The Use of Waste Ceramic in Concrete: A Review

Abstract

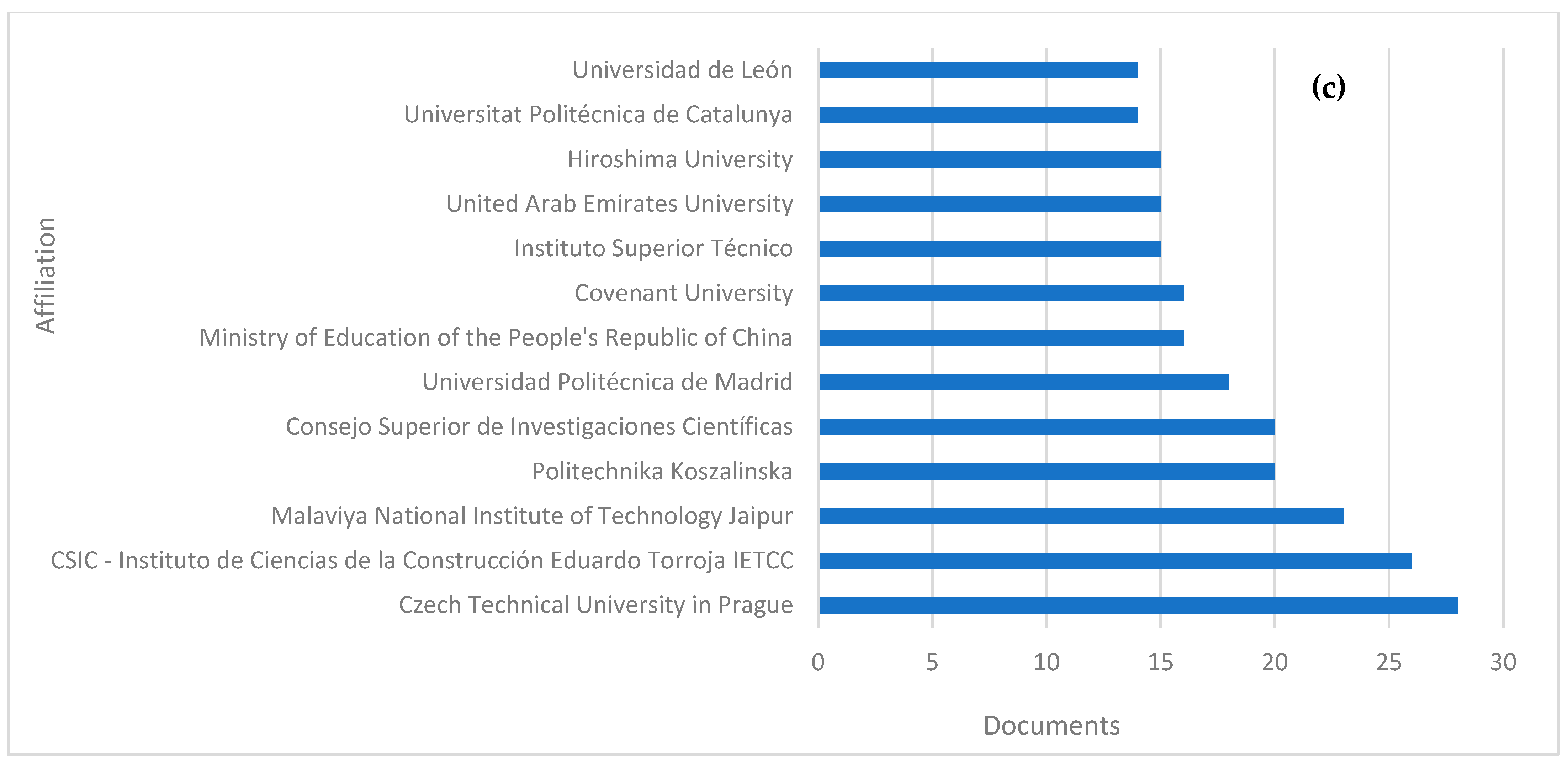

1. Introduction

2. Ceramic

2.1. Raw Materials of Ceramic

2.1.1. Clay

- (i)

- Kaolinite: This involves three components, kaolinite, dickite, and nacrite (Al2Si2O5(OH)4). It is largely used in ceramic production with a structure containing alternating layers of T-O. The properties of kaolinite result from the weak bond with little water that can penetrate the interlayer. These are low-drying shrinkage and plasticity, easy shattering, and poor workability and toughness. Thus, kaolinite is used as a base of very fine and refined paste for the production of porcelain and earthenware. The minerals have existed naturally in China, Germany, France, Spain, and England [34,35].

- (ii)

- Illite ((K, H3O)(Al, Mg, Fe)2 (Si, Al)4O10[(OH2),(H2O)]): This represents the most common form of clay and the main constituent of argillaceous and shale rocks. The structure is T-O-T, with hydrated potassium occupying the space between clay crystals. The properties of illite are no swelling, adequate plasticity and workability, and change in color from grey to red and black depending on the amount of ion oxides calcite, and pyrite, as well as the process of firing. This type of clay is common in the Mediterranean area [36,37].

- (iii)

- Smectite: This involves several minerals, including montmorillonite ((Na, Ca)0.3(Al, Mg)2Si4O10(OH)2n (H2O)). The structure is T-O-T with cations such as Ca++, Mg++, and Na+ capable of surrounding themselves with molecules of water to form interlayer water swelling phenomena. This provides difficulties in modeling, string shrinkage, and significant plasticity. Thus, lean clays are added for ceramic paste. This type is found in particular in France, Germany, Japan, and the USA [32,38].

2.1.2. Non-Clay Materials

2.2. Production Technology

2.3. Waste Ceramic

- Recycled Ceramic tile and bricks

- Porcelain

- Glass

3. Discussion

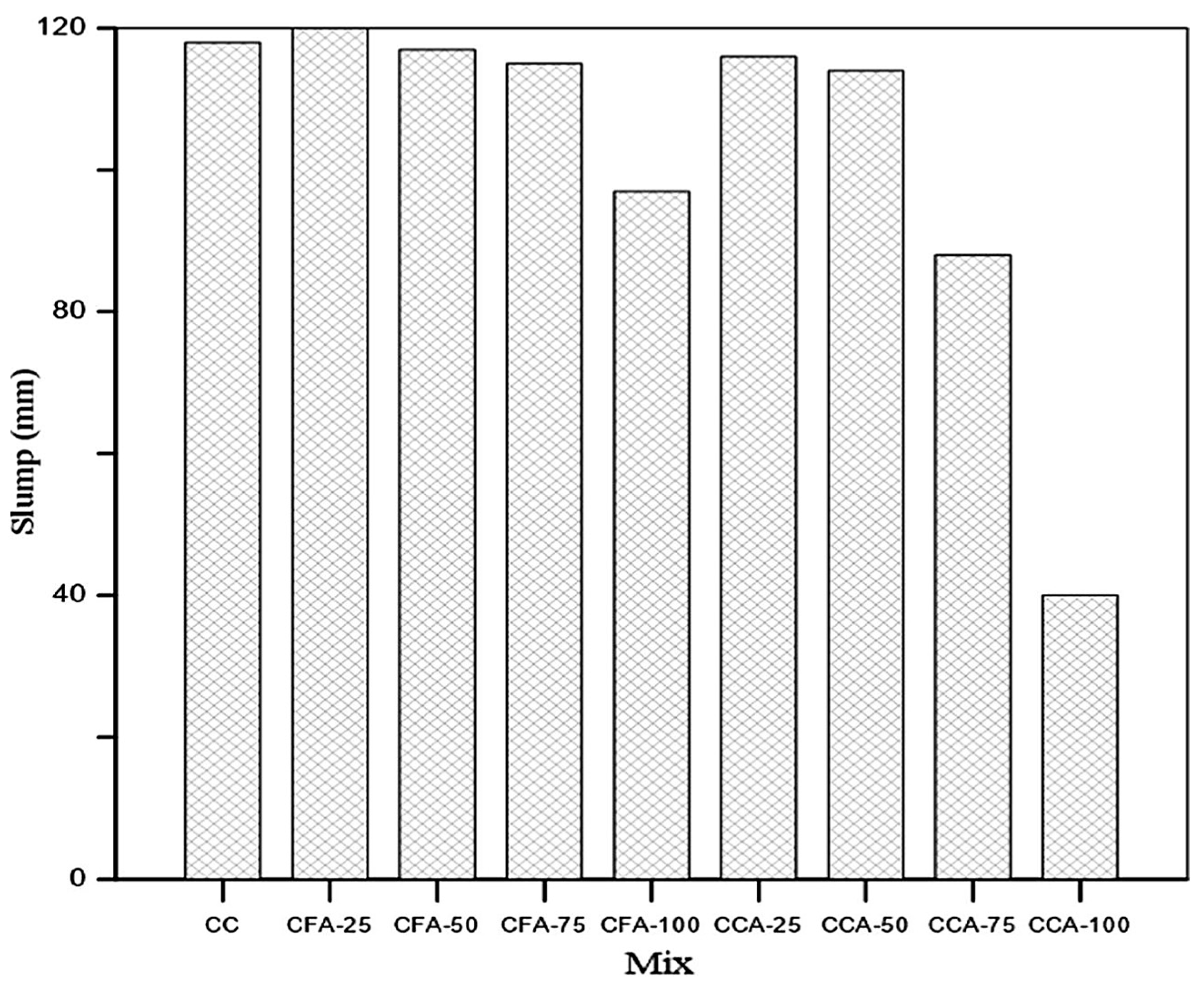

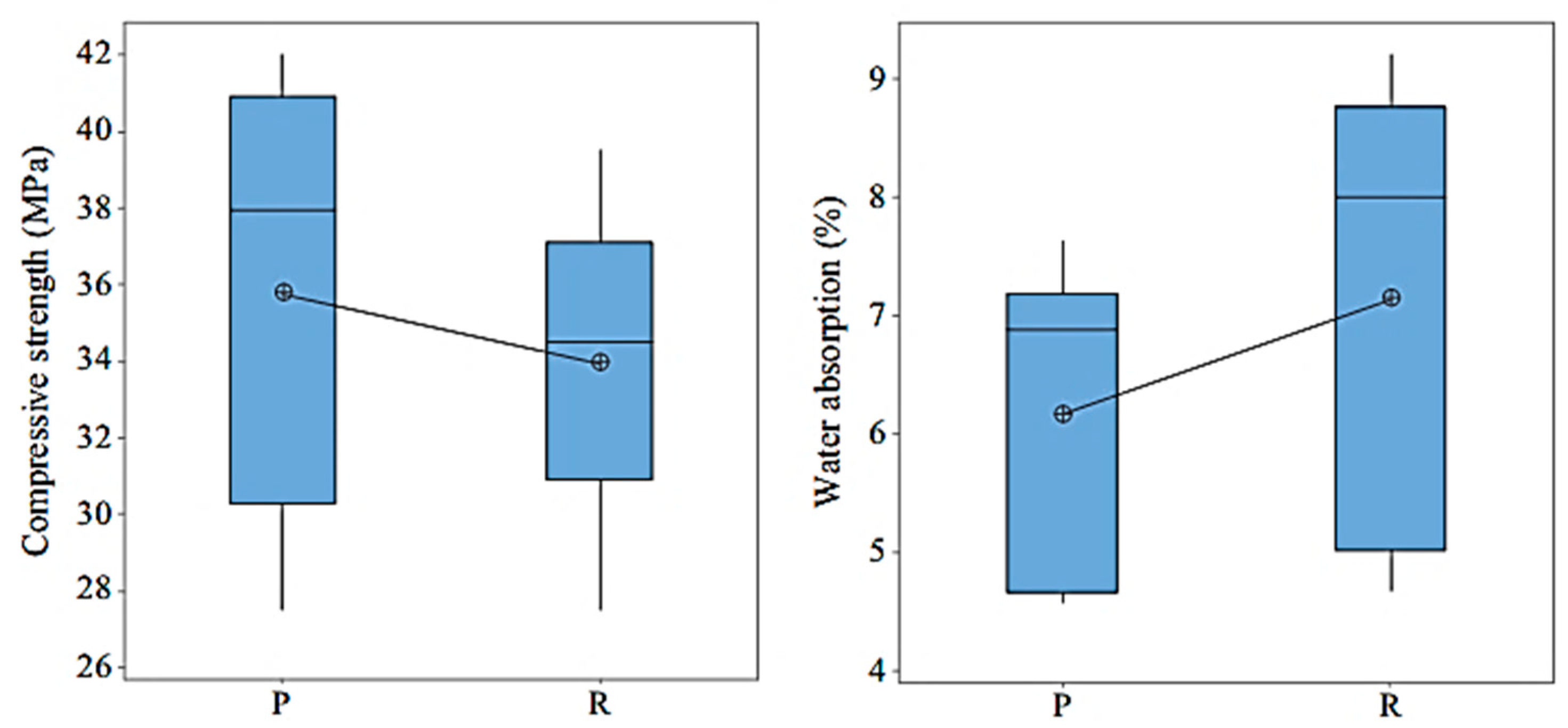

3.1. Replacement of Aggregates

3.2. Replacement of Cement

4. Conclusions and Future Directions

- The use of ceramic waste in concrete production offers several benefits, including reduced environmental impact and improved material properties.

- The reported studies indicated that the replacement of natural aggregates by up to 20% of waste ceramic provided the best improvements in the characteristics of concrete. Researchers suggested that more than 20% replacement of natural coarse and fine aggregates with waste ceramic will decrease the compressive strength of the concrete.

- Waste ceramic as a fine aggregate improves workability and imparts strength to concrete due to its pozzolanic nature. The replacement with coarse aggregates provided higher compressive strength though the reduced the workability of concrete.

- Waste ceramic is also used to replace a percentage of the cement in concrete as an additive, in light of its pozzolanic properties. The waste ceramic is crushed to form a ceramic powder.

- According to the majority of earlier research, replacing some of the cement with waste ceramic can be performed at a percentage of up to 20%, and 15% replacement is the ideal amount.

- The studies indicated that ceramic powder, when replaced with cement in concrete, provides adequate durability and mechanical properties. The use of waste ceramic as a substitution for fine materials is preferable as it aids in achieving better workability, compressive strength, and durability than conventional materials.

- As the importance of sustainability grows, there will likely be increased focus on researching and developing innovative ways to incorporate ceramics waste into concrete production.

- Further research to understand the effects of ceramics waste on concrete properties will help in developing standardized guidelines for its incorporation into concrete mixes.

- Different mix designs can be explored to maximize the utilization of ceramics waste while maintaining the desired concrete performance. This may involve adjusting the proportions of other materials such as aggregates, cement, and admixtures.

- The long-term durability and suitability of ceramics waste concrete for different applications could be tested under various environmental conditions, loading conditions, and exposure scenarios.

- Life cycle assessments should be performed to quantify the environmental benefits compared to traditional materials. This will help in promoting its adoption as a sustainable construction practice.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhao, X.; Hwang, B.-G.; Lim, J. Job Satisfaction of Project Managers in Green Construction Projects: Constituents, Barriers, and Improvement Strategies. J. Clean. Prod. 2020, 246, 118968. [Google Scholar] [CrossRef]

- Nodehi, M.; Taghvaee, V.M. Applying Circular Economy to Construction Industry through Use of Waste Materials: A Review of Supplementary Cementitious Materials, Plastics, and Ceramics. Circ. Econ. Sustain. 2022, 2, 987–1020. [Google Scholar] [CrossRef]

- World Health Organization (WHO). Environmental Impacts on Health. Available online: https://www.who.int/activities/environmental-health-impacts (accessed on 15 September 2023).

- Sauve, G.; Van Acker, K. The environmental impacts of municipal solid waste landfills in Europe: A life cycle assessment of proper reference cases to support decision making. J. Environ. Manag. 2020, 261, 110216. [Google Scholar] [CrossRef] [PubMed]

- Al Nageim, H.; Dulaimi, A.; Ruddock, F.; Seton, L. Development of a new cementitious filler for use in fast-curing cold binder course in pavement application. In Proceedings of the 38th International Conference on Cement Microscopy, Lyon, France, 17–21 April 2016; pp. 167–180. [Google Scholar]

- Abdel-Wahed, T.; Dulaimi, A.; Shanbara, H.K.; Al Nageim, H. The Impact of Cement Kiln Dust and Cement on Cold Mix Asphalt Characteristics at Different Climate. Sustainability 2022, 14, 4173. [Google Scholar] [CrossRef]

- Abduljabbar, N.; Al-Busaltan, S.; Dulaimi, A.; Al-Yasari, R.; Sadique, M.; Nageim, H.A. The effect of waste low-density polyethylene on the mechanical properties of thin asphalt overlay. Constr. Build. Mater. 2022, 315, 125722. [Google Scholar] [CrossRef]

- Ghisellini, P.; Ripa, M.; Ulgiati, S. Exploring environmental and economic costs and benefits of a circular economy approach to the construction and demolition sector. A literature review. J. Clean. Prod. 2018, 178, 618–643. [Google Scholar] [CrossRef]

- López Ruiz, L.A.; Roca Ramón, X.; Gassó Domingo, S. The circular economy in the construction and demolition waste sector—A review and an integrative model approach. J. Clean. Prod. 2020, 248, 119238. [Google Scholar] [CrossRef]

- Debbarma, S.; Ransinchung, G.D.R.N.; Singh, S.; Sahdeo, S.K. Utilization of industrial and agricultural wastes for productions of sustainable roller compacted concrete pavement mixes containing reclaimed asphalt pavement aggregates. Resour. Conserv. Recycl. 2020, 152, 104504. [Google Scholar] [CrossRef]

- Jwaida, Z.; Dulaimi, A.; Bahrami, A.; Mydin, M.A.O.; Özkılıç, Y.O.; Jaya, R.P.; Wang, Y. Analytical review on potential use of waste engine oil in asphalt and pavement engineering. Case Stud. Constr. Mater. 2024, 20, e02930. [Google Scholar] [CrossRef]

- Jwaida, Z.; Dulaimi, A.; Mydin, M.A.O.; Özkılıç, Y.O.; Jaya, R.P.; Ameen, A. The Use of Waste Polymers in Asphalt Mixtures: Bibliometric Analysis and Systematic Review. J. Compos. Sci. 2023, 7, 415. [Google Scholar] [CrossRef]

- Nodehi, M.; Arani, A.A.; Taghvaee, V.M. Sustainability spillover effects and partnership between East Asia & Pacific versus North America: Interactions of social, environment and economy. Lett. Spat. Resour. Sci. 2022, 15, 311–339. [Google Scholar] [CrossRef] [PubMed]

- Adams, K.T.; Osmani, M.; Thorpe, T.; Thornback, J. Circular economy in construction: Current awareness, challenges and enablers. Proc. Inst. Civ. Eng.-Waste Resour. Manag. 2017, 170, 15–24. [Google Scholar] [CrossRef]

- Mohamad Taghvaee, V.; Assari Arani, A.; Nodehi, M.; Khodaparast Shirazi, J.; Agheli, L.; Neshat Ghojogh, H.M.; Salehnia, N.; Mirzaee, A.; Taheri, S.; Mohammadi Saber, R.; et al. Sustainable development goals: Transportation, health and public policy. Rev. Econ. Political Sci. 2023, 8, 134–161. [Google Scholar] [CrossRef]

- Hamada, H.M.; Shi, J.; Abed, F.; Al Jawahery, M.S.; Majdi, A.; Yousif, S.T. Recycling solid waste to produce eco-friendly ultra-high performance concrete: A review of durability, microstructure and environment characteristics. Sci. Total Environ. 2023, 876, 162804. [Google Scholar] [CrossRef] [PubMed]

- Xu, F.; Lin, X.; Zhou, A.; Liu, Q.-f. Effects of recycled ceramic aggregates on internal curing of high performance concrete. Constr. Build. Mater. 2022, 322, 126484. [Google Scholar] [CrossRef]

- Amin, M.; Zeyad, A.M.; Tayeh, B.A.; Saad Agwa, I. Effects of nano cotton stalk and palm leaf ashes on ultrahigh-performance concrete properties incorporating recycled concrete aggregates. Constr. Build. Mater. 2021, 302, 124196. [Google Scholar] [CrossRef]

- Amare, M.; Swara, S.; Haish, M.; Pani, A.K.; Saha, P. Performance of agro-wastes and chemical admixtures used in concrete: A review. Mater. Today Proc. 2023. [Google Scholar] [CrossRef]

- Hamada, H.M.; Shi, J.; Abed, F.; Humada, A.M.; Majdi, A. Recycling solid waste to produce eco-friendly foamed concrete: A comprehensive review of approaches. J. Environ. Chem. Eng. 2023, 11, 111353. [Google Scholar] [CrossRef]

- Ricci, G. Archaeometric Studies of Historical Ceramic Materials. Ph.D. Thesis, Università Ca’ Foscari Venezia, Venezia, Italy, 2017. [Google Scholar]

- Madejová, J.; Komadel, P. Baseline studies of the clay minerals society source clays: Infrared methods. Clays Clay Miner. 2001, 49, 410–432. [Google Scholar] [CrossRef]

- Salamon, D. Advanced Ceramics. In Advanced Ceramics for Dentistry; Shen, J.Z., Kosmač, T., Eds.; Butterworth-Heinemann: Oxford, UK, 2014; Chapter 6; pp. 103–122. [Google Scholar]

- Saleh, T.A. Materials: Types and general classifications. In Polymer Hybrid Materials and Nanocomposites; Saleh, T.A., Ed.; William Andrew Publishing: Norwich, NY, USA, 2021; Chapter 2; pp. 27–58. [Google Scholar]

- Misra, K.P.; Misra, R.D.K. 2-Advanced ceramics. In Ceramic Science and Engineering; Misra, K.P., Misra, R.D.K., Eds.; Elsevier: Amsterdam, The Netherlands, 2022; pp. 21–43. [Google Scholar]

- Ribeiro, M.J.; Tulyaganov, D. Traditional Ceramics Manufacturing. In Ceramics, Glass and Glass-Ceramics: From Early Manufacturing Steps towards Modern Frontiers; Baino, F., Tomalino, M., Tulyaganov, D., Eds.; Springer International Publishing: Cham, Switzerland, 2021; pp. 75–118. [Google Scholar]

- Zainudin, M.N. The Use of Ceramic as a Substitute for Aggregate; IRC: New York, NY, USA, 2015. [Google Scholar]

- Furszyfer Del Rio, D.D.; Sovacool, B.K.; Foley, A.M.; Griffiths, S.; Bazilian, M.; Kim, J.; Rooney, D. Decarbonizing the ceramics industry: A systematic and critical review of policy options, developments and sociotechnical systems. Renew. Sustain. Energy Rev. 2022, 157, 112081. [Google Scholar] [CrossRef]

- Rakshit, R.; Das, A.K. A review on cutting of industrial ceramic materials. Precis. Eng. 2019, 59, 90–109. [Google Scholar] [CrossRef]

- Scopus. Scopus Analyze Search Results. Available online: https://www.scopus.com/results/results.uri?sort=plf-f&src=s&st1=Waste+Ceramic+%2B+Concrete&sid=b15705b33d175e28687642d7197896cb&sot=b&sdt=b&sl=39&s=TITLE-ABS-KEY%28Waste+Ceramic+%2B+Concrete%29&origin=searchbasic&editSaveSearch=&yearFrom=Before+1960&yearTo=Present&sessionSearchId=b15705b33d175e28687642d7197896cb&limit=10 (accessed on 25 March 2024).

- Hein, A.; Kilikoglou, V. Ceramic raw materials: How to recognize them and locate the supply basins: Chemistry. Archaeol. Anthropol. Sci. 2020, 12, 180. [Google Scholar] [CrossRef]

- Bayazit, M.; Işık, I.; Issi, A. Investigating the firing technologies of Part-Roman potsherds excavated from Kuriki (Turkey) using thermal and vibrational spectroscopic techniques. Vib. Spectrosc. 2015, 78, 1–11. [Google Scholar] [CrossRef]

- Palanivel, R.; Velraj, G. FTIR and FT-raman spectroscopic studies of fired clay artifacts recently excavated in Tamilnadu, India. Indian J. Pure Appl. Phys. 2007, 45, 501–508. [Google Scholar]

- Annamalai, G.R.; Ravisankar, R.; Naseerutheen, A.; Chandrasekaran, A.; Rajan, K. Application of various spectroscopic techniques to characterize the archaeological pottery excavated from Manaveli, Puducherry, India. Optik 2014, 125, 6375–6378. [Google Scholar] [CrossRef]

- Kloprogge, J.T. Raman and Infrared Spectroscopies of Intercalated Kaolinite Groups Minerals. In Developments in Clay Science; Gates, W.P., Kloprogge, J.T., Madejová, J., Bergaya, F., Eds.; Elsevier: Amsterdam, The Netherlands, 2017; Chapter 11; Volume 8, pp. 343–410. [Google Scholar]

- Di Pietro, S.A.; Emerson, H.P.; Katsenovich, Y.P.; Johnson, T.J.; Francis, R.M.; Mason, H.E.; Marple, M.A.; Sawvel, A.M.; Szecsody, J.E. Solid phase characterization and transformation of illite mineral with gas-phase ammonia treatment. J. Hazard. Mater. 2022, 424, 127657. [Google Scholar] [CrossRef]

- Barone, G.; Crupi, V.; Longo, F.; Majolino, D.; Mazzoleni, P.; Tanasi, D.; Venuti, V. FT-IR spectroscopic analysis to study the firing processes of prehistoric ceramics. J. Mol. Struct. 2011, 993, 147–150. [Google Scholar] [CrossRef]

- Bahçeli, S.; Güleç, G.; Erdoğan, H.; Söğüt, B. Micro-Raman and FT-IR spectroscopic studies of ceramic shards excavated from ancient Stratonikeia city at Eskihisar village in West–South Turkey. J. Mol. Struct. 2016, 1106, 316–321. [Google Scholar] [CrossRef]

- Rapp, G. (Ed.) Ceramic Raw Materials. In Archaeomineralogy; Springer Berlin Heidelberg: Berlin/Heidelberg, Germany, 2009; pp. 183–200. [Google Scholar]

- Götze, J.; Göbbels, M. (Eds.) Ceramic Materials. In Introduction to Applied Mineralogy; Springer Berlin Heidelberg: Berlin/Heidelberg, Germany, 2023; pp. 79–95. [Google Scholar]

- Ayode Otitoju, T.; Ugochukwu Okoye, P.; Chen, G.; Li, Y.; Onyeka Okoye, M.; Li, S. Advanced ceramic components: Materials, fabrication, and applications. J. Ind. Eng. Chem. 2020, 85, 34–65. [Google Scholar] [CrossRef]

- Majumdar, S.; Singh, S.; Sahoo, P.R. Characterization of organic matter and its implications for pyrite hosted refractory gold mineralization along the South Purulia Shear Zone, eastern India. Ore Geol. Rev. 2020, 124, 103584. [Google Scholar] [CrossRef]

- Hotza, D.; Maia, B.G.O. 20-Environmental performance and energy assessment of fired-clay brick masonry. In Eco-Efficient Masonry Bricks and Blocks; Pacheco-Torgal, F., Lourenço, P.B., Labrincha, J.A., Kumar, S., Chindaprasirt, P., Eds.; Woodhead Publishing: Oxford, UK, 2015; pp. 447–459. [Google Scholar]

- González, J.S.; Gayarre, F.L.; Pérez, C.L.-C.; Ros, P.S.; López, M.A.S. Influence of recycled brick aggregates on properties of structural concrete for manufacturing precast prestressed beams. Constr. Build. Mater. 2017, 149, 507–514. [Google Scholar] [CrossRef]

- Mohammed, T.U.; Hasnat, A.; Awal, M.A.; Bosunia, S.Z. Recycling of Brick Aggregate Concrete as Coarse Aggregate. J. Mater. Civ. Eng. 2015, 27, B4014005. [Google Scholar] [CrossRef]

- Keshavarz, Z.; Mostofinejad, D. Porcelain and red ceramic wastes used as replacements for coarse aggregate in concrete. Constr. Build. Mater. 2019, 195, 218–230. [Google Scholar] [CrossRef]

- Jasim, M.J.; Noh, M.K.Z.; Zaidan, S.A.; Wan, M.H.; Ibrahim; Takai, Z.I. Effect of Superplasticizer on Thermal Properties of Concrete Containing Porcelain Waste as Sand Replacement. J. Adv. Res. Fluid Mech. Therm. Sci. 2019, 63, 82–91. [Google Scholar]

- Du, H.; Tan, K.H. Properties of high volume glass powder concrete. Cem. Concr. Compos. 2017, 75, 22–29. [Google Scholar] [CrossRef]

- Muhedin, D.A.; Ibrahim, R.K. Effect of waste glass powder as partial replacement of cement & sand in concrete. Case Stud. Constr. Mater. 2023, 19, e02512. [Google Scholar] [CrossRef]

- Harkishan Joshi, P.; Parekh, D.N. Assessment of Utilization of Ceramic Waste as A Substitute to Concrete Constituents—A REVIEW. Rev. Ing. Construcción 2022, 37, 69–78. [Google Scholar] [CrossRef]

- Carter, B.; Norton, M.G.; Wang, L. Ceramic Materials: Science and Engineering; Springer: New York, NY, USA, 2013; Volume 716, p. 712. [Google Scholar]

- Pacheco-Torgal, F.; Jalali, S. Reusing ceramic wastes in concrete. Constr. Build. Mater. 2010, 24, 832–838. [Google Scholar] [CrossRef]

- Siddique, S.; Shrivastava, S.; Chaudhary, S. Influence of ceramic waste on the fresh properties and compressive strength of concrete. Eur. J. Environ. Civ. Eng. 2019, 23, 212–225. [Google Scholar] [CrossRef]

- Etxeberria, M.; Vegas, I. Effect of fine ceramic recycled aggregate (RA) and mixed fine RA on hardened properties of concrete. Mag. Concr. Res. 2015, 67, 645–655. [Google Scholar] [CrossRef]

- Awoyera, P.O.; Ndambuki, J.M.; Akinmusuru, J.O.; Omole, D.O. Characterization of ceramic waste aggregate concrete. HBRC J. 2018, 14, 282–287. [Google Scholar] [CrossRef]

- Guendouz, M.; Boukhelkhal, D. Properties of flowable sand concrete containing ceramic wastes. J. Adhes. Sci. Technol. 2019, 33, 2661–2683. [Google Scholar] [CrossRef]

- Anderson, D.J.; Smith, S.T.; Au, F.T.K. Mechanical properties of concrete utilising waste ceramic as coarse aggregate. Constr. Build. Mater. 2016, 117, 20–28. [Google Scholar] [CrossRef]

- Senthamarai, R.M.; Devadas Manoharan, P. Concrete with ceramic waste aggregate. Cem. Concr. Compos. 2005, 27, 910–913. [Google Scholar] [CrossRef]

- Senthamarai, R.M.; Manoharan, P.D.; Gobinath, D. Concrete made from ceramic industry waste: Durability properties. Constr. Build. Mater. 2011, 25, 2413–2419. [Google Scholar] [CrossRef]

- Medina, C.; Sánchez de Rojas, M.I.; Thomas, C.; Polanco, J.A.; Frías, M. Durability of recycled concrete made with recycled ceramic sanitary ware aggregate. Inter-indicator relationships. Constr. Build. Mater. 2016, 105, 480–486. [Google Scholar] [CrossRef]

- Fatima, E.; Jhamb, A.; Kumar, R. Ceramic Dust as Construction Material in Rigid Pavement. Am. J. Civ. Eng. Archit. 2013, 1, 112–116. [Google Scholar] [CrossRef][Green Version]

- Sharma, V.; Dhruw, D.M.H.K.; Tiwari, D.M. Use of Waste Ceramic as Aggregate in Concrete. IJRASET 2022, 39883. [Google Scholar] [CrossRef]

- Xu, J.; Niu, X.; Ma, Q.; Han, Q. Mechanical properties and damage analysis of rubber cement mortar mixed with ceramic waste aggregate based on acoustic emission monitoring technology. Constr. Build. Mater. 2021, 309, 125084. [Google Scholar] [CrossRef]

- Nayana, A.M.; Rakesh, P. Strength and durability study on cement mortar with ceramic waste and micro-silica. Mater. Today Proc. 2018, 5, 24780–24791. [Google Scholar] [CrossRef]

- Medina, C.; Frías, M.; Sánchez de Rojas, M.I. Microstructure and properties of recycled concretes using ceramic sanitary ware industry waste as coarse aggregate. Constr. Build. Mater. 2012, 31, 112–118. [Google Scholar] [CrossRef]

- Ding, Y.; Dong, H.; Cao, M.; Pacheco-Torgal, F.; Azevedo, C. 17-Recycled household ceramic waste in eco-efficient cement: A case study. In Advances in Construction and Demolition Waste Recycling; Pacheco-Torgal, F., Ding, Y., Colangelo, F., Tuladhar, R., Koutamanis, A., Eds.; Woodhead Publishing: Cambridge, UK, 2020; pp. 339–354. [Google Scholar]

- Mohit, M.; Sharifi, Y. Thermal and microstructure properties of cement mortar containing ceramic waste powder as alternative cementitious materials. Constr. Build. Mater. 2019, 223, 643–656. [Google Scholar] [CrossRef]

- AlArab, A.; Hamad, B.; Chehab, G.; Assaad, J.J. Use of Ceramic-Waste Powder as Value-Added Pozzolanic Material with Improved Thermal Properties. J. Mater. Civ. Eng. 2020, 32, 04020243. [Google Scholar] [CrossRef]

- Li, L.; Liu, W.; You, Q.; Chen, M.; Zeng, Q. Waste ceramic powder as a pozzolanic supplementary filler of cement for developing sustainable building materials. J. Clean. Prod. 2020, 259, 120853. [Google Scholar] [CrossRef]

- Heidari, A.; Tavakoli, D. A study of the mechanical properties of ground ceramic powder concrete incorporating nano-SiO2 particles. Constr. Build. Mater. 2013, 38, 255–264. [Google Scholar] [CrossRef]

- Reiterman, P.; Holčapek, O.; Čáchová, M.; Vogel, F.; Jogl, M.; Konvalinka, P. Basic and Hygric Properties of Concrete Containing Fine Ceramic Powder. Adv. Mater. Res. 2014, 897, 188–191. [Google Scholar] [CrossRef]

- Kannan, D.M.; Aboubakr, S.H.; El-Dieb, A.S.; Reda Taha, M.M. High performance concrete incorporating ceramic waste powder as large partial replacement of Portland cement. Constr. Build. Mater. 2017, 144, 35–41. [Google Scholar] [CrossRef]

- Bhargav, M.; Kansal, R. Experimental investigation to substitute of cement with ceramic tiles powder in concrete. Int. J. Res. Appl. Sci. Eng. Technol. 2020, 8, 302–307. [Google Scholar] [CrossRef]

- Matias, G.; Faria, P.; Torres, I. Lime mortars with ceramic wastes: Characterization of components and their influence on the mechanical behaviour. Constr. Build. Mater. 2014, 73, 523–534. [Google Scholar] [CrossRef]

- Puertas, F.; García-Díaz, I.; Barba, A.; Gazulla, M.F.; Palacios, M.; Gómez, M.P.; Martínez-Ramírez, S. Ceramic wastes as alternative raw materials for Portland cement clinker production. Cem. Concr. Compos. 2008, 30, 798–805. [Google Scholar] [CrossRef]

- Puertas, F.; García-Díaz, I.; Palacios, M.; Gazulla, M.F.; Gómez, M.P.; Orduña, M. Clinkers and cements obtained from raw mix containing ceramic waste as a raw material. Characterization, hydration and leaching studies. Cem. Concr. Compos. 2010, 32, 175–186. [Google Scholar] [CrossRef]

- Bignozzi, M.C.; Saccani, A. Ceramic waste as aggregate and supplementary cementing material: A combined action to contrast alkali silica reaction (ASR). Cem. Concr. Compos. 2012, 34, 1141–1148. [Google Scholar] [CrossRef]

| Type of Aggregates | Type of Waste Ceramic | Replacement Level | Results | Reference |

|---|---|---|---|---|

| Fine aggregates | Sanitary Ware Stoneware tile | Up to 20% | does not imply strength loss with superior durability | [52] |

| Bone China ceramic waste | 100% | 2.1% bleeding water loss. 7% air content reduction. Comparable compressive strength. | [53] | |

| Ceramic recycled sand from bricks Fine mixed RA in a recycling plant | 10%, 20%, 35% and 50% | less than a 5% reduction in concrete density. Increased absorption by more than 40%. Maximum increase in compressive strength with 35% replacement. | [54] | |

| Ceramic floor and wall tiles | 25%, 50%, 75% and 100% | Adequate workability. 100% replacement gave maximum mechanical properties. | [55] | |

| Ceramic tile and sanitary ware | 10%, 20%, 30%, 40%, 50%, and 60% | Decreased slump flow. Improved mechanical strengths with 50–60% replacement. | [56] | |

| Course aggregates | Ceramic wall tiles | 20%, 25%, 35%, 50%, 65%, 75%, 80% and 100% | Improved mechanical strengths. | [57] |

| Electrical insulator industrial wastes | 35–60% | Comparable strength characteristics to conventional concrete | [58,59] | |

| Sanitary waste | 20% | Improved durability properties and electrical resistance. | [60] | |

| Bricks, roof and floor tiles and stoneware | 0–30% | Improved mechanical properties. 3.9% increase in compressive strength with 20% replacement. | [61] | |

| Red ceramic waste and porcelain waste | 0–100% | Superior performance of porcelain waste in comparison to red waste ceramic | [46] | |

| Ceramic from industrial ceramic tiles | 100% | Improved compressive strength with low workability. | [62] |

| Type of Waste Ceramic | Replacement Level | Results | Reference |

|---|---|---|---|

| Household/tableware ceramics | 0%, 5%, 15%, and 25% | Pozzolanic activity of ceramic powder. 15% is the effective substitution | [66] |

| From a ceramic factory | 5%, 10%, 15%, 20% and 25% | Improved mechanical strengths at elevated temperatures. Improved thermal resistance. Reduced porosity. | [67] |

| Porcelain tiles | 20% | Improved residual strength and thermal conductivity. Enhanced pozzolanic reactions. | [68] |

| Micro-ceramic powder (decorative vases and flowerpots) | 0-40% | Reduction in mechanical strengths lowered with increased curing. Decreased Pore sizes. | [69] |

| Recycled ceramic tiles | 10–40% | Minor loss in strength. Lowered Absorption capacity | [70] |

| Fine ceramic powder | Up to 30% | Maximum compressive strength with 10% replacement. reduction in bulk density with high replacements. | [71] |

| Ceramic waste powder (ceramic tile polishing) | 10–40% | Comparable compressive strength at. Improved durability performance. | [72] |

| Ceramic Tiles Powder | 5%, 10%, 15% and 20% | Increased concrete density. Improved compressive strength with 15% replacement. | [73] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jwaida, Z.; Dulaimi, A.; Bernardo, L.F.A. The Use of Waste Ceramic in Concrete: A Review. CivilEng 2024, 5, 482-500. https://doi.org/10.3390/civileng5020024

Jwaida Z, Dulaimi A, Bernardo LFA. The Use of Waste Ceramic in Concrete: A Review. CivilEng. 2024; 5(2):482-500. https://doi.org/10.3390/civileng5020024

Chicago/Turabian StyleJwaida, Zahraa, Anmar Dulaimi, and Luís Filipe Almeida Bernardo. 2024. "The Use of Waste Ceramic in Concrete: A Review" CivilEng 5, no. 2: 482-500. https://doi.org/10.3390/civileng5020024

APA StyleJwaida, Z., Dulaimi, A., & Bernardo, L. F. A. (2024). The Use of Waste Ceramic in Concrete: A Review. CivilEng, 5(2), 482-500. https://doi.org/10.3390/civileng5020024