Optimizing the Use of Fly Ash as Partial Replacement of Fine Aggregate and Cement in Portland Cement Concrete Mixes

Abstract

1. Introduction

2. Materials and Experimental Program

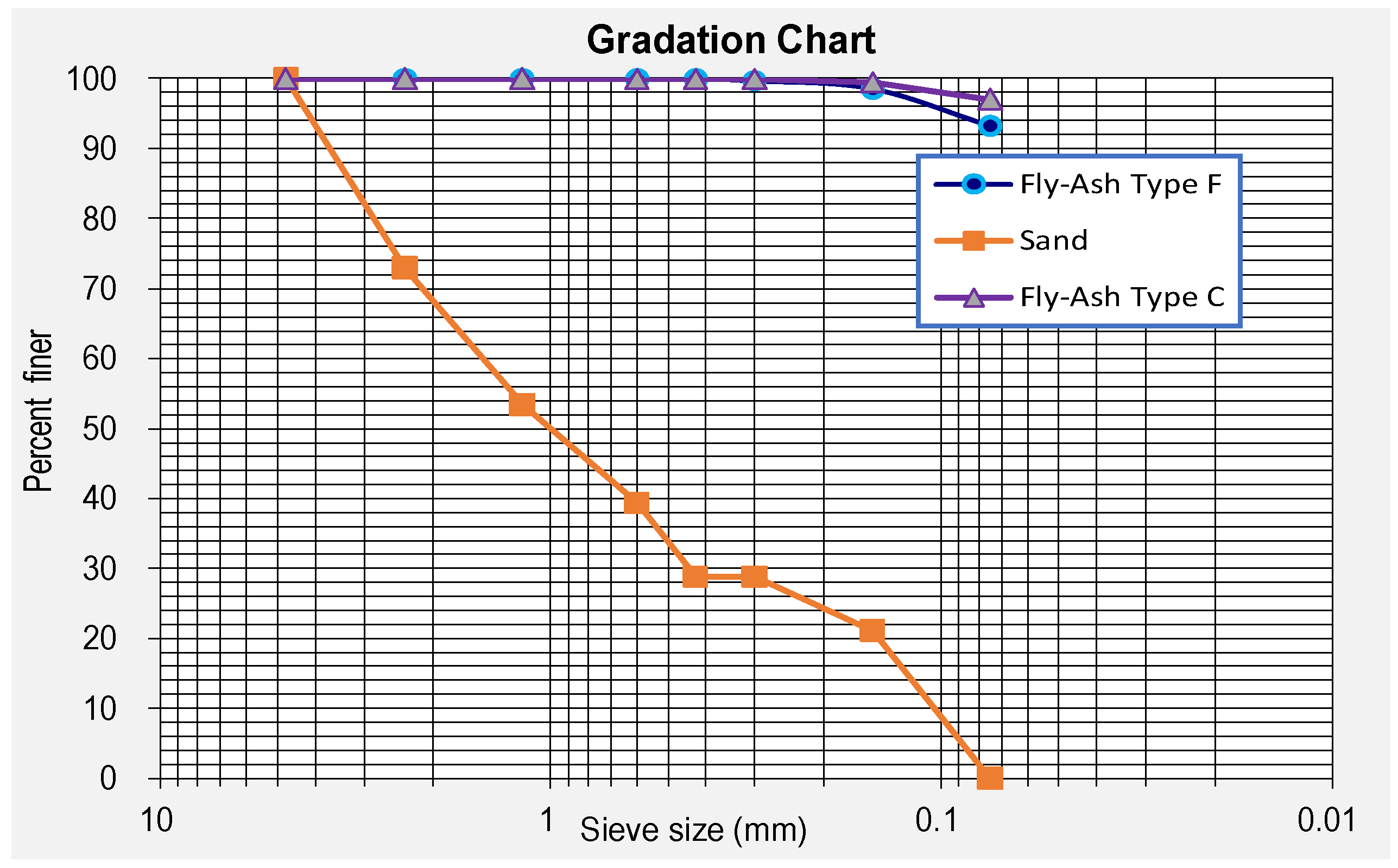

2.1. Fly Ash

2.2. Concrete Batches and Samples

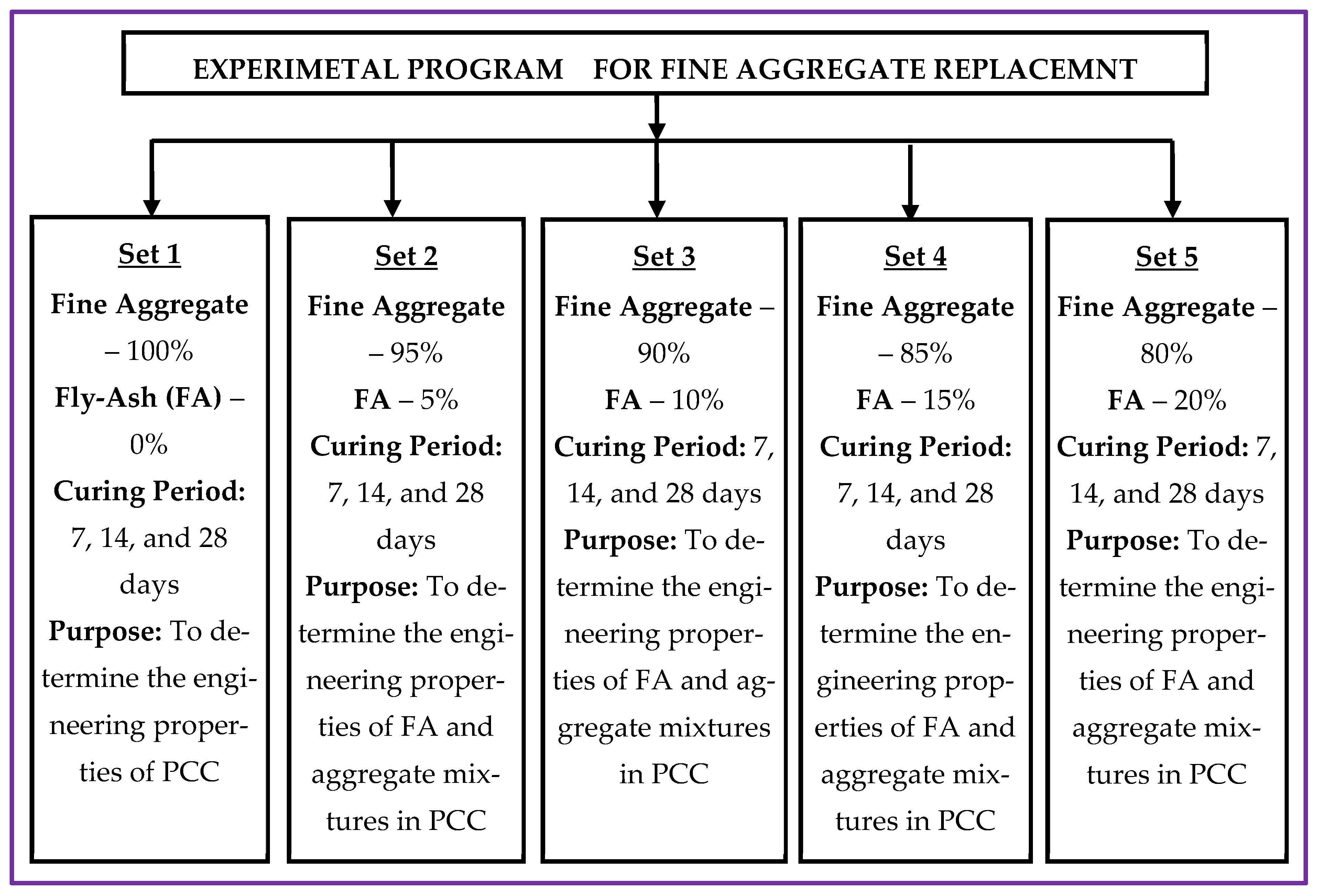

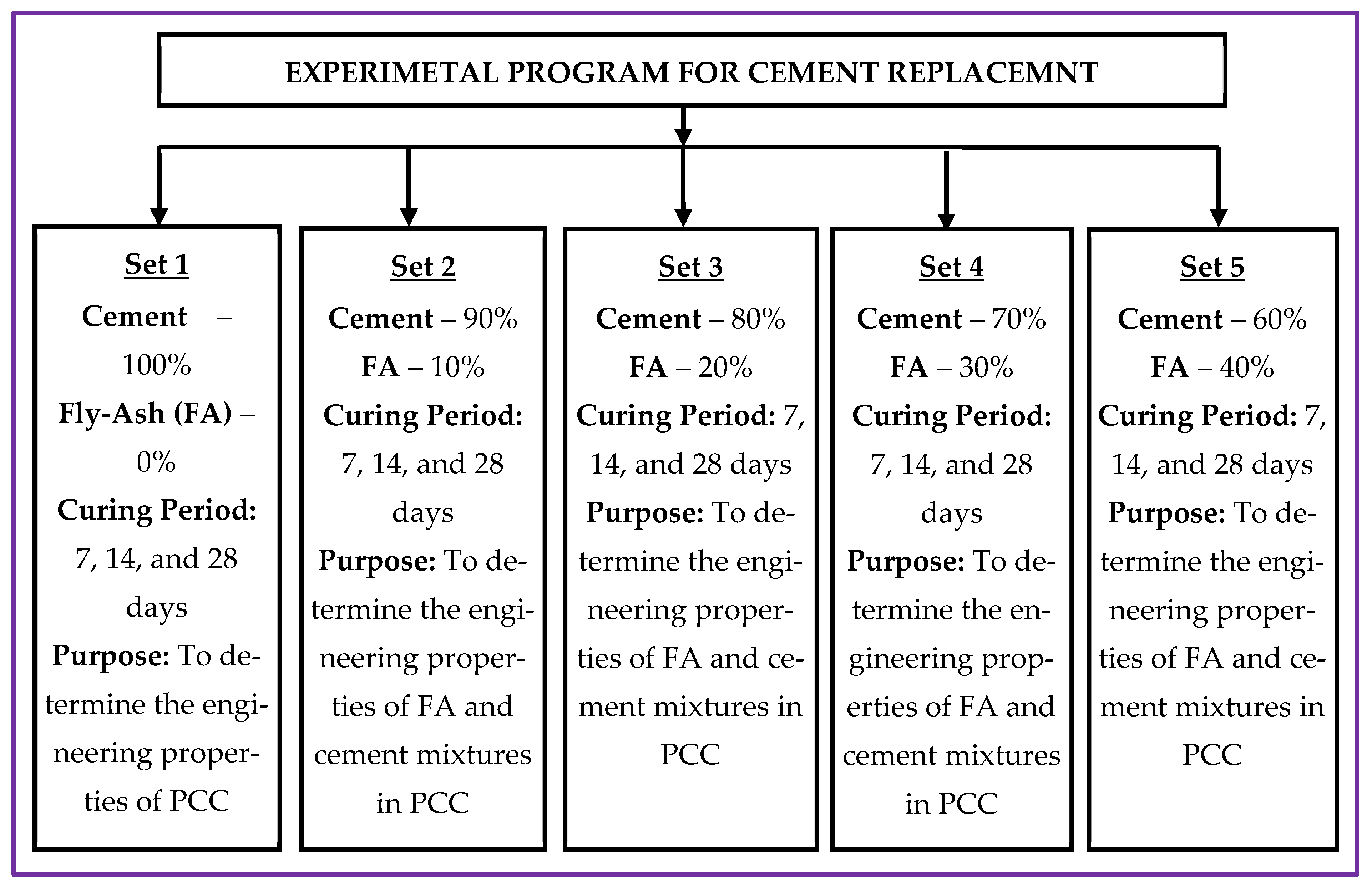

2.3. Experimental Program

3. Results and Discussions

3.1. Impact of FA on Workability

3.2. Impact of FA on Strength and Durability

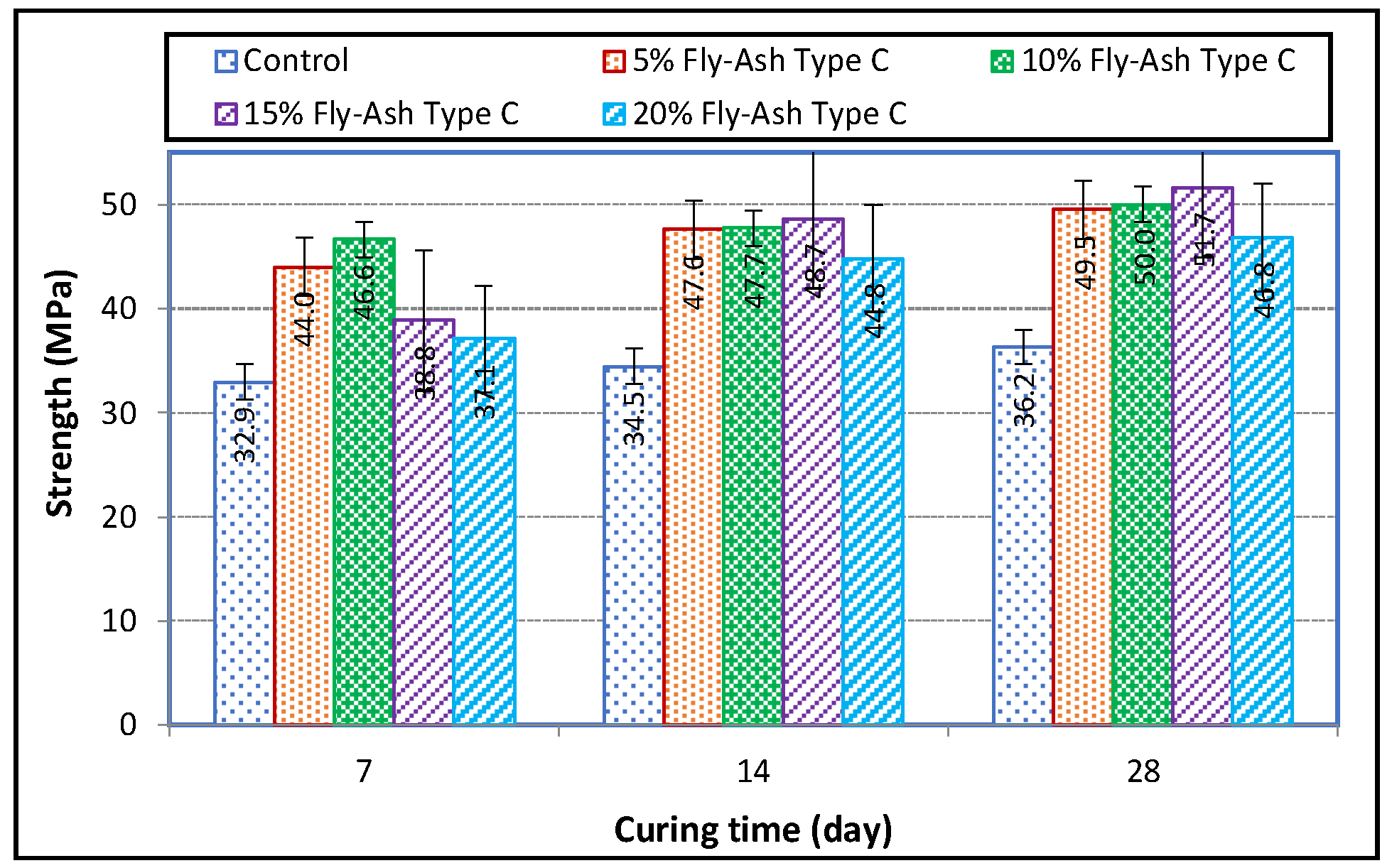

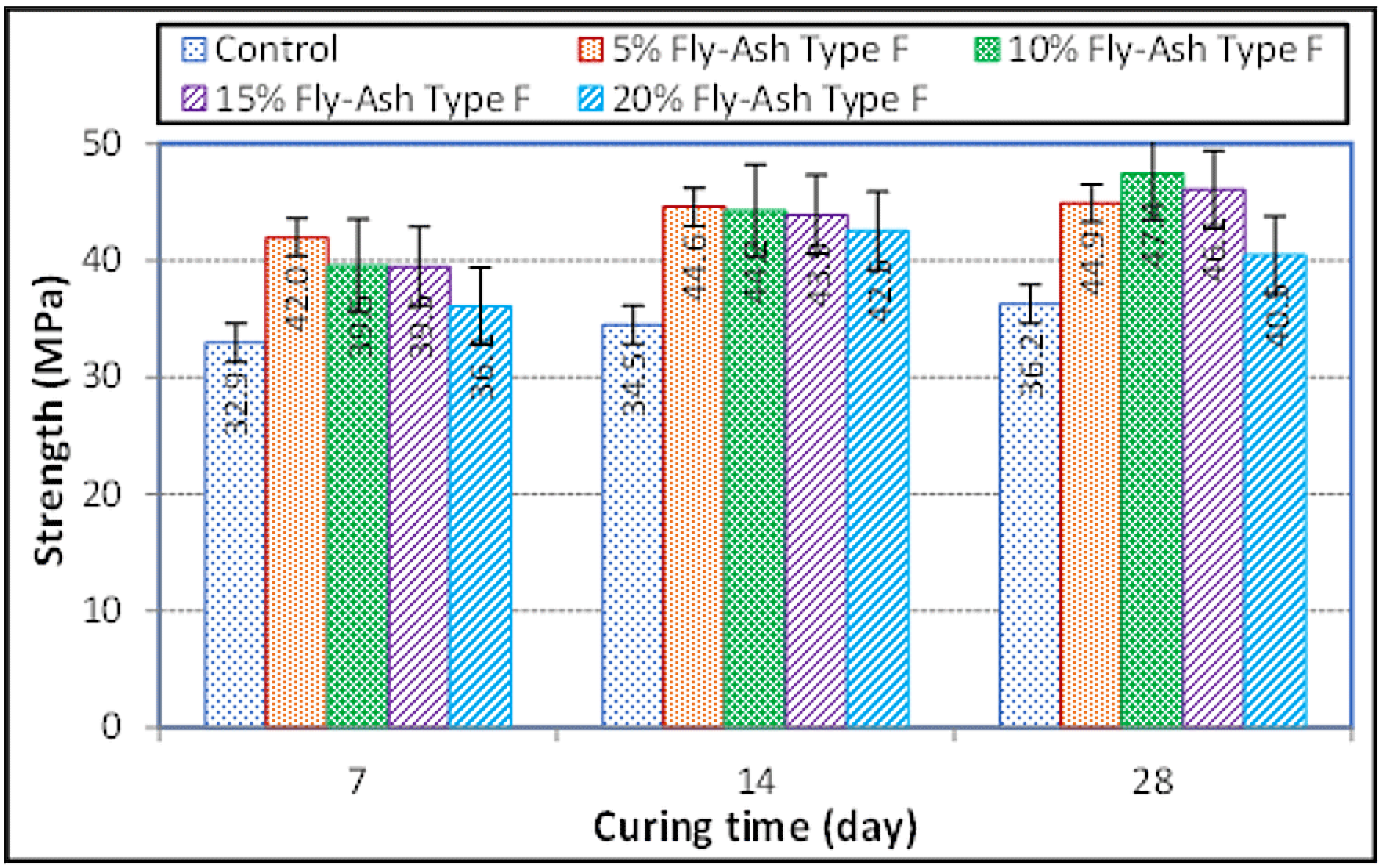

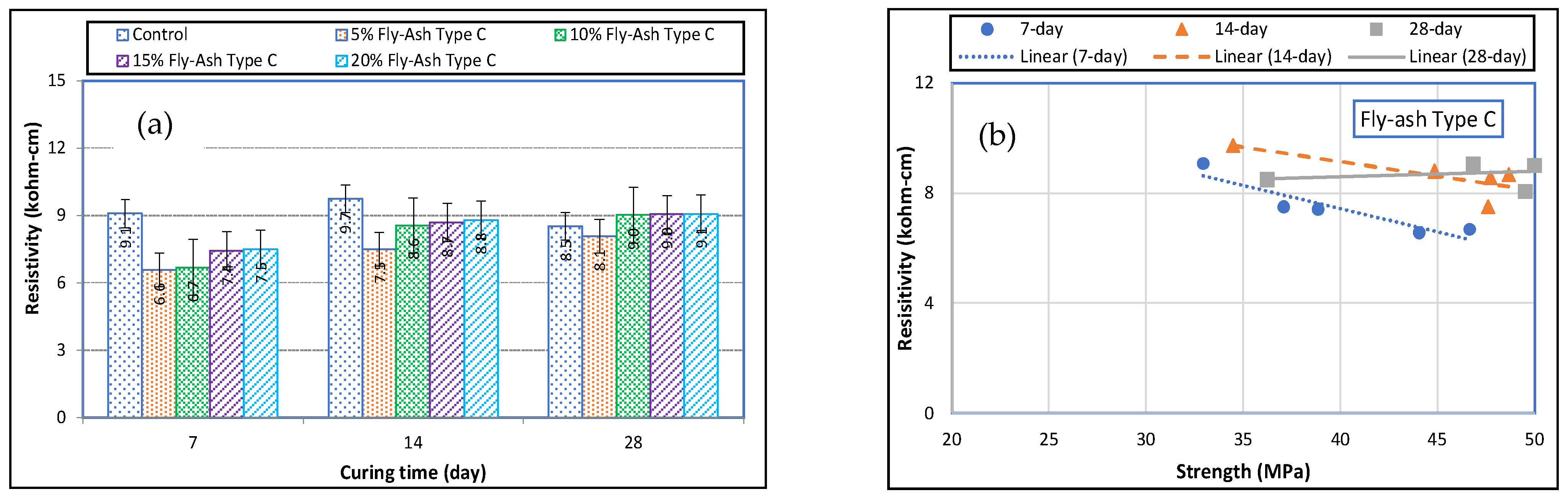

3.2.1. Fine Aggregate Replacement

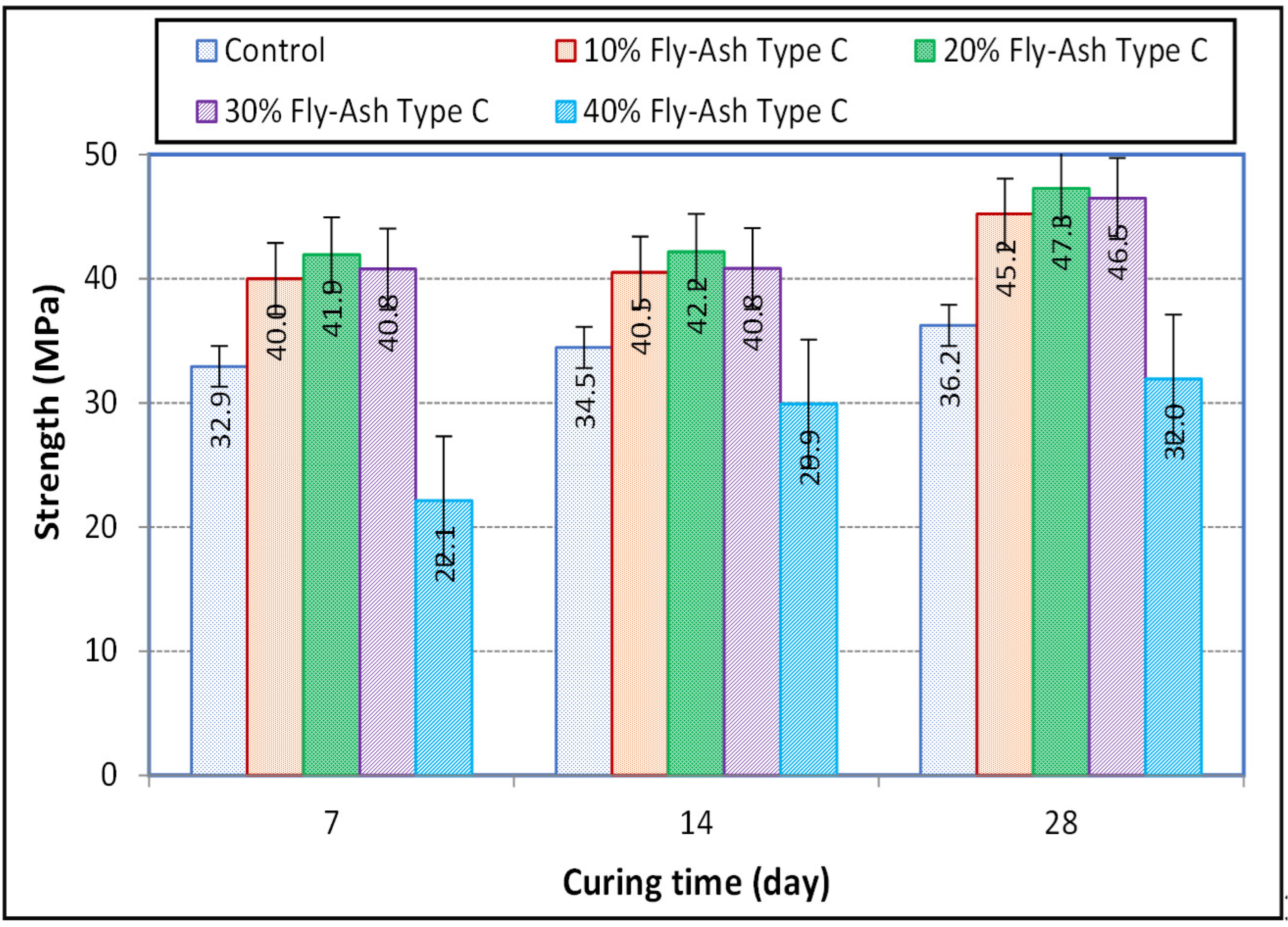

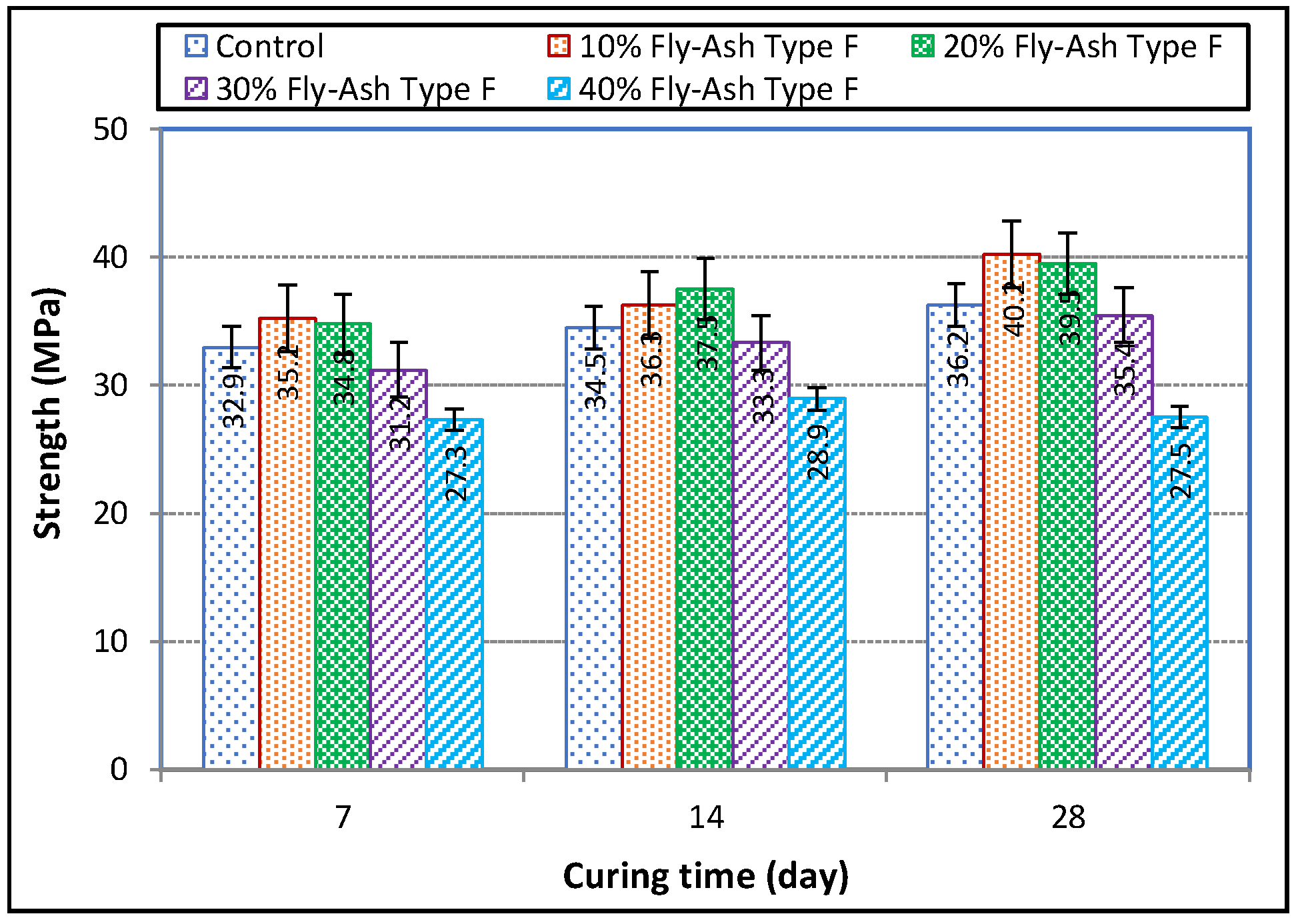

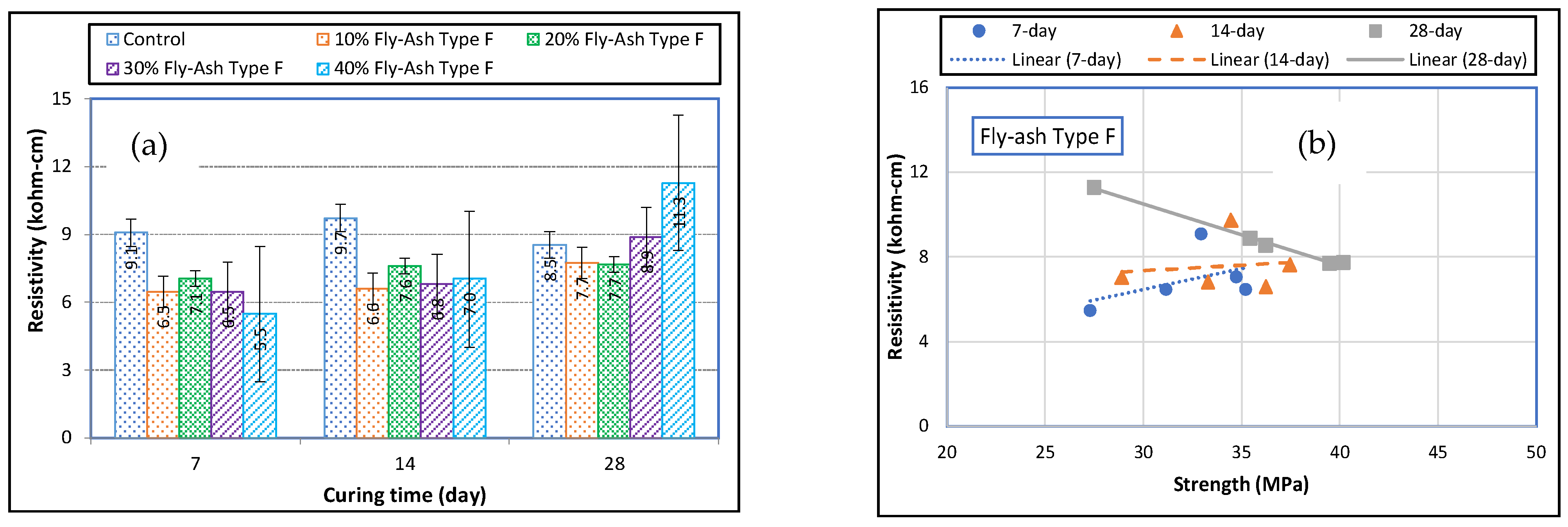

3.2.2. Cement Replacement

4. Conclusions, Recommendations, and Future Research

4.1. Conclusions

4.2. Recommendations and Future Research

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- ACAA American Coal Ash Association (ACAA). 2016 Production and Use Survey Results News Release. Available online: https://acaa-usa.org/publications/production-use-reports/ (accessed on 28 May 2018).

- Al-Sharif, M.M.; Attom, F.M. A geoenvironmental application of burned wastewater sludge ash in soil stabilization. Environ. Earth Sci. 2014, 17, 2453–2463. [Google Scholar] [CrossRef]

- Mahvash, S.; López-Querol, S.; Bahadori-Jahromi, A. Effect of class F fly-ash on fine sand compaction through soil stabilization. Struct. Eng. Civ. Eng. 2007, 3, e00274. [Google Scholar] [CrossRef] [PubMed]

- Yadav, A.K.; Gaurav, K.; Kishor, R.; Suman, S.K. Stabilization of alluvial soil for subgrade using rice husk ash, sugarcane bagasse ash and cow dung ash for rural roads. Int. J. Pavement Res. Technol. 2016, 10, 254–261. [Google Scholar] [CrossRef]

- White, D.J.; Harrington, D.S.; Thomas, Z. Fly-Ash Soil Stabilization for Non-Uniform Subgrade Soil. Volume I: Engineering Properties and Construction Guidelines; IHRB Project TR-461, FHWA Project 4; Iowa Highway Research Board: Ames, IA, USA, 2005.

- Li, H.; Zhang, L. Fly ash as a fine aggregate replacement in concrete. Cem. Concr. Compos. 2016, 71, 38–47. [Google Scholar]

- Gupta, S.; Rani, P.; Sharma, P. Use of fly ash for the development of sustainable construction materials. In New Materials in Civil Engineering; Butterworth-Heinemann: Oxford, UK, 2020; pp. 677–689. [Google Scholar] [CrossRef]

- Siddique, R. Effect of fly ash on the properties of concrete. Constr. Build. Mater. 2015, 87, 103–107. [Google Scholar]

- Zhang, S. Application of fly ash in concrete: A review. J. Build. Mater. 2017, 15, 91–99. [Google Scholar]

- Rashid, M.M.; Aslam, M.M.; Zaman, M. Fly ash as a sustainable alternative material in concrete mixes: A review. J. Sustain. Dev. 2016, 9, 140–151. [Google Scholar]

- Kumar, R.; Kaur, H.; Bansal, P. Effect of fly ash on concrete properties. Int. J. Civ. Eng. 2018, 8, 125–132. [Google Scholar]

- Padhy, P.K.; Mishra, P.K. Fly ash utilization for sustainable construction: A review. J. Clean. Prod. 2021, 319, 128679. [Google Scholar]

- Fauzi, A.; Nuruddin, M.F.; Malkawi, A.B.; Abdullah, M.M.A.B. Study of fly ash characterization as a cementitious material. Procedia Eng. 2016, 148, 487–493. [Google Scholar] [CrossRef]

- Souliman, M.I.; Abd El-Hakim, R.; Davis, M.; Gc, H.; Walubita, L. Mechanistic and Economic Impacts of Using Asphalt Rubber Mixtures at Various Vehicle Speeds. Adv. Civ. Eng. Mater. 2018, 7, 347–359. [Google Scholar] [CrossRef]

- Karim, M.A.; Corazzini, B. The current status of MSW disposal and energy production: A brief review of waste incineration. MOJ Ecol. Environ. Sci. 2019, 4, 34–37. [Google Scholar] [CrossRef]

- Georgia Power’s Plant Bowen Environmental Management System. Available online: http://www.georgiapower.com/company/research-conservation-and-stewardship/management-closures/plant-list/plant-bowen.html (accessed on 21 September 2020).

- Karim, M.A.; Hassan, A.S.; Kaplan, A. Optimization of Soil to Fly-Ash Mix Ratio for Enhanced Engineering Properties of Clayey Sand for Subgrade Use. Appl. Sci. 2020, 10, 7038. [Google Scholar] [CrossRef]

- Hemalatha, T.; Ramaswamy, A. A review on fly ash characteristics—Towards promoting high volume utilization in developing sustainable concrete. J. Clean. Prod. 2017, 147, 546–559. [Google Scholar] [CrossRef]

- Karim, M.A.; Seo, Y.; Vargas, B.; Rosales, K.; Parrar, C.; Henry, M.; Yun, A. Optimum Use of Recycled Waste Materials as Partial Replacement of Fine Aggregate in Portland Cement Concrete Mixes. J. Waste Manag. Recycl. Technol. 2024, 2, 1–7. [Google Scholar] [CrossRef]

- Lübeck, A.; Gastaldini, A.L.G.; Barin, D.S.; Siqueira, H.C. Compressive strength and electrical properties of concrete with white Portland cement and blast-furnace slag. Cem. Concr. Compos. 2012, 34, 392–399. [Google Scholar] [CrossRef]

- Chen, C.-T.; Chang, J.-J.; Yeih, W. The effects of specimen parameters on the resistivity of concrete. Constr. Build. Mater. 2014, 71, 35–43. [Google Scholar] [CrossRef]

- de Bem, D.H.; Lima, D.P.B.; Medeiros-Junior, R.A. Effect of chemical admixtures on concrete’s electrical resistivity. Int. J. Build. Pathol. Adapt. 2018, 36, 174–187. [Google Scholar] [CrossRef]

- Mendes, S.E.; Oliveira, R.L.; Cremonez, C.; Pereira, E.; Pereira, E.; Medeiros-Junior, R.A. Electrical resistivity as a durability parameter for concrete design: Experimental data versus estimation by mathematical model. Constr. Build. Mater. 2018, 192, 610–620. [Google Scholar] [CrossRef]

- Medeiros-Junior, R.A.; Lima, M.G. Electrical resistivity of unsaturated concrete using different types of cement. Constr. Build. Mater. 2016, 107, 11–16. [Google Scholar] [CrossRef]

- Araujo, C.C.; Meira, G.R. Correlation between concrete strength properties and surface electrical resistivity. Rev. IBRACON Struct. Mater. J. 2022, 15, e15103. [Google Scholar] [CrossRef]

- ASTM C143; Standard Test Method for Slump of Hydraulic-Cement Concrete. ASTM International: West Conshohocken, PA, USA, 2015. [CrossRef]

- ASTM C1611; Standard Test Method for Slump Flow of Self-Consolidating Concrete. ASTM International: West Conshohocken, PA, USA, 2021. [CrossRef]

- ASTM C1202; Standard Test Method for Electrical Indication of Concrete’s Ability to Resist Chloride Ion Penetration. ASTM International: West Conshohocken, PA, USA, 2022. [CrossRef]

- ASTM C666; Standard Test Method for Resistance of Concrete to Rapid Freezing and Thawing. ASTM International: West Conshohocken, PA, USA, 2017. [CrossRef]

- ASTM C1012; Standard Test Method for Length Change of Hydraulic-Cement Mortars Exposed to a Sulfate Solution. ASTM International: West Conshohocken, PA, USA, 2024. [CrossRef]

- Seo, Y.; Kim, J.H. Synergistic Impact of Entrained Air and Fly Ash on Chloride Ingress in Concrete Pavement: An Electrical Resistivity Model Approach. Buildings 2025, 15, 1215. [Google Scholar] [CrossRef]

- Menéndez, E.; Sanjuán, M.; García-Roves, R.; Argiz, C.; Recino, H. Durability of Blended Cements Made with Reactive Aggregates. Materials 2021, 14, 2948. [Google Scholar] [CrossRef] [PubMed]

- Bediako, M.; Adjaottor, A.A.; Gawu, S.K.Y.; Amankwah, E.O. Compressive strength and durability properties of pozzolan obtained from co-fired clay and rice husk. Cogent Eng. 2020, 7, 1811453. [Google Scholar] [CrossRef]

- Sanjuán, M.Á.; Andrade, C.; Mora, P.; Zaragoza, A. Carbon Dioxide Uptake by Cement-Based Materials: A Spanish Case Study. Appl. Sci. 2020, 10, 339. [Google Scholar] [CrossRef]

- Abo Hashem, I.A.; Gaber, G.A.; Ahmed, A.S.I.; Gha, N.A.A. Assessment of blended cement containing waste basalt powder: Physicomechanical and electrochemical impedance spectroscopy investigations. Discov. Appl. Sci. 2024, 6, 380. [Google Scholar] [CrossRef]

- Moropoulou, A.; Bakolas, A.; Anagnostopoulou, S. Composite materials in ancient structures. Cement. Concr. Compos. 2005, 27, 295–300. [Google Scholar] [CrossRef]

| Element | Oxide | Concentration (%) | |

|---|---|---|---|

| Type C | Type F | ||

| Calcium (Ca) | CaO | 15.1–54.8 | 0.50–14.0 |

| Silicon (Si) | SiO2 | 11.8–46.4 | 37.0–62.1 |

| Aluminum (Al) | Al2O3 | 2.6–20.5 | 16.6–35.6 |

| Iron (Fe) | Fe2O3 | 1.4–15.6 | 2.6–21.2 |

| Magnesium (Mg) | MgO | 0.1–6.7 | 0.3–5.2 |

| Potassium (K) | K2O | 0.3–9.3 | 0.1–4.1 |

| Sodium (Na) | Na2O | 0.2–2.8 | 0.1–3.6 |

| Sulfur (S) | SO3 | 1.4–12.9 | 0.02–4.7 |

| Phosphorus (P) | P2O5 | 0.2–0.4 | 0.1–1.7 |

| Carbon (C) | TiO2 | 0.6–1.0 | 0.5–2.6 |

| Manganese (Mn) | MnO | 0.03–0.2 | 0.03–0.1 |

| Ingredient | Target |

|---|---|

| Cement (Type I/II) | 448.52 kg/m3 (28.0 lb/ft3) |

| Fine aggregate (#810) | 744.86 kg/m3 (46.5 lb/ft3) |

| Coarse aggregate (#57) | 983.54 kg/m3 (61.4 lb/ft3) |

| Water | 201.83 kg/m3 (12.6 lb/ft3) |

| Strength (28-day) | 20.68 MPa (3000 psi) |

| Criteria | FA Type C | FA Type F |

|---|---|---|

| Early strength (7-day) |  Higher Higher

|  Lower Lower

|

| Long-term strength (28-day) |  Higher Higher

|  Slightly lower Slightly lower

|

| Best FA percentage | 10% | 10% |

| Performance at high FA (>10%) |  Holds strength better Holds strength better

|  Drops more Drops more

|

| Pozzolanic reactivity |  Faster Faster

|  Slower Slower

|

| Best use cases | Where early strength is needed (e.g., precast concrete, rapid construction). | Where long-term durability is prioritized (e.g., mass concrete, sulfate-resistant structures). |

| Criteria | FA Type C | FA Type F | Better Option |

|---|---|---|---|

| Strength development | High early strength due to higher calcium content | Moderate initial strength, but improves with curing | Type C (early strength), Type F (Long-Term Strength) |

| Resistivity (durability indicator) | Higher resistivity (better durability) | Lower resistivity (more conductive) | Type C (better for durability) |

| Optimal replacement (%) | 20–30% for best performance | 10–20% for balanced strength and durability | Type C (more effective at higher dosages) |

| Pozzolanic activity | Faster reaction, and contributes to early strength | Slower reaction, and enhances long-term strength | Type C (faster reaction), Type F (long-term gain) |

| Workability | Similar workability but may need more water | Improves workability, and reduces water demand | Type F (better workability) |

| Best use cases | Pavements, precast elements, applications and needing early strength | High-performance concrete, marine environments, long-term strength applications | Depends on application |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Karim, M.A.; Seo, Y.; Alamayreh, I.; Suttle, S. Optimizing the Use of Fly Ash as Partial Replacement of Fine Aggregate and Cement in Portland Cement Concrete Mixes. CivilEng 2025, 6, 33. https://doi.org/10.3390/civileng6030033

Karim MA, Seo Y, Alamayreh I, Suttle S. Optimizing the Use of Fly Ash as Partial Replacement of Fine Aggregate and Cement in Portland Cement Concrete Mixes. CivilEng. 2025; 6(3):33. https://doi.org/10.3390/civileng6030033

Chicago/Turabian StyleKarim, M. A., Youngguk Seo, Ibrahim Alamayreh, and Stuart Suttle. 2025. "Optimizing the Use of Fly Ash as Partial Replacement of Fine Aggregate and Cement in Portland Cement Concrete Mixes" CivilEng 6, no. 3: 33. https://doi.org/10.3390/civileng6030033

APA StyleKarim, M. A., Seo, Y., Alamayreh, I., & Suttle, S. (2025). Optimizing the Use of Fly Ash as Partial Replacement of Fine Aggregate and Cement in Portland Cement Concrete Mixes. CivilEng, 6(3), 33. https://doi.org/10.3390/civileng6030033