Investigation of the Characteristic Properties of Lignin-Modified Bitumen

Abstract

:1. Introduction

2. Materials and Methods

2.1. Bitumen

2.2. Lignin Powder

2.2.1. Elemental Analysis

2.2.2. Gel Permeation Chromatography (GPC)

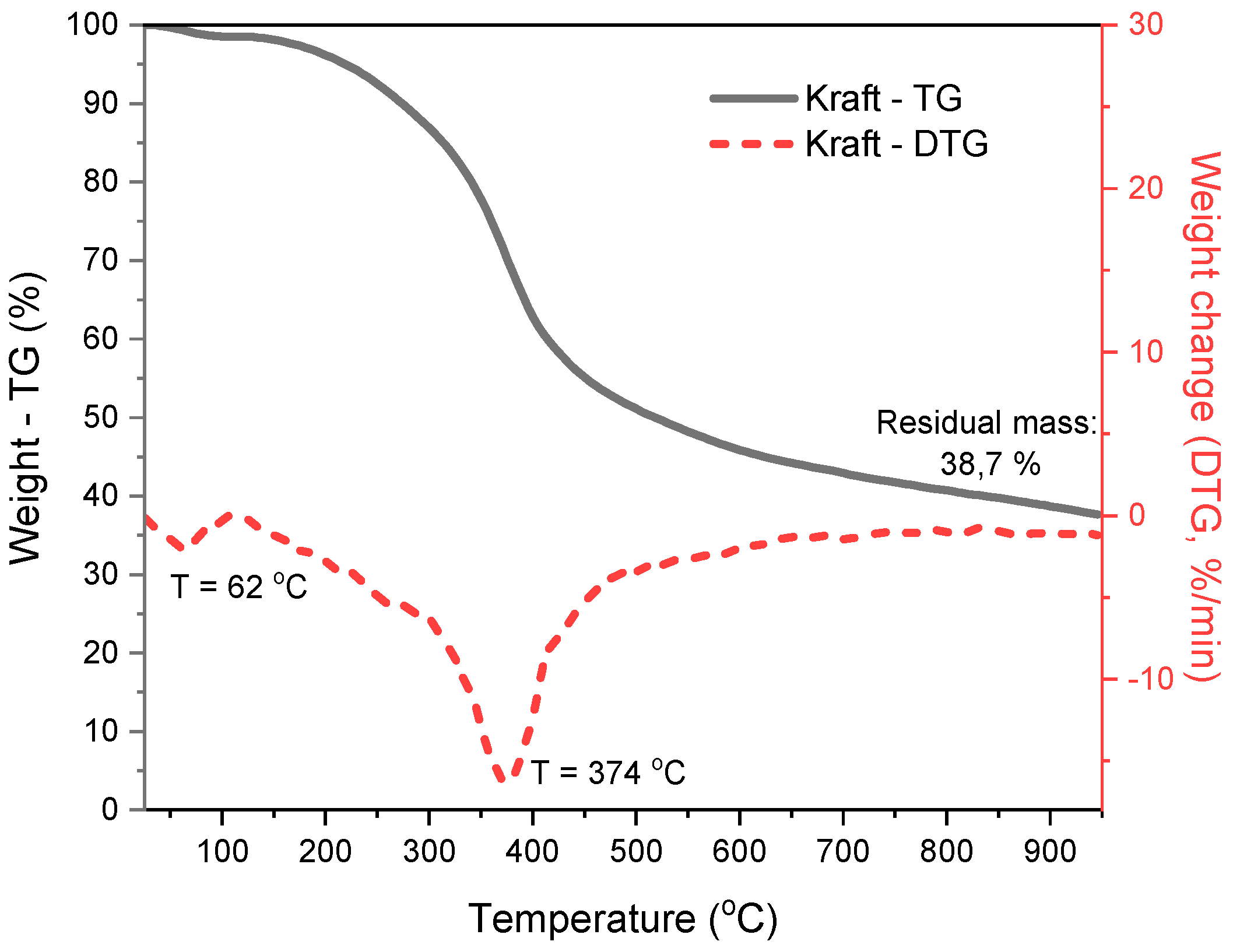

2.2.3. Thermogravimetric Analysis—Derivative Thermogravimetry

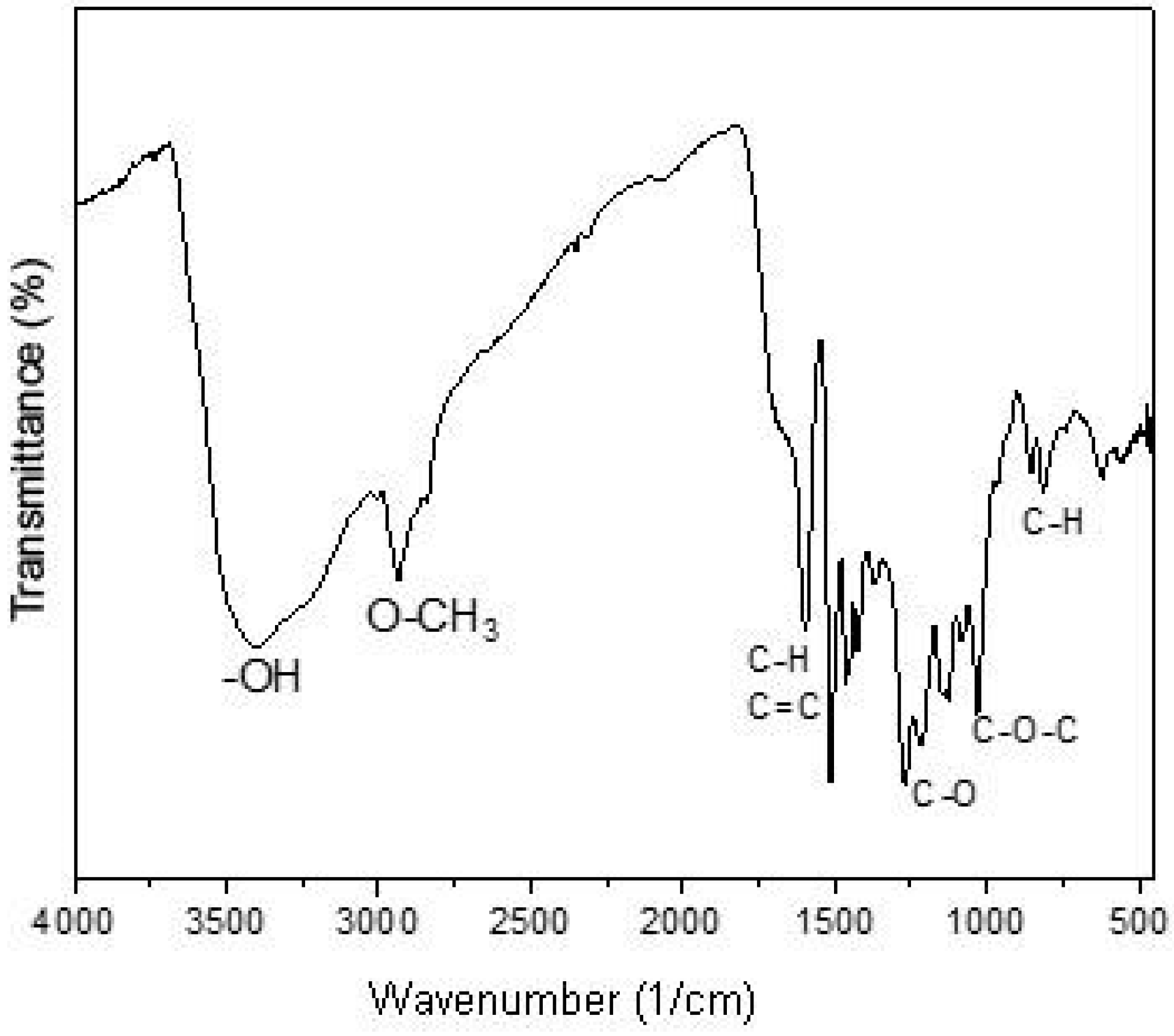

2.2.4. Fourier Transformation Infrared Spectroscopy

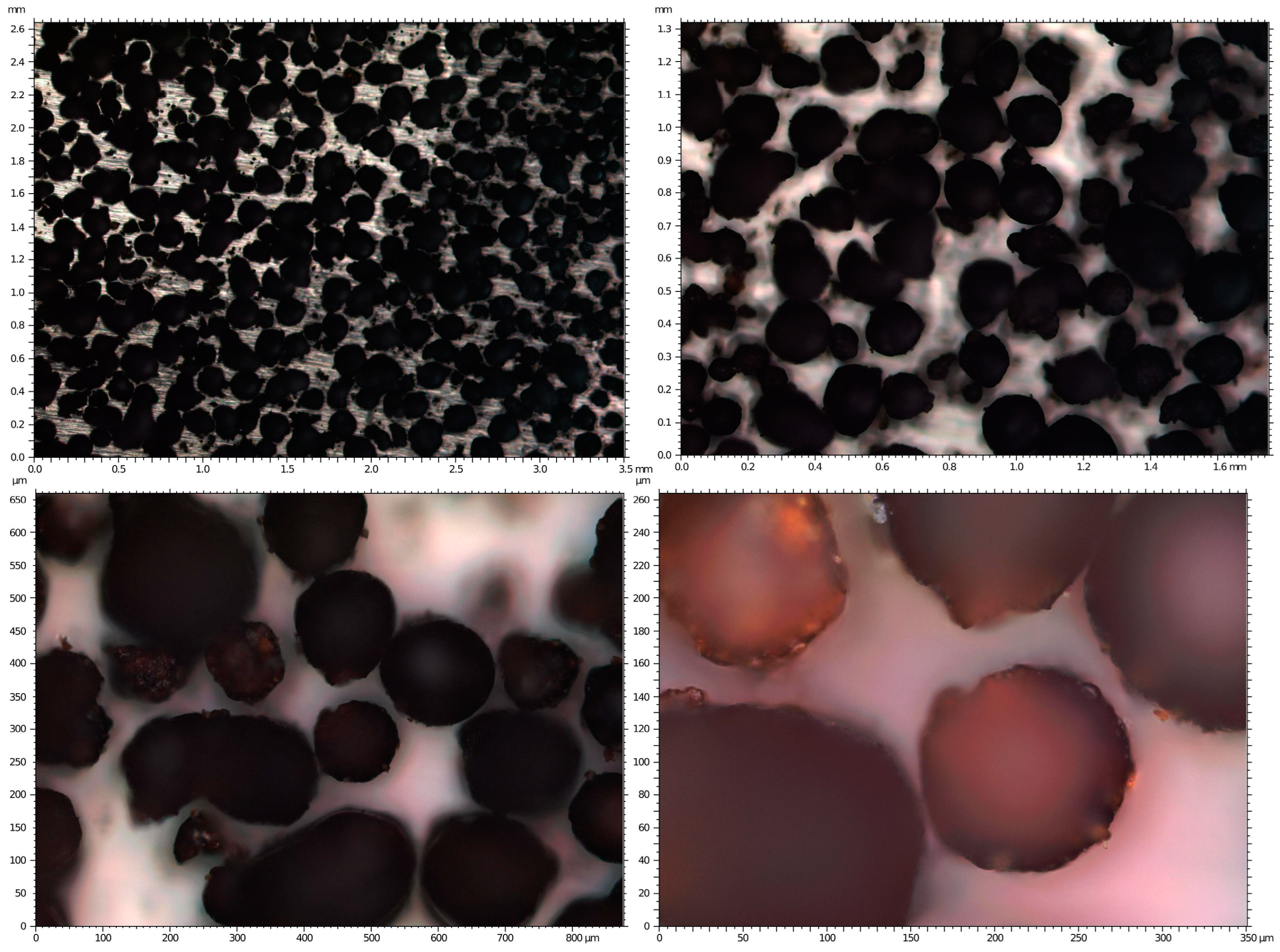

2.2.5. Scanning Electron Microscopy/Dynamic Light Scattering

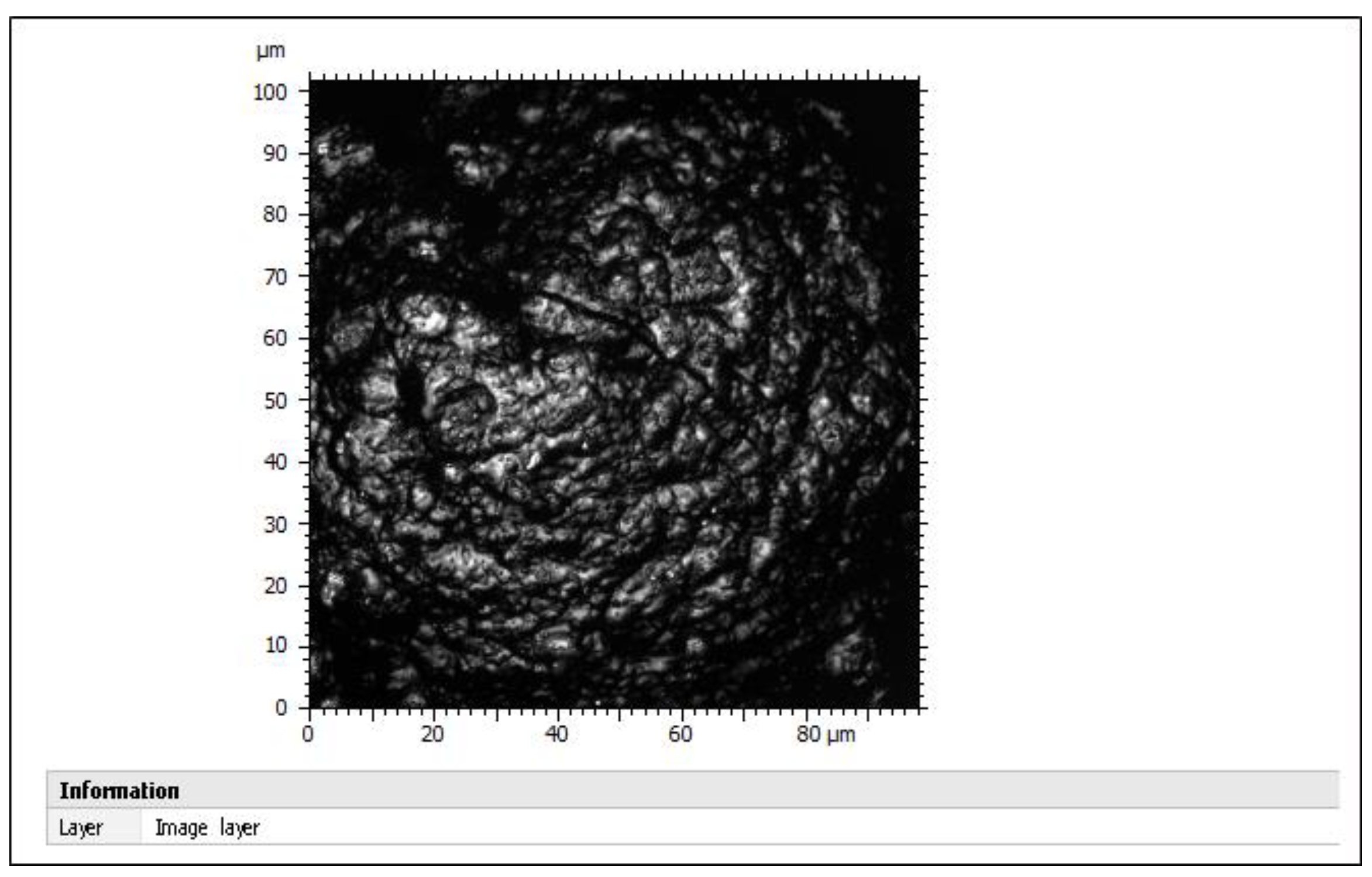

2.2.6. Confocal Microscopy

2.2.7. Mixing Conditions

3. Results

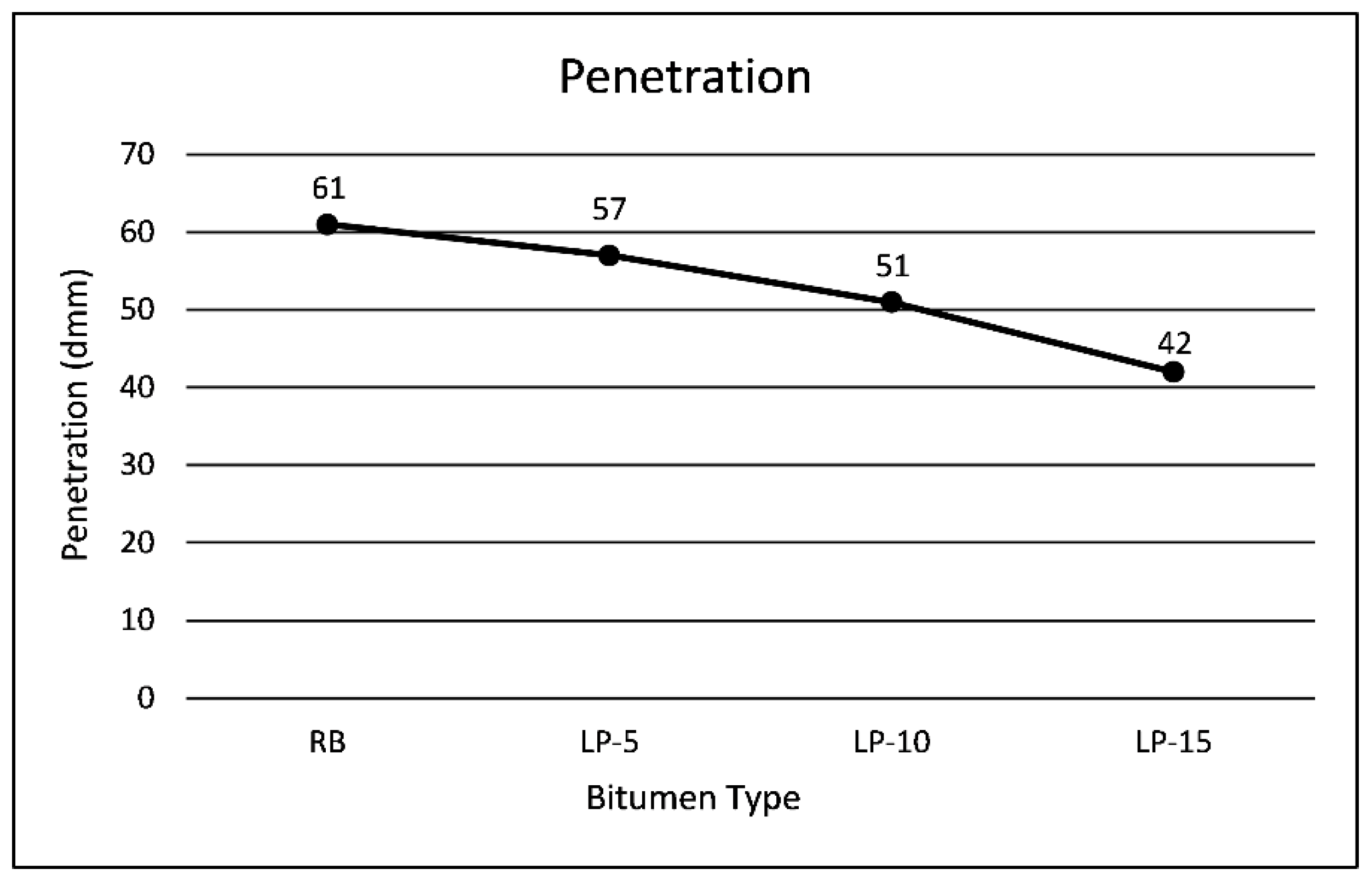

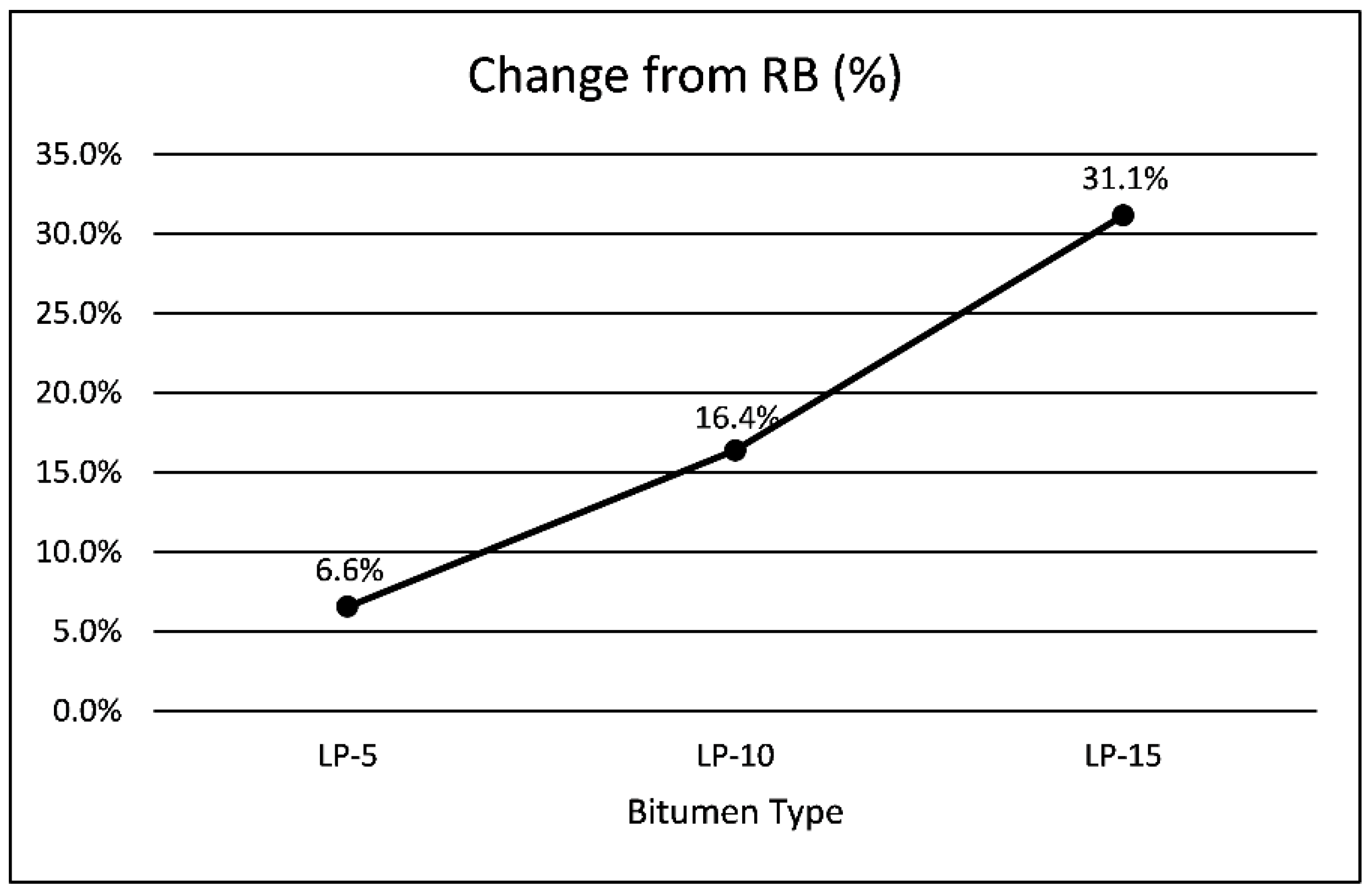

3.1. Needle Penetration Test

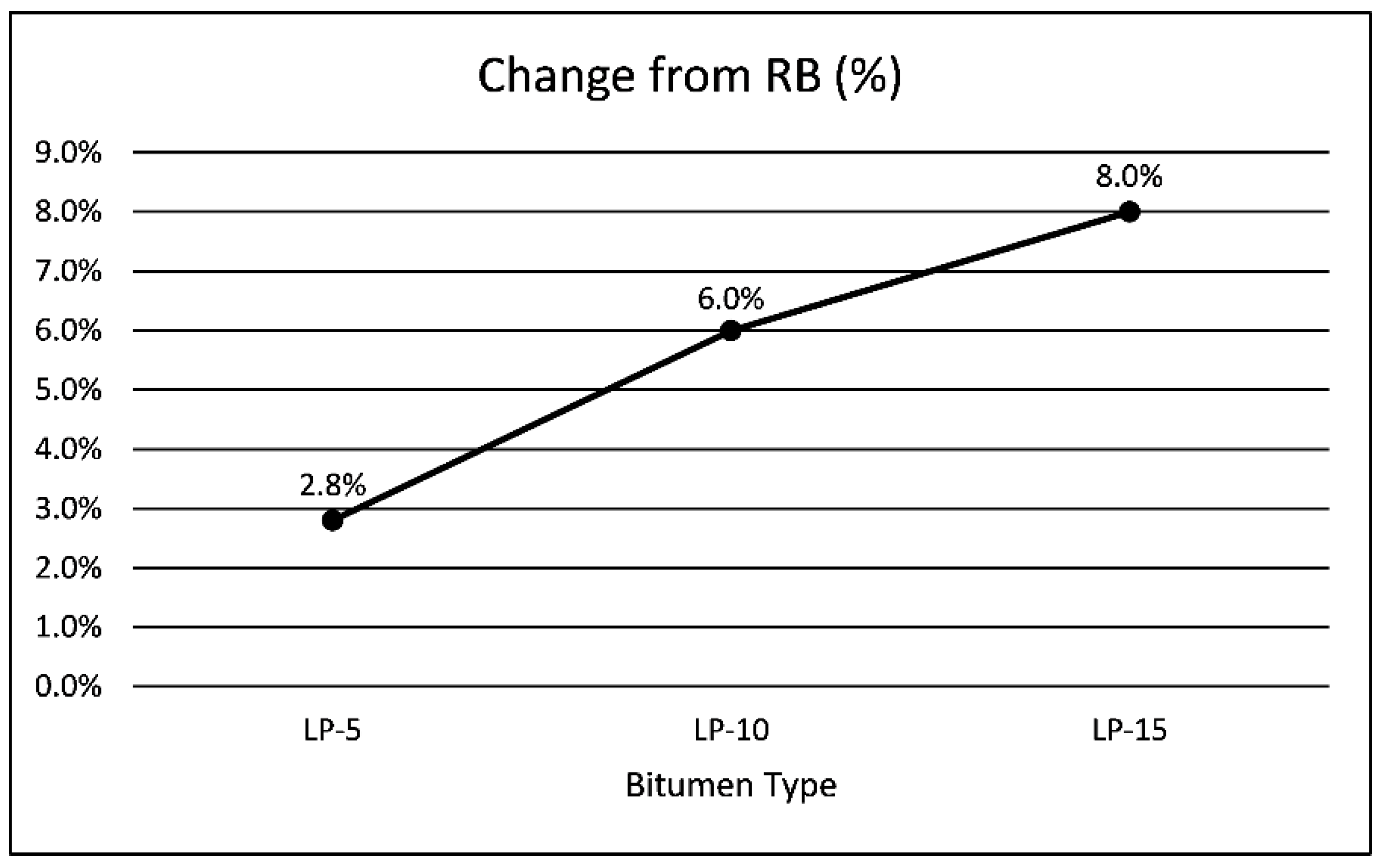

3.2. Softening Point Test

3.3. Elastic Recovery Test

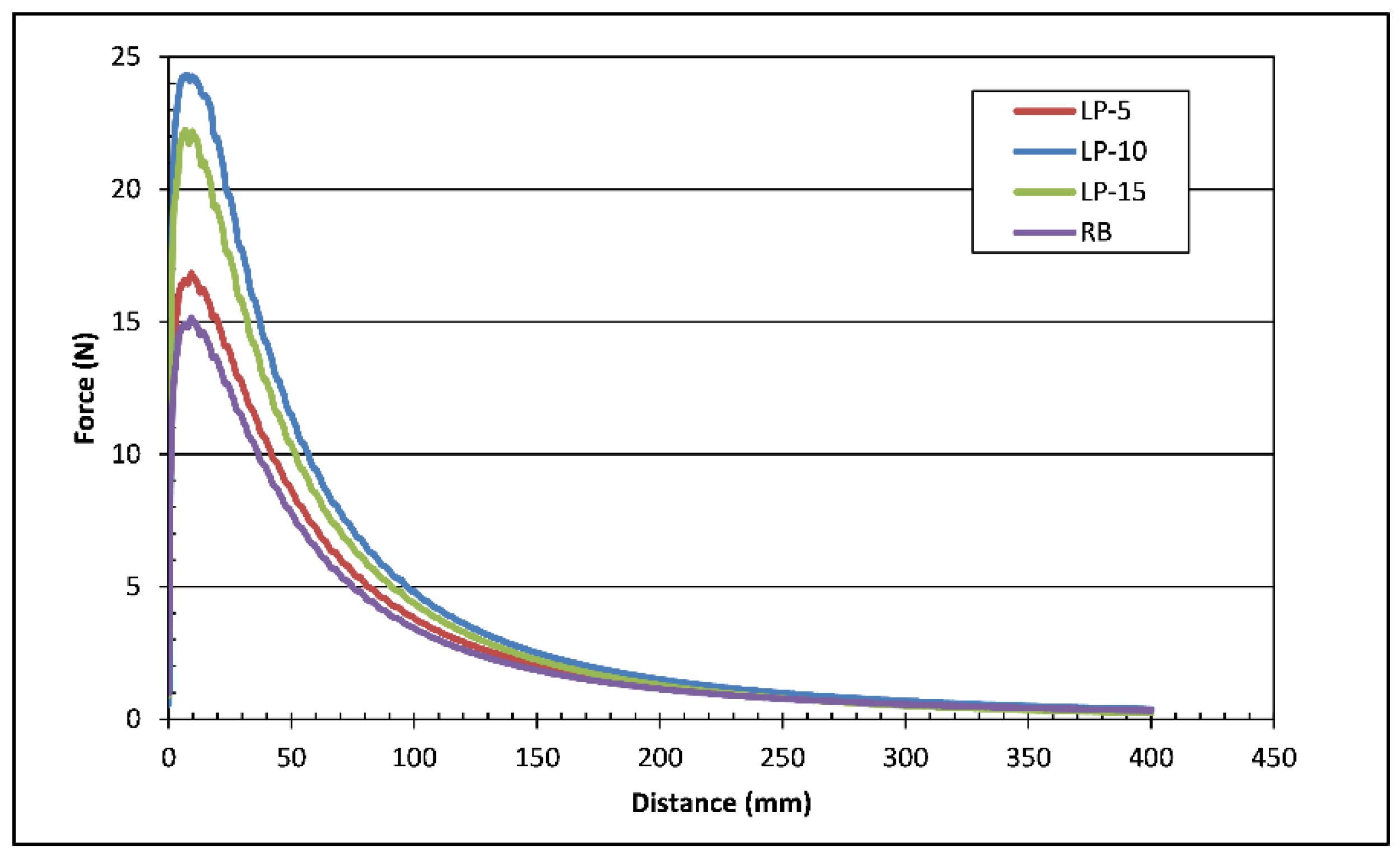

3.4. Force Ductility Test

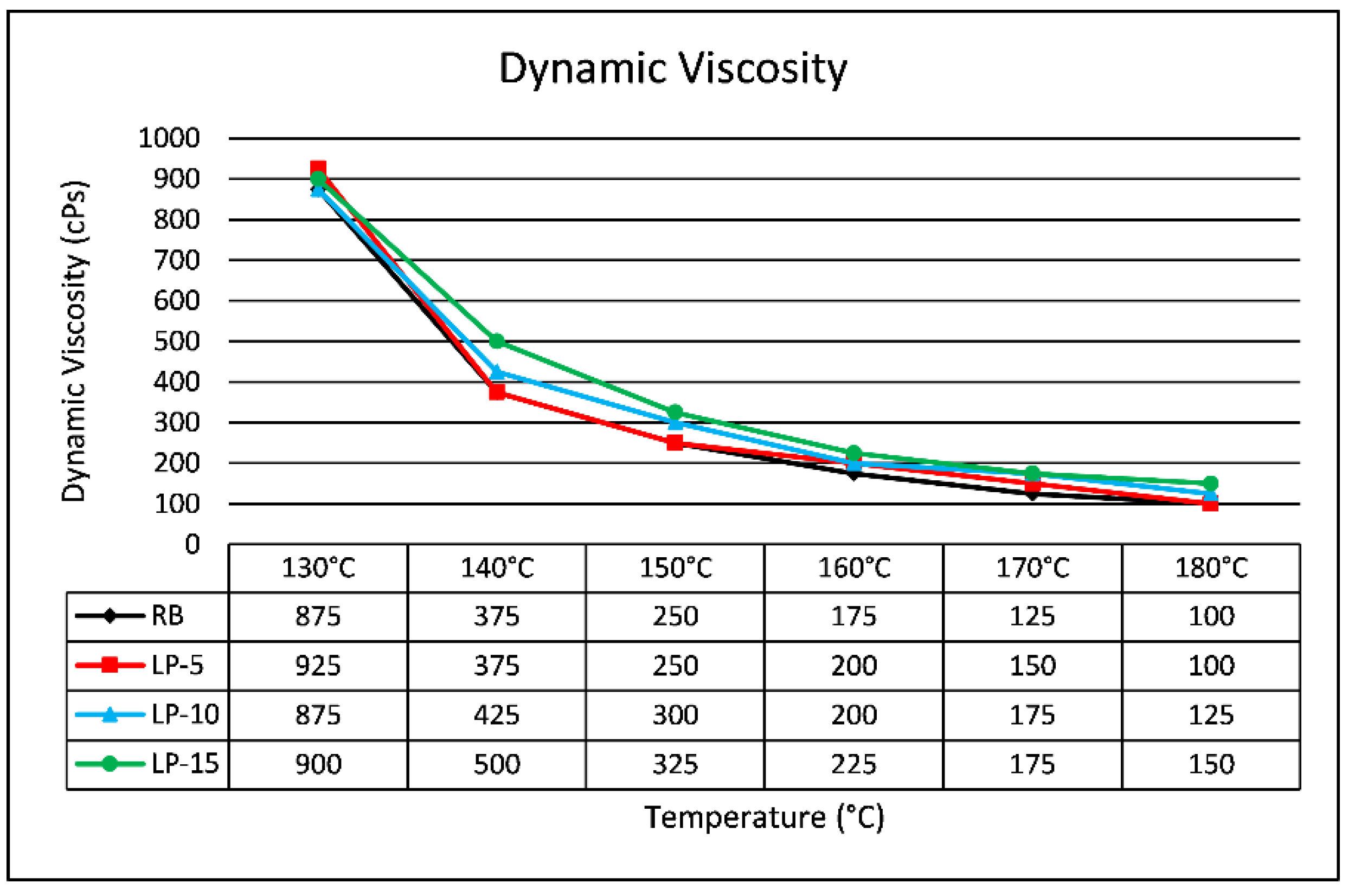

3.5. Dynamic Viscosity Test

3.6. Storage Stability Test

4. Conclusions

- Kraft lignin can be characterized as thermally stable for the mixing and compaction temperatures of asphalt mixtures.

- Mixing conditions for lignin–bitumen blends vary among researchers.

- The addition of kraft lignin had a stiffening impact on the reference 50/70 bitumen as noticed by the decline of penetration values and the increase of the softening point. The addition of 15% lignin hardened the bitumen to such a degree that the bitumen changed category from 50/70 to 35/50 with respect to EN 12591.

- The addition of kraft lignin to the RB had no noticeable changes in terms of the elastic recovery results.

- The force ductility test showed that the addition of kraft lignin resulted in an increase in the maximum tensile force and the total area under the force/displacement plot, which indicates an increase in stiffness of the RB.

- Kraft lignin-modified blends did not show separation between the binder and the lignin under prolonged storage at a high temperature.

- Conclusion No. 6 verifies the proper selection of mixing conditions in the current study.

5. Future Work

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Airey, G.D.; Mohammed, M.H. Rheological properties of polyacrylates used as synthetic road binders. Rheol. Acta 2008, 47, 751–763. [Google Scholar] [CrossRef]

- Metwally, M.; Raouf, M. Development of Non-Petroleum Binders Derived from Fast Pyrolysis Bio-Oils for Use in Flexible Pavement. Ph.D. Thesis, Iowa State University, Ames, IA, USA, 2010. [Google Scholar]

- Mills-Beale, J.; You, Z.; Fini, E.; Zada, B.; Lee, C.H.; Yap, Y.K. Aging Influence on Rheology Properties of Petroleum-Based Asphalt Modified with Biobinder. J. Mater. Civ. Eng. 2014, 26, 358–366. [Google Scholar] [CrossRef]

- Barco Carrión, A.J.; Lo Presti, D.; Pouget, S.; Chailleux, E.; Airey, G.D. Toward Non-Petroleum-Derived Asphalt Mixes: Using Biobinders for High-Modulus Asphalt Mixes with High Reclaimed Asphalt Content. In Proceedings of the Transportation Research Board 96th Annual Meeting, Washington, DC, USA, 8–12 January 2017. [Google Scholar]

- Chailleux, E.; Audo, M.; Bujoli, B.; Queffelec, C.; Legrand, J.; Lepine, O. Alternative Binder from microalgae: Algoroute project. In Proceedings of the Workshop Alternative Binders for Sustainable Asphalt Pavements, Washington, DC, USA, 22 January 2012; pp. 7–14. [Google Scholar]

- Raouf, M.A.; Williams, C.R. General Rheological Properties of Fractionated Switchgrass Bio-Oil as a Pavement Material. Road Mater. Pavement Des. 2010, 11, 325–353. [Google Scholar] [CrossRef]

- Zhang, R.; Wang, H.; Jiang, X.; You, Z.; Yang, X.; Ye, M. Thermal Storage Stability of Bio-Oil Modified Asphalt. J. Mater. Civ. Eng. 2018, 30, 04018054. [Google Scholar] [CrossRef]

- Sun, B.; Zhou, X. Diffusion and Rheological Properties of Asphalt Modified by Bio-Oil Regenerant Derived from Waste Wood. J. Mater. Civ. Eng. 2018, 30, 04017274. [Google Scholar] [CrossRef]

- Fini, E.H.; Oldham, D.; Buabeng, F.S.; Nezhad, S.H. Investigating the aging susceptibility of bio-modified asphalts. Airfield Highw. Pavements 2015, 62, e73. [Google Scholar]

- Yang, X.; Mills-Beale, J.; You, Z. Chemical characterization and oxidative aging of bio-asphalt and its compatibility with petroleum asphalt. J. Clean. Prod. 2017, 142, 1837–1847. [Google Scholar] [CrossRef]

- Li, X.Y.; Zhang, R.; Zhao, X.; Wang, H.N. Sensitivity Analysis of Flexible Pavement Parameters by Mechanistic-Empirical Design Guide. Appl. Mech. Mater. 2014, 590, 539–545. [Google Scholar] [CrossRef]

- Yang, X.; You, Z. High temperature performance evaluation of bio-oil modified asphalt binders using the DSR and MSCR tests. Constr. Build. Mater. 2014, 76, 380–387. [Google Scholar] [CrossRef]

- Fini, E.H.; Kalberer, E.W.; Shahbazi, A.; Basti, M.; You, Z.; Ozer, H.; Aurangzeb, Q. Chemical Characterization of Biobinder from Swine Manure: Sustainable Modifier for Asphalt Binder. J. Mater. Civ. Eng. 2011, 23, 1506–1513. [Google Scholar] [CrossRef]

- Fini, E.; Buehler, M. Reducing Asphalt’s Low Temperature Cracking by Disturbing Its Crystallization. In Proceedings of the 7th RILEM International Conference on Cracking in Pavements, Delft, The Netherlands, 20–22 June 2012; Springer: Dordrecht, Netherlands, 2012. [Google Scholar]

- Yang, X.; You, Z.; Mills-Beale, J. Asphalt Binders Blended with a High Percentage of Biobinders: Aging Mechanism Using FTIR and Rheology. J. Mater. Civ. Eng. 2015, 27, 04014157. [Google Scholar] [CrossRef]

- Yang, X.; You, Z.; Dai, Q. Performance evaluation of asphalt binder modified by bio-oil generated from waste wood resources. Int. J. Pavement Res. Technol. 2013, 6, 431–439. [Google Scholar] [CrossRef]

- Petersen, J.C. Chemical Composition of Asphalt as Related to Asphalt Durability: State of the Art. In Transportation Research Record 999; TRB, National Research Council: Washington, DC, USA, 1984; pp. 13–30. [Google Scholar]

- Petersen, J.C.; Branthaver, J.F.; Robertson, R.E.; Harnsberger, P.M.; Duvall, J.J.; Ensley, E.K. Effects of physicochemical factors on asphalt oxidation kinetics. In Transportation Research Record; Transportation Research Board: Washington, DC, USA, 1993. [Google Scholar]

- Liu, Q.; Wang, C.; Fan, Z.; Shi, S.; Zhang, Z.; Oeser, M. Feasibility analysis of bio-binder as non-petroleum alternative for bituminous materials. Mater. Res. Express 2019, 6, 125115. [Google Scholar] [CrossRef]

- Hamdaoui, O.; Ibos, L.; Mazioud, A.; Safi, M.; Limam, O. Thermophysical characterization of Posidonia Oceanica marine fibers intended to be used as an insulation material in Mediterranean buildings. Constr. Build. Mater. 2018, 180, 68–76. [Google Scholar] [CrossRef]

- Chen, Z.; Yi, J.; Chen, Z.; Feng, D. Properties of asphalt binder modified by corn stalk fiber. Constr. Build. Mater. 2019, 212, 225–235. [Google Scholar] [CrossRef]

- Zofka, A.; Yut, I. Investigation of rheology and aging properties of asphalt binder modified with waste coffee grounds. 2012, pp. 61–72. Available online: https://www.trb.org/Publications/Blurbs/167701.aspx (accessed on 14 July 2022).

- Calabi-Floody, A.; Thenoux, G. Controlling asphalt aging by inclusion of byproducts from red wine industry. Constr. Build. Mater. 2012, 28, 616–623. [Google Scholar] [CrossRef]

- Sandoval, G.; Thenoux, G.; Molenaar, A.A.A.; Gonzalez, M. The antioxidant effect of grape pomace in asphalt binder. Int. J. Pavement Eng. 2016, 20, 163–171. [Google Scholar] [CrossRef]

- Weir, A.; Airey, G.; Snape, C.; Jiménez del Barco Carrión, A. Rheological Characterisation of Modified Bitumens with Biodiesel-Derived Biobinders. In Proceedings of the RILEM International Symposium on Bituminous Materials, Lyon, France, 14–16 December 2020; Springer: Cham, Switzerland, 2020; pp. 1563–1569. [Google Scholar] [CrossRef]

- Van Vliet, D.; Slaghek, T.; Giezen, C.; Haaksman, I. Lignin as a green alternative for bitumen. In Proceedings of the 6th Eurasphalt & Eurobitume Congress, Prague, Czech Republic, 1–3 June 2016. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, X.; Apostolidis, P.; Gard, W.; van de Ven, M.; Erkens, S.; Jing, R. Chemical and Rheological Evaluation of Aged Lignin-Modified Bitumen. Materials 2019, 12, 4176. [Google Scholar] [CrossRef]

- Batista, K.; Padilha, R.; Castro, T.; Silva, C.; Araújo, M.; Leite, L.; Pasa, V.M.D.; Lins, V. High-temperature, low-temperature and weathering aging performance of lignin modified asphalt binders. Ind. Crop. Prod. 2018, 111, 107–116. [Google Scholar] [CrossRef]

- Gao, J.; Wang, H.; Liu, C.; Ge, D.; You, Z.; Yu, M. High-temperature rheological behavior and fatigue performance of lignin modified asphalt binder. Constr. Build. Mater. 2019, 230, 117063. [Google Scholar] [CrossRef]

- Abtahi, S.M.; Sheikhzadeh, M.; Hejazi, S.M. Fiber-reinforced asphalt-concrete—A review. Constr. Build. Mater. 2010, 24, 871–877. [Google Scholar] [CrossRef]

- Chen, H.; Xu, Q.; Chen, S.; Zhang, Z. Evaluation and design of fiber-reinforced asphalt mixtures. Mater. Des. 2009, 30, 2595–2603. [Google Scholar] [CrossRef]

- Arafat, S.; Kumar, N.; Wasiuddin, N.M.; Owhe, E.O.; Lynam, J.G. Sustainable lignin to enhance asphalt binder oxidative aging properties and mix properties. J. Clean. Prod. 2019, 217, 456–468. [Google Scholar] [CrossRef]

- Wu, J.; Liu, Q.; Wang, C.; Wu, W.; Han, W. Investigation of lignin as an alternative extender of bitumen for asphalt pavements. J. Clean. Prod. 2020, 283, 124663. [Google Scholar] [CrossRef]

- Pan, T. A first-principles based chemophysical environment for studying lignins as an asphalt antioxidant. Constr. Build. Mater. 2012, 36, 654–664. [Google Scholar] [CrossRef]

- Ház, A.; Jablonský, M.; Šurina, I.; Kačík, F.; Bubeníková, T.; Ďurkovič, J. Chemical composition and thermal behavior of kraft lignins. Forests 2019, 10, 483. [Google Scholar] [CrossRef]

- Abdelaziz, O.Y.; Hulteberg, C.P. Physicochemical characterisation of technical lignins for their potential valorisation. Waste Biomass Valoriz. 2017, 8, 859–869. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, X.; Ji, G.; Fan, Z.; Guo, Y.; Gao, W.; Xin, L. Mechanical Performance Characterization of Lignin-Modified Asphalt Mixture. Appl. Sci. 2020, 10, 3324. [Google Scholar] [CrossRef]

- Sundstrom, D.W.; Klei, H.E.; Daubenspeck, T.H. Use of byproduct lignins as extenders in asphalt. Ind. Eng. Chem. Prod. Res. Dev. 1983, 22, 496–500. [Google Scholar] [CrossRef]

- Poeran, N. The Effects of a Kraft Lignin and Wood Addition on the Ravelling Resistance of Porous Asphalt Concrete. Ph.D. Thesis, TU Delft, Delft, The Netherlands, 2014. [Google Scholar]

- Pérez, I.; Pasandín, A.R.; Pais, J.C.; Pereira, P.A.A. Feasibility of Using a Lignin-Containing Waste in Asphalt Binders. Waste Biomass Valoriz. 2019, 11, 3021–3034. [Google Scholar] [CrossRef]

- Norgbey, E.; Huang, J.; Hirsch, V.; Liu, W.J.; Wang, M.; Ripke, O.; Li, Y.; Annan, G.E.T.; Ewusi-Mensah, D.; Wang, X.; et al. Unravelling the efficient use of waste lignin as a bitumen modifier for sustainable roads. Constr. Build. Mater. 2019, 230, 116957. [Google Scholar] [CrossRef]

- Nkgapele, M.; Mturi, G.A.J. Force ductility-A 5 year feedback of performance results. In Proceedings of the 32nd Annual Southern African Transport Conference (SATC 2013), Pretoria, South Africa, 8–11 July 2013. [Google Scholar]

- Zhang, C.; Wang, H.; You, Z.; Gao, J.; Irfan, M. Performance Test on Styrene-Butadiene-Styrene (SBS) Modified Asphalt Based on the Different Evaluation Methods. Appl. Sci. 2019, 9, 467. [Google Scholar] [CrossRef]

| Property | Specification | Value |

|---|---|---|

| Penetration | EN1426 | 61 |

| Softening point (°C) | EN1427 | 50.0 |

| Elastic recovery (%) | EN13398 | 7 |

| Force ductility (J/cm2) | EN 13589 & EN 13703 | 0.885 |

| Rotational viscosity (cPs) | ΕΝ 13302 | Various 1 |

| Lignin Type | C (%) | H (%) | S (%) | O 1 (%) | Ash (%) | Moisture (%) | Mw (g/mol) | Mn (g/mol) | PDI 2 |

|---|---|---|---|---|---|---|---|---|---|

| Kraft | 61.84 | 5.62 | 1.50 | 31.04 | 2.04 | 3.50 | 4456 | 856 | 5.2 |

| No. Reference | Mixing Temperature (°C) | Rotational Speed (rpm) | Mixing Time (min) | Mixer Type |

|---|---|---|---|---|

| [2] | 163 | 3000 | 30 | High shear mixer |

| [28] | 160 | 5000 | 60 | Mechanical stirrer |

| [29] | 160 | 6000 | 40 | Shear mixer |

| [30] | 180 | 4000/8000 | 30/30 | High speed shear mixer |

| [31] | 164 | 1200 | 45 | High speed shear mixer |

| [36] | 170 | N.M. 1 | 10 | N.M. 1 |

| [37] | 163 | 3000 | 30 | High shear mixer |

| [38] | 120 | N.M. 1 | 7 | N.M. 1 |

| [39] | 160 | 4800 | N.M. 1 | High shear mixer |

| [40] | 160 | 300 | 60 | Low shear mixer |

| [41] | 150 | 6000 | 60 | High shear mixer |

| Bitumen/Blend | Elastic Recovery (%) |

|---|---|

| RB | 7 |

| LP-5 | 10 |

| LP-10 | 9 |

| LP-15 | 9 |

| Bitumen/Blend | Maximum Force (N) | Deformation Energy (J/cm2) |

|---|---|---|

| RB | 15.2 | 0.89 |

| LP-5 | 16.9 | 1.30 |

| LP-10 | 24.3 | 1.72 |

| LP-15 | 22.3 | 1.53 |

| Bitumen/Blend | Difference in Softening Point (°C) |

|---|---|

| LP-5 | 0.4 |

| LP-10 | 0.6 |

| LP-15 | 0.4 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kalampokis, S.; Papamoschou, M.; Kalama, D.M.; Pappa, C.P.; Manthos, E.; Triantafyllidis, K.S. Investigation of the Characteristic Properties of Lignin-Modified Bitumen. CivilEng 2022, 3, 734-747. https://doi.org/10.3390/civileng3030042

Kalampokis S, Papamoschou M, Kalama DM, Pappa CP, Manthos E, Triantafyllidis KS. Investigation of the Characteristic Properties of Lignin-Modified Bitumen. CivilEng. 2022; 3(3):734-747. https://doi.org/10.3390/civileng3030042

Chicago/Turabian StyleKalampokis, Stavros, Marianna Papamoschou, Danai Maria Kalama, Christina P. Pappa, Evangelos Manthos, and Konstantinos S. Triantafyllidis. 2022. "Investigation of the Characteristic Properties of Lignin-Modified Bitumen" CivilEng 3, no. 3: 734-747. https://doi.org/10.3390/civileng3030042

APA StyleKalampokis, S., Papamoschou, M., Kalama, D. M., Pappa, C. P., Manthos, E., & Triantafyllidis, K. S. (2022). Investigation of the Characteristic Properties of Lignin-Modified Bitumen. CivilEng, 3(3), 734-747. https://doi.org/10.3390/civileng3030042