High Glass Waste Incorporation towards Sustainable High-Performance Concrete

Abstract

1. Introduction

2. Research Significance and Limitations

3. Materials

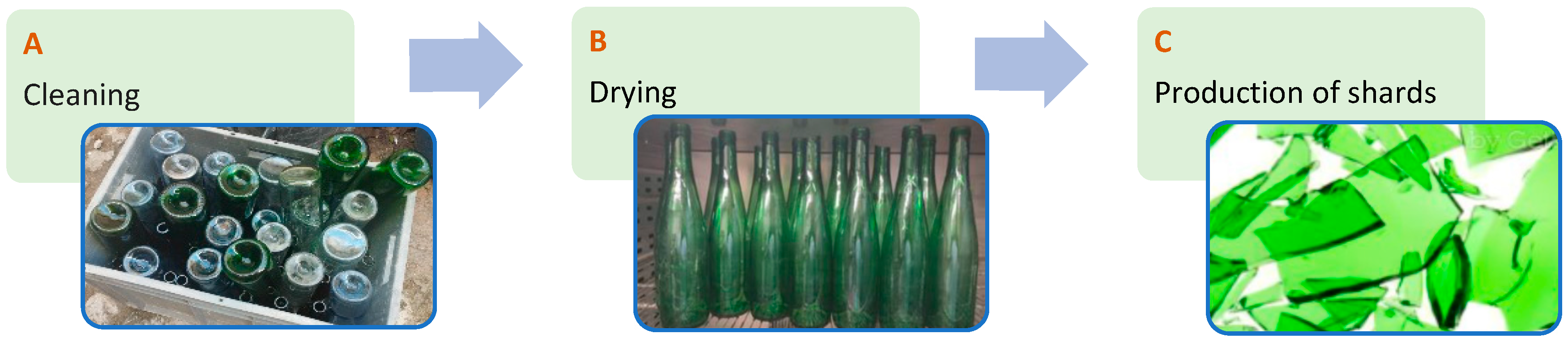

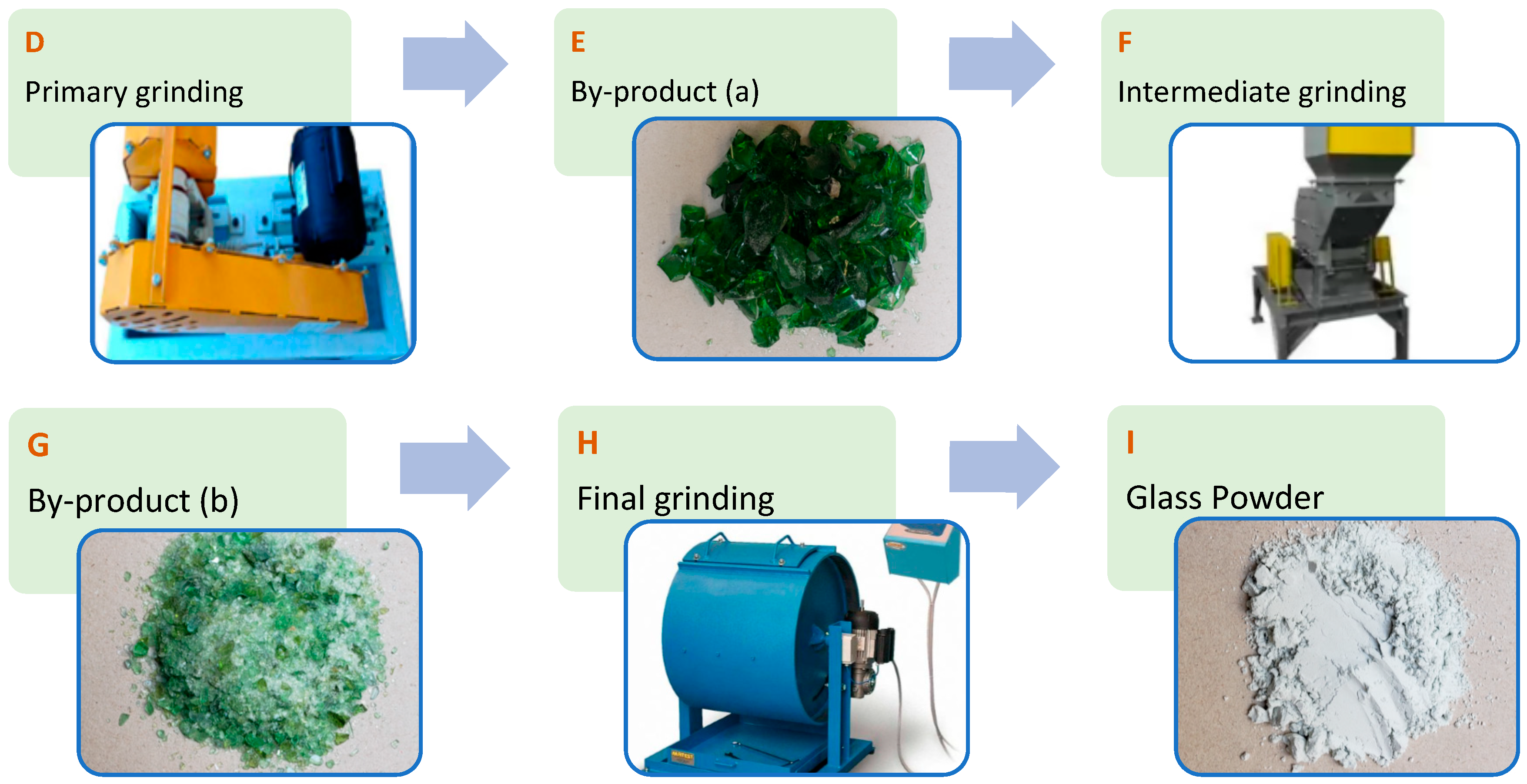

3.1. Obtaining Glass Powder

- Cleaning and decontamination: The bottles were submerged in water for 48 h to facilitate the removal of gross dirt (caps, corks, and beverage residue), labels, and excess glue. Then, the bottles were brushed inside and outside under running water.

- Drying: The bottles were placed in a ventilated oven for one hour at a controlled temperature of 105 ± 1 °C.

- Production of glass shards: The bottles were manually broken, generating glass shards (size about 50 mm).

- Primary grinding: The shards were introduced into a jaw crusher, undergoing two passes (2 cycles), lasting about 5 min.

- The by-product (a), after the cycles in step D, was large glass shards (size about 10 mm).

- Intermediate grinding: The grains obtained in step E were inserted into a hammer mill, again undergoing two passes in the equipment, lasting about 5 min.

- The by-product (b), after the cycles in step F, was fine glass shards (size about 1 mm).

- Final grinding: To reduce the grain size, the material was introduced, in portions of 5 kg, into a metallic ball mill or “Los Angeles” mill, where it remained for 40 cycles of 15 min each, totaling 10 h of grinding (33 rpm), with an abrasive mass of 8.410 kg. The final product obtained was the GP used in concrete compositions.

- Glass powder used in concretes.

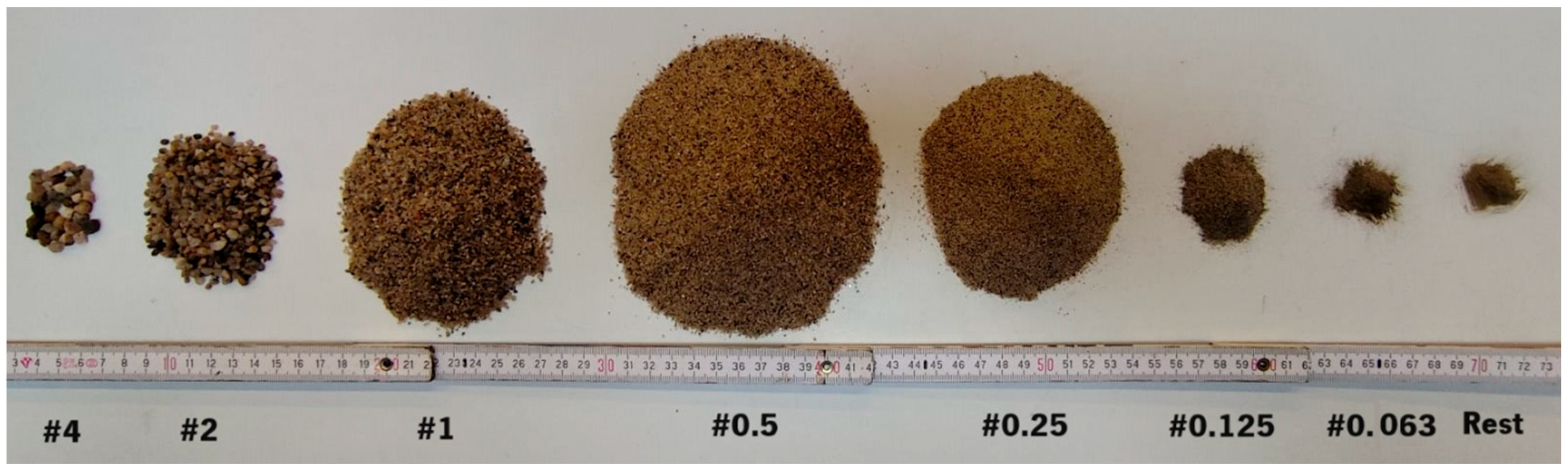

3.2. Materials’ Characterization

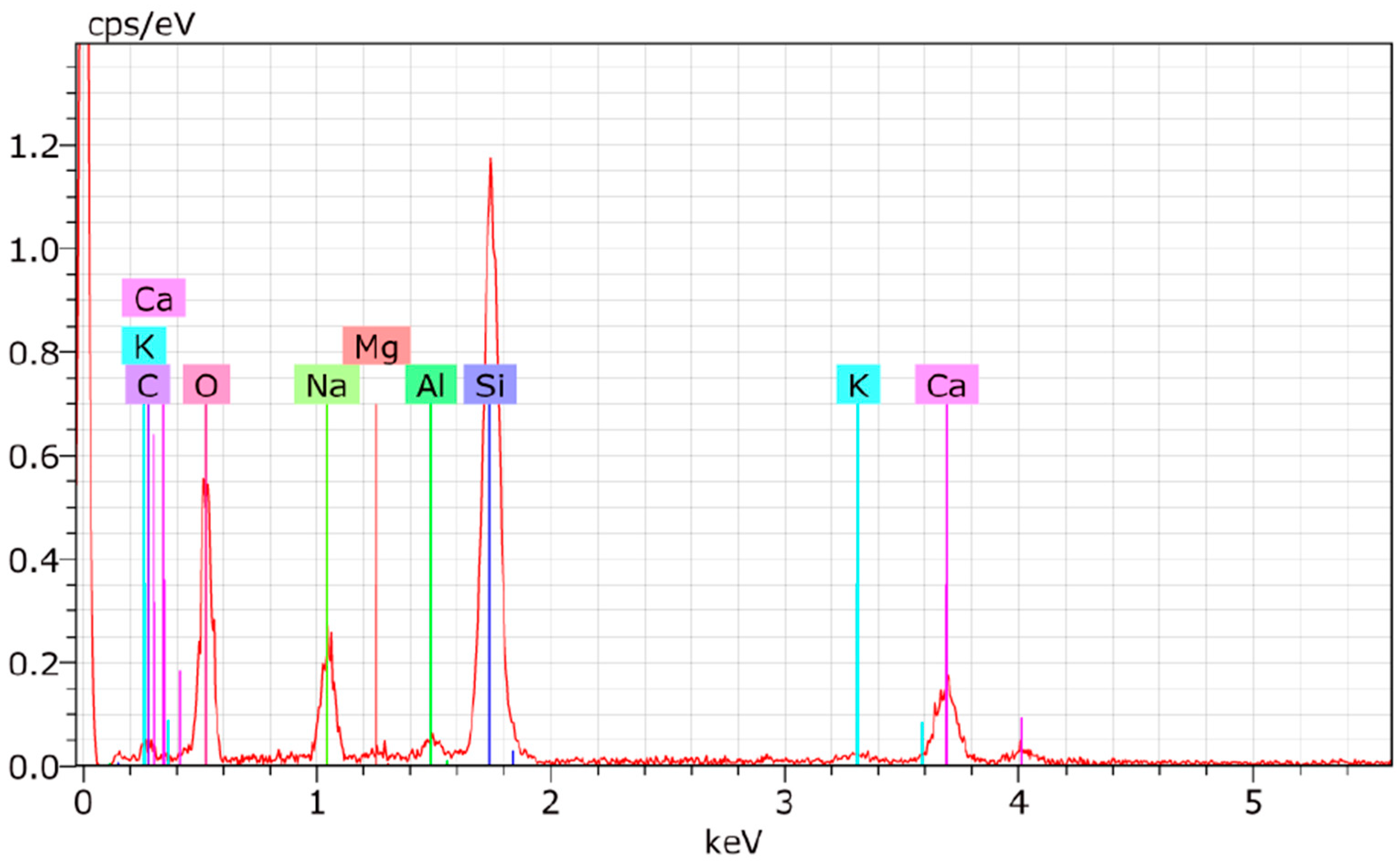

3.2.1. Chemical Composition of the Binders

3.2.2. Specific Surface Area/Bulk Density

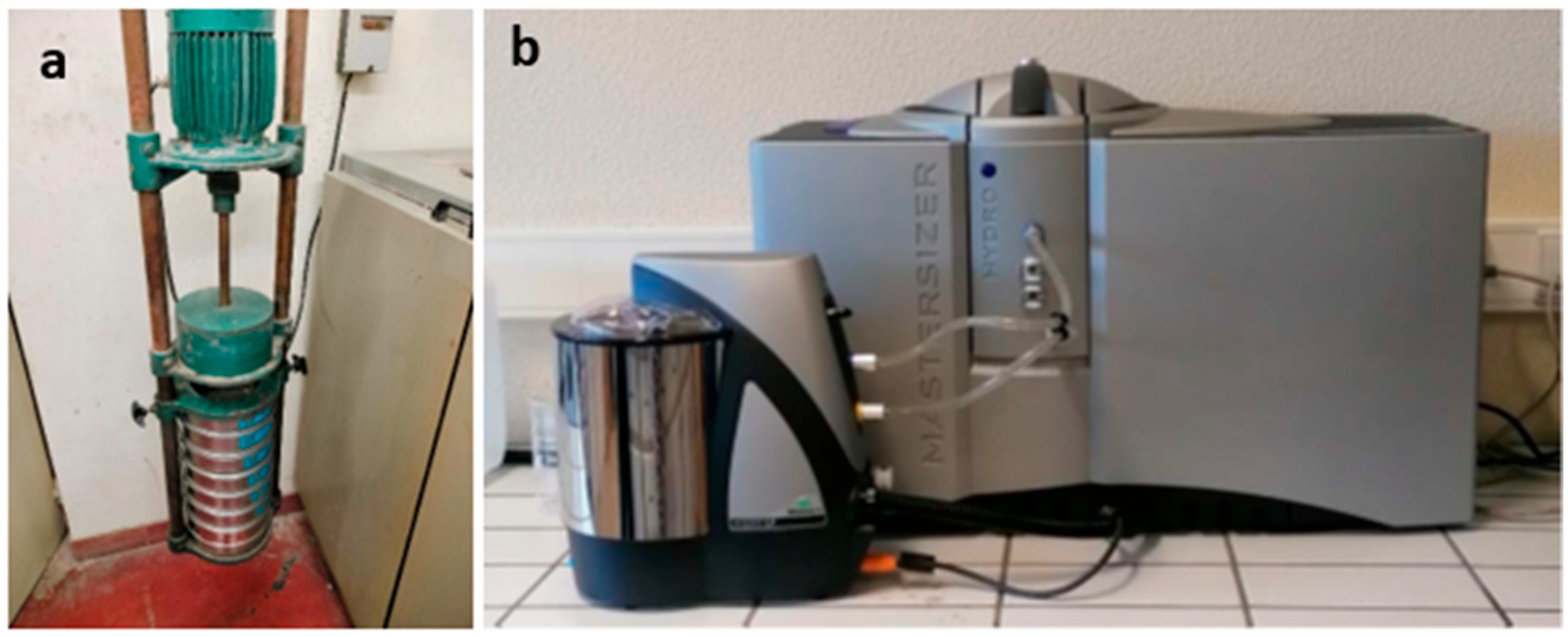

3.2.3. Particle Size

3.2.4. Glass Powder Activity Index

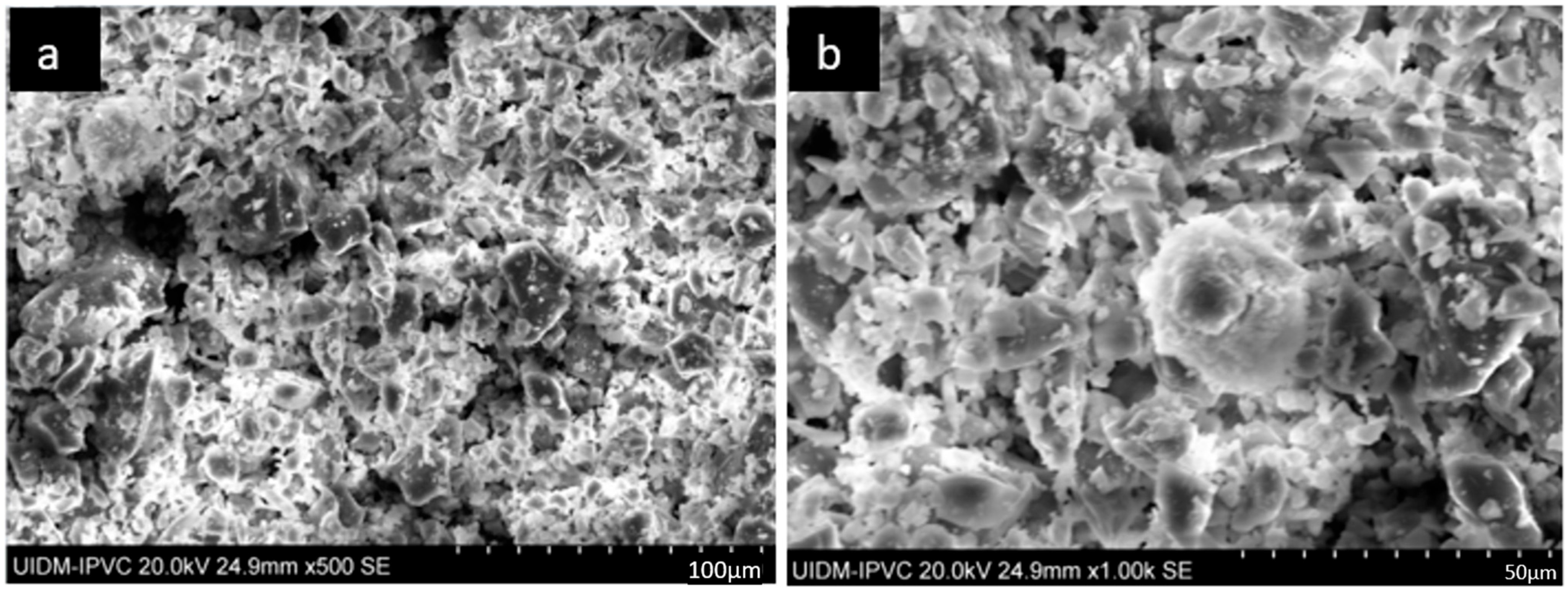

3.2.5. Glass Powder Morphology

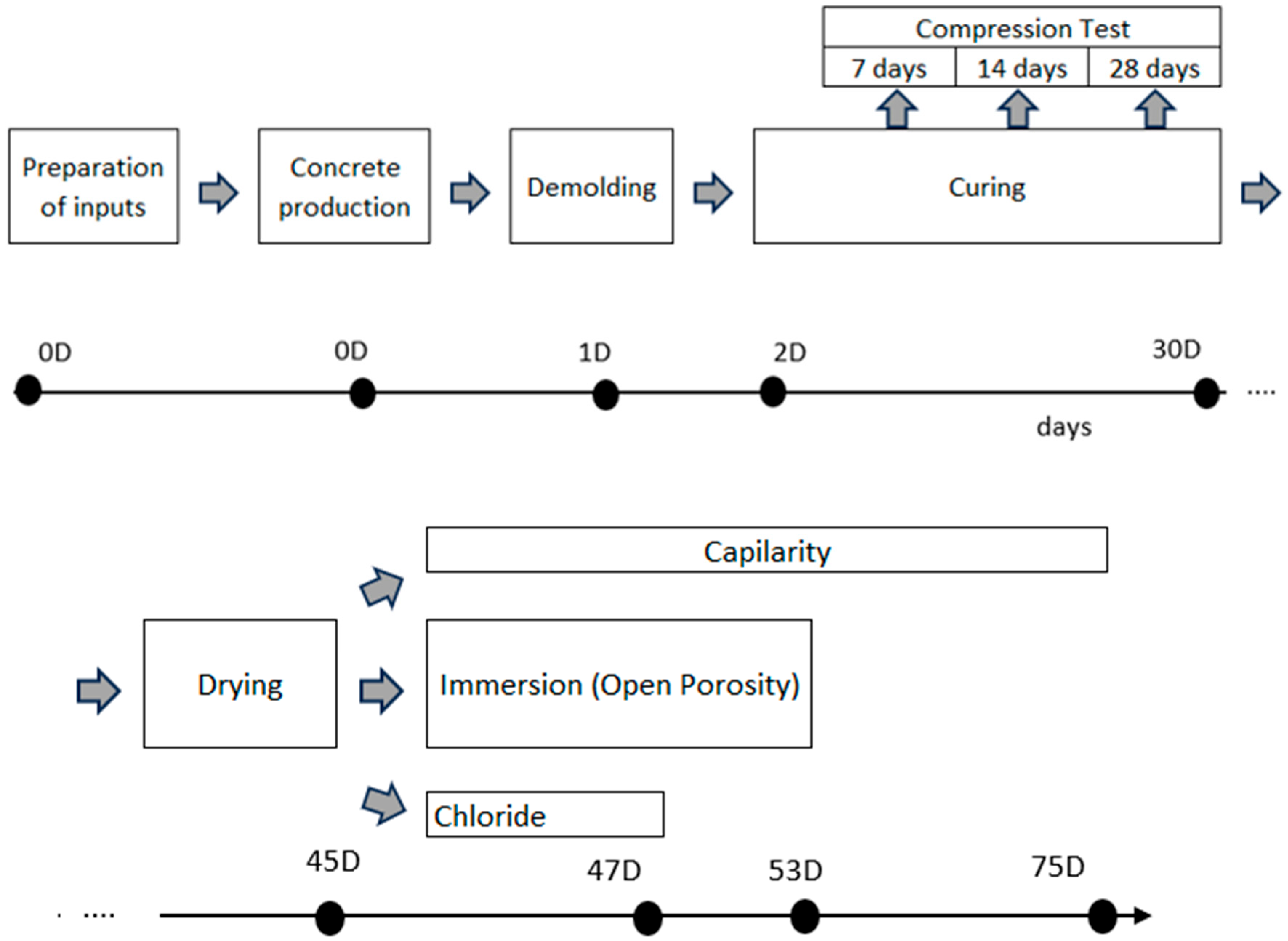

4. Specimens and Test Methods

4.1. Mechanical Resistance

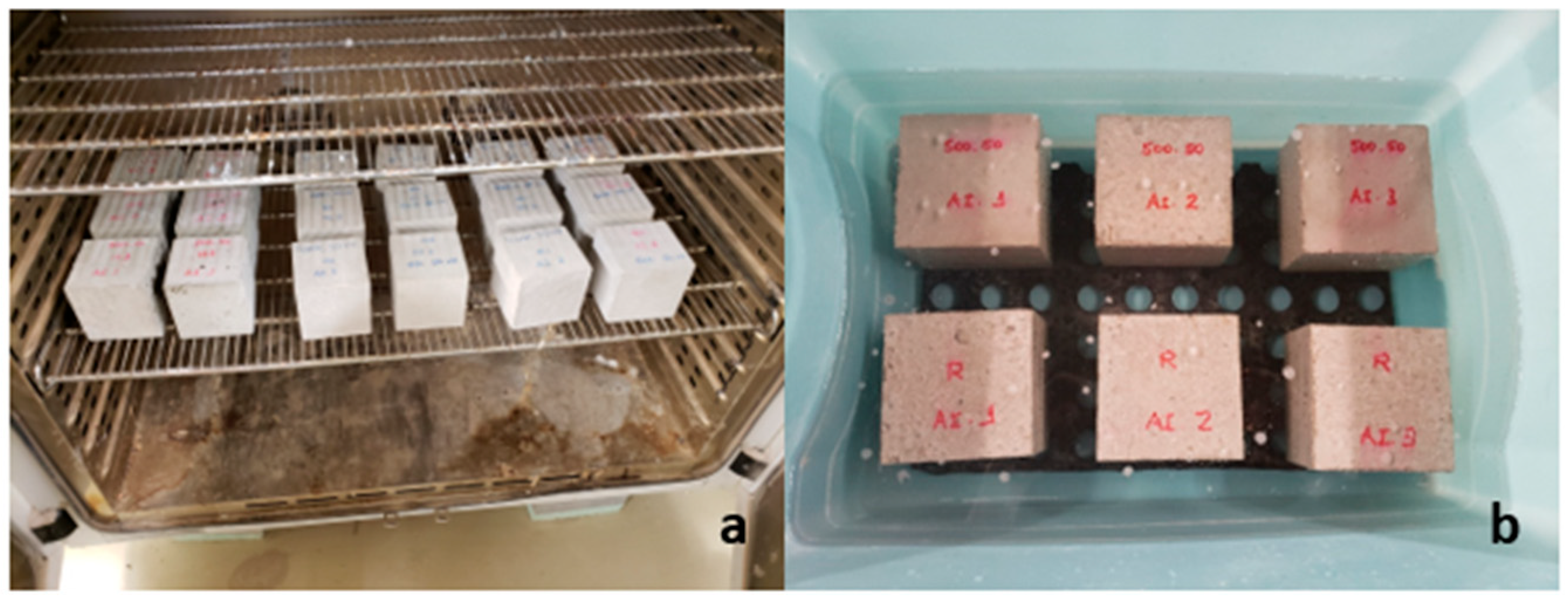

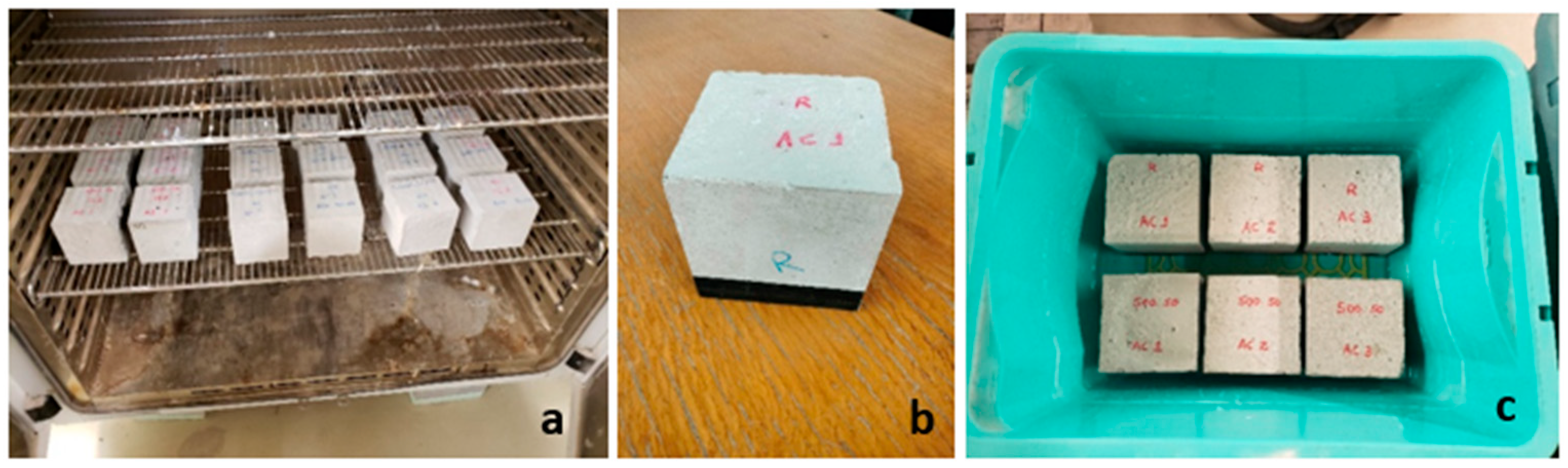

Compressive Strength Test

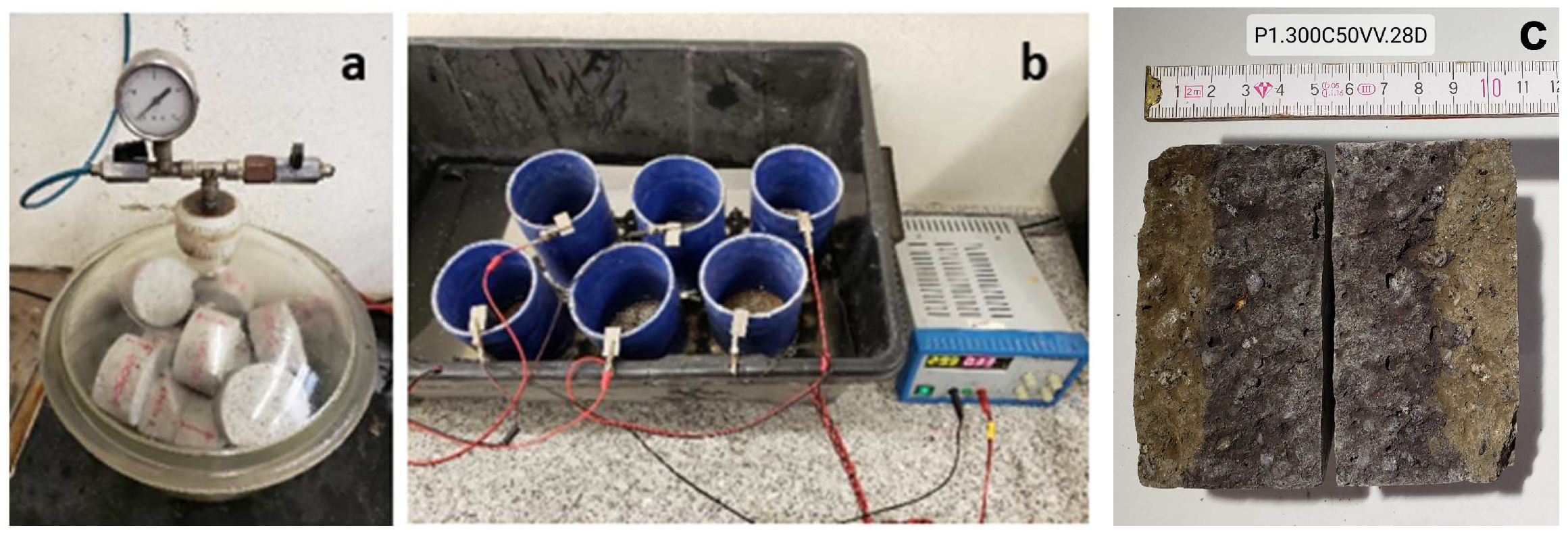

4.2. Durability Indicator Tests

4.2.1. Water Absorption by Immersion (Open Porosity)

4.2.2. Capillary Absorption

4.2.3. Diffusion Coefficient of Chlorides

5. Test Results and Discussion

5.1. Mechanical Resistance

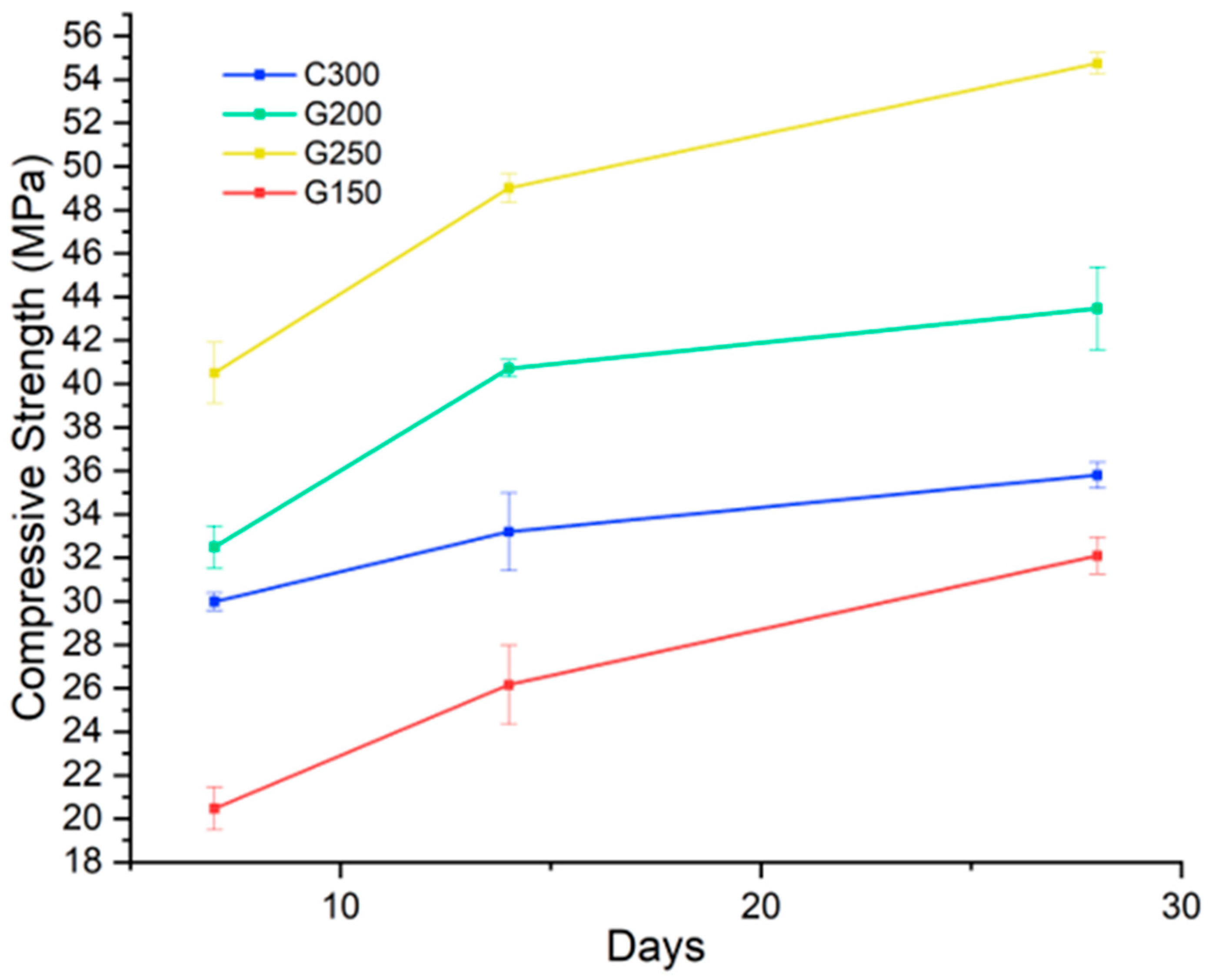

Compressive Strength

5.2. Durability Indicator Tests

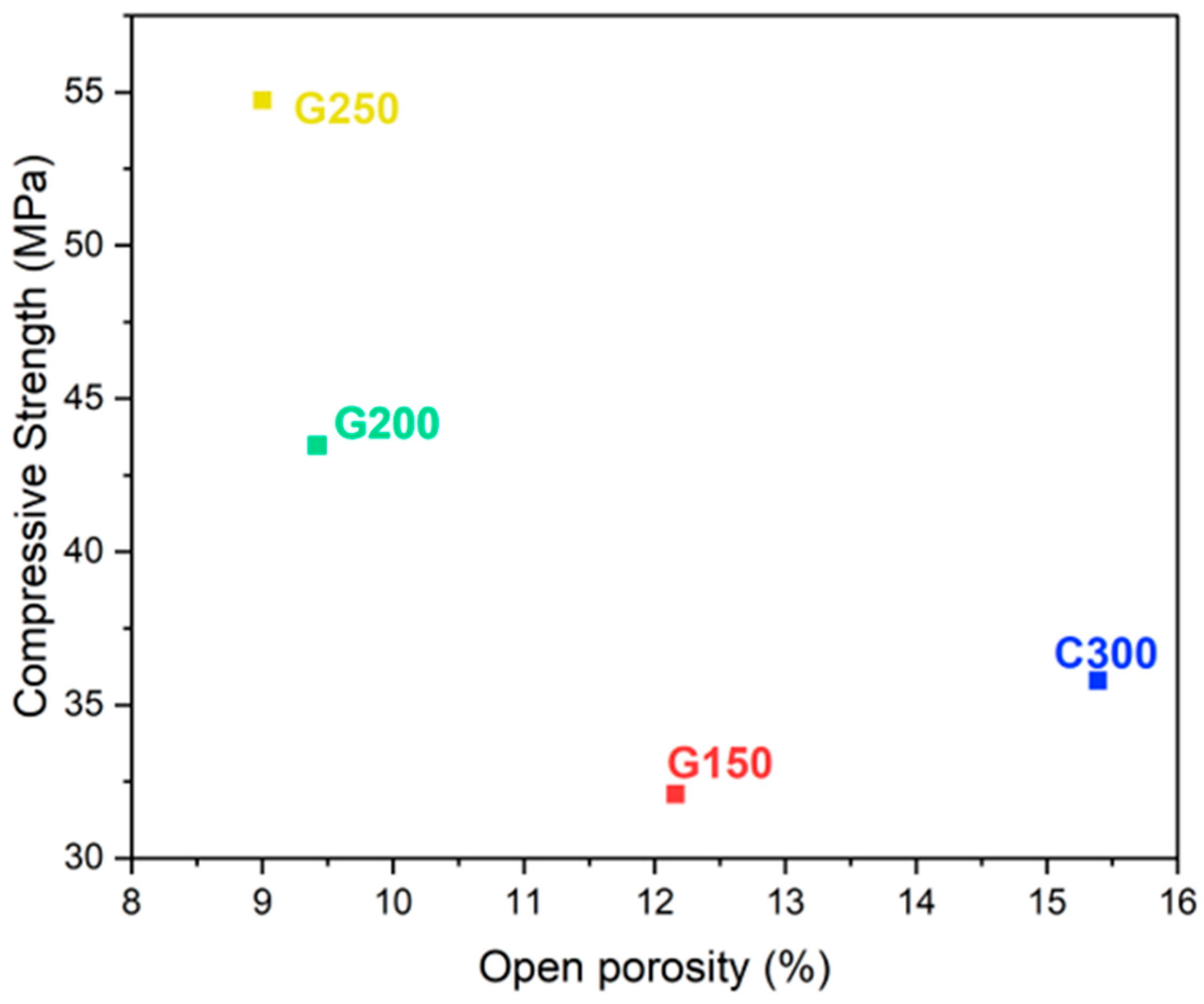

5.2.1. Absorption of Water by Immersion (Open Porosity)

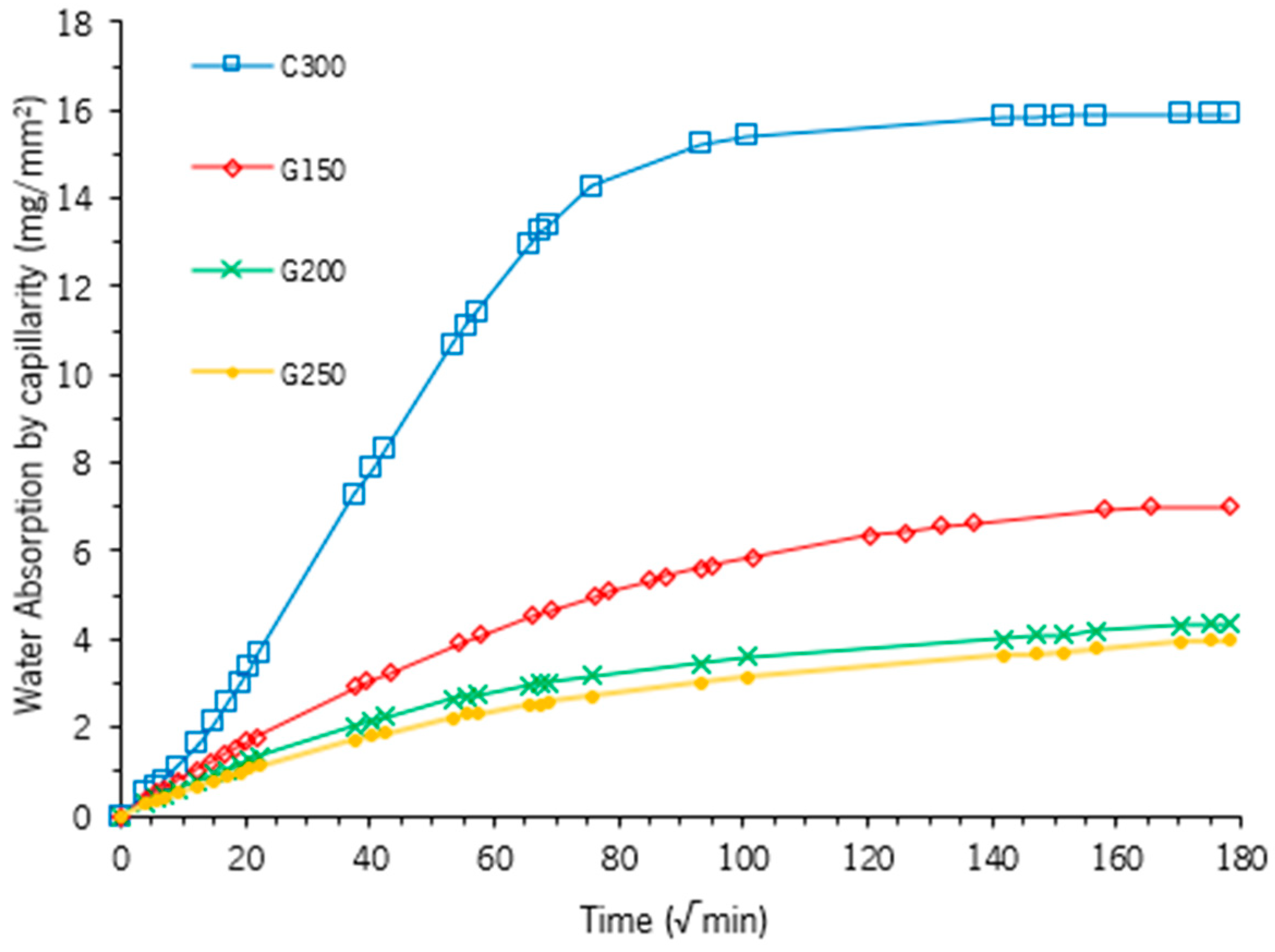

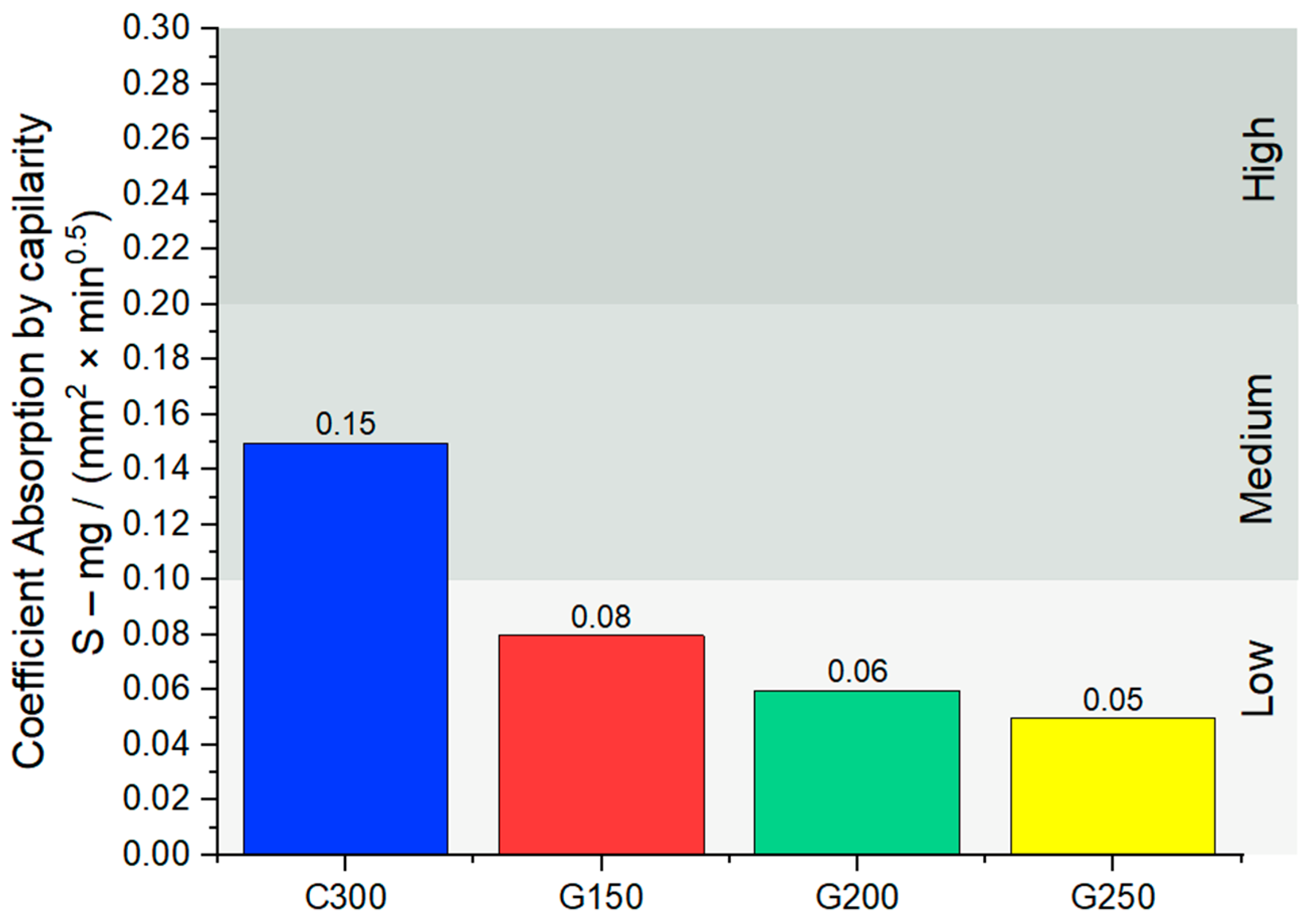

5.2.2. Absorption of Water through Capillarity

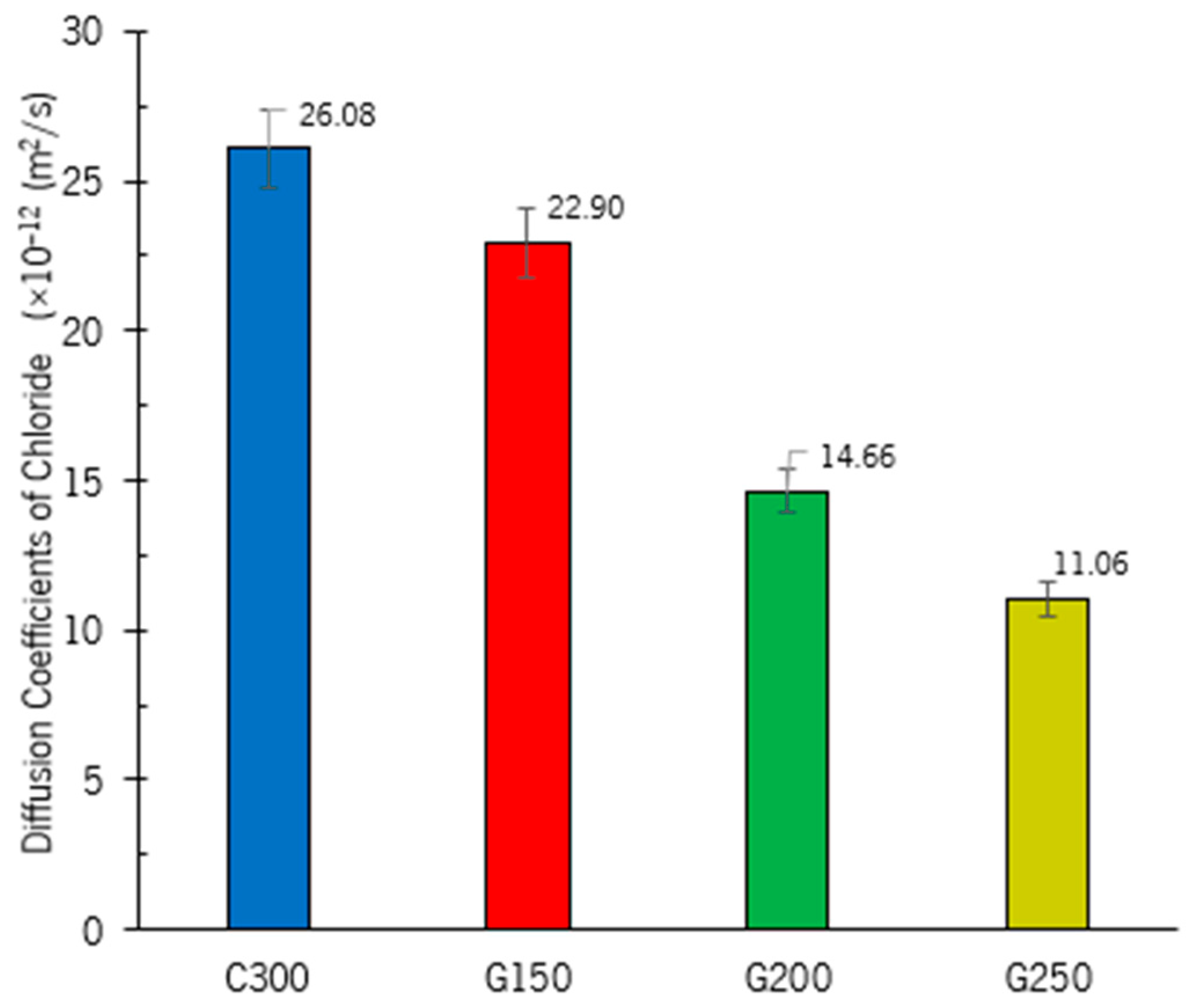

5.2.3. Diffusion Coefficient of Chlorides

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Global Cement and Concrete Association (GCCA). 2022. Available online: http://gccassociation.org (accessed on 15 August 2022).

- IEA—International Energy Agency. Cement Roadmaps 2009. Available online: www.iea.org/roadmaps (accessed on 15 August 2022).

- Jiang, X.; Xiao, R.; Bai, Y.; Huang, B.; Ma, Y. Influence of waste glass powder as a supplementary cementitious material (SCM) on physical and mechanical properties of cement paste under high temperatures. J. Clean. Prod. 2022, 340, 130778. [Google Scholar] [CrossRef]

- Rodier, L.; Savastano, H. Use of glass powder residue for the elaboration of eco-efficient cementitious materials. J. Clean. Prod. 2018, 184, 333–341. [Google Scholar] [CrossRef]

- Esmaeili, J.; Al-Mwanes, A.O. A review: Properties of eco-friendly ultra-high-performance concrete incorporated with waste glass as a partial replacement for cement. Mater. Today Proc. 2021, 42, 1958–1965. [Google Scholar] [CrossRef]

- Patel, D.; Tiwari, R.P.; Shrivastava, R.; Yadav, R.K. Effective utilization of waste glass powder as the substitution of cement in making paste and mortar. Constr. Build. Mater. 2019, 199, 406–415. [Google Scholar] [CrossRef]

- Tamanna, N.; Tuladhar, R. Sustainable Use of Recycled Glass Powder as Cement Replacement in Concrete. Open Waste Manag. J. 2020, 13, 1–13. [Google Scholar] [CrossRef]

- He, Z.-H.; Zhan, P.-M.; Du, S.-G.; Liu, B.-J.; Yuan, W.-B. Creep behavior of concrete containing glass powder. Compos. Part B Eng. 2018, 166, 13–20. [Google Scholar] [CrossRef]

- Qaidi, S.; Najm, H.M.; Abed, S.M.; Özkılıç, Y.O.; Al Dughaishi, H.; Alosta, M.; Sabri, M.M.S.; Alkhatib, F.; Milad, A. Concrete Containing Waste Glass as an Environmentally Friendly Aggregate: A Review on Fresh and Mechanical Characteristics. Materials 2022, 15, 6222. [Google Scholar] [CrossRef]

- Çelik, A.I.; Özkılıç, Y.O.; Zeybek, Ö.; Karalar, M.; Qaidi, S.; Ahmad, J.; Burduhos-Nergis, D.D.; Bejinariu, C. Mechanical Behavior of Crushed Waste Glass as Replacement of Aggregates. Materials 2022, 15, 8093. [Google Scholar] [CrossRef] [PubMed]

- Al Saffar, D.M.A.R. Experimental investigation of using ultra-fine glass powder in concrete. Int. J. Eng. Res. Appl. 2017, 7, 33–39. [Google Scholar]

- Hooton, R.; Thomas, M.; Shehata, M.; Shashiprakash, S. The Use of Fly Ash in Concrete: Classification by Composition. Cem. Concr. Aggregates 1999, 21, 105. [Google Scholar] [CrossRef]

- Çelik, A.I.; Tunç, U.; Bahrami, A.; Karalar, M.; Mydin, A.O.; Alomayri, T.; Özkılıç, Y.O. Use of waste glass powder toward more sustainable geopolymer concrete. J. Mater. Res. Technol. 2023, 24, 8533–8546. [Google Scholar] [CrossRef]

- Özkılıç, Y.O.; Çelik, A.I.; Tunç, U.; Karalar, M.; Deifalla, A.; Alomayri, T.; Althoey, F. The use of crushed recycled glass for alkali activated fly ash based geopolymer concrete and prediction of its capacity. J. Mater. Res. Technol. 2023, 24, 8267–8281. [Google Scholar] [CrossRef]

- Sujjavanich, S.; Sida, V.; Suwanvitaya, P. Chloride permeability and corrosion risk of high-volume fly ash concrete with mid-range water reducer. ACI Mater. J. 2005, 102, 177. [Google Scholar]

- Reis, R.J.A.d.C. Influência da Adição de Cal Hidratada na Carbonatação de Betões de Elevado Volume de Cinzas Volantes. Ph.D. Thesis, Universidade do Minho, Braga, Portugal, 2022. Available online: https://hdl.handle.net/1822/81153 (accessed on 10 June 2023).

- Herath, C.; Gunasekara, C.; Law, D.W.; Setunge, S. Performance of high volume fly ash concrete incorporating additives: A systematic literature review. Constr. Build. Mater. 2020, 258, 120606. [Google Scholar] [CrossRef]

- Soliman, N.; Tagnit-Hamou, A. Development of ultra-high-performance concrete using glass powder—Towards ecofriendly concrete. Constr. Build. Mater. 2016, 125, 600–612. [Google Scholar] [CrossRef]

- Saraya, M.E.-S.I. Study physico-chemical properties of blended cements containing fixed amount of silica fume, blast furnace slag, basalt and limestone, a comparative study. Constr. Build. Mater. 2014, 72, 104–112. [Google Scholar] [CrossRef]

- Rêgo, J.H.S. As Cinzas de Casca de Arroz (CCAs) Amorfa e Cristalina como Adição Mineral ao Cimento—Aspectos de Microestrutura das Pastas. Ph.D. Thesis, UNB, Brasília, Brazil, 2004. Available online: https://repositorio.unb.br/handle/10482/42047 (accessed on 10 September 2022).

- Moreira, O.; Malheiro, R.; Jesus, C.; Camões, A.; Ribeiro, M.J. Incorporation of sludge from the cutting of ornamental rocks in cementitious materials. In Proceedings of the Construction Congress, Portugal, 5–7 December 2022; Universidade do Minho: Braga, Portugal. [Google Scholar]

- Karalar, M.; Özkılıç, Y.O.; Aksoylu, C.; Sabri, M.M.S.; Beskopylny, A.N.; Stel’makh, S.A.; Shcherban’, E.M. Flexural behavior of reinforced concrete beams using waste marble powder towards application of sustainable concrete. Front. Mater. 2022, 9, 1068791. [Google Scholar] [CrossRef]

- Başaran, B.; Aksoylu, C.; Özkılıç, Y.O.; Karalar, M.; Hakamy, A. Shear behaviour of reinforced concrete beams utilizing waste marble powder. Structures 2023, 54, 1090–1100. [Google Scholar] [CrossRef]

- Karalar, M.; Bilir, T.; Çavuşlu, M.; Özkiliç, Y.O.; Sabri, M.M.S. Use of recycled coal bottom ash in reinforced concrete beams as replacement for aggregate. Front. Mater. 2022, 9, 1064604. [Google Scholar] [CrossRef]

- Chang, Q.; Liu, L.; Farooqi, M.U.; Thomas, B.; Özkılıç, Y.O. Data-driven based estimation of waste-derived ceramic concrete from experimental results with its environmental assessment. J. Mater. Res. Technol. 2023, 24, 6348–6368. [Google Scholar] [CrossRef]

- Manoel, J.A.H.M.C. Análise de Processos Fabris na BA Vidro. Master’s Thesis, Faculdade de Engenharia da Universidade do Porto, Porto, Portugal, 2010. Available online: http://hdl.handle.net/10216/59746 (accessed on 10 September 2022).

- FEVE—European Glass Container Glass Federation. Available online: www.feve.org (accessed on 10 September 2022).

- The Eurostat Data Set: Recycling Rates of Packaging Waste for Monitoring Compliance with Policy Targets, by Type of Packaging. Online data code: ENV_WASPACR, 2021. Available online: https://ec.europa.eu/eurostat (accessed on 20 November 2022).

- Shao, Y.; Lefort, T.; Moras, S.; Rodriguez, D. Studies on concrete containing ground waste glass. Cem. Concr. Res. 2000, 30, 91–100. [Google Scholar] [CrossRef]

- Tagnit-Hamou, A.; Zidol, A.; Deschamps, N.S.J.; Omran, A. Ground Glass Pozzolan in Conventional, High, and Ultra-High-Performance Concrete. MATEC Web Conf. 2018, 149, 01005. [Google Scholar] [CrossRef]

- Islam, G.M.S.; Rahman, M.; Kazi, N. Waste glass powder as partial replacement of cement for sustainable concrete practice. Int. J. Sustain. Built Environ. 2017, 6, 37–44. [Google Scholar] [CrossRef]

- Shayan, A.; Xu, A. Performance of glass powder as a pozzolanic material in concrete: A field trial on concrete slabs. Cem. Concr. Res. 2006, 36, 457–468. [Google Scholar] [CrossRef]

- Du, H.; Tan, K.H. Waste Glass Powder as Cement Replacement in Concrete. J. Adv. Concr. Technol. 2014, 12, 468–477. [Google Scholar] [CrossRef]

- Du, H.; Tan, K.H. Transport Properties of Concrete with Glass Powder as Supplementary Cementitious Material. ACI Mater. J. 2015, 112, 429–438. [Google Scholar] [CrossRef]

- Zeybek, Ö.; Özkılıç, Y.O.; Karalar, M.; Çelik, A.I.; Qaidi, S.; Ahmad, J.; Burduhos-Nergis, D.D.; Burduhos-Nergis, D.P. Influence of Replacing Cement with Waste Glass on Mechanical Properties of Concrete. Materials 2022, 15, 7513. [Google Scholar] [CrossRef]

- Patil, D.M.; Sangle, K.K. Experimental investigation of waste glass powder as partial replacement of cement in concrete. Int. J. Adv. Technol. Civ. Eng. 2013, 2, 2231–5721. [Google Scholar] [CrossRef]

- Rahman, S.; Uddin, M. Experimental Investigation of Concrete with Glass Powder as Partial Replacement of Cement. Civ. Eng. Arch. 2018, 6, 149–154. [Google Scholar] [CrossRef]

- Najad, A.A.A.-J.; Kareem, J.H.; Azline, N.; Ostovar, N. Waste glass as partial replacement in cement—A review. IOP Conf. Ser. Earth Environ. Sci. 2019, 357, 012023. [Google Scholar] [CrossRef]

- Zhang, Y.; Xiao, R.; Jiang, X.; Li, W.; Zhu, X.; Huang, B. Effect of particle size and curing temperature on mechanical and microstructural properties of waste glass-slag-based and waste glass-fly ash-based geopolymers. J. Clean. Prod. 2020, 273, 122970. [Google Scholar] [CrossRef]

- Malheiro, R.; Moreira, B.; Pontes, K.; Jesus, C.; Camões, A. Utilização do pó de Vidro como Substituto Parcial do Cimento: Uma Abordagem Experimental Acerca da Resistência Mecânica; CLBMCS: Salvador, Brazil, 2022; Available online: https://hdl.handle.net/1822/81939 (accessed on 10 June 2023).

- Matos, A.M. Estudo de Argamassas com Substituição Parcial de Cimento por Resíduos de Vidro Moídos. Master’s Thesis, FEUP, Porto, Portugal, 2010. Available online: http://hdl.handle.net/10216/59733 (accessed on 15 August 2022).

- Zheng, K. Pozzolanic reaction of glass powder and its role in controlling alkali–silica reaction. Cem. Concr. Compos. 2016, 67, 30–38. [Google Scholar] [CrossRef]

- Jiang, Y.; Ling, T.-C.; Mo, K.H.; Shi, C. A critical review of waste glass powder—Multiple roles of utilization in cement-based materials and construction products. J. Environ. Manag. 2019, 242, 440–449. [Google Scholar] [CrossRef] [PubMed]

- Liu, S.; Xie, G.; Wang, S. Effect of glass powder on microstructure of cement pastes. Adv. Cem. Res. 2015, 27, 259–267. [Google Scholar] [CrossRef]

- Aliabdo, A.A.; Abd Elmoaty, A.E.M.; Aboshama, A.Y. Utilization of waste glass powder in the production of cement and concrete. Constr. Build. Mater. 2016, 124, 866–877. [Google Scholar] [CrossRef]

- Lu, J.X.; Shen, P.; Zhang, Y.; Zheng, H.; Sun, Y.; Poon, C.S. Early-age and microstructural properties of glass powder blended cement paste: Improvement by seawater. Cem. Concr. Compos. 2021, 122, 104165. [Google Scholar] [CrossRef]

- ASTM C1866; Standard Specification for Ground-Glass Pozzolan for Use in Concrete. ASTM International: West Conshohocken, PA, USA, 2020.

- Du, H.; Tan, K.H. Properties of high volume glass powder concrete. Cem. Concr. Compos. 2017, 75, 22–29. [Google Scholar] [CrossRef]

- Kalakada, Z.; Doh, J.-H.; Chowdhury, S. Glass powder as replacement of cement for concrete—An investigative study. Eur. J. Environ. Civ. Eng. 2019, 26, 1046–1063. [Google Scholar] [CrossRef]

- Abdulazeez, A.S.; Idi, M.A.; Kolawole, M.A.; Hamza, B. Effect of Waste Glass Powder as A Pozzolanic Material in Concrete Production. Int. J. Eng. Res. 2020, 9, 589–594. [Google Scholar] [CrossRef]

- Amin, M.; Agwa, I.S.; Mashaan, N.; Mahmood, S.; Abd-Elrahman, M.H. Investigation of the Physical Mechanical Properties and Durability of Sustainable Ultra-High Performance Concrete with Recycled Waste Glass. Sustainability 2023, 15, 3085. [Google Scholar] [CrossRef]

- Guo, P.; Meng, W.; Nassif, H.; Gou, H.; Bao, Y. New perspectives on recycling waste glass in manufacturing concrete for sustainable civil infrastructure. Constr. Build. Mater. 2020, 257, 119579. [Google Scholar] [CrossRef]

- Kamali, M.; Ghahremaninezhad, A. Effect of glass powders on the mechanical and durability properties of cementitious materials. Constr. Build. Mater. 2015, 98, 407–416. [Google Scholar] [CrossRef]

- Neithalath, N.; Weiss, J.; Olek, J. Characterizing Enhanced Porosity Concrete using electrical impedance to predict acoustic and hydraulic performance. Cem. Concr. Res. 2006, 36, 2074–2085. [Google Scholar] [CrossRef]

- Matos, A.M.; Sousa-Coutinho, J. Durability of mortar using waste glass powder as cement replacement. Constr. Build. Mater. 2012, 36, 205–215. [Google Scholar] [CrossRef]

- Nassar, R.-U.; Soroushian, P. Strength and durability of recycled aggregate concrete containing milled glass as partial replacement for cement. Constr. Build. Mater. 2012, 29, 368–377. [Google Scholar] [CrossRef]

- Omran, A.; Tagnit-Hamou, A. Performance of glass-powder concrete in field applications. Constr. Build. Mater. 2016, 109, 84–95. [Google Scholar] [CrossRef]

- Ramakrishnan, K.; Pugazhmani, G.; Sripragadeesh, R.; Muthu, D.; Venkatasubramanian, C. Experimental study on the mechanical and durability properties of concrete with waste glass powder and ground granulated blast furnace slag as supplementary cementitious materials. Constr. Build. Mater. 2017, 156, 739–749. [Google Scholar] [CrossRef]

- ERCMO—European Ready Mixed Concrete Organization. Ready Mixed Industry Statistics 2019. Available online: https://ermco.eu/statistics-previous-years/ (accessed on 15 August 2022).

- Taha, B.; Nounu, G. Utilizing Waste Recycled Glass as Sand/Cement Replacement in Concrete. J. Mater. Civ. Eng. 2009, 21, 709–721. [Google Scholar] [CrossRef]

- Pontes, K. Incorporação de resíduos de vidro moído em betões: Uma alternativa às cinzas volantes? Mestrado em Construção e Reabilitação Sustentáveis. Master’s Thesis, Universidade do Minho, Braga, Portugal, 2023. Available online: https://hdl.handle.net/1822/85024 (accessed on 10 October 2023).

- NP EN 196-6; Métodos de Ensaio de Cimentos—Parte 6: Determinação da Finura. Instituto Português da Qualidade: Lisboa, Portugal, 2019.

- NP EN 1097-6; Ensaios das Propriedades Mecânicas e Físicas dos Agregados—Parte 6: Determinação da Massa Volúmica e da Absorção de Água. Instituto Português da Qualidade: Lisboa, Portugal, 2004.

- NP EN 450-1; Cinzas Volantes para Betão; Parte 1: Definição, Especificações e Critérios de Conformidade. IPQ: Lisbon, Portugal, 2012; p. 35.

- Moreira, B.A.d.S. Incorporação de Resíduo de Vidro Moído em Argamassas como Substituto Parcial do Cimento. Master’s Thesis, Universidade do Minho, Braga, Portugal, 2022. Available online: https://hdl.handle.net/1822/85022 (accessed on 10 July 2023).

- EN 12390-3; Testing Hardened Concrete—Part 3 Compressive Strength of Test Specimens. iTEH Standards: Etobicoke, ON, Canada, 2009.

- LNEC E394; Determinação da Absorção de Água por Imersão. LNEC: Lisbon, Portugal, 1993.

- LNEC E393; Determinação da Absorção de Água por Capilaridade. LNEC: Lisbon, Portugal, 1993.

- LNEC E463; Determinação do Coeficiente de Difusão de Cloretos por Ensaio de Migração em Regime Não Estacionário. LNEC: Lisbon, Portugal, 2004.

- Paul, D.; Bindhu, K.; Matos, A.M.; Delgado, J. Eco-friendly concrete with waste glass powder: A sustainable and circular solution. Constr. Build. Mater. 2022, 355, 129217. [Google Scholar] [CrossRef]

- French Association of Civil Engineering. Conception des Bétons pour Une Durée de Vie Donnée des Ouvrages—Indicateurs de Durabilité; French Association of Civil Engineering: Paris, France, 2004; p. 90. [Google Scholar]

- Elaqra, H.A.; Haloub, M.A.A.; Rustom, R.N. Effect of new mixing method of glass powder as cement replacement on mechanical behavior of concrete. Constr. Build. Mater. 2019, 203, 75–82. [Google Scholar] [CrossRef]

- Coutinho, M.J.A.R.S. Melhoria da Durabilidade dos Betões por Tratamento da Cofragem. Ph.D. Thesis, Faculdade de Engenharia da Universidade do Porto, Porto, Portugal, 1998. Available online: http://hdl.handle.net/10216/11906 (accessed on 20 June 2022).

- Browne, R.D. Field Investigations: Site & Laboratory Tests: Maintenance Repair and Rehabilitation of Concrete Structures; CEEC: Lisbon, Portugal, 1998. [Google Scholar]

| Material | CEM I 42.5 R | GP |

|---|---|---|

| CaO | 62.77 | 11.80 |

| Fe2O3 | 3.06 | 1.30 |

| SiO2 | 20.25 | 69.20 |

| Al2O3 | 4.43 | 2.30 |

| MnO | - | 0.10 |

| MgO | 2.01 | 1.00 |

| SO3 | 3.11 | - |

| TiO2 | - | |

| K2O | 0.76 | 0.90 |

| Na2O | 0.25 | 13.40 |

| Balance to 100% (Others) | 3.36 | - |

| LOI | 2.74 | - |

| RI | 1.23 | - |

| Material | Blaine Specific Surface Se (m2/kg) | Density ρ (kg/m3) |

|---|---|---|

| CEM I 42.5 R | 599s | 3.142 |

| GP | 493 | 2.604 |

| Fine aggregate (sand) | - | 2620 |

| Coarse aggregate (gravel) | - | 2.197 |

| Material | D10 | D50 | D90 |

|---|---|---|---|

| CEM I 42.5R | 4.68 | 21.90 | 54.60 |

| GP | 4.57 | 26.00 | 106.00 |

| Specimens | Binder | Cement | % * | GP | Fine Aggregate | Coarse Aggregate | SP | Water | w/b Ratio |

|---|---|---|---|---|---|---|---|---|---|

| C300 | 300 | 300.00 | 0% | 0.00 | 511.06 | 1087.66 | 0.00 | 206.38 | 0.65 |

| G150 | 300 | 150.00 | 50% | 124.26 | 580.21 | 1158.51 | 5.53 | 145.32 | 0.50 |

| G200 | 400 | 200.00 | 50% | 165.74 | 466.60 | 1134.68 | 7.23 | 151.70 | 0.40 |

| G250 | 500 | 250.00 | 50% | 207.23 | 371.70 | 1125.11 | 9.15 | 162.77 | 0.35 |

| Property | Test Standard | Samples’ Geometry (mm) | Unit per Age | Testing Ages (Days) |

|---|---|---|---|---|

| Compressive strength | EN 12390-3 [37] | Cube—100 × 100 × 100 | 3 | 7,14, and 28 |

| Water absorption by immersion | LNEC E394 [38] | Cube—100 × 100 × 100 | 3 | 28 |

| Capillary absorption | LNEC E393 [39] | Cube—100 × 100 × 100 | 3 | 28 |

| Chloride diffusion | LNEC E463 [40] | Cylinder—H200D100 | 2 | 28 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Moreira, O.; Camões, A.; Malheiro, R.; Jesus, C. High Glass Waste Incorporation towards Sustainable High-Performance Concrete. CivilEng 2024, 5, 41-64. https://doi.org/10.3390/civileng5010003

Moreira O, Camões A, Malheiro R, Jesus C. High Glass Waste Incorporation towards Sustainable High-Performance Concrete. CivilEng. 2024; 5(1):41-64. https://doi.org/10.3390/civileng5010003

Chicago/Turabian StyleMoreira, Othon, Aires Camões, Raphaele Malheiro, and Carlos Jesus. 2024. "High Glass Waste Incorporation towards Sustainable High-Performance Concrete" CivilEng 5, no. 1: 41-64. https://doi.org/10.3390/civileng5010003

APA StyleMoreira, O., Camões, A., Malheiro, R., & Jesus, C. (2024). High Glass Waste Incorporation towards Sustainable High-Performance Concrete. CivilEng, 5(1), 41-64. https://doi.org/10.3390/civileng5010003