Abstract

The innovation inherent to employing expanded polystyrene (EPS) beads lies in its transformative impact on traditional concrete practices. Through the incorporation of EPS beads in concrete mixtures, a novel approach emerges that significantly alters the material’s characteristics, and opens up new avenues for construction and design. Studying the shear behavior of RC beams made with EPS beads is essential for advancing knowledge, improving design practices, ensuring structural integrity, and promoting the effective and responsible use of innovative materials in construction. This research experimentally investigated the effect of using EPS beads and pozzolana aggregate (PA) on the shear behavior of the RC beams. A total of 27 simply supported rectangular beams were cast, using three novel distinct mix designs, and were subjected to two-point load testing until failure. These three mixes were categorized as follows: a control mix, a mix with only EPS, and a mix with EPS, along with an additive. The ultimate failure load was experimentally recorded for all specimens, and the influence of the temperature (300 °C and 600 °C) on the RC beams made with EPS was examined. The findings revealed a reduction in the concrete compressive strength and density in the beams containing EPS and EPS with superplasticizers of (21.7%, 24.9%) and (11.3%, 16.2%), respectively. Additionally, EPS played a significant role in diminishing the ultimate shear capacity of the beams, compared to the control beams, by about 19.4%. However, the addition of a superplasticizer along with the EPS helped to maintain the beam capacity, to some extent. Conversely, the beams exposed to a temperature of 300 °C exhibited an almost similar capacity to that of the control beams without heating. Nevertheless, at 600 °C, the beams displayed a noticeable decrease in the ultimate load capacity, compared to the unheated control beams.

1. Introduction

Nowadays, no structural application action can be imagined without the use of concrete. Concrete is the most largely consumed construction material in nature [1,2]. Reinforced concrete (RC) is the most widely used material for structural applications. Its economy, versatility, and ability to be successfully molded into many shapes make it an extremely proper construction material [3]. Commonly, the three main characteristics of concrete are durability, workability, and strength. Workability is attributed to fresh concrete, while durability and strength are attributed to hardened concrete. The fresh characteristics of the concrete, and the mix design are the most important points that affect the mechanical properties and quality of hardened concrete. The performance of concrete depends on the mix design proportions, and the properties of the materials; accordingly, the early estimation of hardened concrete properties is very necessary [4,5]. Lightweight concretes are not a present-day attainment within concrete technology; rather, they have been known of for a long time, and are mostly the ancestors of today’s concrete. The Pantheon in Rome, Italy, can be considered one of the outstanding known examples that intensely identified the standardized utilization of different types of natural aggregate [6].

Structural lightweight concretes commonly involve aggregates made from expanded fly ash, clays, expanded slags, and preprocessed shales, and those that come from natural porous volcanic sources [7,8]. Lightweight concrete (LWC) is formed via the replacement of the natural normal aggregates with lightweight aggregates (LWAs), to obtain a density ranging from 800 to 2000 kg/m3. The utilization of lightweight materials, particularly LWC, in modern structural construction, such as long-span bridges, high-rise buildings, shear walls, and sandwich panels, has attracted considerable interest. This interest arises from its great benefit as an excellent solution in terms of decreasing the dead load self-weight of the structure and, subsequently, lowering construction costs [9,10,11,12,13].

Pozzolana aggregate is a type of material composed of aluminous and siliceous materials. These materials react chemically with calcium hydroxide and water to form a cementitious composite material. Thus, when pozzolanic substances are included in concrete, the quality and durability of the concrete are further improved [14].

Expanded polystyrene (EPS) beads are an artificial material generated via steam processes or the chemical treatment of expanding polystyrene at high temperatures [15]. Particles of EPS are closed cells with spherical shapes with a density of (20–35) kg/m3 [11,16]. EPS can be used to reduce the dead loads of concrete elements [17]. EPS has proven its effectiveness in enhancing the durability and mechanical properties of concrete [11]. The main advantages of EPS are a uniformity in size and particle gradation; a round shape that reduces the internal friction; a lower absorption of water in the mix; a resistance to fire attack; sound insulation; and a reduced cost of construction compared to other artificial LWC and normal concrete [11,13,18,19].

LWC has been used by many researchers recently. Karaca and Durmuş [20] carried out an experimental procedure to explore and compare the performance of RC beams produced via ordinary aggregate and LWA. They found that the utilization of LWA in RC beams is more suitable than the ordinary aggregate. Gu et al. [21] established an experimental program to explore the effectiveness of using foam or lightweight ceramsite as a replacement for ordinary coarse aggregate in beams, to reach an LWC mix that meets engineering standards, and to investigate the mechanical characteristics of LWC and plain concrete under normal conditions. The results showed that the density of the foamed concrete beams was lower by 23.4% than plain concrete beams. Furthermore, the toughness and ductility of the foamed concrete were higher by 3% and 13% than those of the plain concrete, respectively. The ceramsite concrete beam showed a brittle failure behavior in comparison with the plain concrete. Grzeszczyk and Janus [22] tested LWC beams produced using EPS beads in a quantity replacement from 30% to 60% with the volume of the reactive powder concrete (RPC) mix. They found that the replacement of 60% of the RPC mix with EPS beads produced lower compressive and flexural strength than the replacement of 30%. Nawaz et al. [23] demonstrated that the LWC beams displayed a better bond behavior, a greater number of cracks, and a smaller crack width, compared to normal concrete beams, but the load-deflection curves were the same as those for normal concrete beams. Tang et al. [24] tested RC beam specimens to explore the efficiency of using LWC produced with sedimentary LWA on the shear behavior of beams. The results showed that brittle shear failure accrued in LWC beams, and that the brittleness increases as the compressive strength increases. Ismail et al. [25] studied the efficiency of using lightweight slag aggregates (SL) in the construction industry, and investigated the suitable options for using coarse or fine SL to achieve a better performance. The results showed that using lightweight fine or coarse SL satisfied the serviceability limit states of deflections and cracks, in addition to the sufficient structural capacity of the beams cast.

Concrete mixes that incorporate lightweight additives, such as expanded polystyrene beads, exhibit a distinct susceptibility to the elevated temperatures that can arise during a fire. Recognizing this heightened vulnerability, it becomes imperative to subject these concrete compositions to rigorous testing procedures. The objective behind these tests is to comprehensively assess and comprehend how these lightweight concrete materials react and perform under the influence of high temperatures. By conducting these examinations, we aim to glean insights into the structural behavior, integrity, and thermal response of these specialized concretes when exposed to fire conditions. Such investigations are crucial to formulating effective fire-resistant strategies and engineering solutions that enhance the safety and performance of structures constructed using lightweight concrete, incorporating expanded polystyrene beads. Sullivan and Labani [26] conducted a flexural test on LWC RC beams subjected to temperatures ranging from 20 to 600 °C, to explore and compare the behavior of LWC beams at different temperatures, by measuring the variation in their characteristics. The results showed a reduction by 65% in the strength of the LWC beams at a temperature of 90 °C. There was less of a reduction in strength at the other temperatures and, at 400 °C, the strength recovered, and was higher than that of the concrete at ambient temperature. The highest reduction in strength accrued above 500 °C. Additionally, the authors found that, at all test temperatures, the LWC beams lost weight, and the highest loss accrued in the range of 100–200 °C.

The aforementioned findings present a strong motivation to further explore the shear behavior of LWC RC beams made with a partial replacement of pozzolana aggregate and sand via EPS. As there was no work conducted in the previous studies using EPS in RC beams, this work helps to add new knowledge to the current literature in some areas, such as the behavior of EPS in LWC RC.

This study is carried out to evaluate the shear behavior of LWC beams developed with different volumes of EPS. The 27 tested beams are detailed in three groups. Each group is composed of three beams, classified as follows. The first group consists of three lightweight RC beams. One control beam was designed via the full replacement of the coarse mineral aggregate with coarse pozzolana aggregate (CPA). The second beam was made via CPA, with the partial replacement of EPS by about 12.5% CPA, and 25% fine aggregate (FA). While the third beam was made via CPA and the partial replacement of EPS by about 12.5% CPA and 25% FA, in addition to 250 mL of admixtures (superplasticizer). The second and third groups were similar to the first group; further, they were exposed to high temperatures at 300 °C and 600 °C for the second and third groups, respectively. By addressing both shear behavior and heat performance, while incorporating two distinct materials, expanded polystyrene beads and pozzolana aggregate, in combination with the concrete mix, the study bridges a gap in the existing research, and offers a comprehensive exploration of the multifaceted effects that expanded polystyrene beads and pozzolana aggregate can enact on the behavior and performance of RC beams. This holistic approach has the potential to contribute valuable insights in the fields of structural engineering and material science.

2. Methodology

2.1. Material Properties

2.1.1. Cement

The type of cement used in this research study was ordinary Portland cement (OPC) type I. The chemical composition of OPC type I is provided in Table 1, as provided by the manufacturer.

Table 1.

The chemical composition of the OPC.

2.1.2. Aggregate

In this experimental test, the normal coarse aggregate in the mix design was replaced with CPA, to investigate the effect of using LWA on the shear behavior of the RC structures. Different gradations of the CPA were used between 4.75 mm and 25 mm, as shown in Figure 1. The density, specific gravity, and water absorption for the aggregate were identified based on the ASTM C 127 [27] test requirement. Table 2 provides the properties of the CPA.

Figure 1.

Pozzolana aggregate.

Table 2.

The properties of the Pozzolana aggregate.

2.1.3. Expanded Polystyrene (EPS) Beads

As shown in Figure 2, the color and shape of the EPS used in this study comprised white medium circles of about 4.5 mm in diameter. Table 3 shows the physical and mechanical properties of the EPS, as provided by the manufacturer.

Figure 2.

Expanded polystyrene beads.

Table 3.

Physical and mechanical properties of the EPS.

2.1.4. Superplasticizers

Master Glenium 51 was used in this study. It is a type of superplasticizer that comes from the Polycarboxylic family. The main objective of adding this to the mix design is to enhance the efficiency of the cement dispersions. Table 4 provides the Master Glenium 51 properties, as provided by the supplier.

Table 4.

Master Glenium 51 properties.

2.1.5. Mix Proportion

Three different mix designs were prepared in this experimental study. The parameters that were different between the mixes were the proportion of EPS and superplasticizers in each batch. The optimum proportions of the EPS were 12.5% of the coarse aggregate (CA), and 25% of the fine aggregate (FA) as a partial replacement by volume, in addition to 250 mL of superplasticizer. These percentages were chosen based on several trials. The details of the mix proportions for each batch are provided in Table 5.

Table 5.

Details of the mix proportions.

As shown in Table 5, Mix 1 is the control mix. The main component of this mix is CPA without EPS or additives. Mix 2 consists of CPA, in addition to the 12.5% CA and 25% FA partial replacement of EPS. Finally, Mix 3 has the same components as Mix 2, in addition to 250 mL of superplasticizer.

2.1.6. Steel Reinforcement

The reinforced bars used in the experimental program were deformed steel bars with a 420 and 280 MPa average yield strength for both the longitudinal and transverse bars, respectively.

2.2. Test Specimens

2.2.1. Geometrical and Reinforcement Details

To examine the effect of using the LWA with EPS on the shear behavior of the RC beams, twenty-seven simply supported rectangular RC beams were produced, and designed to fail in shear. Figure 3 illustrates the geometrical and reinforcement details of the RC beams.

Figure 3.

Geometrical and reinforcement details.

2.2.2. Test Matrix

Twenty-seven simply supported rectangular RC beams were classified into three main test groups based on their concrete mix design and exposure to fire attack. Group A consists of three specimens, each specimen designed with a different concrete mix design. The first specimen LS is the control beam, and was designed based on the Mix 1 design details, while the second specimen LS-P, which contains a partial replacement of EPS by volume, was designed based on the Mix 2 design proportions. Finally, the third specimen LS-P*, which contains EPS and superplasticizer, was designed based on the Mix 3 design details. Both Group B and Group C consist of three specimens, similarly to Group A. The main difference is that the specimens were exposed to high temperatures of 300 °C and 600 °C for Group B and Group C, respectively. Table 6 illustrates the test matrix.

Table 6.

Test matrix.

The notations in the naming for the specimens are as follows: L for the LWA; S for the shear reinforcement; P for the EPS; * for the additive; and 300–600 for the temperature.

2.2.3. Test Setup

The tested beams were subjected to a four-point bending test, up to failure. Figure 4 shows the test machine (ADR-Auto) with a maximum load capacity of 2000 kN. The load was applied at a constant rate, and the displacement was recorded for each 1 kN. Three strain gauges were fixed at the bottom of the specimen: one at the mid-span, and the others a quarter length from both the left and right sides.

Figure 4.

The test setup.

2.3. Beams Installation

2.3.1. Casting and Curing

In this study, twenty-seven beam specimens and twenty-seven standard cubes were cast, to investigate several properties. The cube dimensions were 150 × 150 × 150 mm, and the beam dimensions were 150 × 150 × 1150 mm. Three different concrete mixes were prepared, using a mechanical tilting drum mixer. The concrete was poured in three layers, with each layer compacted with 35 strokes, according to ASTM C192. A trowel was used to level the final surface, and the beams and cube samples were left in the mold for one day, and then moved to water tanks with a temperature ranging from 23 to 25 °C, to start the curing for 28 days. Figure 5 shows the casting process.

Figure 5.

The casting process.

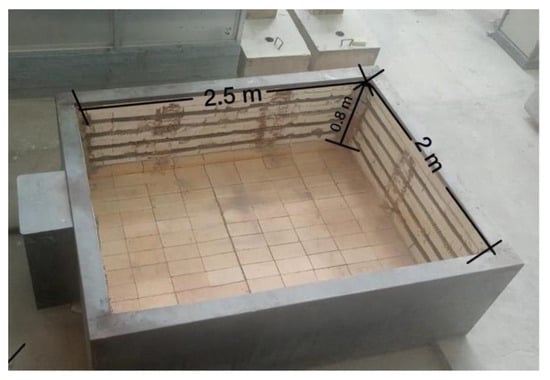

2.3.2. Heat Application

The beams underwent heating within the furnace depicted in Figure 6. The furnace’s distinct dimensions are 2 m × 2.5 m × 0.8 m. A heating control panel was affixed to the furnace, to regulate the temperature and duration. In total, eighteen beam specimens were exposed to a heat treatment lasting 2 h. Among these, nine beams experienced a temperature of 300 °C, while the remaining nine beams were exposed to 600 °C. The objective was to analyze how heat impacts the shear characteristics of control beams, beams consisting solely of EPS beads, and beams crafted using both EPS beads and an additive.

Figure 6.

Heat furnace.

3. Results and Discussion

3.1. Concrete Compressive Strength

A total of twenty-seven concrete cubes were tested, to determine the concrete compressive strength for each mix design. Table 7 shows the results of the average cubic and cylindrical compressive strength for the concrete tested cubes.

Table 7.

Average concrete compressive strength.

As shown in Table 7, the average cylindrical concrete compressive strength for Mix 1, without the addition of EPS and superplasticizer, was 27.74 MPa, while the concrete strength was 19.58 MPa when 12.5% CA and 25% FA were replaced by volume with EPS in Mix 2. Finally, the strength was 21.72 MPa for Mix 3 when EPS and superplasticizer were added into the mix together. It is noticeable that replacing 12.5% of CA and 25% of FA with EPS reduced the concrete strength relatively. Moreover, the superplasticizer played a major role in lowering the reduction in concrete strength. The reduction in compressive strength was 29.4% and 21.7% for Mix 2 and Mix 3, respectively. Figure 7 shows the tested cubes for all the concrete specimens. It can be concluded that the availability of EPS beads in the mix could hinder the mixing process, and affect the bonds between the cement and aggregate. Moreover, EPS beads replace some of the heavier aggregates when added to the concrete mixture, thus, in turn, decreasing the overall concrete compressive strength.

Figure 7.

The tested cubes for all the concrete specimens.

3.2. Concrete Density

Table 8 provides the concrete density for all the concrete mix designs.

Table 8.

Densities of mixes.

Based on Table 8, the concrete density for the three mixes was 2230 kg/m3, 1977 kg/m3, and 1868 kg/m3 for Mix 1, Mix 2, and Mix 3, respectively. It can be noticed that the concrete density was reduced in Mix 2 and Mix 3, compared to Mix 1 (the control mix). We know that both Mix 2 and Mix 3 contain a percentage of EPS of about 12.5% CA and 25% FA, which indicates that EPS is considered a major component responsible for reducing the density of concrete. Moreover, the percentage reduction in was 11.34% for Mix2 and 16.23% for Mix3; therefore, adding a superplasticizer with EPS is more effective in reducing the concrete density.

3.3. Experimental Shear Behavior

Table 9 shows the experimental results including the initial crack load, ultimate failure load, concrete compressive strength, and maximum deflection for 27 beams. The test results are discussed in this section, in terms of the load–deflection curves, load-carrying capacity, and mode of failure.

Table 9.

The experimental results for the tested beam.

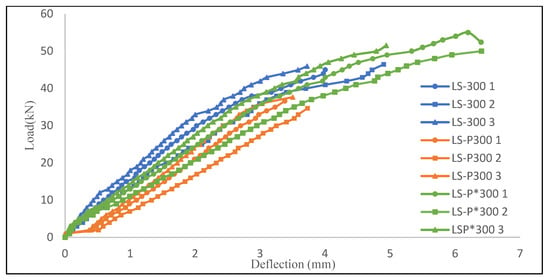

Firstly, the results for Group A showed that the addition of EPS beads in the concrete mix of beams reduced the load-carrying capacity of the beams by 19.39% compared to the control beams, due to the poor connection between the EPS and cement, in addition to the concrete mix’s high compressibility and low elastic modulus [28]. To increase the adhesiveness between the EPS, on the other hand, the load-carrying capacity of the beam mix including the superplasticizer is almost the same as the control beams, which indicates the efficiency of using EPS beads with a superplasticizer in a concrete mix that gives the same behavior and load-carrying capacity as the control mix, where the superplasticizer increases the adhesiveness efficiency between polystyrene particles [28]. Figure 8 shows the load–deflection curve for specimens LS, LS-P, and LS-P*, respectively.

Figure 8.

The load–displacement curves of the LS, LS-P, and LS-P* samples.

For Group B, beams that were poured with a mix containing EPS beads, and heated at 300 °C, showed a reduction in load-carrying capacity of 20.72%, compared to heated control beams subjected to the same heat-exposure level. Meanwhile, the load-carrying capacity for beams with a mix containing ESP and superplasticizer is almost the same as the control beams heated at the same temperature. This behavior occurs due to the process of hydration, which can result in the rapid synthesis of cementitious compounds, and an increase in concrete strength [29]. Figure 9 illustrates the load–deflection behavior for specimens heated at 300 °C, LS-300, LS-P-300, and LS-P*-300, respectively.

Figure 9.

The load–displacement curves of the LS-300, LS-P300, LS-P*300 samples.

A reduction in load-carrying capacity of 17.96% was found for beams containing EPS in their mix and heated at 600 °C, compared to the heated control beams in the same group (Group C), whereas the load-carrying capacity of beams with a mix containing ESP and superplasticizer is almost the same as heated control beams exposed to the same heat temperature. At elevated temperatures, concrete undergoes thermal expansion, causing the material to expand. This expansion generates internal stresses within the concrete, which can lead to cracking, spalling, and even delamination in the concrete cover. These cracks and separations weaken the structural integrity of the beam, reducing its capacity to withstand loads. Moreover, the high temperature can cause the bond between the concrete matrix and the reinforcing steel to weaken or break. This loss of bond reduces the load transfer capability between the steel reinforcement and the concrete, compromising the beam’s overall strength. Figure 10 displays the load–deflection behavior for the specimens LS-600, LS-P-600, and LS-P*-600 in Group C. A reduction in the load-carrying capacity was found in the beams heated at 600 °C, compared to the unheated beams, which indicates that the damage to the mechanical properties of the beams occurred at a temperature of 600 °C.

Figure 10.

The load–displacement curves of the LS-600, LSP-600, and LS-P*-600 samples.

3.4. Failure Mechanisms

In this experimental test, the failure mode for all the beam specimens was a shear failure. The crack monitor for all specimens showed approximately the same behavior. The initial cracks were hair cracks, and started at the maximum moment region. Through an increase in the load, more shear–flexural cracks were noticed. When the applied load approached the ultimate capacity, the cracks became wider, and propagated up to the compression zone. When the beams reached their ultimate capacity, a brittle shear failure occurred. Figure 11 shows the mode of failure for all beams.

Figure 11.

The crack pattern of beam destruction.

3.5. Effect of High Temperatures

Based on the experimental results, a reduction in the ultimate capacity occurred on the RC concrete beams that were exposed to elevated temperatures (600 °C), and a significant deterioration appeared in the beam structure. However, the EPS was evaporated in the concrete cover zone, due to the heat effect in both cases, at 300 °C and 600 °C, while it remains as it is without evaporation inside the RC beam. Figure 12 shows the difference between the availability of EPS at the concrete surface, and that inside the beam. Figure 13 displays the variation in the load-carrying capacity of the unheated, heated-at-300 °C, and heated-at-600 °C beam specimens.

Figure 12.

The effect of high temperature on the EPS at the surface, and inside the RC beams.

Figure 13.

The variation in the load-carrying capacity of the unheated, heated-at-300 °C, and heated-at-600 °C beam specimens.

4. Conclusions

An experimental investigation was carried out on reinforced concrete (RC) beams, to study the effect of using expanded polystyrene (EPS) beads and pozzolana aggregate (PA) on the shear behavior of the RC beams. A total of 27 simply supported rectangular beams were cast, using three different mix designs, and tested under a two-point load test, up to failure. The three mixes were classified into the control mix; a mix with EPS only; and a mix with EPS and additive. The ultimate failure load was experimentally recorded for all specimens, and the effect of high temperatures (300 and 600 °C) on the EPS RC beams was studied. The following conclusions were drawn:

- The concrete compressive strength for the mix containing 12.5% of CA and 25% of FA with EPS was reduced by about 29.4%, and a slight reduction of 21.7% occurred for the mix produced with 12.5% CA and 25% FA with EPS, and 250 mL superplasticizer. When lightweight EPS beads are introduced into the concrete mix, they displace a portion of the heavier aggregates. This can contribute to a reduction in the compressive strength. Moreover, they can potentially hinder the uniform distribution of water and cement particles during the mixing process. This non-uniform distribution can lead to variations in curing and hydration, affecting the development of adequate strength-forming bonds within the concrete matrix.

- The concrete density for the mix containing EPS was reduced by about 11.3% for the mix with EPS only, and 16.2% for the mix with EPS and superplasticizer, which indicates that EPS is considered a major component responsible for reducing the density of concrete. EPS beads are much lighter than conventional aggregates, which results in a lower density for the entire concrete mixture. This reduction in density leads to a corresponding decrease in the weight of the concrete elements, making them easier to handle, transport, and place.

- The reduction in the load-carrying capacity of the beams poured using EPS beads was about 19.4%, compared to the control beams. When EPS beads are added to the mix, they displace a portion of the traditional heavier aggregates and cement paste. As a result, the effective concrete area available to resist applied loads is reduced. Moreover, the connection between the EPS and cement is poor, leading to a decrease in the load-carrying capacity. However, the beams with a mix containing EPS and a superplasticizer showed almost the same behavior as the control beams, which indicates the effectiveness of using EPS beads with a superplasticizer in a concrete mix. A superplasticizer is an admixture used to improve the workability and flowability of concrete. When used in conjunction with EPS beads, the superplasticizer enhances the dispersion of particles, allowing for a better incorporation of the lightweight beads within the concrete matrix. This improved workability can lead to a more uniform distribution and compaction in the mix.

- It was observed that the beams subjected to heat at 300 °C showed almost the same behavior, compared to the unheated beams. When concrete is subjected to a temperature of 300 °C, in this case, the heat from external sources can accelerate the hydration process. This can lead to the rapid formation of cementitious compounds, and an increase in the strength of the concrete. In essence, the heat acts as an energy source that speeds up the chemical reactions within the concrete.

- There was a significant reduction in the ultimate capacity of the beams that were exposed to 600 °C compared to the unheated beams, due to the destruction caused to the mechanical characteristics of the beam element.

- At the same heat exposure level of 300 °C, a reduction of about 20.7% occurred in the ultimate load of the beams produced via EPS, only compared to the heated control beams, whereas the load-carrying capacity for beams with a mix containing ESP and superplasticizer showed almost the same behavior as the heated control beams.

- At the same heat exposure level of 600 °C, a reduction of about 18% occurred in the ultimate load of the beams produced via EPS, only in comparison to the heated control beams, whereas a slight load-carrying capacity for beams with a mix containing ESP and superplasticizer showed almost the same behavior as the heated control beams.

Author Contributions

Conceptualization, M.A.-J., N.S. and H.K.; methodology, M.A.-J., R.A.-N. and H.A.-z.; validation, H.K., N.S., A.A.-Q. and R.A.; formal analysis, M.A.-J., R.A.-N. and H.A.-z.; investigation, H.K., N.S. and A.A.-Q.; resources, R.A.-N. and H.A.-z.; data curation, R.A.-N. and H.A.-z.; writing—original draft preparation, R.A.-N., R.A. and H.A.-z.; writing—review and editing, N.S. and H.K.; visualization, M.A.-J. and A.A.-Q.; supervision, M.A.-J., N.S. and H.K.; project administration, M.A.-J.; funding acquisition, M.A.-J. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

All data of this research were presented in the article.

Acknowledgments

The authors would like to thank Al-Ahliyya Amman University for their technical support in achieving this research work. This work was carried out during the sabbatical leave granted to the author Mu’tasime Abdel-Jaber from the University of Jordan, during the academic year 2022–2023.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Gunasekaran, K.; Kumar, P.S.; Lakshmipathy, M. Mechanical and Bond Properties of Coconut Shell Concrete. Constr. Build. Mater. 2011, 25, 92–98. [Google Scholar] [CrossRef]

- Mathew, S.P.; Nadir, Y.; Arif, M.M. Experimental Study of Thermal Properties of Concrete with Partial Replacement of Coarse Aggregate by Coconut Shell. Mater. Today Proc. 2020, 27, 415–420. [Google Scholar] [CrossRef]

- Al-Osta, M.A.; Isa, M.N.; Baluch, M.H.; Rahman, M.K. Flexural Behavior of Reinforced Concrete Beams Strengthened with Ultra-High Performance Fiber Reinforced Concrete. Constr. Build. Mater. 2017, 134, 279–296. [Google Scholar] [CrossRef]

- Vakhshouri, B.; Nejadi, S. Mix Design of Light-Weight Self-Compacting Concrete. Case Stud. Constr. Mater. 2016, 4, 1–14. [Google Scholar] [CrossRef]

- Domone, P.L. Self-Compacting Concrete: An Analysis of 11 Years of Case Studies. Cem. Concr. Compos. 2006, 28, 197–208. [Google Scholar] [CrossRef]

- Thienel, K.C.; Haller, T.; Beuntner, N. Lightweight Concrete—From Basics to Innovations. Materials 2020, 13, 1120. [Google Scholar] [CrossRef] [PubMed]

- Lamond, J.F.; Pielert, J.H. Significance of Tests and Properties of Concrete and Concrete-Making Materials STP 169D; ASTM International: West Conshohocken, PA, USA, 2006. [Google Scholar]

- Umar, T.; Tahir, A.; Umeokafor, N.; Nawarathna, A.; Zia, A.; Vali, M.S.H. An Experimental Investigation on Strength Characteristics of Concrete Using Wastepaper Sludge Ash (WPSA); University of Greenwich: London, UK, 2022. [Google Scholar]

- Akers, D.J.; Gruber, R.D.; Ramme, B.W.; Boyle, M.J.; Grygar, J.G.; Rowe, S.K.; Kowalsky, M.J. Guide for Structural Lightweight-Aggregate Concrete; ACI 213R-03. Technical Documents; American Concrete Institute (ACI): Farmington Hills, MI, USA, 2003; p. 38. [Google Scholar]

- Liu, N.; Chen, B. Experimental Study of the Influence of EPS Particle Size on the Mechanical Properties of EPS Lightweight Concrete. Constr. Build. Mater. 2014, 68, 227–232. [Google Scholar] [CrossRef]

- Assaad, J.; Chakar, E.; Zéhil, G.P. Testing and Modeling the Behavior of Sandwich Lightweight Panels against Wind and Seismic Loads. Eng. Struct. 2018, 175, 457–466. [Google Scholar] [CrossRef]

- Mousavi, S.A.; Zahrai, S.M.; Bahrami-Rad, A. Quasi-Static Cyclic Tests on Super-Lightweight EPS Concrete Shear Walls. Eng. Struct. 2014, 65, 62–75. [Google Scholar] [CrossRef]

- Cui, C.; Huang, Q.; Li, D.; Quan, C.; Li, H. Stress–Strain Relationship in Axial Compression for EPS Concrete. Constr. Build. Mater. 2016, 105, 377–383. [Google Scholar] [CrossRef]

- Umar, T.; Tahir, A.; Egbu, C.; Honnurvali, M.S.; Saidani, M.; Al-Bayati, A.J. Developing a Sustainable Concrete Using Ceramic Waste Powder. Adv. Sci. Technol. Innov. 2021, 157–162. [Google Scholar]

- Assaad, J.J.; El Mir, A. Durability of Polymer-Modified Lightweight Flowable Concrete Made Using Expanded Polystyrene. Constr. Build. Mater. 2020, 249, 118764. [Google Scholar] [CrossRef]

- Tang, Z.; Zha, X.; Wang, B. Investigation on Wall Panel Sandwiched With Lightweight Concrete You May Also like Finite Element Study on Mechanical Performances of Multi-Span Metal Faced Sandwich Panels under Temperature Actions. IOP Conf. Ser. Mater. Sci. Eng. 2017, 225, 012275. [Google Scholar] [CrossRef]

- Fernando, P.L.N.; Jayasinghe, M.T.R.; Jayasinghe, C. Structural Feasibility of Expanded Polystyrene (EPS) Based Lightweight Concrete Sandwich Wall Panels. Constr. Build. Mater. 2017, 139, 45–51. [Google Scholar] [CrossRef]

- Fathi, M.; Yousefipour, A.; Hematpoury Farokhy, E. Mechanical and Physical Properties of Expanded Polystyrene Structural Concretes Containing Micro-Silica and Nano-Silica. Constr. Build. Mater. 2017, 136, 590–597. [Google Scholar] [CrossRef]

- Assaad, J.J.; Issa, C.A. Mixture Optimisation of Polymer-Modified Lightweight SCC. Mag. Concr. Res. 2017, 69, 745–756. [Google Scholar] [CrossRef]

- Karaca, Z.; Durmuş, A. Investigation of Usability of Lightweight Concrete Produced with Natural Eastern Black Sea Aggregates in Reinforced Concrete Beams. J. Mater. Civ. Eng. 2012, 24, 937–943. [Google Scholar] [CrossRef]

- Fang, Y.; Xu, Y.; Gu, R. Experiment and Analysis of Mechanical Properties of Lightweight Concrete Prefabricated Building Structure Beams. Int. J. Concr. Struct. Mater. 2022, 16, 5. [Google Scholar] [CrossRef]

- Grzeszczyk, S.; Janus, G. Reactive Powder Concrete with Lightweight Aggregates. Constr. Build. Mater. 2020, 263, 120164. [Google Scholar] [CrossRef]

- Nawaz, W.; Abdalla, J.A.; Hawileh, R.A.; Alajmani, H.S.; Abuzayed, I.H.; Ataya, H.; Mohamed, H.A. Experimental Study on the Shear Strength of Reinforced Concrete Beams Cast with Lava Lightweight Aggregates. Arch. Civ. Mech. Eng. 2019, 19, 981–996. [Google Scholar] [CrossRef]

- Tang, C.; Yen, T.; Chen, H. Shear Behavior of Reinforced Concrete Beams Made with Sedimentary Lightweight Aggregate without Shear Reinforcement. J. Mater. Civ. Eng. 2010, 21, 730–740. [Google Scholar] [CrossRef]

- Ismail, M.K.; Hassan, A.A.A.; AbdelAleem, B.H.; El-Dakhakhni, W. Flexural Behavior and Cracking of Lightweight RC Beams Containing Coarse and Fine Slag Aggregates. Structures 2023, 47, 1005–1019. [Google Scholar] [CrossRef]

- Sullivan, P.J.E.; Labani, J.M. Flexural Behaviour of Plain and Reinforced Lightweight Aggregate Concrete Beams up to 600 °C. Cem. Concr. Res. 1974, 4, 231–237. [Google Scholar] [CrossRef]

- ASTM-C127-07; Standard Test Method for Density, Relative Density (Specific Gravity), and Absorption of Coarse Aggregate. ASTM International: West Conshohocken, PA, USA, 2007.

- Mohammed, H.J.; Aayeel, O.K. Flexural Behavior of Reinforced Concrete Beams Containing Recycled Expandable Polystyrene Particles. J. Build. Eng. 2020, 32, 101805. [Google Scholar] [CrossRef]

- Khoury, G.A. Compressive Strength of Concrete at High Temperatures: A Reassessment. Mag. Concr. Res. 1992, 44, 291–309. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).