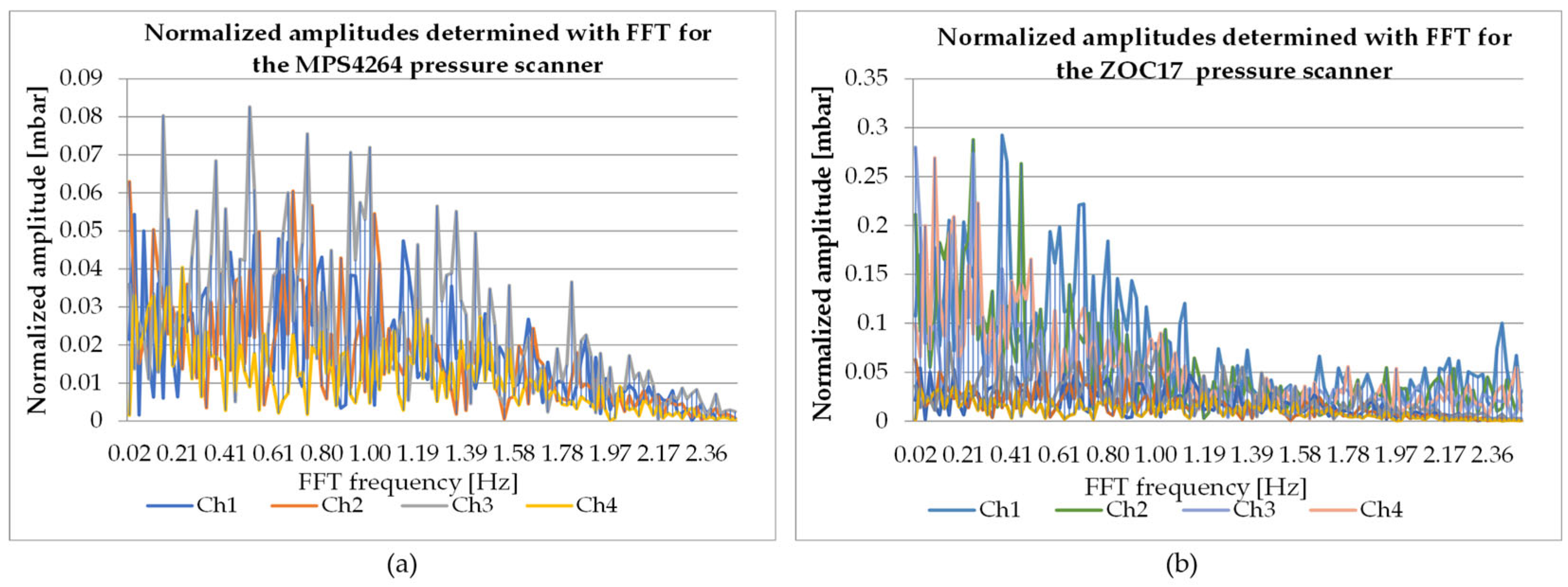

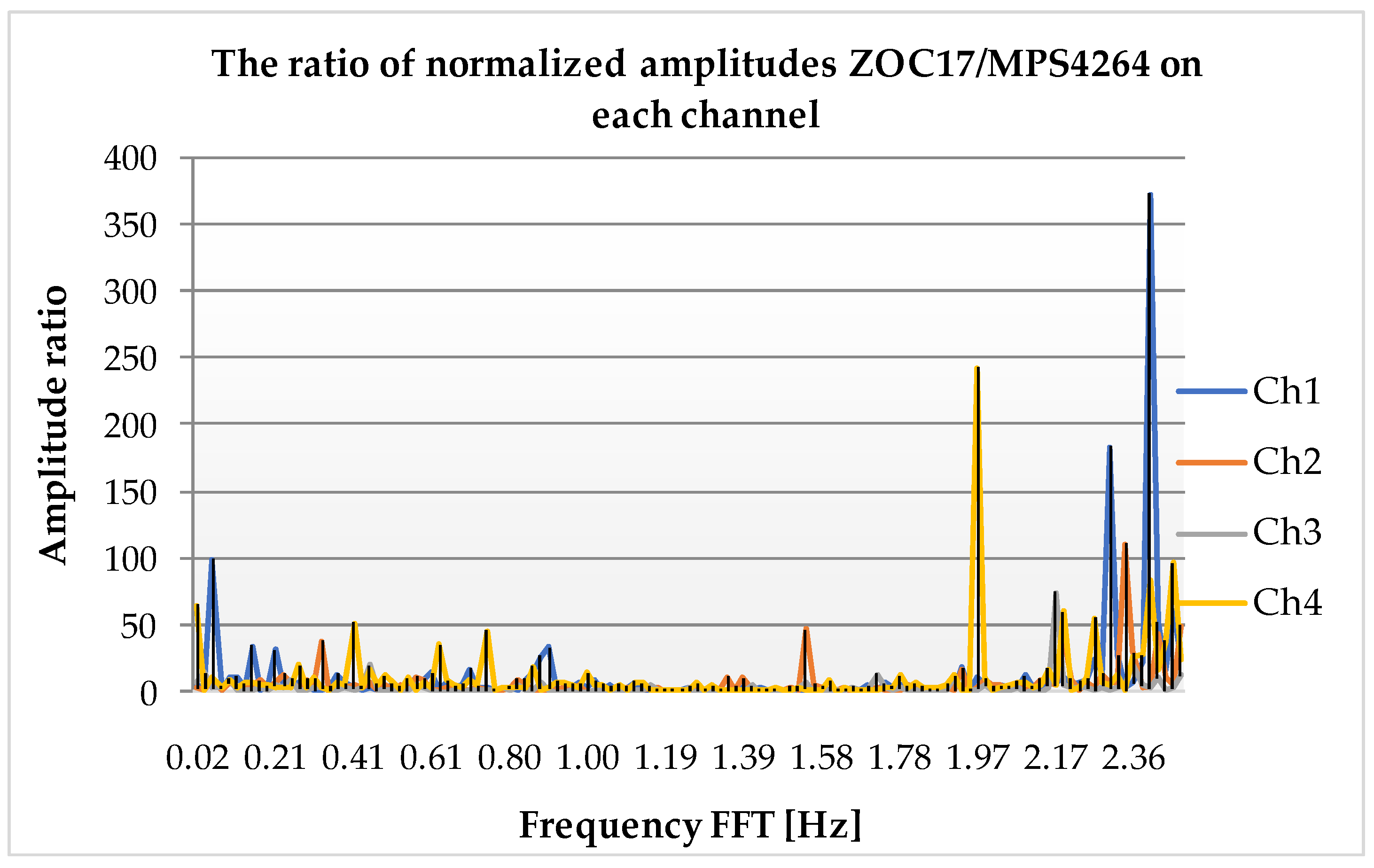

2.4.2. Frequency Analysis by Fast Fourier Transform (FFT)

2.4.3. Normalization of Spectral Amplitudes

2.4.4. Relative Frequency Comparison (Relative Transfer Function)

2.4.5. Two-Sample t-Test

2.5. Data Analysis Methods for Static Regime

2.5.1. Metrological Characteristics

2.5.2. Measurement Uncertainty Calculation

3. Results

3.1. Results in Dynamic Regime

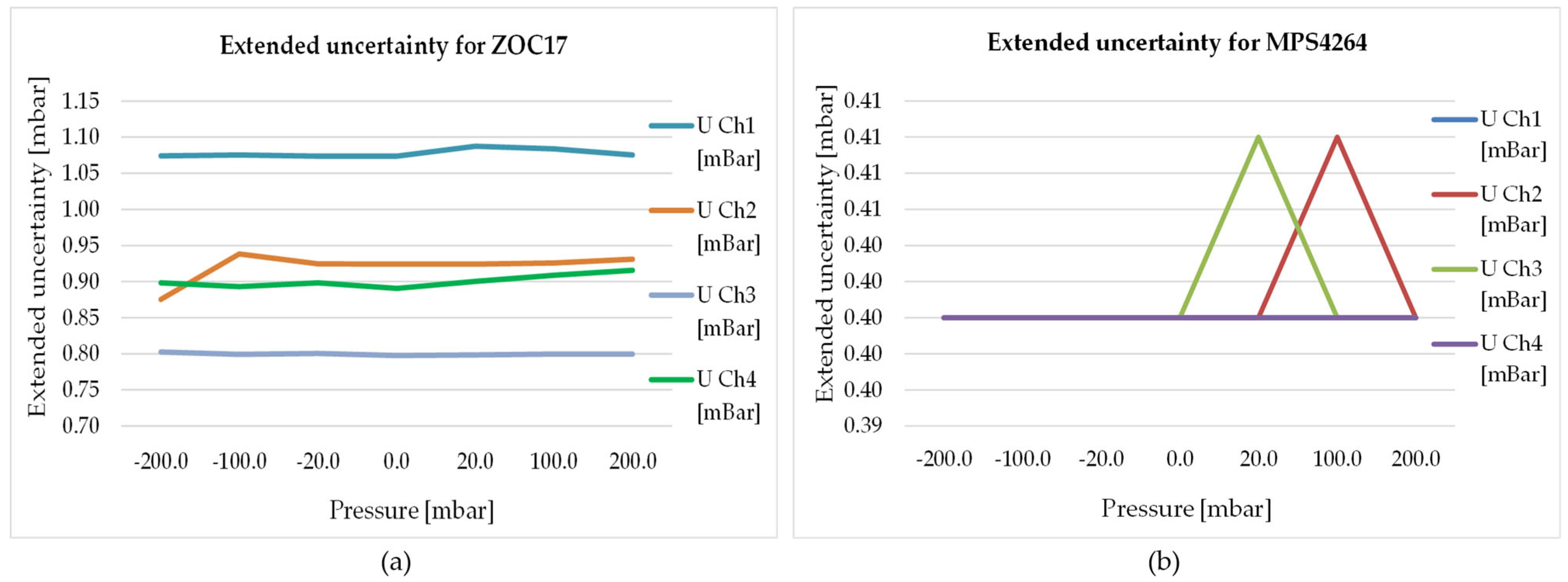

3.2. Results in Static Regime

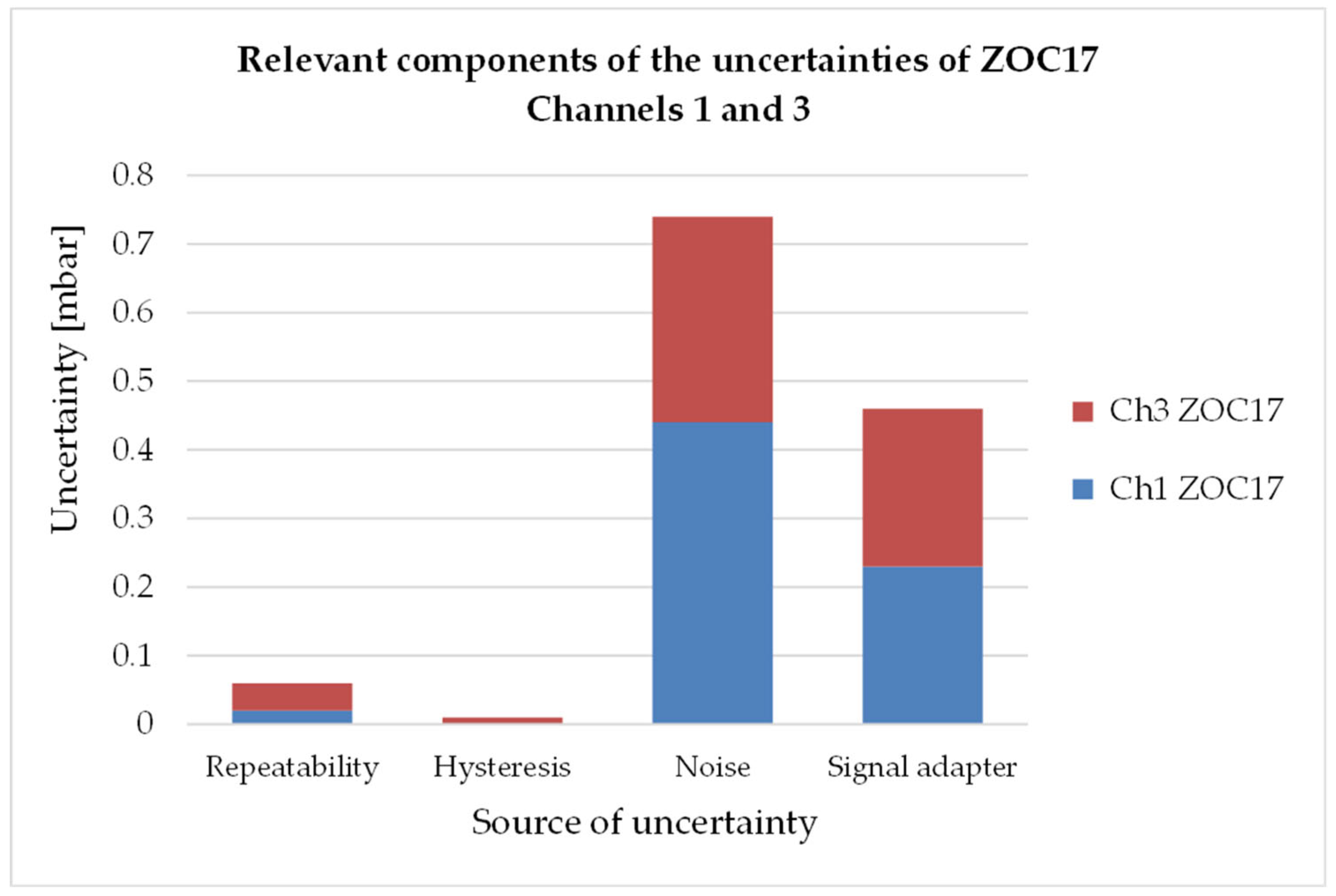

3.2.1. Evaluation of Uncertainty Components

- Hysteresis was evaluated for each measurement point. For ZOC17, (Channel 3), at the pressure point of (−20 mbar), the difference Hi was 0.03 mbar. Thus, the standard Type B uncertainty associated with hysteresis at this point was calculated according to the Equation (15), = 0.01 mbar.

- Pressure standard: The uncertainty of the Fluke pressure standard, with an extended uncertainty of 0.0003 bar (k = 2), was calculated with Equation (16): = 0.15 mbar

- Drift: The contribution from drift was considered negligible, = = 0.0003 bar.

- Noise: The Type B uncertainty associated with noise showed significant differences, with the ZOC17 system having a standard noise deviation of up to 0.523 mbar, while the MPS4264’s deviation was significantly lower, ranging from 0.113 mbar to 0.257 mbar. This was calculated with Equation (18).

- Pressure scanner accuracy: Based on manufacturer specifications, the Type B uncertainty was evaluated at 0.12 mbar for the ZOC17 and 0.007 mbar for the MPS4264. Was calculated with Equation (19).

- Signal adapter: For the ZOC17 system, a Type B uncertainty of 0.23 mbar, calculated with Equation (21), was added due to the PR4114 signal adapter.

- Resolution of the operator panel: The resolution of the display system, LSB, is 0.1 mbar. The standard Type B uncertainty associated with resolution was calculated with the Equation (22), = 0.03 mbar.

- Temperature: For the ZOC17, the Type B uncertainty associated with temperature variations was quantified based on the residual temperature sensitivity and the maximum variation observed by 0.4 °C. was calculated with the Equation (26), = 0.00739 mbar. Also, we calculated for the worst-case thermal effect by considering the full compensated temperature range of the scanner (0 °C to 50 °C). Assuming a maximum temperature variation () of 50 °C, the maximum combined error due to temperature was calculated with Equation (25) as 1.6 mbar. Result = 0.9 mbar. Even under significant thermal variations, the scanner’s performance remains within its specified limits.

3.2.2. Combined Uncertainty and Conclusions

4. Discussion

4.1. Dynamic Behavior and Spectral Analysis

4.2. Uncertainty Analysis and the Advantages of Digital Architecture

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Green, J.E. Uncertainty Analysis of the NASA Glenn 8 × 6 Supersonic Wind Tunnel; NASA Technical Report; National Aeronautics and Space Administration (NASA): Washington, DC, USA, 2016.

- Bhatnagar, L.; Paniagua, G.; Cuadrado, D.G.; Aye-Addo, P.A.N.; Sauca, A.C.; Lozano, F.; Bloxham, M. Uncertainty in High-Pressure Stator Performance Measurement in an Annular Cascade at Engine-Representative Reynolds and Mach. In Proceedings of the ASME Turbo Expo 2022: Turbomachinery Technical Conference and Exposition, Rotterdam, The Netherlands, 13–17 June 2022; ASME: New York, NY, USA, 2022; Volume 10, p. GTP-21-1362. [Google Scholar] [CrossRef]

- Xu, F.; Tan, Y.; Zhao, X.; Zhang, Z. Test Study of Performance of Electronic Scanivalve System. In Proceedings of the 2009 International Conference on Electronic Measurement & Instruments, Beijing, China, 16–19 August 2009; IEEE Xplore: Beijing, China, 2009; pp. 1–4. [Google Scholar] [CrossRef]

- Zhang, W.; Chen, Y.; Li, Y. Research on Multi-Channel Dynamic Pressure Measurement System Based on MEMS Sensors. In Proceedings of the 2017 IEEE International Conference on Mechatronics and Automation (ICMA), Takamatsu, Japan, 6–9 August 2017; IEEE: Piscataway, NJ, USA, 2017; pp. 106–110. [Google Scholar] [CrossRef]

- Pemberton, R. An Overview of Dynamic Pressure Measurement Considerations; Scanivalve Corp.: Liberty Lake, WA, USA, 2010. [Google Scholar]

- Scanivalve DTS3250; Uncertainty Analysis. Scanivalve Corp.: Liberty Lake, WA, USA, 2013.

- Amer, E.; Jönsson, G.; Arrhén, F. Secondary measurement standard for calibration of dynamic pressure sensor to bridge the gap between existing static and dynamic standards. Measurement 2025, 242, 116253. [Google Scholar] [CrossRef]

- Pereira, J.D. Pressure Sensors: Working Principles of Static and Dynamic Calibration. Sensors 2024, 24, 629. [Google Scholar] [CrossRef] [PubMed]

- McCarthy, J.; Jones, M. The Estimation of Uncertainty in Theoretical Corrections to Unsteady Pressure Measurements Through Tubes; DST-Group-TR-3579; Defence Science and Technology Group: Melbourne, Australia, 2019.

- Platte, T. Evaluation of the Uncertainty of Measurement for a Dynamic Calibration Approach for Pressure Sensors. Meas. Sens. 2021, 18, 100252. [Google Scholar] [CrossRef]

- Harris, P.; Østergaard, P.F.; Tabandeh, S.; Söderblom, H.; Kok, G.; van Dijk, M.; Luo, Y.; Pearce, J.; Tucker, D.; Vedurmudi, A.P.; et al. Measurement Uncertainty Evaluation for Sensor Network Metrology. Metrology 2025, 5, 3. [Google Scholar] [CrossRef]

- Esward, T.J.; Eichstädt, S.; Smith, I.; Bruns, T.; Davis, P.; Harris, P.M. Estimating Dynamic Mechanical Quantities and Their Associated Uncertainties. Metrologia 2018, 56, 015002. [Google Scholar] [CrossRef]

- Pallas, N.-P.; Kellaris, K.; Bouris, D. Dynamic Calibration of Complex Tubing Systems Using a Single Pressure Measurement Device. J. Wind Eng. Ind. Aerodyn. 2024, 249, 105715. [Google Scholar] [CrossRef]

- Kovaerk, M.; Amatucci, L.; Gillis, K.A.; Potra, F.; Ratino, J.; Levitan, M.L.; Yeo, D. Calibration of Dynamic Pressure in a Tubing System and Optimized Design of Tube Configuration: A Numerical and Experimental Study; National Institute of Standards and Technology (NIST): Gaithersburg, MD, USA, 2018.

- Li, F.; Shi, B.; Yang, J. Study on Shock Tube Calibration Technology under Low Pressure. Meas. Sens. 2025, 38, 101693. [Google Scholar] [CrossRef]

- Shi, B.; Yao, Z.; Li, F.; Chen, X.; Yao, L.; Ding, Y. Identifying the Frequency Characteristics of the Pressure Measurement System with a Pressure Transmission Tube Using Shock Tube Method. Measurement 2025, 242, 116293. [Google Scholar] [CrossRef]

- Svete, A.; Kutin, J. Identifying the High-Frequency Response of a Piezoelectric Pressure Transducer. Mech. Syst. Signal Process. 2022, 162, 108014. [Google Scholar] [CrossRef]

- Jentzsch, M.; Lechner, W.; Woszidlo, R.; Nayeri, C.N.; Paschereit, C.O. The Dynamic Response of a Pressure Transducer for Measurements in Water. Exp. Fluids 2024, 65, 125. [Google Scholar] [CrossRef]

- Platte, T. Dynamic Sine Calibration of Pressure Transducers. In Proceedings of the XXII IMEKO World Congress, Belfast, UK, 3–6 September 2018; International Measurement Confederation (IMEKO): Budapest, Hungary, 2018. [Google Scholar]

- Durgut, Y.; Ganioglu, O.; Aydemir, B.; Turk, A.; Yilmaz, R.; Hamarat, A.; Bagci, E. Improvement of Dynamic Pressure Standard for Calibration of Dynamic Pressure Transducers. In Proceedings of the 19th International Congress of Metrology, Paris, France, 24–26 September 2019. [Google Scholar] [CrossRef]

- Bandyopadhyay, M.; Kolay, S.C.; Chattopadhyay, S.; Mandal, N. Modification of De’ Sauty Bridge Network for Accurate Measurement of Process Variables by Variable Parameter Transducers. IEEE Trans. Instrum. Meas. 2021, 70, 9506510. [Google Scholar] [CrossRef]

- Lu, J.; Wang, H. Evaluation of the Uncertainty of Measurement for a Dynamic Calibration Approach. Meas. Sci. Technol. 2023, 34, 055008. [Google Scholar]

- Li, Q.; Liu, D.; Zhu, J. Uncertainty Evaluation for Wind Tunnel Test Based on New Flow Field and Balance Models. Aerosp. Sci. Technol. 2025, 167, 110593. [Google Scholar] [CrossRef]

- Kurihara, D.; Sakaue, H. Temperature Dependency Model in Pressure Measurement. Sensors 2023, 23, 9714. [Google Scholar] [CrossRef] [PubMed]

- Svete, A.; Hernández Castro, F.J.; Kutin, J. Effect of the Dynamic Response of a Side-Wall Pressure Measurement System on Determining the Pressure Step Signal in a Shock Tube Using a Time-of-Flight Method. Sensors 2022, 22, 2103. [Google Scholar] [CrossRef] [PubMed]

- Semmelmayer, F.; Reeder, M.; Seymour, R. Determination of a Probability Distribution for Pressure Scanner Noise and Digitization Uncertainty Reporting. Meas. Sci. Technol. 2019, 30, 115011. [Google Scholar] [CrossRef]

- Wang, H.; Zeng, Q.; Zhang, Z.; Wang, H. Temperature Compensation of Multi-Channel Pressure Scanner Based on an Improved Cuckoo Search Optimizing a BP Neural Network. Micromachines 2022, 13, 1351. [Google Scholar] [CrossRef] [PubMed]

- EURAMET. Calibration and Uncertainty for Dynamic Pressure Measurements; EURAMET: Braunschweig, Germany, 2018; Available online: https://www.euramet.org (accessed on 9 September 2025).

- Reinhardt, C.; Masalehdan, H.; Croatto, S.; Franke, A.; Kunze, M.B.K.; Schaffran, J.; Sültmann, N.; Lindner, A.; Schnabel, R. Self-Calibrating Gas Pressure Sensor with a 10-Decade Measurement Range. ACS Photonics 2024, 11, 1438–1446. [Google Scholar] [CrossRef]

| Channels | Mean (ZOC17) [mbar] | Mean (MPS4264) [mbar] | Standard Deviation (ZOC17) | Standard Deviation (MPS4264) | t Stat | p-Value |

|---|---|---|---|---|---|---|

| Ch1 Analog vs. Ch1 Digital | −1.35 | −12.27 | 0.770 | 0.178 | −248.89 | 0 |

| Ch2 Analog vs. Ch2 Digital | −11.10 | −11.85 | 0.607 | 0.175 | −21.29 | <0.05 |

| Ch3 Analog vs. Ch3 Digital | 7.80 | −5.26 | 0.523 | 0.257 | −403.61 | 0 |

| Ch4 Analog vs. Ch4 Digital | 13.56 | −9.03 | 0.570 | 0.113 | −699.66 | 0 |

| Source of Uncertainty | Estimate [mbar] | Divisor | Standard | Method of Evaluation | Probability Distribution | Uncertainty Contribution [mbar] | |

|---|---|---|---|---|---|---|---|

| Repeatability | 0.02 | 1 | 0.02 | A | normal | 1 | 0.02 |

| Hysteresis | 0.00 | 0.00 | B | rectangular | 1 | 0.00 | |

| Standard pressure gauge | 0.30 | 2 | 0.15 | B | normal | 1 | 0.15 |

| Drift of the standard pressure gauge | 0.00 | 0.00 | B | rectangular | 1 | 0.00 | |

| Noise | 0.77 | 0.44 | B | rectangular | 1 | 0.44 | |

| Pressure scanner accuracy | 0.20 | 0.12 | B | rectangular | 1 | 0.12 | |

| Signal adapter | 0.40 | 0.23 | B | rectangular | 1 | 0.23 | |

| Resolution | 0.10 | 0.03 | B | rectangular | 1 | 0.03 | |

| Ambient temperature variations | 0.013 | 0.01 | B | rectangular | 1 | 0.01 | |

| Combined Standard Uncertainty | 0.54 | ||||||

| Expanded Uncertainty (k = 2, 95% confidence) | 1.07 | ||||||

| Source of Uncertainty | Estimate [mbar] | Divisor | Standard Uncertainty ui | Method of Evaluation | Probability Distribution | Sensitivity Coefficient ci | Uncertainty Contribution ci·ui [mbar] |

|---|---|---|---|---|---|---|---|

| Repeatability | 0.04 | 1 | 0.04 | A | normal | 1 | 0.04 |

| Hysteresis | 0.03 | 0.01 | B | rectangular | 1 | 0.01 | |

| Standard pressure gauge | 0.30 | 2 | 0.15 | B | normal | 1 | 0.15 |

| Drift of the standard pressure gauge | 0.30 | 0.00 | B | rectangular | 1 | 0.00 | |

| Noise | 0.52 | 0.30 | B | rectangular | 1 | 0.30 | |

| Pressure scanner accuracy | 0.20 | 0.12 | B | rectangular | 1 | 0.12 | |

| Signal adapter | 0.40 | 0.23 | B | rectangular | 1 | 0.23 | |

| Resolution | 0.10 | 0.03 | B | rectangular | 1 | 0.03 | |

| Ambient temperature variations | 0.013 | 0.01 | B | rectangular | 1 | 0.01 | |

| Combined Standard Uncertainty | 0.40 | ||||||

| Expanded Uncertainty (k = 2, 95% confidence) | 0.80 | ||||||

| Pressure [mbar] | Channel 1 Extended Uncertainty U [mbar] | Channel 2 Extended Uncertainty U [mbar] | Channel 3 Extended Uncertainty U [mbar] | Channel 4 Extended Uncertainty U [mbar] |

|---|---|---|---|---|

| −200.0 | 1.07 | 0.88 | 0.80 | 0.90 |

| −100.0 | 1.08 | 0.94 | 0.80 | 0.89 |

| −20.0 | 1.07 | 0.92 | 0.80 | 0.90 |

| 0.0 | 1.07 | 0.92 | 0.80 | 0.89 |

| 20.0 | 1.09 | 0.92 | 0.80 | 0.90 |

| 100.0 | 1.08 | 0.93 | 0.80 | 0.91 |

| 200.0 | 1.08 | 0.93 | 0.80 | 0.92 |

| Pressure [mbar] | Channel 1 Extended Uncertainty U [mbar] | Channel 2 Extended Uncertainty U [mbar] | Channel 3 Extended Uncertainty U [mbar] | Channel 4 Extended Uncertainty U [mbar] |

|---|---|---|---|---|

| −200.0 | 0.40 | 0.40 | 0.40 | 0.40 |

| −100.0 | 0.40 | 0.40 | 0.40 | 0.40 |

| −20.0 | 0.40 | 0.40 | 0.40 | 0.40 |

| 0.0 | 0.40 | 0.40 | 0.40 | 0.40 |

| 20.0 | 0.40 | 0.40 | 0.41 | 0.40 |

| 100.0 | 0.40 | 0.41 | 0.40 | 0.40 |

| 200.0 | 0.40 | 0.40 | 0.40 | 0.40 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nicolae, R.; Oancea, C.-D.; Secareanu, R.; Lale, D. Performance and Uncertainty Analysis of Digital vs. Analog Pressure Scanners Under Static and Dynamic Conditions. Eng 2025, 6, 263. https://doi.org/10.3390/eng6100263

Nicolae R, Oancea C-D, Secareanu R, Lale D. Performance and Uncertainty Analysis of Digital vs. Analog Pressure Scanners Under Static and Dynamic Conditions. Eng. 2025; 6(10):263. https://doi.org/10.3390/eng6100263

Chicago/Turabian StyleNicolae, Roxana, Constantin-Daniel Oancea, Rares Secareanu, and Daniel Lale. 2025. "Performance and Uncertainty Analysis of Digital vs. Analog Pressure Scanners Under Static and Dynamic Conditions" Eng 6, no. 10: 263. https://doi.org/10.3390/eng6100263

APA StyleNicolae, R., Oancea, C.-D., Secareanu, R., & Lale, D. (2025). Performance and Uncertainty Analysis of Digital vs. Analog Pressure Scanners Under Static and Dynamic Conditions. Eng, 6(10), 263. https://doi.org/10.3390/eng6100263