An AI-Enabled System for Automated Plant Detection and Site-Specific Fertilizer Application for Cotton Crops

Abstract

1. Introduction

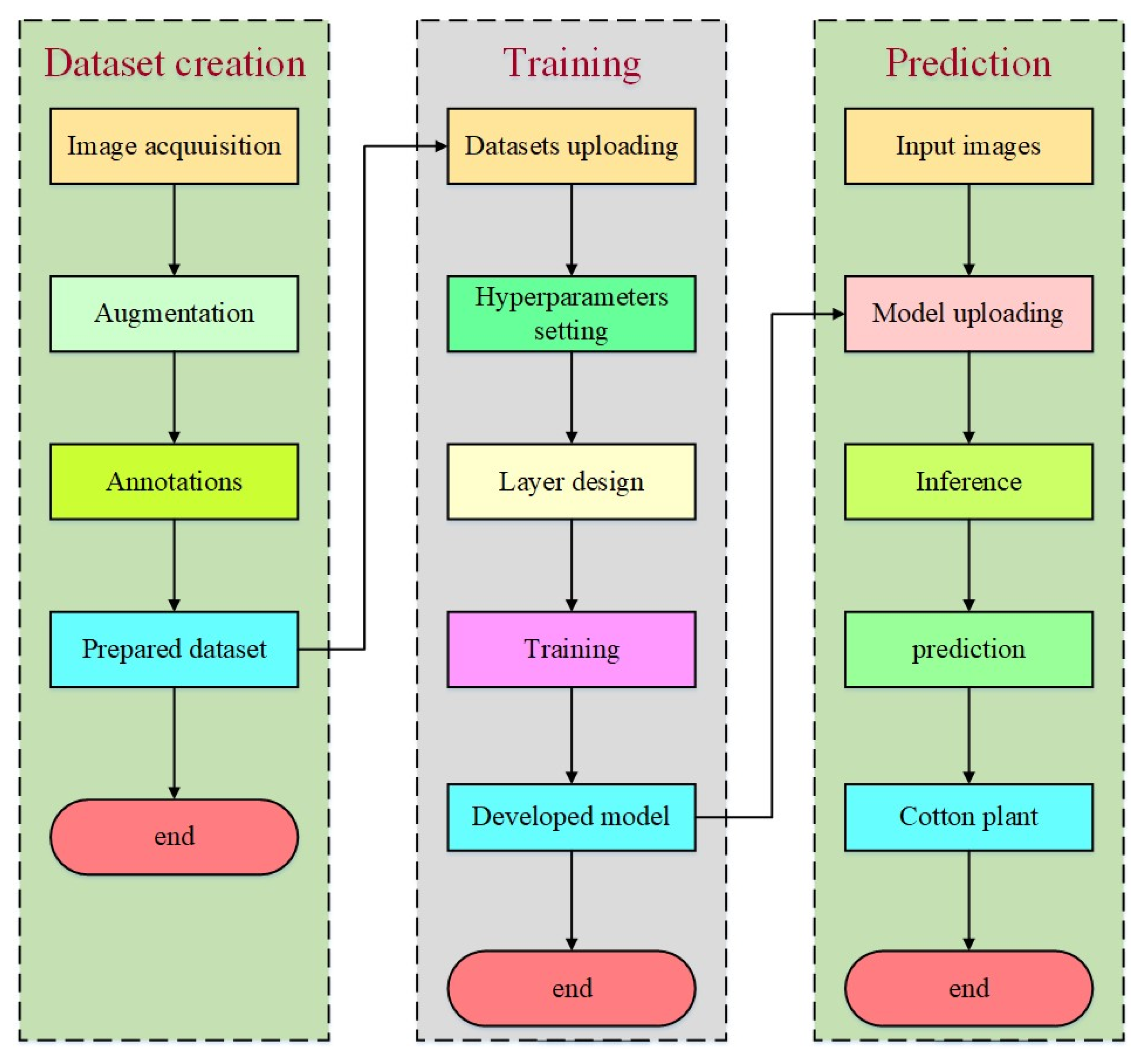

2. Materials and Methods

2.1. Plant Recognition Unit

2.1.1. The AI-Computer Vision Model for Plant Recognition

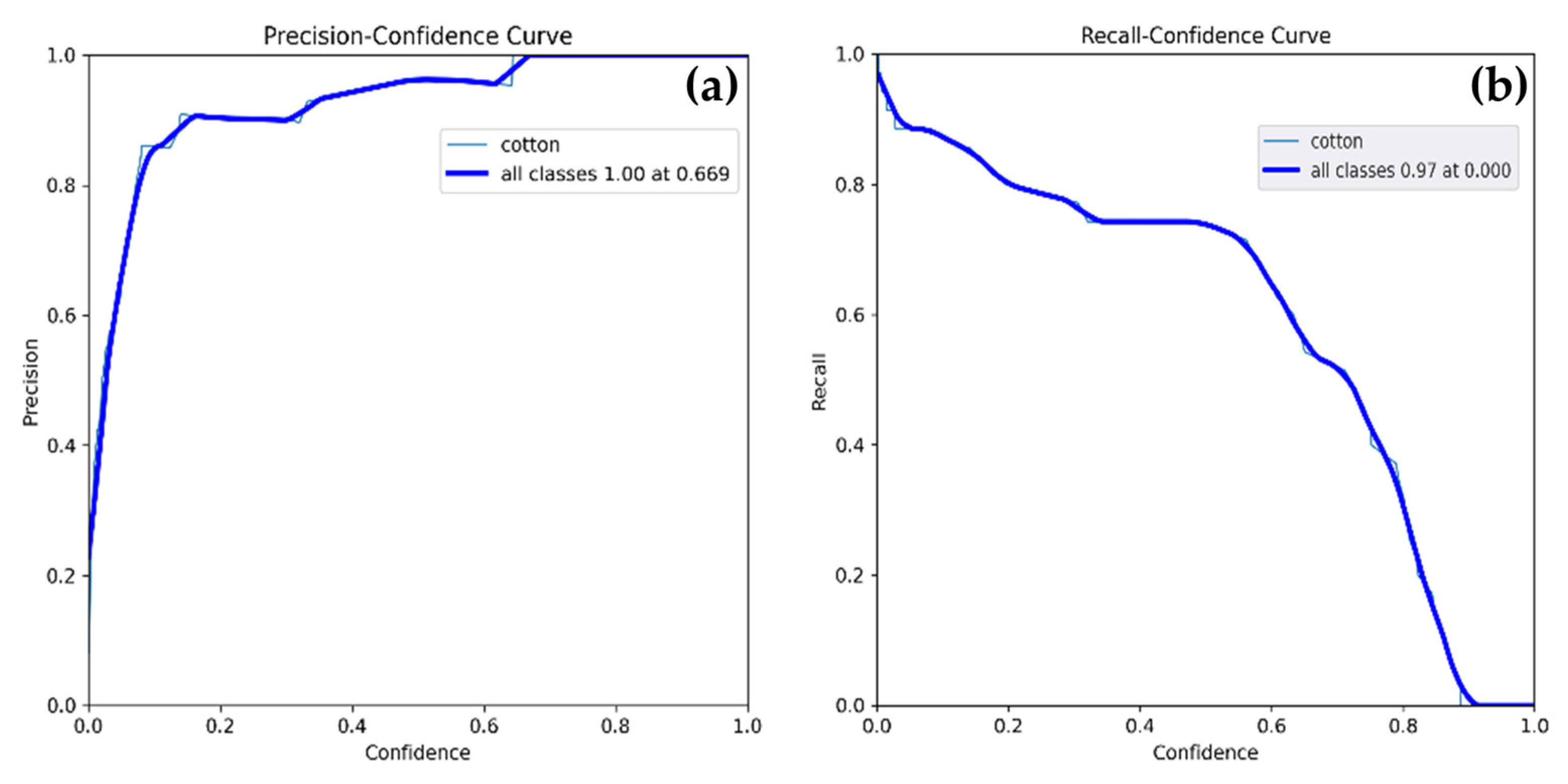

2.1.2. Performance Evaluation of the Plant Recognition Model

2.1.3. Model Training

2.2. Electronic Control Unit

2.3. Fertilizer Metering Unit

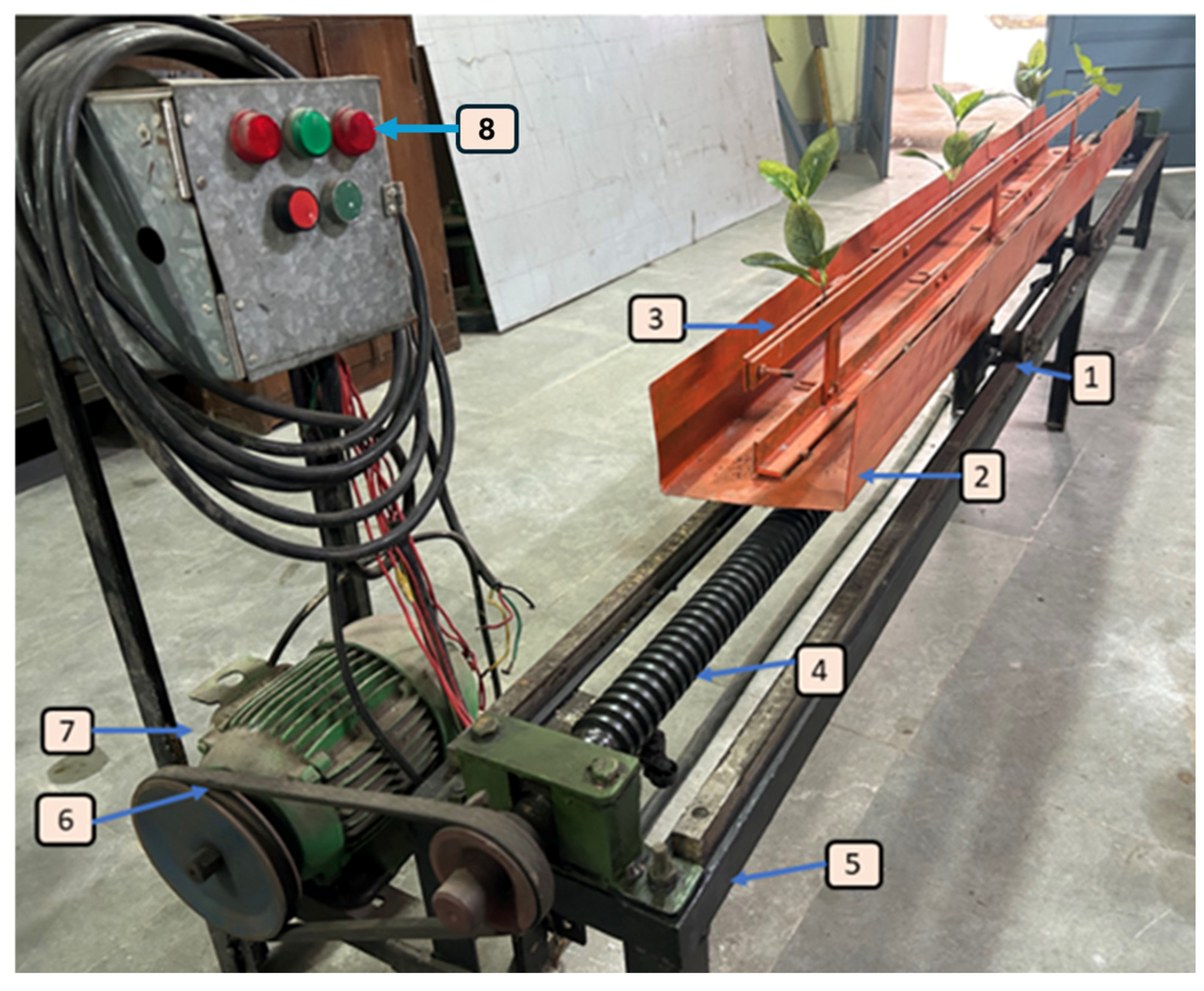

2.4. Prototype Evaluation Testbed

2.5. Prototype Assembly and Performance Evaluation

3. Results and Discussion

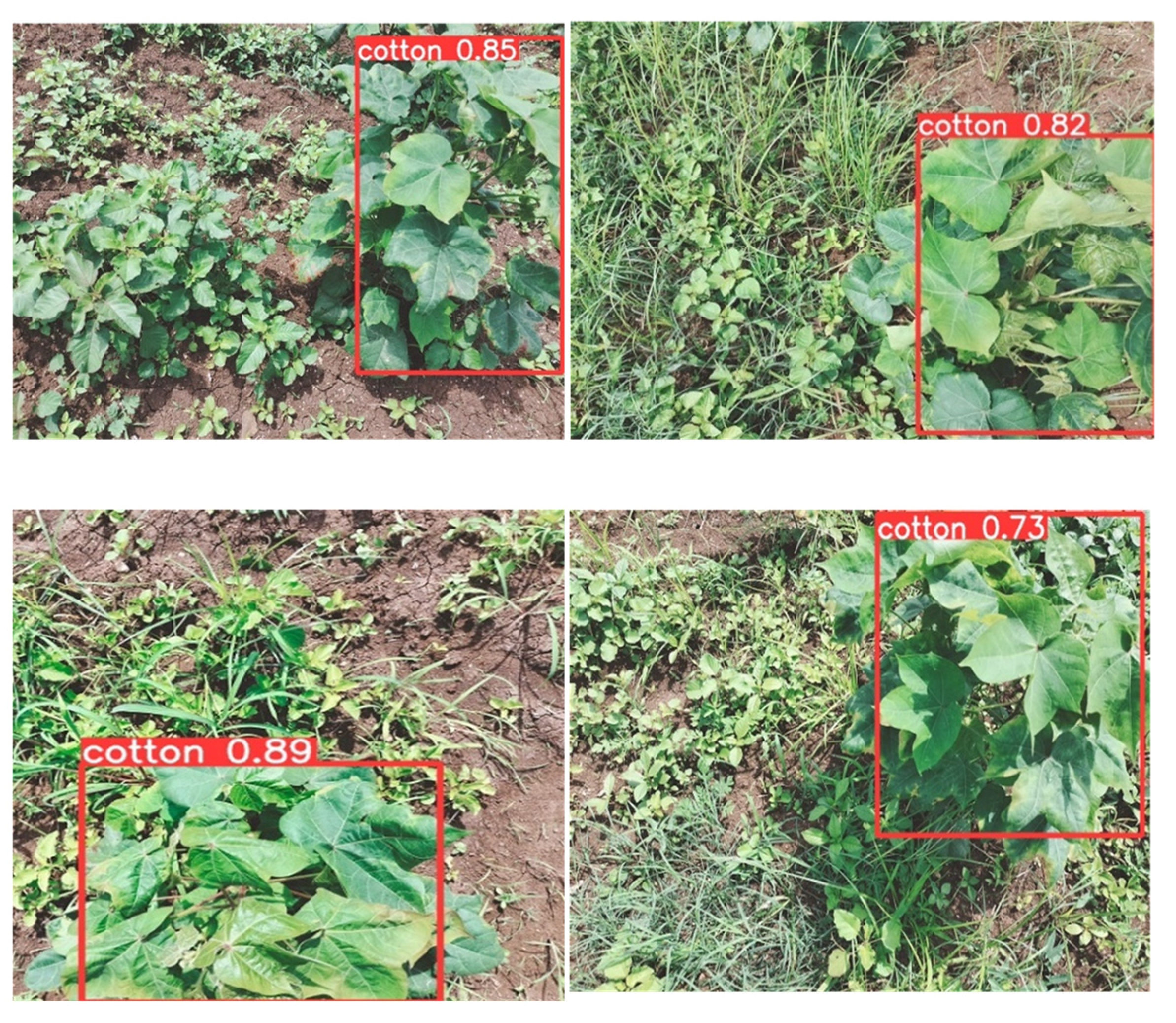

3.1. Performance of Plant Recognition Model

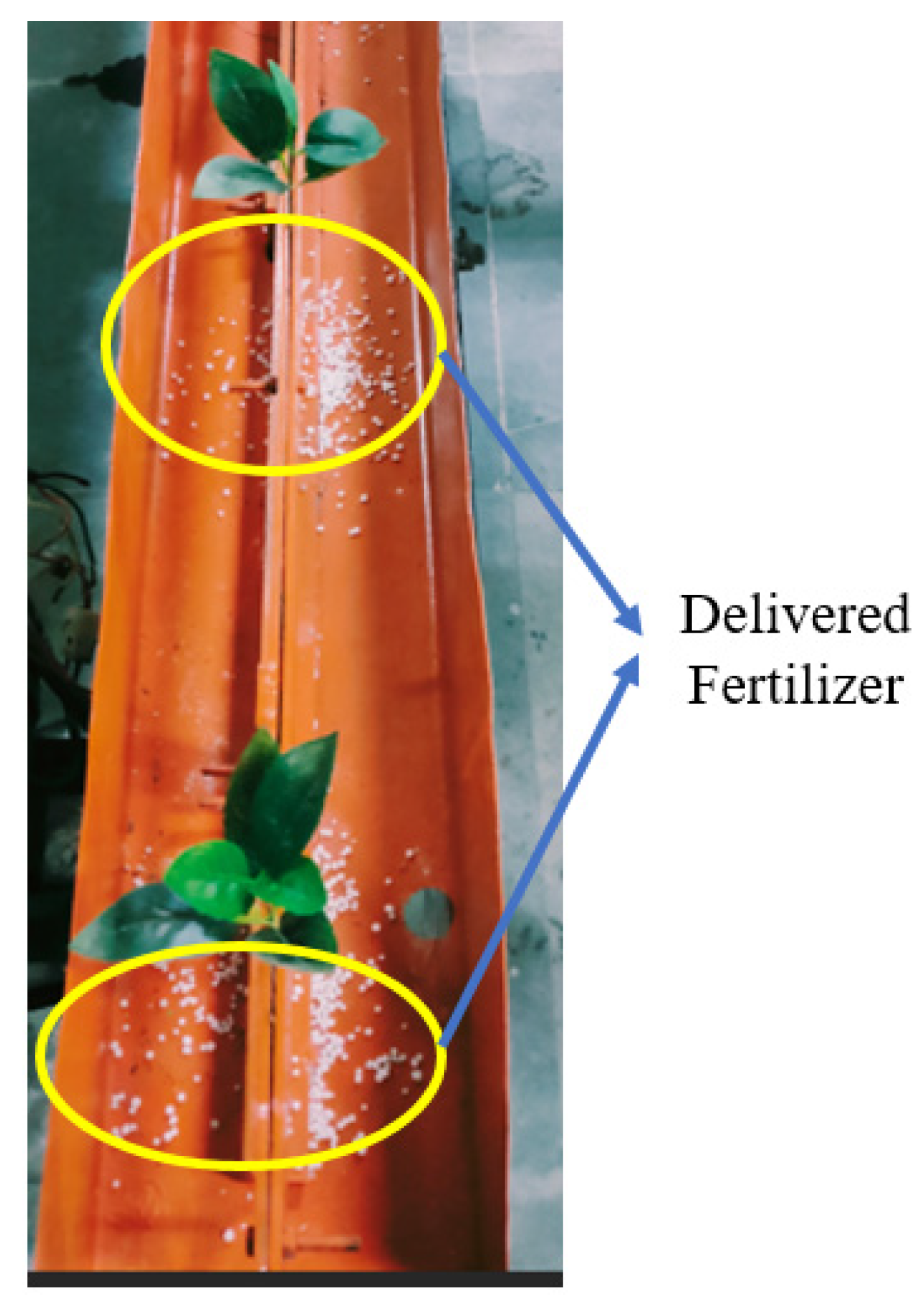

3.2. Effect of Fluted Roller Speed of Metering Unit on Fertilizer Discharge at Different Exposure Lengths

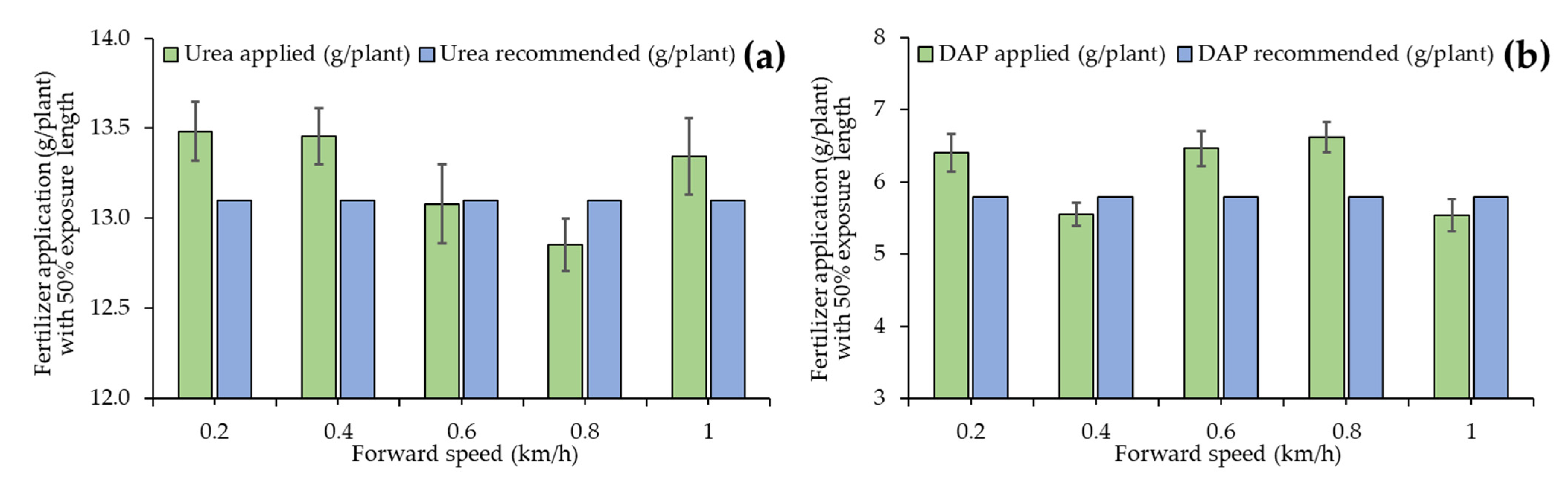

3.3. Effect of Forward Speed on Recommended Fertilizer Amount at Fixed Shaft Exposure Lengths

3.4. Effect of Exposure Length on Fertilizer Amount at Different Forward Speeds

3.5. Effect of Forward Speed on Missing Plant Index

3.6. Effect of Illumination on Fertilizer Delivery

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wu, J.; Chen, X. Present situation, problems, and countermeasures of cotton production mechanization de-velopment in Xinjiang Production and Construction Corps. Trans. Chin. Soc. Agric. Eng. 2015, 31, 5–10. [Google Scholar] [CrossRef]

- Cotton: World Markets and Trade. 2023. Available online: https://apps.fas.usda.gov/psdonline/circulars/cotton.pdf (accessed on 30 April 2023).

- El Naim, A.M. Growth and Yield of Seed Cotton Response to Plant Spacing and Weeding Frequency under Flood Irrigation. J. Renew. Agric. 2013, 1, 27. [Google Scholar] [CrossRef]

- Jalota, S.; Sood, A.; Chahal, G.; Choudhury, B. Crop water productivity of cotton (Gossypium hirsutum L.)–wheat (Triticum aestivum L.) system as influenced by deficit irrigation, soil texture and precipitation. Agric. Water Manag. 2006, 84, 137–146. [Google Scholar] [CrossRef]

- Wang, H.; Wu, L.; Cheng, M.; Fan, J.; Zhang, F.; Zou, Y.; Chau, H.W.; Gao, Z.; Wang, X. Coupling effects of water and fertilizer on yield, water and fertilizer use efficiency of drip-fertigated cotton in northern Xinjiang, China. Field Crop. Res. 2018, 219, 169–179. [Google Scholar] [CrossRef]

- Bronson, K.F.; Keeling, J.W.; Booker, J.D.; Chua, T.T.; Wheeler, T.A.; Boman, R.K.; Lascano, R.J. Influence of Landscape Position, Soil Series, and Phosphorus Fertilizer on Cotton Lint Yield. Agron. J. 2003, 95, 949–957. [Google Scholar] [CrossRef]

- Dong, H.; Kong, X.; Li, W.; Tang, W.; Zhang, D. Effects of plant density and nitrogen and potassium fertilization on cotton yield and uptake of major nutrients in two fields with varying fertility. Field Crop. Res. 2010, 119, 106–113. [Google Scholar] [CrossRef]

- Mózner, Z.; Tabi, A.; Csutora, M. Modifying the yield factor based on more efficient use of fertilizer—The environmental impacts of intensive and extensive agricultural practices. Ecol. Indic. 2012, 16, 58–66. [Google Scholar] [CrossRef]

- Astaneh, N.; Bazrafshan, F.; Zare, M.; Amiri, B.; Bahrani, A. Nano-fertilizer prevents environmental pollution and improves physiological traits of wheat grown under drought stress conditions. Sci. Agropecu. 2021, 12, 41–47. [Google Scholar] [CrossRef]

- Grant, K.N.; Macrae, M.L.; Rezanezhad, F.; Lam, W.V. Nutrient Leaching in Soil Affected by Fertilizer Application and Frozen Ground. Vadose Zone J. 2019, 18, 1–13. [Google Scholar] [CrossRef]

- Ombódi, A.; Saigusa, M. Broadcast application versus band application of polyolefin-coated fertilizer on green peppers grown on andisol. J. Plant Nutr. 2000, 23, 1485–1493. [Google Scholar] [CrossRef]

- Crozier, C.R.; Roberson, G.T. Granular Fertilizer Spreader Swath Uniformity Achieved at Varying Target Application Rates. Crop. Manag. 2014, 13, 1–6. [Google Scholar] [CrossRef]

- Schumann, A.W.; Miller, W.M.; Zaman, Q.U.; Hostler, K.H.; Buchanon, S.; Cugati, S. Variable rate granular fertilization of citrus groves: Spreader performance with single-tree prescription zones. Appl. Eng. Agric. 2006, 22, 19–24. [Google Scholar] [CrossRef]

- Yildirim, Y.; Parish, R.L. Band application performance of single-disc rotary fertilizer spreaders. Appl. Eng. Agric. 2013, 29, 149–153. [Google Scholar] [CrossRef]

- Chandel, N.S.; Mehta, C.R.; Tewari, V.K.; Nare, B. Digital map-based site-specific granular fertilizer application system. Curr. Sci. 2016, 111, 1208–1213. Available online: https://www.jstor.org/stable/24909128 (accessed on 30 April 2023). [CrossRef]

- May, S.; Kocabiyik, H. Design and development of an electronic drive and control system for micro-granular fertilizer metering unit. Comput. Electron. Agric. 2019, 162, 921–930. [Google Scholar] [CrossRef]

- Alameen, A.A.; Al-Gaadi, K.A.; Tola, E. Development and performance evaluation of a control system for variable rate granular fertilizer application. Comput. Electron. Agric. 2019, 160, 31–39. [Google Scholar] [CrossRef]

- Gao, Y.; Qian, X.; Sun, B.; Huang, W. Solid Fertilizer Broadcaster. Patent No. CN102498811B, 27 March 2013. [Google Scholar]

- Sun, Y.; Zhao, X.; Chen, M.; Liu, L. Adjustable Depth Drilling Fertilizer Distributor. Patent No. CN210406184U, 28 April 2020. [Google Scholar]

- Farooque, A.A.; Hussain, N.; Schumann, A.W.; Abbas, F.; Afzaal, H.; McKenzie-Gopsill, A.; Esau, T.; Zaman, Q.; Wang, X. Field evaluation of a deep learning-based smart variable-rate sprayer for targeted application of agrochemicals. Smart Agric. Technol. 2022, 3, 100073. [Google Scholar] [CrossRef]

- Søgaard, H.; Lund, I. Application Accuracy of a Machine Vision-controlled Robotic Micro-dosing System. Biosyst. Eng. 2007, 96, 315–322. [Google Scholar] [CrossRef]

- Diao, Z.; Guo, P.; Zhang, B.; Yan, J.; He, Z.; Zhao, S.; Zhao, C.; Zhang, J. Spatial-spectral attention-enhanced Res-3D-OctConv for corn and weed identification utilizing hyperspectral imaging and deep learning. Comput. Electron. Agric. 2023, 212, 108092. [Google Scholar] [CrossRef]

- Diao, Z.; Guo, P.; Zhang, B.; Zhang, D.; Yan, J.; He, Z.; Zhao, S.; Zhao, C. Maize crop row recognition algorithm based on improved UNet network. Comput. Electron. Agric. 2023, 210, 107940. [Google Scholar] [CrossRef]

- Liu, J.; Abbas, I.; Noor, R.S. Development of Deep Learning-Based Variable Rate Agrochemical Spraying System for Targeted Weeds Control in Strawberry Crop. Agronomy 2021, 11, 1480. [Google Scholar] [CrossRef]

- Gao, P.; Zhang, Y.; Zhang, L.; Noguchi, R.; Ahamed, T. Development of a Recognition System for Spraying Areas from Unmanned Aerial Vehicles Using a Machine Learning Approach. Sensors 2019, 19, 313. [Google Scholar] [CrossRef]

- Zhao, X.; Wang, X.; Li, C.; Fu, H.; Yang, S.; Zhai, C. Cabbage and Weed Identification Based on Machine Learning and Target Spraying System Design. Front. Plant Sci. 2022, 13, 924973. [Google Scholar] [CrossRef] [PubMed]

- Gildow, M.; Aloysius, N.; Gebremariam, S.; Martin, J. Fertilizer placement and application timing as strategies to reduce phosphorus loading to Lake Erie. J. Great Lakes Res. 2016, 42, 1281–1288. [Google Scholar] [CrossRef]

- Prasertsak, P.; Freney, J.; Denmead, O.; Saffigna, P.; Prove, B.; Reghenzani, J. Effect of fertilizer placement on nitrogen loss from sugarcane in tropical Queensland. Nutr. Cycl. Agroecosystems 2002, 62, 229–239. [Google Scholar] [CrossRef]

- Zhang, Y.-Q.; Pang, L.-L.; Yan, P.; Liu, D.-Y.; Zhang, W.; Yost, R.; Zhang, F.-S.; Zou, C.-Q. Zinc fertilizer placement affects zinc content in maize plant. Plant Soil 2013, 372, 81–92. [Google Scholar] [CrossRef]

- Chouriya, A.; Soni, P.; Thomas, E.; Mahore, V.; Patidar, P.; Nagar, H. Detection of Cotton Plants Using the YOLOv7 Deep Learning Model. In Proceedings of the 2023 2nd International Conference on Futuristic Technologies (INCOFT), Karnataka, India, 24–26 November 2023; pp. 1–4. [Google Scholar]

- Yang, H.; Liu, Y.; Wang, S.; Qu, H.; Li, N.; Wu, J.; Yan, Y.; Zhang, H.; Wang, J.; Qiu, J. Improved Apple Fruit Target Recognition Method Based on YOLOv7 Model. Agriculture 2023, 13, 1278. [Google Scholar] [CrossRef]

- Gurjar, B.; Sahoo, P.K.; Kumar, A. Design and development of variable rate metering system for fertilizer application. J. Agric. Eng. 2017, 54, 12–21. [Google Scholar] [CrossRef]

- Chouriya, A.; Thomas, E.V.; Soni, P.; Patidar, V.K.; Dhruw, L. Development and evaluation of a machine vision-based cotton fertilizer applicator. Span. J. Agric. Res. 2024, 22, e0201. [Google Scholar] [CrossRef]

- Chouriya, A.; Tewari, V.K.; Soni, P.; Singh, N.; Kumar, P. Development of microcontroller-based draft measuring system using Xbee technology. Cogent Eng. 2024, 11, 2331178. [Google Scholar] [CrossRef]

- Mahore, V.; Patidar, P.; Soni, P.; Nagar, H.; Chouriya, A.; Paul, A. An IoT-Enabled Tractor Data Sensing System for Precision Agriculture. In Proceedings of the 2023 2nd International Conference on Futuristic Technologies (INCOFT), Karnataka, India, 24–26 November 2023; pp. 1–4. [Google Scholar]

- Tola, E.; Kataoka, T.; Burce, M.; Okamoto, H.; Hata, S. Granular fertiliser application rate control system with integrated output volume measurement. Biosyst. Eng. 2008, 101, 411–416. [Google Scholar] [CrossRef]

- Kim, Y.; Kim, H.; Ryu, K.; Rhee, J. Fertiliser application performance of a variable-rate pneumatic granular applicator for rice production. Biosyst. Eng. 2008, 100, 498–510. [Google Scholar] [CrossRef]

- Hasan, M.; Rahman, M.A.; Ashik-E-Rabbani, M. Design and development of manually push type USG applicator. Agric. Eng. Int. CIGR J. 2018, 20, 80–87. [Google Scholar]

| S. No. | Variables | Levels |

|---|---|---|

| Independent parameters | ||

| 1. | Forward speed of plant conveying unit | Vf1 = 0.2 km/h, Vf2 = 0.4 km/h Vf3 = 0.6 km/h, Vf4 = 0.8 km/h, and Vf5 =1.0 km/h |

| 2. | Exposure length of the metering unit | Le = 25%, Le = 50 %, Le = 75%, and Le = 100% |

| Dependent parameters | ||

| 1. | Missing plant index (MI), % | |

| 2. | Illumination effect | |

| 3. | Delivered amount (g/plant) | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chouriya, A.; Soni, P.; Chandel, A.K.; Patel, A.K. An AI-Enabled System for Automated Plant Detection and Site-Specific Fertilizer Application for Cotton Crops. Automation 2025, 6, 53. https://doi.org/10.3390/automation6040053

Chouriya A, Soni P, Chandel AK, Patel AK. An AI-Enabled System for Automated Plant Detection and Site-Specific Fertilizer Application for Cotton Crops. Automation. 2025; 6(4):53. https://doi.org/10.3390/automation6040053

Chicago/Turabian StyleChouriya, Arjun, Peeyush Soni, Abhilash K. Chandel, and Ajay Kumar Patel. 2025. "An AI-Enabled System for Automated Plant Detection and Site-Specific Fertilizer Application for Cotton Crops" Automation 6, no. 4: 53. https://doi.org/10.3390/automation6040053

APA StyleChouriya, A., Soni, P., Chandel, A. K., & Patel, A. K. (2025). An AI-Enabled System for Automated Plant Detection and Site-Specific Fertilizer Application for Cotton Crops. Automation, 6(4), 53. https://doi.org/10.3390/automation6040053