The Role of Pozzolanic Activity of Siliceous Fly Ash in the Formation of the Structure of Sustainable Cementitious Composites

Abstract

1. Introduction

- chemical composition of SCMs,

- content of active oxides contained in SCMs, mainly SiO2 and Al2O3,

- the content and type of glass and the chemical composition of the glass phase of the material used,

- fineness, particle size distribution, and specific surface area of the OPC substitute used,

- proportions of water to the solid phase occurring in the cement paste with SCMs,

- thermal and humidity conditions prevailing in the area of the modified composition cement matrix.

2. Pozzolanic Activity of Siliceous Fly Ash and Formation of the Structure of Composites in the OPC-FA System

- increase in composite compressive strength,

- refinement of the pore microstructure in concrete by decreasing the general porosity, pore size distribution, and pore diameter and increasing the number of gelled pores, the size of which ranges from 5.7 to 10 nm,

- limitation of the content of CH phase after 28, 60, and 90 days of curing, which brings forth a reduction in intensity of reflections in diffractograms and changes in microstructure visible in SEM images,

- intensification of the hydration reaction, pozzolanic reaction, and the formation of the nuclei of hydrates,

- significant improvement in concrete microstructure density.

3. Experimental Procedure

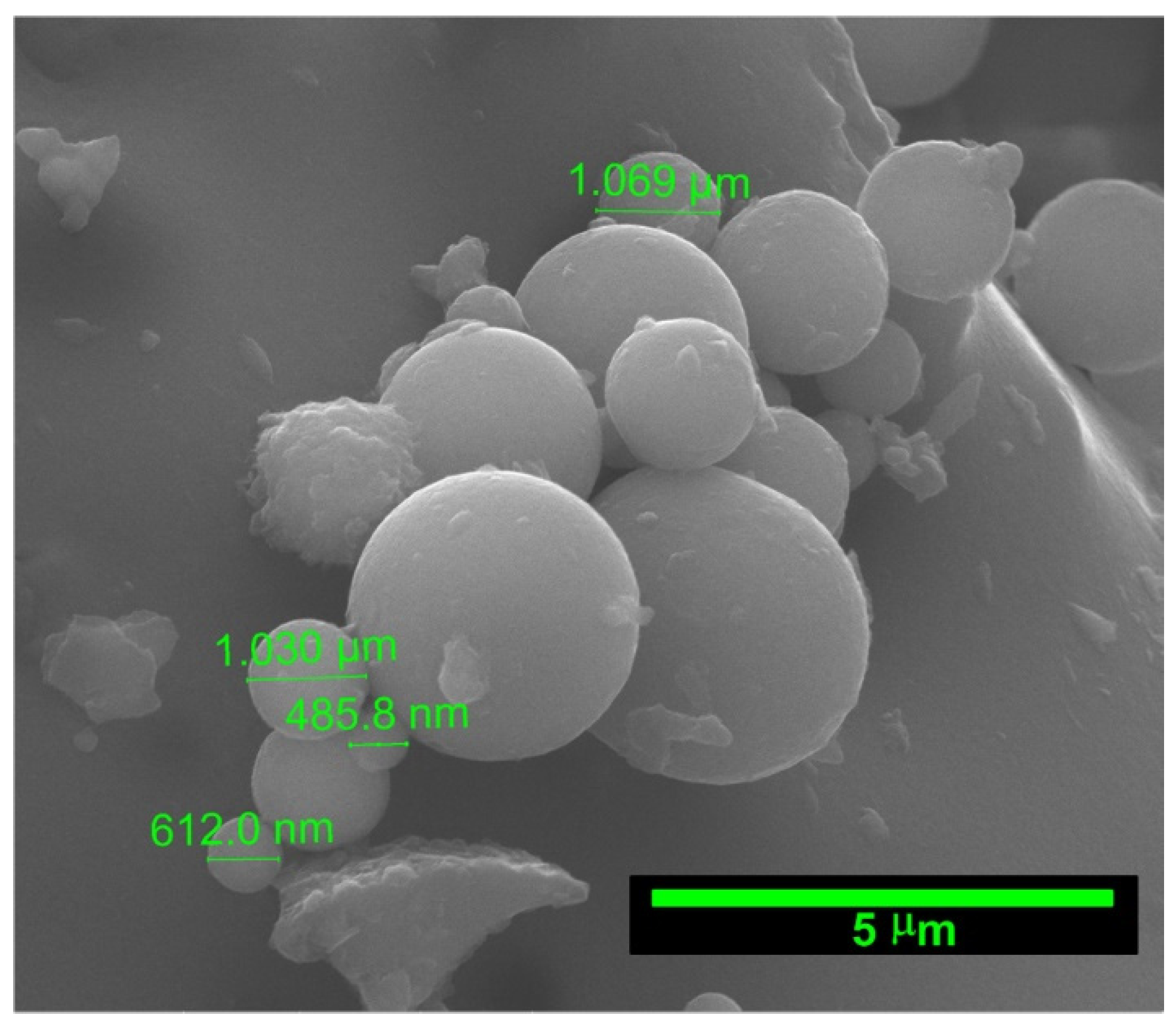

3.1. Materials

3.2. Methods

3.2.1. Preparation of Samples for Experiments

- structure of the cement matrix, with particular attention to the development of phases in the area of FA grains,

- changes occurring in the vitreous phase of the additives used.

- ordinary Portland cement CEM I (OPC) from Chełm cement plant,

- siliceous FA (FA) from the Puławy thermal power station,

- pit sand 0–2 mm in size from Markuszów deposit,

- plasticizer Basf Liquol BV-18,

- laboratory pipeline water.

3.2.2. Microstructural Investigations

- every 12 h until the first day of curing,

- daily until the third day of curing,

- weekly from the seventh to the twenty-eighth day of curing.

3.2.3. Pozzolanic Activity of FA Using Physical Method

3.2.4. Pozzolanic Activity of FA Using Chemical Method

4. Results and Discussion

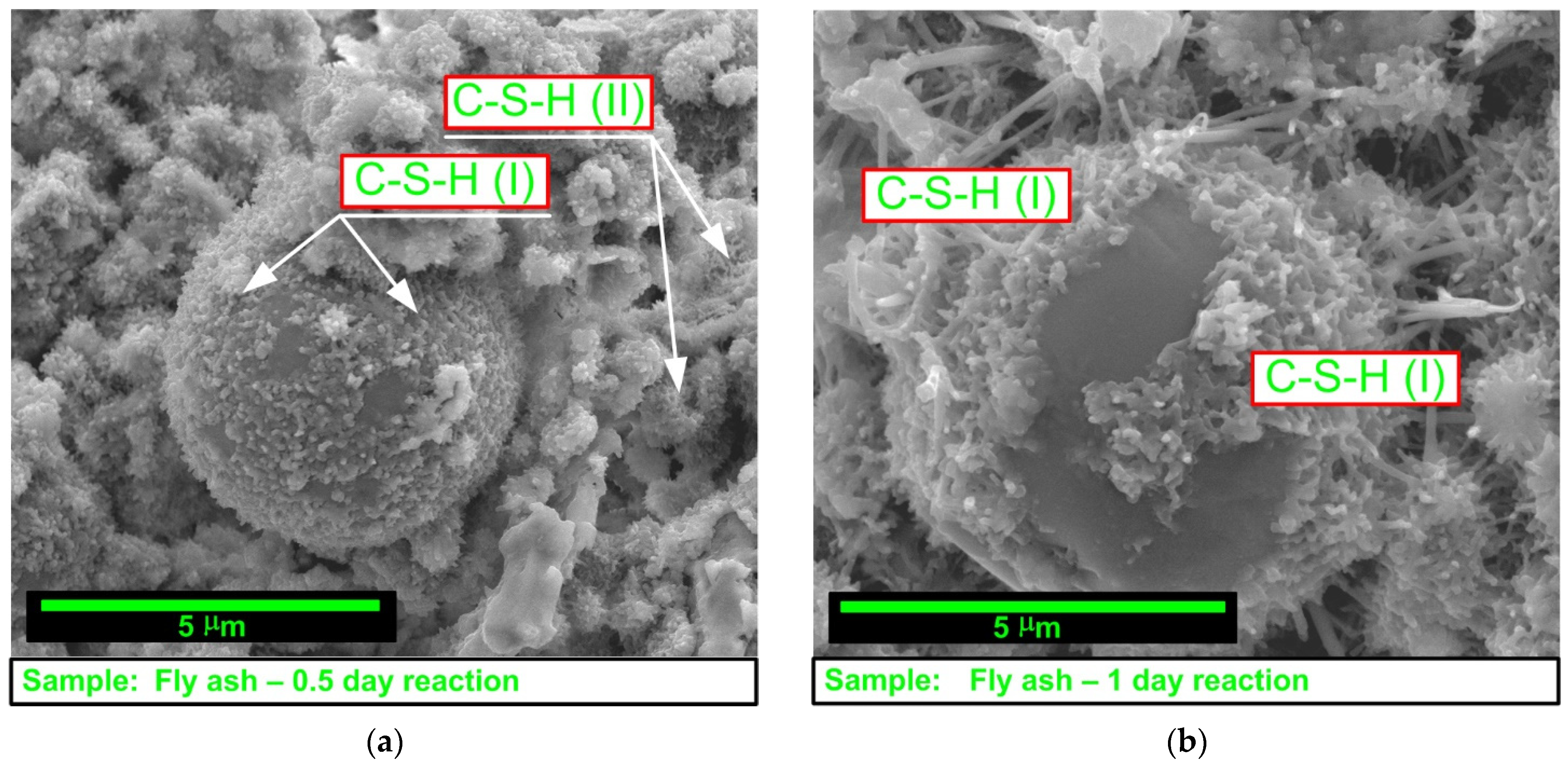

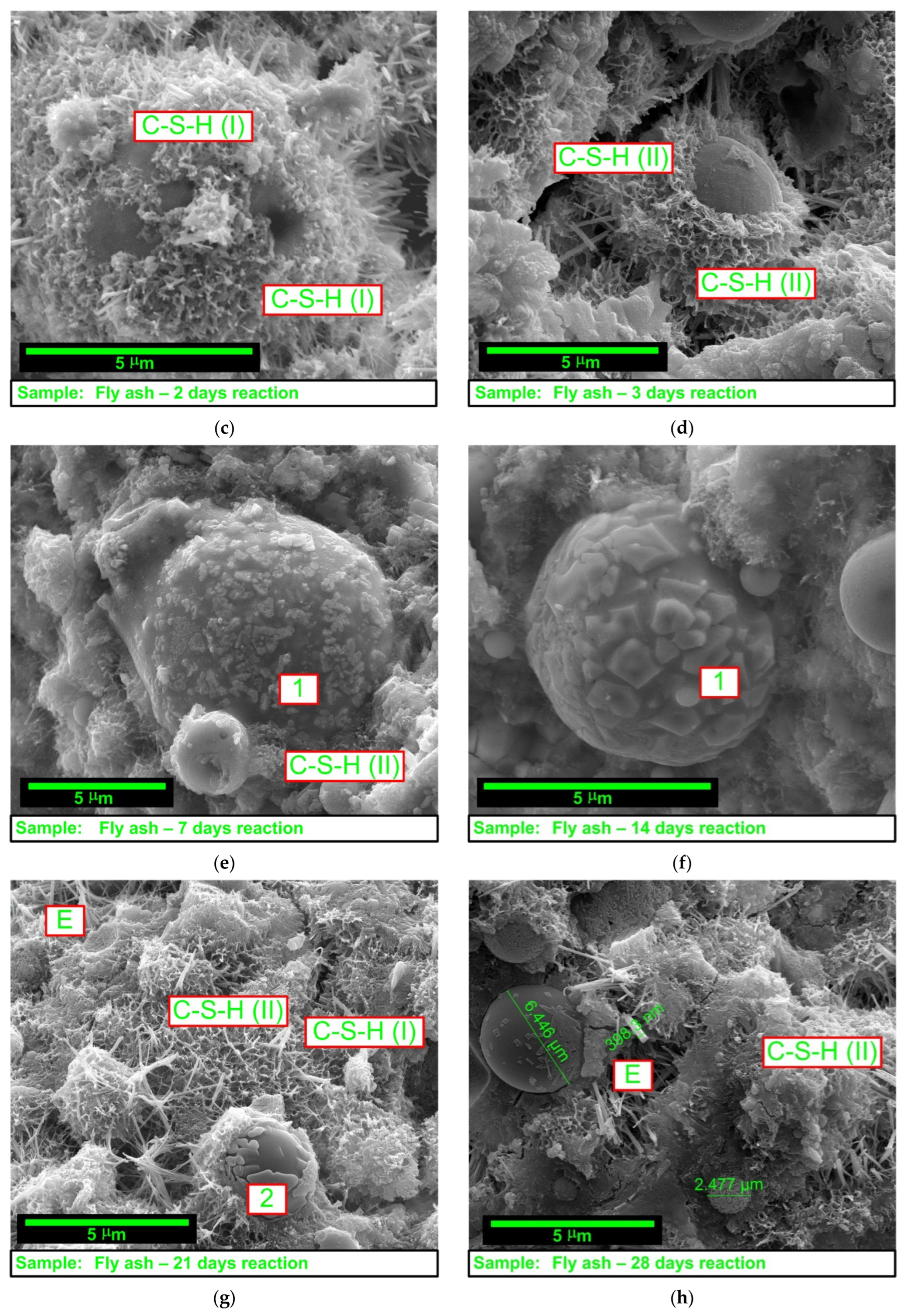

4.1. Microstructural Analysis

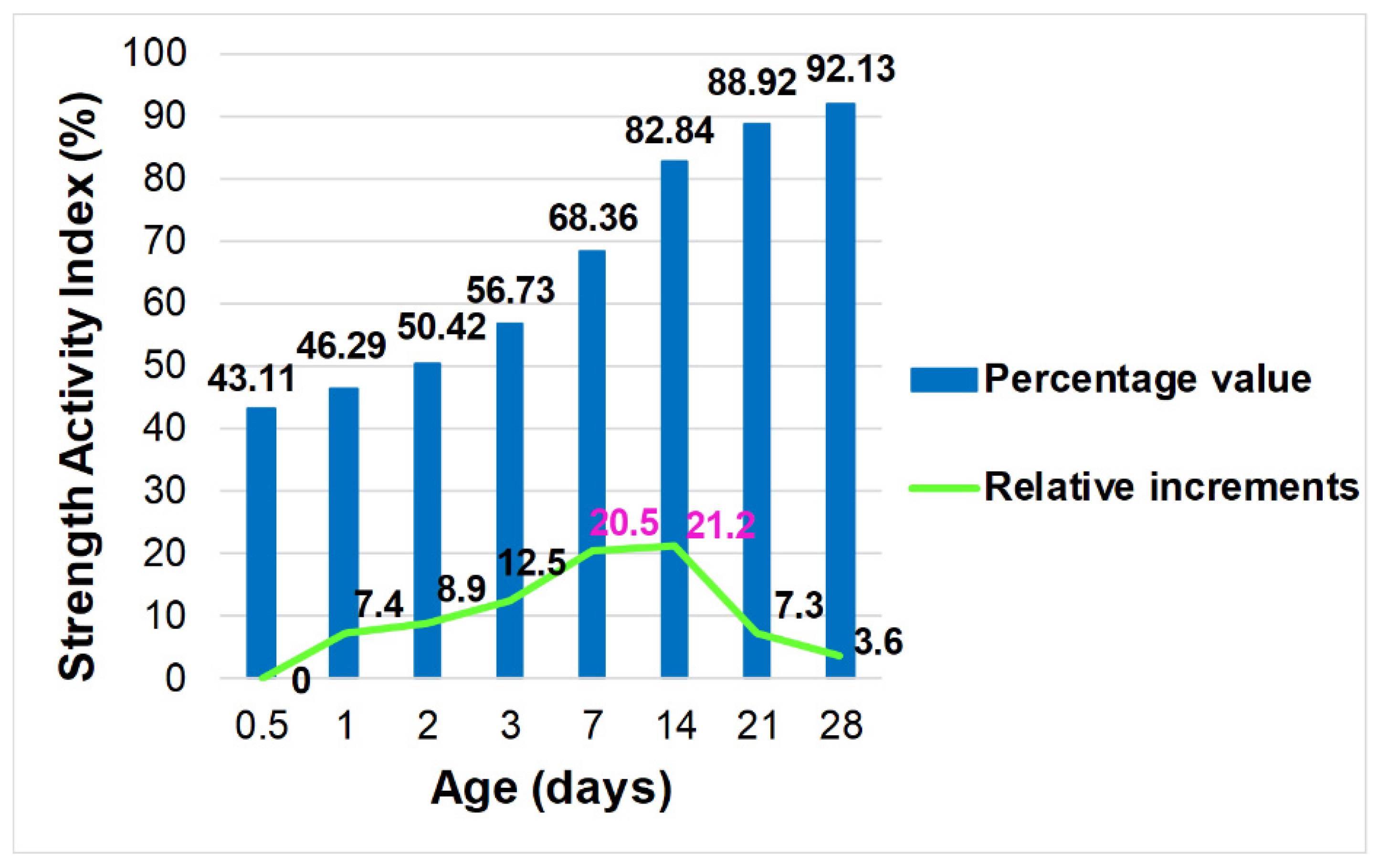

4.2. Pozzolanic Activity Based on the Studies from Physical Method

4.3. Pozzolanic Activity Based on the Studies from Chemical Method

5. Conclusions

- (1)

- In cement composites with the addition of FA, in the period until the third day of curing, the development of the material structure is mainly the result of the hydration reaction.

- (2)

- Between the seventh and fourteenth day after sample preparation, the first signs of pozzolanic reaction on FA grains are visible.

- (3)

- There is a clear correlation of the obtained results between the results obtained on the basis of the analysis of the microstructure of the paste with the addition of FA, and the tests of its pozzolanic activity by the physical method.

- (4)

- The results of the FA pozzolanic activity tests with the chemical method confirm both the high pozzolanic activity of fine-grained FAs assessed by the physical method and the ability of this mineral additive to form additional phases and homogenize the structure of the cement composite within a period of up to 28 days.

- (5)

- The obtained test results can be helpful in predicting the early strengths of FA-modified cement composites and contribute to their more conscious use in concrete and reinforced concrete structures.

Funding

Data Availability Statement

Conflicts of Interest

References

- Steinhäuser, K.G.; Von Gleich, A.; Große Ophoff, M.; Körner, W. The Necessity of a Global Binding Framework for Sustainable Management of Chemicals and Materials—Interactions with Climate and Biodiversity. Sustain. Chem. 2022, 3, 205–237. [Google Scholar] [CrossRef]

- Miraldo, S.; Lopes, S.; Pcheco-Torgal, F.; Lopes, A. Advantages and shortcomings of the utilization of recycled wastes as aggregates in structural concretes. Constr. Build. Mater. 2021, 298, 123729. [Google Scholar] [CrossRef]

- Golewski, G.L. Fracture Performance of Cementitious Composites Based on Quaternary Blended Cements. Materials 2022, 15, 6023. [Google Scholar] [CrossRef] [PubMed]

- Hafez, H.; Teirelbar, A.; Kurda, R.; Tosic, N.; de la Fuente, A. Pre-bcc: A Novel Integrated Machine Learning Framework for Predicting Mechanical and Durability Properties of Blended Cement Concrete. Constr. Build. Mater. 2021, 352, 129019. [Google Scholar] [CrossRef]

- Golewski, G.L. Studies of Natural Radioactivity of Concrete with Siliceous Fly Ash Addition. Cem. Wapno Beton 2015, 2, 106–114. [Google Scholar]

- Fu, J.; Sarfarazi, V.; Haeri, H.; Shahbazian, A.; Marji, M.F.; Yu, Y. Study of Tensile Crack Growth in Rock-Like Materials under Punch Shear Test. Theor. Appl. Fract. Mech. 2022, 121, 103509. [Google Scholar] [CrossRef]

- Tayeh, B.A.; Alyousef, R.; Alabduljabbar, H.; Alaskar, A. Recycling of Rice Husk Waste for Sustainable Concrete: A Critical Review. J. Clean. Prod. 2021, 312, 127734. [Google Scholar] [CrossRef]

- Golewski, G.L. Green Concrete Based on Quaternary Binders with Significant Reduced of CO2 Emissions. Energies 2021, 14, 4558. [Google Scholar] [CrossRef]

- Golewski, G.L. The specificity of shaping and execution of monolithic pocket foundations (PF) in hall buildings. Buildings 2022, 12, 192. [Google Scholar] [CrossRef]

- Pacheco-Torgal, F. High tech startup creation for energy efficient built environment. Ren. Sust. Ener. Rev. 2017, 71, 618–629. [Google Scholar] [CrossRef]

- Ramesh, G. Green concrete: Environment friendly solution. Ind. J. Des. Eng. 2021, 1, 13–20. [Google Scholar]

- Deganello, F.; Bos, J.-W.G. Innovations in Energy Engineering and Cleaner Production: A Sustainable Chemistry Perspective. Sustain. Chem. 2022, 3, 112–113. [Google Scholar] [CrossRef]

- Golewski, G.L. Comparative measurements of Fracture Toughness Combined with Visual Analysis of Cracks Propagation Using the DIC Technique of Concretes Based on Cement Matrix with a Highly Deversified Composition. Theor. Appl. Fract. Mech. 2022, 121, 103553. [Google Scholar] [CrossRef]

- Golewski, G.L. An Extensive Investigations on Fracture Parameters of Concretes Based on Quaternary Binders (QBC) by means of the DIC technique. Constr. Build. Mater. 2022, 351, 128823. [Google Scholar] [CrossRef]

- Lim, B.; Alorro, R.D. Technospheric Mining of Mine Wastes: A Review of Applications and Challenges. Sustain. Chem. 2021, 2, 686–706. [Google Scholar] [CrossRef]

- Beddu, S.; Ahmad, M.; Mohamad, D.; bin Noorul Ameen, M.I.; Itam, Z.; Kamal, N.L.M.; Basri, N.A.N. Utilization of fly ash cenosphere to study mechanical and thermal properties of lightweight concrete. AIMS Mater. Sci. 2020, 7, 911–925. [Google Scholar] [CrossRef]

- Ikponmwosa, E.E.; Ehikhuenmen, S.O.; Irene, K.K. Comparative study and empirical modelling of pulverized coconut shell, periwinkle shell and palm kernel shell as a pozzolans in concrete. Acta Polytech. 2019, 59, 560–572. [Google Scholar] [CrossRef]

- Guan, J.; Yin, Y.; Li, Y.; Yao, X.; Li, L. A design method for determining fracture toughness and tensile strength pertinent to concrete sieving curve. Eng. Fract. Mech. 2022, 271, 108596. [Google Scholar] [CrossRef]

- Golewski, G.L.; Szostak, B. Strength and microstructure of composites with cement matrixes modified by fly ash and active seeds of C-S-H phase. Struct. Eng. Mech. 2022, 82, 543–556. [Google Scholar]

- Zhang, P.; Wei, S.; Wu, J.; Zhang, Y.; Zheng, Y. Investigation of mechanical properties of PVA fiber-reinforced cementitious composites under the coupling effect of wet-thermal and chloride salt environment. Case Stud. Constr. Mater. 2022, 17, e01325. [Google Scholar] [CrossRef]

- Golewski, G.L.; Szostak, B. Application of the C-S-H Phase Nucleating Agents to Improve the Performance of Sustainable Concrete Composites Containing Fly Ash for Use in the Precast Concrete Industry. Materials 2021, 14, 6514. [Google Scholar] [CrossRef]

- Alperen Bulut, H.; Sahin, R. Radilogical Characteristics of Self-Compacting Concretes Incorporating Fly Ash, Silica Fume, and Slag. J. Build. Eng. 2022, 58, 104987. [Google Scholar] [CrossRef]

- Asencios, Y.J.O.; Machado, V.A. Photodegradation of Organic Pollutants in Seawater and Hydrogen Production via Methanol Photoreforming with Hydrated Niobium Pentoxide Catalysts. Sustain. Chem. 2022, 3, 172–191. [Google Scholar] [CrossRef]

- Golewski, G.L.; Szostak, B. Strengthening the Very Early-Age Structure of Cementitious Composites with Coal Fly Ash via Incorporating a Novel Nanoadmixture Based on C-S-H Phase Activators. Constr. Build. Mater. 2021, 312, 125426. [Google Scholar] [CrossRef]

- Gao, Z.; Zhang, P.; Wang, J.; Wang, K.; Zhang, T. Interfacial Properties of Geopolymer Mortar and Concrete Substrate: Effect of Polyvinyl Alcohol Fiber and Nano-SiO2 Contents. Constr. Build. Mater. 2022, 315, 125735. [Google Scholar] [CrossRef]

- Naija, A.; Miled, K. Numerical Study of the Influence of W/C Ratio and Aggregate Shape and Size on the ITZ Volume Fraction in Concrete. Constr. Build. Mater. 2022, 351, 128950. [Google Scholar] [CrossRef]

- Xu, J.; Pu, H.; Sha, Z. Full-Field Deformation and Crack Development Evolution of Red Sandstone under Impact and Chemical Erosion. Minerals 2022, 12, 1038. [Google Scholar] [CrossRef]

- Gil, D.M.; Golewski, G.L. Effect of Silica Fume and Siliceous Fly Ash Addition on the Fracture Toughness of Plain Concrete in Mode I. IOP Conf. Ser. Mater. Sci. Eng. 2018, 416, 012065. [Google Scholar] [CrossRef]

- Szostak, B.; Golewski, G.L. Effect of Nano Admixture of CSH on Selected Strength Parameters of Concrete Including Fly Ash. IOP Conf. Ser. Mater. Sci. Eng. 2018, 416, 012105. [Google Scholar] [CrossRef]

- Zhang, P.; Guan, Q.-Y.; Zhang, T.-H. Fracture Behavior of Fly Ash Concrete Containing Silica Fume. Struct. Eng. Mech. 2016, 59, 261–275. [Google Scholar] [CrossRef]

- Srinath, S. Effect of Fly Ash and Silica Fumes on Compression and Fracture Behavior of Concrete. J. Civ. Archit. Eng. 2016, 1, JCAE-2-006. [Google Scholar]

- Zhang, P.; Li, Q.-F. Effect of Silica Fume on Fracture Properties of High-Performance Concrete Containing Fly Ash. Proc. IMechE Part L J. Mater. Des. Appl. 2012, 227, 336–342. [Google Scholar] [CrossRef]

- Gil, D.M.; Golewski, G.L. Potential of Siliceous Fly Ash and Silica Fume as a Substitute of Binder in Cementitious Concrete. E3S Web Conf. 2018, 49, 00030. [Google Scholar] [CrossRef]

- Dahan, A.M.E.; Alorro, R.D.; Pacaña, M.L.C.; Baute, R.M.; Silva, L.C.; Tabelin, C.B.; Resabal, V.J.T. Hydrochloric Acid Leaching of Philippine Coal Fly Ash: Investigation and Optimisation of Leaching Parameters by Response Surface Methodology (RSM). Sustain. Chem. 2022, 3, 76–90. [Google Scholar] [CrossRef]

- Ho, D.W.S.; Lewis, R.K. Effectiveness of Fly Ash for Strength and Durability of Concrete. Cem. Concr. Res. 1985, 15, 793–800. [Google Scholar] [CrossRef]

- Fraay, A.L.A.; Bijen, J.M.; de Haan, Y.M. The Reaction of Fly Ash in Concrete a Critical Examination. Cem. Concr. Res. 1989, 19, 235–246. [Google Scholar] [CrossRef]

- Kaya, M.; Karahan, O.; Duran Atis, C. Influence of Silica Fume Additive and Activator Ratio on Mechanical Properties in Slaked Lime-Based Alkali-Activated Mortars. Iran. J. Sci. Techn. Trans. Viv. Eng. 2022. [Google Scholar] [CrossRef]

- Barbhuiya, S.A.; Gbagbo, J.K.; Russell, M.I.; Basheer, P.A.M. Properties of fly ash concrete modified with hydrated lime and silica fume. Constr. Build. Mater. 2009, 23, 3233–3239. [Google Scholar] [CrossRef]

- Leung, H.Y.; Kim, J.; Nadeem, A.; Jaganathan, J.; Anwar, M.P. Sorptivity of self-compacting concrete containing fly ash and silica fume. Constr. Build. Mater. 2016, 113, 369–375. [Google Scholar] [CrossRef]

- Zhang, P.; Han, S.; Golewski, G.L.; Wang, X. Nanoparticle-reinforced building materials with applications in civil engineering. Adv. Mech. Eng. 2020, 12, 1687814020965438. [Google Scholar] [CrossRef]

- Rathnayake, H.; Dawood, S.; Pathiraja, G.; Adrah, K.; Ayodele, O. Green Synthesis of De Novo Bioinspired Porous Iron-Tannate Microstructures with Amphoteric Surface Properties. Sustain. Chem. 2022, 3, 192–204. [Google Scholar] [CrossRef]

- Kovacik, J.; Marsavina, L.; Linul, E. Poisson’s Ratio of Closed-Cell Aluminum Foams. Materials 2018, 11, 1904. [Google Scholar] [CrossRef] [PubMed]

- Fakhri, D.; Hosseini, M.; Mahdikhani, M. Effect of Glass and Polypropylene Hybrid Fibers on Mode I, Mode II, and Mixed-Mode Fracture Toughness of Concrete Containing Micro-Silica and Limestone Powder. J. Min. Env. 2022, 13, 559–577. [Google Scholar]

- Ahmad, J.; Zaid, O.; Shahzaib, M.; Usman Abdullah, M.; Ullah, A.; Ullah, R. Mechanical Properties of Sustainable Concrete Modified by Adding Marble Slurry Cement Substitution. AIMS Mater. Sci. 2021, 8, 343–358. [Google Scholar] [CrossRef]

- Khan, K.; Ahmad, W.; Amin, M.N.; Nazar, S. Nano-Silica-Modified Concrete: A Bibliographic Analysis and Comprehensive Review of Material Properties. Nanomaterials 2022, 12, 1989. [Google Scholar] [CrossRef]

- Han, Q.; Zhang, P.; Wu, J.; Jing, Y.; Zhang, D.; Zhang, T. Comprehensive Review of the Properties of Fly Ash-Based Geopolymer with Additive of Nano-SiO2. Nanotech. Rev. 2022, 1, 1478–1498. [Google Scholar] [CrossRef]

- Ibrahim, Y.E.; Adamu, M.; Marouf, M.L.; Ahmed, O.S.; Drmosh, Q.A.; Malik, M.A. Mechanical Performance of Date-Palm-Fiber-Reinforced Concrete Containing Silica Fume. Buildings 2022, 12, 1642. [Google Scholar] [CrossRef]

- Szcześniak, A.; Zychowicz, J.; Stolarski, A. Influence of Fly Ash Additive on the Properties of Concrete with Slag Cement. Materials 2020, 13, 3265. [Google Scholar] [CrossRef]

- Golewski, G.L. An Analysis of Fracture Toughness in Concrete with Fly Ash Addition, Considering All Models of Cracking. IOP Conf. Ser. Mater. Sci. Eng. 2018, 416, 012029. [Google Scholar] [CrossRef]

- Szostak, B.; Golewski, G.L. Rheology of Cement Pastes with Siliceous Fly Ash and the CSH Nano-Admixture. Materials 2021, 14, 3640. [Google Scholar] [CrossRef]

- Craciun, E.M. Energy Criteria for Crack Propagation in Prestresses Elastic Composites. Sol. Mech. Appl. 2008, 154, 193–237. [Google Scholar]

- Golewski, G.L. On the Special Construction and Materials Conditions Reducing the Negative Impact of Vibrations on Concrete Structures. Mater. Today Proc. 2020, 45, 4344–4348. [Google Scholar] [CrossRef]

- Golewski, G.L. Physical Characteristics of Concrete, Essential in Design of Fracture-resistant, Dynamically Loaded Reinforced Concrete Structures. Mater. Des. Proc. Comm. 2019, 1, e82. [Google Scholar] [CrossRef]

- Fakoor, M.; Shahsavar, S. The effect of T-stress on Mixed Mode I/II Fracture of Composite Materials: Reinforcement Isotropic Solid Model in Combination with Maximum Shear Stress Theory. Int. J. Sol. Struct. 2021, 229, 111145. [Google Scholar] [CrossRef]

- Mehri Khansari, N.; Fakoor, M.; Berto, F. Probabilistic Micromechanical Damage Model for Mixed Mode I/II Fracture Investigation of Composite Materials. Theor. Appl. Fract. Mech. 2019, 99, 177–193. [Google Scholar] [CrossRef]

- Li, H.; Xiang, Y.; Xu, C. Effect of C-S-H seed/PCE Nanocomposites and Triisopropanolamine on Portland cement Properties: Hydration Kinetic and Strength. J. Build. Eng. 2022, 57, 104946. [Google Scholar] [CrossRef]

- Han, F.; Pu, S.; Zhou, Y.; Zhang, H.; Zhang, Z. Effect of Ultrafine Mineral Admixtures on the Rheological Properties of Fresh Cement Paste: A review. J. Build. Eng. 2022, 51, 104313. [Google Scholar] [CrossRef]

- Golewski, G.L.; Sadowski, T. Experimental Investigation and Numerical Modeling Fracture Processes in Fly Ash Concrete at Early Age. Solid State Phenom. 2012, 188, 158–163. [Google Scholar] [CrossRef]

- Duartel, M.; Benitez, A.; Gomez, K.; Zuluaga, B.; Meza, J.; Cardona-Maya, Y.; Rudas, J.S.; Isaza, C. Nanomechanical Characterization of a Metal Matrix Composite Reinforced with Carbon Nanotubes. AIMS Mater. Sci. 2020, 7, 33–45. [Google Scholar] [CrossRef]

- Goujon, N.; Demarteau, J.; Lopez de Pariza, X.; Casado, N.; Sardon, H.; Mecerreyes, D. Chemical Upcycling of PET Waste towards Terephthalate Redox Nanoparticles for Energy Storage. Sustain. Chem. 2021, 2, 610–621. [Google Scholar] [CrossRef]

- Kurdowski, W. Cement and Concrete Chemistry; Springer Netherlands: Dordrecht, The Netherlands; New York, NY, USA, 2014. [Google Scholar]

- Neville, A.M. Properties of Concrete; Pearson Education Limited: Edinburg Gate Harlow, Essex, UK, 2011. [Google Scholar]

- Li, Y.; Wu, B.; Wang, R. Critical Review and Gap Analysis on the Use of High-volume Fly Ash as a Substitute Constituent in Concrete. Constr. Build. Mater. 2022, 341, 127889. [Google Scholar] [CrossRef]

- Tkaczewska, E.; Małolepszy, J. Hydration of Coal-biomass Fly Ash Cement. Constr. Build. Mater. 2009, 23, 2694–2700. [Google Scholar] [CrossRef]

- Sear Lindon, K.A. Properties and Use of Coal Fly Ash, a Valuable Industrial Byproduct; Thomas Telford Ltd.: London, UK, 2001. [Google Scholar]

- Wang, A.; Zhang, C.; Sun, W. Fly Ash Effects: I. The Morphological Effect of Fly Ash. Cem. Concr. Res. 2003, 33, 2023–2029. [Google Scholar] [CrossRef]

- Wang, A.; Zhang, C.; Sun, W. Fly Ash Effects: II. The Active Effect of Fly Ash. Cem. Concr. Res. 2004, 34, 2057–2060. [Google Scholar] [CrossRef]

- Wang, A.; Zhang, C.; Sun, W. Fly Ash Effects: III. The Microaggregate Effect of Fly Ash. Cem. Concr. Res. 2004, 34, 2061–2066. [Google Scholar] [CrossRef]

- Bai, W.; Lu, X.; Guan, J.; Yuan, C. Experimental Study on Uniaxial Compression Mechanical Properties of Recycled Concrete with Silica Fume Considering the Effect of Curing Age. Constr. Build. Mater. 2022, 350, 128758. [Google Scholar] [CrossRef]

- Guan, J.; Zhang, Y.; Yao, X.; Li, L.; Zhang, L.; Yi, J. Experimental Study on the Effect of Compound Activator on the Mechanical Properties of Steel Slag Cement Mortar. Crystals 2021, 11, 658. [Google Scholar] [CrossRef]

- Rossen, J.E.; Scrivener, K.L. Optimization of SEM-EDS to determine the C-A-S-H composition in matured cement paste samples. Mater. Charact. 2017, 123, 294–306. [Google Scholar] [CrossRef]

- Chindaprasirt, P.; Jaturapitakkul, C.; Sinsiri, T. Effect of Fly Ash Fineness on Compressive Strength and Pore Size of Blended Cement Paste. Cem. Concr. Compos. 2005, 27, 425–428. [Google Scholar] [CrossRef]

- Golewski, G.L. Determination of Fracture Toughness in Concretes Containing Siliceous Fly Ash during Mode III Loading. Struct. Eng. Mech. 2017, 62, 1–9. [Google Scholar] [CrossRef]

- Li, S.; Li, H.; Yan, C.; Ding, Y.; Zhang, X.; Zhao, J. Investigating the Mechanical and Durability Characteristics of Fly Ash Foam Concrete. Materials 2022, 15, 6077. [Google Scholar] [CrossRef] [PubMed]

- Beaudoin, J.J. Comparison of mechanical properties of compacted calcium hydroxide and Portland cement paste systems. Cem. Concr. Res. 1983, 33, 319–324. [Google Scholar] [CrossRef]

- Beaudoin, J.J.; Gu, P.; Myers, R.E. The fracture of C-S-H and C-S-H/CH mixtures. Cem. Concr. Res. 1988, 28, 341–347. [Google Scholar] [CrossRef]

- Mindess, S. The strength and fracture of concrete: The role of calcium hydroxide. In Materials Science of Concrete, Special Volume, Calcium Hydroxide in Concrete; Skalny, J., Odler, I., Eds.; The American Ceramic Society: Westerville, OH, USA, 2001; pp. 143–154. [Google Scholar]

- Xu, S.; Gao, P.; Huang, L.; Tang, L.; Gu, X.; Wang, L. Experimental Research on Mechanical and Shrinkage Properties of Alkali Activated Low-Carbon Green Concrete. Materials 2022, 15, 5984. [Google Scholar] [CrossRef]

- Abbas, S.N.; Qureshi, M.I.; Abid, M.M.; Zia, A.; Tariq, M.A.U.R. An Investigation of Mechanical Properties of Fly Ash Based Geopolymer and Glass Fibers Concrete. Sustainability 2022, 14, 10489. [Google Scholar] [CrossRef]

- Papadakis, V.G.; Antiohos, S.; Tsimas, S. Supplementary Cementing Materials in Concrete Part II: A Fundamental Estimation of the Efficiency Factor. Cem. Concr. Res. 2002, 32, 1533–1538. [Google Scholar] [CrossRef]

- Delhomme, F.; Prud’homme, E.; Julliot, C.; Guillot, T.; Amziane, S.; Marceau, S. Effect of Hemp on Cement Hydration: Experimental Characterization of the Interfacial Transition Zone. Res. Chem. 2022, 4, 100440. [Google Scholar] [CrossRef]

- Tkaczewska, E.; Smaruń, M. Influence of Temperature and Addition of Silica Fly Ash on Hydration Process and Cement Properties. Mater. Ceram. (Ceram. Mater.) 2019, 71, 45–60. [Google Scholar]

- Gallego, H.; Toro, E.; Rojas, R. State of the Art.: Process of Pozzolan Formation from Ash and its Applications. Rev. Ing. Constr. 2020, 35, 119–125. [Google Scholar] [CrossRef]

- Heikal, M.; El-Diamondy, H.; Helmy, I.M.; Abd El-Raoof, F. Pozzolanic Activity of Fly Ash. Sil. Ind. 2016, 68, 111–117. [Google Scholar]

- Sakai, E.; Miyahara, S.; Ohsawa, S.; Lee, S.-H.; Daimon, M. Hydration of Fly Ash Cement. Cem. Concr. Res. 2005, 35, 1135–1140. [Google Scholar] [CrossRef]

- Golewski, G.L. Effect of Fly Ash Addition on the Fracture Toughness of Plain Concrete at Third Model of Fracture. J. Civ. Eng. Manag. 2017, 23, 613–620. [Google Scholar] [CrossRef]

- Tkaczewska, E. Effect of Chemical Composition and Network of Fly Ash Glass on the Hydration Process and Properties of Portland-Fly Ash Cement. J. Mater. Eng. Perform. 2021, 30, 9262–9282. [Google Scholar] [CrossRef]

- Narmluk, M.; Nawa, T. Effect of Curing Temperature on Pozzolanic Reaction of Fly Ash in Blended Cement Paste. Int. J. Chem. Eng. Appl. 2014, 5, 31–35. [Google Scholar] [CrossRef][Green Version]

- Snellings, R. Solution-Controlled Dissolution of Supplementary Cementitious Material Glasses at pH 13: The Effect of Solution Composition on Glass Dissolution Rates. J. Am. Ceram. Soc. 2013, 96, 2467–2475. [Google Scholar] [CrossRef]

- Pustovgar, E.; Mishra, R.K.; Palacios, M.; de Lacaillerie, J.B.D.E.; Matschei, T.; Andreev, A.S.; Heinz, H.; Verel, R.; Flatt, R.J. Influence of aluminates on the hydration kinetics of tricalcium silicate. Cem. Concr. Res. 2017, 100, 245–262. [Google Scholar] [CrossRef]

- Nocuń-Wczelik, W. Heat Evolution in Hydrated Cementitious Systems Admixtured with Fly Ash. J. Therm. Anal. Cal. 2001, 65, 613–619. [Google Scholar] [CrossRef]

- Langan, B.W.; Weng, K.; Ward, M.A. Effect of Silica Fume and Fly Ash on the Heat of Hydration of Portland Cement. Cem. Concr. Res. 2002, 32, 1045–1051. [Google Scholar] [CrossRef]

- Erdogdu, K.; Turker, P. Effect of Fly Ash Particle Size on Strength of Portland Cement Fly Ash Mortars. Cem. Concr. Res. 1998, 28, 1217–1222. [Google Scholar] [CrossRef]

- Lee, H.J.; Lee, J.H.; Kim, D.G. Study on the Change in Microstructure of Fly Ash Concrete Depending on Ages and Degree of Hydration Using XRD and SEM. Adv. Mater. Res. 2012, 486, 350–355. [Google Scholar] [CrossRef]

- Ogawa, K.; Uchikawa, K.; Takemoto, K.; Yasui, I. The Mechanism of the Hydration in the System C3S-pozzolana. Cem. Concr. Res. 1980, 10, 683–696. [Google Scholar] [CrossRef]

- Nocuń-Wczelik, W.; Maziarz, A. Effect of Some Admixtures on the Properties of Portland and Blended Portland Cement. Cem. Wapno Beton 2012, 4, 225–232. [Google Scholar]

- Zhang, M.H. Microstructure, Crack Propagation, and Mechanical Properties of Cement Pastes Containing High Volumes of Fly Ashes. Cem. Concr. Res. 1995, 25, 1165–1178. [Google Scholar] [CrossRef]

- Park, J.-H.; Yoon, C.-B. Properties and Durability of Cement Mortar Using Calcium Stearate and Natural Pozzolan for Concrete Surface Treatment. Materials 2022, 15, 5762. [Google Scholar] [CrossRef] [PubMed]

- Kramar, S.; Ducman, V. Evaluation of Ash Pozzolanic Activity by Means of the Strength Activity Index Test, Frattini and DTA/TG Analysis. Techn. Gaz. 2018, 25, 1746–1752. [Google Scholar]

- Durdziński, P.T.; Snellings, R.; Dunant, C.F.; Ben Haha, M.; Scrivener, K.L. Fly Ash an assemblage of model CA-Mg-Na-aluminosilicate glasses. Cem. Concr. Res. 2015, 78, 263–272. [Google Scholar] [CrossRef]

- Durdziński, P.T.; Ben Haha, M.; Zając, M.; Scrivener, K.L. Phase assemblage of composite cements. Cem. Concr. Res. 2017, 99, 172–182. [Google Scholar] [CrossRef]

- Wei, Y.; Gao, X.; Liang, S. A combined SPM/NI/EDS method to quantity properties of inner and outer C-S-H in OPC and slag-blended cement pastes. Cem. Concr. Compos. 2018, 85, 56–66. [Google Scholar] [CrossRef]

- EN 450-1:2012; Fly Ash for Concrete–Part 1: Definition, Specifications and Conformity Criterion. British Standards Institution (BSI): London, UK, 2012.

- ASTM C379-65T; Specification for Fly Ash for Use as a Pozzolanic Material with Lime. American Society for Testing and Material: Washington, DC, USA, 1965.

- Diamond, S. Cement paste microstructure: An overview at several levels. In Hydraulic Cement Pastes: Their Structure and Properties; Cement and Concrete Association: London, UK, 1977; pp. 2–31. [Google Scholar]

- Locher, F.W.; Richartz, W.; Sprung, S. Erstarren von Zement Teil 1: Reaktion und Gefügeentwicklung. Zement Kalk Gips 1976, 29, 435–442. (In German) [Google Scholar]

- Hansen, T.C. Long-term Strength of Fly Ash Concretes. Cem. Concr. Res. 1990, 20, 193–196. [Google Scholar] [CrossRef]

- Tkaczewska, E. Methods of testing pozzolanic activity of mineral additives. Mater. Ceram. (Ceram. Mater.) 2011, 63, 536–541. [Google Scholar]

| Component (wt %) | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SCM | CaO | SiO2 | Al2O3 | Fe2O3 | K2O | Na2O | MgO | P2O5 | TiO2 | Cs2O | BaO | SO3 | LOI * |

| FA | 2.15 | 50.96 | 25.88 | 8.25 | 2.65 | 1.26 | 2.60 | 0.35 | 1.36 | 0.09 | 0.32 | 0.65 | 3.20 |

| Component (wt %) | |||

|---|---|---|---|

| SCM | Amorphous | Quartz | Mullite |

| FA | 71.5 | 19.7 | 8.8 |

| Active Components | Results (%) |

|---|---|

| SiO2 | 13.31 |

| Al2O3 | 7.22 |

| SiO2 + Al2O3 | 20.53 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Golewski, G.L. The Role of Pozzolanic Activity of Siliceous Fly Ash in the Formation of the Structure of Sustainable Cementitious Composites. Sustain. Chem. 2022, 3, 520-534. https://doi.org/10.3390/suschem3040032

Golewski GL. The Role of Pozzolanic Activity of Siliceous Fly Ash in the Formation of the Structure of Sustainable Cementitious Composites. Sustainable Chemistry. 2022; 3(4):520-534. https://doi.org/10.3390/suschem3040032

Chicago/Turabian StyleGolewski, Grzegorz Ludwik. 2022. "The Role of Pozzolanic Activity of Siliceous Fly Ash in the Formation of the Structure of Sustainable Cementitious Composites" Sustainable Chemistry 3, no. 4: 520-534. https://doi.org/10.3390/suschem3040032

APA StyleGolewski, G. L. (2022). The Role of Pozzolanic Activity of Siliceous Fly Ash in the Formation of the Structure of Sustainable Cementitious Composites. Sustainable Chemistry, 3(4), 520-534. https://doi.org/10.3390/suschem3040032