Digital-Twin-Based Structural Health Monitoring of Dikes

Abstract

1. Introduction

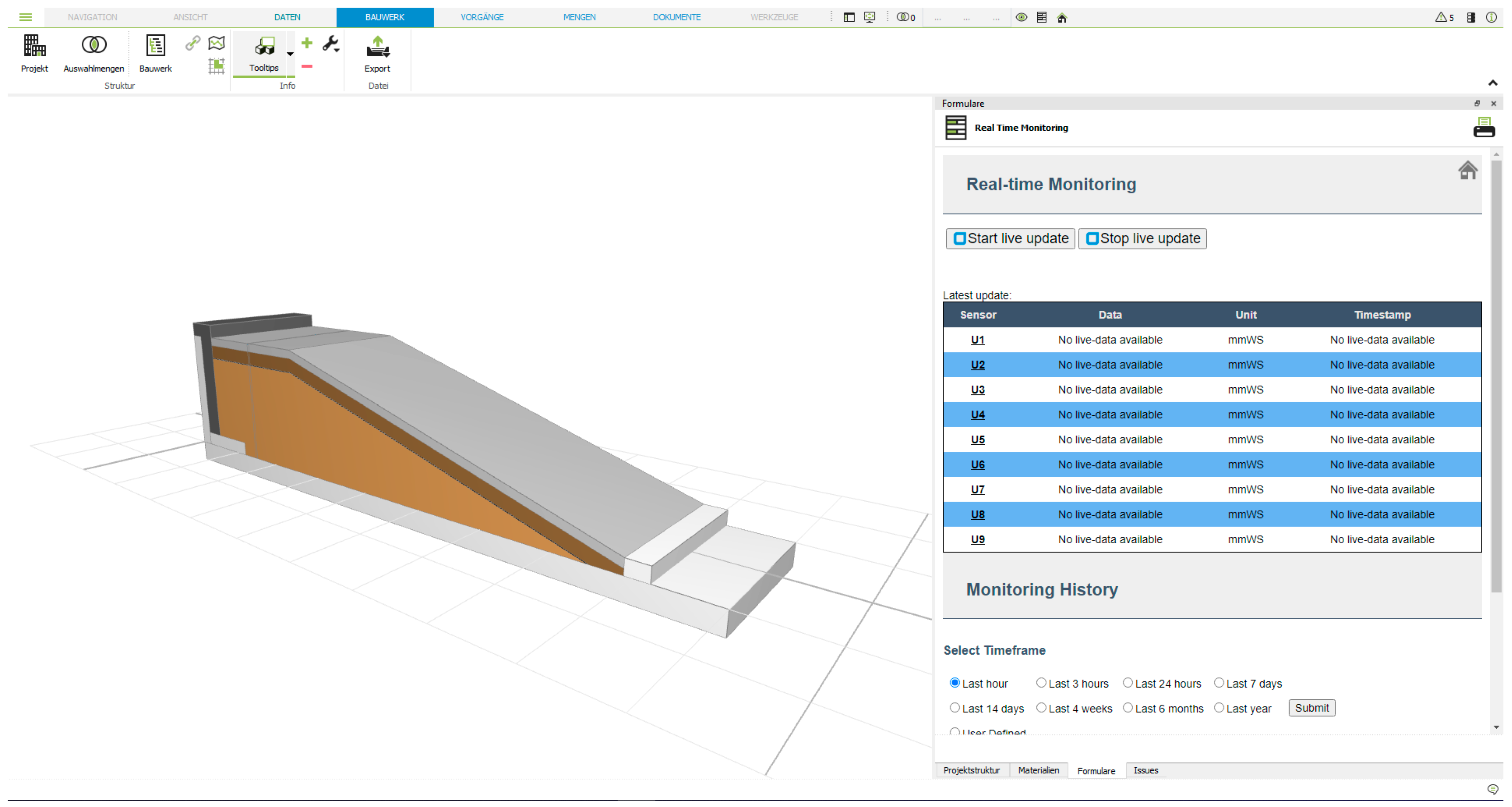

2. Designing a Digital Twin for Monitoring Dikes

3. Implementation of the Digital Twin Environment

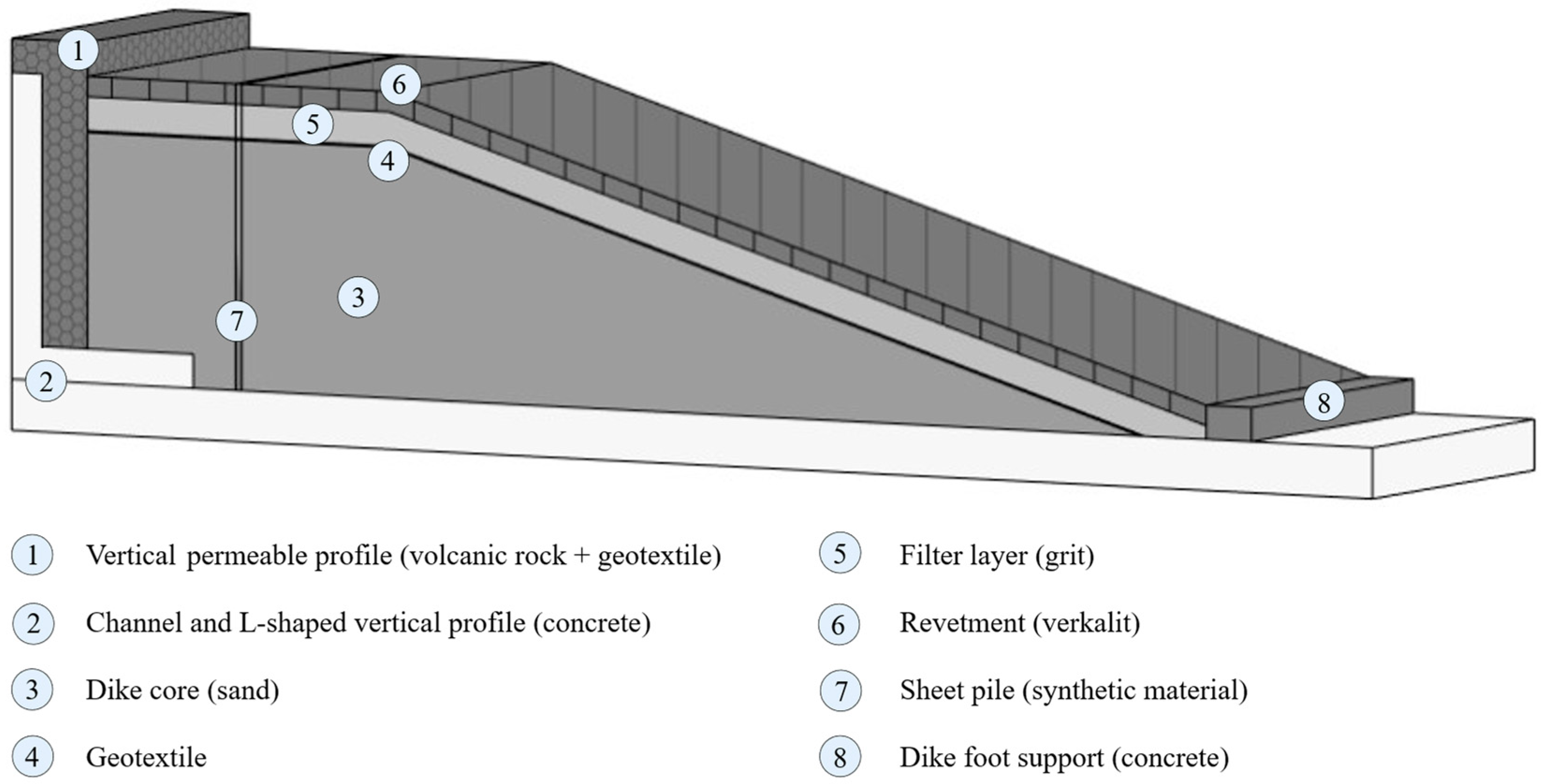

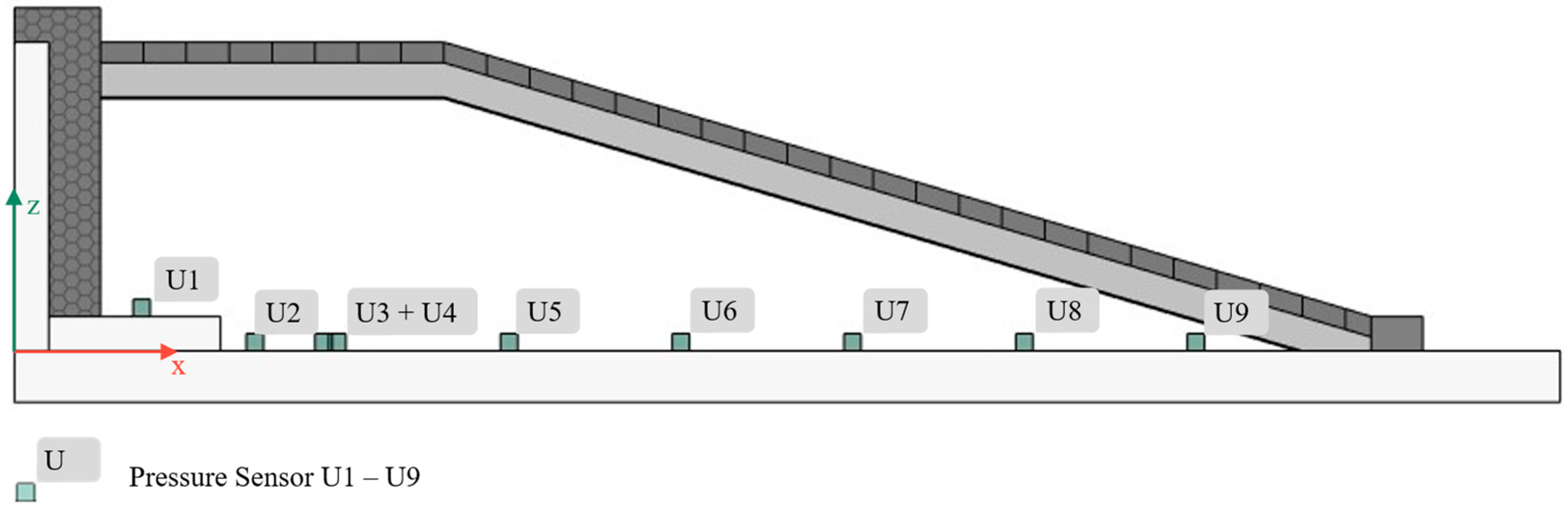

3.1. Dike and BIM Model

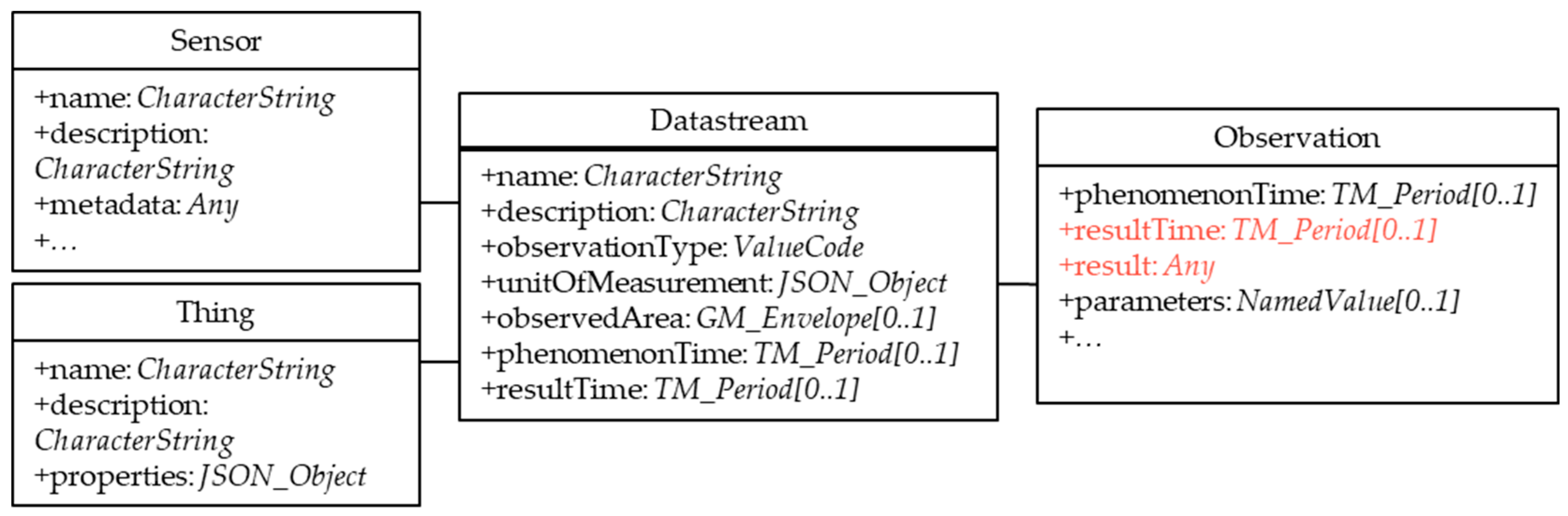

3.2. Digital Twin Environment

4. Validation of the Digital-Twin-Based SHM Approach

4.1. Validation Method and Procedure

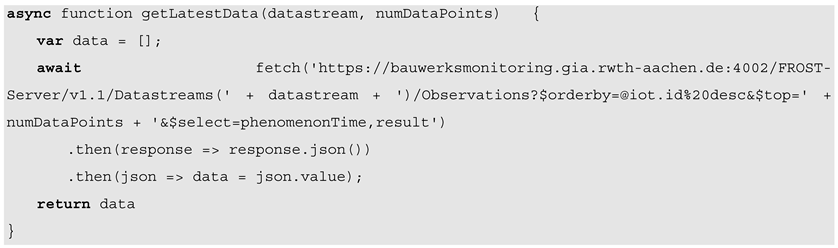

| Listing 1. Asynchronous function within the DESITE md webform that requests the property values belonging to the resultTime and result properties from Observations of a defined Datastream within the OGC SensorThings data model. |

|

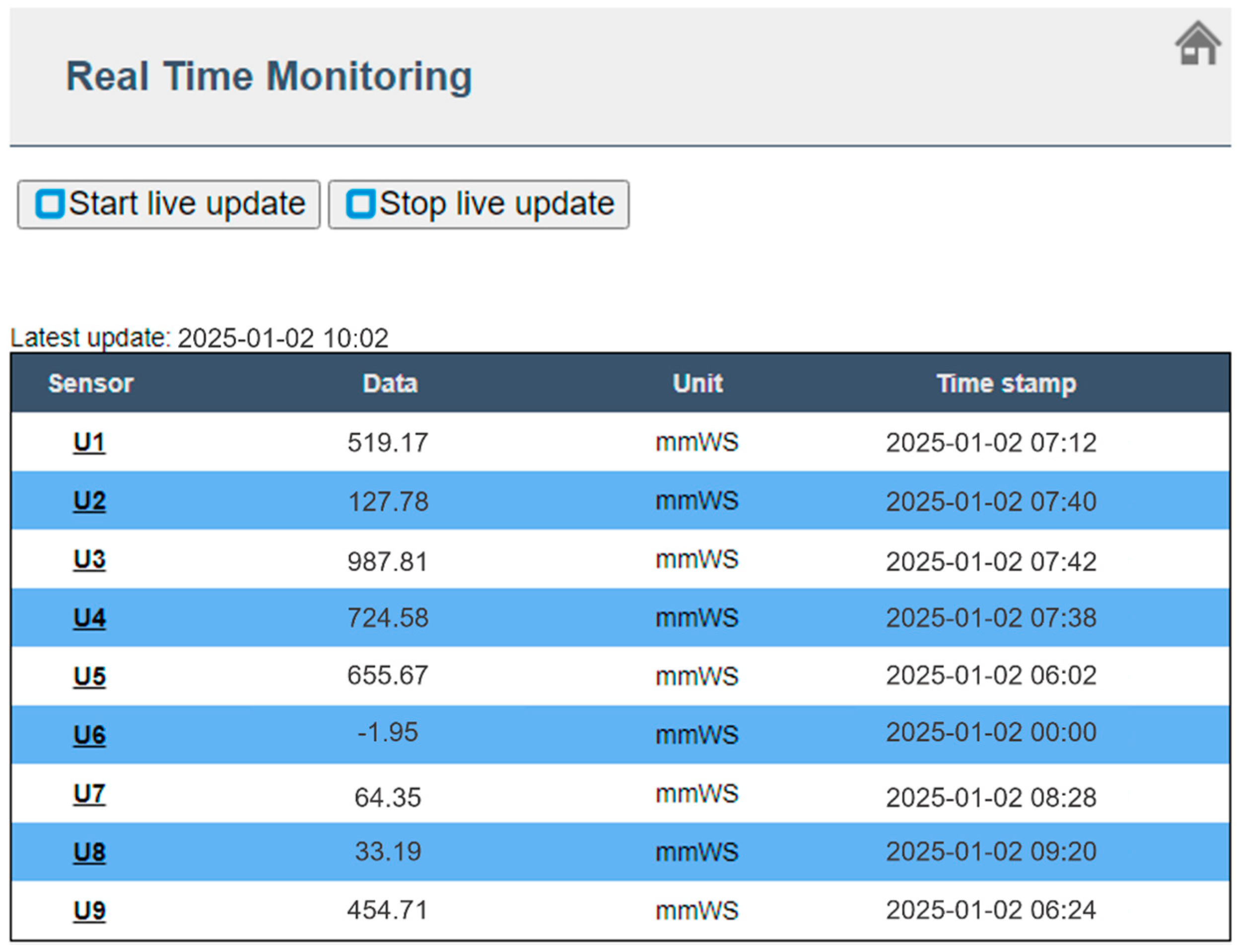

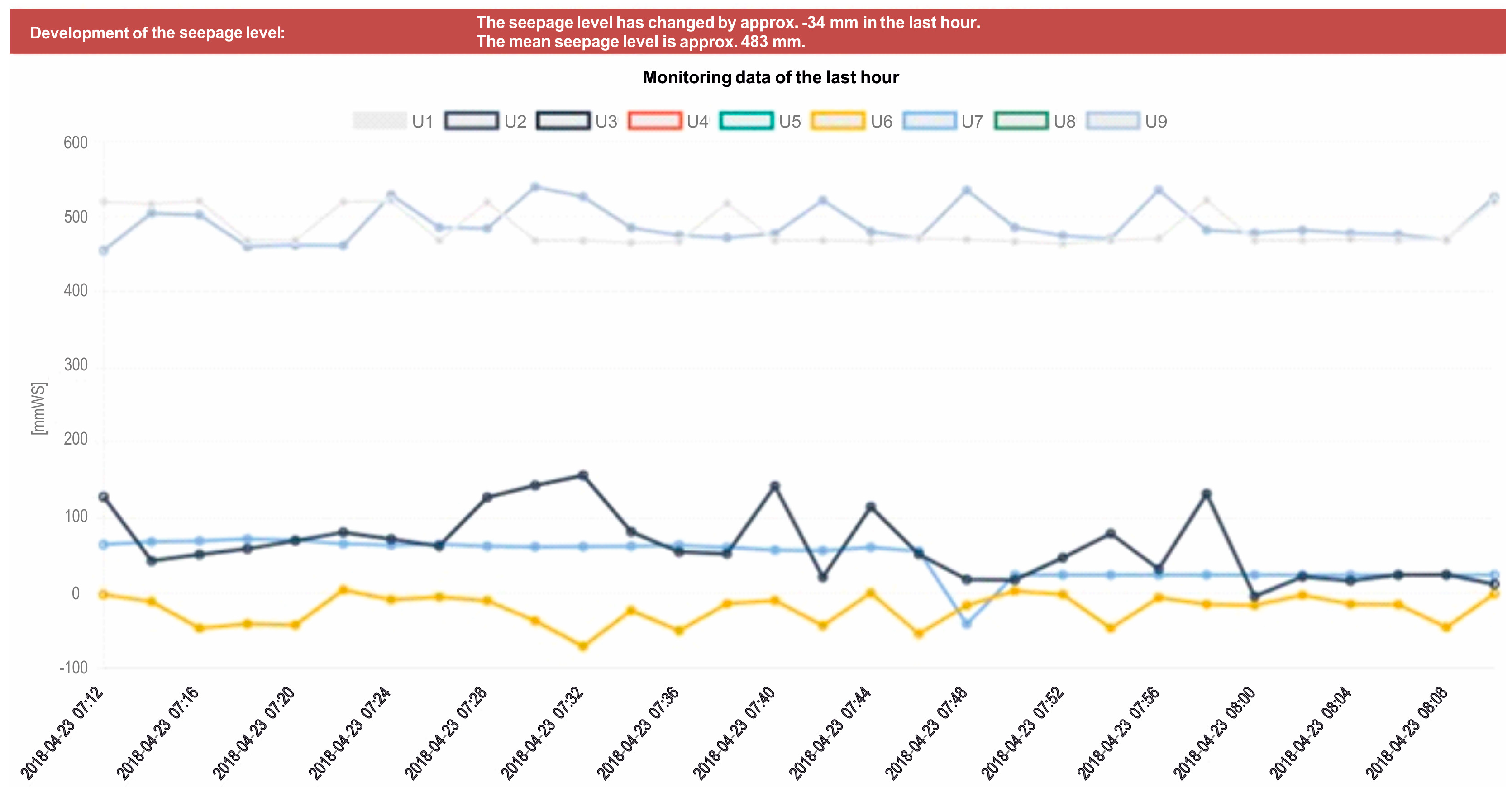

4.2. Results of the Validation

4.3. Discussion of the Results

5. Summary and Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bergmeister, K.; Fingerloos, F.; Wörner, J.-D. (Eds.) Beton-Kalender 2013: Lebensdauer und Instandsetzung, Brandschutz; Ernst & Sohn: Berlin, Germany, 2013; pp. 345–468. ISBN 978-3-433-03000-4. [Google Scholar]

- van Noortwijk, J.M.; Frangopol, D.M. Two probabilistic life-cycle maintenance models for deteriorating civil infrastructures. Probabilistic Eng. Mech. 2004, 19, 345–359. [Google Scholar] [CrossRef]

- DIN 1076:1999-11; Ingenieurbauwerke im Zuge von Straßen und Wegen—Überwachung und Prüfung. Beuth: Berlin, Germany, 1999.

- Große, C.; Helmerich, R.; Herbrand, M. Dauerüberwachung von Ingenieurbauwerken—Merkblatt B09; Deutsche Gesellschaft für Zerstörungsfreie Prüfung e.V.: Berlin, Germany, 2022; ISBN 978-3-947971-22-0. [Google Scholar]

- Bergmeister, K.; Fingerloos, F.; Wörner, J.-D. (Eds.) Beton-Kalender 2015: Bauen im Bestand, Brücken; Ernst & Sohn: Berlin, Germany, 2013; pp. 317–458. ISBN 978-3-433-03073-8. [Google Scholar]

- Hofstede, J. (Ed.) Generalplan Küstenschutz des Landes Schleswig-Holstein; Ministerium für Energiewende, Landwirtschaft, Umwelt, Natur und Digitalisierung des Landes Schleswig-Holstein: Kiel, Germany, 2022; Available online: https://www.schleswig-holstein.de/DE/fachinhalte/K/kuestenschutz/generalplanKuestenschutz.html (accessed on 16 July 2025).

- Balageas, D.; Fritzen, C.P.; Guemes, A. (Eds.) Structural Health Monitoring; ISTE: London, UK, 2006; ISBN 978-1-905209-01-9. [Google Scholar]

- BAW Merkblatt Damminspektion (MDI); Bundesanstalt für Wasserbau: Karlsruhe, Germany, 2017.

- Noel, A.B.; Abdaoui, A.; Elfouly, T.; Ahmed, M.H.; Badawy, A.; Shehata, M.S. Structural health monitoring using wireless sensor networks: A comprehensive survey. IEEE Commun. Surv. Tutor. 2017, 19, 1403–1423. [Google Scholar] [CrossRef]

- Sofi, A.; Regita, J.J.; Rane, B.; Lau, H.H. Structural health monitoring using wireless smart sensor network–An overview. Mech. Syst. Signal Process. 2022, 163, 108113. [Google Scholar] [CrossRef]

- Smarsly, K.; Dragos, K.; Kölzer, T. Sensorintegrierte digitale Zwillinge für das automatisierte Monitoring von Infrastrukturbauwerken. Bautechnik 2022, 99, 471–476. [Google Scholar] [CrossRef]

- Kornblum, W.; Schumann, R. Digitale Zwillinge ermöglichen fundierte Entscheidungen durch vernetzte Daten. Bautechnik 2023, 100, 198–205. [Google Scholar] [CrossRef]

- Jiang, F.; Ma, L.; Broyd, T.; Chen, K. Digital twin and its implementations in the civil engineering sector. Autom. Constr. 2021, 130, 103838. [Google Scholar] [CrossRef]

- Torzoni, M.; Tezzele, M.; Mariani, S.; Manzoni, A.; Willcox, K.E. A digital twin framework for civil engineering structures. Comput. Methods Appl. Mech. Eng. 2024, 418, 116584. [Google Scholar] [CrossRef]

- Smarsly, K.; Ahmad, M.E.; Peralta, P.; Al-Zuriqat, T.; Al-Nasser, H.; Dragos, K.; Chillón Geck, C. Digital Twins, Architectures, and Elements in Civil Engineering—A Multivocal Literature Review. In Advances in Information Technology in Civil and Building Engineering: Proceedings of the 20th International Conference on Computing in Civil and Building Engineering (ICCCBE); Springer: Cham, Switzerland, 2025. [Google Scholar]

- Schmidt, C. (Ed.) Digitainability—Digital Technologies for Environmentally Sustainable Economic Activity: Market Potential and Strategic Implications (Acatech STUDY); Acatech–National Academy of Science and Engineering: Munich, Germany, 2023. [Google Scholar]

- Ariyachandra, M.R.M.F.; Wedawatta, G. Digital Twin Smart Cities for Disaster Risk Management: A Review of Evolving Concepts. Sustainability 2023, 15, 11910. [Google Scholar] [CrossRef]

- Yun, S.-J.; Kwon, J.-W.; Kim, W.-T. A Novel Digital Twin Architecture with Similarity-Based Hybrid Modeling for Supporting Dependable Disaster Management Systems. Sensors 2022, 22, 4774. [Google Scholar] [CrossRef]

- Wenner, M.; Meyer-Westphal, M.; Herbrand, M.; Ullerich, C. The Concept of Digital Twin to Revolutionise Infrastructure Maintenance: The Pilot Project smart-BRIDGE Hamburg. In Proceedings of the 27th ITS World Congress, Hamburg, Germany, 11–15 October 2021. [Google Scholar]

- Pregnolato, M.; Gunner, S.; Voyagaki, E.; de Risi, R.; Carhart, N.; Gavriel, G.; Tully, P.; Tryfonas, T.; Macdonald, J.; Taylor, C. Towards Civil Engineering 4.0: Concept, workflow and application of Digital Twins for existing infrastructure. Autom. Constr. 2022, 141, 104421. [Google Scholar] [CrossRef]

- Brucherseifer, E.; Winter, H.; Mentges, A.; Mühlhäuser, M.; Hellmann, M. Digital Twin conceptual framework for improving critical infrastructure resilience. Automatisierungstechnik 2021, 69, 1062–1080. [Google Scholar] [CrossRef]

- Hakimi, O.; Liu, H.; Abudayyeh, O.; Houshyar, A.; Almatared, M.; Alhawiti, A. Data Fusion for Smart Civil Infrastructure Management: A Conceptual Digital Twin Framework. Buildings 2023, 13, 2725. [Google Scholar] [CrossRef]

- Yu, D.; He, Z. Digital twin-driven intelligence disaster prevention and mitigation for infrastructure: Advances, challenges, and opportunities. Nat. Hazards 2022, 112, 1–36. [Google Scholar] [CrossRef]

- Cheng, R.; Hou, L.; Xu, S. A Review of Digital Twin Applications in Civil and Infrastructure Emergency Management. Buildings 2023, 13, 1143. [Google Scholar] [CrossRef]

- Doğan, Ö.; Şahin, O.; Karaarslan, E. Digital Twin Based Disaster Management System Proposal: DT-DMS. J. Emerg. Comput. Technol. 2021, 1, 25–30. [Google Scholar]

- Riaz, K.; McAfee, M.; Gharbia, S.S. Management of Climate Resilience: Exploring the Potential of Digital Twin Technology, 3D City Modelling, and Early Warning Systems. Sensors 2023, 23, 2659. [Google Scholar] [CrossRef] [PubMed]

- Henriksen, H.J.; Schneider, R.; Koch, J.; Ondracek, M.; Troldborg, L.; Seidenfaden, I.K.; Kragh, S.J.; Bøgh, E.; Stisen, S. A New Digital Twin for Climate Change Adaptation, Water Management, and Disaster Risk Reduction (HIP Digital Twin). Water 2023, 15, 25. [Google Scholar] [CrossRef]

- Blankenbach, J.; Gries, T.; Heins, K.; Herlé, S.; Ingebrandt, S.; Kimm, M.; Klopries, E.-M.; Schüttrumpf, H.; Wetzel, L. Sicherheit durch smarte Bauwerke. RWTH-Themen Forschungsmagazin 2021, 2021, 52–55. [Google Scholar]

- Dittmer, C.; Drews, K.; Eversheim, A. Governance und Kommunikation im Krisenfall des Hochwasserereignisses im Juli 2021; DKKV-Schriftenreihe Nr., 63; Deutsches Komitee Katastrophenvorsorge, e.V.: Bonn, Germany, 2024; ISBN 978-3-933181-73-2. [Google Scholar]

- Bersan, S.; Koelewijn, A.; Simonini, P. Application of distributed temperature sensors in piping-prone dikes. In FMGM 2015: Proceedings of the Ninth Symposium on Field Measurements in Geomechanics; Australian Centre for Geomechanics: Perth, Australia, 2015; pp. 475–486. [Google Scholar]

- de Vries, G.; Koelewijn, A.R.; Hopman, V. IJkdijk Full Scale Underseepage Erosion (Piping) Test: Evaluation of Innovative Sensor Technology. In Proceedings of the 5th International Conference on Scour and Erosion (ICSE-5), San Francisco, CA, USA, 7–10 November 2010; pp. 649–657. [Google Scholar] [CrossRef]

- Kuratorium für Forschung im Küsteningenieurwesen (Ed.) Die Küste—Entwicklung eines sensor- und risikobasierten Frühwarnsystems für Seedeiche—EarlyDike; Bundesanstalt für Wasserbau: Karlsruhe, Germany, 2021; Volume 90, ISBN 978-3-939230-78-6. [Google Scholar]

- Federal Waterways Engineering and Research Institute. MDI-DE—Marine Data Infrastructure Germany—Ocean Data. n.d. Available online: https://projekt.mdi-de.org/en/mdi-de-en/ (accessed on 7 October 2024).

- Federal Agency for Cartography and Geodesy. SDI Germany Geodateninfrastruktur Deutschland. n.d. Available online: https://www.gdi-de.org/GDI-DE (accessed on 7 October 2024).

- Federal Agency for Cartography and Geodesy. INSPIRE Geodateninfrastruktur Deutschland. n.d. Available online: https://www.gdi-de.org/en/INSPIRE (accessed on 7 October 2024).

- Assing, M.; Bange, M.; Bartsch, A.; Gutierrez, R.; Fritsch, D.; Hahn, O.; Harke, T.; Hartung, R.; Herbrand, M.; Käding, M.; et al. DBV Heft 51-Digitaler Zwilling: Strategie für den Bestandserhalt; Deutscher Beton- und Bautechnik Verein e.V.: Berlin, Germany, 2021. [Google Scholar]

- Lee, J.; Yoo, S.; Kim, C.; Sohn, H. Automatic levee surface extraction from mobile LiDAR data using directional equalization and projection clustering. Int. J. Appl. Earth Obs. Geoinf. 2023, 116, 103143. [Google Scholar] [CrossRef]

- Fritsch, C.; Voigt, C.; Burkhardt, J.; Arndt, R.; Marx, S. Digitale Bauwerksdiagnose—Ein Projekt zur digitalen Transformation. Bautechnik 2024, 3, 181–189. [Google Scholar] [CrossRef]

- Condemine, C.; Grau, L.; Masson, Y.; Aubry, S. Live Digital Twin for Hydraulic Structures Fatigue Estimation. In Proceedings of the PIANC Smart Rivers 2022; Springer Nature: Singapore, 2023; pp. 494–505. [Google Scholar]

- Brötzmann, J.; Grunert, G.; Thiele, C.-D.; Rüppel, U.; Lorenzen, S. BIM-Integration von Sensordaten aus dem Monitoring von Eisenbahnbrücken im Betrieb. Bautechnik 2024, 3, 166–173. [Google Scholar] [CrossRef]

- Cremona, C.; Santos, J. Structural Health Monitoring as a Big-Data Problem. Struct. Eng. Int. 2018, 28, 243–253. [Google Scholar] [CrossRef]

- Theiler, M.; Dragos, K.; Smarsly, K. BIM-based design of structural health monitoring systems. In Proceedings of the 11th International Workshop on Structural Health Monitoring (IWSHM), Stanford, CA, USA, 12–14 September 2017. [Google Scholar]

- buildingSMART: Industry Foundation Classes Version 4.1.0.0. 2020. Available online: https://standards.buildingsmart.org/IFC/RELEASE/IFC4_1/FINAL/HTML/ (accessed on 8 April 2025).

- Docker. Docker Desktiop: The #1 Containerization Tool for Developers. 2024. Available online: https://www.docker.com/products/docker-desktop/ (accessed on 2 January 2025).

- Chang, H.-F.; Shokrolah Shirazi, M. Integration with 3D Visualization and IoT-Based Sensors for Real-Time Structural Health Monitoring. Sensors 2021, 21, 6988. [Google Scholar] [CrossRef]

- DESITE BIM User Manual; Thinkproject Deutschland GmbH: Munich, Germany, 2023; Available online: https://focusbim.de/files/content/images/DESITE%20BIM/DESITE%20User%20Documentation_3.2.pdf (accessed on 16 July 2025).

- Fraunhofer Institute of Optronics, System Technologies and Image Exploitation FROST®-Server—An open source implementation of OGC SensorThings API. n.d. Available online: https://www.iosb.fraunhofer.de/en/projects-and-products/frost-server.html (accessed on 20 June 2024).

- SensorUp Inc. OGC SensorThings API Documentation. n.d. Available online: https://developers.sensorup.com/docs/ (accessed on 20 June 2024).

| Requirement | Description | Requirement |

|---|---|---|

| As-built data | Representation of as-built geometry and integration of physical/geotechnical parameters | Modeling based on documentation, site measurements, and geo-survey methods |

| As-is data | Integration of as-is condition data based on sensor network measurements | Integrating constant sensor data stream |

| Localization and contextualization of damage | Establishing a relationship between damage and structural elements | Object-oriented reference of damage objects in a digital twin environment |

| Data acquisition and management | Communication between sensor networks and a digital twin environment | Permanent measurements and automated storage. Effective data reduction and filtering |

| Data evaluation | Data analysis regarding comprehensible condition indicators adapted to the interests of stakeholders | Automated data analysis based on mathematical models |

| Data visualization | Visualization of data for structural condition assessment | Customizable view with either continuous or predefined time frames |

| Usability | Intuitive user interface of the digital twin environment | Customized user interface considering the interests of different stakeholders |

| Documentation | Effortless documentation of states and changes to ensure plausibility and transparency for model-based decision making | Automated export of documents based on analyzed sensor data |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bornholdt, M.; Herbrand, M.; Smarsly, K.; Zehetmaier, G. Digital-Twin-Based Structural Health Monitoring of Dikes. CivilEng 2025, 6, 39. https://doi.org/10.3390/civileng6030039

Bornholdt M, Herbrand M, Smarsly K, Zehetmaier G. Digital-Twin-Based Structural Health Monitoring of Dikes. CivilEng. 2025; 6(3):39. https://doi.org/10.3390/civileng6030039

Chicago/Turabian StyleBornholdt, Marike, Martin Herbrand, Kay Smarsly, and Gerhard Zehetmaier. 2025. "Digital-Twin-Based Structural Health Monitoring of Dikes" CivilEng 6, no. 3: 39. https://doi.org/10.3390/civileng6030039

APA StyleBornholdt, M., Herbrand, M., Smarsly, K., & Zehetmaier, G. (2025). Digital-Twin-Based Structural Health Monitoring of Dikes. CivilEng, 6(3), 39. https://doi.org/10.3390/civileng6030039