Design and Validation of a Low-Cost Automated Dip-Coater System for Laboratory Applications

Abstract

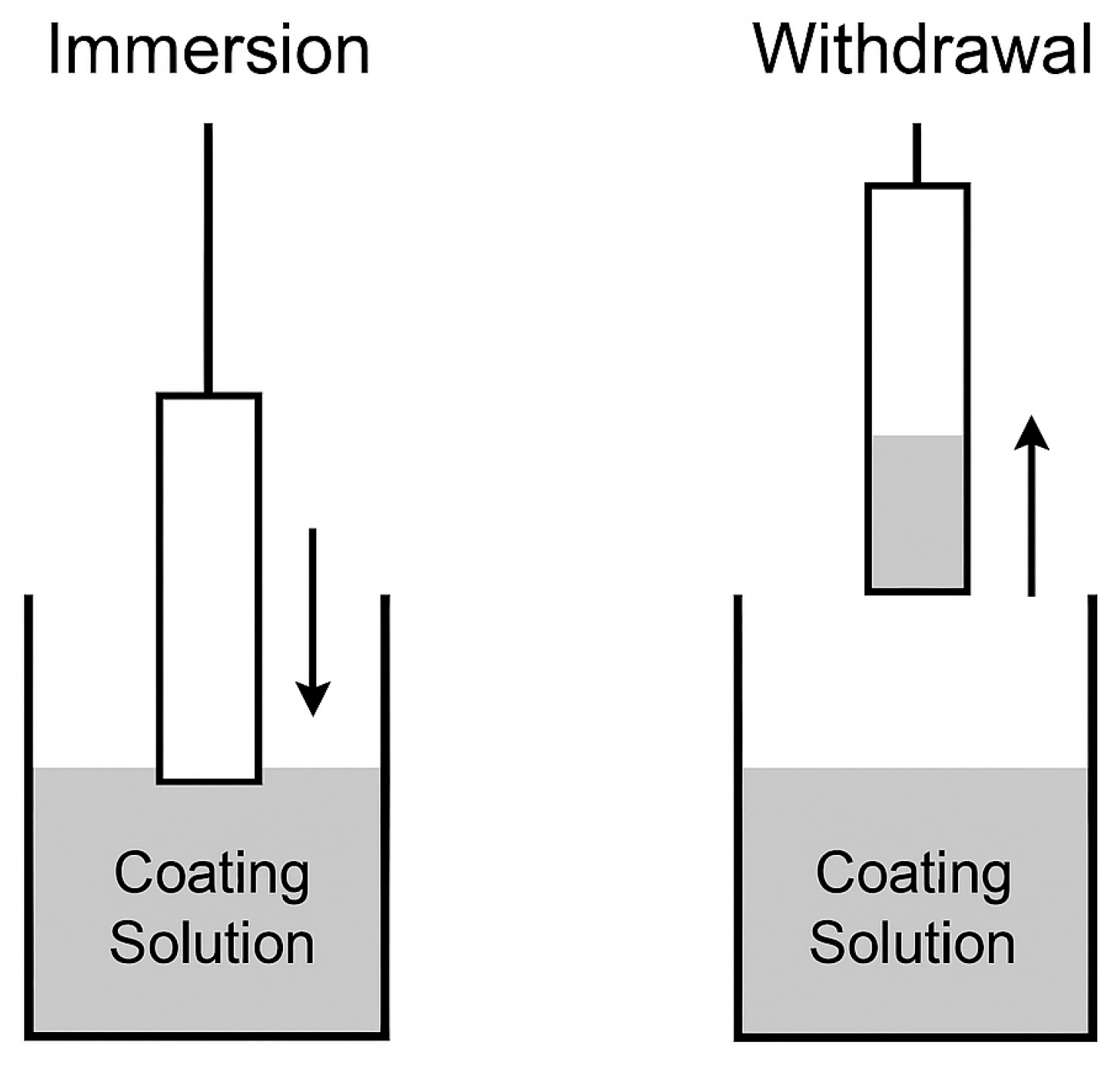

1. Introduction

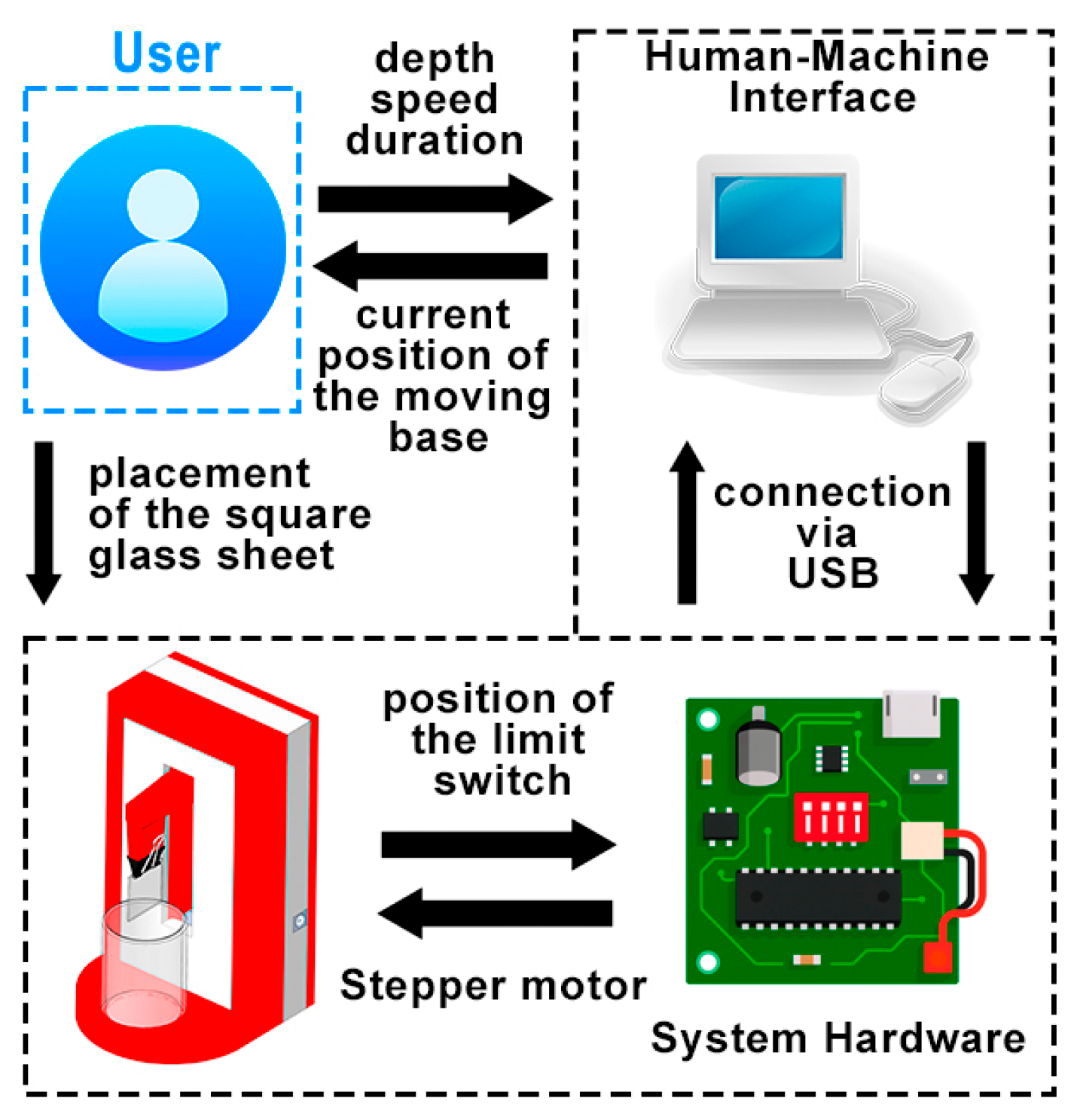

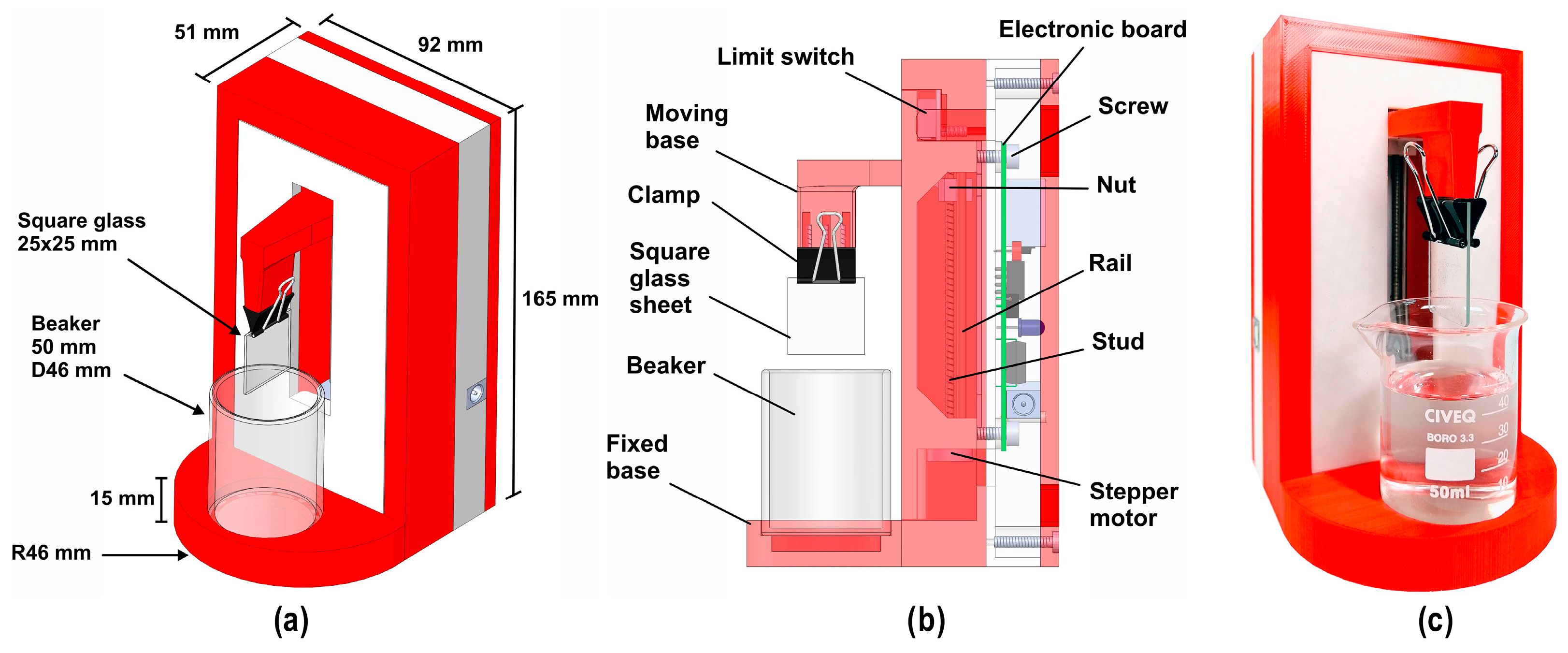

2. System Description

2.1. Dip Coater System

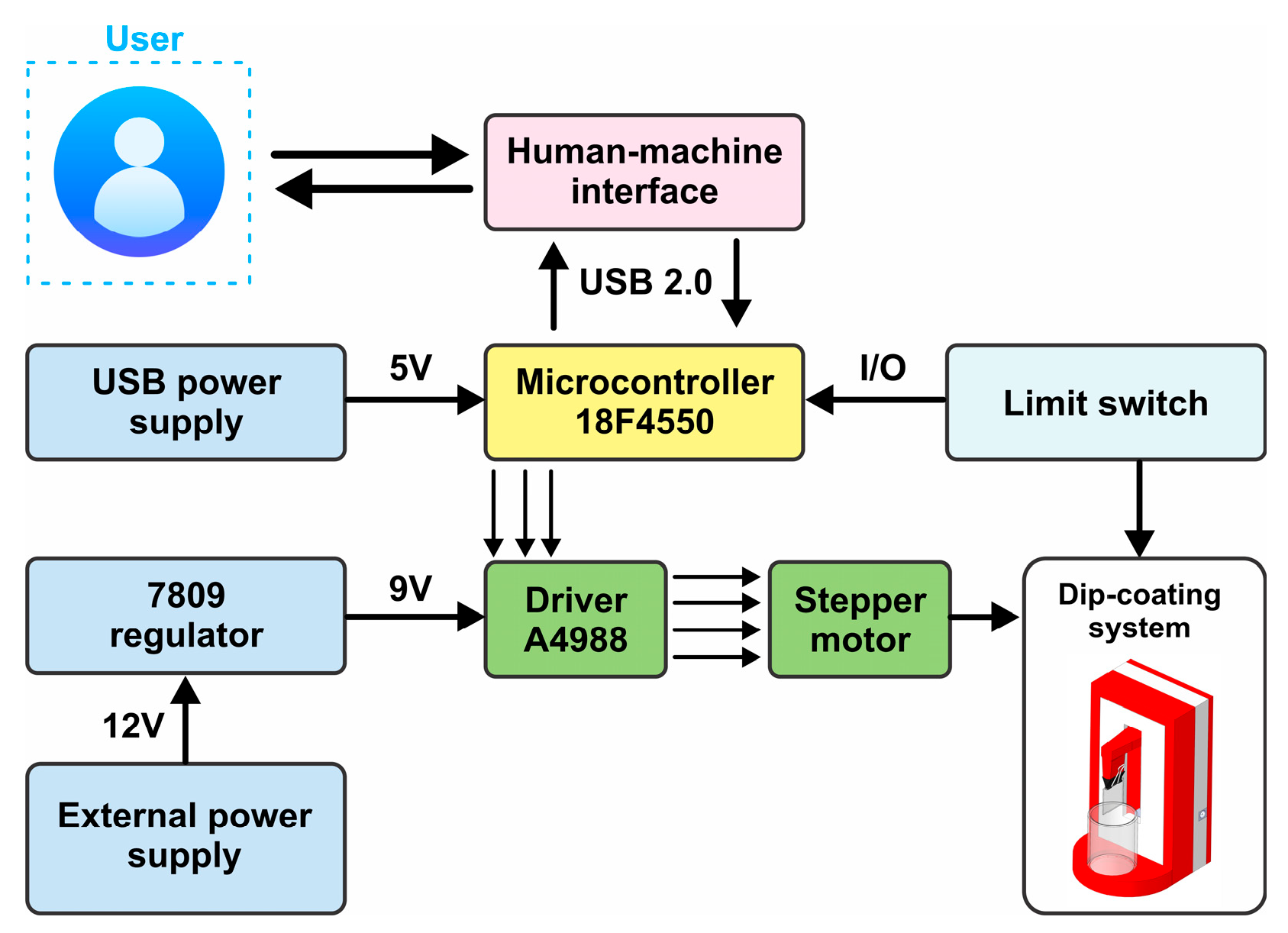

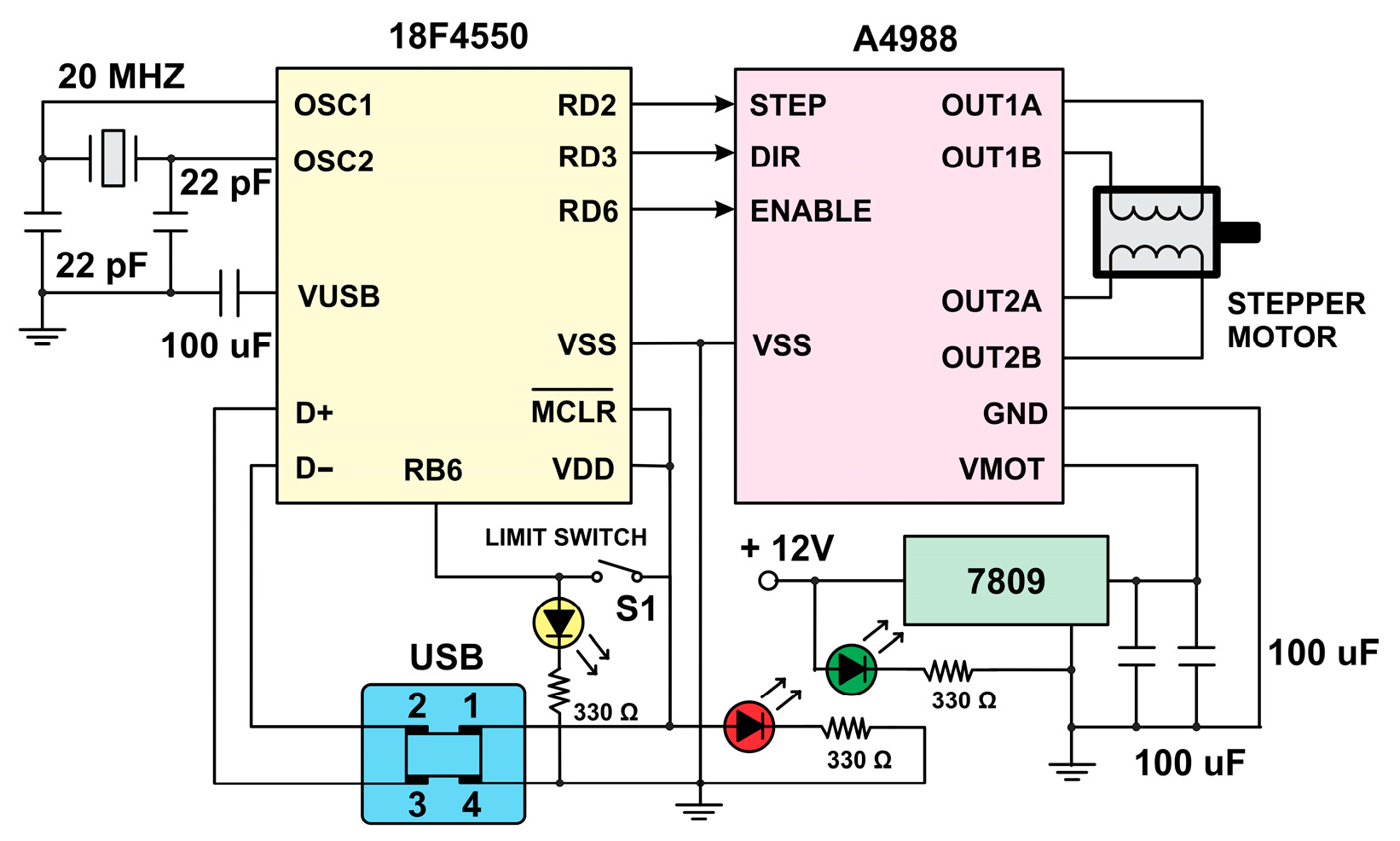

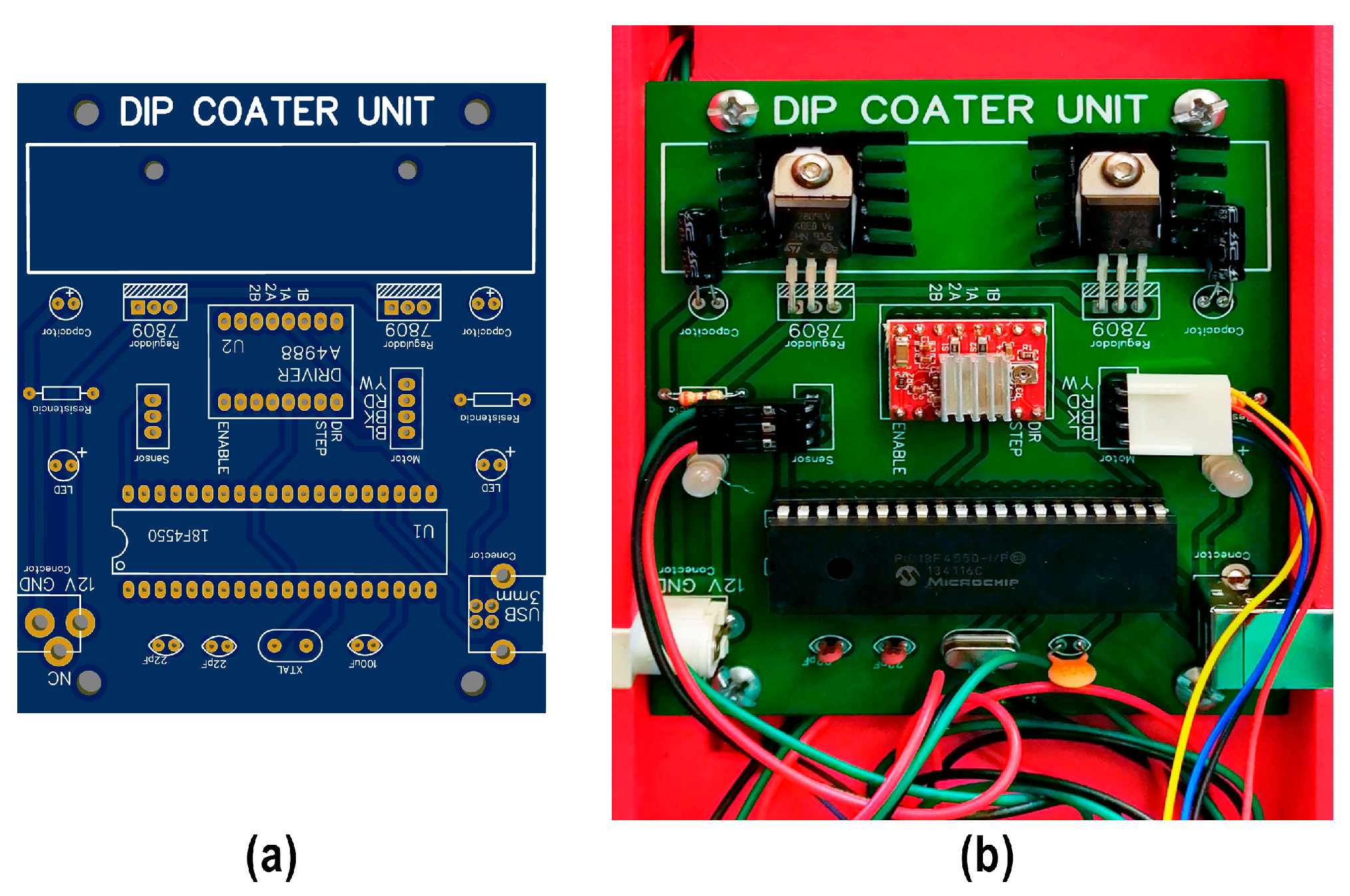

2.2. System Hardware

- Microcontroller: Serves as the central controller and USB 2.0 device. It receives set-points from the HMI (speed, depth, dwell), executes homing/limits logic, and generates step/direction/enable signals for the driver using timer-interrupt pulse trains. The PIC is powered from the USB 5 V rail and provides the digital I/O for the limit switch.

- Stepper driver: A chopper, current-regulated driver that translates the PIC’s step/direction commands into phase currents for the motor. Microstepping is configurable; the enable line is tied to the PIC for controlled start/stop. The driver is powered from a 9 V rail to reduce dissipation while maintaining torque margins.

- Stepper motor: Provides the linear actuation through the lead screw (described in Section 2.1). A shared signal ground is maintained between the driver and the microcontroller to ensure clean edge timing.

- Limit switch: A normally closed end-stop used for homing and travel protection. It is wired to a PIC digital input and monitored continuously; triggering halts pulse generation and initiates the homing routine.

- Power subsystem: Two isolated paths: (i) the USB 5 V line powers the PIC and the USB interface; (ii) an external 12 V supply feeds a 7809 linear regulator that provides a clean 9 V rail for the A4988. Bulk and local decoupling capacitors are placed near the driver and PIC; grounds are star-connected at the driver input to minimize noise coupling.

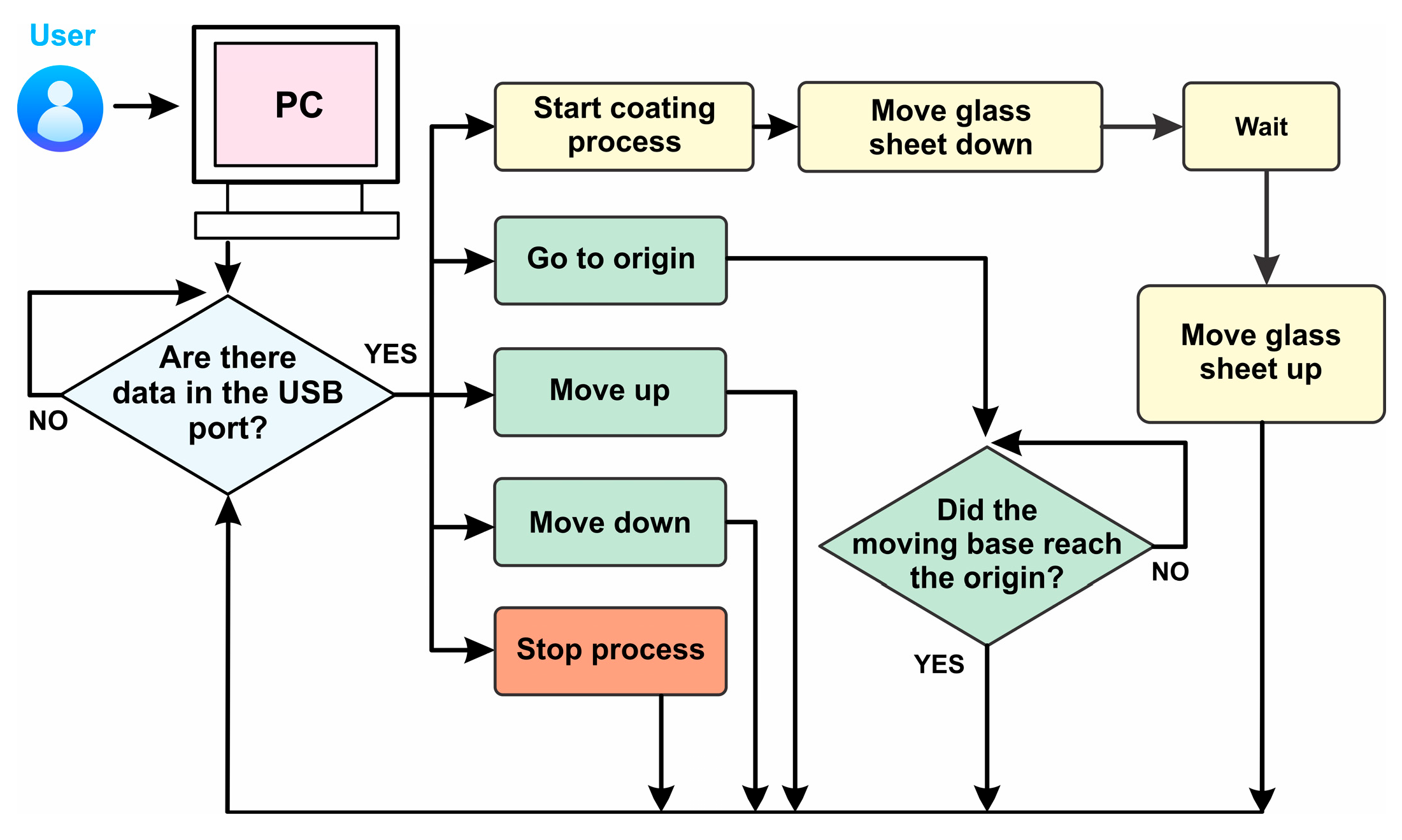

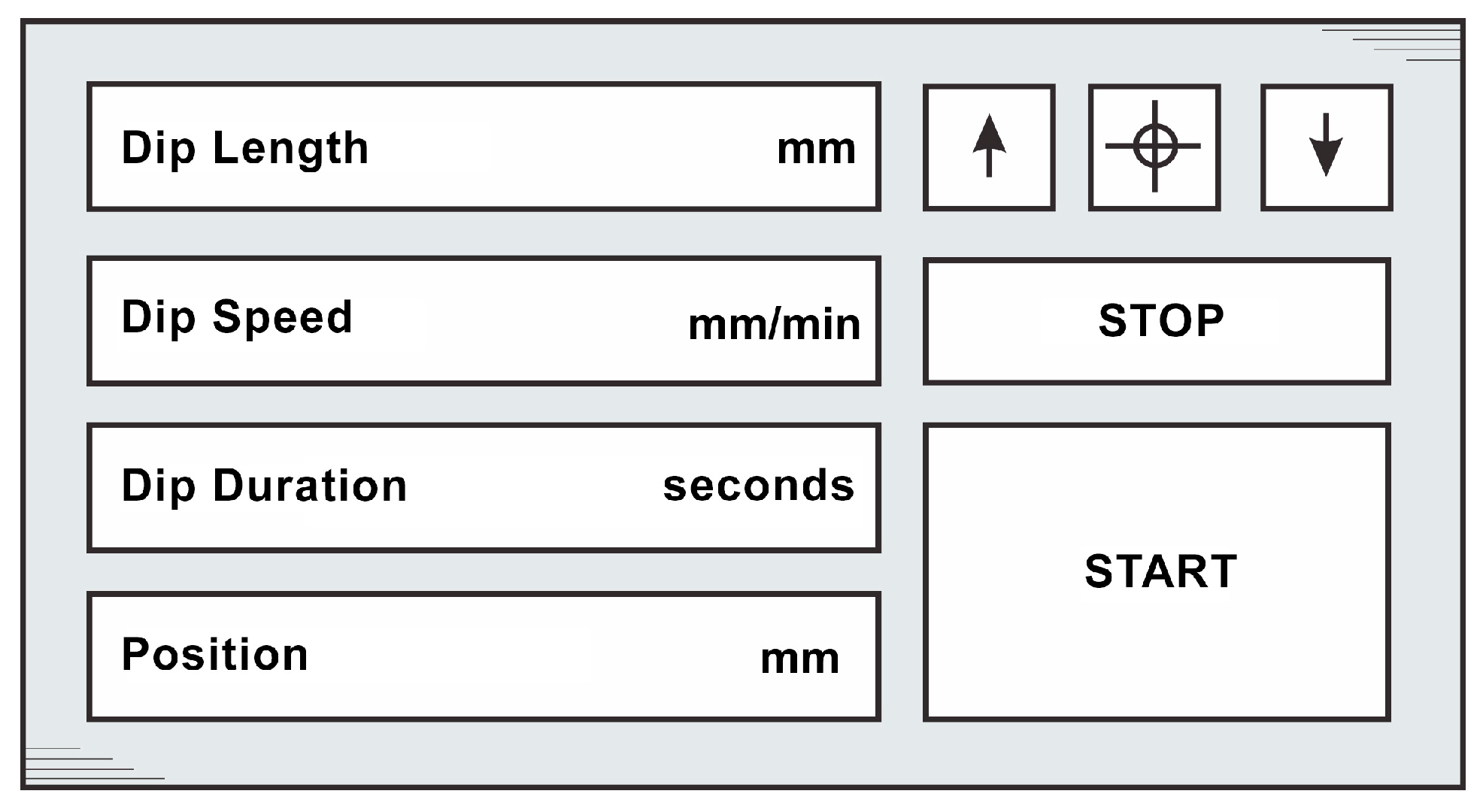

- HMI: Runs on a PC and exchanges commands/status with the PIC over USB 2.0. The HMI displays the current position and allows the user to start homing, set the stroke, cruise speed, acceleration time, and dwell, and execute the rise–dwell–fall trajectory.

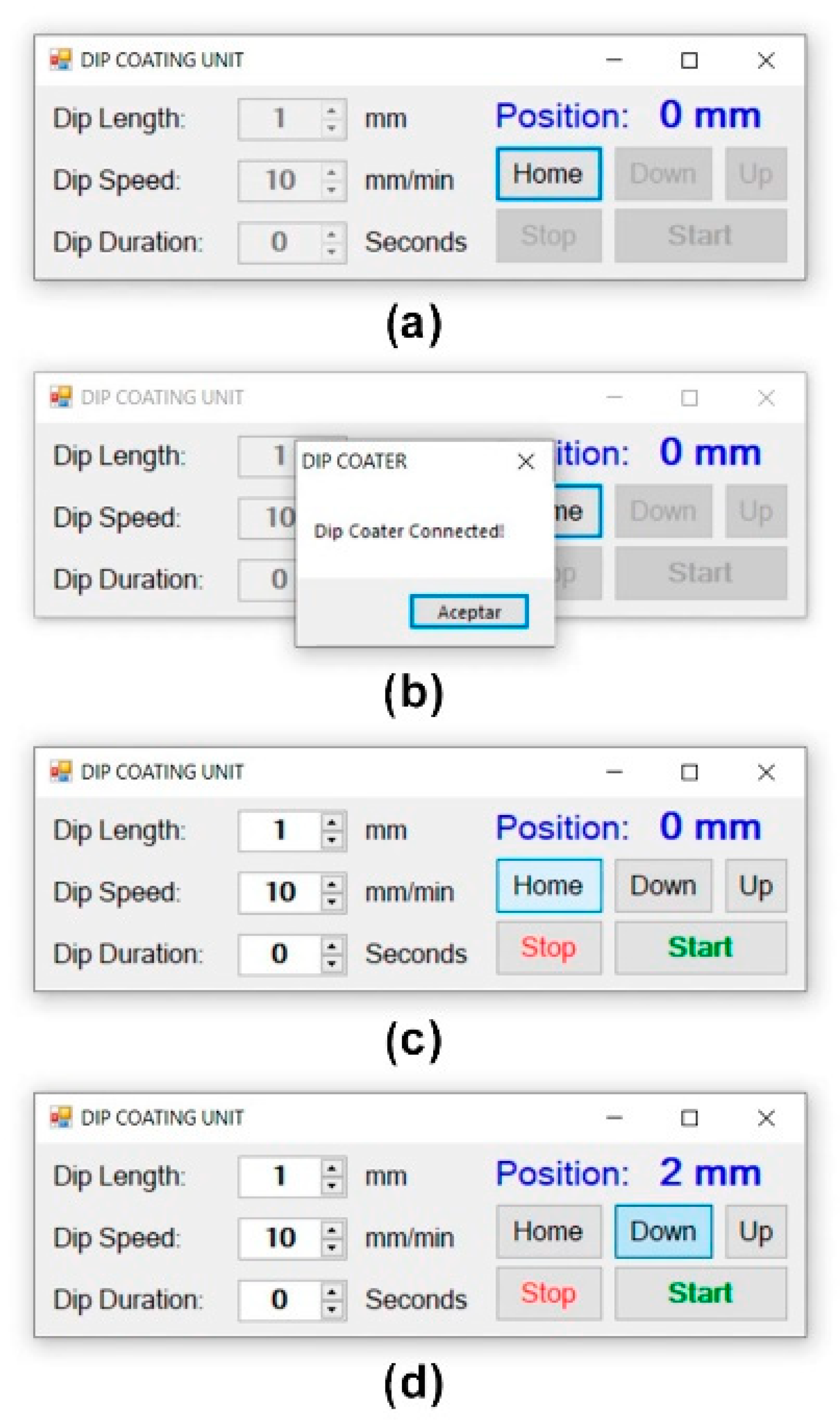

2.3. Human–Machine Interface

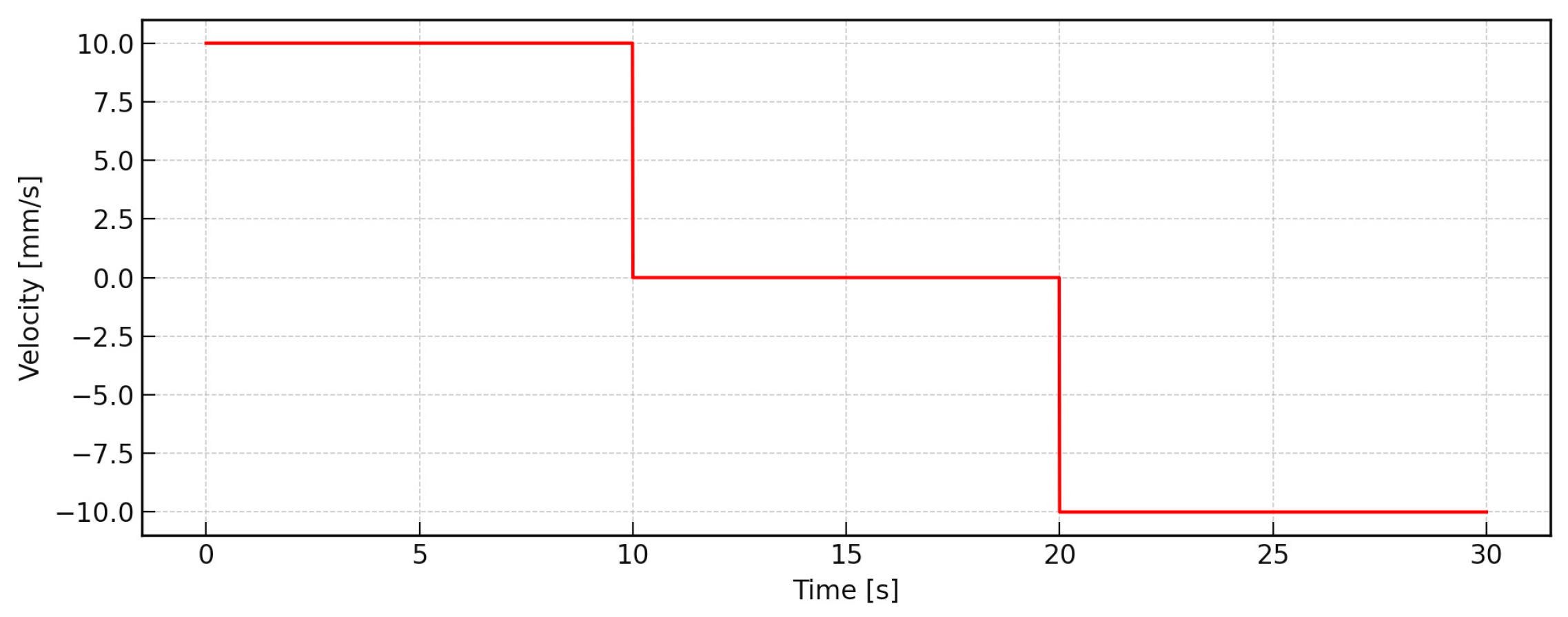

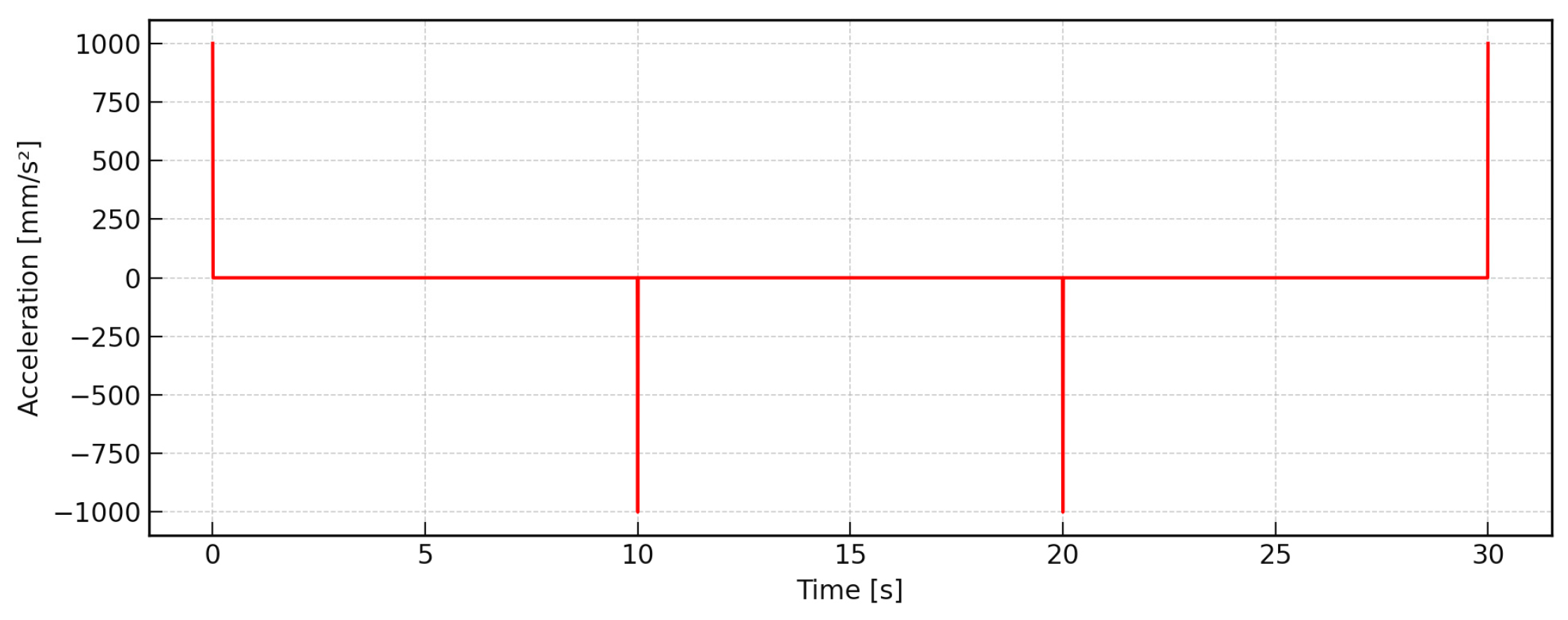

2.4. Control

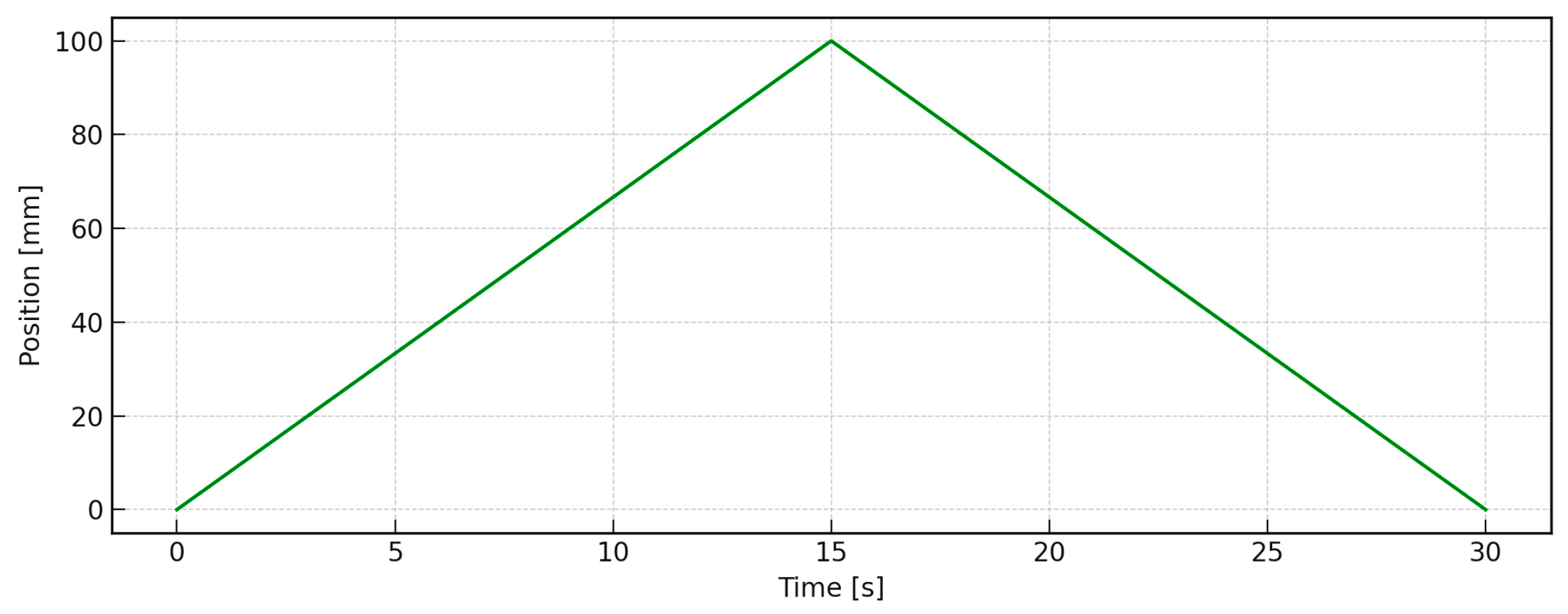

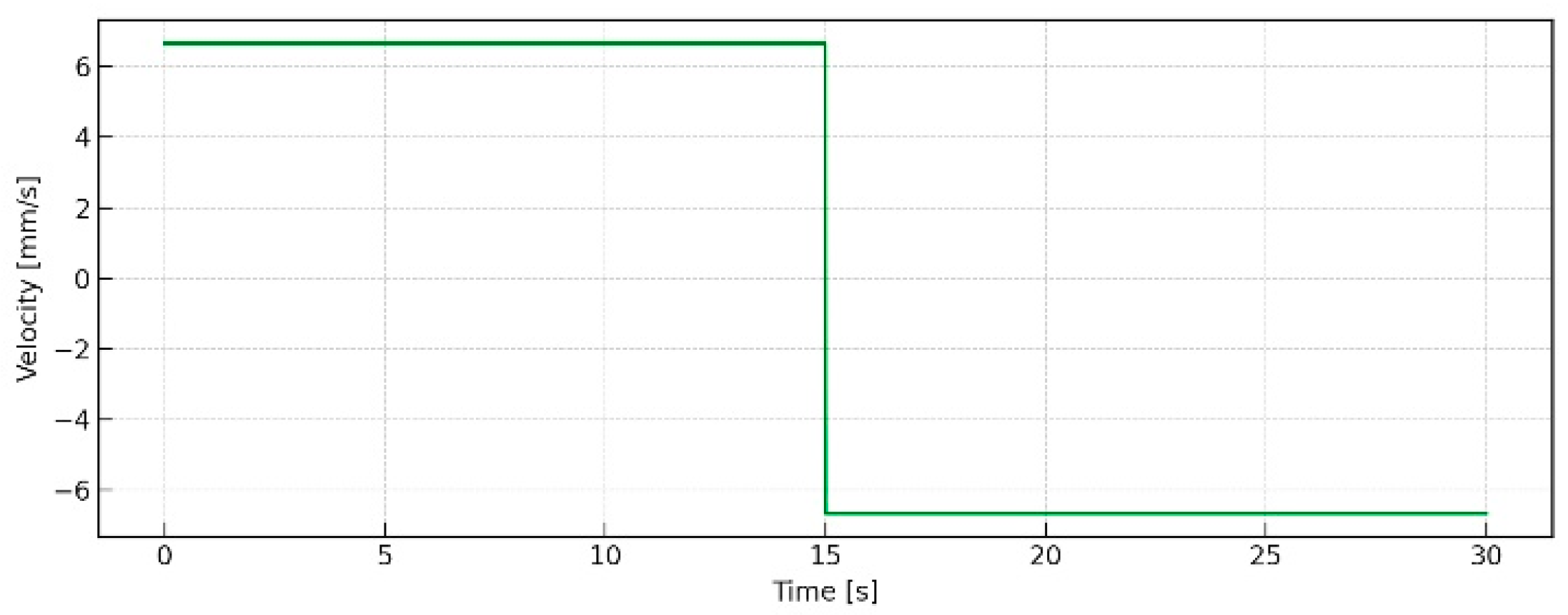

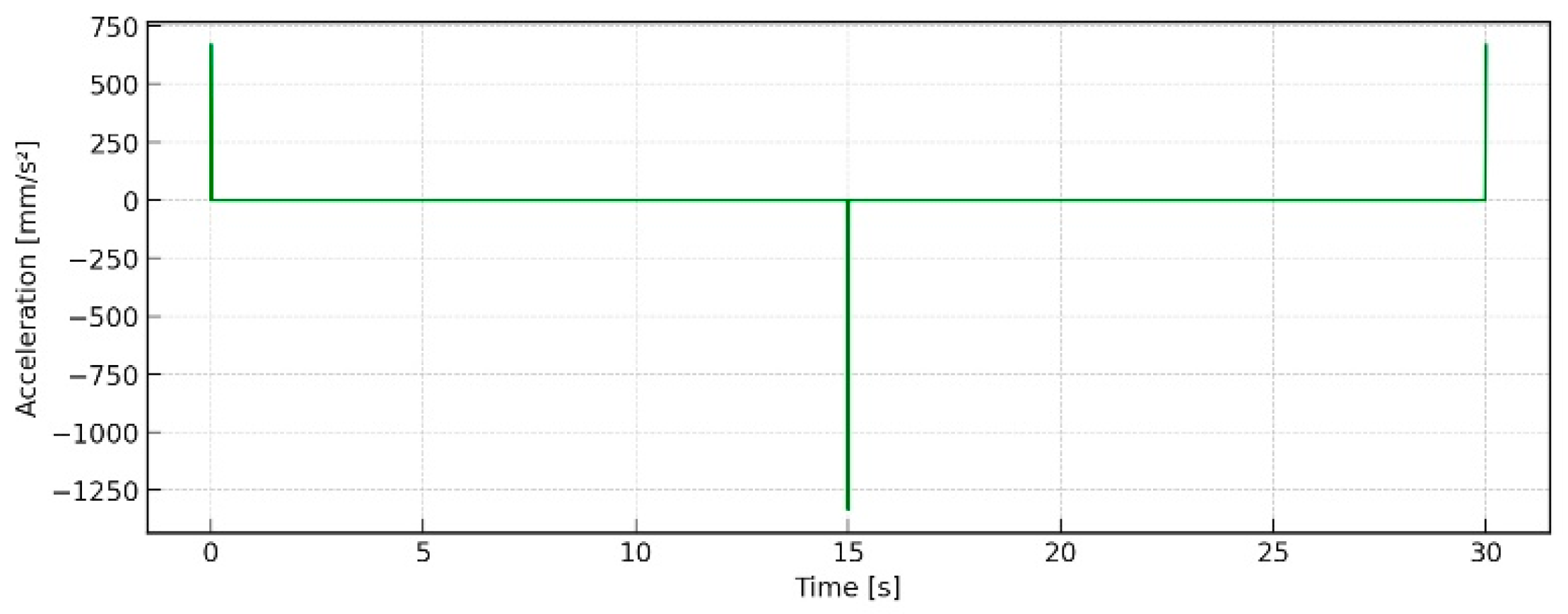

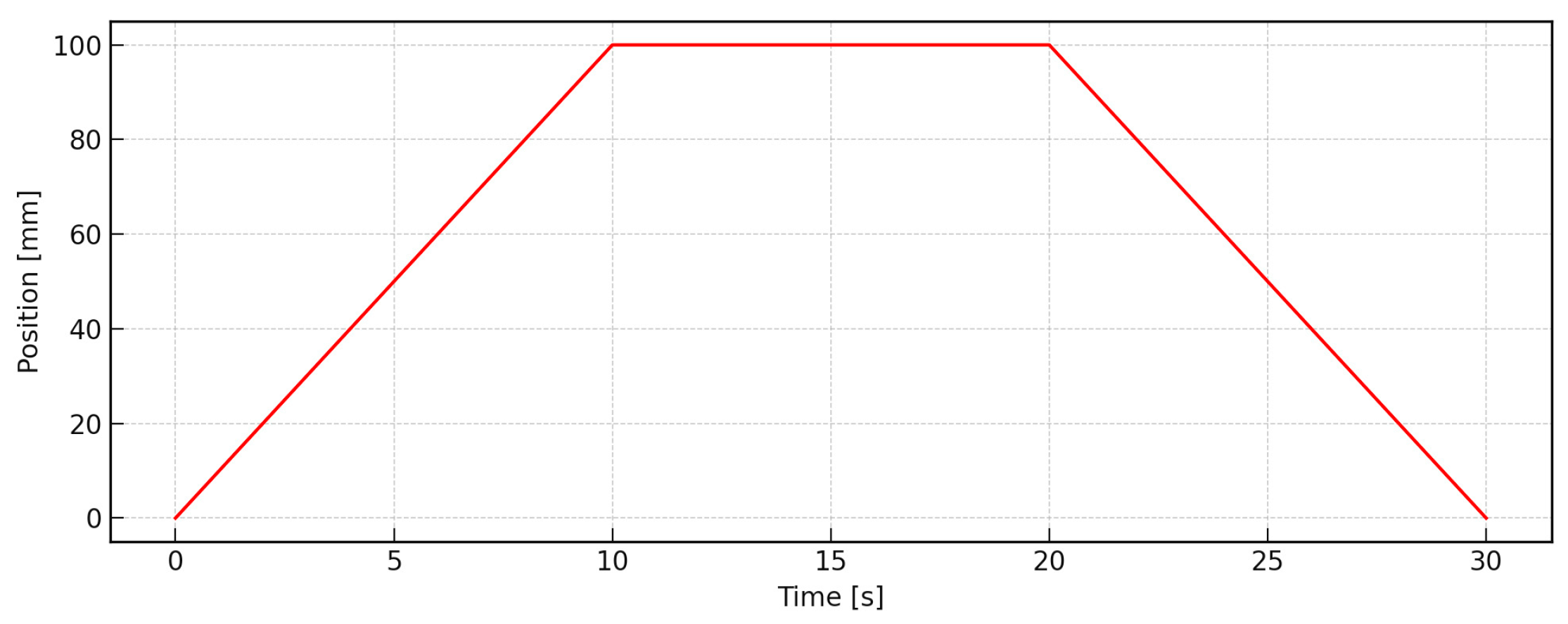

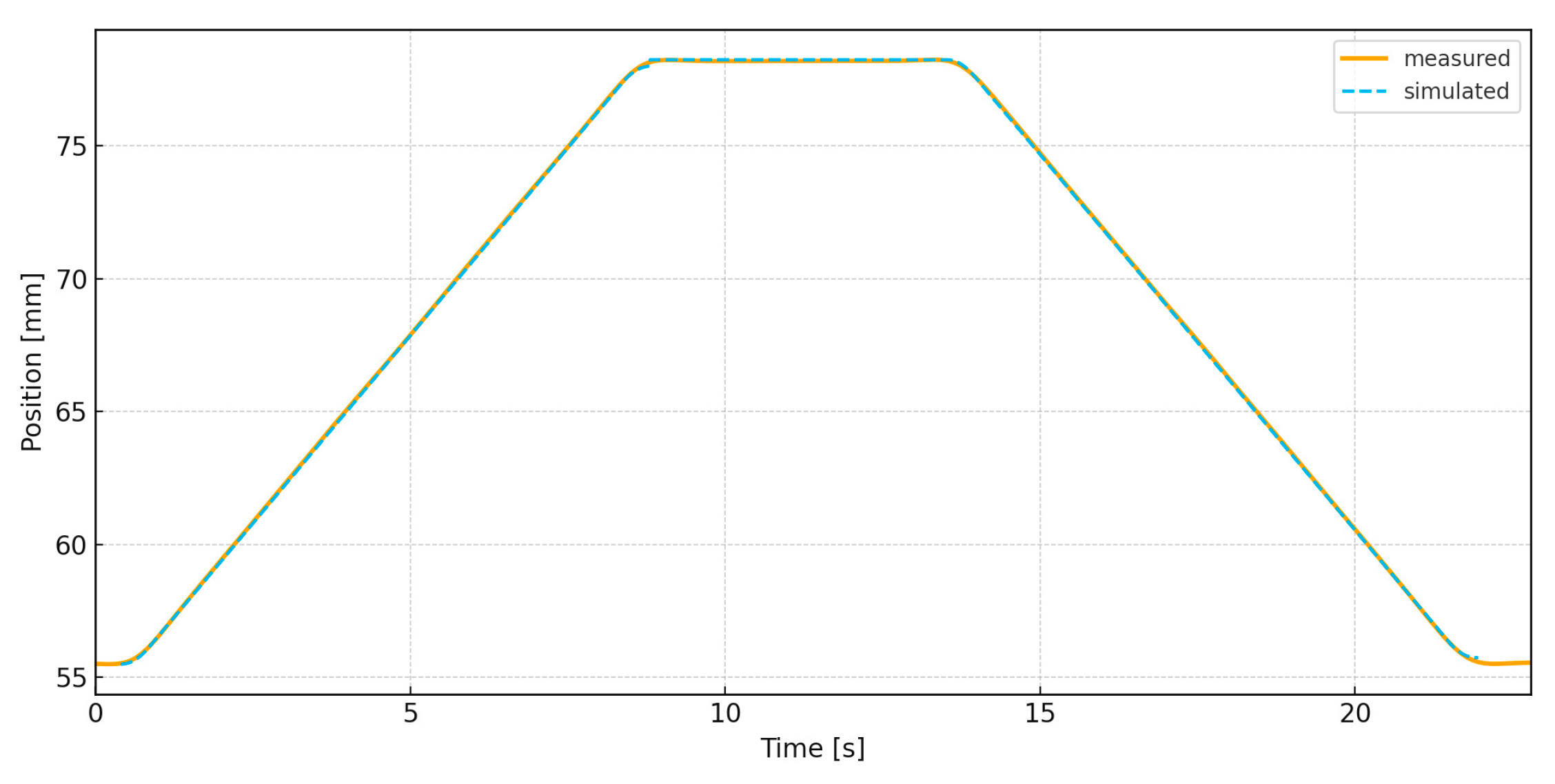

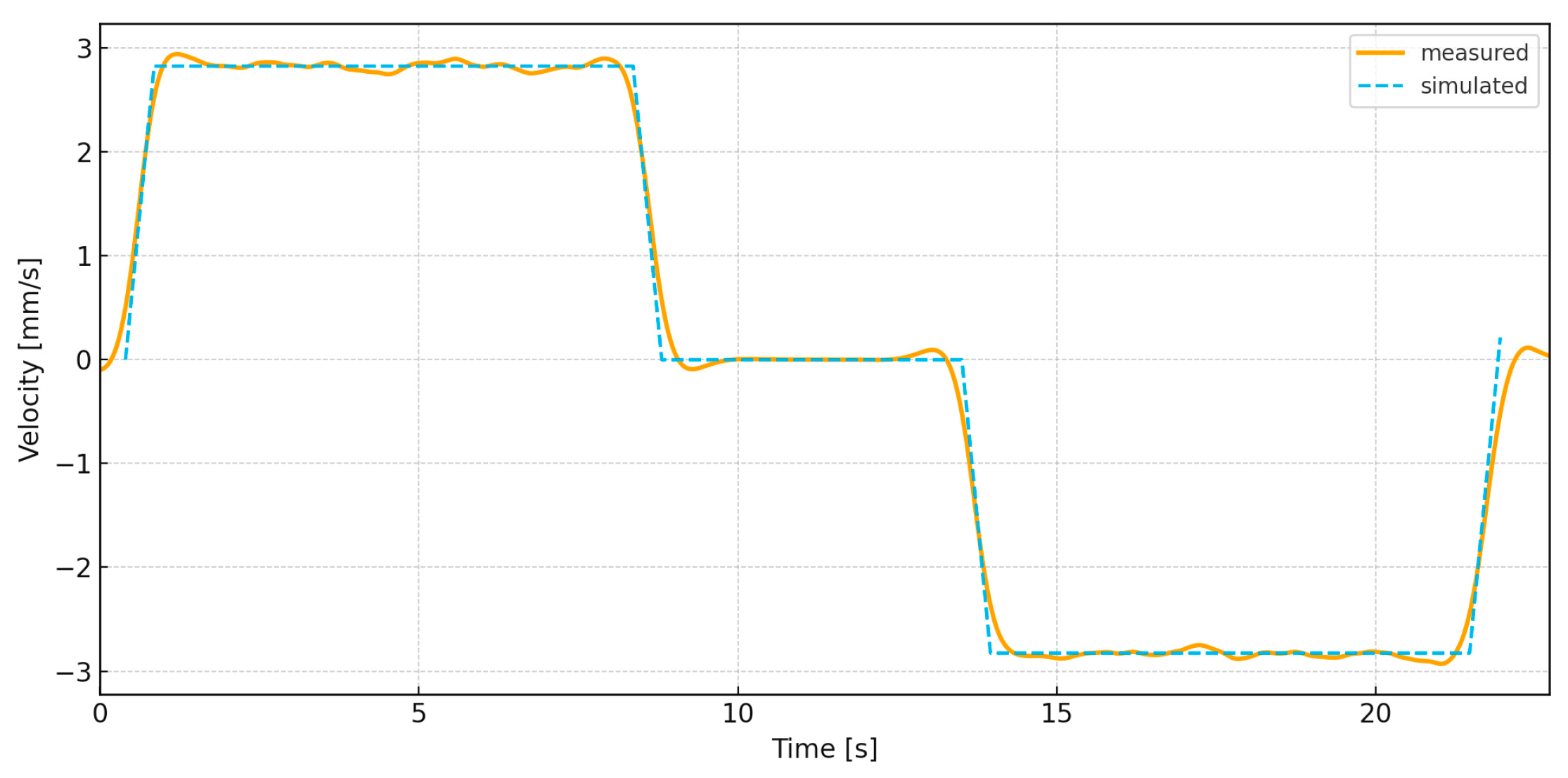

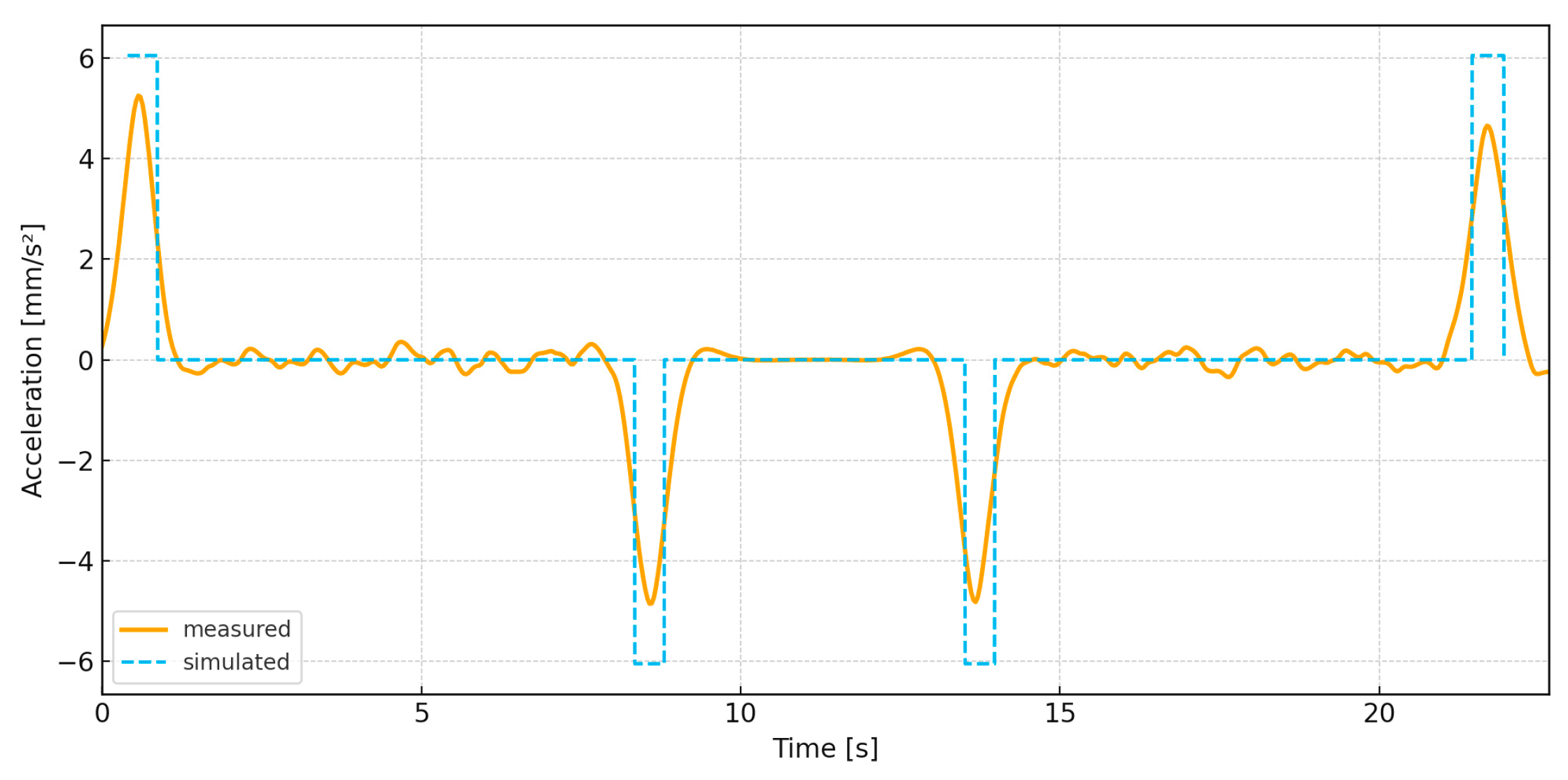

3. Simulation Results

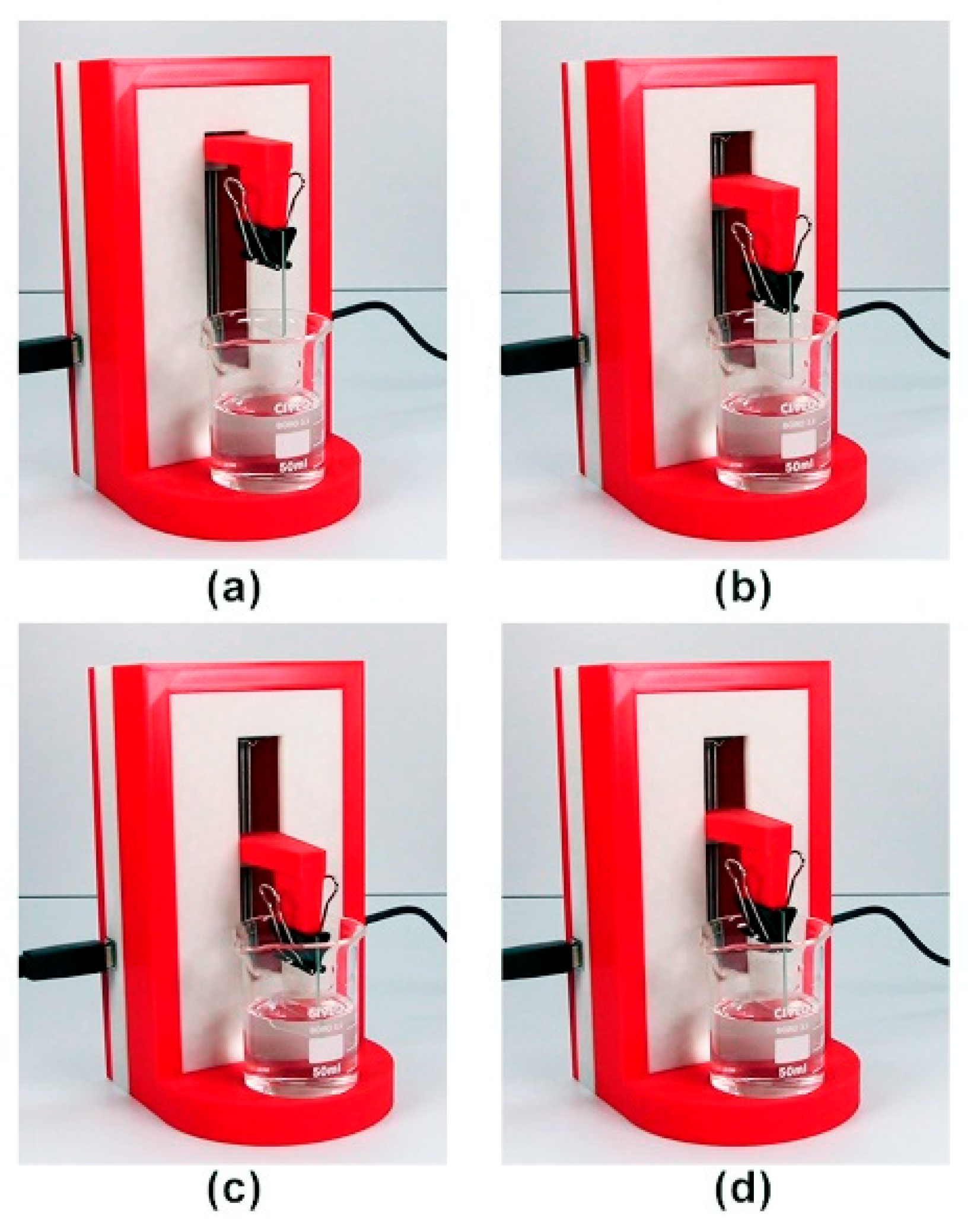

4. Experimental Results

4.1. GUI Operation and Functional Verification

4.2. Calibration and Error Analysis

4.3. Coating Performance Tests

4.4. Validation

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Shigrekar, M.; Amdoskar, V. A review on recent progress and techniques used for fabricating superhydrophobic coatings derived from biobased materials. RSC Adv. 2024, 14, 32668–32699. [Google Scholar] [CrossRef]

- Hossain, M.I.; Mansour, S. A critical overview of thin films coating technologies for energy applications. Cogent Eng. 2023, 10, 2179467. [Google Scholar] [CrossRef]

- Sathish, M.; Radhika, N.; Saleh, B. Current status, challenges, and future prospects of thin film coating techniques and coating structures. J. Bio-Tribo-Corros. 2023, 9, 35. [Google Scholar] [CrossRef]

- Qu, W.; Chen, Y.; Liu, S.; Luo, L. Advances and Prospects of Nanomaterial Coatings in Optical Fiber Sensors. Coatings 2025, 15, 1008. [Google Scholar] [CrossRef]

- Wu, L.; Yang, D.; Fei, L.; Huang, Y.; Wu, F.; Sun, Y.; Shi, J.; Xiang, Y. Dip-coating process engineering and performance optimization for three-state electrochromic devices. Nanoscale Res. Lett. 2017, 12, 390. [Google Scholar] [CrossRef]

- Landau, L.; Levich, B. Dragging of a liquid by a moving plate. In Dynamics of Curved Fronts; Elsevier: Amsterdam, The Netherlands, 1988; pp. 141–153. [Google Scholar]

- Crosley, M.S.; Yip, W.T. Kinetically doped silica sol–gel optical biosensors: Expanding potential through dip-coating. ACS Omega 2018, 3, 7971–7978. [Google Scholar] [CrossRef]

- Raut, H.K.; Ganesh, V.A.; Nair, A.S.; Ramakrishna, S. Anti-reflective coatings: A critical, in-depth review. Energy Environ. Sci. 2011, 4, 3779–3804. [Google Scholar] [CrossRef]

- Patil, S.L.; Sankapal, S.R.; Almuntaser, F.M. Dip coating: Simple way of coating thin films. In Simple Chemical Methods for Thin Film Deposition: Synthesis and Applications; Springer: Berlin/Heidelberg, Germany, 2023; pp. 425–447. [Google Scholar]

- Sarkar, A.K.; Sarmah, D.; Baruah, S.; Datta, P. An optimized dip coating approach for metallic, dielectric, and semiconducting nanomaterial-based optical thin film fabrication. Coatings 2023, 13, 1391. [Google Scholar] [CrossRef]

- Zhang, Z.; Salamatin, A.; Peng, F.; Kornev, K.G. Dip coating of cylinders with Newtonian fluids. J. Colloid Interface Sci. 2022, 607, 502–513. [Google Scholar] [CrossRef]

- Selvam, G.K.P.; de la Luz Olvera Amador, M.; Álvarez, A.M. Gas sensing capabilities of sol–gel dip-coated pure SnO2 thin films for CO and C3H8 detection. J. Mater. Sci. Mater. Electron. 2024, 35, 1621. [Google Scholar] [CrossRef]

- Adnan, M.; Lee, J.K. All sequential dip-coating processed perovskite layers from an aqueous lead precursor for high efficiency perovskite solar cells. Sci. Rep. 2018, 8, 2168. [Google Scholar] [CrossRef]

- Sutha, S.; Suresh, S.; Raj, B.; Ravi, K. Transparent alumina based superhydrophobic self–cleaning coatings for solar cell cover glass applications. Sol. Energy Mater. Sol. Cells 2017, 165, 128–137. [Google Scholar] [CrossRef]

- Huang, Y.-Y.; Chou, K.-S. Studies on the spin coating process of silica films. Ceram. Int. 2003, 29, 485–493. [Google Scholar] [CrossRef]

- Shahzadi, P.; Gilani, S.R.; Rana, B.B.; Ghaffar, A.; Munir, A. Transparent, self-cleaning, scratch resistance and environment friendly coatings for glass substrate and their potential applications in outdoor and automobile industry. Sci. Rep. 2021, 11, 20743. [Google Scholar] [CrossRef] [PubMed]

- Tudu, B.K.; Sinhamahapatra, A.; Kumar, A. Surface modification of cotton fabric using TiO2 nanoparticles for self-cleaning, oil–water separation, antistain, anti-water absorption, and antibacterial properties. ACS Omega 2020, 5, 7850–7860. [Google Scholar] [CrossRef]

- Li, Z.; Li, C.; Ou, J.; Fang, X.; Cong, M.; Wang, C.; Mao, F.; Mao, T.; Amirfazli, A. Water and mildew proof SiO2 & ZnO/silica sol superhydrophobic composite coating on a circuit board. RSC Adv. 2021, 11, 21862–21869. [Google Scholar]

- Butt, M.; Kaźmierczak, A.; Tyszkiewicz, C.; Karasiński, P.; Piramidowicz, R. Recent Advances in the Realization of a Low-Cost Integrated Photonic Platform Developed via a Sol-gel Dip-Coating Method. In Proceedings of the Solar Energy Industries Association (SEIA) 2022, Anaheim, CA, USA, 19–22 September 2022; Volume 45. [Google Scholar]

- Maharjan, S.; Liao, K.-S.; Wang, A.J.; Curran, S.A. Highly effective hydrophobic solar reflective coating for building materials: Increasing total solar reflectance via functionalized anatase immobilization in an organosiloxane matrix. Constr. Build. Mater. 2020, 243, 118189. [Google Scholar] [CrossRef]

- Touam, T.; Atoui, M.; Hadjoub, I.; Chelouche, A.; Boudine, B.; Fischer, A.; Boudrioua, A.; Doghmane, A. Effects of dip-coating speed and annealing temperature on structural, morphological and optical properties of sol-gel nano-structured TiO2 thin films. Eur. Phys. J. Appl. Phys. 2014, 67, 30302. [Google Scholar] [CrossRef]

- Dabirian, R.; Guerrero, V.H.; Matovelle, D.C.L.; Segura, L.J. Mechanical and electronic systems of an open source based spin and dip coater. Rev. Politécnica 2016, 37, 53. [Google Scholar]

- Adámek, P. Construction of dip-coater. Eduk.-Tech.-Inform. 2016, 7, 152–156. [Google Scholar] [CrossRef]

- Yohandri, Y.; Khairunnisa, K.; Ramli, R.; Zainul, R. Development of a Digital Dip Coating System Based Microcontroller. Eksakta Berk. Ilm. Bid. MIPA 2019, 20, 62–69. [Google Scholar] [CrossRef]

- Ramírez, I.E.M.; Miranda, L.E.A.; Díaz, F.R.; Loera, A.R. Diseño y fabricación de un aparato para el depósito de películas delgadas por el método de rotación. Investig. Y Cienc. Univ. Autónoma Aguascalientes 2009, 17, 44–49. [Google Scholar]

- Yepuri, V.; Addala, S. Construction of Economical Dip-Coater for the Fabrication of Hydrophobic Coatings. Kuwait J. Sc. 2023, 50, 1–8. [Google Scholar] [CrossRef]

- Bulut, F.; Günel, E. Design of New Generation Low-Cost Dip Coating Device and Performance Tests in ZnO Thin Film Production. Sak. Univ. J. Sci. 2024, 28, 1307–1314. [Google Scholar] [CrossRef]

- Rahman, N.R.; Syaâ, I.; Hartanto, A.; Prasetyono, A.D.; Subiantoro, I. Design and build a microcontroller based dip coater tool with an automatic calibration system. Indones. Phys. Rev. 2025, 8, 48–61. [Google Scholar] [CrossRef]

- Bedoya, L.A.F.; Joaqui, L.E.M.; Muñoz, B.C.; Dorantes, R.J.; Castro, S.O.; Gaviria, A.R. Implementation of an automated film deposition equipment under the sol/gel Dip-coating technique. Ing. Y Univ. 2022, 26, 1. [Google Scholar]

- Rauh, F.; Bienek, O.; Sharp, I.; Stutzmann, M. Conversion of a 3D printer for versatile automation of dip coating processes. Rev. Sci. Instrum. 2023, 94, 083901. [Google Scholar] [CrossRef]

- Dunlap, C.; Featherstone, S.; Smith, M.; Vu, M.; Williams, A.; Bailey, J.; Hu, H. Design and fabrication of a low-cost and programmable dip coating machine. HardwareX 2022, 12, e00364. [Google Scholar] [CrossRef] [PubMed]

- Pérez, J.S.; Chávez, I.P.; González, M.A.C.; Pérez, O.S.; Pacheco, J. Dip-coater revolver machine for layer processing on metallic substrates. Pädi Boletín Científico Cienc. Básicas E Ing. Del ICBI 2023, 11, 109–116. [Google Scholar] [CrossRef]

- Ospina-Calderón, J.A.; Lota-Mendoza, C.A.; Betin-Bohórquez, B.S.; García-Gómez, C.A.; Rincón-Ortiz, R.J.; Llamosa-Pérez, D. Diseño y construcción de una máquina Dip Coater para la obtención de recubrimientos de SiO2 mediante la técnica sol-gel. Rev. Ontare 2020, 7, 72–96. [Google Scholar] [CrossRef]

- Castillo-Vilcatoma, D.A.; Loarte, S.J.; Fernandez-Chillcce, A.A.; Pastrana, E.C.; Pastrana, R.Y. Designing and fabrication of a low-cost dip-coater for rapid production of uniform thin films. Quim. Nova 2022, 45, 97–100. [Google Scholar] [CrossRef]

- Wenzel, T. Open hardware: From DIY trend to global transformation in access to laboratory equipment. PLoS Biol. 2023, 21, e3001931. [Google Scholar] [CrossRef]

- Oberloier, S.; Pearce, J.M. General design procedure for free and open-source hardware for scientific equipment. Designs 2017, 2, 2. [Google Scholar] [CrossRef]

- Pearce, J.M. Building research equipment with free, open-source hardware. Science 2012, 337, 1303–1304. [Google Scholar] [CrossRef]

- Baden, T.; Chagas, A.M.; Gage, G.; Marzullo, T.; Prieto-Godino, L.L.; Euler, T. Open Labware: 3-D printing your own lab equipment. PLoS Biol. 2015, 13, e1002086. [Google Scholar] [CrossRef]

- Maia Chagas, A. Haves and have nots must find a better way: The case for open scientific hardware. PLoS Biol. 2018, 16, e3000014. [Google Scholar] [CrossRef]

- Hnatiuk, M.; Kimball, D.; Kolanthai, E.; Neal, C.J.; Kumar, U.; Sakthivel, T.S.; Seal, S. High-throughput and versatile design for multi-layer coating deposition using lab automation through Arduino-controlled devices. Rev. Sci. Instrum. 2021, 92, 084105. [Google Scholar] [CrossRef] [PubMed]

- Llorente-García, B.E.; Hernández-López, J.M.; Zaldívar-Cadena, A.A.; Siligardi, C.; Cedillo-González, E.I. First insights into photocatalytic degradation of HDPE and LDPE microplastics by a mesoporous N–TiO2 coating: Effect of size and shape of microplastics. Coatings 2020, 10, 658. [Google Scholar] [CrossRef]

- Vital-Grappin, A.D.; Ariza-Tarazona, M.C.; Sandoval, I.; Rojas-Guerrero, C.A.; Villarreal-Chiu, J.F.; Cedillo-González, E.I. Design of Green TiO2-Based Semiconductors for Microplastic and Nanoplastic Photocatalytic Degradation. Preprints 2023, 2023010544. [Google Scholar]

| Reference | Control Architecture | Key Features |

|---|---|---|

| Dabirian et al. [22] | Arduino + DC motor | Combined spin/dip coater; programmable cycles |

| Yepuri & Addala [26] | Arduino + linear actuator | Hydrophobic TiO2 coatings; flame resistant |

| Bulut & Günel [27] | Arduino + stepper motor | Heating control; ZnO coatings |

| Rahman et al. [28] | Microcontroller + calibration algorithm | Auto-calibration, low error (<2%) |

| Bedoya et al. [29] | Arduino + PWM control | Stainless-steel frame; sol–gel coatings |

| Rauh et al. [30] | 3D printer (Ender-3) firmware | Multi-sample automation; high throughput |

| Adámek [23] | PC + stepper driver | Educational setup; 3D-printed parts |

| Dunlap et al. [31] | Arduino + touchscreen GUI | Smartphone control; dust enclosure |

| Pérez et al. [32] | Arduino + PID control | Revolver-type multilayer dip-coater |

| Ospina-Calderón et al. [33] | Arduino Mega + HMI | SiO2 sol–gel coatings; tunable parameters |

| Castillo-Vilcatoma et al. [34] | Arduino + recycled materials | Eco-friendly build; ZnO and oxide films |

| This work | PIC18F4550 + PC-hosted GUI (USB) | Hybrid 3D-printed/aluminum design; USB control; modular, programmable automation |

| Component | Cost (USD) |

|---|---|

| PLA | 10 |

| Stepper motor | 10 |

| Microcontroller | 10 |

| PCB | 10 |

| Electronic components | 10 |

| Total | 50 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guzmán-Valdivia, C.H.; Azcaray-Rivera, H.R.; Martínez-Mata, A.J.; Brizuela-Mendoza, J.A.; Buenabad-Arias, H.M.; Barrera-Sánchez, A.; Blanco-Ortega, A. Design and Validation of a Low-Cost Automated Dip-Coater System for Laboratory Applications. Automation 2025, 6, 75. https://doi.org/10.3390/automation6040075

Guzmán-Valdivia CH, Azcaray-Rivera HR, Martínez-Mata AJ, Brizuela-Mendoza JA, Buenabad-Arias HM, Barrera-Sánchez A, Blanco-Ortega A. Design and Validation of a Low-Cost Automated Dip-Coater System for Laboratory Applications. Automation. 2025; 6(4):75. https://doi.org/10.3390/automation6040075

Chicago/Turabian StyleGuzmán-Valdivia, Cesar H., Héctor R. Azcaray-Rivera, Arturo J. Martínez-Mata, Jorge A. Brizuela-Mendoza, Héctor M. Buenabad-Arias, Agustín Barrera-Sánchez, and Andrés Blanco-Ortega. 2025. "Design and Validation of a Low-Cost Automated Dip-Coater System for Laboratory Applications" Automation 6, no. 4: 75. https://doi.org/10.3390/automation6040075

APA StyleGuzmán-Valdivia, C. H., Azcaray-Rivera, H. R., Martínez-Mata, A. J., Brizuela-Mendoza, J. A., Buenabad-Arias, H. M., Barrera-Sánchez, A., & Blanco-Ortega, A. (2025). Design and Validation of a Low-Cost Automated Dip-Coater System for Laboratory Applications. Automation, 6(4), 75. https://doi.org/10.3390/automation6040075