Multi-Criteria Risk Analysis of Ultra-High Performance Concrete Application in Structures

Abstract

1. Introduction

2. Ultra-High-Performance Concrete

2.1. Background

2.2. Definition and Properties

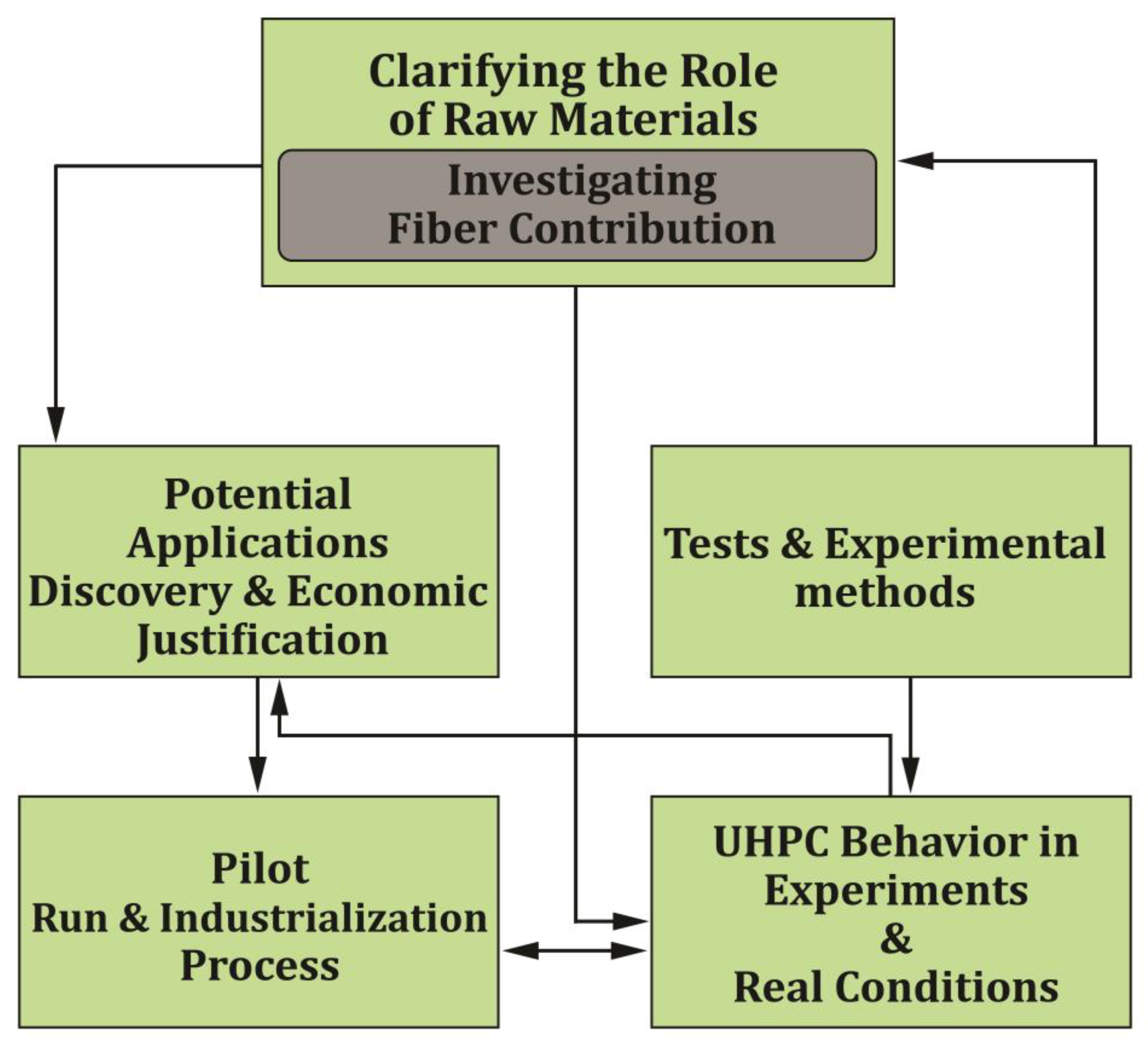

2.3. Introduction to Industry

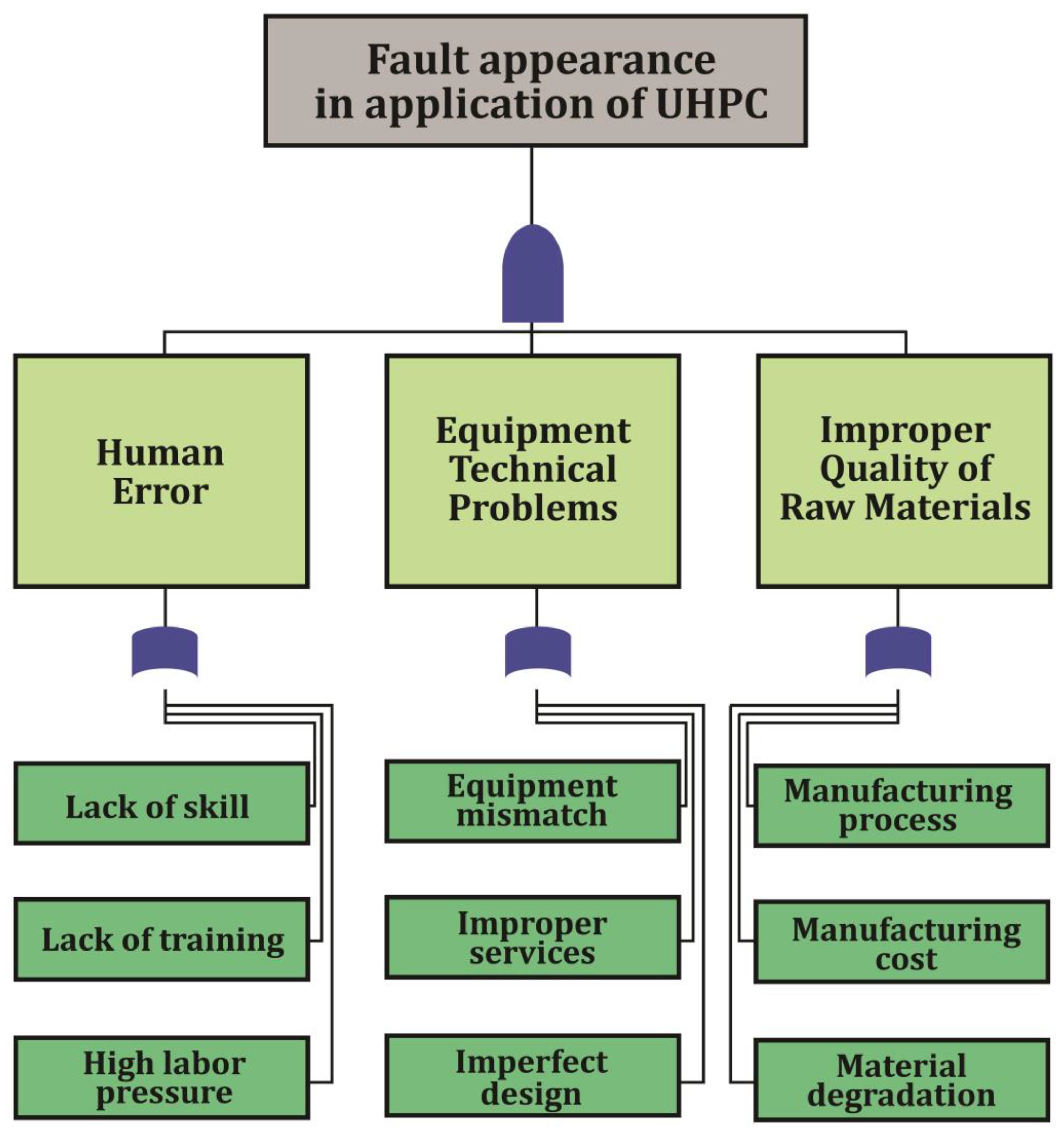

2.4. Technical Problems

- 1.

- High Cost and Economic Justification Gap: The production cost of UHPC is notably higher, amounting to a minimum of 6.6 times that of ordinary concrete [69,70] Moreover, limited manufacturers, such as Lafarge, offer comprehensive industrial support for the requisite raw materials [70,71,72,73]. Nonetheless, intricate applications such as concrete-filled steel tubes (CFST) for columns and steel–concrete–steel sandwich composites are garnering attention [72,73].

- 2.

- Compatibility of Indigenous Materials: UHPC necessitates specific materials in its mixture, which may not always be locally available. The intricate task of gauging and optimizing material quantities further complicates the attainment of the desired concrete formulation at every project site.

- 3.

- Sensitivity to In Situ Casting Conditions: The imperative for exceptionally high strength (exceeding 120 MPa) renders UHPC exceedingly susceptible to environmental and placement conditions. Mixing, curing, relative humidity, thermal conditions, and setting time collectively impact the mechanical attributes of UHPC.

- 4.

- Technical Complexities in Connections: The realm of connections and bonds involving UHPC layers/elements and other structural materials remains largely uncharted. The bond between UHPC and the hardened layer of structural concrete, whether in early stages or from existing structures, has been a subject of research for an extended period [74,75].

- 5.

- Absence of Standard Specifications: While numerous tests devised for conventional concrete by ASTM are applied to UHPC, a consensus is yet to be reached regarding grading and mix proportions. Moreover, in dynamic loading scenarios, this type of concrete exhibits behavior that is relatively unexplored.

- 6.

- Demand for UHPC Production Facilities and Skilled Workforce: Given the substantial cost of UHPC and the limited operational capacity, establishing production facilities lacks economic viability. Additionally, a trained workforce is essential for the proper casting and placement of UHPC components.

3. Multi-Criteria Risk Assessment

| Effects | |||||||

|---|---|---|---|---|---|---|---|

| Negligible | Low | Moderate | High | Critical | |||

| 0.1 | 0.3 | 0.5 | 0.7 | 0.9 | |||

| Incidence probability | Certain | 0.9 | Moderate | Moderate | High | High | High |

| Probable | 0.7 | Low | Moderate | Moderate | High | High | |

| Possible | 0.5 | Low | Moderate | Moderate | Moderate | High | |

| Improbable | 0.3 | Low | Low | Moderate | Moderate | High | |

| Rare | 0.1 | Low | Low | Low | Moderate | Moderate | |

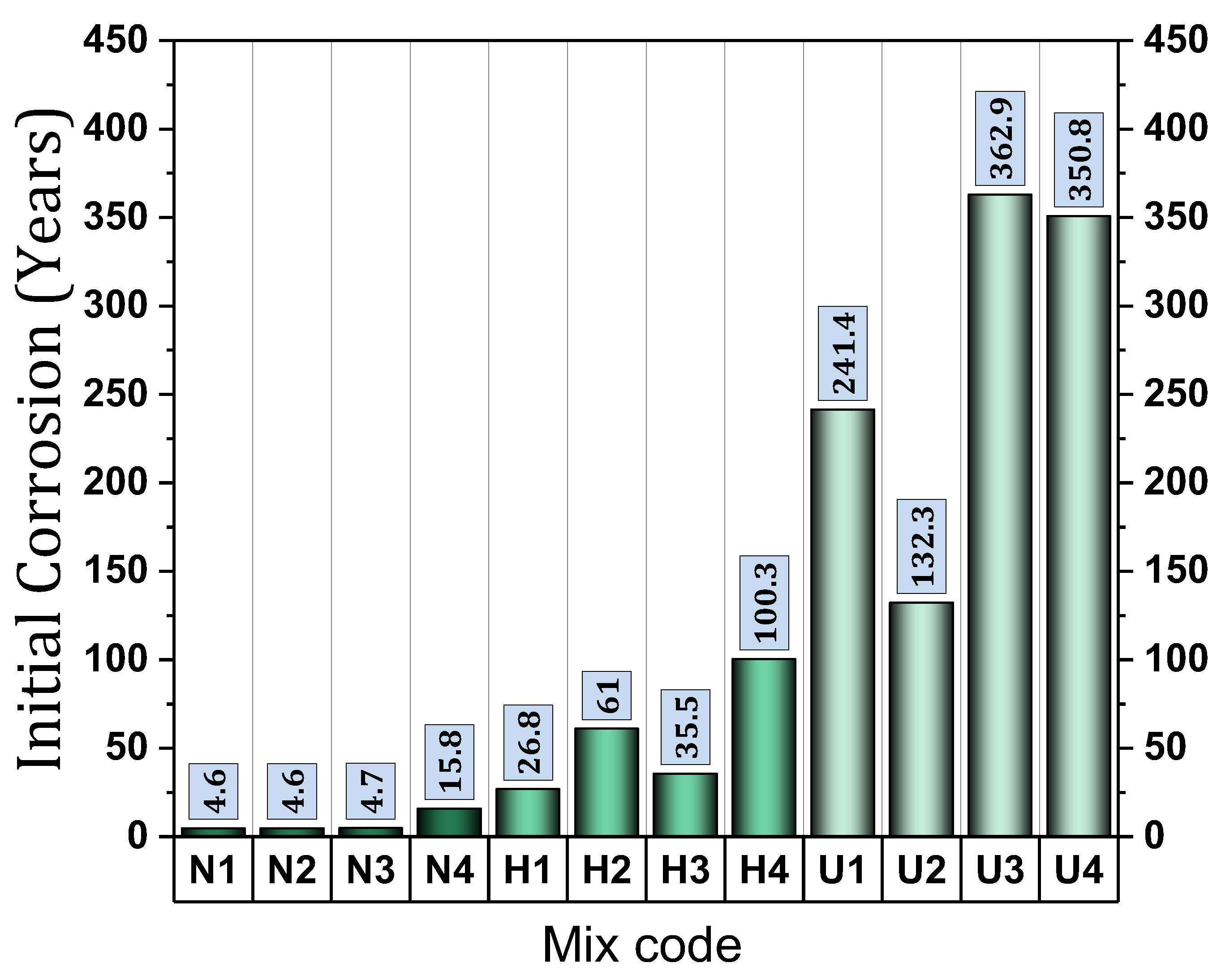

3.1. Risk Evaluation Based on Mix Proportions

- 1.

- Economic Risk: This pertains to the potential undesirable escalation of costs and the risk associated with selecting a more economically efficient option that may compromise technical quality.

- 2.

- Technical Risk: This encompasses complexities and factors beyond control, such as unknown chemical parameters in superplasticizers, where an increase in these parameters can raise the risk level.

- 3.

- Environmental Risk: This is determined based on the constituents and the environmental impact emitted by the manufacturing industry, which can either be negative or positive (e.g., pollution reduction).

3.2. Weighing and Synchronizing

| Mix | Cementitious Materials (CM) (Kg/m3) | Ratios (/CM) | Fiber Content (Kg/m3) | f′c (MPa) | Ref. | ||

|---|---|---|---|---|---|---|---|

| Silica Fume | Water | Superplasticizer | |||||

| N1 | 413 | 0 | 0.46 | 0 | 0 | 35.9 | [95] |

| N2 | 413 | 0 | 0.46 | 0 | 59 | 46.9 | [96] |

| N3 | 440 | 0 | 0.45 | 0.0125 | 0 | 39 | [97] |

| N4 | 440 | 0.1 | 0.45 | 0.021 | 0 | 41.8 | [56] |

| H1 | 413 | 0.1 | 0.35 | 0.04 | 29.5 | 75.2 | [96] |

| H2 | 500 | 0.15 | 0.35 | 0.0267 | 0 | 70 | [98] |

| H3 | 500 | 0.1 | 0.3 | 0.0018 | 0 | 107.9 | [99] |

| H4 | 520 | 0.15 | 0.26 | 0.035 | 0 | 95.7 | [100] |

| U1 | 600 | 0.2 | 0.25 | 0.025 | 0 | 130 | [101] |

| U2 | 853 | 0.15 | 0.2 | 0.0352 | 155 | 166.1 | [102] |

| U3 | 1187 | 0.2 | 0.15 | 0.014 | 146 | 198.5 | [103] |

| U4 | 1125 | 0.2 | 0.16 | 0.032 | 157 | 140 | [104] |

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

| No. Samples | Diameter of Samples | Age (Days) | Additives (Substitute Part of Cement) | Fiber Length (mm) | Curing Method | References |

|---|---|---|---|---|---|---|

| 18 | 100 × 200 mm | 28 | Silica fume | 50, 30 and 60 | - | [95] |

| 10 | 100 × 200 mm | 28–91 | Silica fume | - | Dry air curing Water curing | [97] |

| 5 | 76 × 152 mm | 1–5–7–14–28–90–160–180 | Silica fume | 30, 20 and 13 | Moist | [56] |

| 24 | 100 × 100 × 100 mm | 7–14–28–42–90–365–400 | Silica fume | - | Moist Dry | [98] |

| 48 | 100 × 100 × 100 mm 100 × 200 mm | 3, 7, 28, 90 | Metakaolin Silica fume | - | Moist | [99] |

| 32 | 150 × 150 × 150 mm | 28 | Silica fume | - | Moist | [100] |

| 3 | 100 × 100 × 100 mm | 28 | Quartz powder Silica fume | 6 | Air curing | [101] |

| 4 | 100 × 100 × 100 mm | 28 | Slag Fly ash | 15 | 7 days of storage under water in a curing tank, after which it was processed in the air under laboratory conditions until day 28. | [102] |

| 3 | 90 × 180 mm 70 × 140 mm | 28 | Crushed quartz Silica fume | 13, and 3 | The concrete was cured for 7 days in water at 20 °C followed by heat treatment for 4 days in water at 90 °C and 2 days in dry air at 90 °C. | [103] |

| 16 | 50 × 50 × 50 mm | 7–28–56 | Quartz powder Silica fume | - | Moist | [104] |

References

- Mohtasham Moein, M.; Saradar, A.; Rahmati, K.; Ghasemzadeh Mousavinejad, S.H.; Bristow, J.; Aramali, V.; Karakouzian, M. Predictive Models for Concrete Properties Using Machine Learning and Deep Learning Approaches: A Review. J. Build. Eng. 2023, 63, 105444. [Google Scholar] [CrossRef]

- Tahmouresi, B.; Nemati, P.; Asadi, M.A.; Saradar, A.; Mohtasham Moein, M. Mechanical Strength and Microstructure of Engineered Cementitious Composites: A New Configuration for Direct Tensile Strength, Experimental and Numerical Analysis. Constr. Build. Mater. 2021, 269, 121361. [Google Scholar] [CrossRef]

- Mohtasham Moein, M.; Mousavi, S.Y.; Madandoust, R.; Naser Saeid, H.N.S. The Impact Resistance of Steel Fiber Reinforcement Concrete under Different Curing Conditions: Experimental and Statistical Analysis. J. Civ. Environ. Eng. 2019, 49, 109–121. [Google Scholar]

- Moein, M.M.; Saradar, A.; Rahmati, K.; Rezakhani, Y.; Ashkan, S.A.; Karakouzian, M. Reliability Analysis and Experimental Investigation of Impact Resistance of Concrete Reinforced with Polyolefin Fiber in Different Shapes, Lengths, and Doses. J. Build. Eng. 2023, 69, 106262. [Google Scholar] [CrossRef]

- Rahmati, K.; Saradar, A.; Mohtasham Moein, M.; Sardrinejad, I.; Bristow, J.; Yavari, A.; Karakouzian, M. Evaluation of Engineered Cementitious Composites (ECC) Containing Polyvinyl Alcohol (PVA) Fibers under Compressive, Direct Tensile, and Drop-Weight Test. Multiscale Multidiscip. Model. Exp. Des. 2022, 6, 147–164. [Google Scholar] [CrossRef]

- Saradar, A.; Nemati, P.; Paskiabi, A.S.; Moein, M.M.; Moez, H.; Vishki, E.H. Prediction of Mechanical Properties of Lightweight Basalt Fiber Reinforced Concrete Containing Silica Fume and Fly Ash: Experimental and Numerical Assessment. J. Build. Eng. 2020, 32, 101732. [Google Scholar] [CrossRef]

- Mohtasham Moein, M.; Saradar, A.; Rahmati, K.; Hatami Shirkouh, A.; Sadrinejad, I.; Aramali, V.; Karakouzian, M. Investigation of Impact Resistance of High-Strength Portland Cement Concrete Containing Steel Fibers. Cem. Mater. High Perform. Concr. 2022, 15, 7157. [Google Scholar] [CrossRef]

- Sadrmomtazi, A.; Tahmouresi, B.; Saradar, A. Effects of Silica Fume on Mechanical Strength and Microstructure of Basalt Fiber Reinforced Cementitious Composites (BFRCC). Constr. Build. Mater. 2018, 162, 159. [Google Scholar] [CrossRef]

- Mosavinejad, H.G.; Saradar, A.; Tahmouresi, B. Hoop Stress-Strain in Fiber-Reinforced Cementitious Composite Thin-Walled Cylindrical Shells. J. Mater. Civ. Eng. 2018, 30, 1–12. [Google Scholar] [CrossRef]

- Sadrmomtazi, A.; Noorollahi, Z.; Tahmouresi, B.; Saradar, A. Effects of Hauling Time on Self-Consolidating Mortars Containing Metakaolin and Natural Zeolite. Constr. Build. Mater. 2019, 221, 283–291. [Google Scholar] [CrossRef]

- Saradar, A.; Tahmouresi, B.; Mohseni, E.; Shadmani, A. Restrained Shrinkage Cracking of Fiber-Reinforced High-Strength Concrete. Fibers 2018, 6, 12. [Google Scholar] [CrossRef]

- Mousavinejad, S.H.G.; Saradar, A.; Jabbari, M.; Moein, M.M. Evaluation of Fresh and Hardened Properties of Self-Compacting Concrete Containing Different Percentages of Waste Tiles. J. Build. Pathol. Rehabil. 2023, 8, 1–38. [Google Scholar] [CrossRef]

- Akl, A.; Ezzeldin, M. Seismic Collapse Risk Assessment of Low-Aspect-Ratio Reinforced Concrete Shear Walls Using the FEMA P695 Methodology. J. Struct. Eng. 2023, 149, 04022237. [Google Scholar] [CrossRef]

- Manjunatha, M.; Preethi, S.; Malingaraya; Mounika, H.G.; Niveditha, K.N.; Ravi. Life Cycle Assessment (LCA) of Concrete Prepared with Sustainable Cement-Based Materials. Mater. Today Proc. 2021, 47, 3637–3644. [Google Scholar] [CrossRef]

- Al-Bahar, J.F.; Crandall, K.C. Systematic Risk Management Approach for Construction Projects. J. Constr. Eng. Manag. 1990, 116, 533–546. [Google Scholar] [CrossRef]

- Wang, S.Q.; Dulaimi, M.F.; Aguria, M.Y. Risk Management Framework for Construction Projects in Developing Countries. Constr. Manag. Econ. 2004, 22, 237–252. [Google Scholar] [CrossRef]

- Zhi, H. Risk Management for Overseas Construction Projects. Int. J. Proj. Manag. 1995, 13, 231–237. [Google Scholar] [CrossRef]

- Akintoye, A.S.; MacLeod, M.J. Risk Analysis and Management in Construction. Int. J. Proj. Manag. 1997, 15, 31–38. [Google Scholar] [CrossRef]

- Tah, J.H.M.; Carr, V. A Proposal for Construction Project Risk Assessment Using Fuzzy Logic. Constr. Manag. Econ. 2000, 18, 491–500. [Google Scholar] [CrossRef]

- Malek, M.; Tumeo, M.; Saliba, J. Fuzzy Logic Approach to Risk Assessment Associated with Concrete Deterioration. ASCE ASME J. Risk Uncertain. Eng. Syst. A Civ. Eng. 2015, 1, 04014004. [Google Scholar] [CrossRef]

- Vieira, D.R.; Calmon, J.L.; Coelho, F.Z. Life Cycle Assessment (LCA) Applied to the Manufacturing of Common and Ecological Concrete: A Review. Constr. Build. Mater. 2016, 124, 656–666. [Google Scholar] [CrossRef]

- Gheibi, M.; Karrabi, M.; Shakerian, M.; Mirahmadi, M. Life Cycle Assessment of Concrete Production with a Focus on Air Pollutants and the Desired Risk Parameters Using Genetic Algorithm. J. Environ. Health Sci. Eng. 2018, 16, 89–98. [Google Scholar] [CrossRef] [PubMed]

- de Larrard, F.; Sedran, T. Optimization of Ultra-High-Performance Concrete by the Use of a Packing Model. Cem. Concr. Res. 1994, 24, 997–1009. [Google Scholar] [CrossRef]

- Richard, P.; Cheyrezy, M. Composition of Reactive Powder Concretes. Cem. Concr. Res. 1995, 25, 1501–1511. [Google Scholar] [CrossRef]

- Cheyrezy, M.; Maret, V.; Frouin, L. Microstructural Analysis of RPC (Reactive Powder Concrete). Cem. Concr. Res. 1995, 25, 1491–1500. [Google Scholar] [CrossRef]

- Roy, N.; Proulx, J.; Paultre, P.; Legeron, F. Dynamic Testing of the Sherbrooke Pedestrian Bridge. In Proceedings of the IABSE Congress: Structural Engineering for Meeting Urban Transportation Challenges, Lucerne, Switzerland, 18–21 September 2000; pp. 1254–1261. [Google Scholar] [CrossRef]

- Behloul, M.; Ricciotti, R. Footbridge of Peace—Seoul. In Role of Concrete Bridges in Sustainable Development; Thomas Telford Publishing: London, UK, 2003; pp. 63–72. [Google Scholar]

- Yang, S.L.; Millard, S.G.; Soutsos, M.N.; Barnett, S.J.; Le, T.T. Influence of Aggregate and Curing Regime on the Mechanical Properties of Ultra-High Performance Fibre Reinforced Concrete (UHPFRC). Constr. Build. Mater. 2009, 23, 2291–2298. [Google Scholar] [CrossRef]

- Kim, D.J.; Park, S.H.; Ryu, G.S.; Koh, K.T. Comparative Flexural Behavior of Hybrid Ultra High Performance Fiber Reinforced Concrete with Different Macro Fibers. Constr. Build. Mater. 2011, 25, 4144–4155. [Google Scholar] [CrossRef]

- Abbas, S.; Nehdi, M.L.; Saleem, M.A. Ultra-High Performance Concrete: Mechanical Performance, Durability, Sustainability and Implementation Challenges. Int. J. Concr. Struct. Mater. 2016, 10, 271–295. [Google Scholar] [CrossRef]

- Moreno, J.D.; Pellicer, T.M.; Adam, J.M.; Bonilla, M. Exposure of RC Building Structures to the Marine Environment of the Valencia Coast. J. Build. Eng. 2018, 15, 109–121. [Google Scholar] [CrossRef]

- Kumar Mehta, P.; Monteiro, P.J.M. Concrete: Microstructure, Properties, and Materials, 4th ed.; McGraw Hill: New York, NY, USA, 2014. [Google Scholar]

- Ullah, R.; Qiang, Y.; Ahmad, J.; Vatin, N.I.; El-Shorbagy, M.A. Ultra-High-Performance Concrete (UHPC): A State-of-the-Art Review. Materials 2022, 15, 4131. [Google Scholar] [CrossRef]

- Chen, H.; Cao, Y.; Liu, Y.; Qin, Y.; Xia, L. Enhancing the Durability of Concrete in Severely Cold Regions: Mix Proportion Optimization Based on Machine Learning. Constr Build Mater 2023, 371. [Google Scholar] [CrossRef]

- Sun, Z.; Yang, S.; Hang, M.; Wang, J.; Yang, T. Optimization Design of Ultrahigh-Performance Concrete Based on Interaction Analysis of Multiple Factors. Case Stud. Constr. Mater. 2022, 16, e00858. [Google Scholar] [CrossRef]

- Akhnoukh, A.K.; Buckhalter, C. Ultra-High-Performance Concrete: Constituents, Mechanical Properties, Applications and Current Challenges. Case Stud. Constr. Mater. 2021, 15, e00559. [Google Scholar] [CrossRef]

- ACI PRC-440.2-17; Guide for the Design and Construction of Externally Bonded FRP Systems for Strengthening Concrete Structures Reported by ACI Committee 440. American Concrete Institute: Farmington Hills, MI, USA, 2002.

- El-Joukhadar, N.; Pantazopoulou, S.J. Effectiveness of UHPFRC Cover in Delaying Bar Corrosion. Constr. Build. Mater. 2021, 269, 121288. [Google Scholar] [CrossRef]

- Guo, J.Y.; Wang, J.Y.; Wu, K. Effects of Self-Healing on Tensile Behavior and Air Permeability of High Strain Hardening UHPC. Constr. Build. Mater. 2019, 204, 342–356. [Google Scholar] [CrossRef]

- Teng, L.; Addai-Nimoh, A.; Khayat, K.H. Effect of Lightweight Sand and Shrinkage Reducing Admixture on Structural Build-up and Mechanical Performance of UHPC. J. Build. Eng. 2023, 68, 106144. [Google Scholar] [CrossRef]

- Tamataki, K.; Ito, T.; Fujino, Y.; Yoshitake, I. Development of an Ultra-High-Performance Fibre-Reinforced Concrete (UHPFRC) Manufacturable at Ambient Temperature. Buildings 2022, 12, 740. [Google Scholar] [CrossRef]

- Fischer, G. Keynote Lecture 4 Review of Japanese Recommendations on Design and Construction of Different Classes of Fiber Reinforced. In Proceedings of the 8th International Symposium on Utilization of High-Strength and High-Performance Concrete, Tokyo, Japan, 27–29 October 2008. [Google Scholar]

- Sugano, S.; Kimura, H.; Shirai, K. Study of New RC Structures Using Ultra-High-Strength Fiber-Reinforced Concrete (UFC). J. Adv. Concr. Technol. 2007, 5, 133–147. [Google Scholar] [CrossRef]

- Kunieda, M.; Rokugo, K. Recent Progress on HPFRCC in Japan Required Performance and Applications. J. Adv. Concr. Technol. 2006, 4, 19–33. [Google Scholar] [CrossRef]

- Romualdi, J.P.; Batson, G.B. Mechanics of Crack Arrest in Concrete. J. Eng. Mech. Div. 1963, 89, 147–168. Available online: http://cedb.asce.org/cgi/WWWdisplay.cgi?13075 (accessed on 13 April 2023). [CrossRef]

- Li, V.C.; Wu, H.-C. Conditions for Pseudo Strain-Hardening in Fiber Reinforced Brittle Matrix Composites. Appl. Mech. Rev. 1992, 45, 390–398. [Google Scholar] [CrossRef]

- Li, V.C.; Stang, H.; Krenchel, H. Micromechanics of Crack Bridging in Fibre-Reinforced Concrete. Mater Struct 1993, 26. [Google Scholar] [CrossRef]

- Habel, K.; Gauvreau, P. Response of Ultra-High Performance Fiber Reinforced Concrete (UHPFRC) to Impact and Static Loading. Cem. Concr. Compos. 2008, 30, 938–946. [Google Scholar] [CrossRef]

- Garas, V.Y.; Kahn, L.F.; Kurtis, K.E. Short-Term Tensile Creep and Shrinkage of Ultra-High Performance Concrete. Cem. Concr. Compos. 2009, 31, 147–152. [Google Scholar] [CrossRef]

- Pyo, S.; Wille, K.; El-Tawil, S.; Naaman, A.E. Strain Rate Dependent Properties of Ultra High Performance Fiber Reinforced Concrete (UHP-FRC) under Tension. Cem. Concr. Compos. 2015, 56, 15–24. [Google Scholar] [CrossRef]

- Yang, J.; Chen, B.; Su, J.; Xu, G.; Zhang, D.; Zhou, J. Effects of Fibers on the Mechanical Properties of UHPC: A Review. J. Traffic Transp. Eng. 2022, 9, 363–387. [Google Scholar]

- Sherzer, G.; Gao, P.; Schlangen, E.; Ye, G.; Gal, E. Upscaling Cement Paste Microstructure to Obtain the Fracture, Shear, and Elastic Concrete Mechanical LDPM Parameters. Materials 2017, 10, 242. [Google Scholar] [CrossRef]

- Lifshitz Sherzer, G.; Fadakar Alghalandis, Y.; Peterson, K. Introducing Fracturing through Aggregates in LDPM. Eng. Fract. Mech. 2022, 261, 108228. [Google Scholar] [CrossRef]

- Muzenski, S.; Haber, Z.B.; Graybeal, B. Interface Shear of Ultra-High-Performance Concrete. ACI Struct. J. 2022, 119, 267–280. [Google Scholar] [CrossRef]

- Gunes, O.; Yesilmen, S.; Gunes, B.; Ulm, F.J. Use of UHPC in Bridge Structures: Material Modeling and Design. Adv. Mater. Sci. Eng. 2012, 2012, 1–12. [Google Scholar] [CrossRef]

- Haber, Z.B.; la Varga, I.D.; Graybeal, B.A.; Nakashoji, B.; El-Helou, R. Properties and Behavior of UHPC-Class Materials; FHWA-HRT-18-036; U.S. Department of Transportation: Washington, DC, USA, 2018. [Google Scholar]

- Japan Society of Civil Engineers Recommendations for Design and Construction of High Performance Fiber Reinforced Cement Composites with Multiple Fine Cracks (HPFRCC). Concr. Eng. Ser. 2008, 82, Testing Method 6–10. Available online: http://www.jsce.or.jp/committee/concrete/e/index.html (accessed on 13 April 2023).

- Toutlemonde, F.; Resplendino, J. Designing and Building with UHPFRC, 1st ed.; Wiley-ISTE: Marseille, France, 2013. [Google Scholar] [CrossRef]

- Perry, V.H.; White, P.; Ahlborn, T.M. The First North American Broad Based Structural Design Guide on UHPC—ACI 239C. In Proceedings of the International Interactive Symposium on Ultra-High Performance Concrete 1, Des Moines, IA, USA, 18–20 July 2016. [Google Scholar]

- ASTM C1856/C1856M-17; Standard Practice for Fabricating and Testing Specimens of Ultra-High Performance Concrete. ASTM International: West Conshohocken, PA, USA, 2017.

- Micelli, F.; Renni, A.; Kandalaft, A.G.; Moro, S. Fiber-Reinforced Concrete and Ultrahigh-Performance Fiber-Reinforced Concrete Materials. In New Materials in Civil Engineering; Elsevier: Amsterdam, The Netherlands, 2020; pp. 273–314. [Google Scholar]

- Chen, S.; Zhang, R.; Jia, L.-J.; Wang, J.-Y.; Gu, P. Structural Behavior of UHPC Filled Steel Tube Columns under Axial Loading. Thin Walled Struct. 2018, 130, 550–563. [Google Scholar] [CrossRef]

- Hoang, A.L.; Fehling, E.; Lai, B.; Thai, D.K.; Chau, N. Van Experimental Study on Structural Performance of UHPC and UHPFRC Columns Confined with Steel Tube. Eng. Struct. 2019, 187, 457–477. [Google Scholar] [CrossRef]

- Naud, N.; Sorelli, L.; Salenikovich, A.; Cuerrier-Auclair, S. Fostering GLULAM-UHPFRC Composite Structures for Multi-Storey Buildings. Eng. Struct. 2019, 188, 406–417. [Google Scholar] [CrossRef]

- Popa, M.; Kiss, Z.; Constantinescu, H.; Bolca, G. Case Study: Designing a 40 Storey High Office Building Using Two Variants, with Regular Concrete Columns and with Compound Ultra-High Performance Concrete Columns and Regular Concrete Columns. Procedia Technol. 2016, 22, 40–47. [Google Scholar] [CrossRef][Green Version]

- Naeimi, N.; Moustafa, M.A. Numerical Modeling and Design Sensitivity of Structural and Seismic Behavior of UHPC Bridge Piers. Eng. Struct. 2020, 219, 110792. [Google Scholar] [CrossRef]

- Tong, T.; Lei, H.; Yuan, S.; Liu, Z. Experimental Investigation and Seismic Vulnerability Assessment of Low Flexural Strength Rectangular Bridge Piers Retrofitted with Ultrahigh-Performance Concrete Jackets. Eng. Struct. 2020, 206, 110132. [Google Scholar] [CrossRef]

- Xu, T.; Zheng, D.; Yang, C.; Deng, K. Seismic Performance Evaluation of Damage Tolerant Steel Frame with Composite Steel-UHPC Joint. J. Constr. Steel Res. 2018, 148, 457–468. [Google Scholar] [CrossRef]

- Hasan, T.M.; Gilbert, L.; Allena, S.; Owusu-Danquah, J.; Torres, A. Development of Non-Proprietary Ultra-High Performance Concrete Mixtures. Buildings 2022, 12, 1865. [Google Scholar] [CrossRef]

- Lim, K.; Lee, N.; Ryu, G.; Koh, K.; Kim, K. Electrical Characteristics of Ultra-High-Performance Concrete Containing Carbon-Based Materials. Appl. Sci. 2022, 12, 7858. [Google Scholar] [CrossRef]

- Graybeal, B.A. Design and Construction of Field-Cast UHPC Connections: TECHNOTE; Federal Highway Administration: Washington, DC, USA, 2014. [Google Scholar]

- Yan, J.B.; Guan, H.; Wang, T. Steel-UHPC-Steel Sandwich Composite Beams with Novel Enhanced C-Channel Connectors: Tests and Analysis. J. Constr. Steel Res. 2020, 170, 106077. [Google Scholar] [CrossRef]

- Hoang, A.L.; Fehling, E. A Review and Analysis of Circular UHPC Filled Steel Tube Columns under Axial Loading. Struct. Eng. Mech. 2017, 62, 417–430. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhu, P.; Liao, Z.; Wang, L. Interfacial Bond Properties between Normal Strength Concrete Substrate and Ultra-High Performance Concrete as a Repair Material. Constr. Build. Mater. 2020, 235, 117431. [Google Scholar] [CrossRef]

- Carbonell Muñoz, M.A.; Harris, D.K.; Ahlborn, T.M.; Froster, D.C. Bond Performance between Ultrahigh-Performance Concrete and Normal-Strength Concrete. J. Mater. Civ. Eng. 2014, 26, 04014031. [Google Scholar] [CrossRef]

- Ighravwe, D.E.; Oke, S.A. A Multi-Criteria Decision-Making Framework for Selecting a Suitable Maintenance Strategy for Public Buildings Using Sustainability Criteria. J. Build. Eng. 2019, 24, 100753. [Google Scholar] [CrossRef]

- Stengel, T.; Schie, P. Life Cycle Assessment of Uhpc Bridge Constructions: Sherbrooke Footbridge, Kassel Gärtnerplatz Footbridge. Archit. Civ. Eng. Environ. 2009, 1, 109–118. [Google Scholar]

- Müller, H.S.; Haist, M.; Vogel, M. Assessment of the Sustainability Potential of Concrete and Concrete Structures Considering Their Environmental Impact, Performance and Lifetime. Constr. Build. Mater. 2014, 67, 321–337. [Google Scholar] [CrossRef]

- Silvestri, A.; De Felice, F.; Petrillo, A. Multi-Criteria Risk Analysis to Improve Safety in Manufacturing Systems. Int. J. Prod. Res. 2012, 50, 4806–4821. [Google Scholar] [CrossRef]

- Yu, Z.; Wu, L.; Yuan, Z.; Zhang, C.; Bangi, T. Mechanical Properties, Durability and Application of Ultra-High-Performance Concrete Containing Coarse Aggregate (UHPC-CA): A Review. Constr. Build. Mater. 2022, 334, 127360. [Google Scholar] [CrossRef]

- Amran, M.; Huang, S.-S.; Onaizi, A.M.; Makul, N.; Abdelgader, H.S.; Ozbakkaloglu, T. Recent Trends in Ultra-High Performance Concrete (UHPC): Current Status, Challenges, and Future Prospects. Constr. Build. Mater. 2022, 352, 129029. [Google Scholar] [CrossRef]

- Stengel, T.; Schießl, P. Life Cycle Assessment (LCA) of Ultra High Performance Concrete (UHPC) Structures. In Eco-Efficient Construction and Building Materials; Elsevier: Amsterdam, The Netherlands, 2014; pp. 528–564. [Google Scholar]

- Li, Y.; Zeng, X.; Shi, Y.; Yang, K.; Zhou, J.; Umar, H.A.; Long, G.; Xie, Y. A Comparative Study on Mechanical Properties and Environmental Impact of UHPC with Belite Cement and Portland Cement. J. Clean. Prod. 2022, 380, 135003. [Google Scholar] [CrossRef]

- García-Segura, T.; Yepes, V.; Alcalá, J. Life Cycle Greenhouse Gas Emissions of Blended Cement Concrete Including Carbonation and Durability. Int. J. Life Cycle Assess. 2014, 19, 3–12. [Google Scholar] [CrossRef]

- Flower, D.J.M.; Sanjayan, J.G. Green House Gas Emissions Due to Concrete Manufacture. Int. J. Life Cycle Assess. 2007, 12, 282–288. [Google Scholar] [CrossRef]

- Pacheco-Torgal, F.; Cabeza, L.F.; Labrincha, J.; de Magalhães, A. Eco-Efficient Construction and Building Materials: Life Cycle Assessment (LCA), Eco-Labelling and Case Studies; Woodhead Publishing: Sawston, UK, 2013. [Google Scholar]

- Yang, R.; Yu, R.; Shui, Z.; Gao, X.; Han, J.; Lin, G.; Qian, D.; Liu, Z.; He, Y. Environmental and Economical Friendly Ultra-High Performance-Concrete Incorporating Appropriate Quarry-Stone Powders. J. Clean. Prod. 2020, 260, 121112. [Google Scholar] [CrossRef]

- Hacker, J.N.; De Saulles, T.P.; Minson, A.J.; Holmes, M.J. Embodied and Operational Carbon Dioxide Emissions from Housing: A Case Study on the Effects of Thermal Mass and Climate Change. Energy Build. 2008, 40, 375–384. [Google Scholar] [CrossRef]

- Scottish Water. Scottish Water Carbon Footprint Report 2007–2008; Scottish Water: Dunfermline, UK, 2008. [Google Scholar]

- Shi, Y.; Long, G.; Ma, C.; Xie, Y.; He, J. Design and Preparation of Ultra-High Performance Concrete with Low Environmental Impact. J. Clean. Prod. 2019, 214, 633–643. [Google Scholar] [CrossRef]

- Long, G.; Gao, Y.; Xie, Y. Designing More Sustainable and Greener Self-Compacting Concrete. Constr. Build. Mater. 2015, 84, 301–306. [Google Scholar] [CrossRef]

- Chiaia, B.; Fantilli, A.P.; Guerini, A.; Volpatti, G.; Zampini, D. Eco-Mechanical Index for Structural Concrete. Constr. Build. Mater. 2014, 67, 386–392. [Google Scholar] [CrossRef]

- Kumar, S.; Barai, S.V. Introduction to Fracture Mechanics of Concrete. In Concrete Fracture Models and Applications; Springer: Berlin/Heidelberg, Germany, 2011. [Google Scholar]

- Ferdosian, I.; Camões, A. Mechanical Performance and Post-Cracking Behavior of Self-Compacting Steel-Fiber Reinforced Eco-Efficient Ultra-High Performance Concrete. Cem. Concr. Compos. 2021, 121, 104050. [Google Scholar] [CrossRef]

- Ezeldin, A.S.; Balaguru, P.N. Normal- and High-Strength Fiber-Reinforced Concrete under Compression. J. Mater. Civ. Eng. 1992, 4, 415–429. [Google Scholar] [CrossRef]

- Portland Cement Association Ultra-High Performance Concrete. Available online: https://www.cement.org/learn/concrete-technology/concrete-design-production/ultra-high-performance-concrete (accessed on 13 April 2023).

- Zain, M.F.M.; Safiuddin, M.; Mahmud, H. Development of High Performance Concrete Using Silica Fume at Relatively High Water-Binder Ratios. Cem. Concr. Res. 2000, 30, 1501–1505. [Google Scholar] [CrossRef]

- Mazloom, M.; Ramezanianpour, A.A.; Brooks, J.J. Effect of Silica Fume on Mechanical Properties of High-Strength Concrete. Cem. Concr. Compos. 2004, 26, 347–357. [Google Scholar] [CrossRef]

- Poon, C.S.; Kou, S.C.; Lam, L. Compressive Strength, Chloride Diffusivity and Pore Structure of High Performance Metakaolin and Silica Fume Concrete. Constr. Build. Mater. 2006, 20, 858–865. [Google Scholar] [CrossRef]

- Bhanja, S.; Sengupta, B. Influence of Silica Fume on the Tensile Strength of Concrete. Cem. Concr. Res. 2005, 35, 743–747. [Google Scholar] [CrossRef]

- Piérard, J.; Dooms, B.; Cauberg, N. Evaluation of Durability Parameters of UHPC Using Accelerated Lab Tests. In Proceedings of the 3rd International Symposium on UHPC and Nanotechnology for High Performance Construction Materials, Kassel, Germany, 7–9 March 2012. [Google Scholar]

- Randl, N.; Steiner, T.; Ofner, S.; Baumgartner, E.; Mészöly, T. Development of UHPC Mixtures from an Ecological Point of View. Constr. Build. Mater. 2014, 67, 373–378. [Google Scholar] [CrossRef]

- Dugat, J.; Roux, N.; Bernier, G. Mechanical Properties of Reactive Powder Concretes. Mater. Struct. 1996, 29, 233–240. [Google Scholar] [CrossRef]

- Raheem, A.H.A.; Mahdy, M.; Mashaly, A.A. Mechanical and Fracture Mechanics Properties of Ultra-High-Performance Concrete. Constr. Build. Mater. 2019, 213, 561–566. [Google Scholar] [CrossRef]

- Meng, W.; Valipour, M.; Khayat, K.H. Optimization and Performance of Cost-Effective Ultra-High Performance Concrete. Mater. Struct. Mater. Constr. 2017, 50, 1–16. [Google Scholar] [CrossRef]

- Špak, M.; Kozlovská, M.; Struková, Z.; Bašková, R. Comparison of Conventional and Advanced Concrete Technologies in Terms of Construction Efficiency. Adv. Mater. Sci. Eng. 2016, 2016, 1–6. [Google Scholar] [CrossRef]

- Song, Q.; Yu, R.; Shui, Z.; Rao, S.; Wang, X.; Sun, M.; Jiang, C. Steel Fibre Content and Interconnection Induced Electrochemical Corrosion of Ultra-High Performance Fibre Reinforced Concrete (UHPFRC). Cem. Concr. Compos. 2018, 94, 191–200. [Google Scholar] [CrossRef]

- Pyo, S.; Tafesse, M.; Kim, H.; Kim, H.K. Effect of Chloride Content on Mechanical Properties of Ultra High Performance Concrete. Cem. Concr. Compos. 2017, 84, 175–187. [Google Scholar] [CrossRef]

- Li, J.; Wu, Z.; Shi, C.; Yuan, Q.; Zhang, Z. Durability of Ultra-High Performance Concrete—A Review. Constr. Build. Mater. 2020, 255, 119296. [Google Scholar] [CrossRef]

- Wei, C.; Zhang, Q.; Yang, Z.; Li, M.; Cheng, Z.; Bao, Y. Flexural Cracking Behavior of Reinforced UHPC Overlay in Composite Bridge Deck with Orthotropic Steel Deck under Static and Fatigue Loads. Eng. Struct. 2022, 265, 114537. [Google Scholar] [CrossRef]

- Ghasemzadeh Mosavinejad, S.H.; Barandoust, J.; Ghanizadeh, A.; Sigari, M. Crack Detection of a HPCFRCC Thin Plate Using Electrical Resistivity Method. Constr. Build. Mater. 2018, 193, 255–267. [Google Scholar] [CrossRef]

- Jamali, A.; Angst, U.; Adey, B.; Elsener, B. Modeling of Corrosion-Induced Concrete Cover Cracking: A Critical Analysis. Constr. Build. Mater. 2013, 42, 225–237. [Google Scholar] [CrossRef]

- Ghasemzadeh Mosavinejad, S.H.; Langaroudi, M.A.M.; Barandoust, J.; Ghanizadeh, A. Electrical and Microstructural Analysis of UHPC Containing Short PVA Fibers. Constr. Build. Mater. 2020, 235, 117448. [Google Scholar] [CrossRef]

| Risk | Incidence Probability | Effects | Risk Evaluation | |||

|---|---|---|---|---|---|---|

| Qualitative Index | Probability | Qualitative Index | Effect | Qualitative Index | Risk Index | |

| Improper quality of raw materials | ||||||

| Manufacturing process | Improbable | 0.35 | Low | 0.4 | Low | 0.61 |

| Manufacturing cost | Rare | 0.15 | Negligible | 0.2 | Low | 0.32 |

| Material degradation | Improbable | 0.35 | Moderate | 0.6 | Moderate | 0.74 |

| Equipment technical problems | ||||||

| Equipment mismatch | Certain | 0.85 | Moderate | 0.45 | High | 0.92 |

| Improper services | Rare | 0.2 | Moderate | 0.45 | Low | 0.56 |

| Imperfect design | Improbable | 0.35 | High | 0.75 | Moderate | 0.84 |

| Human error | ||||||

| Lack of skill | Rare | 0.2 | High | 0.65 | Moderate | 0.72 |

| Lack of training | Probable | 0.8 | High | 0.65 | High | 0.93 |

| High labor pressure | Rare | 0.15 | Moderate | 0.45 | Low | 0.53 |

| N.O. | Material | Economic Risk | Technical Risk | Environmental Risk | eCO2/Ref. |

|---|---|---|---|---|---|

| 1 | Cement | 0.2 | 0.3 | 0.85 | 0.83 [88] |

| 2 | Aggregate | 0.1 | 0.1 | 0.15 | 0.01 [78] |

| 3 | Water | 0.05 | 0.05 | 0.05 | 0.001 [89] |

| 4 | Silica Fume | 0.5 | 0.2 | 0.05 | 0.016 [90] |

| 5 | Superplasticizer | 0.85 | 0.9 | 0.45 | 0.72 [91] |

| 6 | Steel Fiber | 0.75 | 0.25 | 0.65 | 1.497 [92] |

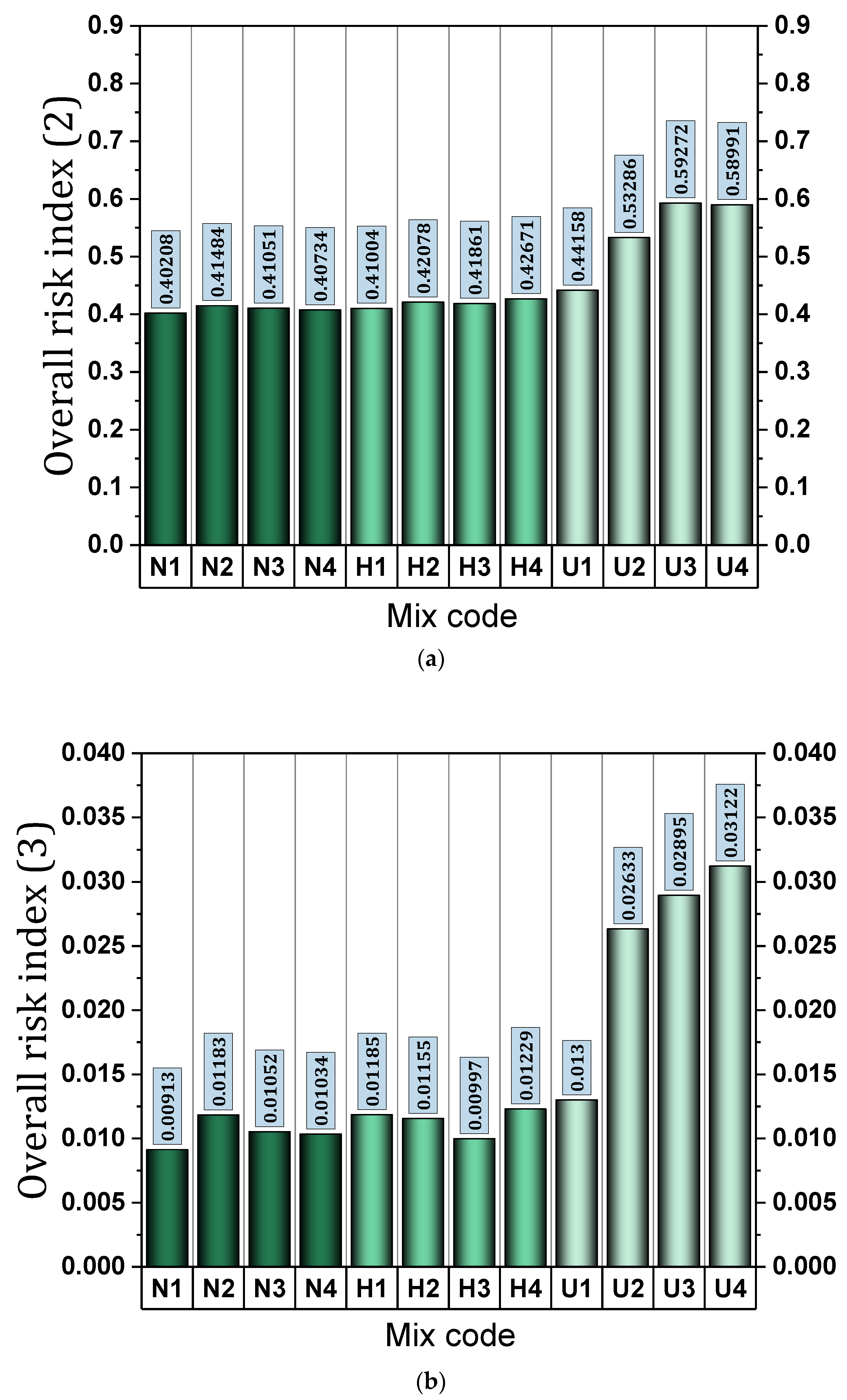

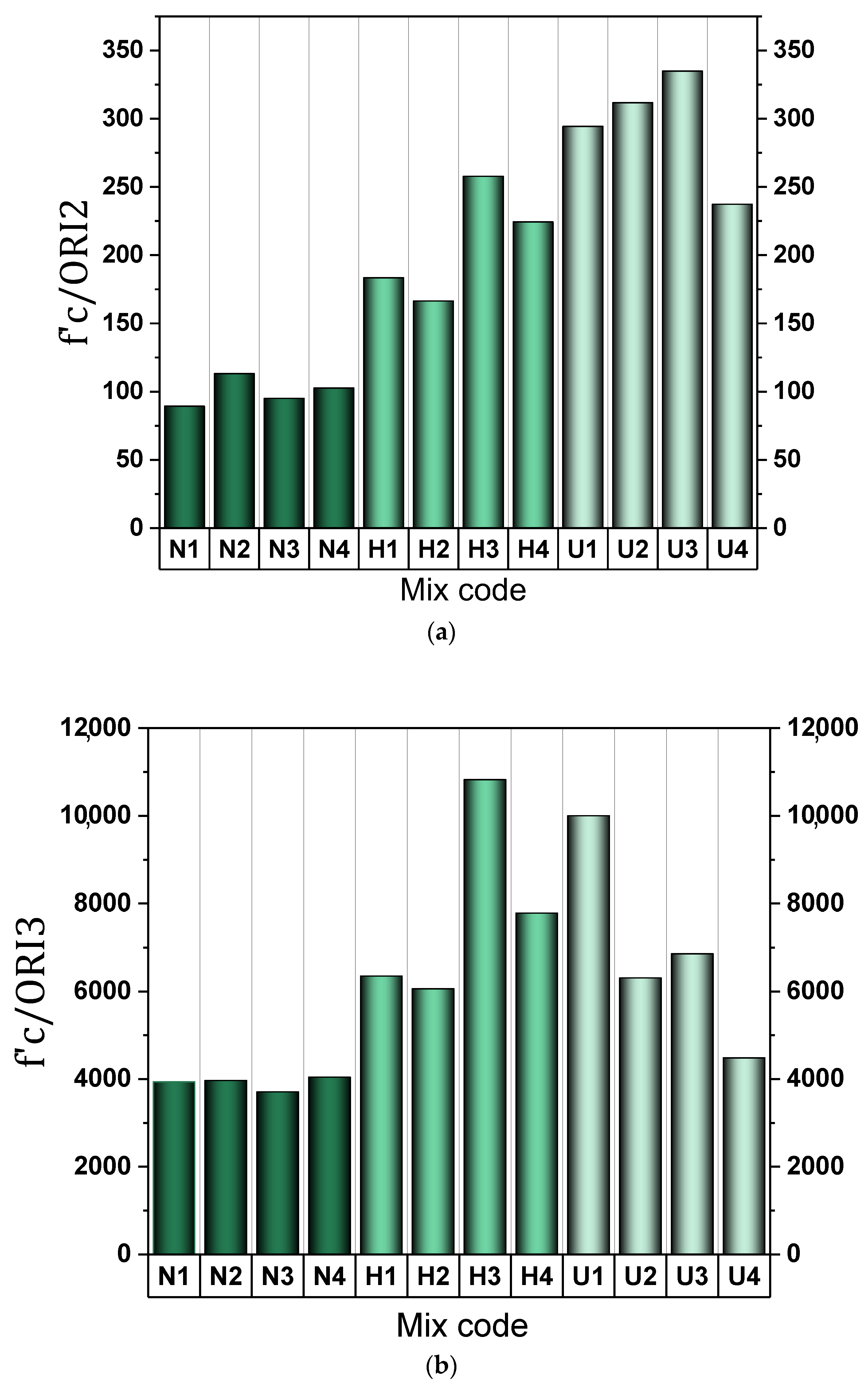

| Mix | Weight Ratios of Constituent Materials | Overall Risk Index (2) | Overall Risk Index (3) | |||||

|---|---|---|---|---|---|---|---|---|

| Cement | Silica Fume | Water | S.P | Aggregate | Steel Fiber | |||

| N1 | 0.172 | 0.000 | 0.079 | 0.000 | 0.749 | 0.000 | 0.402 | 0.0091 |

| N2 | 0.168 | 0.000 | 0.077 | 0.000 | 0.731 | 0.024 | 0.415 | 0.0118 |

| N3 | 0.185 | 0.000 | 0.083 | 0.002 | 0.730 | 0.000 | 0.411 | 0.0105 |

| N4 | 0.169 | 0.017 | 0.084 | 0.004 | 0.727 | 0.000 | 0.407 | 0.0103 |

| H1 | 0.152 | 0.015 | 0.059 | 0.006 | 0.756 | 0.012 | 0.410 | 0.0118 |

| H2 | 0.181 | 0.027 | 0.073 | 0.005 | 0.713 | 0.000 | 0.421 | 0.0116 |

| H3 | 0.184 | 0.018 | 0.061 | 0.000 | 0.736 | 0.000 | 0.419 | 0.0100 |

| H4 | 0.184 | 0.028 | 0.055 | 0.007 | 0.726 | 0.000 | 0.427 | 0.0123 |

| U1 | 0.205 | 0.041 | 0.061 | 0.006 | 0.687 | 0.000 | 0.442 | 0.0130 |

| U2 | 0.288 | 0.043 | 0.066 | 0.011 | 0.531 | 0.060 | 0.533 | 0.0263 |

| U3 | 0.381 | 0.076 | 0.069 | 0.006 | 0.412 | 0.056 | 0.593 | 0.0289 |

| U4 | 0.365 | 0.073 | 0.070 | 0.013 | 0.418 | 0.061 | 0.590 | 0.0312 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tajasosi, S.; Saradar, A.; Barandoust, J.; Mohtasham Moein, M.; Zeinali, R.; Karakouzian, M. Multi-Criteria Risk Analysis of Ultra-High Performance Concrete Application in Structures. CivilEng 2023, 4, 1016-1035. https://doi.org/10.3390/civileng4030055

Tajasosi S, Saradar A, Barandoust J, Mohtasham Moein M, Zeinali R, Karakouzian M. Multi-Criteria Risk Analysis of Ultra-High Performance Concrete Application in Structures. CivilEng. 2023; 4(3):1016-1035. https://doi.org/10.3390/civileng4030055

Chicago/Turabian StyleTajasosi, Sama, Ashkan Saradar, Jalil Barandoust, Mohammad Mohtasham Moein, Reza Zeinali, and Moses Karakouzian. 2023. "Multi-Criteria Risk Analysis of Ultra-High Performance Concrete Application in Structures" CivilEng 4, no. 3: 1016-1035. https://doi.org/10.3390/civileng4030055

APA StyleTajasosi, S., Saradar, A., Barandoust, J., Mohtasham Moein, M., Zeinali, R., & Karakouzian, M. (2023). Multi-Criteria Risk Analysis of Ultra-High Performance Concrete Application in Structures. CivilEng, 4(3), 1016-1035. https://doi.org/10.3390/civileng4030055