1. Introduction

In the present economic age, a sizable proportion of huge construction projects has been steadily expanding. Concurrently, the pandemic-induced economic crisis in 2020 strongly demonstrated that successful project delivery is dependent on sustainable project lifecycle management as well as project management principles and methodologies [

1]. Interfaces are points of interaction between two or more aspects of a project which might be between clients, contractors, subcontractors, and other project stakeholders. Poor interface management gives rise to interface risks. Interface risks and the failure to manage them effectively is a common cause of problems in construction projects, which can negatively affect project objectives and goals.

The construction industry encounters interface risks which are complex, difficult, and require diverse solution to solve and manage, involving interface risk management (IRM). Interface risks are the most commonly encountered problem in the industry. In the highly risky and complex environment of a construction project, if effective decisions are not made in the conceptualisation, planning, design, contracting, procurement, and execution phases, then disagreements, loss of profit, claims, industrial actions, disputes, conflicts, change orders, and claims can occur at any phase of the construction project. The traditional construction industry usually depends on the project participants’ work experiences to solve interface risk problems, including issues between designers, owners, project team members, main contractors, subcontractors, host communities, licensing and regulatory bodies, vendors, maintenance contractors, and material suppliers. Formal risk management plans are rarely used in executing construction projects because contractors and subcontractors rely on their past experiences and judgements, and this can result in unforeseen circumstances that can negatively impact project objectives since these individuals are not fully equipped with the tools to effectively manage the unidentified risks and uncertainties associated with interfaces and numerous stakeholders. Stakeholder management is often not effectively incorporated into risk management plans as the numerous stakeholders and their roles and influences are not carefully identified in the conceptualisation stage of a project, and this gives rise to additional interface risks.

Interface risk management is primarily overseen and regulated by project managers. However, the intricate handling of these interface incidents is frequently evaluated and appraised based on the expertise of engineers. The involvement of a systematic approach to interface problems is infrequent. In essence, the conventional approach to interface problem solving lacks objectivity, relies heavily on subjective experiences, and lacks a systematic framework for identifying interface issues and proposing comprehensive solutions. The professionalisation of interface risk management (IRM) practise has been shown to have a positive impact on the project performance of construction projects [

2]. This, in turn, leads to enhanced social benefits for public projects. While the advantages of interface risk management (IRM) may be more readily apparent in large-scale projects, the effective management of interfaces is considered significant for projects of all sizes and levels of complexity. Furthermore, recent research conducted by [

3,

4] has revealed that project managers have utilised building information modelling (BIM) to effectively oversee extensive construction projects and address the challenges associated with interfaces. In addition to its academic significance, this study also demonstrates its social relevance by potentially contributing to the professionalisation of IRM. The academic literature suggests that IRM holds promising benefits. One can anticipate several benefits from improving the exchange of information and reducing costs associated with interface issues, such as the promotion of inter-organizational collaboration [

2,

5].

Construction projects employ principles and protocols that encompass a multitude of complexities in the management of various stakeholders, including owners; technical clients; and engineering, procurement, and construction (EPC) contractors. The reason for this is that the phases of the construction project encompass numerous contracts that involve a diverse range of contractors. According to [

6], therefore, it is important to recognise that the application of principles and approaches may vary among different stakeholders, both internal and external. Firstly, it is not feasible to effectively manage the relational connections between a singular project team consisting of the general contractor, client, designer, and customer [

7]. Furthermore, the premise of a singular project team is predicated on the explicit consideration of the individual interests and objectives of all the participants [

8]. In practical applications, the interests of the individuals engaged in a construction endeavour exhibit variation and frequently encompass multiple facets. This phenomenon arises in scenarios where the proprietor aims to reduce the expenses associated with construction, while the general contractor or subcontractor seeks to augment the construction costs. Additionally, the technical customer plans to delegate the tasks and coordination work to the design firm, thereby necessitating supplementary compensation [

9]. According to [

10], when considering the selection of the most economically efficient alternatives, the practicality of implementing a sole project team is questionable. The contractor expresses a favourable perspective regarding the evaluation of the most financially advantageous construction project. Nevertheless, the limited availability of construction orders to contractors can be attributed to competition from other industry players and market conditions. The primary concern for customers is the fulfilment of technical construction orders. Interface risk management is commonly employed in intricate projects and overseen by multiple stakeholders with diverse areas of expertise, resulting in a multitude of overlapping activities. Stakeholder management is one of the major challenges faced in construction projects as these numerous stakeholders have personal and diverse interests and objectives ranging from personal monetary gains, political and economic interests, opportunities, and favours and these, in essence, compromise the objectives of the project to successfully and in a timely fashion complete the project. This paper identifies and proposes new methods to manage stakeholders and, in essence, mitigate interface risks from these stakeholders and interfaces.

Interface risk management is a potential solution for effectively managing the complexities of construction projects. It primarily involves the management of communications, relationships, and deliverables among project stakeholders. By establishing improved methods for identifying, documenting, monitoring, and tracking project interfaces and the associated risks, interface risk management can contribute to the successful execution of construction projects. The present study undertakes a comprehensive review of relevant literature in order to establish a solid theoretical foundation for the research. The term “interfaces” in the context of construction projects refers to the points of connection or interaction between different components, systems, or stakeholders involved in the project. These interfaces play a crucial role in ensuring the successful coordination and integration of various elements within the construction process. Interfaces are significant for the overall project execution.

The study objective was to carry out a literature review on interfaces in construction, as well as interface risks and interface risk management. The study three main objectives were:

To identify the consequences of poor and ineffective interface risk management approaches and how they influence construction project delivery.

To identify the current interface risk management methods utilised by organisations.

To identify the causes of interface risks and how they influence project objectives.

To support the objectives of the study, these three research questions were asked. Respondents were asked to identify:

The causes of interface risks.

The consequences of poor and ineffective interface risk management approaches.

The interface risk management approaches implemented by their organisations.

The study focuses on a systematic approach of identifying and managing risks associated with every interface in construction projects in every phase. The literature review was carried out to identify critical areas of knowledge in the field of study, with the purpose of presenting a summary of the recent literature on the topic. The primary objective of the study was to develop a framework on how to identify and manage interface risks in construction for overall project success.

This paper is composed of the following: the study background is discussed after the Introduction, then

Section 3 discusses the materials and methods used,

Section 4 encompasses the findings and analysis, and the results and discussion are given in

Section 5, followed by the conclusion in

Section 6.

3. Materials and Methods

The primary data were collected from project managers, civil/structural engineers, mechanical engineers, risk managers, architects, quantity surveyors, electrical engineers, construction managers, HSE managers, estate managers, and other construction industry professionals actively working in construction projects in South Africa through an online questionnaire developed specifically for this study in order to answer the research questions and to realise the research objectives. Secondary data were collected through a review of the relevant literature, articles, and journals in the construction industry. A total of 205 research questionnaires were distributed to participants active in the construction industry. The study focused only on the South African construction industry and active industry professionals. All respondents were South African residents and had experience in the South African construction industry. Industry professionals living outside of South Africa were not part of the study. Every participant was involved in the conceptualisation, planning, contracting, subcontracting, procurement, construction, execution, HSE management, or commissioning phases of a project. These three Likert-type scale response anchors were chosen for the questionnaire in order to find out the level of agreement with the individual statements in the questionnaire and the frequencies of each statement or items in the questionnaire, and the extent scale was used to find out the extent to which each statement or item in the questionnaire influences construction projects. The data collection process commenced by administering a biographical questionnaire to ascertain the appropriate research participants in Section A; this included size of the organisation, profession, age, and highest academic qualifications. Section B had three subsections, namely B2, B3, and B4. Section B2 involved questions related to the consequences of poor and ineffective interface risk management approach, where respondents were asked to identify these consequences and rate them according to the extent scale. Section B3 comprised questions related to interface risk management methods currently adopted by their organisations and the extent to which they influenced project objectives, and Section B4 comprised questions related to the causes of interface risks and the respondents were asked to identify the extents the causes of interface risks influenced the successful execution of construction projects.

The items or questions in each section were coded for ease of analysis. For the five-point Linkert scale chosen, “rarely” was coded as a 2, “sometimes” was coded as a 3, “often” was coded as a 4, and “always” was coded as a 5. Also, “strongly disagree” was coded as a 1, “disagree” was coded as a 2, “neutral” was coded as a 3, “agree” was coded as a 4, and “strongly agree” was coded as a 5. In addition, “to no extent” was coded as a 1, “to a small extent” was coded as a 2, “to a moderate extent” was coded as a 3, “to a large extent” was coded as a 4, and “to a very large extent” was coded as a 5.

The data obtained from the questionnaire were coded, recorded, and analysed utilising the Statistical Package for the Social Sciences (SPSS, V25). Factor analysis was conducted in order to identify the latent dimensions underlying the measured variables, as these variables are expected to exhibit correlations or anticipated correlations. This study aims to assess the impact of measured variables and examine the interrelationships among a predetermined set of defined, observed, and quantifiable constructs. According to the guidelines provided in the SPSS manual, the Kaiser–Meyer–Olkin (KMO) measurement and the Bartlett’s test of sphericity were employed to assess the suitability of the correlation matrix as an identity matrix, thereby determining the appropriateness of the factor model.

4. Findings and Analysis

The study employed the Kaiser–Meyer–Olkin (KMO) measurement and Bartlett’s test to assess the interrelationships among variables, thereby informing the decision to proceed with the factor analysis of the collected data. A comprehensive set of 205 responses was obtained from the designated target population, which primarily comprised individuals within the construction industry, as described in the context of questionnaire design and target group identification.

Table 1 below shows the summary of the biographical data of the respondents who participated in the online survey.

As seen in

Table 1 above, out of the 205 responses from the online questionnaire, 16 respondents were quantity surveyors, 9 were architects, 7 were builders, 8 were project engineers, 9 were project administrators, 10 were safety officers/engineers/managers, 10 were risk managers, 20 were mechanical engineers, 13 were construction engineers, 18 were project managers, 8 were estate managers, 22 were electrical engineers, 25 were construction managers, 27 were civil/structural engineers, and 3 respondents were other construction professionals.

Table 2 below shows age distribution of participants.

As seen in

Table 2 above, out of the 205 respondents, 4 respondents were in the age group of 21–25 years, 16 were in the age group of 26–30 years, 32 were in the age group of 31–35 years, 42 were in the age group of 36–40 years, 53 were in the age group of 41–45 years, and 46 respondents were in the age group of 46 years and above.

Table 3 below shows the academic qualifications of the respondents.

As seen in

Table 3 above, 11 respondents out of the 205 respondents, which represented 5.4% of the respondents, had post-matric certificates or diplomas as their highest academic qualifications; 55 (26.8%) had Bachelor’s degrees; 28 (13.7%) had Honours degrees; 70 (34.1%) had Master’s degrees; and 41 respondents, which represented 20.0% of the total respondents, had doctoral degrees.

Table 4 below shows the size of the respondents’ organizations.

As seen in

Table 4 above, 72 respondents, which represents 35.1% of the total respondents, work in the small-sized industries, and 74, which represents 36.1%, work at medium-sized industries, while 59 of the respondents, which represents 28.8%, work in large-scale construction industries.

Table 5 below represents the frequency distribution for question 1 (How often do you encounter interface risks between project stakeholders in a project?)

As seen in

Table 5 above, 11 (5.4%) respondents chose “rarely”, 63 (30.7%) chose “sometimes”, 66 (32.2%) chose “often”, and 65 (31.2%) of the total respondents chose “always”.

Table 6 below shows the mean and standard deviation for research question 1.

As seen in

Table 6 above, the mean was 3.90, which was slightly below “often” (4), and most people answered “sometimes” (3) and “always” (5). The median was 4.00, which means that half of the respondents chose between “often” and “always”, and the other half chose between “often” and “always”. The mode was 4, which means most people chose “often”.

Table 7 below shows the responses for the research question 2 on work cultures related to interface risks. Interfaces are points of interaction between two or more aspects of a project, which might be between clients, contractors, subcontractors, or other project stakeholders, while interface risks are risks generated because of poor interface management in construction projects.

Table 7 above shows the responses for questions on work culture related to interface risks. The respondents were asked to answer the questions and rank them according to their level of agreement.

For the first statement (“Interface risks between project stakeholders can be classified as uncertainties.”), 1 respondent strongly disagreed with the statement, which represents 0.5% of the total responses; 15 (7.3%) respondents disagreed; 39 (19.0%) respondents were neutral; 129 (62.9%) agreed; while 21 (10.2%) of the respondents strongly agreed.

For the second statement (“Interface risks between project stakeholders can be classified as unidentified risks.”), 1 respondent strongly disagreed with the statement, which represents 0.5% of the responses; 12 (5.9%) disagreed with the statement; 57 (27.8%) respondents were neutral; 118 (57.6%) agreed; while 17 (8.3%) respondents strongly agreed.

For the third statement (“Identification of hard interface risks encourages effective collaboration between project stakeholders.”), 1 respondent strongly disagreed with the statement, which represents 0.5% of the responses; 2 (1.0%) disagreed with the statement; 11 (5.4%) respondents were neutral; 119 (58.0%) agreed; while 72 (35.1%) respondents strongly agreed.

For the fourth statement (“Identification of soft interface risks encourages effective collaboration between project stakeholders.”), no respondent strongly disagreed with the statement, which represented 0.0% of the responses; 6 (2.9%) disagreed with the statement; 27 (13.2%) respondents were neutral; 107 (52.2%) agreed; while 65 (31.7%) respondents strongly agreed.

Table 8 below shows the KMO and Bartlett’s test for research objective 1 (consequences of poor and ineffective interface risk management approach). KMO seeks to determine the applicability of a result to a set of measures when conducting factor analysis, where the values must be greater than 0.6, while Bartlett’s test of sphericity must be less than 0.05 to establish the applicability of factor analysis.

As shown in

Table 8 above, the Kaiser–Meyer–Olkin measure of sampling adequacy was 0.898, which was greater than 0.6 and demonstrates that factor analysis can be carried out. For the Bartlett’s test of sphericity, the significance, which is the

p value, was less than 0.001, and thus was less than 0.05, and this supports its factorability.

Table 9 below shows the KMO and Bartlett’s test for research objective 2 (interface risk management approaches by organisations).

As shown in

Table 9 above, the Kaiser–Meyer–Olkin measure of sampling adequacy was 0.915, which was greater than 0,6, and therefore, factor analysis can be carried out. For Bartlett’s test of sphericity, the significance, which is the

p value, is 0.000, which is less than 0.05, and this supports its factorability.

Table 10 below represents KMO and Bartlett’s test for research objective 3 (causes of interface risks).

As shown in

Table 10 above, the Kaiser–Meyer–Olkin measure of sampling adequacy was 0.917, which was greater than 0.6 and shows that the factor analysis can be carried out. For Bartlett’s test of sphericity, the significance, which is the

p value, was 0.000, which is less than 0.05, and this supports its factorability.

Table 11 below shows the responses received for research objective 1 for B2, which is related to consequences of a poor and ineffective interface risk management approach. The respondents were asked to rank these consequences according to the extent scale.

As can be seen in

Table 11 above, project delays, the extension of project delivery time, poor safety standards, stakeholders’ complaints, project overall failure, poor workflow planning and development, the loss of profit, additional costs, the reputational damage of an organisation, and claims for damage were identified as the major consequences of a poor and ineffective interface risk management approach in construction projects according to the responses received.

Table 12 below shows the responses received for research objective 2—the extent to which interface risk management approaches influence project goals and objectives and the successful execution of construction projects in South Africa. The respondents rated their answers using the extent scale.

As shown in

Table 12 above, alliancing and partnering agreements, the identification of construction supply chain risks during interface establishment, conflict resolution carried out by parties involved, clash detection as an integral part of the construction process for interface risk management, interface risk management by all the parties involved, clash detection as an integral part of the design process for interface risk management, assessing third parties’ dependencies to identify new interfaces, the identification of interface risks in the conceptualisation stage of a project, the identification of interface risks in the interface’s establishment phases, the identification of interface risks in the execution stage, defining standard methods and procedures, establishing a building information modelling (BIM) volume strategy, and creating a virtual construction model during the construction phase were identified as the major interface risk management approaches that have the most impact on project goals and objectives and the successful execution of construction projects in South Africa.

Table 13 below shows the responses received regarding to what extent the following are causes of interface risks in construction projects.

As can be seen in

Table 13 above, the responses indicated that disorganized construction supply chain management, incompetency, poor workflow planning and development, subcontractors’ negative attitudes towards teamwork, unpredictable and low delivery reliability, poor inventories, a lack of knowledge sharing, procurement delays, ineffective communication in site layout changes with stakeholders, a poor understanding of the construction project process among project stakeholders, not updating changes in site layout with stakeholders, and disorganized construction supply chain management were identified as the major causes of interface risks in construction projects.

4.1. Exploratory Factor Analysis

Since the sample size was 205, exploratory factor analysis was performed to reduce the data or summarise using a smaller set of factors or components. This was achieved by looking for groups among the intercorrelations of the set of variables. By using factor analytic techniques, data were refined and reduced to form a smaller number of related variables to a more manageable number before using them in other analyses. The factorability of the correlation matrix was as follows: to be considered suitable for factor analysis, the correlation matrix should show at least have some correlations of r = 0.3 or greater. Barlett’s test of sphericity should be statistically significant at

p < 0.05, and the Kaiser–Meyer–Olkin values should be 0.6 or above. These values are presented as part of the output of the factor analysis.

Table 14 below depicts the exploratory factor analysis for research objective 1.

As shown in

Table 14 above, the consequences of poor and ineffective interface risk management approaches were loaded on two factors with eigenvalues of 6.206 and 1.438. These two factors explained 58.805% of the variance before rotation and 51.576% of the variance after rotation, and they represent the major and minor consequences of poor and ineffective interface risk management approaches.

Table 15 below shows the corelation matrix for research objective 1.

As can be seen in

Table 15 above, many of the correlations were greater than 0.3. B2.2 and B2.1 had a correlation of 0.267, B2.6 and B2.1 had a correlation of 0.288, B2.11 and B2.2 had a correlation of 0.298, B2.2 and B2.5 had a correlation of 0.259, and B2.1 and B2.10 had a correlation of 0.265.

Table 16 below shows the communalities for research objective 1–B2.

As shown in

Table 16 above, the extractions were all above 0.3, which means there was at least a 30% common variance shared among the items in Section B2.

Figure 1 below shows the scree plot for Section B2.

In

Figure 1 above, variables 3 to 13 were not significant, so they were not added to the factor rotation. For the first factor, the eigenvalue was around 6.2; for the second factor, the eigenvalue was around 1.4.

Table 17 below depicts the rotated factor matrix for research objective 1–B2.

Table 17 shows that these items were grouped into two factors based on the ten key performance factors (KPIs) that are related to construction projects, namely time, cost, people, quality, safety and health, internal and external stakeholder, client satisfaction, financial performance, environment, information, and technology and innovation. Factor 1 items are associated with quality, people, IT and innovations, time, cost, safety and health, and environment and client satisfaction, while items in factor 2 items are associated with cost, time, external and internal stakeholders, financial performance, people, environment, and client satisfaction.

Table 18 below represents the exploratory factor analysis for research objective 2 (“What are the interface risk management approaches by organisations?”)

As seen in

Table 18 above, “Interface risk management approaches by organisation” the values were loaded on four factors with eigenvalues of 11.460, 2.787, 1.581, and 1.209. These four factors explained 70.987% of the variance before rotation and 65,383% of the variance after rotation.

Table 19 below shows the correlation matrices for research objective 2–B3.

As shown in

Table 19 above, many of the correlations were greater than 0.3. B3.13 and B3.24 had a correlation of 0.221, B3.2 and B3.9 had a correlation of 0.286, B3.5 and B3.22 had a correlation of 0.265, B3.4 and B3.1 had a correlation of 0.265, and B3.2 and B3.23 had a correlation of 0.263.

Table 20 below shows the communalities for research objective 2–B3.

Table 20 above shows that the extractions are all above 0.3, which means there was at least a 30% common variance shared between them.

Figure 2 below shows the scree plot of research objective 2–B3.

As can be seen in the scree plot above, variables 5 to 24 are not significant, so they were not added in the factor rotation. For the first factor, the eigenvalue was around 11.460; for the second factor, the eigenvalue was around 2.787; for the third factor, the eigenvalue was about 1.581; and for the fourth factor, the eigenvalue was 1.209.

Table 21 below is the rotated factor matrix for Section B3.

As seen in

Table 21 above, B3.11, B3.19, B3.15, B3.17, B3.23, B3.9, B3.5, B3.7, B3.1, B3.13, and B3.21 were grouped into factor 1, while B3.8, B3.6, B3.10, B3.12, and B3.14 were grouped into factor 2 and B3.18, B3.20, B3.22, B3.16, and B3.24 were grouped into factor 3, while B3.4 and B3.2 were grouped into factor 4. These items were grouped into two factors based on the KPIs listed above; they are associated with as stated earlier. Factor 1 items are associated with quality, people, IT and innovations, time, financial performance, cost, safety and health, environment, internal and external stakeholders, and client satisfaction, while items in factor 2 items are associated with cost, time, environment, quality, client satisfaction, information technology and innovation, external and internal stakeholders, people, environment and client satisfaction; factor 3 are items associated with environment, client satisfaction, safety and health, and external and internal stakeholders; and factor 4 are items associated with internal and external stakeholders.

Table 22 below shows the exploratory factor analysis for research objective 3 (“The causes of interface risks”).

As shown in

Table 22 above, the causes of interface risks were loaded on three factors with eigenvalues of 9.587, 1.960, and 1.194. These three factors explained 67.061% of the variance before rotation and 61.014% of the variance after rotation.

Table 23 below shows the communalities for research objective 3.

Table 23 below depicts the communalities for research objective 3–B4.

As seen in

Table 23 above, the extractions are all above 0.3, which means there was at least a 30% common variance shared among them.

Figure 3 below shows the scree plot for research objective 3–B4.

As can be seen in the scree plot above, variables 4 to 19 are not significant, so they were not added to the factor rotation. For the first factor, the eigenvalue was around 9.587; for the second factor, the eigenvalue was around 1.960; and for the third factor, the eigenvalue was about 1.194.

Table 24 below is the rotated factor matrix for research objective 3–B4.

As shown in

Table 24 above, each item was grouped into factors based on the KPIs they are associated with, as stated earlier. B4.7, B4.1, B4.5, B4.9, B4.11, B4.15, B4.17, and B4.19 were grouped into factor 1; B4.10, B4.6, B4.8, B4.14, B4.4, and B4.2 were grouped into factor 2; and B4.18, B6.16, B4.13, and B4.12 were grouped into factor 3.

4.2. Reliability Statistics of Collected Data

4.2.1. Reliability Statistics of Theoretical Factors

To establish the consistency of the data, the value of the Cronbach’s alpha (coefficient alpha) was determined.

Table 25 below shows the reliability statistics for research objective 1, and Cronbach’s alpha coefficients must be greater than 0.7 to confirm reliability and internal consistency.

As shown in the above

Table 25, Cronbach’s alpha is 0.907, which was above 0.7; therefore, it is reliable.

Table 26 below shows the item-total statistics for research objective 1.

Table 26 above contains total statistics for all the items in B2 for research objective1.

Table 27 below shows a Cronbach’s alpha value of 0.952, which was above 0.7; therefore, it is reliable.

Table 28 below shows the item-total statistics for research objective 2.

Table 28 above contains total statistics for all the items in B3 for research objective 2.

Table 29 below depicts the reliability statistics for research objective 3–B4.

As seen in

Table 29 above, Cronbach’s alpha is 0.945; therefore, it is reliable.

Table 30 below shows the item-total statistics for research objective 3–B4 (“The causes of interface risks.”).

Table 30 above contains total statistics for all the items in B4 for research objective 3. Please see

Appendix A on page 32 for the item- statistics for the research objectives 1, 2 and 3 and the correlation matrix for research objective 3–B4.

4.2.2. Reliability Statistics of Empirical Factors

To confirm reliability and internal consistency, the reliability of the empirical factors was identified, and

Table 31 below depicts the reliability statistics for research objective 1–B2–factor 1.

As seen in

Table 31 above, Cronbach’s alpha is 0.880, which is greater than 0.7; therefore, it is reliable.

Table 32 below shows the reliability statistics for research objective 1–B2–factor 2.

Table 32 above shows a Cronbach alpha value of 0.861, which is greater than 0.7; therefore, it is reliable.

Table 33 below illustrates the reliability statistics for research objective 2–B3–factor 1.

As seen in

Table 33 above, the Cronbach alpha is 0.941, which is above 0.7; so, it is reliable.

Table 34 below illustrates the reliability statistics for research objective 2–B3–factor 2.

Table 34 above has a Cronbach alpha value of 0.903, which was above 0.7; therefore, it is reliable. The reliability statistics for research objective 2–B3–factor 3 is illustrated in

Table 35 below.

As shown in

Table 35 above, the Cronbach alpha is 0.895, which is greater than 0.7; therefore, it is reliable.

Table 36 below shows the reliability statistics for research objective 2–B3–factor 4.

As shown in

Table 36 above, the Cronbach Alpha is 0.826, which is greater than 0.7; therefore, it is reliable.

Table 37 below shows the reliability statistics for research objective 3–B4–factor 1.

As shown in

Table 37 above, the Cronbach alpha is 0.926, so it is reliable.

Table 38 below shows the reliability statistics for research objective 3–B4–factor 2.

Table 38 above shows a Cronbach alpha of 0.881; therefore, it is reliable.

Table 39 below shows the reliability statistics for research objective 3–B4–factor 3.

As shown in

Table 39 above, the Cronbach alpha is 0.836, which is higher than 0.7, and this confirms its reliability.

5. Results and Discussion

The respondents were asked to answer questions on work culture related to interface risks. As depicted in

Table 7 above, 1 respondent strongly disagreed that interface risks between project stakeholders can be classified as uncertainties, which represents 0.5% of the total responses; 15 (7.3%) respondents disagreed; 39 (19.0%) respondents were neutral; 129 (62.9%) agreed; while 21 (10.2%) of the respondents strongly agreed. A total of 1 respondent strongly disagreed that interface risks between project stakeholders can be classified as unidentified risks, representing 0.5% of the responses; 12 (5.9%) disagreed with the statement; 57 (27.8%) respondents were neutral; 118 (57.6%) agreed; while 17 (8.3%) respondents strongly agreed with the statement. The responses showed that 119 (58%) respondents agreed that the identification of hard interface risks encourages effective collaboration between project stakeholders, while 72 (35.1%) respondents strongly agreed. A total of 107 (52.2%) respondents agreed that the identification of soft interface risks encourages effective collaboration between project stakeholders, while 65 (31.7%) respondents strongly agreed.

For research objective 1, Spearman’s rho showed that there is a correlation between the consequences of poor and ineffective interface risk management approaches and their influence on a project, since the values of the Spearman’s coefficient are greater than 0.3 and, as shown in

Table 8 above, for Bartlett’s test of sphericity, the significance, i.e., the

p value, was less than 0.001, which was less than 0.05. This means that the higher the probability of the consequences, such as project delays, poor quality, industrial actions, additional costs, etc., the higher the impacts on the project. The Kaiser–Meyer–Olkin measure of sampling adequacy was 0.898, which was greater than 0.6 and demonstrates that factor analysis can be carried out.

For the research objective 2, Spearman’s rho showed that there was a correlation between the interface risk management approaches and their influences on the project goals and objectives and the successful execution of construction projects, since the values of Spearman’s coefficient were greater than 0.3 and, as shown in

Table 9 above, for Bartlett’s test of sphericity, the significance, i.e., the

p value, was 0.000, which was less than 0.05. This means that the higher the probability of the interface risk management approaches, such as defining standard methods and procedures, creating a virtual construction model during the construction phase, establishing a building information modelling (BIM) volume strategy, etc., the higher the impacts on the project goals and objectives. The Kaiser–Meyer–Olkin measure of sampling adequacy was 0.915, which was greater than 0.6, which shows that factor analysis can be carried out.

For the research objective 3, Spearman’s rho showed that there was correlation between the extent to which the following causes of interface risks influences construction projects, since the values of Spearman’s coefficient are greater than 0.3. And, as shown in

Table 10 above, for the Bartlett’s test of sphericity, the significance,

p value was 0.000, which was less than 0.05. This means that the higher the probability of the causes of interface risks, such as incompetency, poor inventories, lack of knowledge sharing, procurement delays, etc., the higher the impacts on the project execution. The Kaiser–Meyer–Olkin measure of sampling adequacy was 0.917, which was greater than 0.6 and shows that factor analysis can be carried out.

Proposed New Framework

Discussion

This study investigated interface risks, the various causes of interface risks, the consequences of poor interface risk management and their levels of influence on projects, and interface risk management approaches by organisations and how they influence the overall project objectives.

Figure 4 below depicts the new proposed framework to identify and manage interface risks in construction projects.

As shown in

Figure 4 above, for an effective interface risk assessment, it is recommended that construction industry must effectively establish a building information modelling volume strategy and create a virtual construction model during the construction phase; in addition, construction supply chain risks must be carefully identified during the interfaces establishment stages; interface risks must be carefully identified during the conceptualisation; and planning, construction, and execution stages and standard methods and procedures must be defined to effectively identify and manage interface risks as the occur in the project lifecycle. Effective stakeholder management is also crucial for effective interface risk management since many interface risks are created by the numerous stakeholders involved in the project. The proposed stakeholder management approaches will be shown in

Figure 5 below.

As shown in the proposed framework in

Figure 5, for an effective stakeholder management in construction projects, it is recommended that construction industry must encourage and implement alliancing and partnering agreements, conflicts resolution must be carried out by every party involved in the project, clash detection and avoidance must integrated into the construction and design processes for interface risk management, third parties’ dependencies must be carefully and continually identified and assessed in order to identify and manage new interfaces, and interface risk management must be carried out by all parties involved for overall project success. Stakeholder mapping must be carried out to determine how stakeholders influence the project and how the project influences the stakeholders.

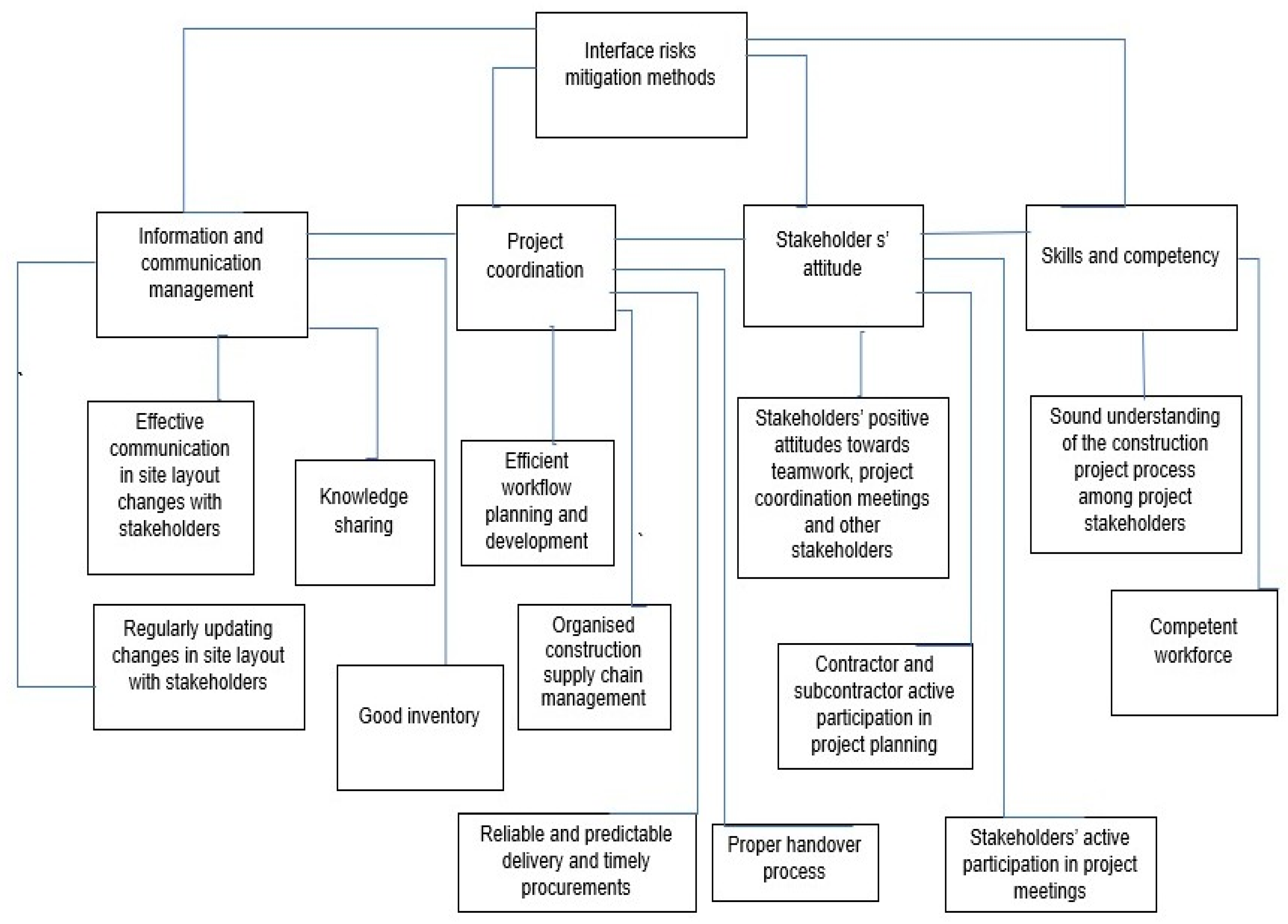

Figure 6 below shows the proposed interface risk mitigation methods.

The proposed framework in

Figure 6 above ensures that information and communication are effectively managed throughout the project, that project coordination is improved and effective, that stakeholders’ attitudes produce positive outcomes, and that appropriate skills and competent workers are adequately utilized in all phases of the project to minimise interface risk occurrence and effectively manage them as they occur in the project in order to realise project objectives. The last chapter will focus on the conclusion of the results, findings, proposed frameworks and recommendations.

6. Conclusions

Interface risk is one of the major challenges facing the construction industry because construction projects are complex by nature—involving many activities and participants with different responsibilities and tasks. It is crucial to carefully identify and manage these risks arising from the interfaces since they are inherent in all the construction project phases according to the findings of this research. This study revealed that most construction projects encountered interface risks throughout a project lifecycle, and if they were not carefully and properly identified and managed during the project, they had negative influences on project objectives and could evidently lead to project failure or abandonment. Interface risks must be continually identified and managed during the conceptualisation, planning, and interface establishment phases and must be carefully assessed, monitored, and managed throughout the project. Stakeholder management was identified as one of the main ways to effectively manage interface risks because stakeholders play vital roles in interface risk management.

The effective communication, knowledge, and information sharing among project stakeholders have positive impacts on the success of the project because coordinated and evenly distributed knowledge and information flow on site layout changes and construction processes facilitate successful project delivery as well as identifying both soft and hard interface risks, as these encourage effective collaboration, alliancing, and partnering agreements between project stakeholders and, in essence, mitigate conflicts and clashes among stakeholders. The integration of clash detection and avoidance into a project’s lifecycle is vital for success, as this provides the project team with initial tools and ideas to effectively identify and manage such events and mitigate them in advance. Suppliers, vendors, clients, contractors, and subcontractors must communicate effectively to ensure timely and reliable delivery, procurement, and timely funding in order not to delay the project or incur additional costs. Clients must provide timely and sufficient funding because poor and delayed funding results in supply chain disruptions and labour and material delays, which ultimately prolong the project and result in additional costs. Effective interface risk management in construction projects will minimise and save costs and time; mitigate industrial action and damage claim; improve and maintain project quality and safety; protect the environment; facilitate good workflow planning and development; and protect the reputation of the organisation that would have been damaged as a result of regulatory infringements, industrial actions, damage claims, extended projected delivery time, stakeholder complaints, project abandonment, and failure. Identifying and assessing parties’ dependencies to identify and manage new interfaces is vital for project success. For effective interface risk management, standard methods and procedures must be defined, a building information modelling volume strategy must be established and utilised effectively, and a virtual construction model must be created and monitored regularly. Regular meetings with stakeholders facilitate effective interface risk management because every stakeholder will have updated and firsthand information on the project’s progress and schedule. Stakeholders’ attitudes towards project coordination are vital to project success as they determine how effectively each project phase will be completed. Clash detection and avoidance must be integrated into the planning, design, and construction stages and conflicts must be resolved by every party involved. Effective construction supply chain management is important in project delivery, and procurement deliveries must be timely, predictable, and reliable to avoid material and labour shortages or surplus, and inventories must be updated regularly for effective project site coordination and workflows. An incompetent labour force; a poor understanding of construction project processes; and contractors’, clients’, and subcontractors’ negative attitudes generate many interface risks, and these must be carefully identified and managed during the planning and contracting stages of a project. Changes in site layout must be updated and communicated to project participants. To save time; minimise costs; and maintain anticipated project quality, safety, and standards, interface risks must be carefully identified and managed by project participants, and every stakeholder must participate in project coordination meetings, comply with the project guidelines, and actively participate in identifying and managing interface risks throughout the project for its successful execution. Implementing the proposed stakeholder management framework and integrating it into the interface risk management framework will greatly minimise the risks involved that are generated by every party in a construction project.