1. Introduction

The control of induction motors (IMs) continues to attract strong research interest due to their nonlinear structure, sensitivity to parameter variations, and widespread use in industrial applications. Traditional control methods often rely on accurate measurements of rotor speed and flux, which may not always be available or reliable in sensorless configurations. In this context, passivity-based control has emerged as a promising framework due to its solid theoretical foundation and robustness to system uncertainties. Early works demonstrated the use of passivity theory to ensure stable torque and flux regulation in IMs. For example, Cecati [

1] proposed a passivity-based position controller, while Duarte-Mermoud [

2] introduced an adaptive passivity approach for robust speed control. Travieso-Torres [

3] extended this framework with adaptive structures for enhanced robustness under parameter variations. Moreover, Mansouri [

4] applied passivity theory to sensorless IM control by integrating it with nonlinear observers for improved state reconstruction. In parallel, adaptive control strategies have played a pivotal role in addressing variations in machine parameters, such as rotor resistance and load torque, which frequently degrade control performance. Marino [

5] introduced an adaptive input–output linearizing controller for IMs, achieving asymptotic tracking despite parametric uncertainties. Similarly, Chenafa [

6] and Espinosa-Pérez [

7] developed globally stable adaptive schemes using nonlinear feedback structures. In the sensorless domain, Belkacem Bekhiti [

8,

9] proposed an adaptive Luenberger and extended Kalman filter observers to enhance rotor speed estimation without mechanical sensors. More recently, Bekhiti [

10] extended the adaptation ideas by validating a hyper-stability-based multivariable nonlinear adaptive control framework on induction motors, demonstrating strong experimental performance under non-ideal conditions. The integration of nonlinear state observers has further strengthened sensorless control by enabling full-state estimation based solely on measurable stator currents and voltages. Gauthier [

11] and Busawon [

12] contributed to the theoretical foundations of nonlinear observers, while Mansouri [

13] tailored these concepts to IMs operating under field-oriented control. These observer designs significantly improve robustness and observability, especially at low speeds and under load disturbances.

More recently, artificial intelligence (AI) and neural networks have emerged as powerful tools in intelligent motor control. Neural models can approximate complex nonlinear mappings and adapt online, making them particularly suitable for estimation and control in dynamic environments. Beltran-Carbajal [

14] and Moghadasian [

15] proposed neural network-based controllers for IMs that adapt to system variations in real time. Sujatha and Vaisakh [

16], along with Brandstetter and Kuchar [

17], demonstrated the effectiveness of adaptive neuro-fuzzy inference systems (ANFIS) and radial basis function (RBF) networks in sensorless IM control. Acikgoz [

18] implemented a real-time speed controller using a type-2 fuzzy neural network, while Hussain [

19] introduced a type-II adaptive neuro-fuzzy controller with strong transient response capabilities.

Several studies have specifically integrated AI-based observers into MRAS or passivity-based frameworks. For instance, Medjadji [

20] and Govindharaj [

21] enhanced speed estimation using fuzzy and neuro-fuzzy observers. Parimalasundar [

22] combined artificial neural networks with sliding mode control for power steering applications, and Mekrini [

23] applied fuzzy logic in the control of asynchronous machines. Recent contributions by Sun [

24] and Mienye [

25] explored adaptive learning and recurrent neural network architectures to further strengthen robustness. Wu [

26] addressed neural optimization by improving the convergence of online learning through gradient normalization—relevant to real-time motor drive applications.

Sensorless control of induction motors poses several interrelated challenges. The absence of rotor speed and flux sensors severely limits observability, particularly at low speeds or during rapid transients. Control performance also deteriorates under parameter variations, model uncertainties, and unmodeled nonlinearities. While significant progress has been made in adaptive, passivity-based, and learning-driven control, a critical gap remains in unifying these approaches into a robust and practical sensorless framework. Existing methods often treat passivity and learning separately or depend on fixed observers with limited adaptability. Neural and neuro-fuzzy controllers, though effective for nonlinear systems, frequently lack formal stability guarantees or disrupt the energy-preserving structure. Moreover, many nonlinear observers are structurally complex or computationally demanding, limiting their real-time applicability. Estimators such as MRAS become unreliable under noisy or imperfect measurements. These limitations, particularly under industrial conditions involving load transients and parameter drift, motivate a cohesive architecture that integrates passivity, adaptive learning, and efficient observer design into a unified sensorless control strategy.

This paper addresses the above challenges by presenting a unified, learning-enhanced, passivity-based control scheme for sensorless induction motors. The main contributions are as follows: (1) a novel nonlinear observer enhanced with a radial basis neural network to estimate rotor flux and speed under uncertainty, (2) the integration of a fuzzy MRAS estimator for robust speed reconstruction, (3) a passivity-based control law ensuring global asymptotic stability while tolerating model mismatches, and (4) real-time implementation and validation on a 1.1 kW induction motor using a dSPACE DS1104 board. Compared to existing approaches, the proposed scheme offers superior robustness, sensorless operation, and estimation accuracy under dynamic conditions, demonstrating up to an 88.6% reduction in torque estimation error and a 75.3% improvement in flux accuracy, thereby validating its effectiveness over conventional methods.

This architecture bridges the gap between model-based passivity control and data-driven adaptation, offering a scalable and robust solution for high-performance industrial IM drives. The remainder of this paper is organized as follows:

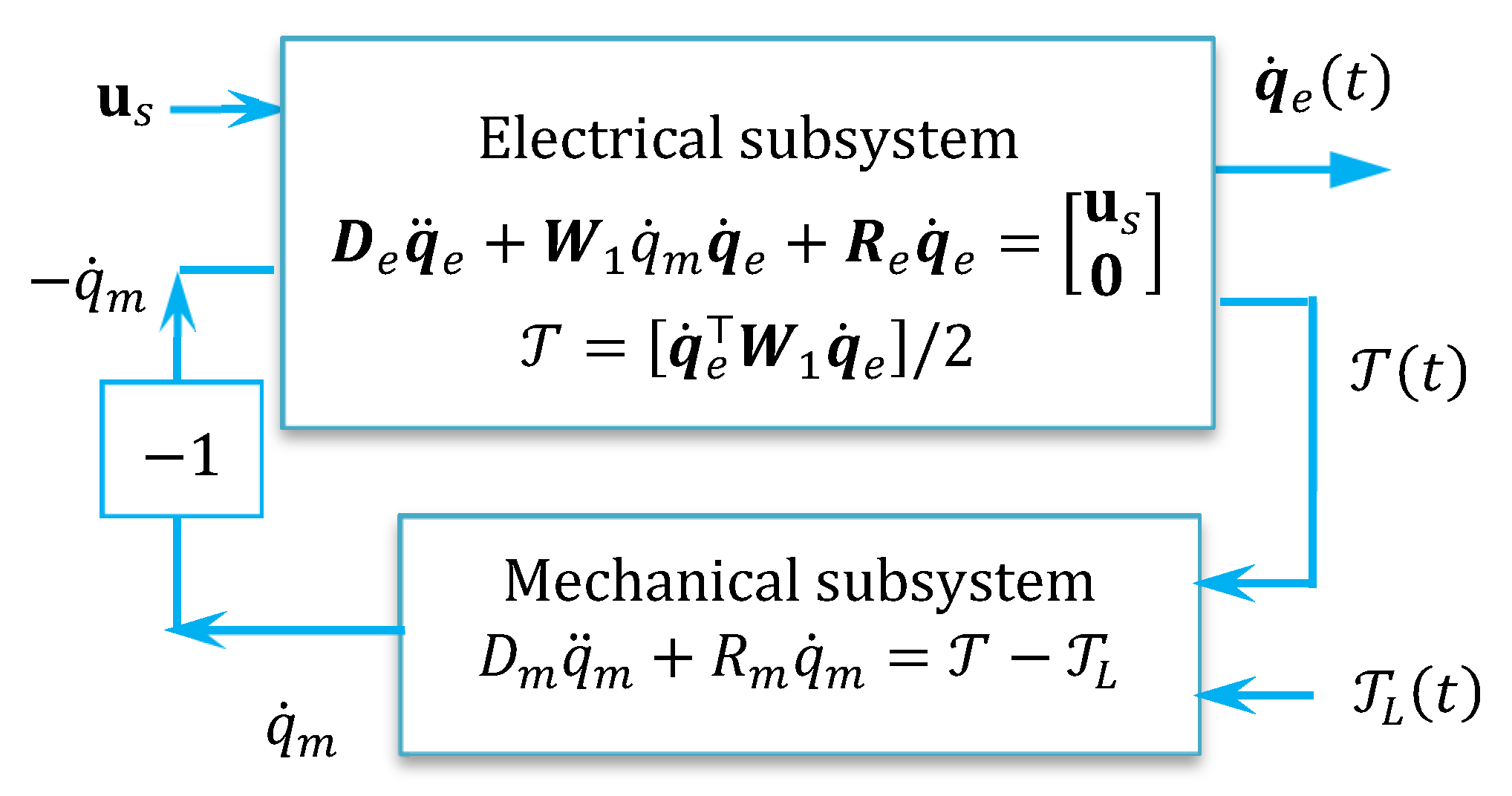

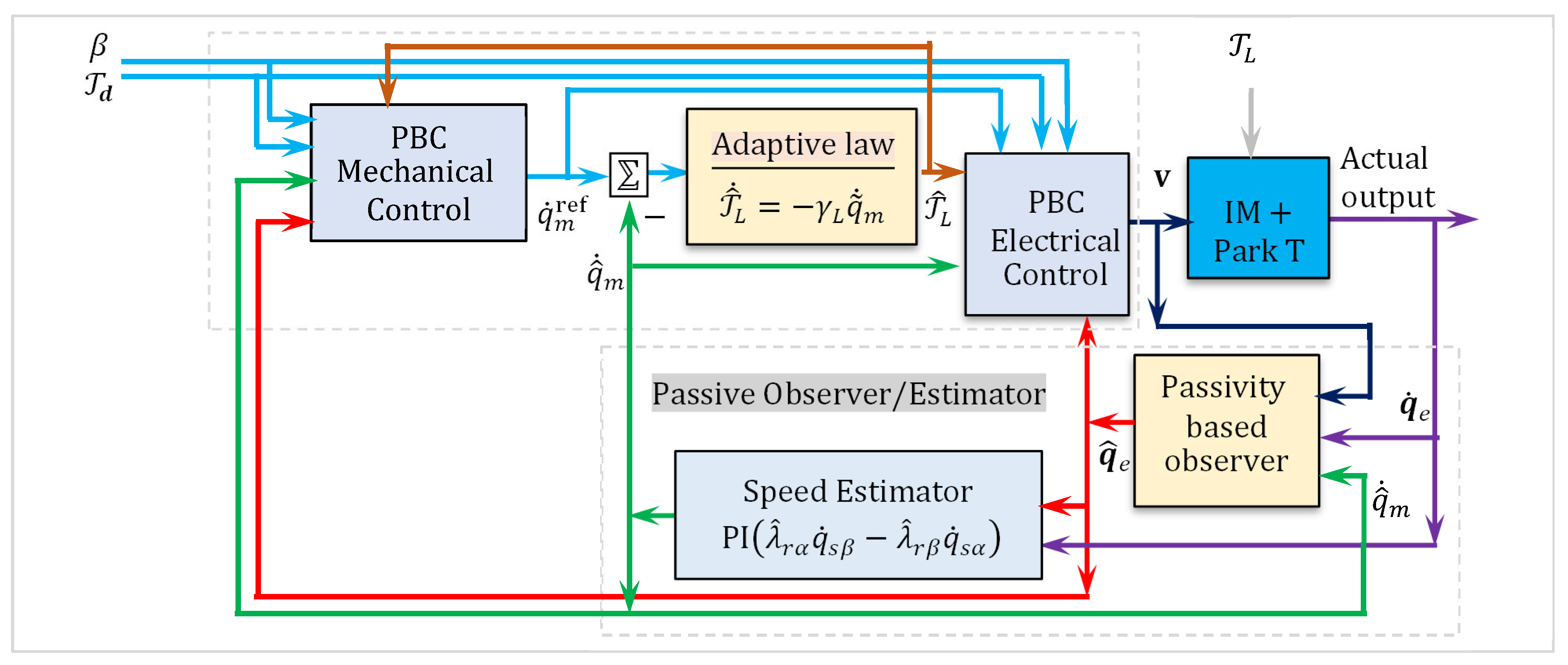

Section 2 presents the nonlinear dynamic model of the IM motor and the passivity framework.

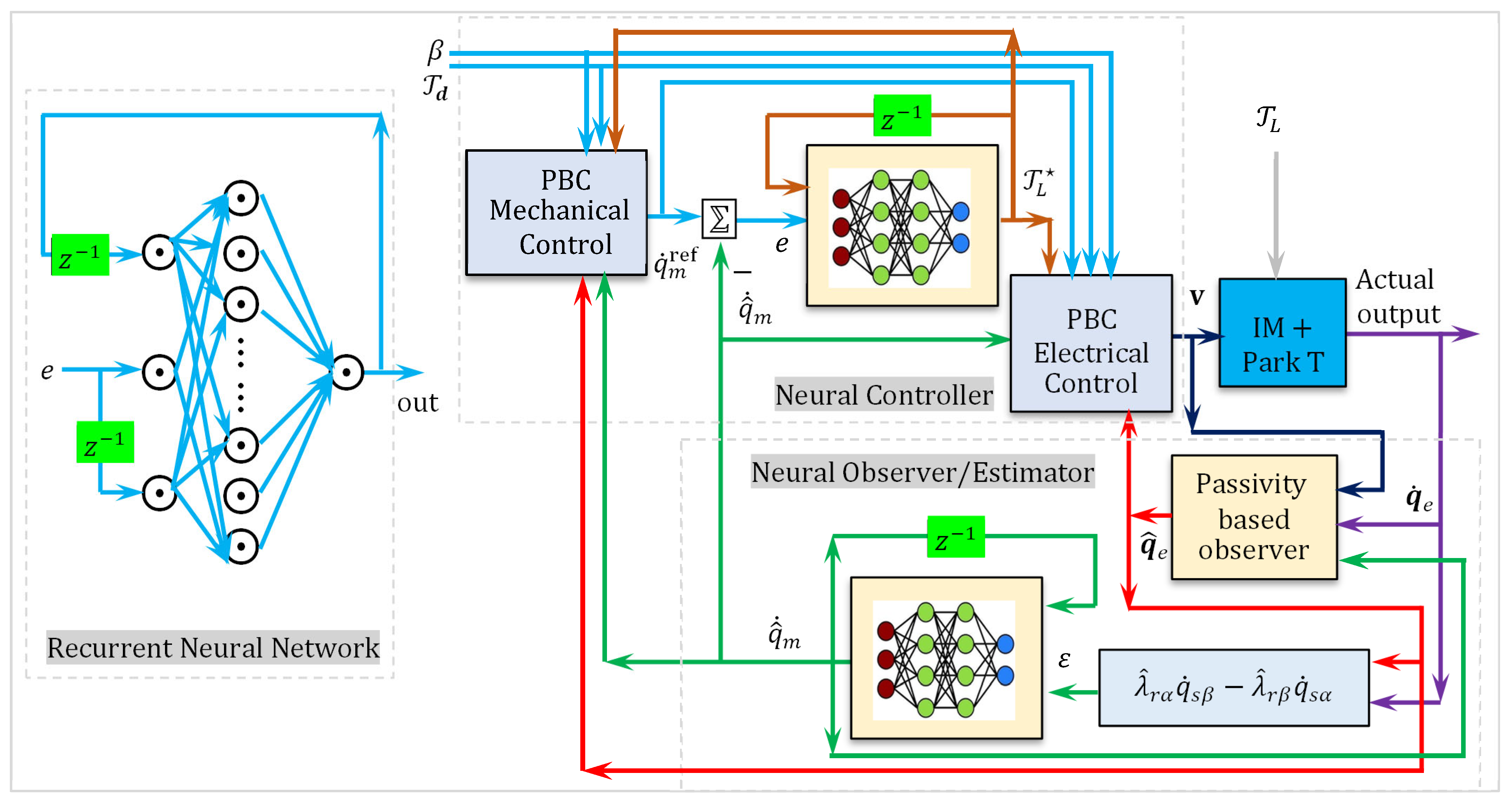

Section 3 details the neural adaptive observer design and learning algorithm.

Section 4 introduces the passivity-based control strategy and its integration with the observer.

Section 5 describes the experimental platform and test scenarios and discusses the results. Finally,

Section 6 concludes the paper and outlines future directions.

3. Nonlinear Observer Design

In this section, we review several flux observer designs from the literature [

30,

31], followed by the development of a tailored observer formulated specifically for the nonlinear framework considered in this work.

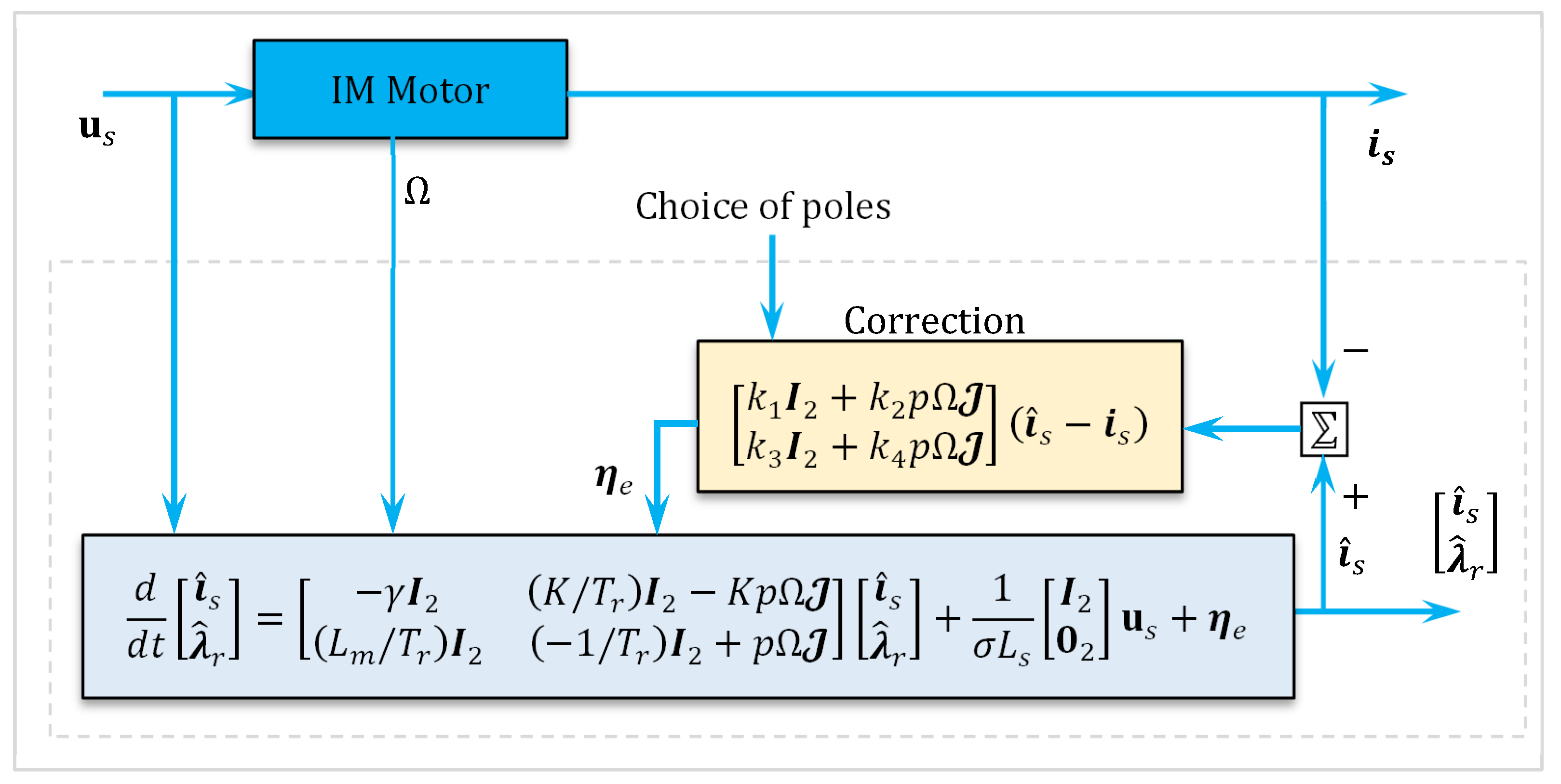

3.1. Flux Observer in a Closed Loop

A foundational reference in this area is the observer introduced by Verghese and Sanders [

32], which has since inspired several variants, including those proposed by De Luca and Ulivi [

33], Garcia in [

34], and by Mansouri [

4]. The general structure of this classical observer is as follows:

where

,

,

,

,

, the

being scalars and

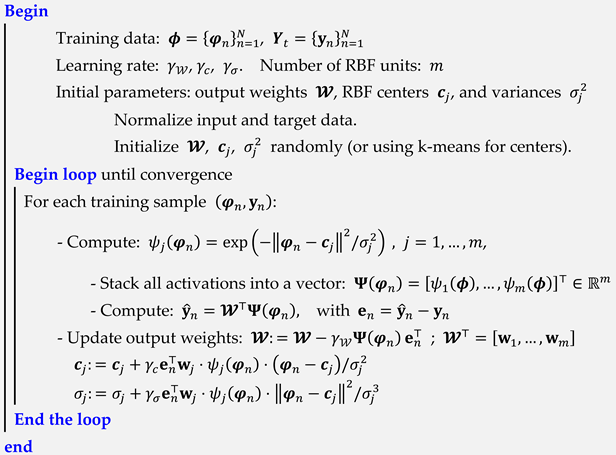

. Note that the gains depend on the speed in (8). We show the diagram block of this observer in

Figure 1.

The resulting model for the observer error dynamics is then

Note that we can freely determine the scalar coefficients in Equation (9). If

and

are selected such that

,

the error dynamics is as follows:

We select and to place the eigenvalues of in arbitrary positions. Note that the characteristic polynomial of is . If the eigenvalues of are (twice) and (twice), then the eigenvalues of time varying matrix are and using the slow dynamics theory.

3.2. The Proposed Nonlinear Intelligent Observer Design

Passivity-based control strategies are widely recognized for their reliance on rotor flux information, which is often challenging to measure directly. Consequently, considerable research efforts have been directed toward developing methods for estimating these values [

35,

36,

37,

38]. Now, we introduce the design of a reduced-order flux observer for an asynchronous motor operating in the

αβ reference frame. The proposed observer requires inputting only the stator voltage, current, and rotor speed. Specifically, this new nonlinear observer incorporates the speed measurements, ensuring that only the electrical quantities are required in the estimation process [

13]. Consider the

αβ model for induction motor:

where

The system (11) is the form:

with

Here, we make the following assumptions as posed by K. Busawon (see [

12]):

(A4) There exists a class of bounded admissible controls, a compact set and positive constants α, β > 0 such that for every and every output associated with and with an initial state , we have .

(A5) and its time derivative are bounded.

(A6) The matrix is of class , with respect to their arguments.

(A7) Functions , are global Lipschitz with respect to uniformly in and .

We characterize the observer design for the system (12) in the following theorem:

Theorem 1. Assume that the system (12) satisfies Assumptions (A4) to (A7). Then there exists such that the systemis an exponential observer for the system (12), where is the unique solution of the algebraic Lyapunov equation , , , and the explicit formula of isMoreover, we can make the dynamics of this observer arbitrarily fast. So, by multiplying the left- and right-hand sides of (14) by

and

, respectively, the following algebraic equation holds:

The choice of θ permits the pole placement of the observer according to the speed.

In summary the system can be written as

or

The observer is

or

So the error equation is

with

or

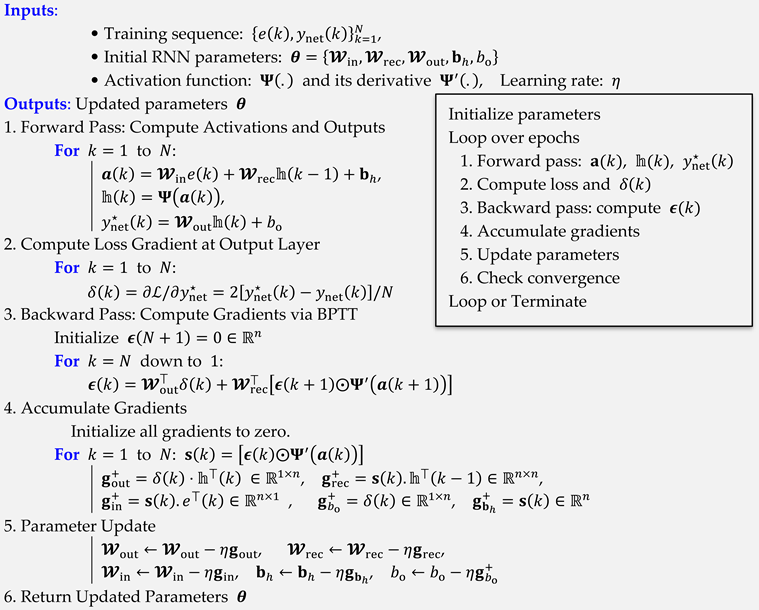

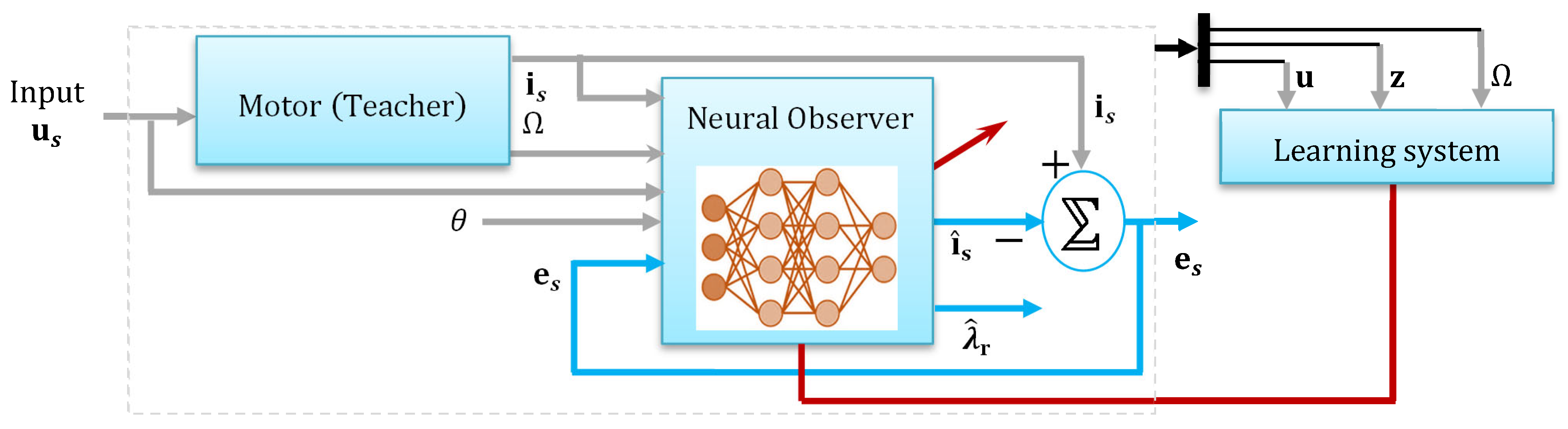

To incorporate learning-based compensation for model uncertainties and to enhance the robustness of the nonlinear observer, we introduce a radial basis function neural networks (RBFNN) term into the observer dynamics. The network approximates unknown disturbances or residual nonlinearities using a regressor composed of observable and estimated signals. Let represent an unknown nonlinear function (e.g., modeling error or disturbance). The universal approximation theorem states that, for any continuous function , there exists a feedforward neural network (three-layer NN) of the form: with or we omit the intermediary variable as where

is the activation vector;

is the output weight matrix;

are nonlinear sigmoids activation functions (e.g., tanh, ReLUs, etc.);

: stacked weight matrix ( row is ), : stacked biases;

The exponential and division are elementwise.

The coefficients

and

bi are the hidden layer parameters (

Input-to-hidden weights “nonlinear layer” and

are the bias of neuron

). Now, the resulting enhanced observer is given as follows:

Here,

is the adaptive weight matrix of the neural network and the vector

is a vector of radial basis activation functions; typically Gaussian (

and

is the regressor vector, e.g.,

). The network parameters are updated online via adaptation rules derived from Lyapunov stability analysis to ensure convergence and passivity preservation. The RBF neural term

is added as a correction to the standard observer dynamics, to compensate for unknown nonlinearities or disturbances not captured by

and

. This term acts like a learning system and is updated online (see

Figure 2).

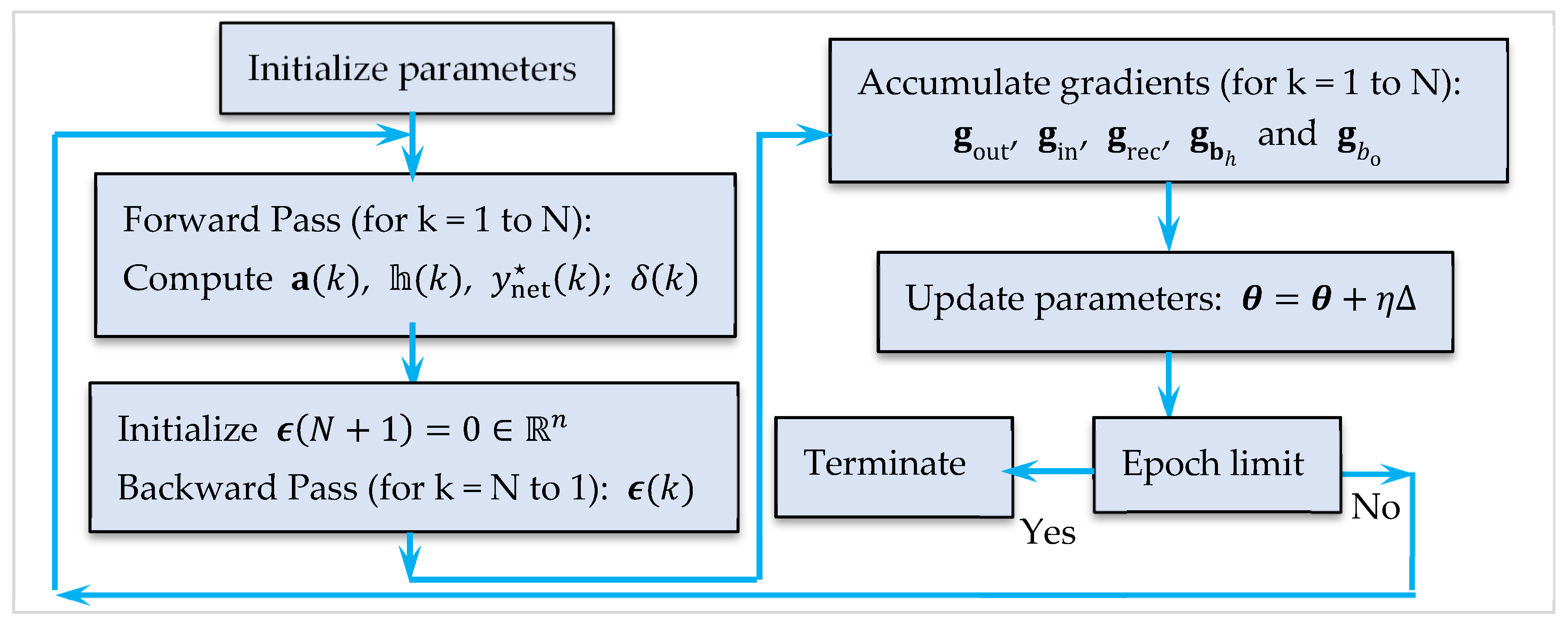

So the RBFNN becomes: . In order to train the RBFNN, we should minimize the objective function: . To adapt , perform . Again, for we have: . Here is a formal description of this training algorithm (Algorithm 1):

| Algorithm 1: RBF Neural Network Training via Gradient Descent |

![Automation 06 00045 i001 Automation 06 00045 i001]() |

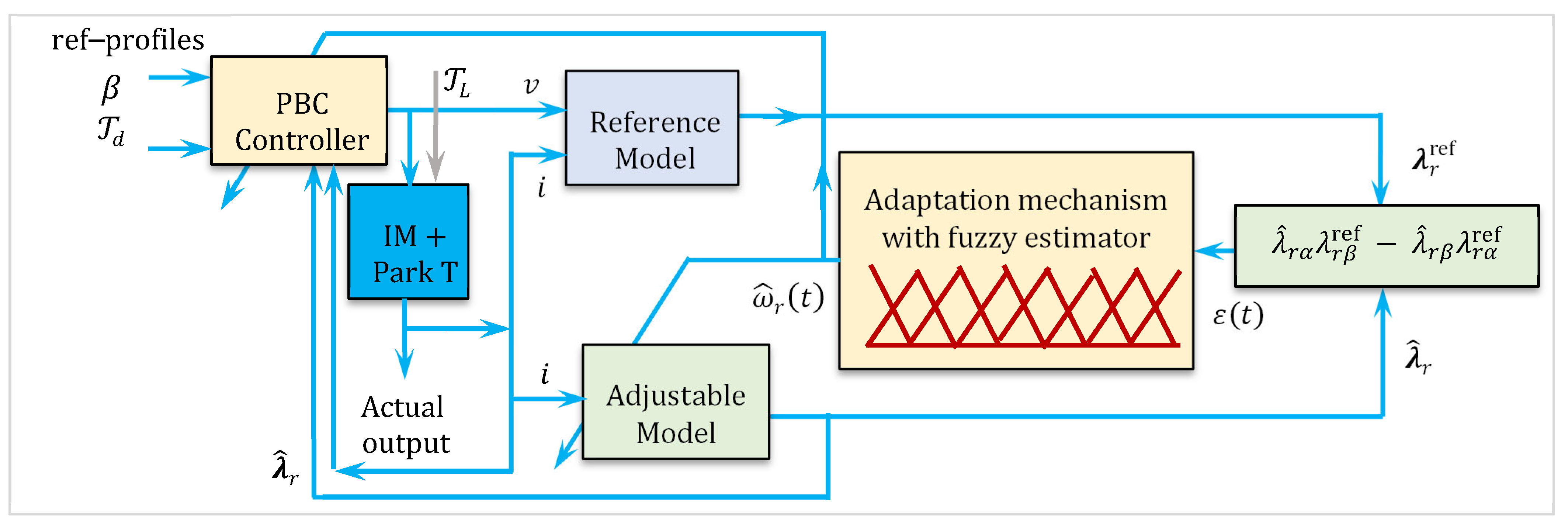

3.3. The Proposed Fuzzy-MRAS Estimator

Rotor speed

can be estimated using a model reference adaptive system (MRAS) structure composed of two estimators: a

reference model and an

adaptive model. Both models independently compute the rotor flux linkage components

and

in the stationary

αβ reference frame. By comparing the flux-linkage estimates, the adaptive model adjusts its internal speed estimate to minimize the discrepancy, thereby converging to the true rotor speed [

8,

9]. The reference model, derived from the stator voltage equations, does not depend on rotor speed and is therefore suitable for speed-independent flux estimation. Its expression in the stationary frame is as follows:

In contrast, the adaptive model, formulated from the rotor voltage equations, explicitly depends on the rotor flux components and the estimated speed

. It is expressed as

The angular discrepancy between the estimated and reference flux vectors serves as the adaptation signal, which is processed by a linear PI controller to adjust the estimated speed. Applying the Popov

criterion [

10,

20] to guarantee global asymptotic stability of the closed-loop estimation system, the adaptive law is given by

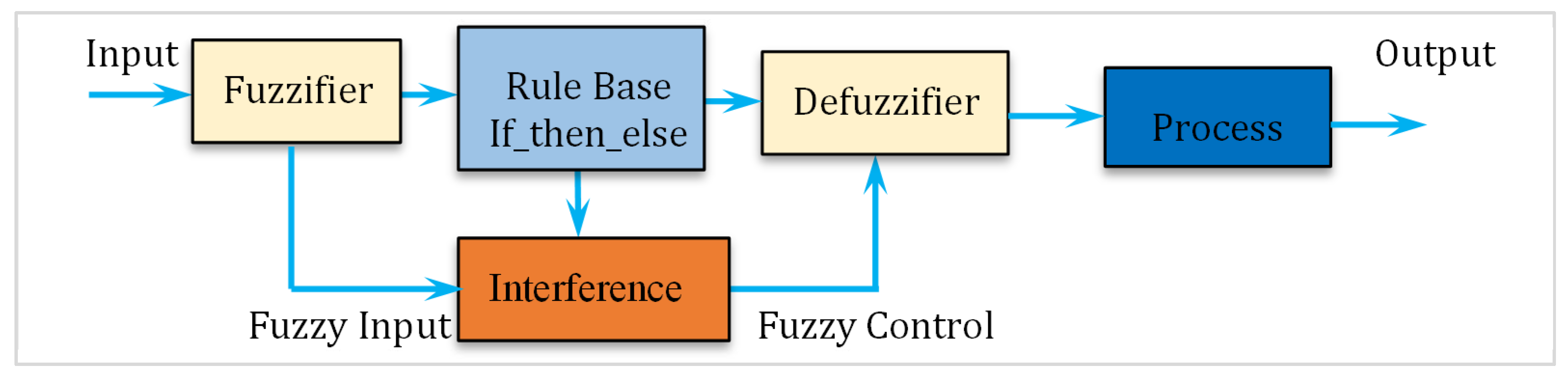

Fuzzy logic is particularly advantageous for systems that are difficult to model analytically, due to limited data availability, incomplete information, or the inherent complexity of the underlying process [

16]. These systems can be easily extended by adding new rules, allowing for performance enhancements and the inclusion of additional features. In conventional MRAS-based speed observers, a proportional integral (PI) controller is typically employed within the adaptation mechanism to estimate rotor speed by minimizing the error between the reference and adaptive models [

18]. In the proposed approach, the PI controller is replaced by a fuzzy logic controller, as depicted in

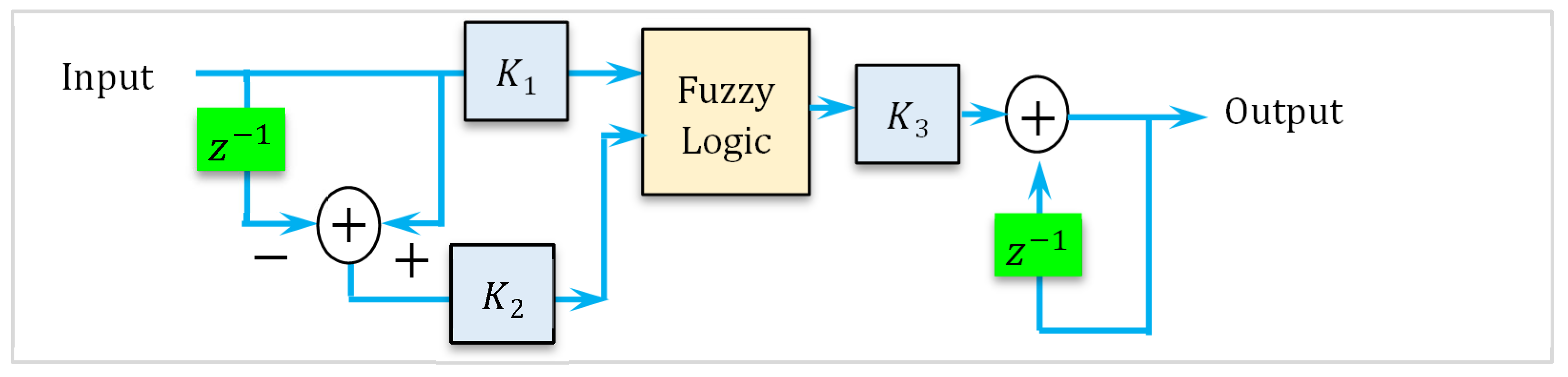

Figure 3. The complete block diagram of the fuzzy controller is presented in

Figure 4, and its internal structure is illustrated in

Figure 5. The fuzzy logic system operates by first processing the input variables through a fuzzification stage, where crisp input values are mapped to fuzzy sets using predefined membership functions and scale transformations. This scale mapping adjusts the range of the input variables to match the domain expected by the controller. The rule base stores the fuzzy inference rules, while the inference mechanism applies these rules to derive fuzzy conclusions. Common inference strategies include the Mamdani method, which typically uses the logical AND operator for rule evaluation, and the Takagi–Sugeno Model (TSM), which generates functional outputs based on the input variables [

23,

36,

39]. Finally, the defuzzification stage converts the fuzzy output set into a crisp control signal suitable for direct application to the system.

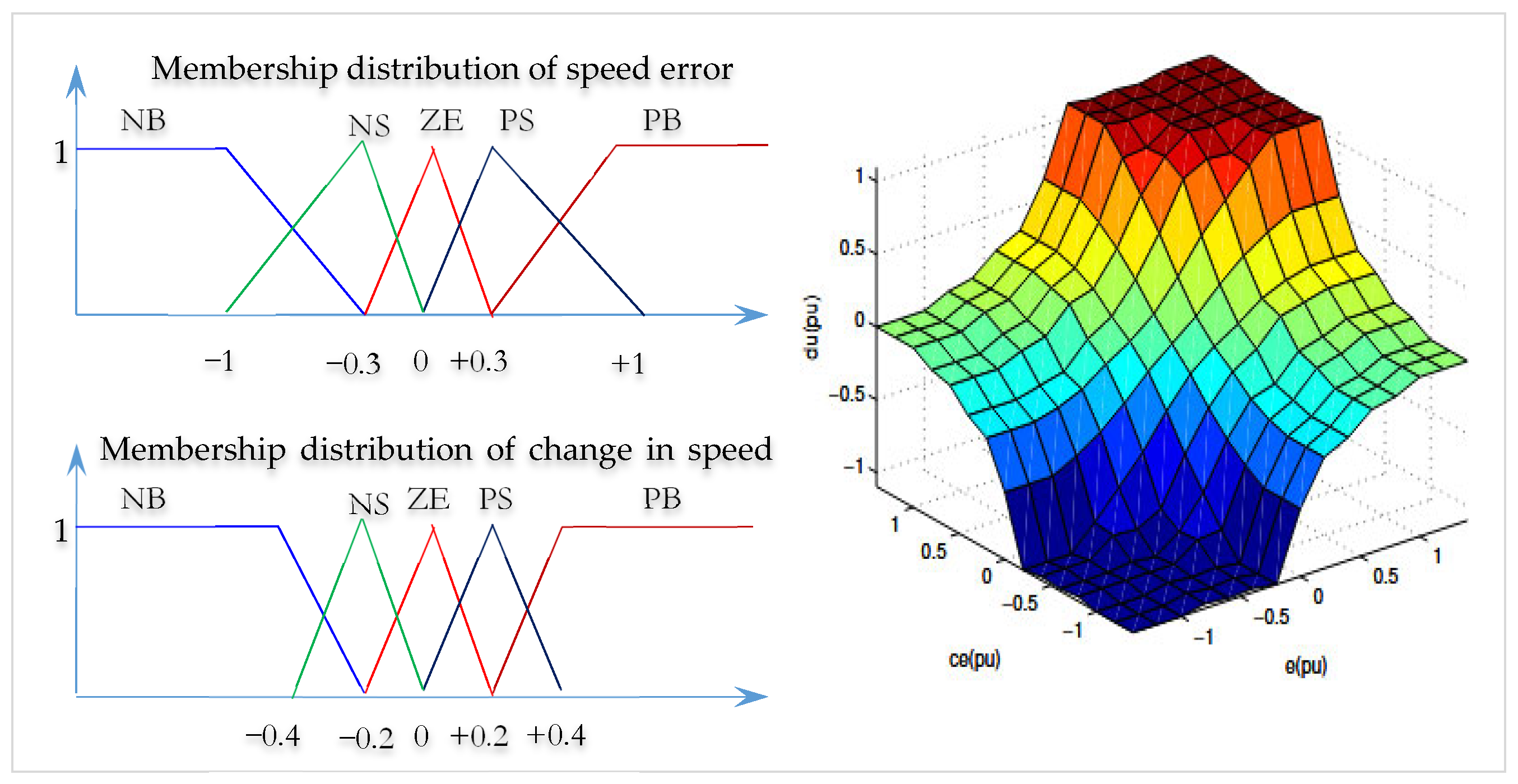

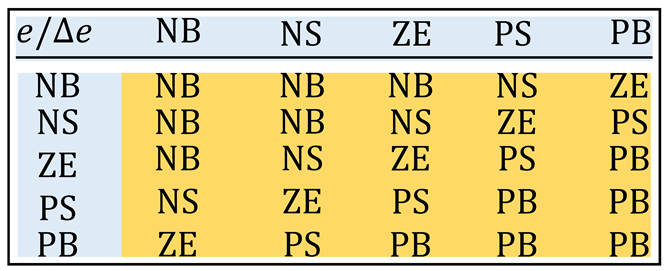

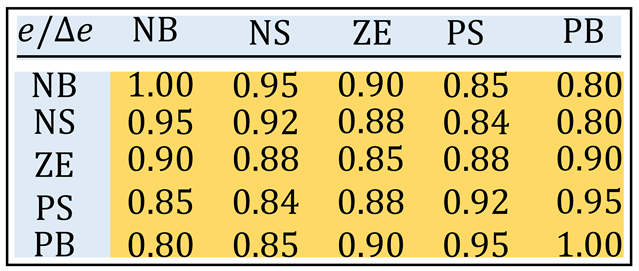

Knowing that gains

,

and

are scaling factors, they should be chosen carefully after performing the trial-and-error technique to obtain the optimal performance of the controller. From the expert estimator, the following memberships of fuzzy sets are used. The rules supporting this system are expressed in

Table 1, where NB: Negative Big, PB: Positive Big, NS: Negative Small, PS: Positive Small, and ZE: Zero Equal. The number of inputs to the fuzzy controller can be two or three. In the proposed method to reduce complexity, the two inputs are considered. The linguistics values that can be considered for each input are 3, 5, 7 or 9, as the case may be. Since there are two inputs, the numbers of rules that are possible are

or

which gives 9, 25, 49 or 81 rules for the above linguistic values, respectively. The choice of linguistic value should be made keeping into consideration that the control should be good, and computation taken by the fuzzy controller should not be high or make the process slow. The linguistic value 3 which gives 9 rules is too small to achieve the better control.

Figure 6 shows the fuzzy membership functions and control surface of the proposed adaptive system.

The fuzzy inference rules used in the proposed system are summarized in

Table 1.

5. Experimental Results and Discussion

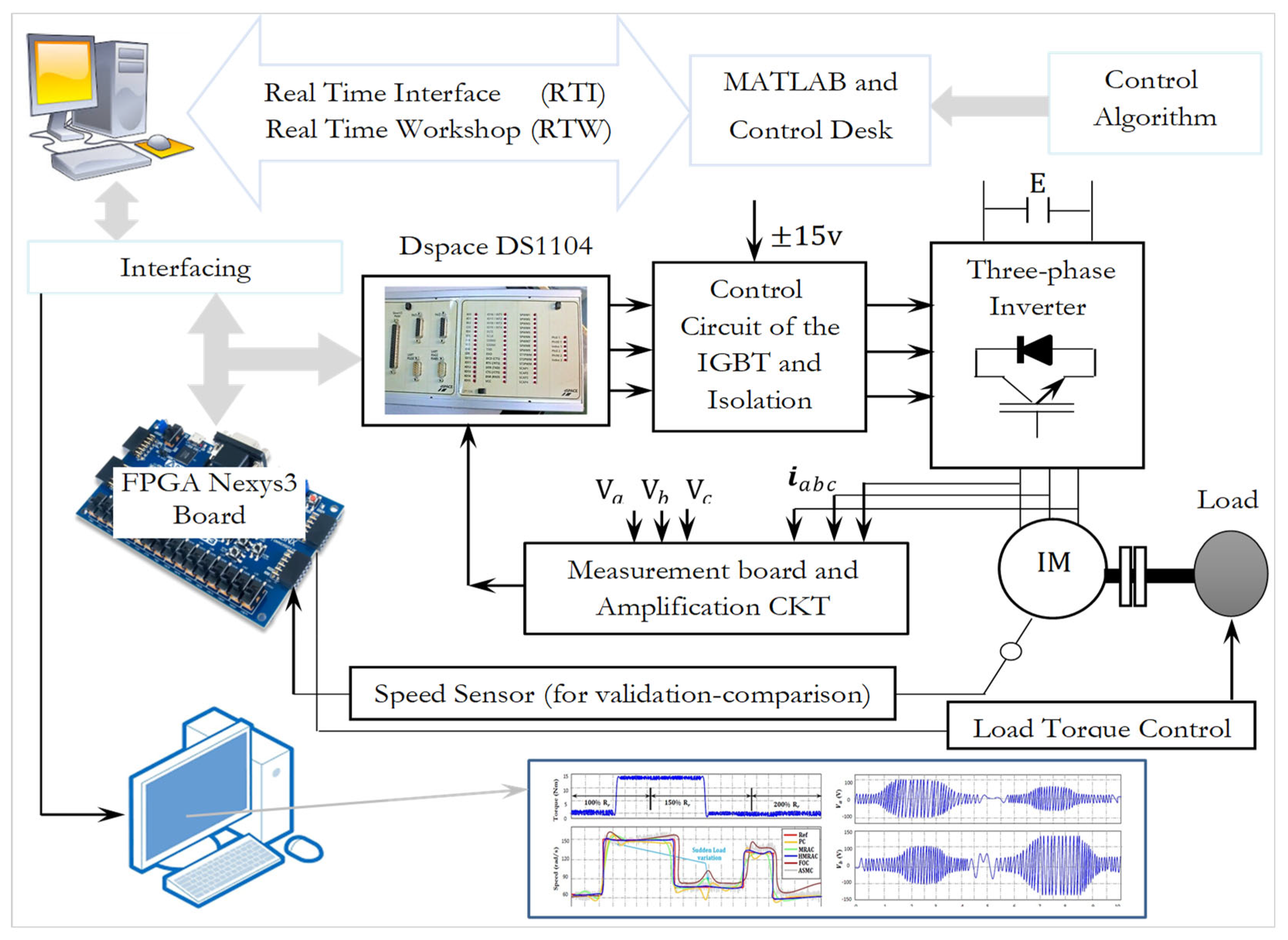

The NN-PBC controller has been tested on a test setup (

Figure 11) which consists of

Three-phase induction motor with rated values:

Rated voltage: 380 V. Rated current: 2.2 A. Number of phases: 3.

| |

Synchronous machine with powder brake for loading the IM.

Electronic power converter (without any control system).

3 (three-phase) diode rectifier and

VSI composed of three IGBT modules.

Electronic card for monitoring the stator phase (LEM Int’l SA, Geneva, Switzerland)

Voltage sensor for monitoring the instantaneous value of

The dc-link voltage (model LEM CV3-1000) (LEM Int’l SA, Geneva, Switzerland).

Incremental encoder only for comparison measurements.

Model RS 256-499, 2500 pulses per round, (for validation–comparison, not for control) (Renishaw plc, Wotton-under-Edge, UK).

dSPACE card (DS1104) with a PowerPC 604e at 400 MHz and floating-point digital signal processor DSP—TMS320F240 (dSPACE GmbH, Paderborn, Germany). During the real-time operation of the control, the supervision/capturing of the important data can be performed by the CONTROLDESK software (ControlDesk software, version 5.1). provided with DSP board.

Simulations in MATLAB verified the proposed control scheme using a rated flux reference and 500 V DC-link voltage. The feedback signal reconstruction was confirmed in simulation, and experimental results further validated the effectiveness and robustness of the sensorless control strategy. The electrical and mechanical parameters of the induction motor are listed in

Table 2.

The “Control/Command” part is based on the R&D Controller Board developed by the German company dSPACE and housed in a computer. This control card is made up of two processors. The master processor manages the application while the slave processor, a DSP (“Digital Signal Processor”) from TEXAS INSTRUMENT (type ), generates the (Pulse Width Modulation) control signals in 0/5 V TTL logic. This constitutes the “hardware” part of . The “software” part consists of two software programs. The first, , allows easy programming of the real-time application under Simulink by using specific blocks (belonging to the “Real Time Interface () toolbox”) allowing the configuration of the inputs/outputs of the card. The second software, , allows the program code to be loaded onto the card (written in graphical form in Simulink, compiled and transformed into C code), to create a complete experimental environment and, in particular, a graphical interface for controlling the real-time process, to process the data and save it in a format compatible with (for later processing) or even to monitor in real time the evolution of the measured or calculated data using graphical or digital displays. The exchange of information between the two parts described is carried out via an external connection box (Connector Panel from ) connected to the card via a shielded cable and receiving the analog signals via connectors, an interface for conditioning the control signals and any error signals returned by the Semikron converter and a measurement environment consisting of various sensors. The signal conditioning interface converts the signals from 0/5 V logic to 0/15 V logic and vice versa. This modification is essential because the control card works with 0/5 V logic signals, while these must be in 0/15 V logic for the voltage inverter. The measurement environment consists of LEM type LA25TP sensors (closed-loop current sensors using the Hall effect) for current measurements, LEM type LV100-500 sensors (closed-loop voltage sensors using the Hall effect) for voltage measurements and an incremental encoder to measure the motor rotation speed. Finally, the measured analog currents are intended for digital processing and must therefore be sampled. Therefore, in order to avoid any spectral aliasing phenomenon, it is necessary to insert a guard filter (with an estimated cut-off frequency of 500 Hz, one order of magnitude above the fundamental frequency of 50 Hz) between each sensor and the analog-to-digital converter.

Analyzing the operation of an IM supplied by a voltage inverter is complex due to its complicated nonlinear nature. Moreover, neural (or neuro-fuzzy) adaptive control of an IM requires solid theoretical foundations in areas such as electrical machines, power electronics, and control systems [

41]. Using the

-instrumented platform, the proposed control strategy is first implemented in Simulink, then deployed in real-time via

. The

-driven inverter operates at a switching frequency of 9.5 kHz. A detailed view of the experimental setup is provided in

Figure 12.

5.1. Study of the Proposed Nonlinear Intelligent Observer

The performance of the proposed nonlinear observer is first evaluated in open-loop and then integrated into a closed-loop configuration with the nonlinear controller of the induction motor. To align the observer dynamics with those of the plant, a tuning parameter

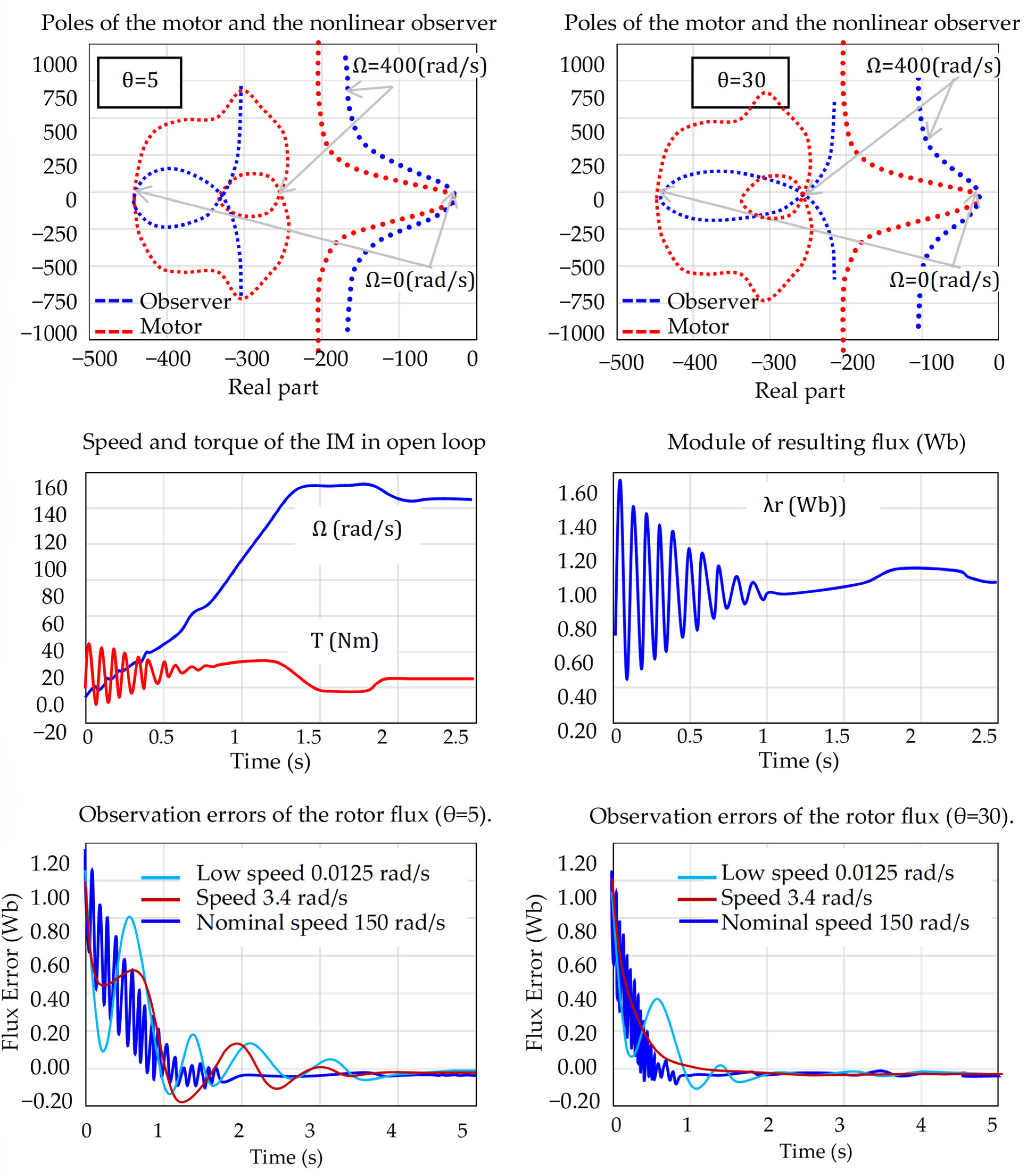

is used. The trajectories of the motor and observer poles are experimentally analyzed under this setting.

Figure 13 illustrates the rotor flux observation error obtained at various operating speeds (0.0125, 3.4, and 150 rad/s), with

, demonstrating the accuracy and robustness of the observer. The given architecture is tested under different perturbation scenarios, including parameter variations and unmodeled dynamics, to validate the strength and reliability of the proposed intelligent strategy.

The convergence characteristics of the proposed nonlinear observer are significantly affected by the tuning parameter

, which shapes the placement of its eigenvalues relative to those of the motor. As shown in the upper subplots of

Figure 14, increasing

shifts the observer poles (blue) to follow the motor poles (red) more closely across the operating range

to 400 rad/s. For

, the observer exhibits a moderately damped response, while

yields faster convergence with reduced transients. The lower subplots of

Figure 14 illustrate the corresponding rotor flux observation errors under three representative speeds (0.0125, 3.4, and 150 rad/s). In both cases, the observer demonstrates strong convergence properties, but higher

improves transient rejection and tracking precision, especially at low and nominal speeds.

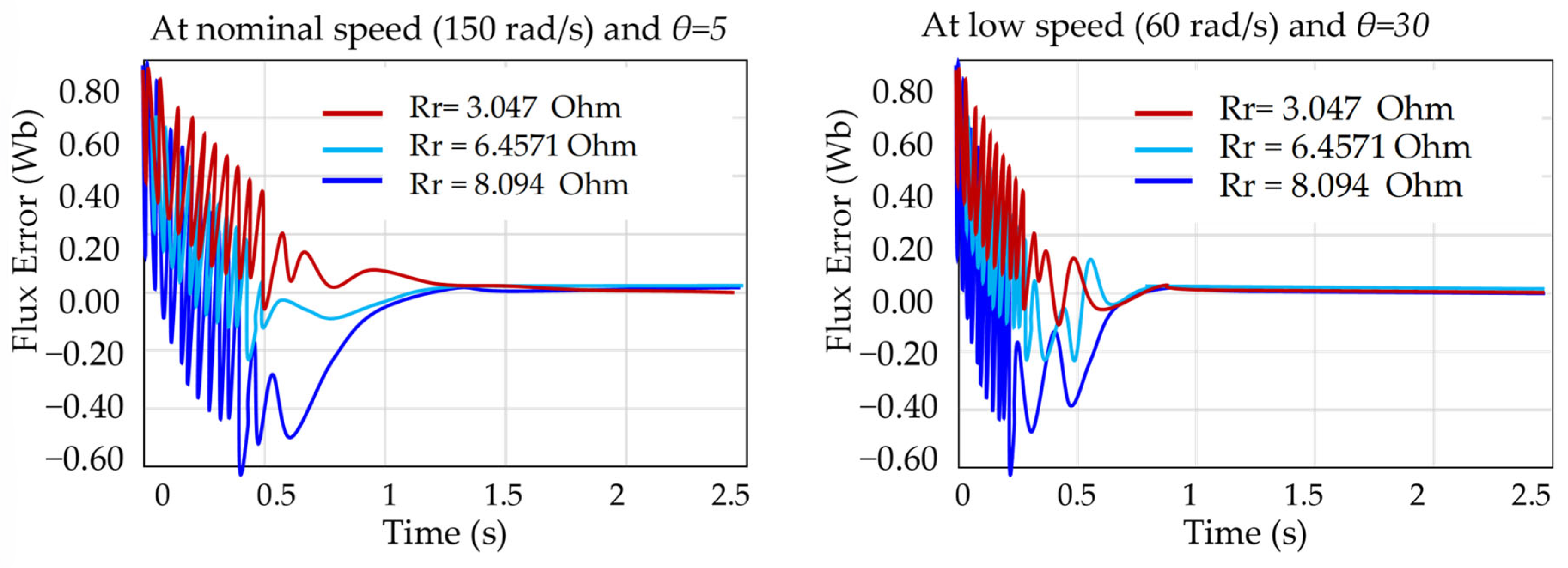

To evaluate the sensitivity of the proposed nonlinear observer to rotor resistance variations,

Figure 14 presents experimental results under three resistance values:

(nominal),

(+50%), and

(+100%). The observer is initialized with rotor flux components set to

.

Figure 14 demonstrates that, even with

increased from

(nominal) to

(+50%) and

(+100%), the nonlinear observer ensures rapid flux convergence. At both nominal (150 rad/s) and low speed (60 rad/s), transients settle within 0.6 s, showing strong disturbance rejection. A small steady-state offset remains (about 0.15 Wb at +50% and 0.30 Wb at +100%) indicating sensitivity to parameter mismatch. To address this, an RBFNN-based observer is introduced (

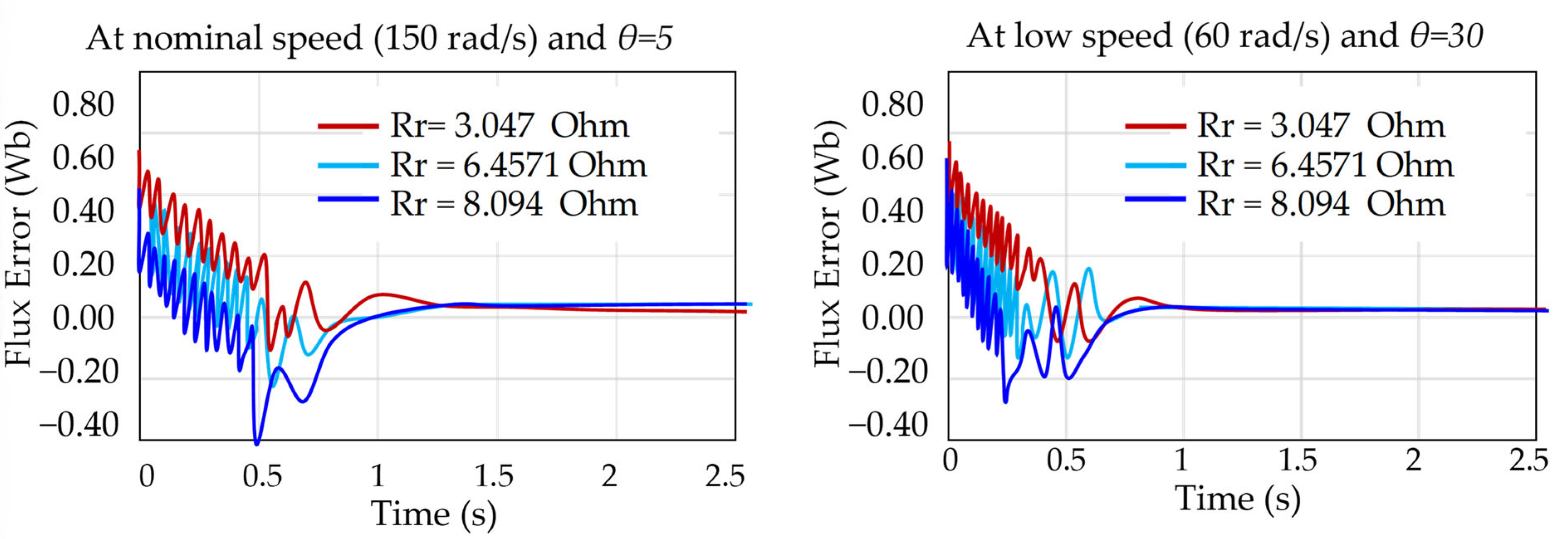

Figure 15), incorporating an adaptive term that continuously compensates for rotor resistance errors and effectively eliminates steady-state flux bias under large uncertainties.

Figure 15 highlights the impact of the RBFNN augmentation on the observer’s transient performance under large rotor resistance variations. In the baseline observer, the flux error exhibits pronounced oscillations and peak deviations nearing 0.8 Wb for a +100% resistance change, with settling oscillations persisting beyond 0.6 s. With the RBFNN-enhanced observer, the peak error is reduced by over 50%, and oscillations are significantly damped—settling in under 0.4 s across all resistance cases. This clear reduction in transient amplitude and faster damping confirms that the online neural adaptation effectively compensates for parameter mismatches, yielding smoother and more responsive flux estimation throughout the speed range.

5.2. Comprehensive Evaluation of the Proposed Nonlinear Intelligent Passivity-Based Control

This section presents an overall assessment of the proposed nonlinear intelligent passivity-based control, which integrates a neural PBC controller, an RNN-based adaptive observer, and a sensorless speed estimator. The complete system is tested in a closed loop with the induction motor under various conditions, including load disturbances, speed reversals, and parameter variations. The results highlight the dynamic performance of key signals such as torque, rotor flux, speed, and control voltages, confirming the robustness, adaptability, and precision of the proposed scheme.

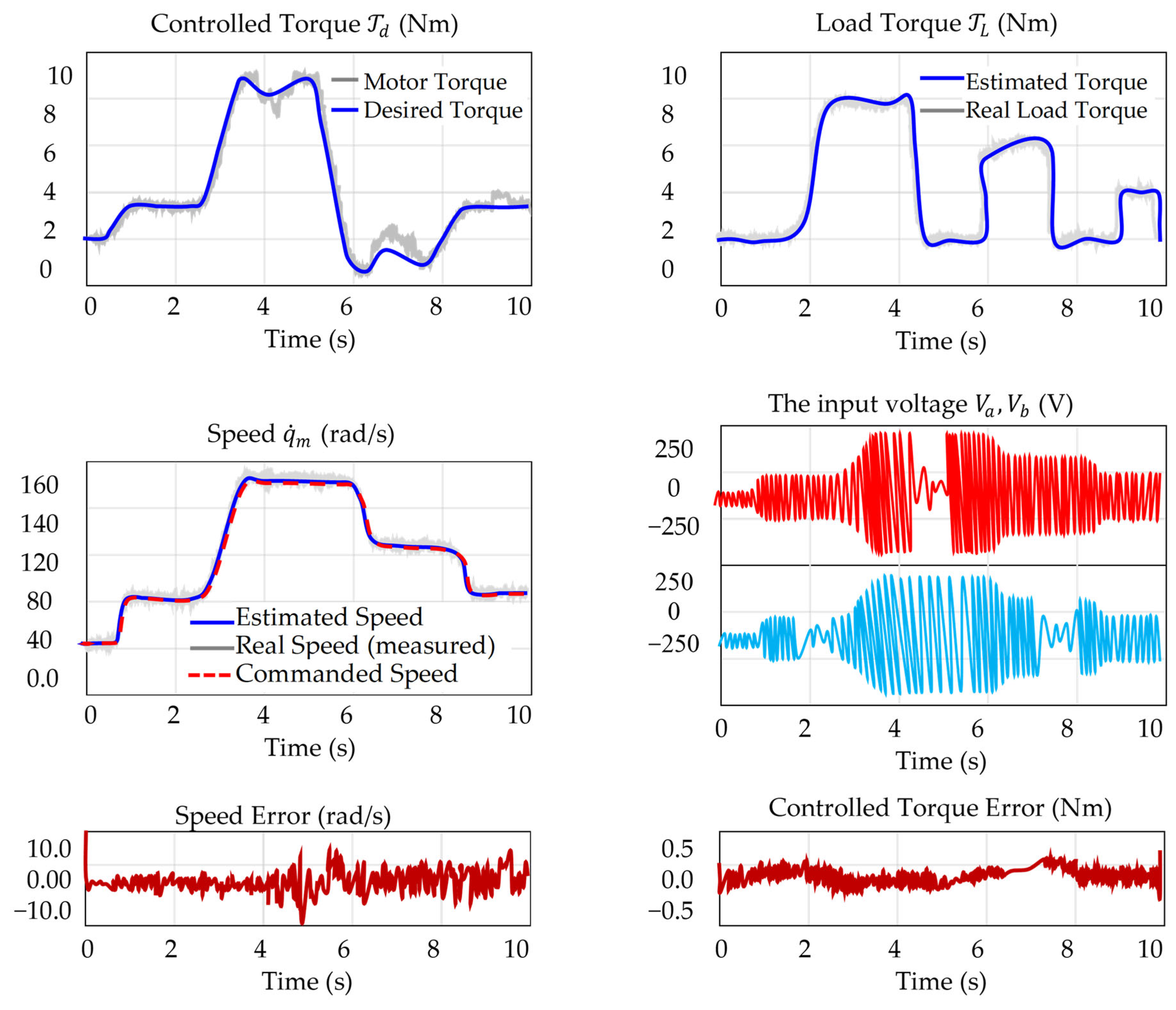

Figure 16 presents these responses under all test scenarios.

The performance of the proposed nonlinear intelligent PBC strategy is illustrated in

Figure 16, which presents both control and estimation results under time-varying speed and load torque conditions. The top-left subplot shows that the controlled electromagnetic torque

tracks the reference smoothly with minimal steady-state error. The top-right plot confirms accurate load torque estimation

, closely matching the timing and magnitude of applied disturbances. The middle-left subplot shows that both estimated and measured speeds follow the commanded reference

throughout acceleration, cruising, deceleration, and re-acceleration phases. The speed error, shown on the bottom-left, remains within ±8 rad/s, demonstrating the precision of the RNN-based speed estimator. The control voltages

and

, in the middle-right plot, reach ±250 V with consistent modulation behavior. The bottom-right plot shows torque error bounded within ±0.5 Nm, confirming high tracking accuracy and effective disturbance rejection. These results validate the proposed architecture’s capability for precise tracking, reliable estimation, and smooth control under sensorless operation.

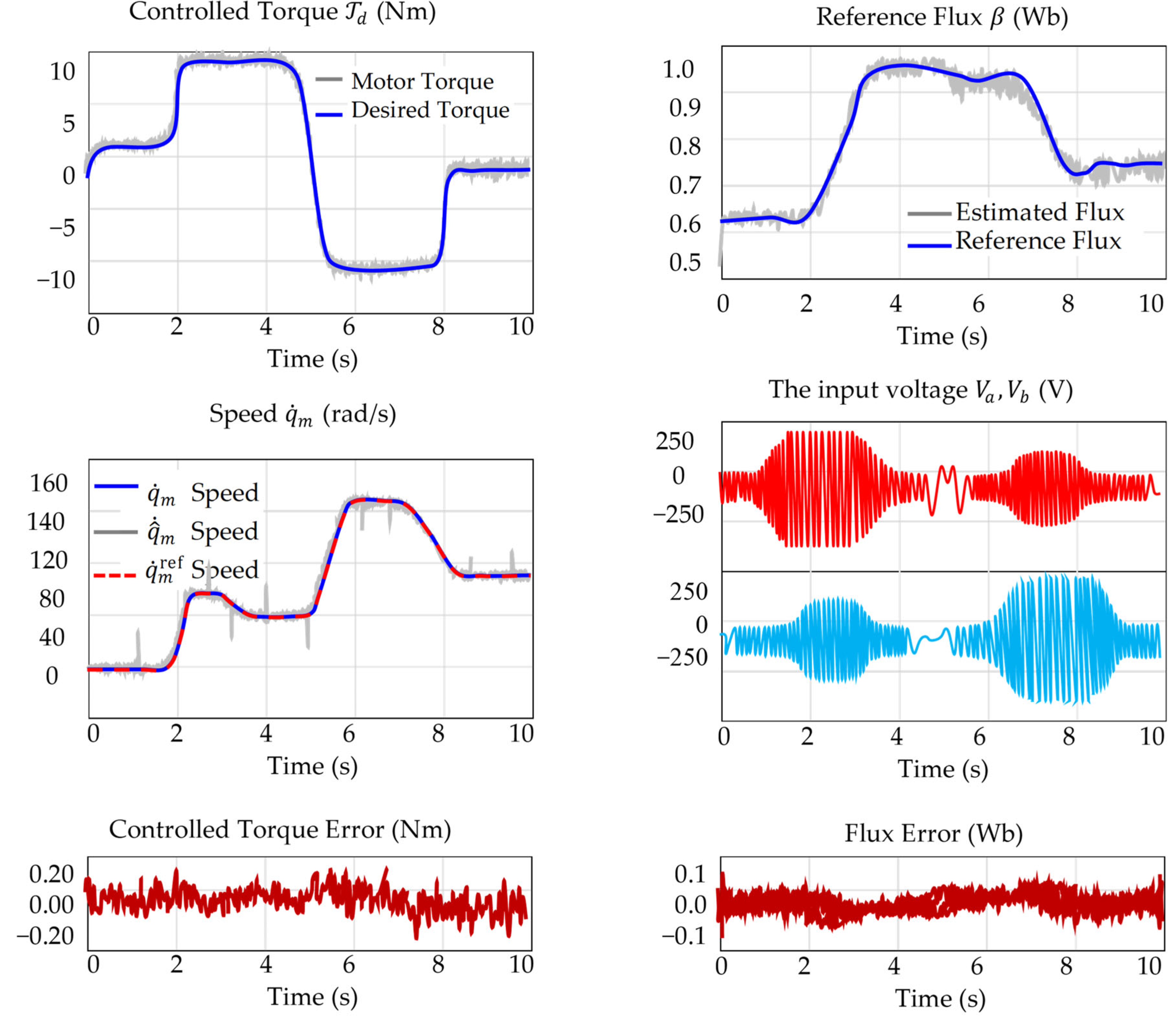

Figure 17 was performed on a sensorless induction motor using the proposed PBC strategy for torque and flux control. The system faced load variations, noise, and rotor resistance mismatch, with all estimations handled observer-based. Control ran in real time with a PWM injection, and key signals were precisely recorded for evaluation. The applied torque includes direction reversals to assess robustness.

The experimental results clearly confirm the effectiveness of the proposed nonlinear intelligent passivity-based control strategy. The motor tracks the torque reference with high accuracy, including during rapid transients and full torque reversal, maintaining a peak error within ±0.2 Nm. The estimated load torque closely matches the real applied load, capturing both magnitude and timing under dynamic conditions. The speed response aligns well with the reference, and the speed estimation remains precise even during acceleration and sharp changes. The flux estimation error is well confined within ±0.1 Wb, indicating strong observer performance. Input voltages exhibit clean modulation without saturation or chattering, demonstrating the quality of PWM-based voltage control. Despite load disturbances, parameter uncertainties, and a full sensorless operation, the controller preserves stability, accurate tracking, and robustness, confirming its suitability for advanced industrial applications.

5.3. Comparative Study and Performance Evaluation

To evaluate the performance of the proposed control, we use standard electrical engineering (EE) control metrics based on the response to torque amplitude or flux amplitude (i.e., |final − initial|):

is the time at which the response signal has covered 2% of the ramp amplitude.

is the time after which the response remains at less than 5% of the target value.

Peak overshoot relative to target (% of ramp amplitude).

(steady-state error settling) the error once the has been reached.

Error when reference reaches 50% of ramp.

Max torque deviation during speed ramp.

And in order to analyze the performance at global scope, we employ standard machine learning (ML) metrics: mean absolute error (MAE), symmetric mean absolute percentage error (SMAPE), and coefficient of determination (). These metrics are defined as follows: ; ; and where is the ground truth, is the predicted output of the model at time , and is the total experiment duration. denotes the mean of . These metrics jointly characterize accuracy, relative error, and explained variance, enabling a comprehensive assessment of model fidelity.

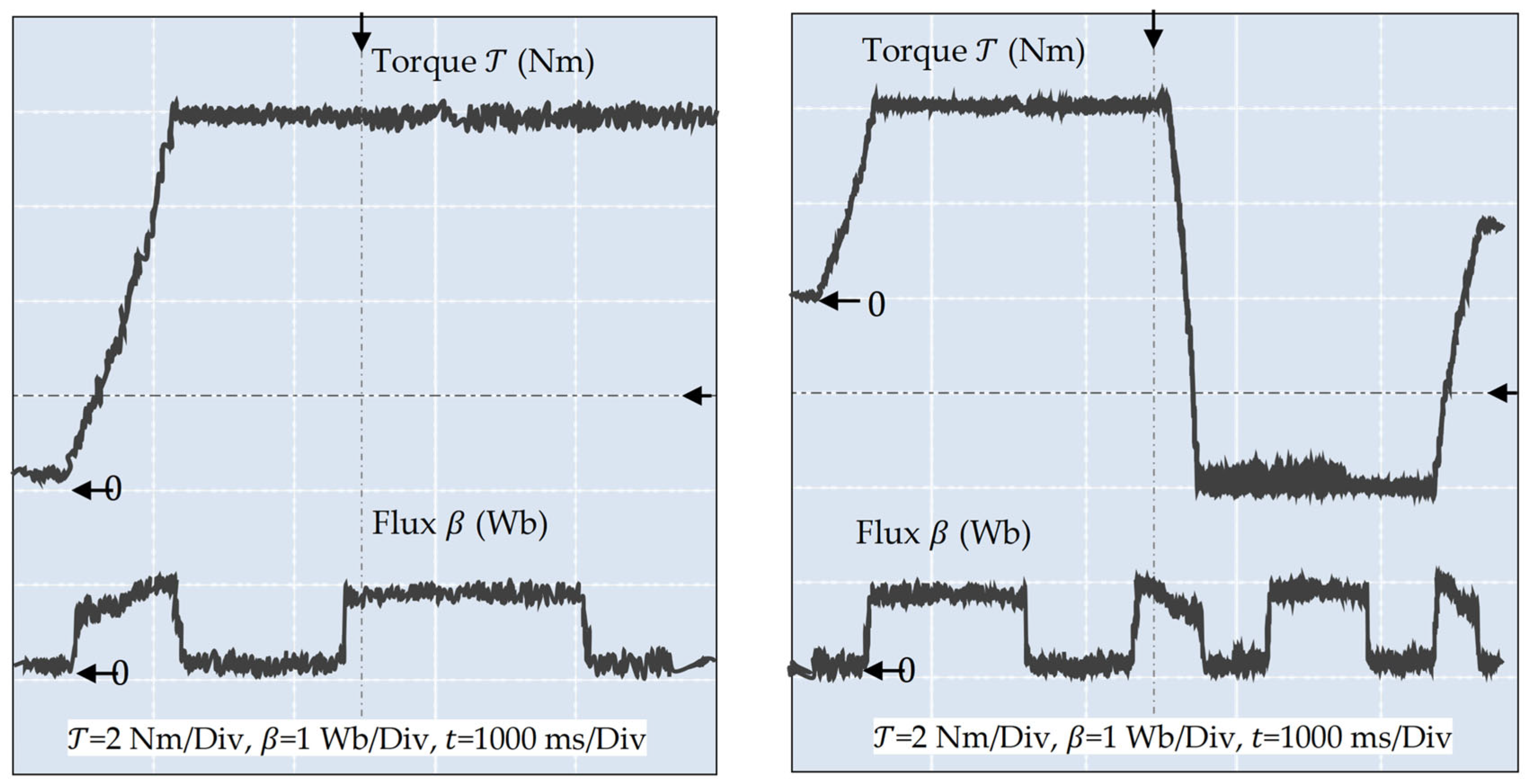

To comprehensively assess the effectiveness of the proposed adaptive neuro-PBC sensorless control scheme under realistic and demanding operating conditions, two benchmark trajectories were designed:

Pseudo-Static Benchmark: The torque reference ramps from 0 to 8 Nm in the first second and remains constant for the rest of the experiment. During the period from 1 s to 3 s and 5 s to 8.5 s, a flux reference step of 8 Wb is applied with superimposed ripples to emulate disturbances. This test evaluates steady-state tracking and disturbance rejection.

Dynamic Benchmark: Here, the torque follows a complex trajectory: it ramps from 0 to 8 Nm in the first second, holds steady until 5 s, then reverses sharply to approximately −8 Nm, followed by a final ramp back to 6 Nm by 10 s. Simultaneously, the flux reference features a sequence of four-step changes (switch on to 8 Wb in some time intervals), testing the controller’s performance under rapid transients and flux variations.

Figure 18 shows the profiles used during the experimental tests.

Throughout the entire profile, small random perturbations are superimposed to simulate external disturbances, ensuring a challenging scenario for evaluating control robustness, responsiveness, and adaptation under dynamic and load-varying conditions.

Now we present a comparative evaluation of the proposed neural adaptive PBC controller against four advanced control strategies. These include

CNO-PBC: classical PBC control with a nonlinear observer;

CFE-PBC: classical PBC control with a fuzzy enhanced MRAS estimator;

CRBF-PBC: classical PBC control with an RBF network enhanced observer;

DRNN-PBC: deep learning adaptive PBC strategy with RNN network observer.

To evaluate steady-state accuracy and low-dynamic performance, all four control strategies were tested under the pseudo-static benchmark, where the torque reference

ramps from 0 to 8 Nm within the first second and is then held constant. During the intervals

and

, a flux reference step of 8 Wb is applied, with superimposed ripple signals to emulate realistic disturbance conditions. This scenario is designed to assess tracking precision, overshoot suppression, robustness to steady-state perturbations, and the quality of torque/flux estimation in a low-dynamic environment. A summary of comparative performance under this benchmark is presented in

Table 3.

The results in

Table 3 confirm a progressive improvement in performance from classical observer-based control to advanced neural network-enhanced strategies. The baseline CNO-PBC controller shows the highest errors in both torque and flux estimation, with a torque MAE of 0.68 Nm and SMAPE of 21.40%, along with the highest overshoot (1.92%) and torque deviation (36.83%). Introducing fuzzy enhancement in CFE-PBC improves tracking accuracy significantly, reducing torque MAE to 0.15 Nm and improving flux SMAPE by nearly 8.4 percentage points. Further enhancement with radial basis function networks (CRBF-PBC) yields even lower errors (torque MAE = 0.09 Nm, SMAPE = 15.13%), shorter rise and settling times, and better rejection of steady-state disturbances. The best overall performance is achieved by the proposed DRNN-PBC controller, which achieves the lowest torque and flux estimation errors (MAE = 0.06 Nm and 0.10 Wb), fastest response (

= 13 ms), and minimal steady-state error (0.05 Hz). It also maintains the smallest overshoot (0.43%) and torque deviation (24.81% of nominal), confirming its robustness, adaptability, and estimation fidelity under pseudo-static conditions. All controllers maintain a high model fit with R

2 ≈ 0.998.

To evaluate the controllers under dynamic and nonlinear conditions, a challenging dynamic benchmark was executed. The torque reference

ramps from 0 to 8 Nm within the first second, holds steady until 5 s, then reverses sharply to approximately −8 Nm before ramping back to 6 Nm by 10 s. Simultaneously, the flux reference β undergoes multiple step changes up to 8 Wb, simulating rapid flux variations. Throughout the test, small random perturbations emulate external disturbances, creating a demanding scenario to assess the controllers’ robustness, responsiveness, and adaptation under rapid transients and load variations. This benchmark emphasizes each control strategy’s ability to maintain estimation accuracy and transient response quality under simultaneous nonlinear torque and flux variations. The results of this dynamic benchmark, including the speed reversal and load variation, are presented in

Table 4.

Under dynamic torque and flux variation conditions involving rapid torque ramps, reversals, and flux step changes, the performance disparities between control strategies become more pronounced. The classical CNO-PBC controller exhibits relatively high tracking errors and slower transient response, with a torque disturbance index () of 4.02% and steady-state frequency error () of 1.10 Hz. Conversely, the adaptive neuro-based controllers significantly improve tracking precision and responsiveness. Notably, the DRNN-PBC achieves the best overall performance, attaining the lowest torque MAE (0.18 Nm) and SMAPE (18.5%), alongside minimized maximum transient torque deviation ( = 30.85% nominal). Intermediate controllers, such as CRBF-PBC and CFE-PBC, also provide substantial enhancements in flux and torque estimation accuracy. These findings confirm the superior adaptability and robustness of proposed neural adaptive PBC schemes in handling rapid and complex torque and flux dynamics, ensuring stable and precise control during challenging real world transient conditions.

6. Conclusions

This work introduced a learning-driven intelligent passivity control strategy for induction motors, integrating a nonlinear state observer with an adaptive recurrent neural framework. The proposed observer significantly enhances the estimation accuracy of key motor variables such as torque, speed, and rotor flux, while simplifying the tuning process by requiring only a single gain adjustment over a wide speed range. Unlike traditional control schemes, this approach ensures rapid convergence and robust performance even under low-torque (i.e., low-speed) and highly dynamic operating conditions. Extensive simulation studies validated the global stability of the closed-loop system using Lyapunov-based analysis and demonstrated the observer’s robustness against various torque disturbances and flux variations. The integration of neural adaptive mechanisms into the passivity-based control framework yielded superior transient response, disturbance rejection, and steady-state tracking performance. Future work will focus on real-time experimental validation and extending the methodology to other induction motor topologies, including doubly fed and coaxial configurations, to establish the broad applicability and scalability of this intelligent control approach in advanced industrial drive systems.

Despite its strong real-time performance and robustness, the proposed scheme has certain limitations. Its computational complexity, while manageable on a DSP-based platform, may challenge ultra-low-power embedded systems. Additionally, the adaptive laws rely on continuous excitation and assume bounded modeling uncertainties. Future work will focus on reducing the neural and fuzzy estimator load through lightweight learning mechanisms, extending the observer design to support sensor faults and saturation effects, and validating the approach on higher-power industrial motors under more complex mechanical loads and grid disturbances.