Factors Affecting Properties of Polymer Grouted Sands

Abstract

1. Introduction

2. Materials

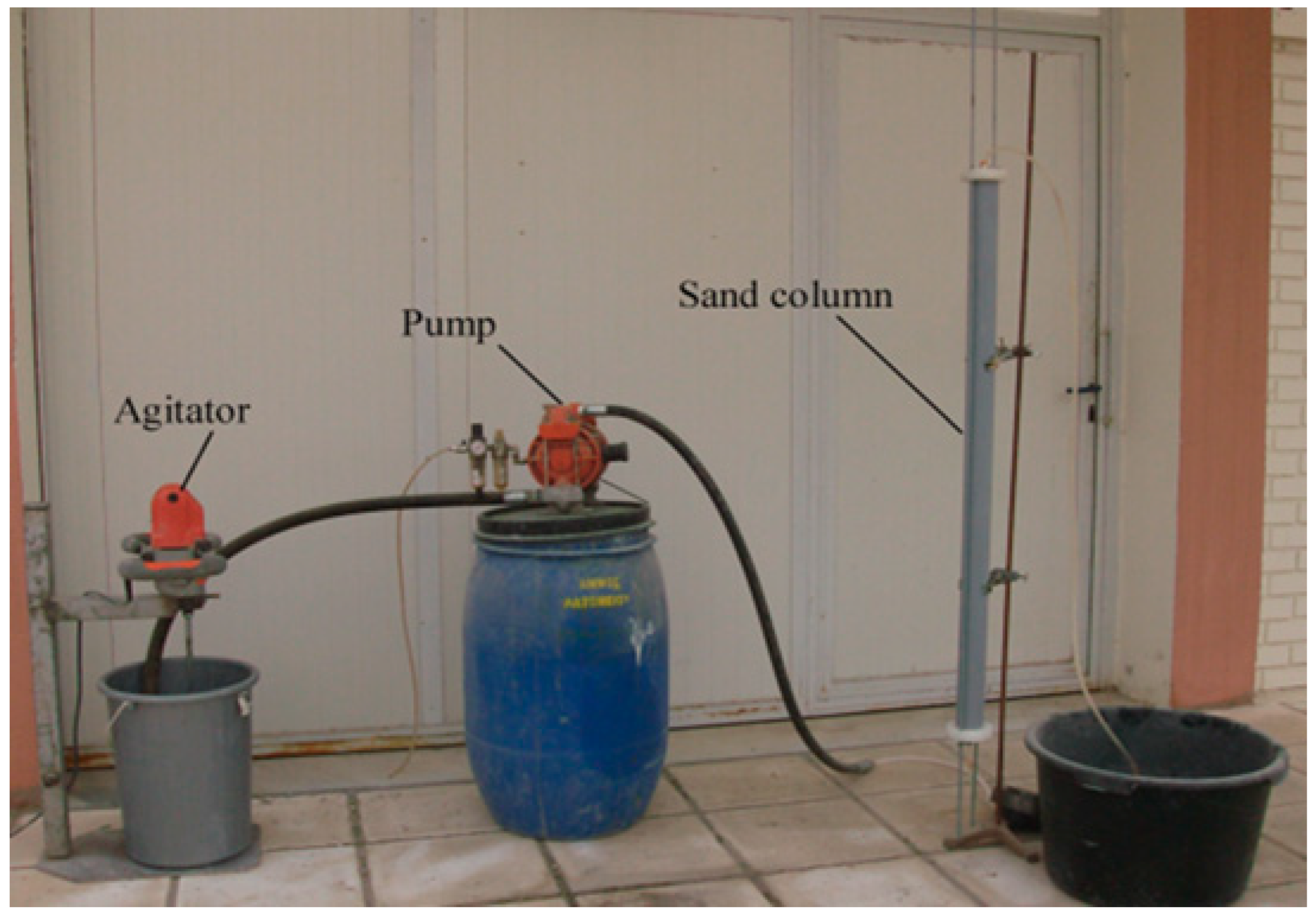

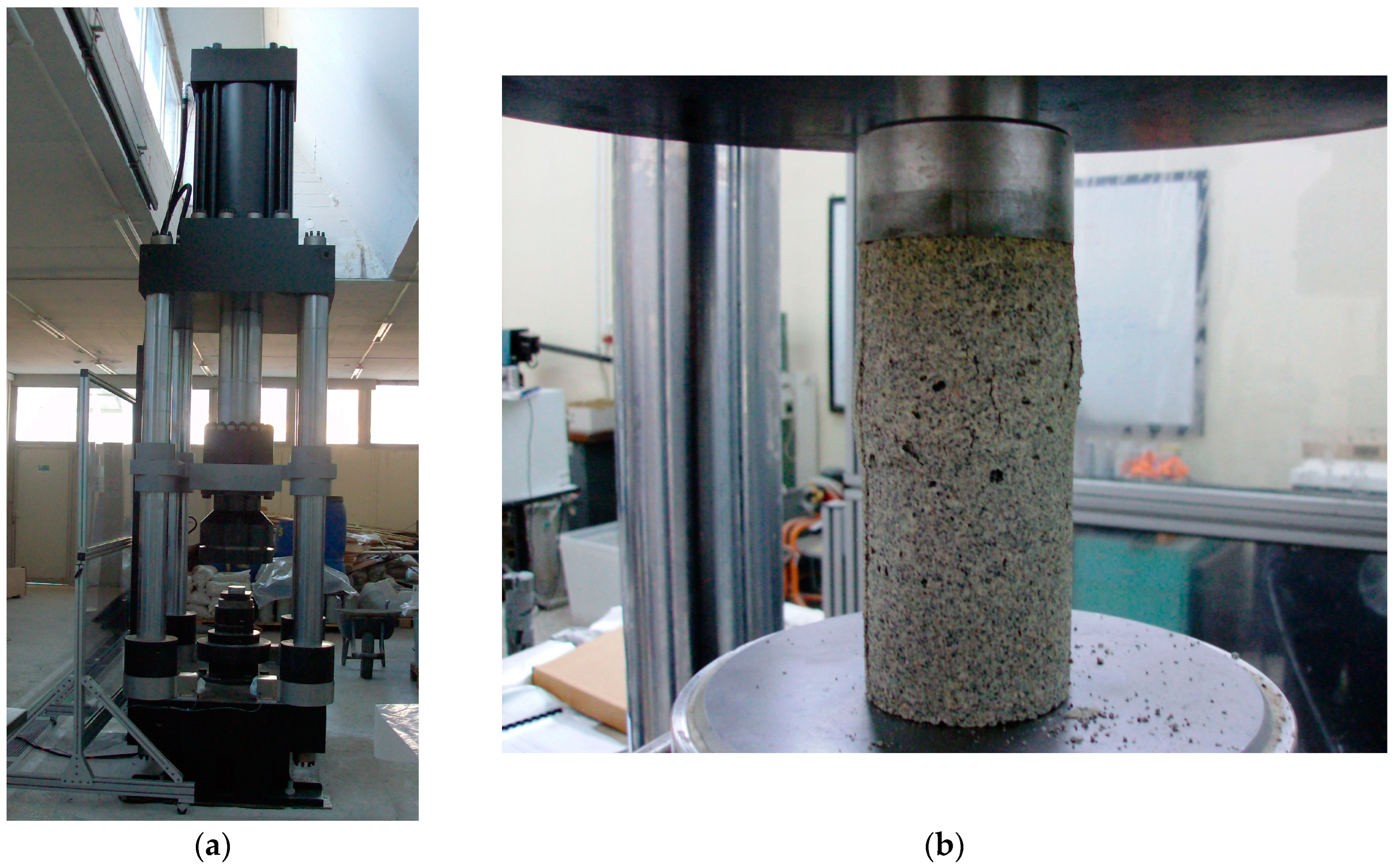

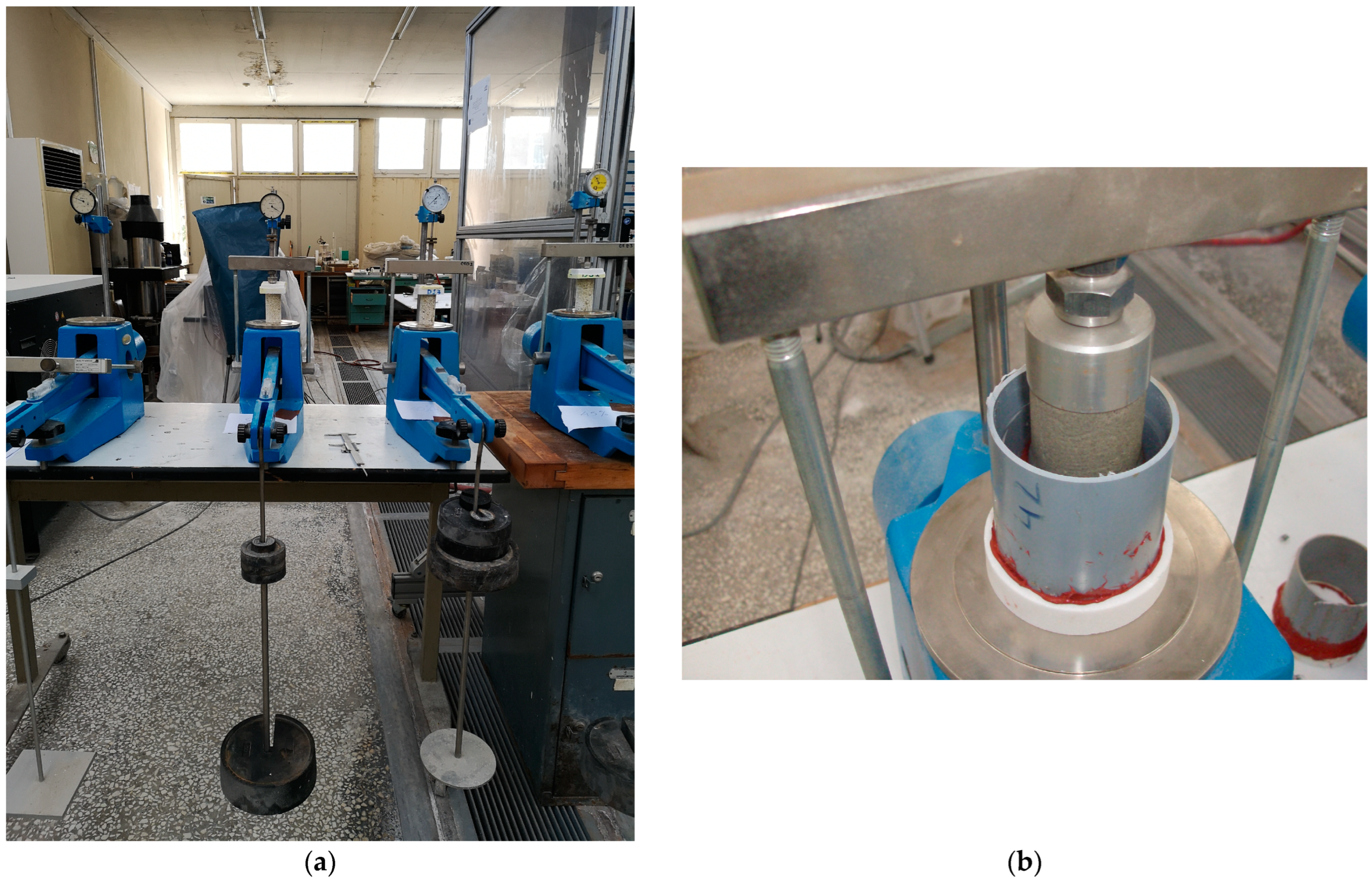

3. Laboratory Procedure

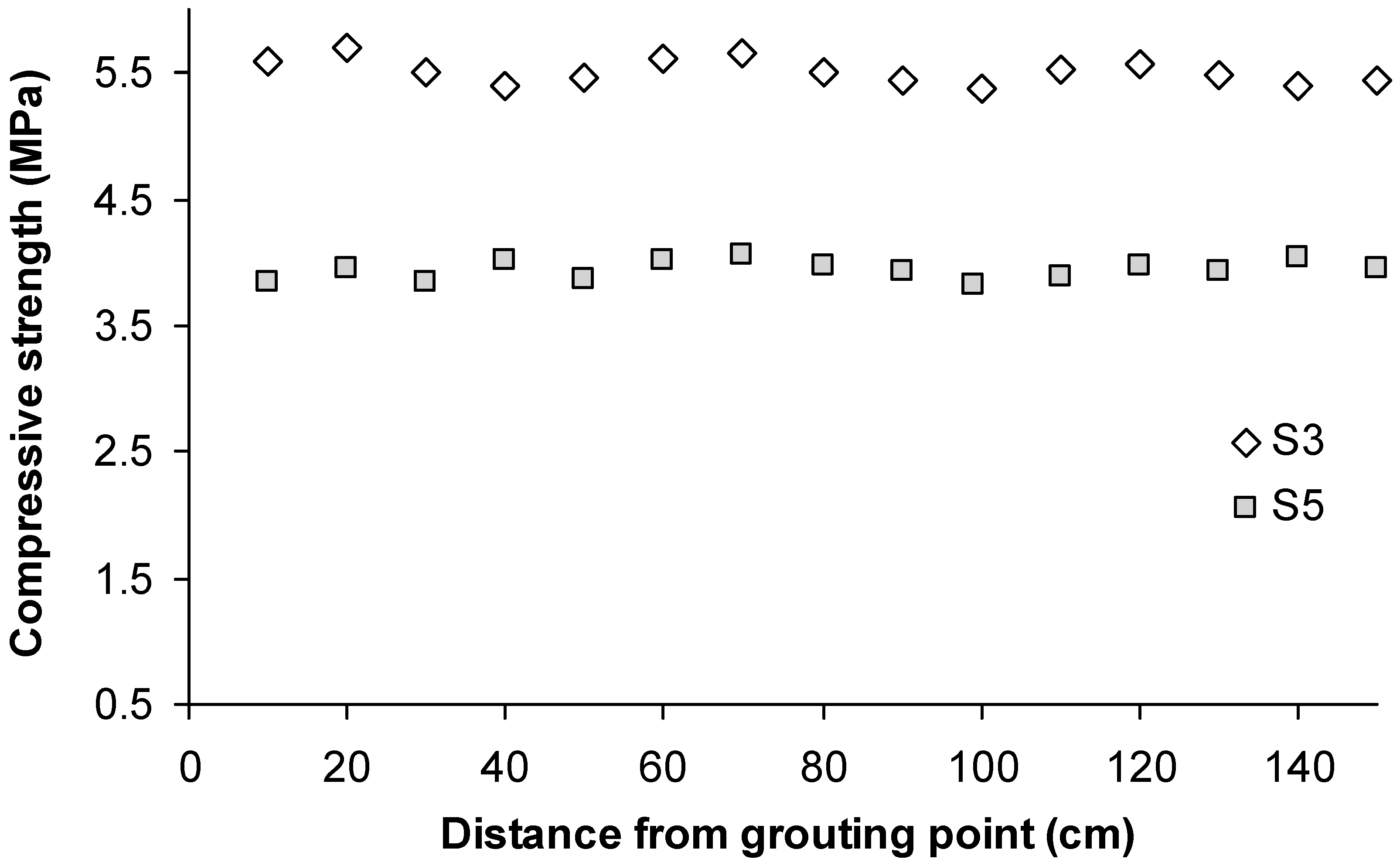

4. Results and Discussion

5. Conclusions

- (1)

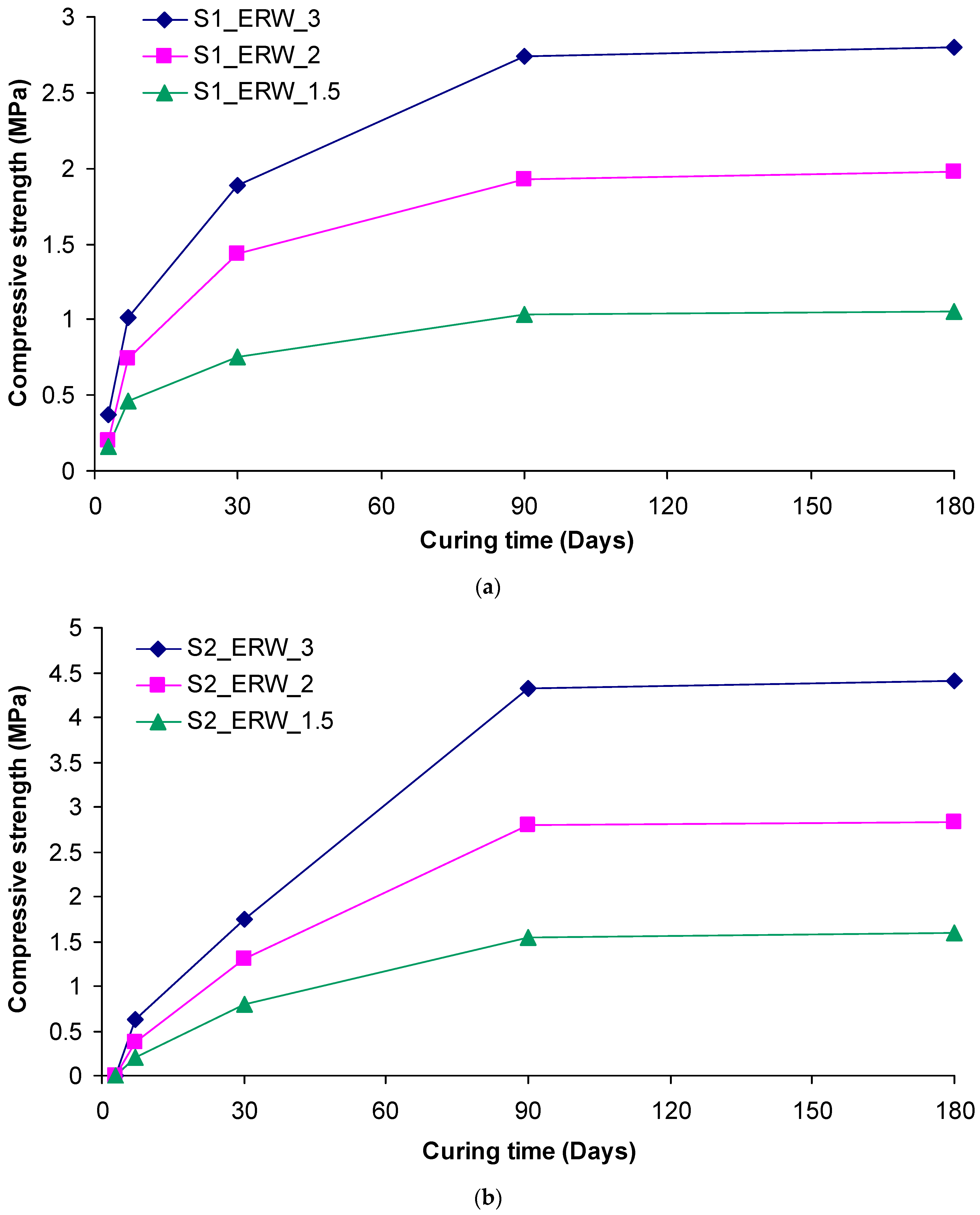

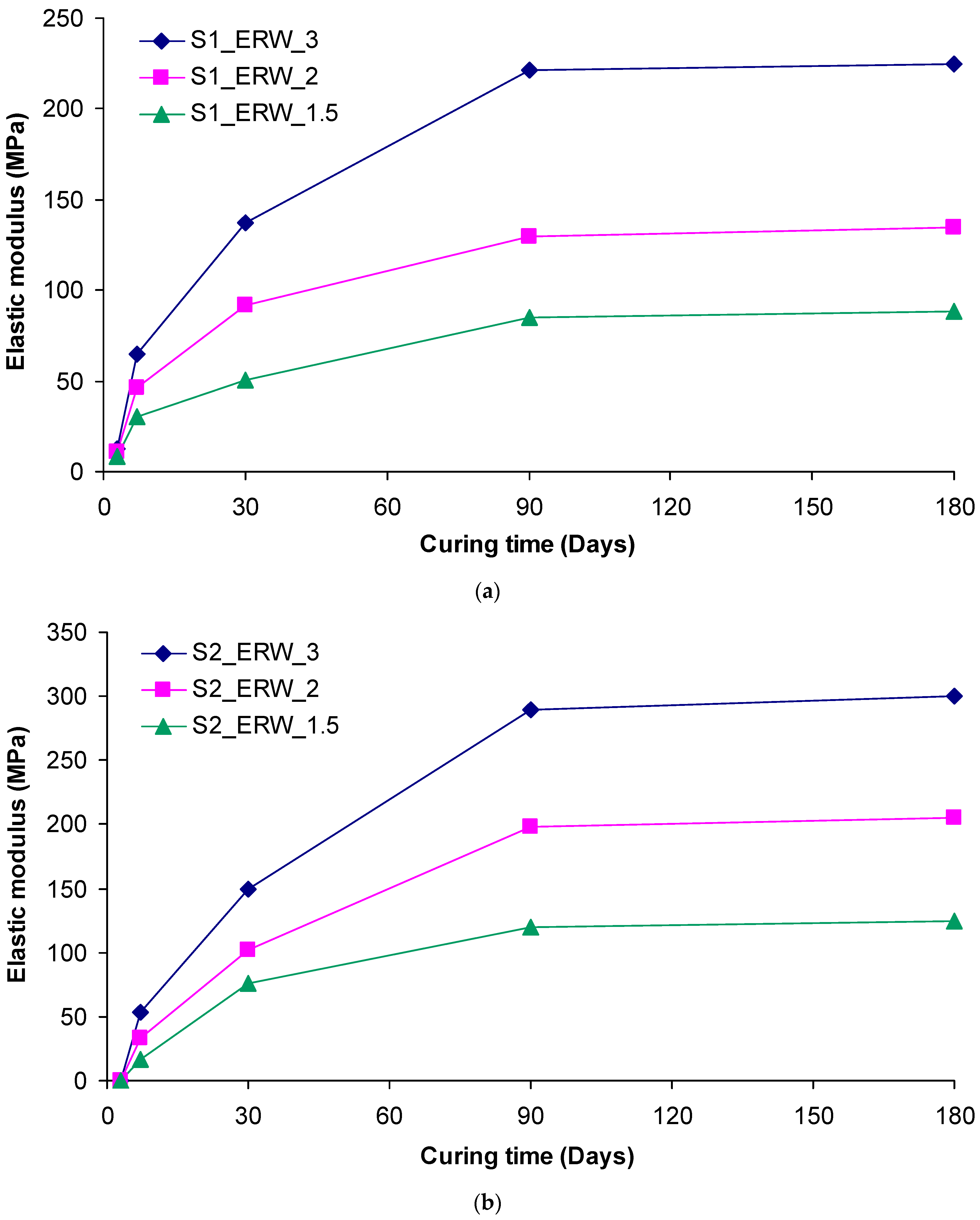

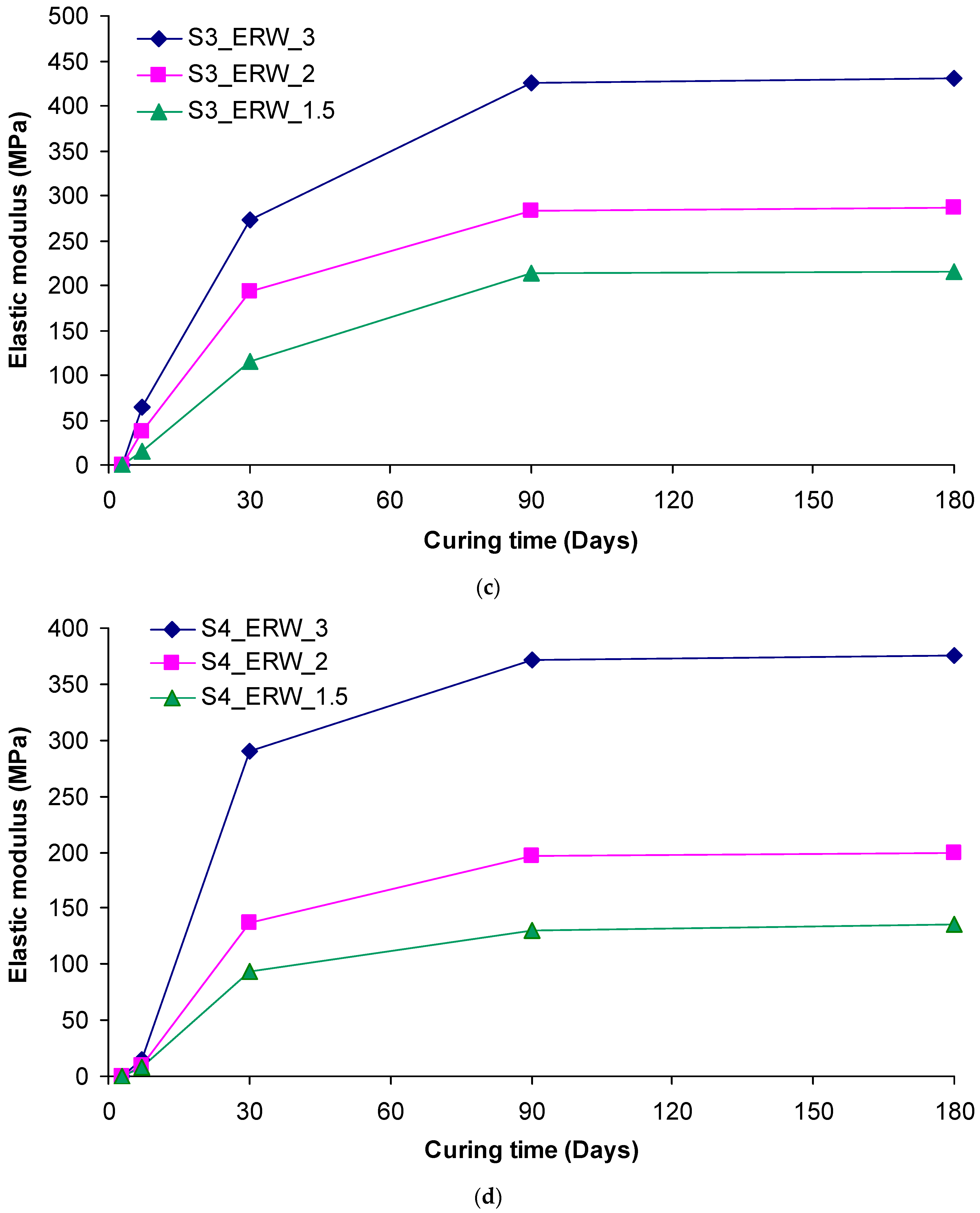

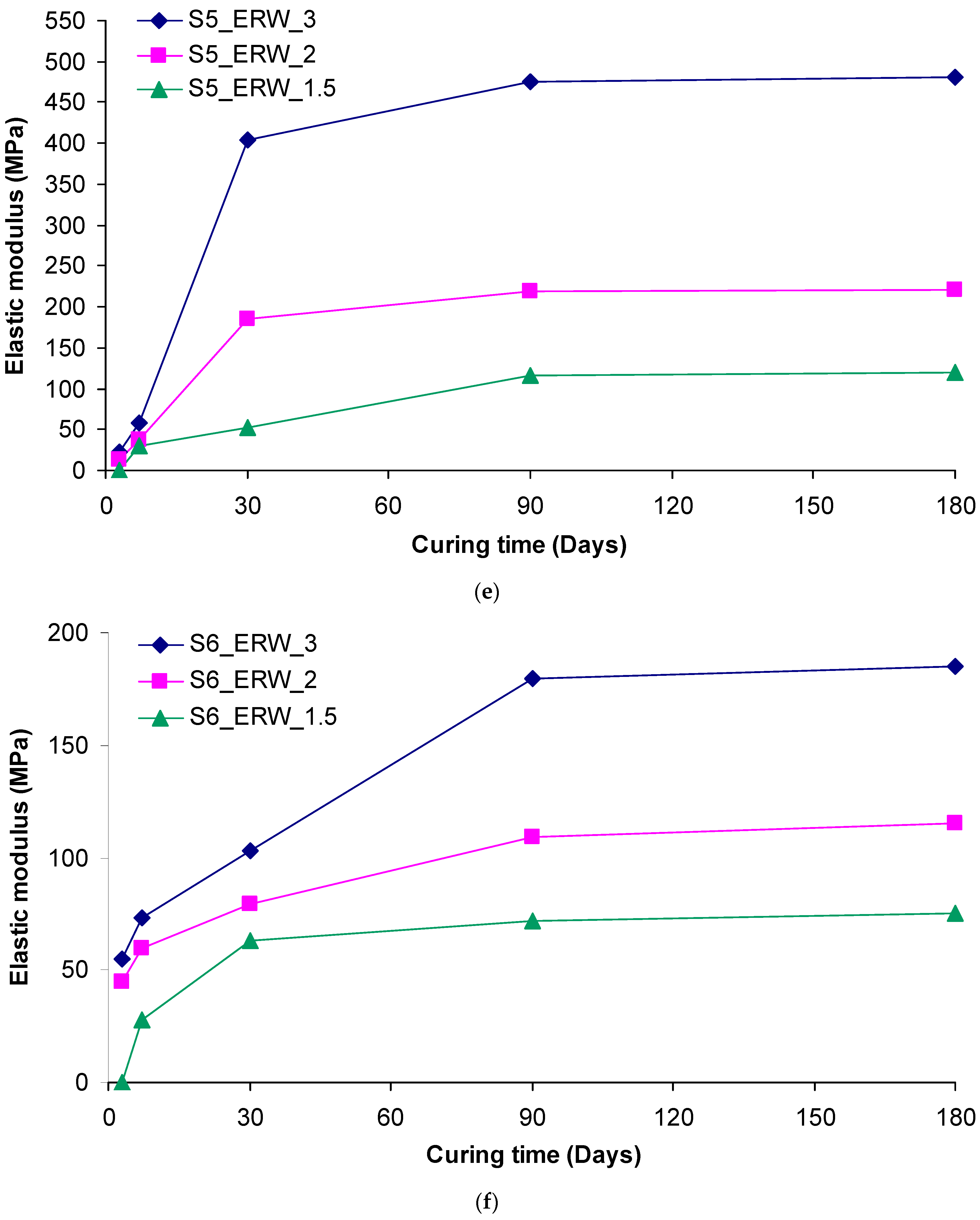

- All grouted sands with the different grouts gain their final strength after 90 days of curing. The higher the ER/W ratio, the greater the strength development, at all curing ages.

- (2)

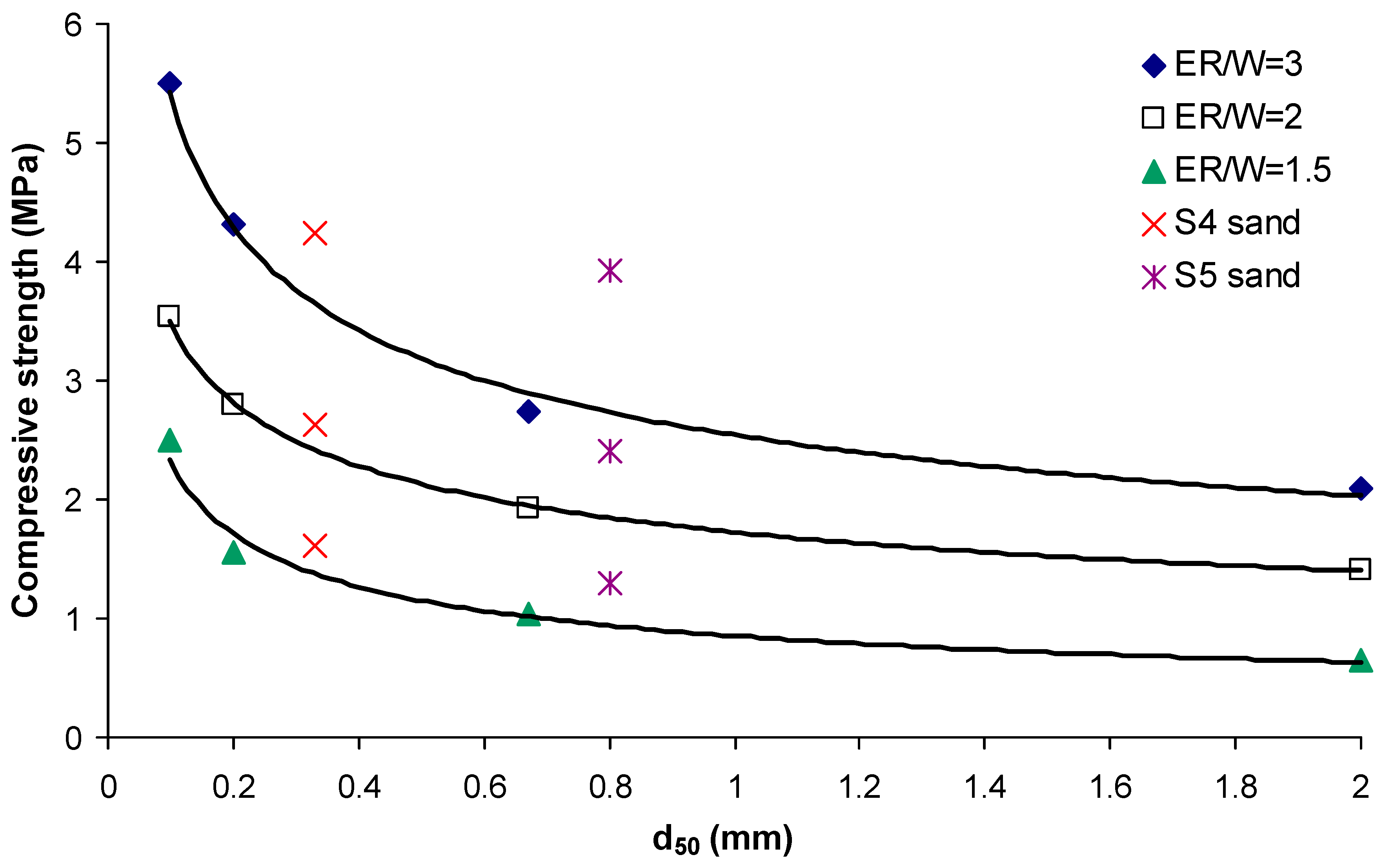

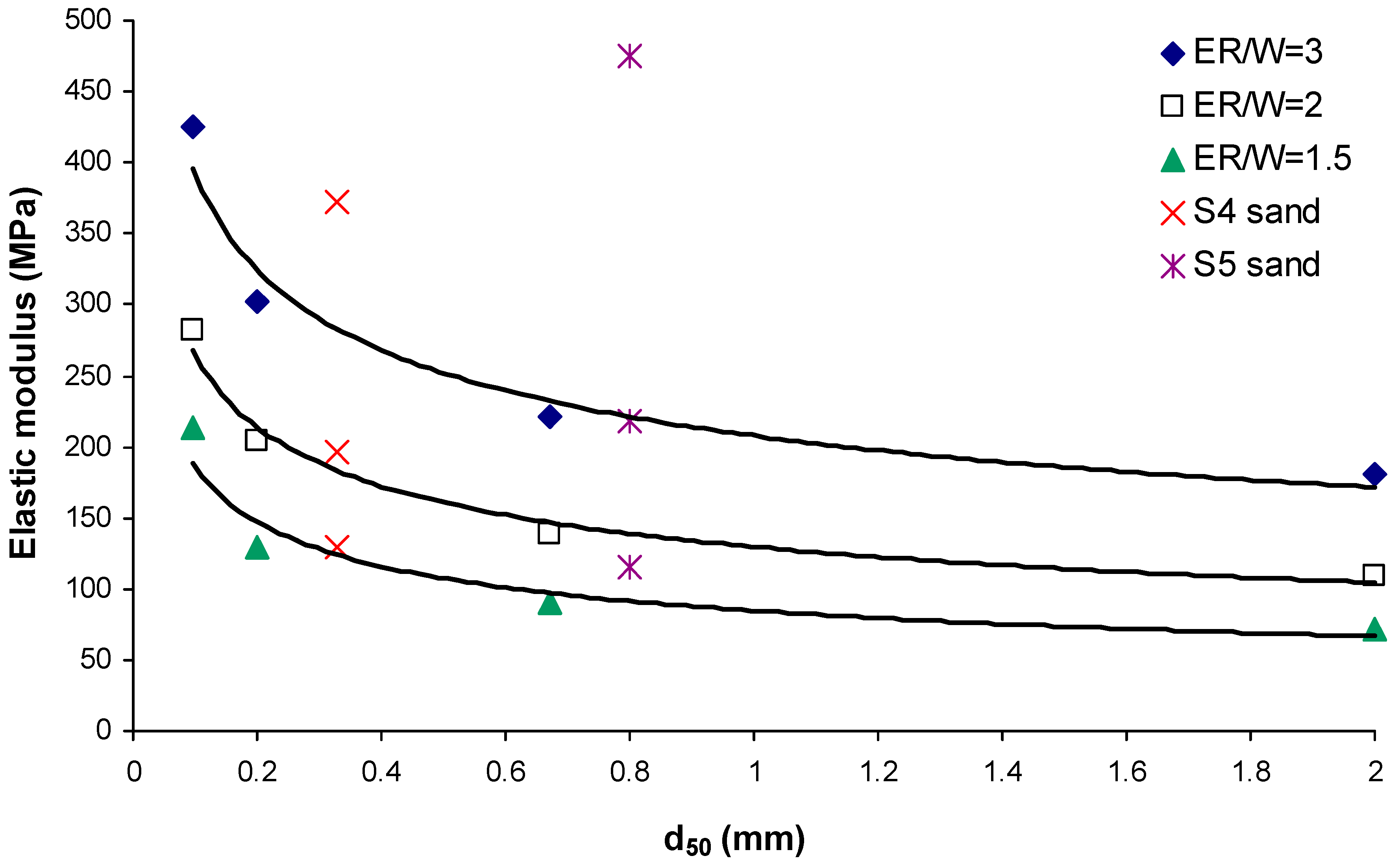

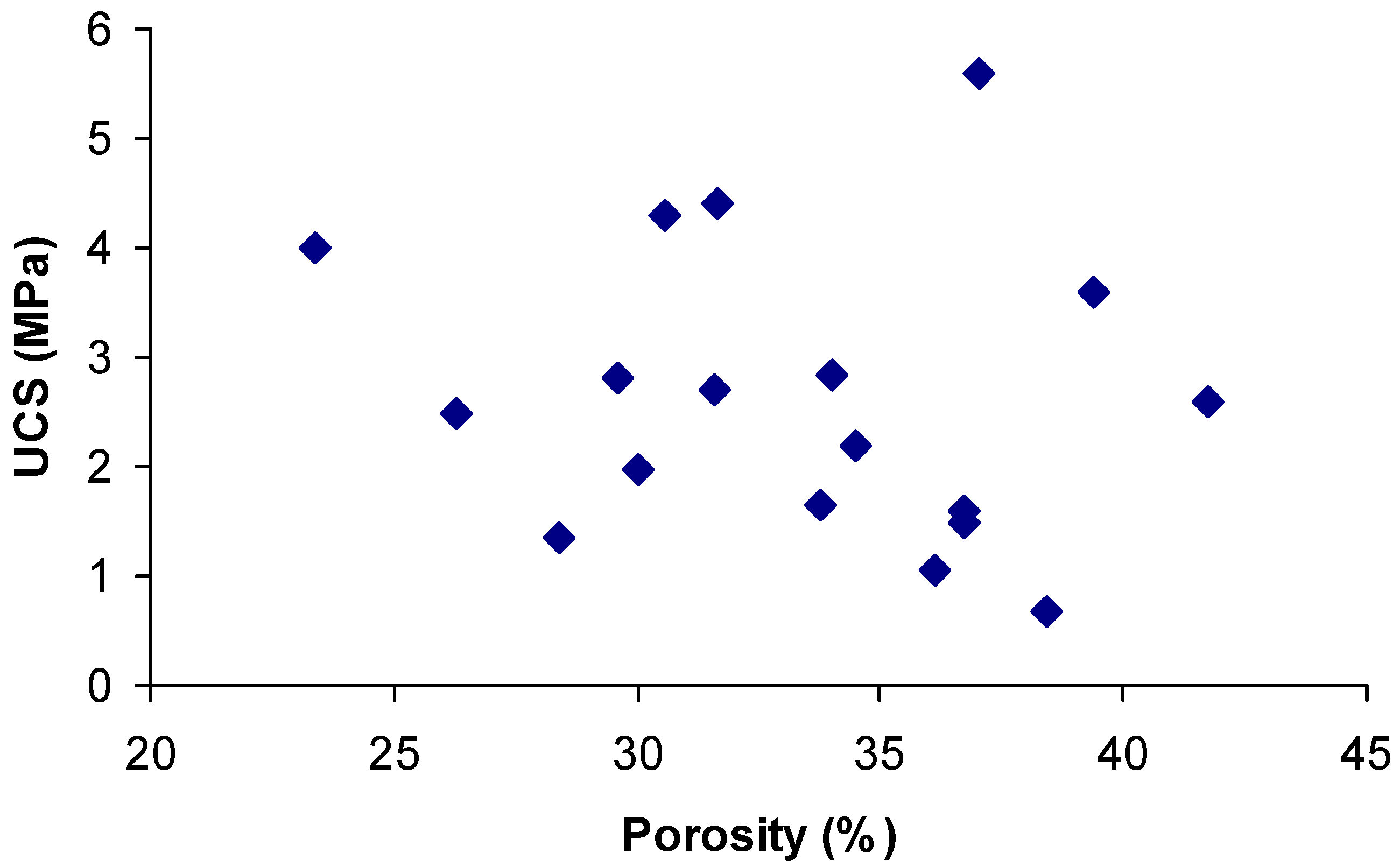

- The final compressive strength and elastic modulus of grouted sands depend directly on the ER/W ratio, d50 and cu. The higher the ER/W ratio and cu, and the finer the sand, the greater the strength development at all curing ages. In particular, the highest compressive strength and elastic modulus values at the age of 180 days are obtained for the finer sand (S3), grouted with the different grouts, ranging from 2.6 to 5.6 MPa and 216 to 430 MPa, respectively. These values are much higher than those obtained by the use of other chemical grouts. On the contrary, the lowest compressive strength and elastic modulus values are obtained for the coarser sand (S6) with a low cu value, ranging from 0.68 to 2.2 MPa and 75 to 185 MPa, respectively, which are slightly higher but comparable to those achieved with common chemical grouts.

- (3)

- All the grouted sands considered in this study exhibit strain-hardening behaviour. This response suggests their potential application in geotechnical structures that may suffer significant deformations.

- (4)

- The mineralogical composition of sand does not seem to influence the strength development.

- (5)

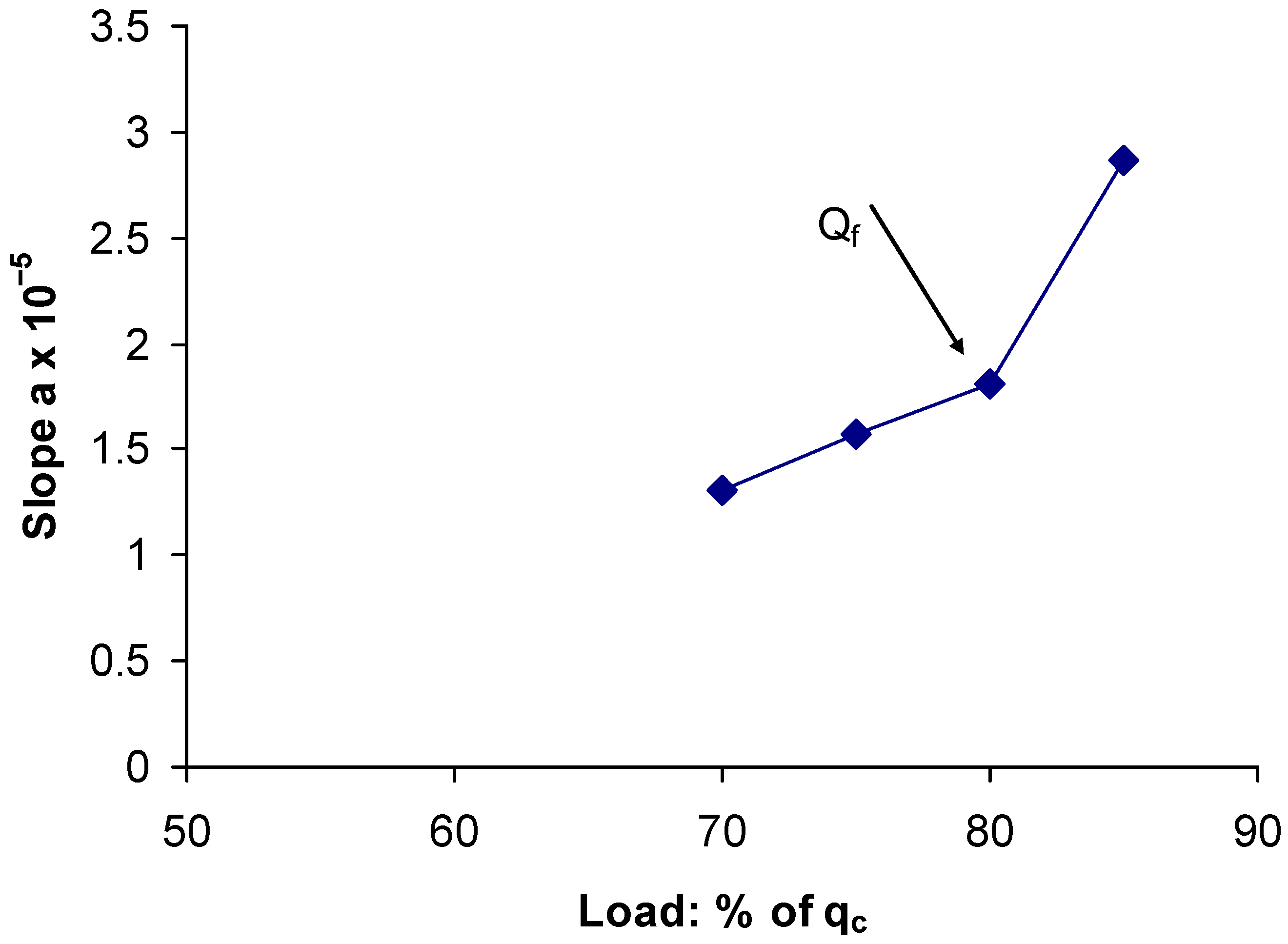

- All the grouted sands have stable long-term creep behaviour with high values of Qf ranging from 67.5 to 80% of qc. These values are higher than those obtained with other chemical grouts. Even under the adverse influence of water, the reduction of the Qf values is very low in most cases.

- (6)

- The permeability of the grouted sands decreases by two to four orders of magnitude when the grouts are injected into fine sands or sands with high cu. However, the values of k for all the grouted sands are comparable to those obtained with other chemical grouts.

- (7)

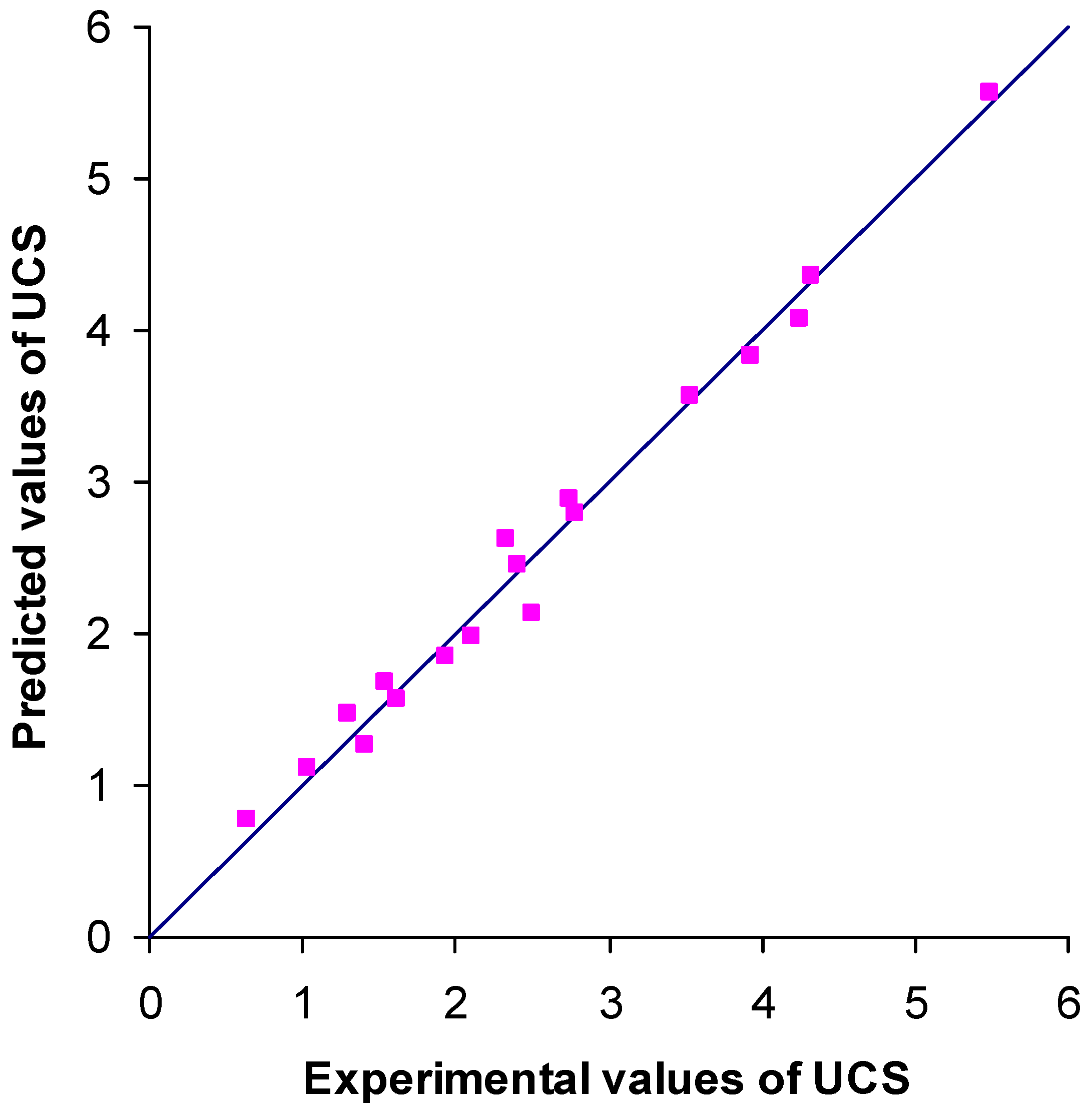

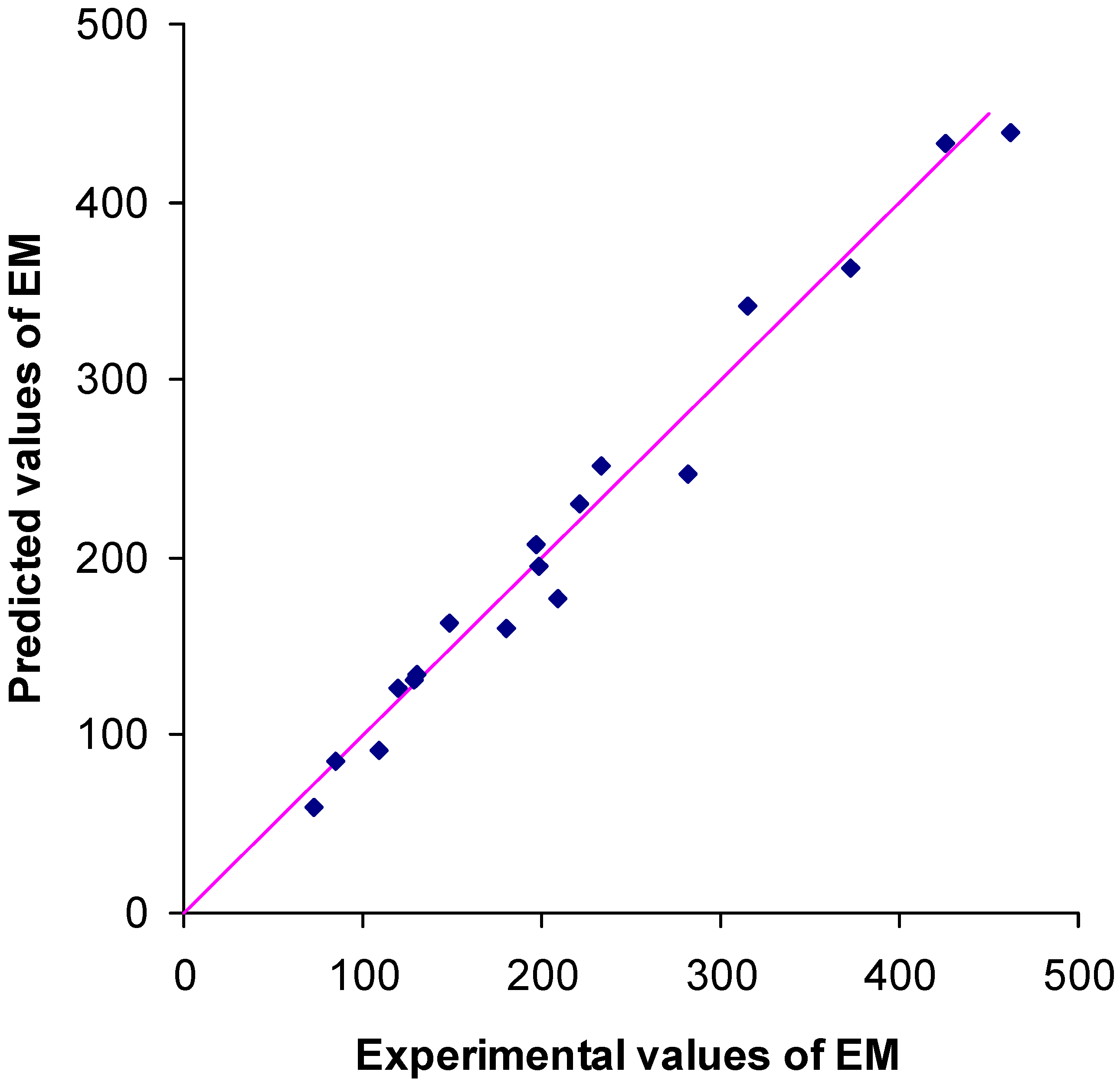

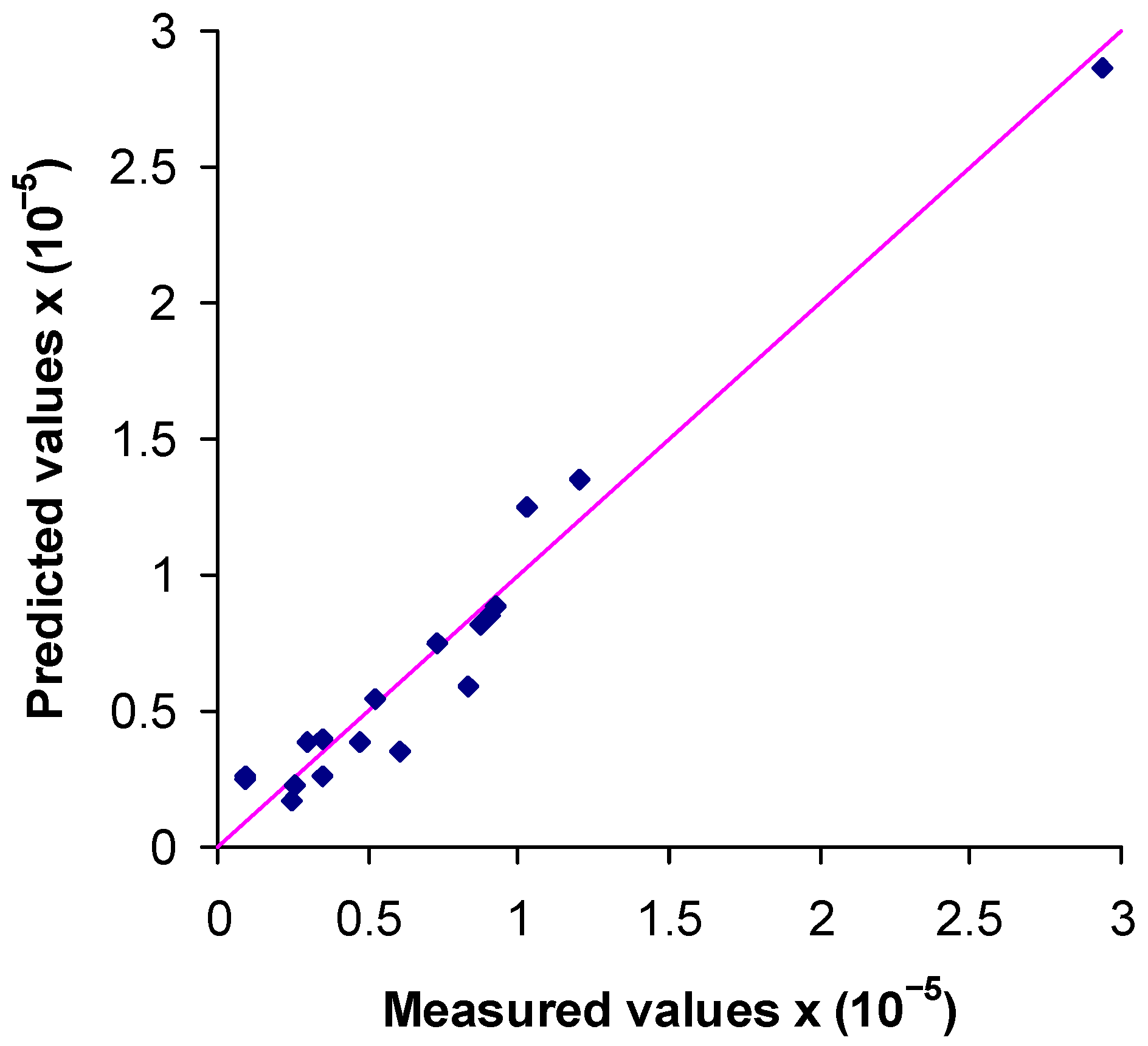

- The models derived from non-linear regression analysis relate the UCS, EM and k of the grouted sands to the ER/W ratio, d50 and cu. The predictive accuracy of the regression equations was found to be remarkably high.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Celik, F. The observation of permeation grouting method as soil improvement technique with different grout flow models. Geomech. Eng. 2019, 17, 367–374. [Google Scholar]

- Saleh, S.; Yunus, N.Z.M.; Ahmad, K.; Ali, N. Improving the strength of weak soil using polyurethane grouts: A review. Constr. Build. Mater. 2019, 202, 738–752. [Google Scholar] [CrossRef]

- Anagnostopoulos, C.A. Laboratory study of an injected granular soil with polymer grouts. Tunn. Undergr. Space Technol. 2005, 20, 525–533. [Google Scholar] [CrossRef]

- Anagnostopoulos, C.A. Physical and mechanical properties of injected sand with latex-superplasticized grouts. Geotech. Test J. 2006, 29, 490–496. [Google Scholar]

- Gallagher, P.M.; Lin, Y. Colloidal silica transport through liquefiable porous media. J. Geotech. Geoenvironmental Eng. 2009, 135, 1702–1712. [Google Scholar] [CrossRef]

- Ajalloeian, R.; Matinmanesh, H.; Abtani, S.M.; Rowshanzamir, M. Effect of polyvinyl acetate grout injection on geotechnical properties of fine sand. Geomech. Geoengin. 2013, 8, 86–96. [Google Scholar] [CrossRef]

- Lim, S.K.; Hussin, M.W.; Zakaria, F.; Ling, T.C. GGBFS as potential filler in polyester grout: Flexural and toughness. Constr. Build. Mater. 2009, 23, 2007–2015. [Google Scholar] [CrossRef]

- Chhun, K.T.; Lee, S.H.; Keo, S.A.; Yune, C.Y. Effect of Acrylate-Cement Grout on the Unconfined Compressive Strength of Silty Sand. KSCE J. Civ. Eng. 2019, 23, 2495–2502. [Google Scholar] [CrossRef]

- Persoff, P.; Apps, J.; Moridis, G.; Whang, J.M. Effect of dilution and contaminants on sand grouted with colloidal silica. J. Geotech. Geoenviron. Eng. 1999, 125, 461–469. [Google Scholar] [CrossRef]

- Ciardi, G.; Vannucchi, G.; Madiai, C. Effects of Colloidal Silica Grouting on Geotechnical Properties of Liquefiable Soils: A Review. Geotechnics 2021, 1, 460–491. [Google Scholar] [CrossRef]

- Vranna, A.; Tika, T. The Mechanical Response of a Silty Sand Stabilized with Colloidal Silica. Geotechnics 2021, 1, 243–259. [Google Scholar] [CrossRef]

- Anagnostopoulos, C.A.; Dimitriadi, M. Study on high performance polymer-modified cement grouts. CivilEng 2021, 2, 134–157. [Google Scholar] [CrossRef]

- Xia, Q.; Wen, J.; Tang, X.; Zhu, Y.; Xu, Z.; Du, Z.; Liu, X. Optimal preparation and degradation characterization of repair mortar containing waterborne epoxy resin emulsions. Constr. Build. Mater. 2021, 298, 123839. [Google Scholar] [CrossRef]

- Issa, S.A.; Debs, P. Experimental study of epoxy repairing of cracks and concrete. Constr. Build. Mater. 2007, 21, 157–163. [Google Scholar] [CrossRef]

- Wu, L.; Hoa, S.V.; Ton-That, M. Effects of water on the curing and properties of epoxy adhesive used for bonding FRP composite sheet to concrete. J. Appl. Polym. Sci. 2003, 92, 2261–2268. [Google Scholar] [CrossRef]

- Anagnostopoulos, C.A.; Hadjispyrou, S. Laboratory study of an epoxy resin grouted sand. Proc. Inst. Civ. Eng. Ground Improv. 2004, 8, 39–45. [Google Scholar] [CrossRef]

- Al-Khanbashi, A.; Abdala, S.W. Evaluation of three waterborne polymers as stabilizers for sandy soil. Geotech. Geol. Eng. 2006, 24, 1603–1625. [Google Scholar] [CrossRef]

- Anagnostopoulos, C.A.; Kandiliotis, P.; Lola, M.; Karavatos, S. Improving properties of sand using epoxy resin and electrokinetics. Geotech. Geol. Eng. 2014, 32, 859–872. [Google Scholar] [CrossRef]

- Anagnostopoulos, C.A.; Sapidis, G. Mechanical behaviour of epoxy resin-grouted sand under monotonic or cyclic loading. Geotech. Lett. 2017, 7, 298–303. [Google Scholar] [CrossRef]

- Anagnostopoulos, C.A. Strength properties of an epoxy resin and cement-stabilized silty clay soil. Appl. Clay Sci. 2015, 114, 517–529. [Google Scholar] [CrossRef]

- Ghasemzadeh, H.; Mehrpajouh, A.; Pishvaei, M. Laboratory analyses of kaolinite stabilized by vinyl polymers with different monomer types. Eng. Geol. 2021, 280, 105938. [Google Scholar] [CrossRef]

- Halabian, A.M.; Shakibzadeh, A.; Rowshan, Z.M.A. The static and dynamic behavior of sands grouted with amino-based resin. Proc. Inst. Civ. Eng. Ground Improv. 2018, 171, 21–37. [Google Scholar] [CrossRef]

- Anagnostopoulos, C.A.; Dimitriadi, M.; Konstantinidis, D. Static and cyclic behavior of epoxy resin and bentonite-grouted sands. Transp. Geotech. 2022, 33, 100725. [Google Scholar] [CrossRef]

- ASTM D 4320; Standard Practice for Laboratory Preparation of Chemically Grouted Soil Specimens for Obtaining Engineering Parameters. ASTM International: West Conshohocken, PA, USA, 2009.

- Anagnostopoulos, C.A. Effect of different superplasticisers on the physical and mechanical properties of cement grouts. Constr. Build. Mater. 2014, 50, 162–168. [Google Scholar] [CrossRef]

- ASTM D 4219; Standard Test Method for Unconfined Compressive Strength Index of Chemical-Grouted Soils. ASTM International: West Conshohocken, PA, USA, 2002.

- Neithalath, N.; Weiss, J.; Olek, J. Characterizing enhanced porosity concrete using electrical impedance to predict acoustic and hydraulic performance. Cem. Concr. Res. 2006, 36, 2074–2085. [Google Scholar] [CrossRef]

- ASTM D 5084; Standard Test Methods for Measurement of Hydraulic Conductivity of Saturated Porous Materials Using a Flexible Wall Permeameter. ASTM International: West Conshohocken, PA, USA, 2003.

- Powers, D.A. Interaction of Water with Epoxy; Sandia Report, SAND2009-4405; U.S. Department of Energy’s National Nuclear Security Administration: Albuquerque, NW, USA, 2009. [Google Scholar]

- Consoli, N.C.; Foppa, D.; Festugato, L.; Heineck, K.S. Key parameters for strength control of artificially cemented soils. J. Geotech. Geoenvironmental Eng. 2007, 133, 197–205. [Google Scholar] [CrossRef]

- Markou, I.; Droudakis, A. Factors affecting engineering properties of microfine cement grouted sands. Geotech. Geol. Eng. 2013, 31, 1041–1058. [Google Scholar] [CrossRef]

- Avci, E.; Mollamahmutoğlu, M. UCS properties of superfine cement–grouted sand. J. Mater. Civ. Eng. 2016, 28, 06016015. [Google Scholar] [CrossRef]

- Doherty, P.; Spagnoli, G.; Doherty, M. Laboratory investigations to assess the feasibility of employing a novel mixed-in-place offshore pile in calcareous deposits. Ships Offshore Struct. 2020, 15, 29–38. [Google Scholar] [CrossRef]

- Jafarian, Y.; Javdanian, H. Dynamic Properties of Calcareous Sand from the Persian Gulf in Comparison with Siliceous Sands Database. Int. J. Civ. Eng. 2020, 18, 245–249. [Google Scholar] [CrossRef]

- Cui, M.J.; Zheng, J.J.; Chu, J.; Wu, C.C.; Lai, H.J. Bio-mediated calcium carbonate precipitation and its effect on the shear behaviour of calcareous sand. Acta Geotech. 2021, 16, 1377–1389. [Google Scholar] [CrossRef]

- Hamidi, S.; Marandi, S.M. Clay concrete and effect of clay minerals types on stabilized soft clay soils by epoxy resin. Appl. Clay Sci. 2018, 151, 92–101. [Google Scholar] [CrossRef]

- Ata, A.; Vipulanandan, C. Factors affecting mechanical and creep properties of silicate-grouted sands. Geotech. Geol. Eng. 1999, 125, 868–876. [Google Scholar] [CrossRef]

- Ribay, E.D.; Maigre, I.D.; Cabrillac, R.; Gouvenot, D. Influence of grouts on unconfined creep behaviour of grouted Fontainebleau sand: Experimental and primary creep modeling. Proc. Inst. Civ. Eng. Ground Improv. 2002, 6, 23–37. [Google Scholar] [CrossRef]

- Ribay, E.; Maigre, I.; Cabbrillac, R.; Gouvenot, D. Comparison of creep behavior and fatigue behavior of grouted sand. Soils Found. 2007, 47, 185–194. [Google Scholar] [CrossRef]

- Chen, Z.J.; Feng, W.Q.; Yin, J.H. A new simplified method for calculating short-term and long-term consolidation settlements of multi-layered soils considering creep limit. Comput. Geotech. 2021, 138, 104324. [Google Scholar] [CrossRef]

- Mollamahmutoglu, M.; Avci, E.; Deveci, E. Strength and permeability properties of sodium silicate-glyoxal-stabilized silt and fine sand. Q. J. Eng. Geol. Hydrogeol. 2022, 55, qjegh2021-115. [Google Scholar] [CrossRef]

| S1 | S2 | S3 | S4 | S5 | S6 | |

|---|---|---|---|---|---|---|

| D60 (mm) | 0.8 | 0.28 | 0.11 | 0.5 | 1.19 | 1.85 |

| D50 (mm) | 0.67 | 0.2 | 0.097 | 0.33 | 0.8 | 2 |

| D30 (mm) | 0.57 | 0.21 | 0.091 | 0.15 | 0.39 | 1.31 |

| D10 (mm) | 0.46 | 0.17 | 0.08 | 0.09 | 0.149 | 1.22 |

| Coefficient of uniformity, Cu | 1.74 | 1.65 | 1.37 | 5.55 | 7.98 | 1.52 |

| Coefficient of curvature, Cc | 0.88 | 0.92 | 0.94 | 0.5 | 0.86 | 0.76 |

| Specific gravity, Gs | 2.66 | 2.66 | 2.66 | 2.66 | 2.66 | 2.66 |

| Maximum void ratio, emax | 0.78 | 0.87 | 0.96 | 0.64 | 0.564 | 0.88 |

| Minimum dry unit weight, γdmin (kN/m3) | 14.9 | 14.2 | 13.5 | 16.25 | 17 | 14.15 |

| Minimum void ratio, emin | 0.62 | 0.61 | 0.64 | 0.47 | 0.364 | 0.576 |

| Maximum dry unit weight, γdmax (kN/m3) | 16.4 | 16.5 | 16.2 | 18.1 | 19.5 | 16.87 |

| ER/W Ratio | a | b | R2 | |||

|---|---|---|---|---|---|---|

| UCS | EM | UCS | EM | UCS | EM | |

| 3 | 2.543 | 206.66 | −0.324 | −0.272 | 0.99 | 0.95 |

| 2 | 1.726 | 126.05 | −0.304 | −0.313 | 0.99 | 0.96 |

| 1.5 | 0.852 | 82.08 | −0.432 | −0.339 | 0.98 | 0.92 |

| Notation | k (m/s) | n (%) |

|---|---|---|

| S1 | 3.04 × 10−3 | 41.7 |

| S1 + ER/W = 3 | 4.72 × 10−6 | 29.62 |

| S1 + ER/W = 2 | 8.29 × 10−6 | 30 |

| S1 + ER/W = 1.5 | 1.03 × 10−5 | 36.14 |

| S2 | 2.89 × 10−4 | 43.4 |

| S2 + ER/W = 3 | 2.6 × 10−6 | 31.68 |

| S2 + ER/W = 2 | 6.1 × 10−6 | 34 |

| S2 + ER/W = 1.5 | 7.34 × 10−6 | 36.7 |

| S3 | 4.94 × 10−5 | 45.4 |

| S3 + ER/W = 3 | 8.76 × 10−7 | 37.04 |

| S3 + ER/W = 2 | 2.97 × 10−6 | 39.41 |

| S3 + ER/W = 1.5 | 8.72 × 10−6 | 41.72 |

| S4 | 7.04 × 10−5 | 36.3 |

| S4 + ER/W = 3 | 2.46 × 10−6 | 30.56 |

| S4 + ER/W = 2 | 3.5 × 10−6 | 31.6 |

| S4 + ER/W = 1.5 | 5.27 × 10−6 | 33.79 |

| S5 | 3.4 × 10−4 | 32.6 |

| S5 + ER/W = 3 | 9.68 × 10−7 | 23.4 |

| S5 + ER/W = 2 | 3.47 × 10−6 | 26.3 |

| S5 + ER/W = 1.5 | 9 × 10−6 | 28.4 |

| S6 | 9.56 × 10−2 | 43.1 |

| S6 + ER/W = 3 | 9.2 × 10−6 | 34.5 |

| S6 + ER/W = 2 | 1.2 × 10−5 | 36.7 |

| S6 + ER/W = 1.5 | 2.94 × 10−5 | 38.4 |

| ER/W Ratio | Compressive Strength (MPa) | Elastic Modulus (MPa) | ||

|---|---|---|---|---|

| Calcareous | Siliceous | Calcareous | Siliceous | |

| 3 | 2.8 | 2.66 | 225 | 230 |

| 2 | 1.98 | 1.88 | 135 | 128 |

| 1.5 | 1.05 | 1.1 | 88 | 92 |

| Notation | Qf | |

|---|---|---|

| Dry Condition | Wet Condition | |

| S1 + ER/W = 3 | 80 | 72.5 |

| S1 + ER/W = 2 | 77.5 | 70 |

| S1 + ER/W = 1.5 | 75 | 70 |

| S2 + ER/W = 3 | 82 | 75 |

| S2 + ER/W = 2 | 80 | 75 |

| S2 + ER/W = 1.5 | 78 | 72.5 |

| S3 + ER/W = 3 | 85 | 77.5 |

| S3 + ER/W = 2 | 82.5 | 75 |

| S3 + ER/W = 1.5 | 80 | 75 |

| S4 + ER/W = 3 | 82 | 75 |

| S4 + ER/W = 2 | 80 | 72.5 |

| S4 + ER/W = 1.5 | 80 | 72.5 |

| S5 + ER/W = 3 | 80 | 75 |

| S5 + ER/W = 2 | 78.5 | 72.5 |

| S5 + ER/W = 1.5 | 77.5 | 70 |

| S6 + ER/W = 3 | 72.5 | 62.5 |

| S6 + ER/W = 2 | 70 | 60 |

| S6 + ER/W = 1.5 | 67.5 | 55.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Anagnostopoulos, C.A.; Aggelidis, V. Factors Affecting Properties of Polymer Grouted Sands. CivilEng 2024, 5, 65-88. https://doi.org/10.3390/civileng5010004

Anagnostopoulos CA, Aggelidis V. Factors Affecting Properties of Polymer Grouted Sands. CivilEng. 2024; 5(1):65-88. https://doi.org/10.3390/civileng5010004

Chicago/Turabian StyleAnagnostopoulos, Costas A., and Vasilios Aggelidis. 2024. "Factors Affecting Properties of Polymer Grouted Sands" CivilEng 5, no. 1: 65-88. https://doi.org/10.3390/civileng5010004

APA StyleAnagnostopoulos, C. A., & Aggelidis, V. (2024). Factors Affecting Properties of Polymer Grouted Sands. CivilEng, 5(1), 65-88. https://doi.org/10.3390/civileng5010004