Improving the Properties of Saline Soil Using a Deep Soil Mixing Technique

Abstract

:1. Introduction

2. Materials Properties

3. Developed Apparatus for Laboratory Deep Mixing

3.1. Apparatus Components

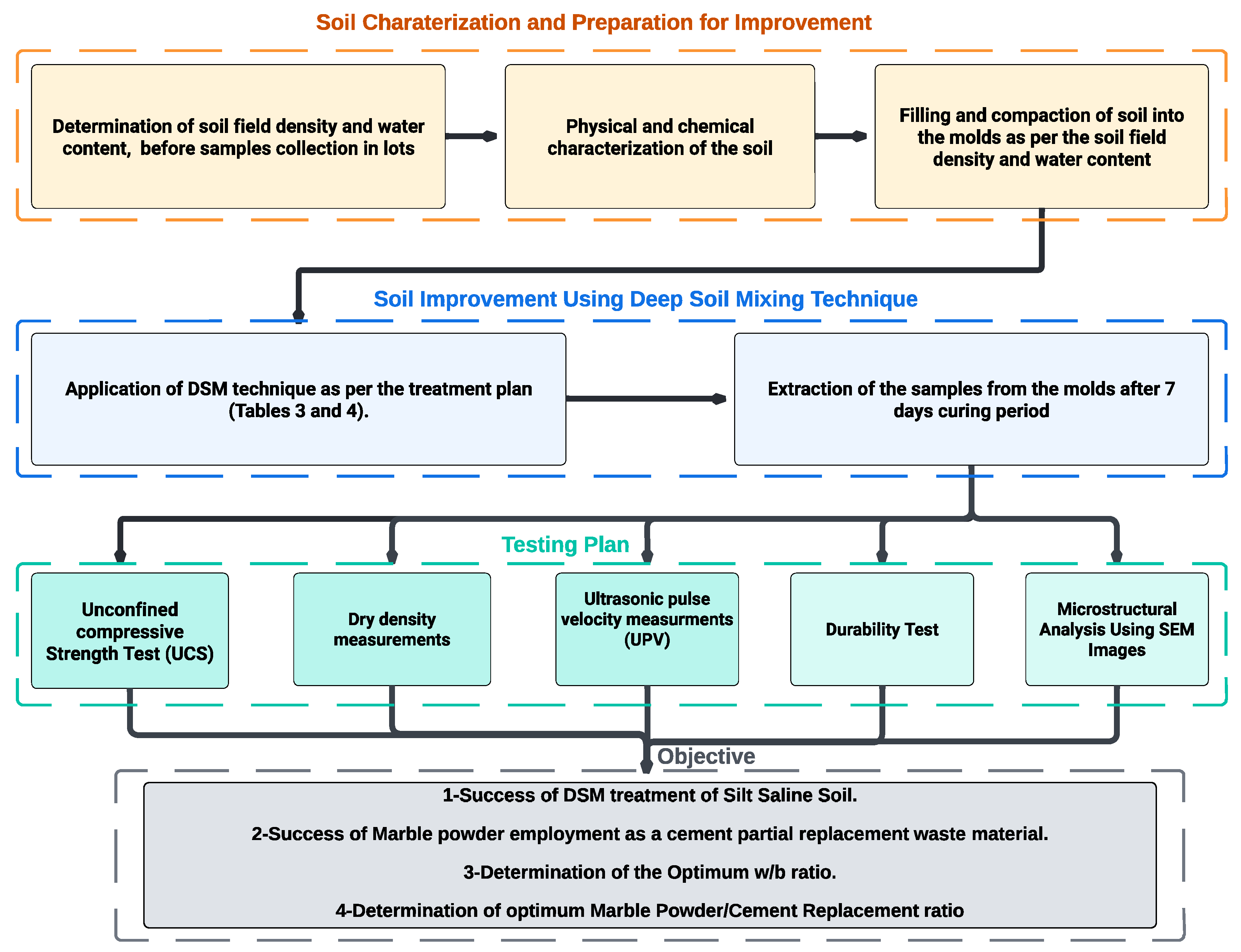

3.2. Operational Parameters

4. Stabilization Mixture Ratios

5. Specimens Preparation

5.1. Binder Slurry Preparation

5.2. Specimens Treatment Procedures

6. Testing Program

7. Test Results

7.1. Effect of Cement/Marble Powder Mixture Proportions Employing UCS

7.2. Water/Binder Proportion Effect on UCS

7.3. Dry Density Measurements

7.4. UPV Test Results

7.5. Durability Test Results

7.6. Microstructural Analysis Using SEM

8. Conclusions

- The developed DSM apparatus succeeded in forming an intact and uniform appearance of the cylindrical samples;

- Employment of marble powder as a wastage material with a replacement proportion of cement ranging from (20% to 30%) and 30% total binder ratio showed a significant increase in the UCS values owing to the gradual cementitious compounds’ formation (calcium aluminate hydrate and calcium silicate hydrate);

- A water/binder ratio ranging from 1.1 to 1.3 showed intact and uniform samples with acceptable UCS values;

- The UPV values for samples with 20% and 30% MP in the treated samples exhibited the highest velocity due to the high density of the samples;

- The dry density measurements revealed that the 80C:20MP and 70C:30MP samples showed the highest values;

- The selected sample with 20% to 30% MP meets the durability requirements;

- The microstructure analysis of the treated samples is in good harmony with the UCS values;

- According to the findings, the optimum binder proportion is 30% and consists of (70%C:30%MP) with a w/b ratio equal to 1.3;

- Marble powder is explored as a cleaner alternative with low carbon dioxide emission to be employed in a deep soil mixing industry.

9. Recommendation for Future Work

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Al-Amoudi, O.S.B. Chemical stabilization of sabkha soils at high moisture contents. Eng. Geol. 1994, 36, 279–291. [Google Scholar] [CrossRef]

- Elsawy, M.B.D.; Lakhouit, A.A. A review on the impact of salinity on foundation soil of coastal infrastructures and its implications to north of Red Sea coastal constructions. Arab. J. Geosci. 2020, 13, 555. [Google Scholar] [CrossRef]

- Shuja, D.; Rollakanti, C.R.; Poloju, K.K.; Joe, A. An experimental investigation on -stabilization of sabkha soils with cement and Cement Kiln Dust (CKD) in Sultanate of Oman. Mater. Today Proc. 2022, 65, 1033–1039. [Google Scholar] [CrossRef]

- Al-Alawi, H.S.; Ganiyu, A.A.; Badr, A. Stabilisation of Sohar’s sabkha soil using waste gypsum plasterboard. IOP Conf. Ser. Mater. Sci. Eng. 2020, 849, 012028. [Google Scholar] [CrossRef]

- Al-Homidy, A.A.; Dahim, M.H.; El Aal, A.K.A. Improvement of geotechnical properties of sabkha soil utilizing cement kiln dust. J. Rock Mech. Geotech. Eng. 2017, 9, 749–760. [Google Scholar] [CrossRef]

- Moayed, R.Z.; Izadi, E.; Heidari, S. Stabilization of saline silty sand using lime and micro silica. J. Cent. S. Univ. 2012, 19, 3006–3011. [Google Scholar] [CrossRef]

- Mohamedzein, Y.E.A.; Al-Rawas, A.A. Cement-stabilization of sabkha soils from Al-Auzayba, Sultanate of Oman. Geot. Geol. Eng. 2011, 29, 999–1008. [Google Scholar] [CrossRef]

- Han, J. Principles and Practice of Ground Improvement; Wiley: Hoboken, NJ, USA, 2015. [Google Scholar]

- Jung, C.; Ceglarek, R.; Clauvelin, T.; Ayeldeen, M.; Kim, D. Deep soil mixing in Sabkha soils for foundation support in United Arab Emirates. Int. J. Geosynth. Ground Eng. 2020, 6, 3. [Google Scholar] [CrossRef]

- Esmaeili, M.; Astaraki, F.; Yaghouti, H.; Rad, M.M. Laboratory Investigation on the Effect of Microsilica Additive on the Mechanical Behavior of Deep Soil Mixing Columns in Saline Dry Sand. Period. Polytech. Civ. Eng. 2021, 65, 1080–1091. [Google Scholar] [CrossRef]

- Farouk, A.; Shahien, M.M. Ground improvement using soil–cement columns: Experimental investigation. Alex. Eng. J. 2013, 52, 733–740. [Google Scholar] [CrossRef]

- Canakci, H.; Güllü, H.; Dwle, M.I.K. Effect of glass powder added grout for deep mixing of marginal sand with clay. Arab. J. Sci. Eng. 2018, 43, 1583–1595. [Google Scholar] [CrossRef]

- Alnunu, M.Z.; Nalbantoglu, Z. Performance of using waste marble dust for the improvement of loose sand in deep soil mixing. Arab. J. Sci. Eng. 2021, 47, 4681–4694. [Google Scholar] [CrossRef]

- Puppala, A.J.; Madhyannapu, R.S.; Nazarian, S. Full-scale field studies to evaluate deep soil mixing in stabilizing expansive soils. J. Geotech. Geoenviron. Eng. 2022, 148, 04021163. [Google Scholar] [CrossRef]

- Chang, I.; Im, J.; Cho, G.C. Introduction of microbial biopolymers in soil treatment for future environmentally-friendly and sustainable geotechnical engineering. Sustainability 2016, 8, 251. [Google Scholar] [CrossRef]

- Oss, H.G.V. Cement Statistics and Information; US Geological Survey: Reston, VA, USA, 2014.

- Capuano, L. Us Energy Information Administration’s International Energy Outlook 2020 (Ieo2020); US Department of Energy: Washington, DC, USA, 2020; p. 7.

- Ruiz-Sánchez, A.; Sánchez-Polo, M.; Rozalen, M. Waste marble dust: An interesting residue to produce cement. Constr. Build. Mater. 2019, 224, 99–108. [Google Scholar] [CrossRef]

- Kavas, T.; Olgun, A. Properties of cement and mortar incorporating marble dust and crushed brick. Ceram. Silik. 2008, 52, 24. [Google Scholar]

- Selim, F.A.; Hashem, F.S.; Amin, M.S. Mechanical, microstructural and acid resistance aspects of improved hardened Portland cement pastes incorporating marble dust and fine kaolinite sand. Constr. Build. Mater. 2020, 251, 118992. [Google Scholar] [CrossRef]

- Awad, A.H.; Abdellatif, M.H. Assessment of mechanical and physical properties of LDPE reinforced with marble dust. Compos. Part B Eng. 2019, 173, 106948. [Google Scholar] [CrossRef]

- Bhadriraju, V.; Puppala, A.J.; Madhyannapu, R.S.; Williammee, R. Laboratory procedure to obtain well-mixed soil binder samples of medium stiff to stiff expansive clayey soil for deep soil mixing simulation. Geotech. Test. J. 2007, 31, 225–238. [Google Scholar]

- Frikha, W.; Zargayouna, H.; Boussetta, S.; Bouassida, M. Experimental study of Tunis soft soil improved by deep mixing column. Geotech. Geol. Eng. 2017, 35, 931–947. [Google Scholar] [CrossRef]

- Porbaha, A.; Shibuya, S.; Kishida, T. State of the art in deep mixing technology. Part III: Geomaterial characterization. Proc. Inst. Civ. Eng.-Ground Improv. 2000, 4, 91–110. [Google Scholar] [CrossRef]

- ASTM D6913-04; Standard Test Methods for Particle Size Distribution (Gradation) of Soils Using Sieve Analysis. ASTM International: West Conshohocken, PA, USA, 2009. [CrossRef]

- ASTM D4318-10; Standard Test Methods for Liquid Limit, Plastic Limit, and Plasticity Index of Soils. ASTM International: West Conshohocken, PA, USA, 2010. [CrossRef]

- ASTM D698-12e1; Standard Test Methods for Laboratory Compaction Characteristics of Soil Using Standard Effort (12,400 ft-lbf/ft3 (600 kN-m/m3)). ASTM International: West Conshohocken, PA, USA, 2012.

- ASTM D1556-07; Standard Test Method for Density and Unit Weight of Soil in Place by the Sand-Cone Method. American Society for Testing and Materials: West Conshohocken, PA, USA, 2007.

- ASTM ASTM C150; Standard specification for Portland cement. Annual Book of ASTM Standards. ASTM International: West Conshohocken, PA, USA, 2001.

- ASTM D854-14; Standard Test Methods for Specific Gravity of Soil Solids by Water Pycnometer. ASTM International: West Conshohocken, PA, USA, 2014. [CrossRef]

- Topolnicki, M. General overview and advances in Deep Soil Mixing. In Proceedings of the XXIV Geotechnical Conference of Torino Design, Construction and Controls of Soil Improvement Systems, Torino, Italy, 25–26 February 2016; pp. 25–26. [Google Scholar]

- Bruce, M.E.C.; Berg, R.R.; Collin, J.G.; Filz, G.M.; Terashi, M.; Yang, D.S. Federal Highway Administration Design Manual: Deep Mixing for Embankment and Foundation Support (FHWA-HRT-13-046); Federal Highway Administration: Washington, DC, USA, 2013.

- Bushra, I.; Robinson, R.G. Effect of fly ash on cement admixture for a low plasticity marine soil. Adv. Civ. Eng. Mater. 2013, 2, 608–621. [Google Scholar] [CrossRef]

- Pourakbar, S.; Huat, B.B.; Asadi, A.; Fasihnikoutalab, M.H. Model study of alkali-activated waste binder for soil stabilization. Int. J. Geosyn. Ground Eng. 2016, 2, 35. [Google Scholar] [CrossRef]

- Arulrajah, A.; Yaghoubi, M.; Disfani, M.M.; Horpibulsuk, S.; Bo, M.W.; Leong, M. Evaluation of fly ash-and slag-based geopolymers for the improvement of a soft marine clay by deep soil mixing. Soils Found. 2018, 58, 1358–1370. [Google Scholar] [CrossRef]

- Smith, K.W.G. Some problems of salts in semi-arid soils for stabilization with cement. In Proceedings of the ARRB Conference; Australian Road Research Board: Canberra, Australia, 1962; Volume 1, pp. 1078–1084. [Google Scholar]

- ASTM D1633-17; Standard Test Methods for Compressive Strength of Molded Soil-Cement Cylinders. ASTM International: West Conshohocken, PA, USA, 2017.

- ASTM D7263-09; Standard Test Methods for Laboratory Determination of Density (Unit Weight) of Soil Specimens. ASTM International: West Conshohocken, PA, USA, 2009.

- ASTM D559/D559M-15; Standard Test Methods for Wetting and Drying Compacted Soil-Cement Mixtures. ASTM International: West Conshohocken, PA, USA, 2015. [CrossRef]

- ASTM C 597; Standard Test Method for Pulse Velocity through Concrete. American Society for Testing and Materials: West Conshohocken, PA, USA, 2016.

- Toubal Seghir, N.; Mellas, M.; Sadowski, Ł.; Krolicka, A.; Żak, A. The effect of curing conditions on the properties of cement-based composites blended with waste marble dust. JOM 2019, 71, 1002–1015. [Google Scholar] [CrossRef]

- Ergün, A. Effects of the usage of diatomite and waste marble powder as partial replacement of cement on the mechanical properties of concrete. Constr. Build. Mater. 2011, 25, 806–812. [Google Scholar] [CrossRef]

- Arel, H.Ş. Recyclability of waste marble in concrete production. J. Clean. Prod. 2016, 131, 179–188. [Google Scholar] [CrossRef]

- Ulubeyli, G.C.; Artir, R. Properties of hardened concrete produced by waste marble powder. Procedia-Soc. Behav. Sci. 2015, 195, 2181–2190. [Google Scholar] [CrossRef]

- Gesoğlu, M.; Güneyisi, E.; Kocabağ, M.E.; Bayram, V.; Mermerdaş, K. Fresh and hardened characteristics of self-compacting concretes made with combined use of marble powder, limestone filler, and fly ash. Constr. Build. Mater. 2012, 37, 160–170. [Google Scholar] [CrossRef]

- Kumar, S.; Babu, V.; Sharmila, S.M.R. Soil Stabilization Using Marble Dust. Int. J. Civ. Eng. Technol. 2017, 8, 1705–1712. Available online: http://www.iaeme.com/IJCIE (accessed on 15 May 2023).

- Gurbuz, A. Marble powder to stabilise clayey soils in sub-bases for road construction. Road Mater. Pavement Des. 2015, 16, 481–492. [Google Scholar] [CrossRef]

- Puppala, A.J.; Madhyannapu, R.S.; Nazarian, S. Special Specification for Deep Soil Mixing (No. 0-5179-P1); University of Texas at Arlington: Arlington, TX, USA, 2008. [Google Scholar]

- Szymkiewicz, F.; Tamga, F.S.; Kouby, A.L.; Reiffsteck, P. Optimization of strength and homogeneity of deep mixing material by the determination of workability limit and optimum water content. Can. Geotech. J. 2013, 50, 1034–1043. [Google Scholar] [CrossRef]

- Ribeiro, D.; Néri, R.; Cardoso, R. Influence of Water Content in the UCS of Soil-Cement Mixtures for Different Cement Dosages. Advances in Transportation Geotechnics 3. In Proceedings of the 3rd International Conference on Transportation Geotechnics (ICTG 2016), Guimaraes, Portugal, 4–7 September 2016. [Google Scholar]

| Physical Properties | Soil | MP |

|---|---|---|

| Liquid Limit (%) | 35 | 36 |

| Plastic Limit (%) | 21 | 21 |

| Plasticity Index | 14 | 15 |

| Specific Gravity | 2.67 | 2.69 |

| Maximum Dry Unit Weight (kN/m3) | 1.88 | - |

| Optimum Water Content (%) | 13.70 | - |

| Field Dry Unit Weight (kN/m3) | 1.54 | - |

| Field Water Content (%) | 18 | - |

| Salt Proportion (%) | 20 | - |

| Chemical Composition | Soil | OPC | MP |

|---|---|---|---|

| Oxide * | |||

| SiO2 | 46.0 | 20.8 | 42.5 |

| CaO | 20.7 | 65.1 | 9.9 |

| MgO | 11.1 | 1.9 | 11.7 |

| Al2O3 | 10.7 | 4.6 | 17.4 |

| Fe2O3 | 7.2 | 4.5 | 7.5 |

| Na2O | 2.4 | 0.2 | 1.5 |

| K2O | 1.1 | 0.3 | 0.1 |

| TiO2 | 0.8 | 0.4 | 0.3 |

| P2O5 | 0.1 | 0.1 | 0.1 |

| MnO | 0.1 | 0.1 | 0.1 |

| Other Properties | |||

| Loss on ignition (LOI) (%) | 22 | 2 | 9 |

| No. | Materials | Total Binder (%) | Mixture ID | Percentage from the Total Dry Solids |

|---|---|---|---|---|

| 1 | Soil Only | - | Untreated Soil | Soil in its natural water content |

| 2 | Soil, OPC and MP | 30% | 100C0MP | (Soil: OPC: MP)70%:30%:0% |

| 3 | 90C10MP | (Soil: OPC: MP)70%:27%:3% | ||

| 4 | 80C20MP | (Soil: OPC: MP)70%:24%:6% | ||

| 5 | 70C30MP | (Soil: OPC: MP)70%:21%:9% | ||

| 6 | 50C50MP | (Soil: OPC: MP)70%:15%:15% | ||

| 7 | 30C70MP | (Soil: OPC: MP)70%:9%:21% |

| No. | Binder% (Cement: MP) | w/b (%) | Mixture ID |

|---|---|---|---|

| 1 | 30% (70C30MP) | 0.7 | 0.7W70C30MP |

| 2 | 0.9 | 0.9W70C30MP | |

| 3 | 1.1 | 1.1W70C30MP | |

| 4 | 1.3 | 1.3W70C30MP | |

| 5 | 1.5 | 1.5W70C30MP |

| Sr. | Sample ID | Max. UCS (kPa) | Min. UCS (kPa) | Avg. Value (kPa) | Standard Deviation (kPa) | Absolute Variation (kPa) |

|---|---|---|---|---|---|---|

| 1 | 100C0MP1,2,3 | 1625.3 | 1500.3 | 1562.8 | 62.5 | 125.0 |

| 2 | 90C10MP1,2,3 | 1767.7 | 1664.8 | 1716.2 | 51.5 | 103.0 |

| 3 | 80C20MP1,2,3 | 1906.4 | 1813.4 | 1859.9 | 46.5 | 93.0 |

| 4 | 70C30MP1,2,3 | 1839.3 | 1725.2 | 1782.2 | 57.0 | 114.1 |

| 5 | 50C50MP1,2,3 | 893.2 | 866.8 | 880.0 | 13.2 | 26.4 |

| 6 | 30C70MP1,2,3 | 658.4 | 623.7 | 641.0 | 17.3 | 34.6 |

| Element | Soil | 100C0MP | 90C10MP | 80C20MP | 70C30MP | 50C50MP |

|---|---|---|---|---|---|---|

| Weight (%) | ||||||

| Ca | 2.69 | 18.29 | 20.91 | 23.67 | 28.80 | 17.06 |

| Si | 14.30 | 10.11 | 9.24 | 10.57 | 16.84 | 10.23 |

| Mg | 3.4 | 2.30 | 1.85 | 2.69 | 5.75 | 3.55 |

| Fe | 3.71 | 1.87 | 1.63 | 4.01 | 2.96 | 4.75 |

| Cl | 0.91 | 2.03 | 2.21 | 3.69 | 1.80 | 1.26 |

| Na | 0.39 | 0.55 | - | 0.80 | 0.68 | - |

| K | 0.96 | 0.81 | 0.29 | 0.69 | 0.40 | 0.32 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hammad, M.A.; Mohamedzein, Y.; Al-Aghbari, M. Improving the Properties of Saline Soil Using a Deep Soil Mixing Technique. CivilEng 2023, 4, 1052-1070. https://doi.org/10.3390/civileng4040057

Hammad MA, Mohamedzein Y, Al-Aghbari M. Improving the Properties of Saline Soil Using a Deep Soil Mixing Technique. CivilEng. 2023; 4(4):1052-1070. https://doi.org/10.3390/civileng4040057

Chicago/Turabian StyleHammad, Mohamed A., Yahia Mohamedzein, and Mohamed Al-Aghbari. 2023. "Improving the Properties of Saline Soil Using a Deep Soil Mixing Technique" CivilEng 4, no. 4: 1052-1070. https://doi.org/10.3390/civileng4040057

APA StyleHammad, M. A., Mohamedzein, Y., & Al-Aghbari, M. (2023). Improving the Properties of Saline Soil Using a Deep Soil Mixing Technique. CivilEng, 4(4), 1052-1070. https://doi.org/10.3390/civileng4040057