Mechanical and Performance Characteristics of Warm Mix Asphalt Modified with Phase Change Materials and Recycled Cigarette Filters

Abstract

1. Introduction

1.1. Research Background

1.2. Literature Review

1.3. The Novelty of the Study

1.4. The Objectives of the Study

2. Experimental Work

2.1. The Incorporated Materials

2.1.1. Asphalt Binder

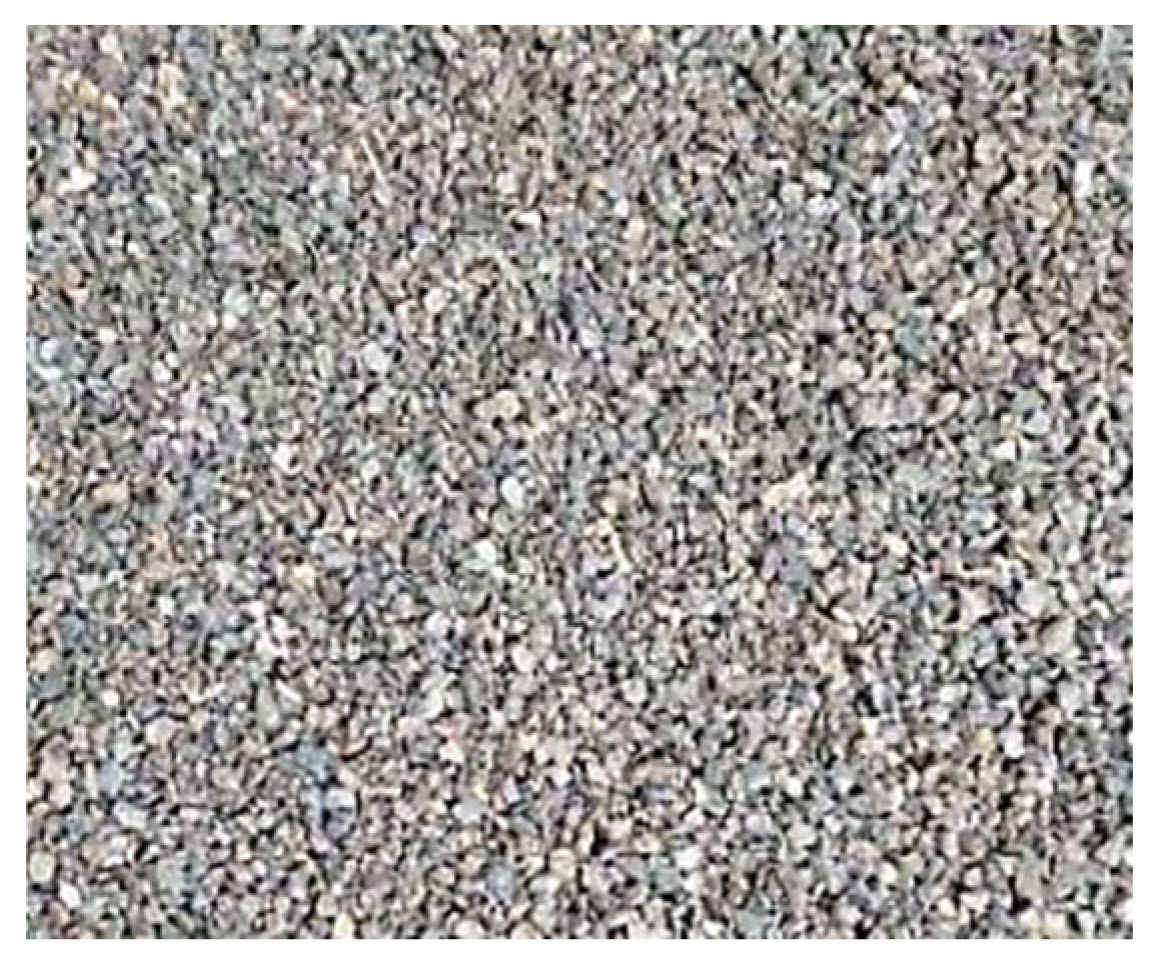

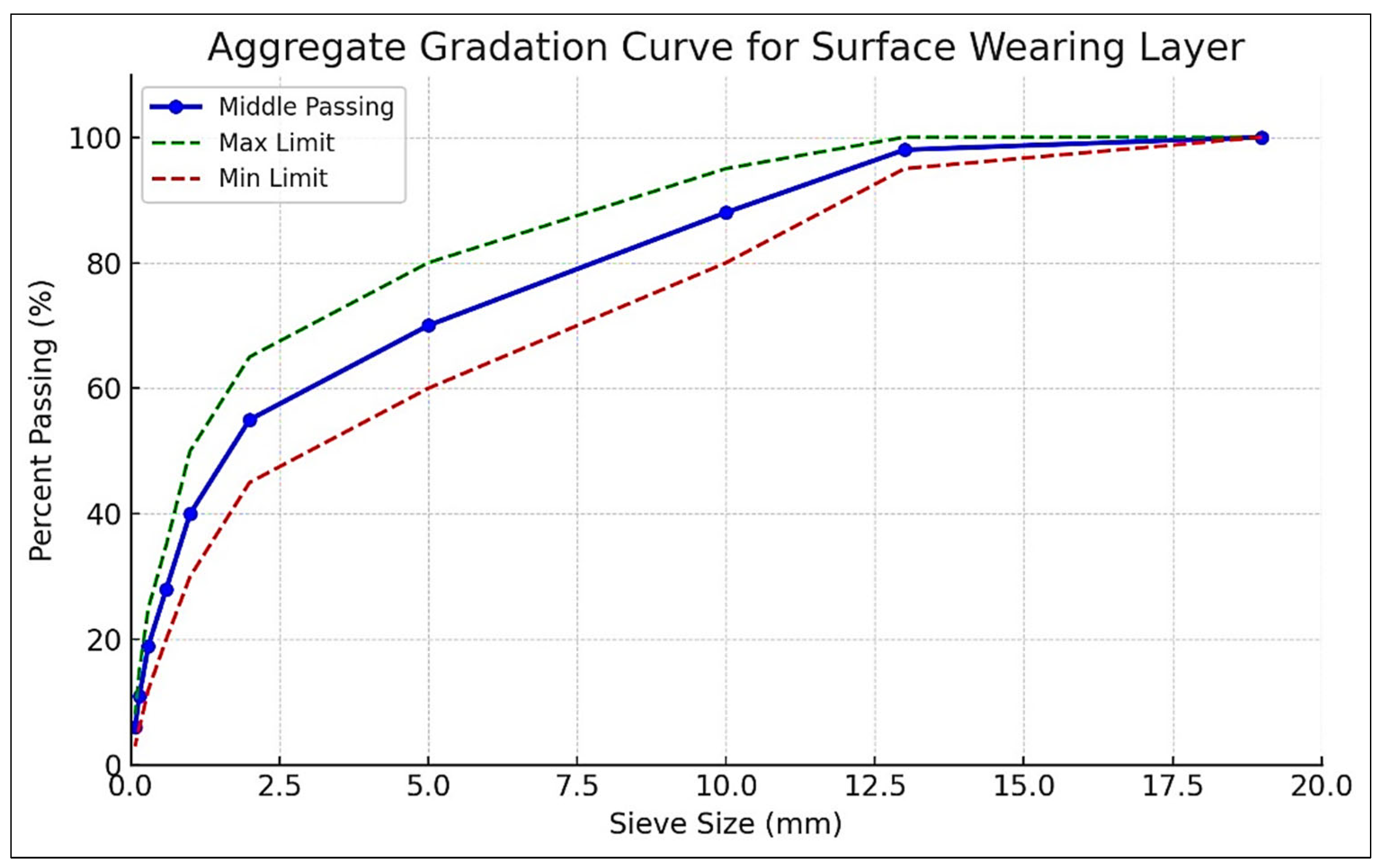

2.1.2. The Adopted Aggregate

2.1.3. The Elected Filler

2.1.4. Paraffin-Based Wax (Rubitherm RT55)

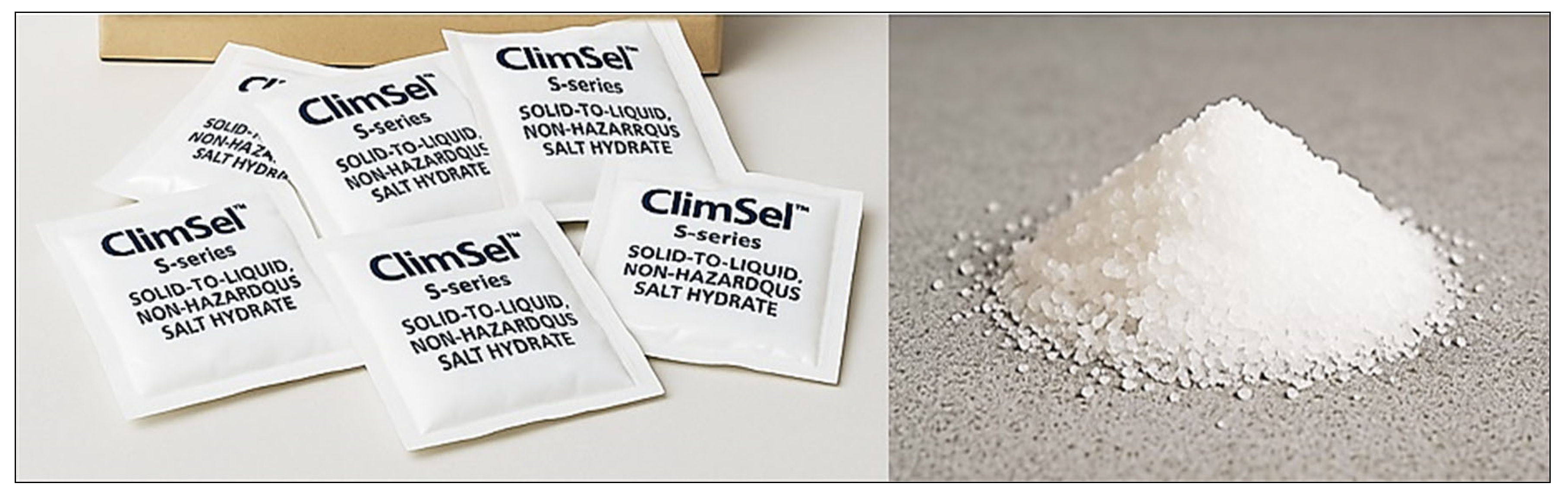

2.1.5. Hydrated Salt (Climator Salt S10)

2.1.6. Fatty Acid (Lauric Acid)

2.1.7. Cigarette Filters (CFs)

- Air-dry in a ventilated area or oven-dry at 80–100 °C for 24–48 hr.

- Cut or shred CFs into small fibers or flakes, as shown in Figure 9.

- Store shredded CFs in dry, sealed bags or containers to prevent moisture reabsorption and contamination.

2.2. Lab-Based Performance Analysis

2.2.1. Asphalt Binder Modification Process

2.2.2. WMA Specimen Preparation

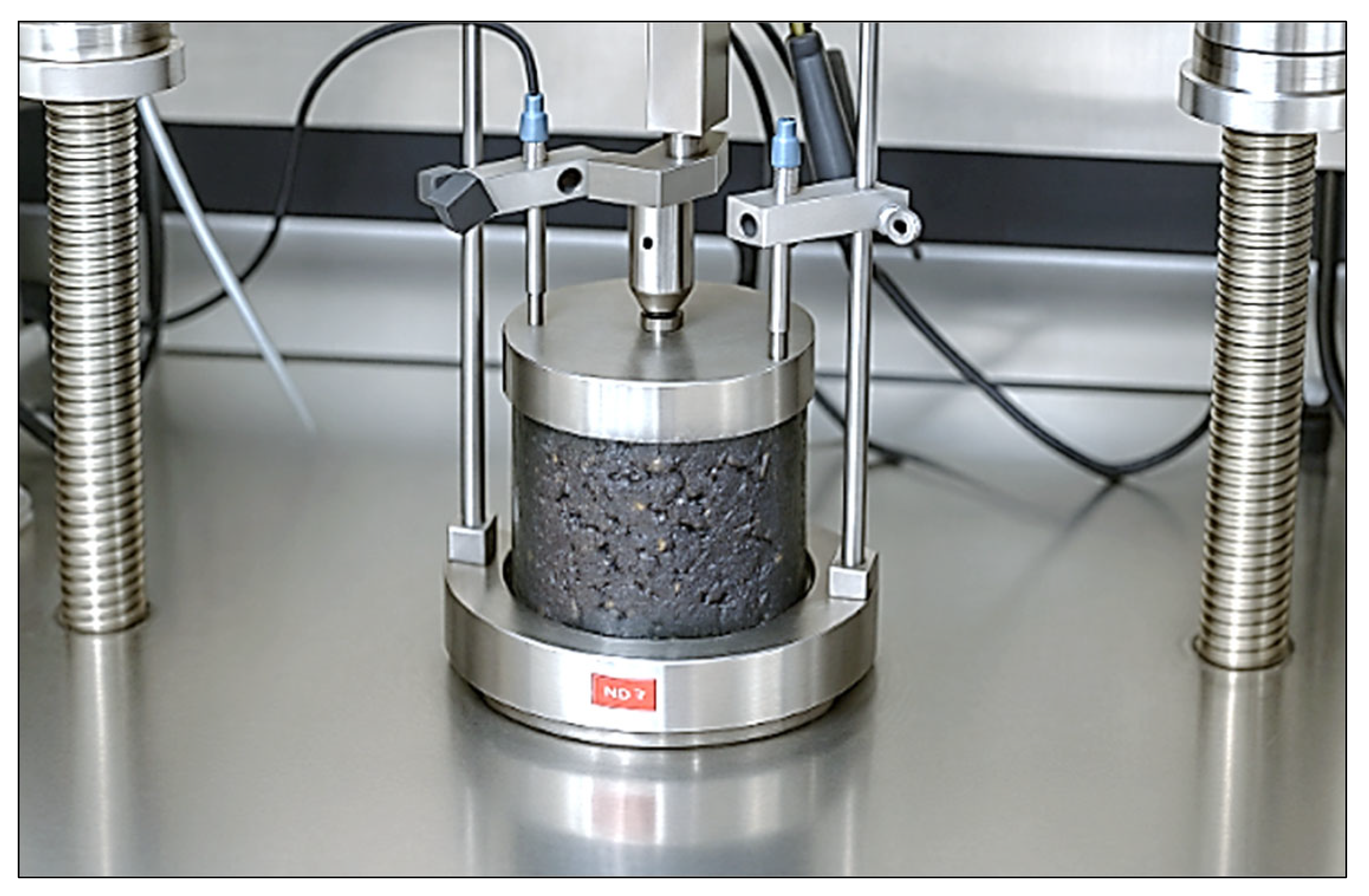

2.2.3. The Indirect Tensile Stiffness Modulus (ITSM) Test

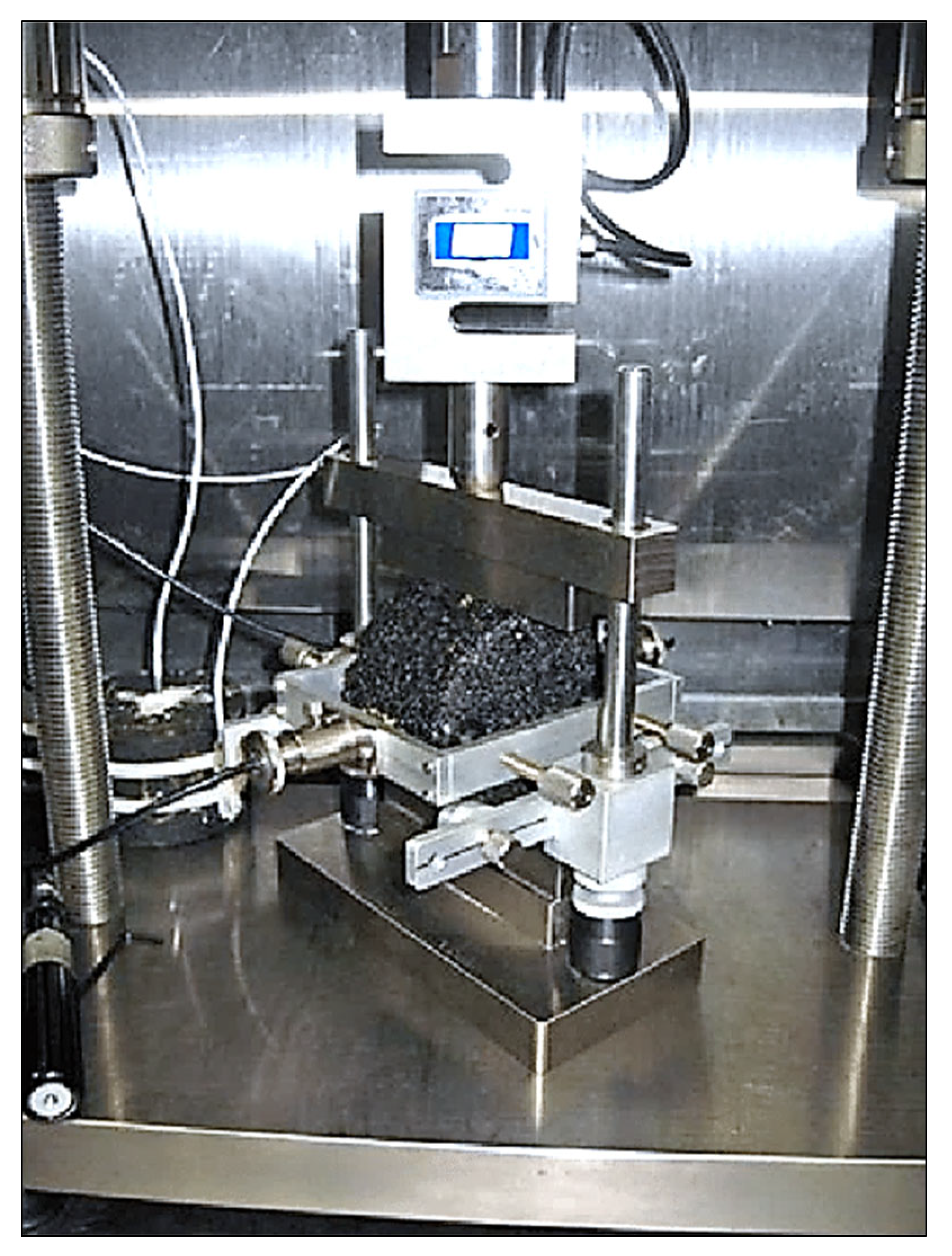

2.2.4. Static Creep Strain Test

2.2.5. Hamburg Wheel-Track Test (HWTT)

3. Results and Discussion

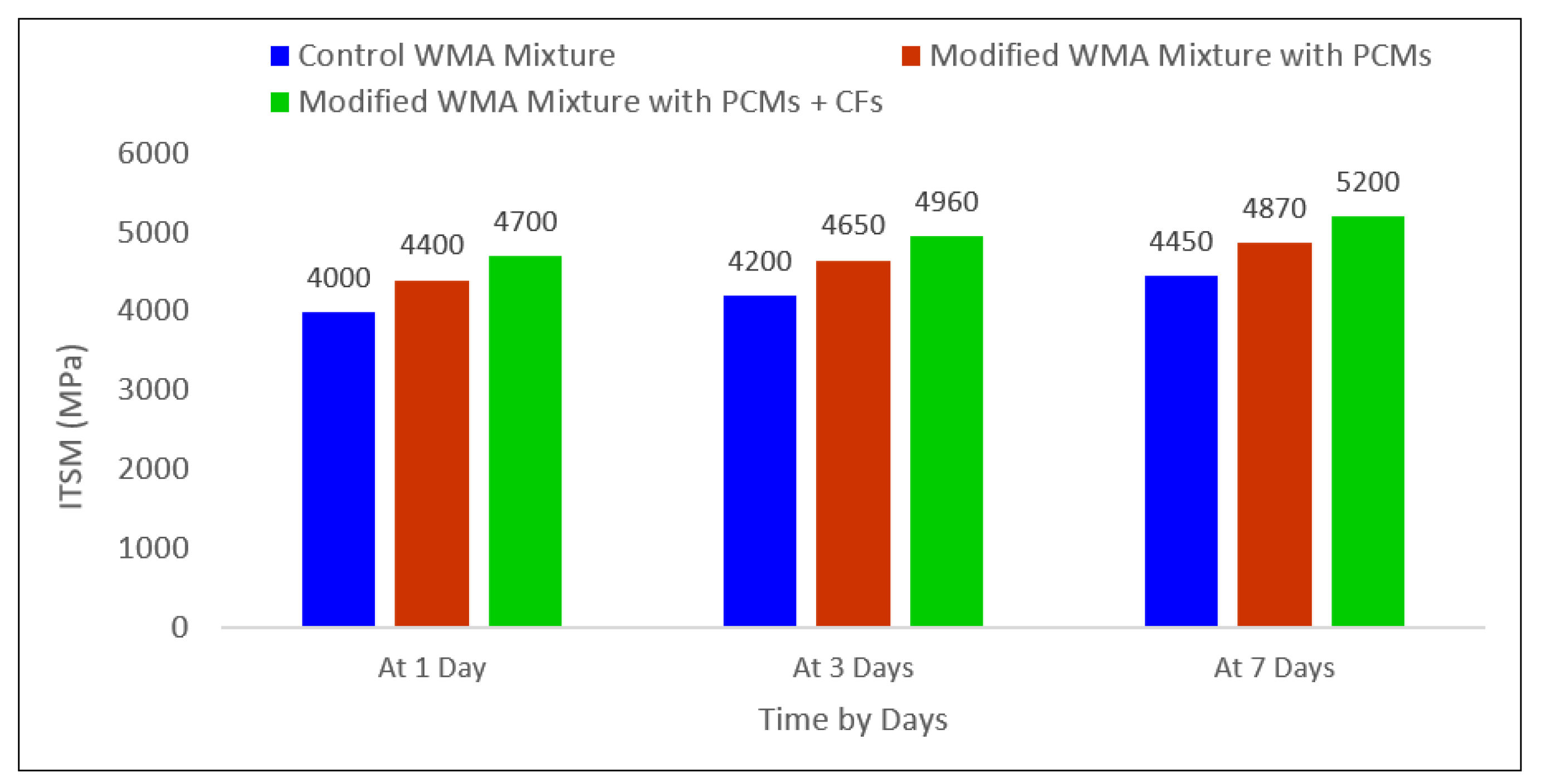

3.1. The Results of the ITSM Test

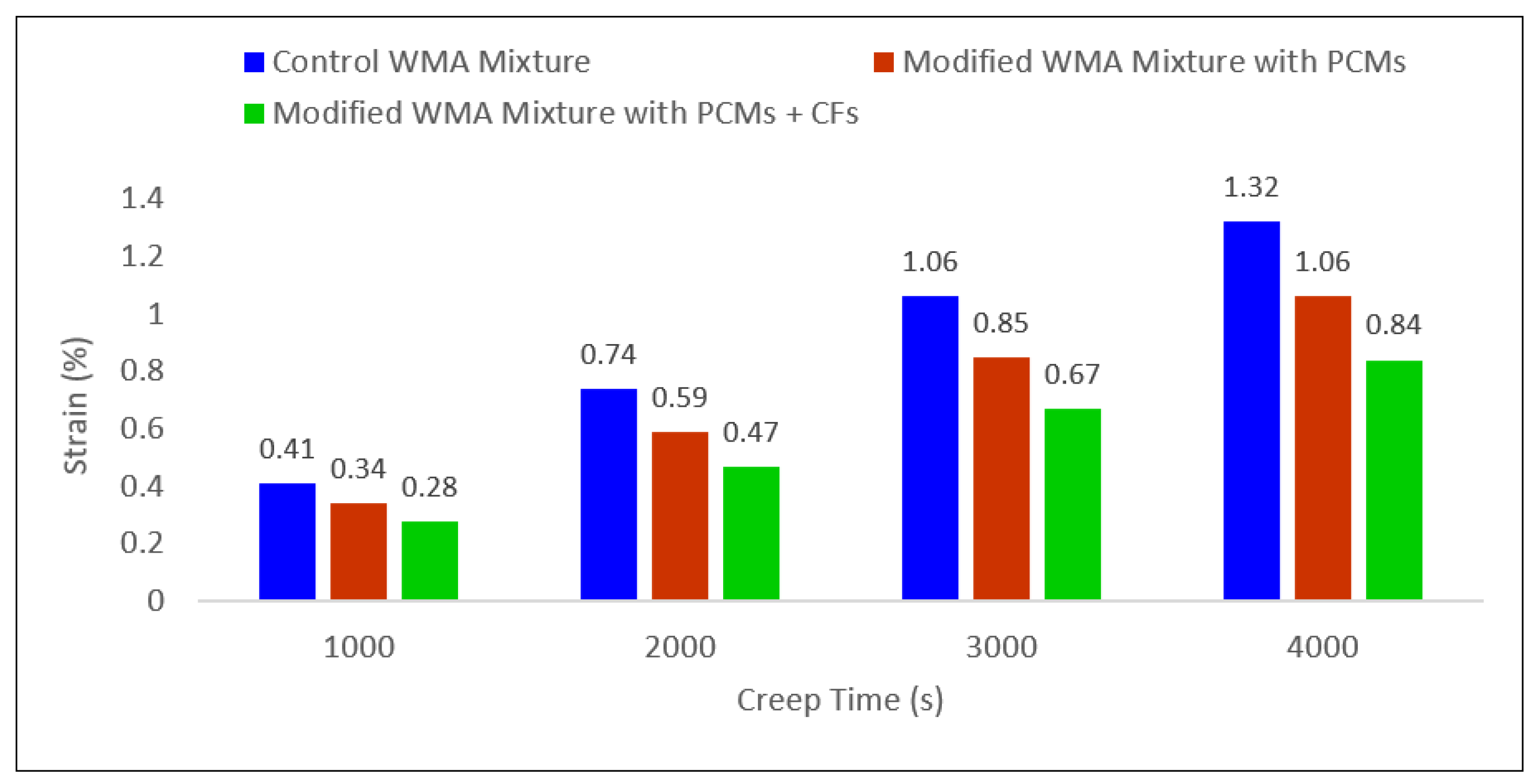

3.2. The Results of the Static Creep Strain Test

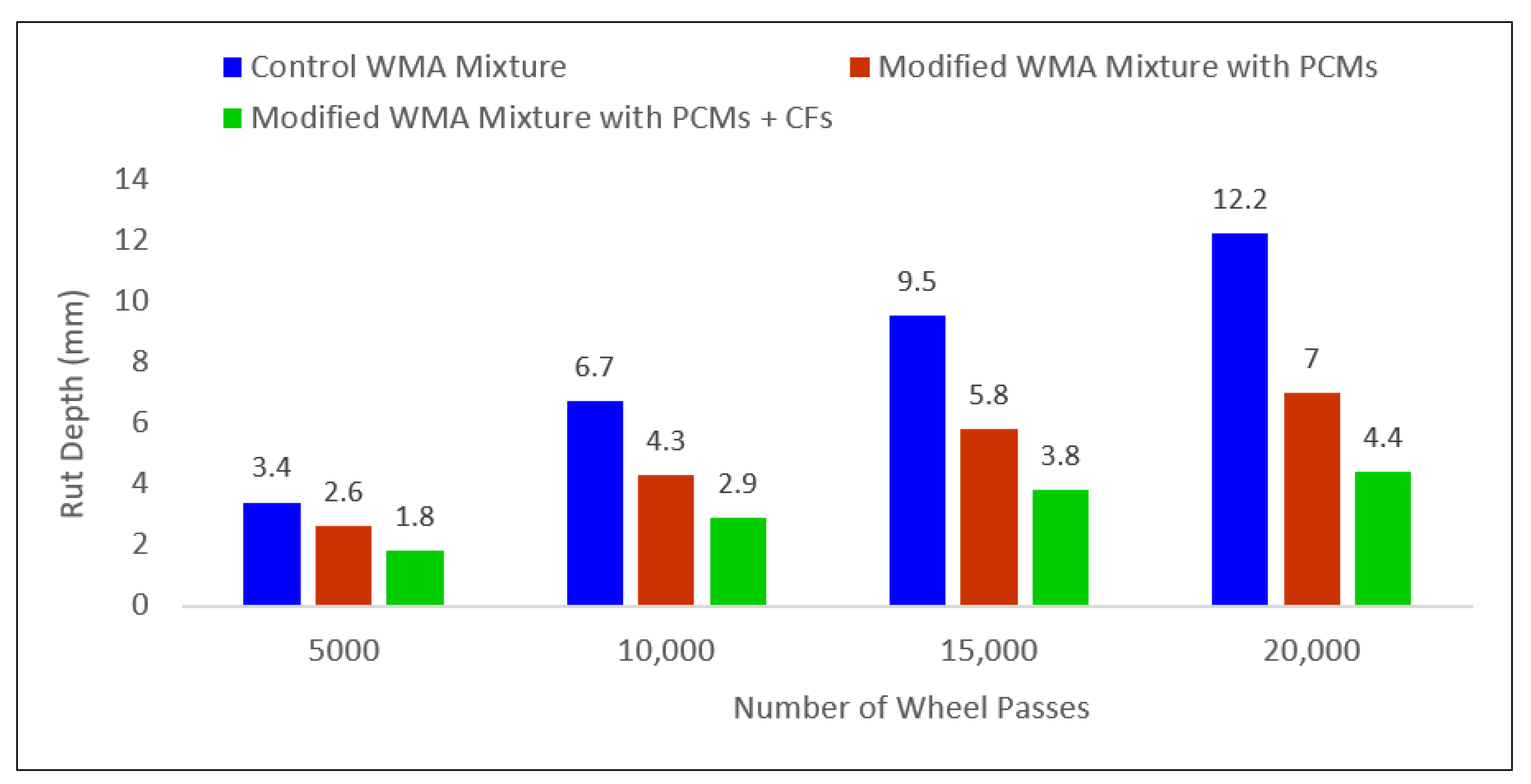

3.3. The Results of the Hamburg Wheel-Track Test (HWTT)

4. Analytical Assessment

4.1. Cost–Benefit Analysis

- Aggregates: 104.3 kg × USD 0.015 = USD 1.57

- Filler: 8.26 kg × USD 0.082 = USD 0.68

- Binder: 5.43 kg × USD 0.195 = USD 1.06

- Total: USD 3.31

- Aggregates: 103 kg × USD 0.015 = USD 1.55

- Filler: 8.16 kg × USD 0.082 = USD 0.65

- Binder: 5.36 kg × USD 0.195 = USD 1.04

- Paraffin Wax: 0.108 kg × USD 3.30 = USD 0.36

- Hydrated Salt: 0.053 kg × USD 0.75 = USD 0.04

- Lauric Acid: 0.053 kg × USD 5.0 = USD 0.26

- CFs: 0.245 kg × USD 0.5 = 0.12

- Total: USD 4.02

4.2. Analytical Prediction of Service Life

- Step 1:

- Choosing the Design Service Life of the Control WMA Mixture

- Step 2:

- Calculating the Service Life of the Modified WMA Mixture Using the Rut Depth Ratio

- Step 3:

- Projected Service Life for Modified WMA Mixture

- Step 4:

- Applying a Correction Factor

5. Conclusions

- Blending paraffin-based wax, hydrated salt, lauric acid, and recycled cigarette filters into warm mix asphalt is not just innovative; it delivers real results. Compared to the control, the modified mixes showed stiffness improvements of up to 10–15% after just 1 day, and by the 7th day, the specimen containing cigarette filters achieved a 15% higher stiffness modulus than the standard mix. This proves that not only do these additives, especially the recycled filters, make WMA stronger and more durable, but they also give a valuable new use for waste materials, turning trash into tougher roads.

- The static creep strain test demonstrated that modifying WMA mixtures with PCMs and CFs significantly reduces permanent deformation under sustained loading. The observed decrease in creep strain values, up to 36% lower than the control, highlights the effectiveness of these additives in enhancing the long-term stability and durability of warm mix asphalt pavements.

- The Hamburg wheel-track test results confirmed that modifying WMA mixtures with PCMs and CFs greatly improved rutting resistance, achieving up to a 64% reduction in rut depth compared to the control. The combination of additives, with or without CFs, effectively minimized permanent deformation and significantly enhanced the durability of WMA mixtures under repeated loading.

- The modified WMA mixture costs USD 0.71 more per square meter than the control for a 5 cm thick slab, but this small increase is offset by its improved performance. With the inclusion of PCMs and recycled cigarette filters, the modified mixture shows higher rutting resistance and durability, resulting in an estimated service life of 19–29 years compared to 10–15 years for the control. These results indicate that the modifications offer a practical and effective way to enhance pavement longevity and sustainability.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Almeida, A.; Picado-Santos, L. Asphalt road pavements to address climate change challenges—An overview. Appl. Sci. 2022, 12, 12515. [Google Scholar] [CrossRef]

- Abbas, A.S. Temperature zoning of Iraq for asphalt mix design. J. Eng. Sustain. Dev. 2017, 21, 54–63. [Google Scholar]

- Decky, M.; Hodasova, K.; Papanova, Z.; Remisova, E. Sustainable adaptive cycle pavements using composite foam concrete at high altitudes in central Europe. Sustainability 2022, 14, 9034. [Google Scholar] [CrossRef]

- Nazir, H.; Batool, M.; Osorio, F.J.; Isaza-Ruiz, M.; Xu, X.; Vignarooban, K.; Phelan, P.; Kannan, A.M. Recent developments in phase change materials for energy storage applications: A review. Int. J. Heat Mass Transf. 2019, 129, 491–523. [Google Scholar] [CrossRef]

- Vafaeva, K.M.; Zegait, R. Carbon nanotubes: Revolutionizing construction materials for a sustainable future: A review. Res. Eng. Struct. Mater. 2023, 10, 559–621. [Google Scholar] [CrossRef]

- Barz, T.; Krämer, J.; Emhofer, J. Identification of phase fraction–temperature curves from heat capacity data for numerical modeling of heat transfer in commercial paraffin waxes. Energies 2020, 13, 5149. [Google Scholar] [CrossRef]

- Thakkar, J. Optimizing Design of Salt Hydrate Phase Change Materials for Building and Cold Chain Efficiency Applications. Ph.D. Thesis, University of Massachusetts Lowell, Lowell, MA, USA, 2024. [Google Scholar]

- Saleel, C.A. A review on the use of coconut oil as an organic phase change material with its melting process, heat transfer, and energy storage characteristics. J. Therm. Anal. Calorim. 2022, 147, 4451–4472. [Google Scholar] [CrossRef]

- Torkashvand, J.; Farzadkia, M.; Sobhi, H.R.; Esrafili, A. Littered cigarette butt as a well-known hazardous waste: A comprehensive systematic review. J. Hazard. Mater. 2020, 383, 121242. [Google Scholar] [CrossRef]

- Jamshidi, A.; Hamzah, M.O.; You, Z. Performance of warm mix asphalt containing Sasobit®: State-of-the-art. Constr. Build. Mater. 2013, 38, 530–553. [Google Scholar] [CrossRef]

- Ma, F.; Hou, Y.; Fu, Z.; Qin, W.; Tang, Y.; Dai, J.; Wang, Y.; Peng, C. Microencapsulated binary eutectic phase change materials with high energy storage capabilities for asphalt binders. Constr. Build. Mater. 2023, 392, 131814. [Google Scholar] [CrossRef]

- Fu, Z.; Hou, Y.; Ma, F.; Fu, Z.; Cui, J.; Liu, Z.; Liu, J. Investigation of rheological properties of asphalt modified with low-temperature microencapsulated eutectic phase change materials. Case Stud. Constr. Mater. 2024, 20, e03201. [Google Scholar] [CrossRef]

- Milad, A.; Babalghaith, A.M.; Al-Sabaeei, A.M.; Dulaimi, A.; Ali, A.; Reddy, S.S.; Bilema, M.; Yusoff, N.I. A comparative review of hot and warm mix asphalt technologies from environmental and economic perspectives: Towards a sustainable asphalt pavement. Int. J. Environ. Res. Public Health 2022, 19, 14863. [Google Scholar] [CrossRef] [PubMed]

- Saboo, N.; Das, A. Research Trends in materials and design of Asphalt Pavements. In Transportation Research in India: Practices and Future Directions; Springer: Singapore, 2022; p. 31. [Google Scholar]

- Obaid, H.A.; Hashim, T.M.; Al-Abody, A.A.; Nasr, M.S.; Abbas, G.H.; Kadhim, A.M.; Sadique, M. Properties of modified warm-mix asphalt mixtures containing different percentages of reclaimed asphalt pavement. Energies 2022, 15, 7813. [Google Scholar] [CrossRef]

- Sukhija, M.; Saboo, N.; Pani, A. Effect of warm mix asphalt (WMA) technologies on the moisture resistance of asphalt mixtures. Constr. Build. Mater. 2023, 369, 130589. [Google Scholar] [CrossRef]

- ASTM C127-24; Standard Test Method for Relative Density (Specific Gravity) and Absorption of Coarse Aggregate. ASTM International: West Conshohocken, PA, USA, 2015.

- ASTM C131/C131M-14; Resistance to Degradation of Small-Size Coarse Aggregate by Abrasion and Impact in the Los Angeles Machine. ASTM: West Conshohocken, PA, USA, 2014.

- ASTM C29/C29M-23; Standard Test Method for Bulk Density (“Unit Weight”) and Voids in Aggregate. ASTM International: West Conshohocken, PA, USA, 2023.

- ASTM C128-22; Standard Test Method for Relative Density (Specific Gravity) and Absorption of Fine Aggregate. ASTM International: West Conshohocken, PA, USA, 2022.

- ASTM C136; Standard Test Method for Sieve Analysis of Fine and Coarse Aggregates. ASTM International: West Conshohocken, PA, USA, 2006.

- ASTM C117-17; Standard Test Method for Materials Finer than 75-μm (No 200) Sieve in Mineral Aggregates by Washing. American Society for Testing and Materials: West Conshohocken, PA, USA, 2020.

- AL Sa’adi, A.H.; Al-Khafaji, F.F.; Hashim, T.M.; Hussein, M.L.; Ali, Y.A.; Ali, A.H.; Jebur, Y.M.; Ali, L.H.; Al-Mulali, M.Z.; Al-Khazraji, A.A. Prospect of using geotextile reinforcement within flexible pavement layers to reduce the effects of rutting in the middle and southern parts of Iraq. J. Mech. Behav. Mater. 2022, 31, 323–336. [Google Scholar] [CrossRef]

- Gu, P.; Wu, H.; Li, L.; Li, Z.; Hong, J.; Zhuang, M.L. Effect of Traffic Vibration on Compressive Strength of High-Strength Concrete and Tensile Strength of New-to-Old Concrete Interfaces. Buildings 2024, 14, 3765. [Google Scholar] [CrossRef]

- ASTM C204; Standard Test Methods for Fineness of Hydraulic Cement by Air-Permeability Apparatus. ASTM: West Conshohocken, PA, USA, 2023.

- ASTM C188-17; Standard Test Method for Density of Hydraulic Cement. ASTM International: West Conshohocken, PA, USA, 2017.

- Yu, H.; Leng, Z.; Zhou, Z.; Shih, K.; Xiao, F.; Gao, Z. Optimization of preparation procedure of liquid warm mix additive modified asphalt rubber. J. Clean. Prod. 2017, 141, 336–345. [Google Scholar] [CrossRef]

- ASTM D3418-21; Standard Test Method for Transition Temperatures and Enthalpies of Fusion and Crystallization of Polymers by Differential Scanning Calorimetry. ASTM: West Conshohocken, PA, USA, 2021.

- DIN EN ISO 1183-1:2024; Plastics—Methods for Determining the Density of Non-Cellular Plastics—Part 1: Immersion Method, Liquid Pycnometer Method and Titration Method. DIN Deutsches Institut für Normung e.V.: Berlin, Germany, 2024.

- ASTM D93-20; Standard Test Methods for Flash Point by Pensky-Martens Closed Cup Tester. ASTM International: West Conshohocken, PA, USA, 2020.

- Fabiani, C.; Piselli, C.; Pisello, A.L. Thermo-optic durability of cool roof membranes: Effect of shape stabilized phase change material inclusion on building energy efficiency. Energy Build. 2020, 207, 109592. [Google Scholar] [CrossRef]

- ASTM C177-19; Standard Test Method for Steady-State Heat Flux Measurements and Thermal Transmission Properties by Means of the Guarded-Hot-Plate Apparatus. ASTM (American Society for Testing and Materials): West Conshohocken, PA, USA, 2019.

- Sarı, A.; Karaipekli, A.; Alkan, C. Preparation, characterization and thermal properties of lauric acid/expanded perlite as novel form-stable composite phase change material. Chem. Eng. J. 2009, 155, 899–904. [Google Scholar] [CrossRef]

- ASTM D4052-22; Standard Test Method for Density and Relative Density of Liquids by Digital Density Meter. ASTM International: West Conshohocken, PA, USA, 2022.

- Vanapalli, K.R.; Sharma, H.B.; Anand, S.; Ranjan, V.P.; Singh, H.; Dubey, B.K.; Mohanty, B. Cigarettes butt littering: The story of the world’s most littered item from the perspective of pollution, remedial actions, and policy measures. J. Hazard. Mater. 2023, 453, 131387. [Google Scholar] [CrossRef]

- Abidoye, N.A. Impact of Blended Salt Anti-icers/Deicers on Properties of Asphalt Binders. Master’s Thesis, Geogia Southern University, Statesboro, GA, USA, 2021. [Google Scholar]

- Sharma, N.; Verma, M.; Sharma, P. Influence of Lauric acid on mechanical properties of Portland cement. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1116, 012153. [Google Scholar] [CrossRef]

- Pinheiro, C.; Landi, S., Jr.; Lima, O., Jr.; Ribas, L.; Hammes, N.; Segundo, I.R.; Homem, N.C.; Castelo Branco, V.; Freitas, E.; Costa, M.F.; et al. Advancements in phase change materials in asphalt pavements for mitigation of urban heat island effect: Bibliometric analysis and systematic review. Sensors 2023, 23, 7741. [Google Scholar] [CrossRef] [PubMed]

- ASTM D5; Standard Test Method for Penetration of Bituminous Materials. American Society for Testing and Materials: West Conshohocken, PA, USA, 2006.

- ASTM D36-06; Standard Test Method for Softening Point of Bitumen (Ring-and-Ball Apparatus). ASTM International: West Conshohocken, PA, USA, 2020.

- ASTM D113; Standard Test Method for Ductility of Bituminous Materials. Annual Book of ASTM Standards USA; American Standard Testing Methods: West Conshohocken, PA, USA, 2007.

- ASTM D92-24; Standard Test Method for Flash and Fire Points by Cleveland Open Cup Tester. ASTM International: West Conshohocken, PA, USA, 2018.

- ASTM D70; Standard Test Method for Specific Gravity and Density of Semi-Solid Bituminous Materials (Pycnometer Method). ASTM International: West Conshohocken, PA, USA, 1997.

- ASTM D4402; Standard Test Method for Viscosity Determination of Asphalt at Elevated Temperatures Using a Rotational Viscometer. American Society for Testing Materials (ASTM): West Conshohocken, PA, USA, 2015.

- Tataranni, P.; Sangiorgi, C. A preliminary laboratory evaluation on the use of shredded cigarette filters as stabilizing fibers for stone mastic asphalts. Appl. Sci. 2021, 11, 5674. [Google Scholar] [CrossRef]

- Baldo, N.; Dal Ben, M.; Pasetto, M.; Van de Ven, M.; Molenaar, A.A. Indirect tensile test for the determination of the stiffness and the resilient modulus of asphalt concretes: Experimental analysis of the EN 12697-26 and the ASTM D 4123 standards. In Proceedings of the 11th International Conference on Asphalt Pavements, Nagoya, Japan, 1–6 August 2010; pp. 796–878. [Google Scholar]

- Kim, S.H.; Yoon, S.J.; Choi, W. Experimental Study on Long-Term Ring Deflection of Glass Fiber-Reinforced Polymer Mortar Pipe. Adv. Mater. Sci. Eng. 2019, 2019, 6937540. [Google Scholar] [CrossRef]

- Hashim, T.M.; Nasr, M.S.; Jebur, Y.M.; Kadhim, A.; Alkhafaji, Z.; Baig, M.G.; Adekunle, S.K.; Al-Osta, M.A.; Ahmad, S.; Yaseen, Z.M. Evaluating rutting resistance of rejuvenated recycled hot-mix asphalt mixtures using different types of recycling agents. Materials 2022, 15, 8769. [Google Scholar] [CrossRef]

- Mazhari Pakenari, M.; Hamedi, G.H. Investigating the effective laboratory parameters on the stiffness modulus and fatigue cracking of warm mix asphalt. Int. J. Civ. Eng. 2021, 19, 685–698. [Google Scholar] [CrossRef]

- Abed, A.; Thom, N.; Lo Presti, D.; Airey, G. Thermo-rheological analysis of WMA-additive modified binders. Mater. Struct. 2020, 53, 52. [Google Scholar] [CrossRef]

- Fakhri, M.; Maleki, H.; Hosseini, S.A. Investigation of different test methods to quantify rutting resistance and moisture damage of GFM-WMA mixtures. Constr. Build. Mater. 2017, 152, 1027–1040. [Google Scholar] [CrossRef]

- Papagiannakis, A.T.; Masad, E.A. Pavement Design and Materials; John Wiley & Sons: Hoboken, NJ, USA, 2024. [Google Scholar]

- Badgley, J.; Fowler, J.; Mahavier, K.; Peirce, S. FHWA Research and Technology Evaluation TechBrief: Innovative Intersection Design. United States; Federal Highway Administration. Research and Technology Evaluation: Washington, DC, USA, 2021. [Google Scholar]

| Test Property | Result | Requirement |

|---|---|---|

| Penetration @ 25 °C | 64 dmm | 60–70 |

| Softening Point (R&B) | 52 °C | 48–56 °C |

| Ductility @ 25 °C | 110 cm | ≥100 cm |

| Flash Point | 240 °C | ≥230 °C |

| Specific Gravity @ 25 °C | 1.03 | 1.01–1.06 |

| Viscosity @ 135 °C | 400 cP | 300–600 cP |

| Test Property | Result | Standard | Requirement |

|---|---|---|---|

| Specific Gravity | 2.85 | ASTM C127 [17] | ≥2.5 |

| Water Absorption | 1.2% | ASTM C127 [17] | ≤3% |

| Los Angeles Abrasion | 25% | ASTM C131 [18] | ≤40% |

| Bulk Density | 1550 kg/m3 | ASTM C29 [19] | - |

| Test Property | Result | Standard | Requirement |

|---|---|---|---|

| Specific Gravity | 2.65 | ASTM C128 [20] | ≥2.5 |

| Water Absorption | 1.0% | ASTM C128 [20] | ≤3% |

| Fineness Modulus | 2.8 | ASTM C136 [21] | - |

| Bulk Density | 1550 kg/m3 | ASTM C29 [19] | - |

| Silt Content | 1.5% | ASTM C117 [22] | ≤3% |

| Test Property | Result | Standard | Requirement |

|---|---|---|---|

| Fineness (m2/kg) | 330 | ASTM C204 [25] | ≥320 |

| Specific Gravity | 3.12 | ASTM C188 [26] | 3.10–3.15 |

| Test Property | Result | Standard | Requirement |

|---|---|---|---|

| Appearance | White waxy solid | Visual inspection | White, waxy solid |

| Melting Point (°C) | 55 | ASTM D3418 [28] | 51–57 °C |

| Heat of Fusion (kJ/kg) | 190 | ASTM D3418 [28] | 180–200 kJ/kg |

| Density (kg/m3) | 780 | ISO 1183 [29] | 770–790 kg/m3 |

| Flash Point | 210 | ASTM D93 [30] | 190–230 °C |

| Test Property | Result | Standard | Requirement |

|---|---|---|---|

| Appearance | White crystalline solid | Visual Inspection | White/off-white crystals |

| Melting Point (°C) | 30 | ASTM D3418 [28] | 28–32 °C |

| Heat of Fusion (kJ/kg) | 175 | ASTM D3418 [28] | 150–200 |

| Density (kg/m3) | 1650 | ISO 1183 [29] | 1600–1700 |

| Thermal Conductivity (W/m·K) | 0.6 | ASTM C177 [32] | 0.5–0.7 |

| Test Property | Result | Standard | Requirement |

|---|---|---|---|

| Appearance | White crystalline solid | Visual Inspection | White waxy solid |

| Melting Point (°C) | 43.8 | ASTM D3418 [28] | 43.5–44 °C |

| Density (g/cm3) | 0.85 | ASTM D4052 [34] | 0.84–0.85 |

| Flash Point (°C) | 200 | ASTM D93 [30] | 200–210 °C |

| Test Property | Result | Standard |

|---|---|---|

| Penetration @ 25 °C | 58 dmm | ASTM D5 [39] |

| Softening Point (R&B) | 53 °C | ASTM D36 [40] |

| Ductility @ 25 °C | 78 cm | ASTM D113 [41] |

| Flash Point | 272 °C | ASTM D92 [42] |

| Specific Gravity @ 25 °C | 1.04 | ASTM D70 [43] |

| Viscosity @ 135 °C | 355 cP | ASTM D4402 [44] |

| Used Material | Price in USD |

|---|---|

| Aggregates | USD 15 per ton = USD 0.015 per kg |

| 60/70 Asphalt Binder | USD 195 per ton = USD 0.195 per kg |

| Filler | USD 82 per ton = USD 0.082 per kg |

| Paraffin Wax (Rubitherm RT55) | USD 3.30 per kg |

| Hydrated Salt (Climator Salt S10) | USD 0.75 per kg |

| Lauric Acid | USD 5.0 per kg |

| Cigarette Filters (CFs) | USD 0.5 per kg |

| Component | Conducted Percentage | Amount by kg |

|---|---|---|

| Aggregates | 88.4% by mix | 0.884 × 118 = 104.3 |

| Filler | 7% by mix | 0.07 × 118 = 8.26 |

| Binder | 4.6% by mix | 0.046 × 118 = 5.43 |

| Component | Conducted Percentage | Amount by kg |

|---|---|---|

| Aggregates | 88.4% by mix | 0.884 × 116.5 = 103 |

| Filler | 7% by mix | 0.07 × 116.5 = 8.16 |

| Binder | 4.6% by mix | 0.046 × 116.5 = 5.36 |

| Paraffin Wax | 2% of binder | 0.02 × 5.36 = 0.108 |

| Hydrated Salt | 1% of binder | 0.01 × 5.36 = 0.053 |

| Lauric Acid | 1% of binder | 0.01 × 5.36 = 0.053 |

| CFs | 3% of filler | 0.03 × 8.16 = 0.245 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

al-Mammori, Z.A.; Al-Janabi, I.M.K.; Abbas, G.H.; Aziz, D.H.; Alaaraji, F.H.; Abbas, E.S.; AL-shimmery, B.M.; Hashim, T.M.; Al-Jameel, G.Q.; Shubbar, A.; et al. Mechanical and Performance Characteristics of Warm Mix Asphalt Modified with Phase Change Materials and Recycled Cigarette Filters. CivilEng 2025, 6, 41. https://doi.org/10.3390/civileng6030041

al-Mammori ZA, Al-Janabi IMK, Abbas GH, Aziz DH, Alaaraji FH, Abbas ES, AL-shimmery BM, Hashim TM, Al-Jameel GQ, Shubbar A, et al. Mechanical and Performance Characteristics of Warm Mix Asphalt Modified with Phase Change Materials and Recycled Cigarette Filters. CivilEng. 2025; 6(3):41. https://doi.org/10.3390/civileng6030041

Chicago/Turabian Styleal-Mammori, Zahraa Ahmed, Israa Mohsin Kadhim Al-Janabi, Ghadeer H. Abbas, Doaa Hazim Aziz, Fatin H. Alaaraji, Elaf Salam Abbas, Beshaer M. AL-shimmery, Tameem Mohammed Hashim, Ghanim Q. Al-Jameel, Ali Shubbar, and et al. 2025. "Mechanical and Performance Characteristics of Warm Mix Asphalt Modified with Phase Change Materials and Recycled Cigarette Filters" CivilEng 6, no. 3: 41. https://doi.org/10.3390/civileng6030041

APA Styleal-Mammori, Z. A., Al-Janabi, I. M. K., Abbas, G. H., Aziz, D. H., Alaaraji, F. H., Abbas, E. S., AL-shimmery, B. M., Hashim, T. M., Al-Jameel, G. Q., Shubbar, A., & Nasr, M. S. (2025). Mechanical and Performance Characteristics of Warm Mix Asphalt Modified with Phase Change Materials and Recycled Cigarette Filters. CivilEng, 6(3), 41. https://doi.org/10.3390/civileng6030041