1. Introduction

The increasing demand for sustainable alternatives to fossil fuels and chemical-intensive agricultural amendments has intensified research into biomass-derived materials such as biochar [

1,

2]. Biochar, a carbon-rich solid obtained from thermochemical conversion of biomass under limited-oxygen conditions, offers numerous applications in soil amendment, carbon sequestration, energy storage, and environmental remediation [

3,

4]. Among various thermochemical conversion techniques, downdraft gasification is particularly notable for its dual function of energy recovery and biochar generation, with the added advantage of a relatively high-temperature and uniform combustion zone [

5,

6]. Biochars produced via downdraft gasifiers at elevated temperatures (typically above 800 °C) often exhibit distinct physical properties, including well-developed pore structures and thermally stable matrices [

7,

8,

9].

The nature and composition of feedstock significantly influence the physicochemical characteristics of biochar. Woody biomass such as oak and pine has been extensively studied due to its lignocellulosic richness and relatively low ash content, leading to stable, carbon-rich chars [

10,

11]. However, in the context of resource optimization and waste valorization, there is a growing interest in integrating refuse-derived fuel (RDF) with conventional biomass feedstocks. RDF, a heterogeneous mixture of processed municipal solid waste components, introduces a complex chemical profile including plastics, textiles, and inorganic residues [

12,

13,

14]. While RDF offers the potential for enhancing energy output during gasification, its impact on biochar structure and stability remains insufficiently explored, particularly when co-fed with lignocellulosic wood in a downdraft gasifier [

12,

15].

Recent studies also point to the increasing potential of engineered biochars, where defect modulation and heteroatom incorporation improve their functional properties. For instance, Chen et al. [

16,

17] demonstrated that tailoring carbon nitride nanosheets with biochar-derived carbon bridges and nitrogen vacancies dramatically enhanced charge mobility and catalytic efficiency in a piezo-photocatalytic context. This dual-defect architecture not only increased surface polarization and piezoelectric responses but also sustained structural stability in water-rich systems, underscoring the versatility of biochar as a customizable scaffold for advanced applications beyond conventional sorption or amendment roles.

Existing studies on RDF-blended biochars have largely focused on combustion efficiency or emissions, with limited attention paid to the morphological and thermal behavior of the resulting chars [

18,

19]. Additionally, most prior investigations have centered on slow pyrolysis or fluidized-bed systems, which differ significantly in terms of heat transfer dynamics compared to downdraft gasification. This presents a critical gap in our understanding of how RDF inclusion affects the structural integrity and thermal decomposition profile of biochars produced at high temperatures in downdraft systems.

The conceptual synergy between recent photocatalytic applications and traditional thermochemical research on biochar suggests that exploring RDF-induced carbon disorder and heterogeneity may offer unexpected opportunities for valorization in CO

2 conversion and solar fuel generation technologies [

17].

Although previous studies have investigated blending RDF with biomass, most have concentrated on combustion efficiency, emission profiles, or pyrolysis-based systems. In contrast, very limited attention has been directed toward the structural and thermal behavior of biochars produced in downdraft gasifiers, particularly when RDF is co-fed with lignocellulosic feedstocks at elevated temperatures [

20,

21]. The novelty of this study lies in its systematic comparison of biochars derived from pure oak, an oak–pine blend, and an oak–pine–RDF mixture under identical downdraft gasification conditions. By integrating multiple characterization techniques—SEM, BET, TGA, XRD, Raman spectroscopy, and CHN analysis—this work establishes direct correlations between RDF incorporation and critical parameters such as surface area, porosity, and thermal stability. These insights provide a unique contribution to the field by clarifying the trade-offs between RDF’s role in waste valorization and its detrimental effects on biochar quality, an aspect that has not been comprehensively documented in prior studies.

The objective of this study is to conduct a comparative analysis of the morphological and thermal properties of biochars derived from three feedstock configurations: pure oak, a 1:1 blend of oak and pine, and a ternary blend of 50% oak, 30% pine, and 20% RDF. All samples were processed using a downdraft gasifier operating at 850 °C, ensuring consistency in terms of thermal exposure and reaction environment. Scanning electron microscopy (SEM), Brunauer–Emmett–Teller (BET) surface area analysis, thermogravimetric analysis (TGA), X-ray diffraction (XRD), and Raman spectroscopy were employed to evaluate structural features, porosity, and thermal stability.

By isolating the physical and thermal response of each feedstock blend, this study seeks to establish clear correlations between feedstock composition and resultant biochar quality. Emphasis is placed on identifying how RDF alters the char’s morphology and heat resistance, with implications for applications in soil conditioning, combustion systems, and carbon storage. This work contributes to establishing a better-informed approach to feedstock selection in biochar engineering, especially where waste streams are being considered for co-gasification with lignocellulosic materials.

2. Materials and Methods

2.1. Biochar Production via Downdraft Gasification

The biochar samples used in this study were produced using a downdraft gasifier operating at 850 °C. Three distinct feedstocks were utilized: 100% oak pellets (HW), a 1:1 blend of oak and pine pellets (HW/SW), and a ternary mixture (HW/SW/RDF) comprising 50% oak, 30% pine, and 20% refuse-derived fuel (RDF) by mass. The pellets of oak and pine feedstock were commercially sourced from a local Lowe’s store in Rolla, Missouri, United States, while the RDF consisted of pre-processed combustible municipal waste components sourced from Idaho National Lab (INL), United States.

The gasifier employed was a fixed-bed downdraft unit with a vertically configured throat design, capable of processing approximately one ton of biomass per day. Biomass was introduced from the top of the reactor and progressed downward through the drying, pyrolysis, oxidation, and reduction zones. Air was used as the gasifying agent, delivered at a controlled superficial velocity to maintain consistent thermal distribution across the reactor core [

22]. The maximum temperature within the combustion zone reached approximately 985 °C, while the gasification zone averaged 850 °C. Temperatures were continuously monitored using thermocouples interfaced with LabVIEW 2011 SP1 software version.

This configuration facilitated effective thermal cracking of volatile matter, optimized gas–solid interactions and produced a consistent stream of high-quality biochar. More comprehensive details regarding the design and operation of the gasifier system, as well as the reactor geometry, are available in a previous publication [

23].

Figure 1 presents an image of the downdraft gasifier.

For this study, a total of nine gasification batches were conducted—three for each feedstock configuration—to ensure experimental consistency and replicate variation. Each batch run processed approximately 42 kg of feedstock with a residence time ranging between 45 min and 1 h, depending on the feedstock composition and combustion rate. This allowed for controlled and repeatable operation within the fixed-bed downdraft gasifier system. The study was comparative and experimental in design, aiming to systematically evaluate the influence of varying feedstock blends on the physicochemical and thermal behavior of the resulting biochars under identical thermal conditions.

2.2. Biochar Characterization

A suite of analytical techniques was used to evaluate the Physicochemical and structural characterization of the biochars.

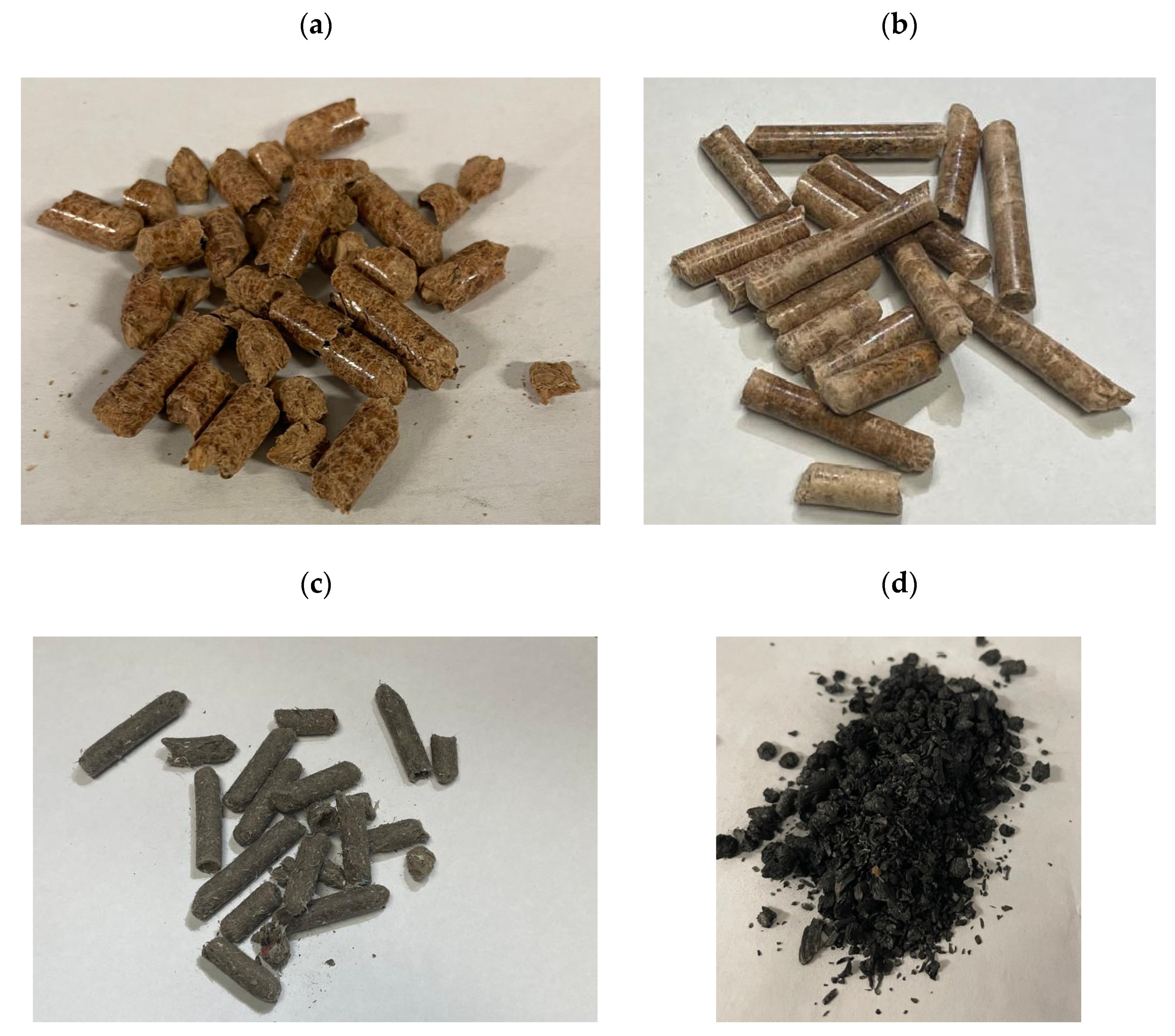

Figure 2 shows the biomass pellets and gasified biochar, with a focus on the key properties relevant to thermal performance and morphological integrity. All measurements were performed in triplicate to ensure reproducibility. The specific methods used are briefly described below, with full procedural details and analytical parameters reported in an earlier study [

23].

2.2.1. Scanning Electron Microscopy (SEM)

The surface morphology of each biochar was examined using a TESCAN Vega 3 scanning electron microscope operated with VegaTC version 4.2.30 software (TESCAN, Brno, Czech Republic). The instrument was used over a magnification range of 2× to 1,000,000× with an electron-beam accelerating voltage between 200 eV and 30 keV. Samples were gold-coated to enhance conductivity and prevent beam charging. Images were captured at magnifications of 10 µm to observe pore development and matrix structure. Sample preparation followed the ASTM E1252 standards [

24,

25].

2.2.2. Thermogravimetric Analysis (TGA)

Thermal decomposition behavior was analyzed using a Netzsch STA 449 F5 Jupiter system, using a soft ware version of version 8.03, the instrument was sourced from Gerätebau GmbH, Selb, Bayern, Germany. Biochar samples were subjected to a two-stage heating profile: an initial ramp to 150 °C under nitrogen, followed by a second ramp to 900 °C and an isothermal hold in air. This method conformed to the ASTM E1131 specifications, enabling an accurate assessment of mass loss, ash content, and residual carbon [

26].

2.2.3. BET Surface Area and Porosity Analysis

Nitrogen adsorption–desorption measurements were performed using a physisorption analyzer, manufactured by (Anton Paar 600 GmbH), Graz, Austria. In accordance with the ISO 9277:2010 standards. Samples were degassed at 300 °C before 44-point Nitrogen adsorption–desorption analysis at −196 °C. The surface area was calculated using the Brunauer–Emmett–Teller (BET) method, while pore volume and pore size distribution were derived using Density Functional Theory (DFT) [

25].

2.2.4. X-Ray Diffraction (XRD)

Crystallographic features and the degree of graphitization were examined using a PANalytical X’Pert diffractometer–manufactured by malvern panalytical, Geat Malvrn, United Kingdom. It employs the use of Cu Kα radiation. XRD patterns were collected over a 2θ range of 5° to 90° at a scan rate of 3°/min. Data were used to assess the presence of amorphous and crystalline phases in the biochar samples. The analytical procedure followed ASTM D1762-84 [

27].

2.2.5. Raman Spectroscopy

Raman spectral analysis was carried out using the Thermo Scientific Nexsa system (East Grinstead, UK), which integrates X-ray photoelectron spectroscopy (XPS) and a ThermoFisher iXR Raman Spectrometer., the instrument was manufactured and sourced from Madison, Wisconsin, United States. Raman measurements were conducted with a 532 nm excitation laser, and data processing was performed using Omnic Software version 9.11.706. The methodology followed the ISO/TS 21356-1:2021 standard to ensure spectral accuracy and reproducibility. The intensity ratio of the D and G bands (I

D/I

G) was used to assess structural disorder in the biochar matrix [

28].

2.2.6. CHN Ultimate Analysis

Elemental composition was determined using a LECO 828 CHN analyzer (Laboratory Equipment Corporation, St. Joseph, MI, USA), with procedures conforming to the ASTM D3176 and ISO 16948 standards. Carbon, hydrogen, and nitrogen content were directly measured through combustion analysis, while oxygen content was estimated based on differences. This analysis provides insight into the fuel potential and fixed-carbon ratio of the samples [

29].

Further procedural details of all the analyses can also be found in our previous work [

23].

3. Results and Discussion

This section presents the comparative analysis of the morphological and thermal characteristics of biochars produced from three distinct feedstock configurations. The findings are derived from a series of targeted characterization techniques aimed at evaluating structural features, surface area, pore development, and thermal stability. The results offer insight into how variations in biomass composition influence the physical integrity and thermal behavior of biochar generated in a downdraft gasifier at 850 °C.

3.1. Morphological Characterization (SEM Analysis)

Scanning Electron Microscopy (SEM) was employed to assess the surface morphology of the biochar samples produced from three distinct feedstock configurations. Images obtained at 10 μm magnification revealed notable differences in the surface architecture, directly attributable to the feedstock composition.

The biochar derived from 100% oak (HW) is characterized by clearly developed pores and longitudinal channels. These features are typical of high-quality lignocellulosic biochar and reflect the anatomical integrity of the hardwood precursor. The porous network observed is indicative of the enhanced specific surface area, which is known to support improved moisture retention, nutrient absorption, and colonization by beneficial soil microorganisms. Such properties are favorable for applications in soil amendment and remediation, where structural porosity plays a critical role [

30,

31].

HW/SW produced from a 1:1 blend of oak and pine exhibited a comparable morphological profile and displayed a fibrous, well-structured surface. The pore distribution and surface texture closely resembled those of the pure-oak biochar, suggesting that the inclusion of softwood did not significantly compromise the structural characteristics. On the contrary, the blend appeared to preserve the beneficial microstructural features of the hardwood biochar. This suggests that co-gasification of hardwood and softwood at 850 °C in a downdraft gasifier can yield biochar with consistent morphological attributes, maintaining suitability for soil-based applications [

32,

33,

34].

In contrast, the biochar from the oak–pine–RDF blend (HW/SW/RDF) presented a markedly different surface structure. The SEM images revealed a disrupted and irregular morphology, with a significant reduction or complete absence of visible pore channels. The surface appeared fused or clogged, which is likely a consequence of RDF constituents undergoing melting or partial vitrification at high gasification temperatures. This loss of porous structure implies a reduced surface area, which may compromise the material’s capacity for water retention, microbial support, and adsorption of nutrients or contaminants [

35].

These observations underscore the sensitivity of biochar morphology to feedstock composition, particularly when non-lignocellulosic materials such as RDF are introduced. While RDF integration may offer advantages in terms of waste valorization, its impact on the microstructural integrity of biochar should be carefully considered. The diminished porosity observed in the distorted and compacted matrix observed in the RDF-blended sample suggests compromised structural features that are essential for effective nutrient anchoring and microbial colonization in soil-based applications.

These observations align with earlier reports by Suarez-Hernandez et al. [

36] and Xingzhu Ma et al. [

37], who emphasized the significance of surface and pore structures in determining biochar performance. Their SEM-based analyses similarly highlighted the role of porosity as a defining parameter in biochar’s environmental utility. In both studies, the architecture of the pores was directly linked to the functional attributes of the biochar, particularly at adsorption and catalytic interfaces. Such corroborative evidence reinforces the notion that pore integrity remains a central design criterion for biochar intended for soil amendment or environmental applications.

Altogether, the results presented here emphasize the sensitivity of biochar microstructure to feedstock variability. While lignocellulosic compositions preserve functional morphology, the integration of RDF introduces heterogeneity that compromises structural fidelity.

Figure 3 presents the SEM images of the three biochar samples at 10 μm.

3.2. Surface Area and Pore Structure Analysis

The specific surface area, pore volume, and pore size distribution of the biochar samples were assessed through nitrogen adsorption–desorption isotherms using the BET method. These parameters are critical for evaluating the physical performance of biochar, particularly in applications involving adsorption, nutrient retention, and water-holding capacity [

38,

39].

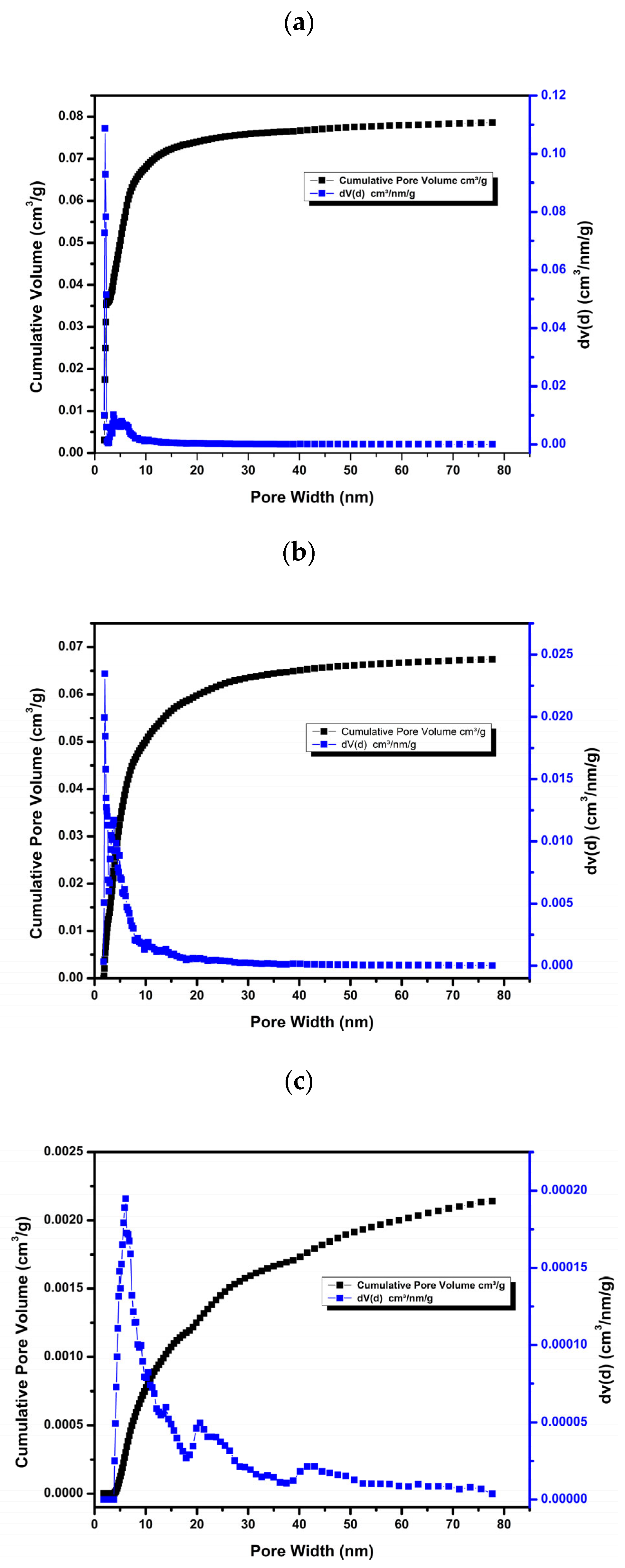

The HW biochar exhibited the most well-developed porous architecture, with a specific surface area of 107.73 m2/g and a cumulative pore volume of 0.0786 cm3/g. The pore size distribution spanned a wide range, from 1.868 nm to 77.698 nm, covering micropores (<2 nm), mesopores (2–50 nm), and macropores (>50 nm). The isotherm revealed pronounced peaks across all pore-size regions, confirming the presence of a multi-scale pore system. This extensive porosity enhances the material’s capacity for water retention, ion exchange, and interaction with soil microbes, making it particularly suitable for agricultural and environmental remediation purposes.

The blended HW/SW biochar displayed a similar pore size range (1.8 nm to 77.698 nm) but with noticeably lower intensity in the adsorption isotherm, indicating reduced pore development. Its surface area was measured at 72.821 m2/g, with a cumulative pore volume of 0.0671 cm3/g. While these values represent a reduction compared to pure-oak biochar, the presence of micropores and mesopores still suggests moderate adsorption potential. These results imply that blending hardwood and softwood does not significantly alter the fundamental pore architecture, although it may slightly diminish the overall pore density and surface area.

In contrast, the ternary blend incorporating RDF (HW/SW/RDF) exhibited a significant decline in both surface area and pore volume. The measured surface area was only 0.861 m

2/g, and the cumulative pore volume dropped to 0.00214 cm

3/g. Although the pore width distribution technically spanned the same range (1.78 nm to 77.698 nm), the low isotherm peak intensities indicated that the porous network was poorly developed. This sharp decline in the internal surface area indicates the limited ability of the material to facilitate physico-chemical interactions, thereby constraining its utility in sorptive, energy-application, and moisture-regulation contexts [

40,

41]. This outcome is attributed to the nature of RDF, which typically contains thermoplastic materials and fine particulates that may melt or fuse under high-temperature gasification, effectively sealing or collapsing pore structures during carbonization [

42].

Figure 4 shows a graph of particle size distribution for the three samples under study:

Adsorption Isotherm

Microporous and mesoporous domains are advantageous for applications requiring a large surface interface, such as nutrient adsorption, water retention, and pollutant immobilization.

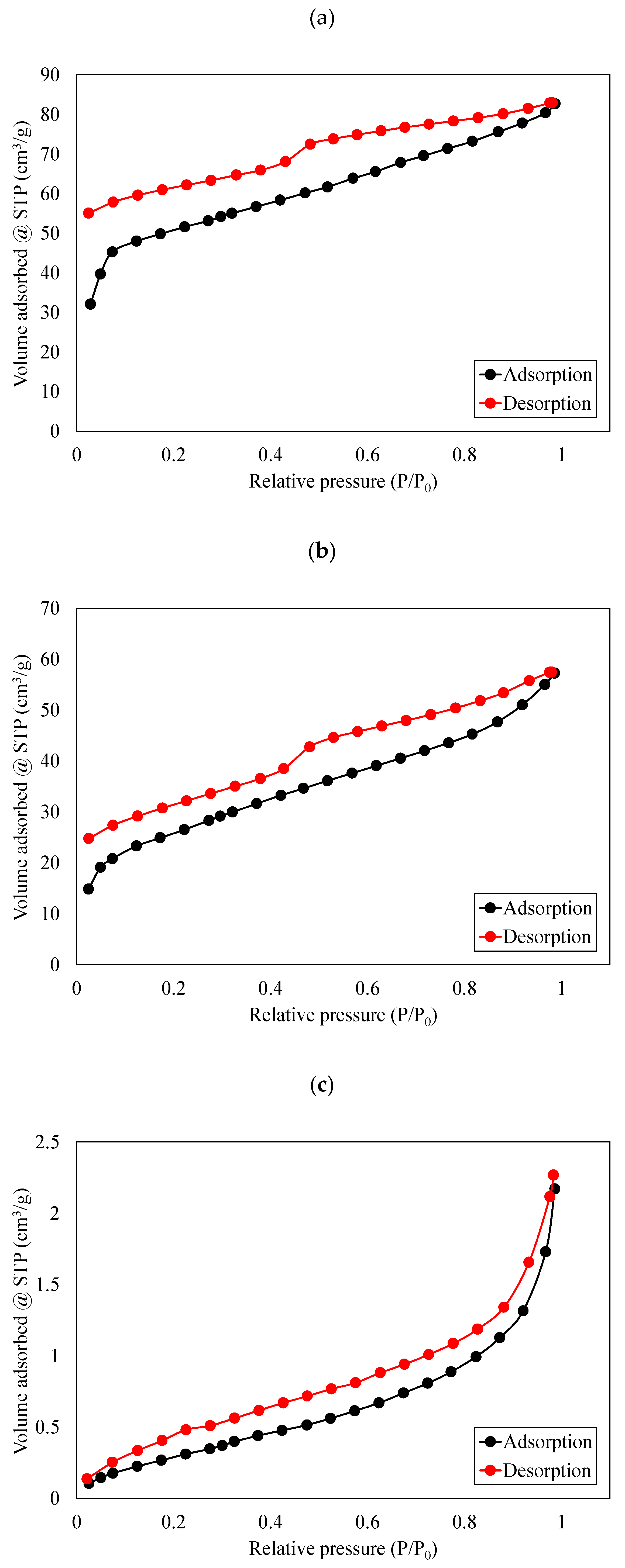

In addition, HW/SW biochar also exhibited a Type IV isotherm [

43], although the hysteresis loop was narrower and the overall nitrogen uptake was reduced to 60.570 cm

3/g. This reduction indicates a modest decline in mesopore volume and surface area relative to the pure-biochar sample (HW). The nitrogen adsorption–desorption isotherms offer critical insight into the pore structure and adsorption behavior of the biochar samples. As shown in

Figure 5a–c, distinct differences were observed among the samples, corresponding to their respective feedstock compositions.

The biochar produced from pure oak (HW), as shown in

Figure 5a, displayed a Type IV isotherm with a well-defined hysteresis loop, characteristic of mesoporous materials. The initial steep rise in nitrogen uptake at low relative pressures (P/P

0) indicates the presence of micropores, while the hysteresis loop reflects capillary condensation within mesopores [

43,

44]. The total nitrogen adsorption capacity reached 82.950 cm

3/g at standard temperature and pressure (STP), signifying a well-developed and accessible pore network. This isotherm profile confirms the formation of both types, and the isotherm still reflects adequate pore development for moderate adsorption functions. The similarity in isotherm types between the first two samples suggests that substituting part of the hardwood with softwood does not fundamentally alter the pore-forming behavior during gasification, although it may slightly lower the total pore accessibility.

In stark contrast, the biochar incorporating RDF (HW/SW/RDF) exhibited a markedly different profile. Its isotherm closely resembled a Type III pattern, which is typically associated with weak adsorbate–absorbent interactions and minimal surface heterogeneity [

44]. The absence of a hysteresis loop and the very low nitrogen adsorption volume of 2.260 cm

3/g underscore the poor development of internal pore structures. This behavior suggests that the RDF components interfered with the formation of micro- and mesopores during high-temperature gasification, possibly through partial melting or sintering of thermoplastic constituents. As a result, the absence of a developed pore network and the diminished sorptive affinity observed in the RDF-based char render it less viable for roles demanding high interfacial surface activity, moisture regulation, or nutrient exchange [

44]. Shimizu et al. [

45], in their study, also emphasize the effectiveness of BET surface area analysis as a pivotal method in the characterization of biochar and other porous solids, reaffirming its critical role in assessing structural integrity and adsorption potential.

Figure 5a–c presents a graph of the adsorption–desorption isotherms for the three biochar samples.

Table 1 presents a summary of the BET surface area and porosity results for the three biochar samples.

The results in

Table 1 and

Figure 5 reflect the influence of feedstock selection on the adsorption characteristics of biochar produced under identical thermal conditions in a downdraft gasifier at 850 °C. While both the HW and HW/SW biochars exhibited favorable isotherm patterns for environmental applications, the inclusion of RDF significantly impaired pore development and surface accessibility. This loss of porosity and adsorption capacity limits the potential of RDF-based biochar in roles where a high surface area is essential.

The reduction in surface area and collapse of porous structure in the RDF-blended sample is closely linked to the physicochemical properties of its constituents [

46]. Oak-derived biochar, with high lignocellulosic content and thermal resistance, retains its anatomical porosity under gasification [

36]. Pine, while also lignocellulosic, introduces slightly lower density and structural uniformity, which explains the moderate decline in surface area in the HW/SW blend. However, the RDF fraction—composed of thermoplastics, polymers, and inorganics—undergoes partial melting, fusion, or sintering at high temperatures. These processes obstruct pore formation by clogging or collapsing micro- and mesopores. Additionally, the RDF’s elevated content of ash and volatiles disrupts carbon matrix development, leaving a less porous and more amorphous solid. The resulting material exhibits weaker sorptive interactions and poor internal connectivity, thus explaining the observed decline in BET surface area and nitrogen uptake, and the shift from a Type IV to a Type III isotherm profile in the HW/SW/RDF biochar [

47,

48,

49].

Furthermore, Type IV isotherms are indicative of high-quality mesoporous biochars, while Type III profiles point to poor adsorption potential and limited structural functionality. A recent investigation by Skic et al. [

50] illustrates the importance of BET analysis: using nitrogen adsorption isotherms, they effectively determined biochar surface areas and adsorption energies, while also comparing the results with water vapor adsorption—a comparison that highlighted significant differences in pore characteristics across adsorption media.

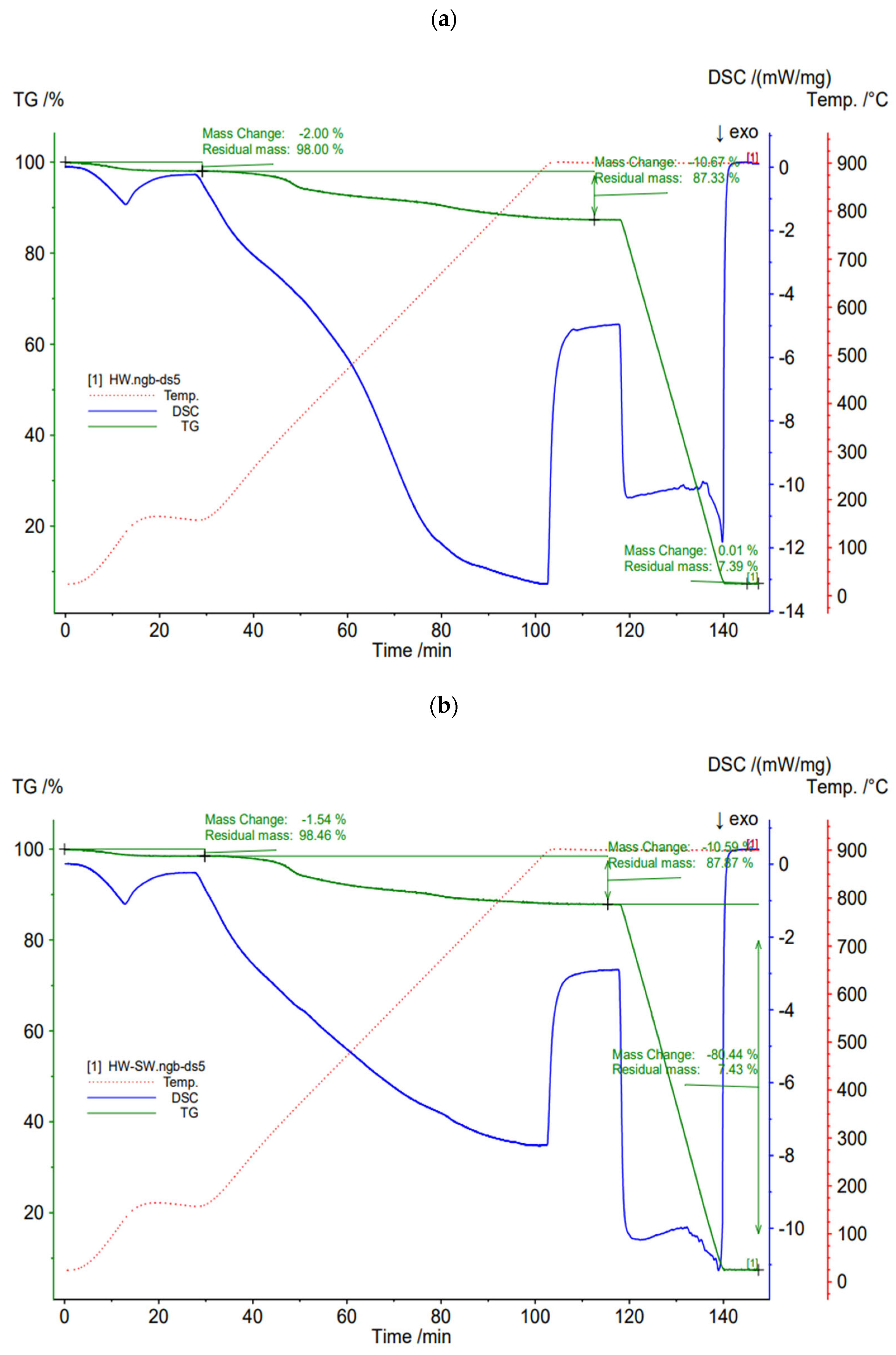

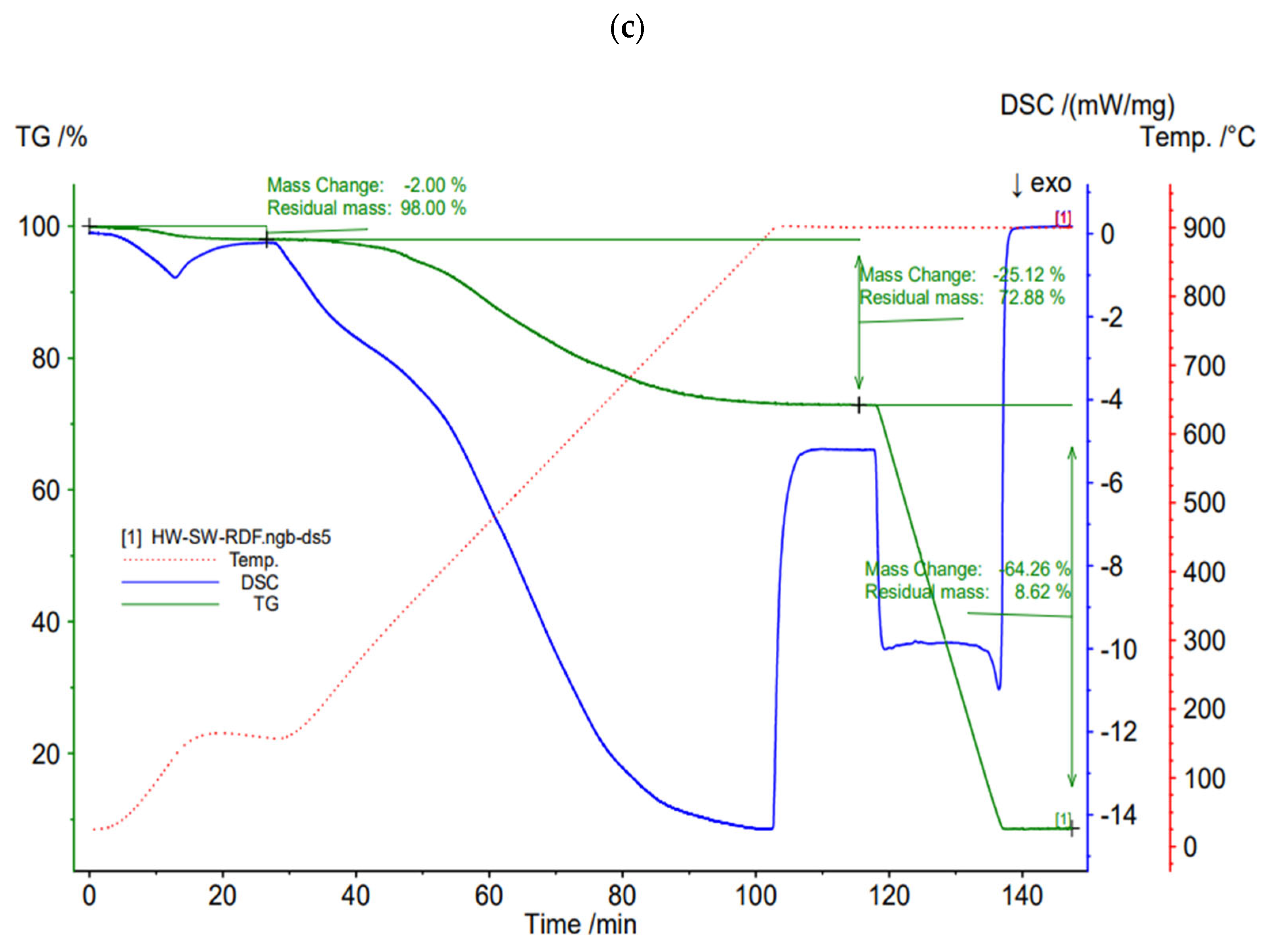

3.3. Thermal Stability and Decomposition Behavior (TGA and DSC Analysis)

Thermogravimetric analysis (TGA) identifies key stages of weight loss, including moisture evaporation, release of volatile compounds, and oxidation of fixed carbon, and is used to assess thermal and decomposition behavior [

51,

52]. The HW biochar displayed a relatively small initial weight loss of approximately 2% around 200 °C, corresponding to moisture evaporation. Between 180 °C and 370 °C, the sample maintained a stable mass, indicating good thermal resistance across this range. More pronounced weight loss occurred between 400 °C and 800 °C, accounting for 10.67% of the original mass, and is attributed to the decomposition of volatile compounds. The sample retained a high proportion of fixed carbon, which was fully oxidized upon the introduction of air at 900 °C during the final stage of analysis. The total combustion of fixed carbon reached 79.94%, leaving behind 7.39% residual ash. These results confirm the thermal robustness of hardwood-derived biochar, with minimal early degradation and efficient carbon retention.

The HW/SW blend exhibited a similar thermal profile, with slightly reduced moisture content evidenced by a 1.54% weight loss at around 200 °C. The thermally stable region between 270 °C and 330 °C suggests comparable resistance to thermal breakdown. Volatile release occurred between 400 °C and 800 °C, with a mass loss of 10.59%, nearly matching the behavior of the HW biochar. At 900 °C, the combustion of fixed carbon reached 80.44%, with residual ash accounting for 7.43% of the original sample weight. These values also indicate that incorporating softwood into the feedstock does not significantly impair the thermal performance of the resulting biochar under gasification conditions.

By comparison, the HW/SW/RDF sample demonstrated a distinctly different decomposition pattern. Initial moisture loss was consistent at 2%, but the major volatilization phase occurred earlier and more abruptly, between 300 °C and 650 °C, resulting in a substantial 25.12% weight loss. This heightened volatile content reflects the heterogeneous and polymeric nature of RDF components. The oxidation of fixed carbon during the final stage reached 64.26%, markedly lower than in the other two samples. The residual ash content was slightly higher at 8.62%, likely due to the inorganic content inherent in RDF-derived materials. These findings suggest that RDF inclusion reduces the thermal stability and fixed-carbon content of biochar, which could limit its performance in applications requiring high carbon retention or consistent combustion behavior.

The complementary differential scanning calorimetry (DSC) results in [

53] supported these observations. For all three samples, endothermic peaks were observed during the drying and volatilization phases, indicating heat absorption, while exothermic peaks corresponded to the oxidation of carbon during the final combustion stage. The HW and HW/SW biochars exhibited sharper and more defined thermal transitions, consistent with their higher fixed-carbon fractions and thermal resilience. In contrast, the HW/SW/RDF sample showed broader, less distinct transitions, reflecting a more complex and unstable thermal profile.

Collectively, the TGA confirms that feedstock composition has a significant impact on the thermal behavior of biochar. While both HW and HW/SW blends yield thermally stable biochar with high fixed-carbon content, the addition of RDF compromises thermal integrity and accelerates volatile release. These differences highlight the importance of feedstock selection when producing biochar intended for energy storage, thermal applications, or long-term carbon sequestration.

Figure 6a–c show a thermogram curve for the analysis of the three biochar samples.

A summary of the proximate analysis, including moisture content, volatile matter, fixed carbon, and ash content for all three samples, is provided in

Table 2.

Furthermore,

Table 2 shows that all three Samples with relatively high carbon contents show potential for carbon sequestration and soil amendments [

54]. HW/SW/RDF, while showing less thermal stability, could find potential applications in waste management. In other similar studies and methodologies using proximate analysis, Yakout [

55] and Choudhary et al. [

56] demonstrated through their findings that carbon sequestration and soil enhancement depend on the high carbon content and stability of this biochar. This also indicates that they play a significant role in long-term soil carbon storage and improving soil properties.

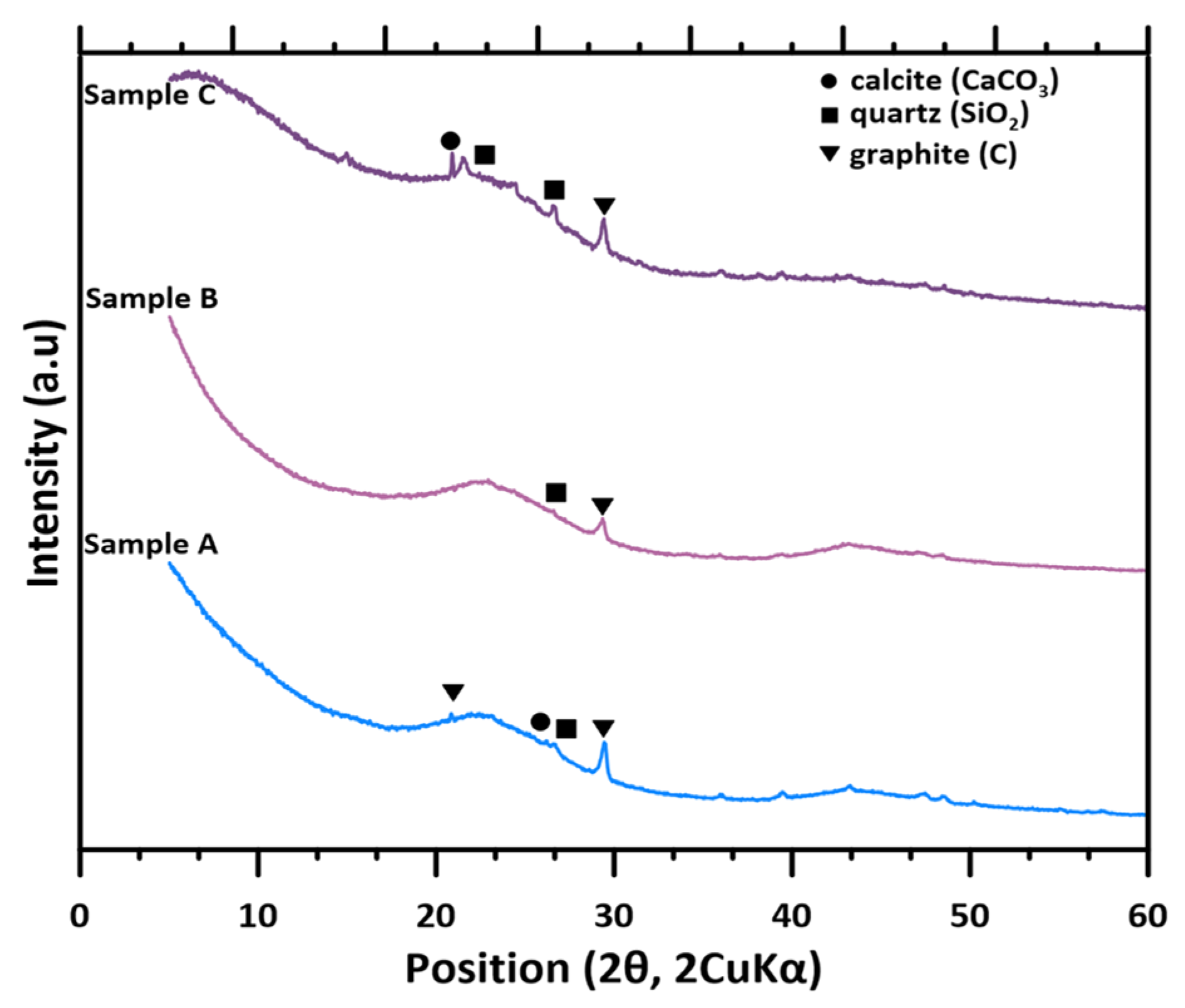

3.4. Crystallographic Structure and Phase Composition (XRD Analysis)

X-ray diffraction (XRD) analysis was conducted to assess the crystalline and amorphous phases present in the biochars [

57,

58]. The resulting diffraction patterns offer details into mineral stability, carbon structure ordering, and phase distribution, all of which directly influence the physical durability, chemical reactivity, and potential application of biochar materials.

Figure 7 presents a diffractogram of the three samples.

The XRD profiles of all three samples—HW, HW/SW, and HW/SW/RDF —revealed dominant crystalline phases of calcite (CaCO

3), quartz (SiO

2), and graphite. The consistent presence of calcite across all samples indicates that calcium carbonates either remained thermally stable during gasification or formed through high-temperature transformations [

59]. Calcite contributes to the basicity of biochar and plays a central role in pH buffering when applied to acidic soils. This buffering capacity is particularly valuable for agricultural and environmental remediation purposes, where chemical stability and ion exchange are crucial [

59].

Quartz was also observed in all samples, originating from inherent silicate minerals within the biomass or from environmental contamination. While quartz is chemically inert and contributes little to surface reactivity, its structural rigidity enhances the mechanical stability of biochar. This makes quartz-enhanced biochar suitable for integration into building materials, such as concrete composites or polymer-reinforced systems [

60].

Notably, the formation of graphitic carbon was evident in all samples, most prominently in the HW and HW/SW biochars. The presence of graphitic peaks suggests a significant degree of carbon ordering, which can be attributed to the elevated temperature (850 °C) employed during gasification. Graphitic structures are known to improve electrical conductivity, thermal resistance, and long-term carbon stability. These characteristics broaden the applicability of the biochar to include electrochemical systems, electrode fabrication, and carbon sequestration technologies [

61].

The HW biochar exhibited the most defined graphitic structure, reflecting the ability of oak-derived biomass to produce thermally stable carbon forms under gasification. The HW/SW sample maintained a similar phase composition, indicating that the addition of pine did not significantly alter mineral identity but may have had a subtle influence on the extent of graphitization. This reinforces the earlier conclusion that blending hardwood with softwood does not compromise biochar quality, at least in terms of crystallographic integrity [

61,

62].

The HW/SW/RDF sample showed no new crystalline phases but may exhibit microstructural disruptions due to the heterogeneous nature of RDF. While the same primary minerals were detected and major mineral phases remained unaltered, the RDF blend appeared to disrupt the continuity of carbonaceous domains, as evidenced by weakened graphitic ordering rather than alteration of the overall crystallographic fingerprint. This could explain the observed reduction in the adsorption surface and thermal stability reported in previous sections, even though the dominant crystalline phases remained unchanged [

63].

Finally, the XRD analysis highlights the structural consistency among biochars derived from lignocellulosic feedstocks, while also revealing the potential impact of RDF inclusion on carbon ordering and application performance. The co-existence of calcite and graphite in the HW and HW/SW samples points to a favorable combination of chemical reactivity and electrical functionality, supporting their use in both environmental and electrochemical domains. The quartz phase, while inert, contributes to physical durability, making these materials suitable for structural or composite-based applications [

63,

64,

65].

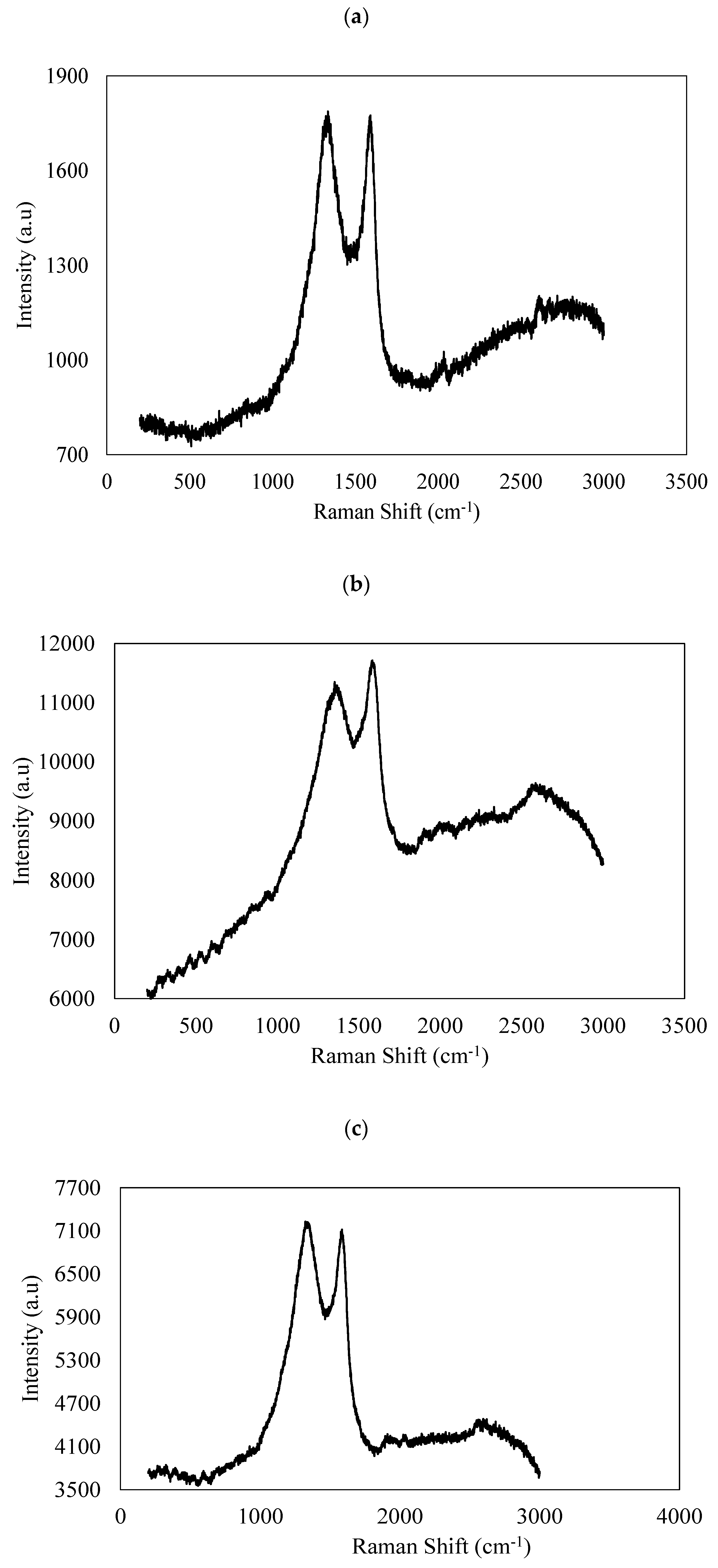

3.5. Structural Ordering and Carbon Framework Analysis (Raman Spectroscopy)

The analysis of key spectral features, such as the D and G bands, allows for the assessment of defect density and overall carbon ordering [

66]. These characteristics influence the physicochemical properties of biochar, affecting its stability, reactivity, and potential applications. By comparing biochar samples derived from single and blended feedstocks, Raman spectroscopy helps elucidate how feedstock composition and gasification conditions impact structural integrity. This section explores the Raman spectra of the three biochar samples, identifying key differences in graphitic and disordered carbon phases [

67,

68].

Figure 8 shows the Raman spectra graphs of the three biochar samples for comparison and a summary of their I

D/I

G ratios.

The Raman analysis provides insights into the structural properties of biochar samples derived from single and blended feedstocks by examining the D and G bands. The D band, located around 1340–1360 cm

−1, is associated with the presence of structural defects and disordered carbon, while the G band, appearing between 1580 and 1600 cm

−1, represents graphitic sp

2 carbon structures [

67]. The intensity ratio (I

D/I

G) is a key parameter for assessing the degree of disorder and graphitization, which directly affects the physicochemical properties of biochar [

68].

The HW/SW sample exhibits an ID/IG ratio of 0.965, suggesting a relatively high degree of graphitic ordering with some structural disorder in comparison to HW.

The HW/SW/RDF sample shows a lower ID/IG ratio compared to HW/SW, which indicates a relatively higher level of disorder but with a reduced graphitic contribution. The inclusion of RDF in the feedstock may introduce inorganic impurities and structural disruptions, affecting the carbon framework. This could influence the adsorption properties and electrochemical stability, potentially limiting its conductivity compared to more graphitic biochar.

The HW biochar sample exhibits a nearly equal intensity of the D and G bands, with an I

D/I

G ratio of 1.001, suggesting a balance between graphitic and amorphous carbon structures. This indicates a moderate degree of graphitization with retained disorder, which can contribute to surface reactivity and adsorption properties [

69].

The comparative analysis reveals that the degree of structural disorder and graphitization varies with feedstock composition. The HW/SW sample exhibits the highest level of ordered graphitic structures, which may enhance its electrical conductivity and stability. The HW/SW/RDF sample displays a moderate level of disorder, likely due to RDF inclusion, which may influence its physicochemical interactions [

70]. The HW sample maintains a balance between graphitic and amorphous structures.

Table 3 shows a summary of their band values, intensities, and ratios.

Materials with higher graphitic content are generally preferred in energy-storage, catalysis, and composite materials, whereas disordered structures with functional defects are often advantageous in adsorption and chemical reactivity [

70].

3.6. Elemental Composition (CHN Ultimate Analysis)

CHNS analysis is a high-temperature combustion method used to determine the elemental composition of materials, particularly carbon, hydrogen, nitrogen, and sulfur. Known for its speed and accuracy, it is widely applied in biochar research to analyze its elemental composition, providing essential insights into biochar’s chemical properties and potential uses, such as soil amendment, carbon sequestration, and pollutant adsorption [

71].

Table 4 presents the results of the CHN analysis of the three samples HW, HW/SW, and HW/SW/RDF.

The CHN analysis highlights significant variations in the bulk elemental composition of the three biochar samples, demonstrating how different feedstock blends impact the final biochar properties.

The carbon content in the biochar samples decreases as the feedstock composition changes. The 100% oak sample (HW) has the highest carbon content at 78.3%, which drops to 74.9% in the oak/pine blend (HW/SW), and further declines to 68% in the blend with refuse-derived fuel (HW/SW/RDF). This trend is linked to the feedstock types: oak, being dense and high in lignin, produces biochar with high carbon content, while pine, a softer wood with lower density and lignin, causes a slight decrease [

72,

73]. The biggest drop occurs with the addition of RDF, which contains materials with lower carbon and higher ash content, further reducing the overall carbon percentage.

The hydrogen content increases across the samples, rising from 2.52% in HW to 2.79% in HW/SW, with a significant jump to 4.06% in HW/SW/RDF. This rise, especially in the RDF sample, suggests more hydrogenated compounds or possibly incomplete carbonization in the RDF components, which may affect the biochar’s reactivity and application behavior.

The nitrogen content follows a non-linear pattern, starting at 0.141% in HW, dropping sharply to 0.0796% in HW/SW, and increasing to 0.188% in HW/SW/RDF. The low nitrogen in the HW/SW sample could be due to the low nitrogen content in pine wood, while the rise in the HW/SW/RDF sample is expected, as RDF often includes nitrogen-rich materials like food waste or synthetic products.

The decrease in carbon content from HW to HW/SW/RDF suggests that the lowered carbon-to-hydrogen ratio and elevated oxygen content in the RDF-integrated sample highlight a less-condensed carbon lattice, which is more prone to oxidation and degradation in soil systems and reduced carbon sequestration potential. The higher hydrogen content in the HW/SW/RDF sample may indicate increased reactivity or more functional groups, which could improve its performance in applications like contaminant adsorption. The variation in nitrogen content, especially the spike in the HW/SW/RDF sample, could impact its effectiveness in soil amendments by influencing nutrient dynamics [

74,

75].

Oxygen–Carbon (O/C) Ratio, Hydrogen–Carbon (H/C) Ratio, and Carbon–Nitrogen (C/N) Ratio

The oxygen–carbon ratio (O/C ratio) in biochar measures the amount of oxygen relative to carbon and reflects its degree of oxidation and stability. A lower O/C ratio (0.2–0.6) generally indicates a more stable, carbon-rich biochar, which is less likely to degrade over time and is better suited to long-term carbon sequestration. A higher O/C ratio suggests a more reactive biochar. This ratio is important for assessing the extent of charring, post-gasification oxidation, and the biochar’s potential in soil amendment, as it affects water and nutrient retention and overall chemical reactivity [

76,

77].

The H/C ratio (hydrogen-to-carbon ratio) is a critical measure of biochar’s aromaticity, stability, and carbon structure. A lower H/C ratio (below 0.7, per European standards) signifies stronger aromaticity, a more stable, carbon-dominant structure, and greater resistance to microbial decomposition, enhancing its long-term carbon storage capacity. The H/C ratio decreases with higher pyrolysis temperatures, reflecting reduced volatile organic compounds and a more graphitic structure. This metric helps predict biochar’s durability, its effectiveness in improving soil health, and its potential for carbon sequestration over time [

76].

The carbon-to-nitrogen (C/N) ratio is a critical factor in understanding nutrient dynamics and mineralization, decomposition processes, and biochar–soil interactions. Biochar typically increases the C/N ratio in composts and soils, which can reduce carbon loss during composting, affect nitrogen availability, and influence microbial activity and organic matter decomposition rates [

4].

A higher C/N ratio suggests more carbon relative to nitrogen, slowing microbial decomposition and providing a stable carbon source over time. A lower C/N ratio indicates greater nitrogen availability for soil organisms, influencing nutrient cycling and soil fertility. Understanding and optimizing the C/N ratio is essential for tailoring biochar properties to specific environmental and agricultural applications [

4]. A summary of the elemental ratios is shown below in

Table 5.

The analysis of O/C, H/C, and C/N ratios for the HW, HW/SW, and HW/SW/RDF biochar samples reveals how feedstock composition influences their chemical properties. The O/C ratios, indicative of stability, range from 0.1825 in HW to 0.2228 in HW/SW, with HW/SW/RDF showing the lowest ratio at 0.1297, suggesting higher aromaticity and stability due to the RDF’s heterogeneous nature. The H/C ratios increased from 0.3834 in HW to 0.4437 in HW/SW, both below the European threshold of 0.7, signifying stability. However, HW/SW/RDF shows a higher ratio of 0.7113, suggesting reduced aromaticity and stability due to RDF’s diverse organic content.

The C/N ratios are very high, typical for biochar, ranging from 555.31 in HW to 940.95 in HW/SW, indicating reduced nitrogen from softwood. HW/SW/RDF shows a lower C/N ratio of 361.70, reflecting higher nitrogen content from RDF materials. The HW and HW/SW samples exhibit greater stability and aromaticity, making them more suitable for long-term carbon sequestration, while the HW/SW/RDF sample, with higher reactivity and nutrient availability, may be better for short-term soil applications [

78].

Choudhary et al. [

56] examined biochars derived from sugarcane filter cake, farmyard manure, and rice husk, demonstrating that variations in feedstock type significantly influenced elemental profiles, thermal resilience, and resistance to degradation. These differences, in turn, played a critical role in determining the biochars’ capacity for nutrient retention and their effectiveness in soil enhancement applications. Lehmann et al. [

79], Spokas [

77], and Schmidt et al. [

80], who obtained similar findings, highlighted the use of elemental ratios in their studies to detail biochar stability and degradation, nutrient mobilization, soil amendment potentials, and how their composition will impact these biochar parameters. These findings emphasize that feedstock composition significantly affects biochar stability, reactivity, and suitability for various applications.

In addition to the physicochemical characterization presented, it is important to outline how these findings translate to soil enhancement applications, as suggested by the reviewer of this study. The structural and chemical properties observed in this study directly inform the agricultural relevance of the produced biochars. The SEM and BET analyses demonstrated that the oak biochar retained a highly porous network and a large surface area (107.7 m

2/g), conditions favorable for soil aeration, moisture retention, and microbial colonization. Such features have been consistently linked with improved nutrient anchoring and contaminant immobilization in prior agronomic studies. Similarly, the oak–pine blend preserved much of this structural integrity, supporting its suitability for long-term soil application [

74,

81].

Our thermal stability results further reinforce these conclusions. The high fixed-carbon contents measured in oak (79.9%) and oak–pine (80.4%) biochars, along with their resistance to mass loss under elevated temperatures, suggest that these materials are likely to persist in soils, contributing to long-term carbon storage and gradual improvements in soil structure. In contrast, the RDF-containing sample, with a reduced fixed-carbon content (64.3%) and an elevated volatile fraction, is expected to degrade more readily. While this limits its long-term stability, it may provide short-term soil benefits by releasing labile compounds and improving nutrient availability [

82,

83,

84].

Elemental analysis provides additional context for soil applications. The favorable O/C and H/C ratios of the oak and oak–pine biochars are consistent with stable, aromatic structures that resist microbial breakdown, supporting their role in sustainable carbon sequestration. Meanwhile, the elevated nitrogen content and lower C/N ratio observed in the RDF blend highlight potential contributions to soil nutrient cycling, though with less persistence than lignocellulose-based chars. Finally, the XRD results revealed a consistent presence of calcite, which provides a natural liming effect and enhances the buffering capacity of acidic soils, a critical factor in improving soil fertility [

85,

86,

87].

4. Conclusions

This study comprehensively evaluated the influence of feedstock composition—specifically pure oak, oak–pine, and oak–pine–RDF blends—on the physicochemical characteristics of biochar produced through downdraft gasification at 850 °C. The results confirm that biochar properties are strongly dependent on the nature of the input biomass, with significant implications for its suitability in environmental and industrial applications.

The oak-derived biochar exhibited the highest surface area, superior thermal stability, and moderate graphitic ordering, underscoring its potential in soil enhancement, contaminant sorption, and carbon sequestration. The inclusion of pine in an equal proportion to oak did not substantially compromise the structural or thermal integrity of the biochar, and in some respects, enhanced graphitic ordering, suggesting that softwood co-gasification can be a viable approach to feedstock diversification without quality loss.

However, the introduction of refuse-derived fuel (RDF) led to notable degradation in key quality indicators. RDF integration resulted in a 99% drop in surface area, pore collapse, reduced fixed-carbon retention, and increased structural disorder. These effects are primarily attributed to the heterogeneous nature of RDF, including thermoplastics and inorganic contaminants that melt or sinter at high temperatures, thereby obstructing pore formation and destabilizing carbon frameworks.

In addition to these structural drawbacks, RDF incorporation raises concerns about the presence of pollutants such as heavy metals, inorganic salts, and residues from plastics, which may persist in the biochar matrix. Such constituents could affect the suitability of RDF-derived biochar in sensitive applications, particularly in agriculture or soil remediation, where the leaching of contaminants poses risks to ecosystems and food safety. These findings underscore the need for careful preprocessing of RDF, including separation of high-ash and polymeric fractions, as well as pollutant characterization of the resulting biochar prior to large-scale use.

Despite these drawbacks, RDF remains a valuable resource from a circular-economy perspective, offering opportunities for energy recovery and waste volume reduction. To reconcile its sustainability advantages with the performance requirements of functional biochar, future efforts should prioritize strategic pretreatment and blending protocols. Thermal preconditioning, selective separation of high-ash or plastic fractions, and pelletization with lignocellulosic binders are potential approaches to mitigating the structural disruptions observed. Additionally, co-pyrolysis with alkaline additives such as calcium carbonate or clay minerals could enhance RDF’s thermal behavior, promote porosity development, and stabilize carbon matrices.

Further investigations should also focus on optimizing RDF blending ratios below the 20% threshold used in this study, with incremental additions to identify the inflection point where performance begins to deteriorate. Moreover, in situ monitoring of gasifier parameters and post-treatment methods such as steam activation or chemical functionalization may help recover lost surface area or adsorption capacity in RDF-based chars.

Field-scale trials evaluating RDF-derived biochar’s interaction with soil systems, nutrient dynamics, and contaminant immobilization are also essential to determine its environmental viability beyond laboratory metrics.

In conclusion, while lignocellulosic feedstocks continue to produce high-quality biochars suitable for a range of applications, RDF offers a promising—though complex—alternative. Its future lies in targeted engineering solutions that enable its valorization without compromising the structural and functional properties critical to biochar performance. Balancing waste recovery with application-specific quality standards will be key to unlocking RDF’s full potential in sustainable biochar production.

Author Contributions

Conceptualization, J.D.S., P.C.A., H.J.A.-A.; methodology, J.D.S., H.J.A.-A.; formal analysis, P.C.A.; investigation, P.C.A. and H.J.A.-A.; resources, J.D.S., H.J.A.-A.; data curation, H.J.A.-A., P.C.A.; writing—original draft preparation, P.C.A., J.D.S., H.J.A.-A., Z.Z.; writing—review and ed-iting, P.C.A., J.D.S., H.J.A.-A., Z.Z.;; supervision, J.D.S.; pro-ject administration, J.D.S.; funding acquisition, J.D.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Syntech Graphene Technologies, LLC.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflict of interest.

Correction Statement

This article has been republished with a minor correction to Data Availability Statement. This change does not affect the scientific content of the article.

References

- Woolf, D.; Amonette, J.E.; Street-Perrott, F.A.; Lehmann, J.; Joseph, S. Sustainable biochar to mitigate global climate change. Nat. Commun. 2010, 1, 56. [Google Scholar] [CrossRef] [PubMed]

- Yadav, R.; Ramakrishna, W. Biochar as an environment-friendly alternative for multiple applications. Sustainability 2023, 15, 13421. [Google Scholar] [CrossRef]

- Basu, P. Biomass Gasification, Pyrolysis and Torrefaction: Practical Design and Theory; Academic Press: Cambridge, MA, USA, 2018. [Google Scholar]

- Ok, Y.S.; Uchimiya, S.M.; Chang, S.X.; Bolan, N. Biochar: Production, Characterization, and Applications; CRC Press: Boca Raton, FL, USA, 2015. [Google Scholar]

- Golpour, H.; Boravelli, T.; Smith, J.D.; Safarpour, H.R. Production of syngas from biomass using a downdraft gasifier. Int. J. Eng. Res. Appl 2017, 7, 61–71. [Google Scholar]

- Shin, D.; Francis, A.; Aravind, P.V.; Woudstra, T.; de Jong, W.; Roekaerts, D. Numerical evaluation of biochar production performance of downdraft gasifier by thermodynamic model. Energies 2022, 15, 7650. [Google Scholar] [CrossRef]

- Gutiérrez, J.; Rubio-Clemente, A.; Pérez, J.F. Analysis of biochars produced from the gasification of Pinus patula pellets and chips as soil amendments. Maderas. Cienc. Tecnol. 2022, 24, 49. [Google Scholar] [CrossRef]

- Schroeder, J.; Neomagus, H.; Bunt, J.; Everson, R.; Uwaoma, R. Steam gasification kinetics of biochar at elevated pressures. Heliyon 2024, 10, e31172. [Google Scholar] [CrossRef]

- Al-Rubaye, H.A.; Yu, J.; Smith, J.D.; Al-Abedi, H.J. Experimental investigation of tar recycling in pilot-scale down-draft biomass gasifiers: Prospects, operating procedures, process variations, and controls. Biofuels 2023, 14, 201–210. [Google Scholar] [CrossRef]

- Kalina, M.; Sovova, S.; Svec, J.; Trudicova, M.; Hajzler, J.; Kubikova, L.; Enev, V. The effect of pyrolysis temperature and the source biomass on the properties of biochar produced for the agronomical applications as the soil conditioner. Materials 2022, 15, 8855. [Google Scholar] [CrossRef]

- Ulusal, A.; Apaydın Varol, E.; Bruckman, V.J.; Uzun, B.B. Opportunity for sustainable biomass valorization to produce biochar for improving soil characteristics. Biomass Convers. Biorefinery 2021, 11, 1041–1051. [Google Scholar] [CrossRef]

- Magdziarz, A.; Jerzak, W.; Wądrzyk, M.; Sieradzka, M. Benefits from co-pyrolysis of biomass and refuse derived fuel for biofuels production: Experimental investigations. Renew. Energy 2024, 230, 120808. [Google Scholar] [CrossRef]

- Al-Abedi, H.J.; Smith, J.D.; Al-Rubaye, H.; Shakor, Z.M.; Erdem, A.; Ani, P.C. Synergistic co-pyrolysis of corn stover and refuse-derived fuel with microplastics: Kinetic and thermodynamic study. Biofuels 2024, 15, 1197–1213. [Google Scholar] [CrossRef]

- Al-Abedi, H.J.; Smith, J.D.; Al-Rubaye, H.; Ani, P.C.; Moellenhoff, C.; McLeland, T.; Zagorac, K. Experimental and Aspen Simulation Study of the Co-Pyrolysis of Refuse-Derived Fuel and Oil Shale: Product Yields and Char Characterization. Fuels 2025, 6, 38. [Google Scholar] [CrossRef]

- Zaini, I.N.; Gomez-Rueda, Y.; López, C.G.; Ratnasari, D.K.; Helsen, L.; Pretz, T.; Jönsson, P.G.; Yang, W. Production of H2-rich syngas from excavated landfill waste through steam co-gasification with biochar. Energy 2020, 207, 118208. [Google Scholar] [CrossRef]

- Chen, Z.; Yan, D.; Wang, X.; Ding, G.; Wang, Z.; Xiao, Y.; Liu, X.; Wang, P.; Chen, L.; Shuai, L. Biochar-Tailored Carbon Nitride Enables Piezo-Photocatalytic H 2 O 2 Production via Boosted Charge Transport. ACS Catal. 2025, 15, 13568–13580. [Google Scholar] [CrossRef]

- Chen, Z.; Ding, G.; Wang, Z.; Xiao, Y.; Liu, X.; Chen, L.; Li, C.; Huang, H.; Liao, G. Precision molecular engineering of carbon nitride for efficient and selective photoreduction of CO2 to C2H6 in pure water. Adv. Funct. Mater. 2025, 35, 2423213. [Google Scholar] [CrossRef]

- Liu, R.; Graebner, M.; Tsiava, R.; Zhang, T.; Xu, S. Simulation analysis of the system integrating oxy-fuel combustion and char gasification. J. Energy Resour. Technol. 2021, 143, 032304. [Google Scholar] [CrossRef]

- Wu, Z.; Yang, W.; Yang, B. Thermal characteristics and surface morphology of char during co-pyrolysis of low-rank coal blended with microalgal biomass: Effects of Nannochloropsis and Chlorella. Bioresour. Technol. 2018, 249, 501–509. [Google Scholar] [CrossRef]

- Almusafir, R.; Smith, J.D. Thermal decomposition and kinetic parameters of three biomass feedstocks for the performance of the gasification process using a thermogravimetric analyzer. Energies 2024, 17, 396. [Google Scholar] [CrossRef]

- Braghiroli, F.L.; Bouafif, H.; Neculita, C.M.; Koubaa, A. Influence of pyro-gasification and activation conditions on the porosity of activated biochars: A literature review. Waste Biomass Valorization 2020, 11, 5079–5098. [Google Scholar] [CrossRef]

- Gao, Y.; Wang, M.; Raheem, A.; Wang, F.; Wei, J.; Xu, D.; Song, X.; Bao, W.; Huang, A.; Zhang, S. Syngas production from biomass gasification: Influences of feedstock properties, reactor type, and reaction parameters. ACS Omega 2023, 8, 31620–31631. [Google Scholar] [CrossRef]

- Ani, P.C.; Alhameedi, H.; Al-Abedi, H.J.; Al-Rubaye, H.; Zeitoun, Z.; Ewuzie, U.; Smith, J.D. The Comprehensive Quantification and Characterization of Oak Biochar Produced via a Gasification Process Using a Downdraft Reactor. Fuels 2025, 6, 51. [Google Scholar] [CrossRef]

- Park, J.; Kim, Y.; Kim, S.; Yoo, J.; Kim, Y.; Gorbachev, R.; Barbolina, I.; Kim, S.; Kang, S.; Yoon, M. Non-destructive electron microscopy imaging and analysis of biological samples with graphene coating. 2D Mater. 2016, 3, 045004. [Google Scholar] [CrossRef]

- Capareda, S.C. Physicochemical characterization of biochar derived from biomass. In Sustainable Biochar for Water and Wastewater Treatment; Elsevier: Amsterdam, The Netherlands, 2022; pp. 93–134. [Google Scholar]

- Masís-Meléndez, F.; Segura-Chavarría, D.; García-González, C.A.; Quesada-Kimsey, J.; Villagra-Mendoza, K. Variability of physical and chemical properties of TLUD stove derived biochars. Appl. Sci. 2020, 10, 507. [Google Scholar] [CrossRef]

- Domene, X.; Enders, A.; Hanley, K.; Lehmann, J. Ecotoxicological characterization of biochars: Role of feedstock and pyrolysis temperature. Sci. Total Environ. 2015, 512, 552–561. [Google Scholar] [CrossRef] [PubMed]

- Yuan, S.-J.; Wang, J.-J.; Dong, B.; Dai, X.-H. Biomass-derived carbonaceous materials with graphene/graphene-like structures: Definition, classification, and environmental applications. Environ. Sci. Technol. 2023, 57, 17169–17177. [Google Scholar] [CrossRef] [PubMed]

- Chaturvedi, S.; Singh, S.V.; Dhyani, V.; Govindaraju, K.; Vinu, R.; Mandal, S. Characterization, bioenergy value, and thermal stability of biochars derived from diverse agriculture and forestry lignocellulosic wastes. Biomass Convers. Biorefinery 2023, 13, 879–892. [Google Scholar] [CrossRef]

- Amin, F.R.; Huang, Y.; He, Y.; Zhang, R.; Liu, G.; Chen, C. Biochar applications and modern techniques for characterization. Clean Technol. Environ. Policy 2016, 18, 1457–1473. [Google Scholar] [CrossRef]

- George, O.S.; Dennison, M.S.; Yusuf, A.A. Characterization and energy recovery from biomass wastes. Sustain. Energy Technol. Assess. 2023, 58, 103346. [Google Scholar]

- Razzaghi, F.; Obour, P.B.; Arthur, E. Does biochar improve soil water retention? A systematic review and meta-analysis. Geoderma 2020, 361, 114055. [Google Scholar] [CrossRef]

- Brtnicky, M.; Datta, R.; Holatko, J.; Bielska, L.; Gusiatin, Z.M.; Kucerik, J.; Hammerschmiedt, T.; Danish, S.; Radziemska, M.; Mravcova, L. A critical review of the possible adverse effects of biochar in the soil environment. Sci. Total Environ. 2021, 796, 148756. [Google Scholar] [CrossRef]

- Wang, Y.; Gu, J.; Ni, J. Influence of biochar on soil air permeability and greenhouse gas emissions in vegetated soil: A review. Biogeotechnics 2023, 1, 100040. [Google Scholar] [CrossRef]

- Stępień, P.; Pulka, J.; Serowik, M.; Białowiec, A. Thermogravimetric and calorimetric characteristics of alternative fuel in terms of its use in low-temperature pyrolysis. Waste Biomass Valorization 2019, 10, 1669–1677. [Google Scholar] [CrossRef]

- Suárez-Hernández, L.; Barrera-Zapata, R.; Ardila-A, A.N. Morphological and physicochemical characterization of biochar produced by gasification of selected forestry species. Rev. Fac. Ing. 2017, 26, 123–130. [Google Scholar] [CrossRef]

- Ma, X.; Zhou, B.; Budai, A.; Jeng, A.; Hao, X.; Wei, D.; Zhang, Y.; Rasse, D. Study of biochar properties by scanning electron microscope–energy dispersive X-ray spectroscopy (SEM-EDX). Commun. Soil Sci. Plant Anal. 2016, 47, 593–601. [Google Scholar] [CrossRef]

- Adeniyi, A.G.; Iwuozor, K.O.; Ezzat, A.O.; Muritala, K.B.; Emenike, E.C.; Oyekunle, I.P. Unlocking the potential of teak seed waste: Carbonization for sustainable resource transformation. Biofuels Bioprod. Biorefining 2024, 18, 226–236. [Google Scholar] [CrossRef]

- Chowdhury, Z.Z.; Karim, M.Z.; Ashraf, M.A.; Khalid, K. Influence of carbonization temperature on physicochemical properties of biochar derived from slow pyrolysis of durian wood (Durio zibethinus) sawdust. BioResources 2016, 11, 3356–3372. [Google Scholar] [CrossRef]

- Mehdi, R.; Khoja, A.H.; Naqvi, S.R.; Gao, N.; Amin, N.A.S. A review on production and surface modifications of biochar materials via biomass pyrolysis process for supercapacitor applications. Catalysts 2022, 12, 798. [Google Scholar] [CrossRef]

- Ravindiran, G.; Rajamanickam, S.; Janardhan, G.; Hayder, G.; Alagumalai, A.; Mahian, O.; Lam, S.S.; Sonne, C. Production and modifications of biochar to engineered materials and its application for environmental sustainability: A review. Biochar 2024, 6, 62. [Google Scholar] [CrossRef]

- Nobre, C.; Longo, A.; Vilarinho, C.; Gonçalves, M. Gasification of pellets produced from blends of biomass wastes and refuse derived fuel chars. Renew. Energy 2020, 154, 1294–1303. [Google Scholar] [CrossRef]

- Thommes, M.; Kaneko, K.; Neimark, A.V.; Olivier, J.P.; Rodriguez-Reinoso, F.; Rouquerol, J.; Sing, K.S. Physisorption of gases, with special reference to the evaluation of surface area and pore size distribution (IUPAC Technical Report). Pure Appl. Chem. 2015, 87, 1051–1069. [Google Scholar] [CrossRef]

- Cychosz, K.A.; Thommes, M. Progress in the physisorption characterization of nanoporous gas storage materials. Engineering 2018, 4, 559–566. [Google Scholar] [CrossRef]

- Shimizu, S.; Matubayasi, N. Cooperative sorption on porous materials. Langmuir 2021, 37, 10279–10290. [Google Scholar] [CrossRef]

- Tomczyk, A.; Sokołowska, Z.; Boguta, P. Biochar physicochemical properties: Pyrolysis temperature and feedstock kind effects. Rev. Environ. Sci. Bio/Technol. 2020, 19, 191–215. [Google Scholar] [CrossRef]

- Hyväluoma, J.; Kulju, S.; Hannula, M.; Wikberg, H.; Källi, A.; Rasa, K. Quantitative characterization of pore structure of several biochars with 3D imaging. Environ. Sci. Pollut. Res. 2018, 25, 25648–25658. [Google Scholar] [CrossRef]

- Huang, Y.; Chu, H.; Wang, D.; Hui, S. Performance and mechanism of benzene adsorption on ZnCl2 one-step modified corn cob biochar. Environ. Sci. Pollut. Res. 2024, 31, 15209–15222. [Google Scholar] [CrossRef] [PubMed]

- Srocke, F.; Han, L.; Dutilleul, P.; Xiao, X.; Smith, D.L.; Mašek, O. Synchrotron X-ray microtomography and multifractal analysis for the characterization of pore structure and distribution in softwood pellet biochar. Biochar 2021, 3, 671–686. [Google Scholar] [CrossRef]

- Skic, K.; Adamczuk, A.; Gryta, A.; Boguta, P.; Tóth, T.; Jozefaciuk, G. Surface areas and adsorption energies of biochars estimated from nitrogen and water vapour adsorption isotherms. Sci. Rep. 2024, 14, 30362. [Google Scholar] [CrossRef] [PubMed]

- Călin, C.; Sîrbu, E.-E.; Tănase, M.; Győrgy, R.; Popovici, D.R.; Banu, I. A Thermogravimetric Analysis of Biomass Conversion to Biochar: Experimental and Kinetic Modeling. Appl. Sci. 2024, 14, 9856. [Google Scholar] [CrossRef]

- Panizio, R.; Castro, C.; Pacheco, N.; Assis, A.C.; Longo, A.; Vilarinho, C.; Teixeira, J.C.; Brito, P.; Gonçalves, M.; Nobre, C. Investigation of biochars derived from waste lignocellulosic biomass and insulation electric cables: A comprehensive TGA and Macro-TGA analysis. Heliyon 2024, 10, e37882. [Google Scholar] [CrossRef]

- Liu, S.; Peng, S.; Zhang, B.; Xue, B.; Yang, Z.; Wang, S.; Xu, G. Effects of biochar pyrolysis temperature on thermal properties of polyethylene glycol/biochar composites as shape-stable biocomposite phase change materials. RSC Adv. 2022, 12, 9587–9598. [Google Scholar] [CrossRef]

- Stella Mary, G.; Sugumaran, P.; Niveditha, S.; Ramalakshmi, B.; Ravichandran, P.; Seshadri, S. Production, characterization and evaluation of biochar from pod (Pisum sativum), leaf (Brassica oleracea) and peel (Citrus sinensis) wastes. Int. J. Recycl. Org. Waste Agric. 2016, 5, 43–53. [Google Scholar] [CrossRef]

- Yakout, S.M. Physicochemical characteristics of biochar produced from rice straw at different pyrolysis temperature for soil amendment and removal of organics. Proc. Natl. Acad. Sci. India Sect. A Phys. Sci. 2017, 87, 207–214. [Google Scholar] [CrossRef]

- Choudhary, T.K.; Khan, K.S.; Hussain, Q.; Ahmad, M.; Ashfaq, M. Feedstock-induced changes in composition and stability of biochar derived from different agricultural wastes. Arab. J. Geosci. 2019, 12, 617. [Google Scholar] [CrossRef]

- Luo, Q.; Deng, Y.; Li, Y.; He, Q.; Wu, H.; Fang, X. Effects of pyrolysis temperatures on the structural properties of straw biochar and its adsorption of tris-(1-chloro-2-propyl) phosphate. Sci. Rep. 2024, 14, 25711. [Google Scholar] [CrossRef]

- Mobarak, M.B.; Pinky, N.S.; Mustafi, S.; Chowdhury, F.; Nahar, A.; Akhtar, U.S.; Quddus, M.S.; Yasmin, S.; Alam, M.A. Unveiling the reactor effect: A comprehensive characterization of biochar derived from rubber seed shell via pyrolysis and in-house reactor. RSC Adv. 2024, 14, 29848–29859. [Google Scholar] [CrossRef]

- Pan, T.; Jiang, J.; Li, Y.; Zhong, T.; Wang, H.; Pu, C.; Jin, P. Preparation and characterization of calcite/biochar composites fabricated by co-pyrolysis technique. Int. J. Electrochem. Sci. 2024, 19, 100554. [Google Scholar] [CrossRef]

- Mujtaba, G.; Hayat, R.; Hussain, Q.; Ahmed, M. Physio-chemical characterization of biochar, compost and co-composted biochar derived from green waste. Sustainability 2021, 13, 4628. [Google Scholar] [CrossRef]

- Chen, C.; Sun, K.; Huang, C.; Yang, M.; Fan, M.; Wang, A.; Zhang, G.; Li, B.; Jiang, J.; Xu, W. Investigation on the mechanism of structural reconstruction of biochars derived from lignin and cellulose during graphitization under high temperature. Biochar 2023, 5, 51. [Google Scholar] [CrossRef]

- Ike, S.; Vander Wal, R. Effect of carbonization methods on graphitization of soft and hard carbons. Carbon Trends 2024, 16, 100382. [Google Scholar] [CrossRef]

- Khalili, D.; Ramjerdi, A.A.; Boostani, H.R.; Ghaderi, A. Biochar: A high performance and renewable basic carbocatalyst for facilitating room temperature synthesis of 4 H-benzo [h] chromene and pyranopyrazoles in water. Biochar 2024, 6, 6. [Google Scholar] [CrossRef]

- Arwenyo, B.; Varco, J.J.; Dygert, A.; Brown, S.; Pittman, C.U.; Mlsna, T. Contribution of modified P-enriched biochar on pH buffering capacity of acidic soil. J. Environ. Manag. 2023, 339, 117863. [Google Scholar] [CrossRef]

- Guye, M.E.; Dabaro, M.D.; Kim, H. Biomass-derived graphitic-like hierarchical porous carbon for electrochemical supercapacitor application. J. Energy Storage 2025, 115, 116037. [Google Scholar] [CrossRef]

- Pimenta, M.; Dresselhaus, G.; Dresselhaus, M.S.; Cancado, L.; Jorio, A.; Saito, R. Studying disorder in graphite-based systems by Raman spectroscopy. Phys. Chem. Chem. Phys. 2007, 9, 1276–1290. [Google Scholar] [CrossRef] [PubMed]

- Xu, Y.; Chen, X.; Wang, L.; Bei, K.; Wang, J.; Chou, I.M.; Pan, Z. Progress of Raman spectroscopic investigations on the structure and properties of coal. J. Raman Spectrosc. 2020, 51, 1874–1884. [Google Scholar] [CrossRef]

- Pusceddu, E.; Santilli, S.; Fioravanti, G.; Montanaro, A.; Miglietta, F.; Foscolo, P. Chemical-physical analysis and exfoliation of biochar-carbon matter: From agriculture soil improver to starting material for advanced nanotechnologies. Mater. Res. Express 2019, 6, 115612. [Google Scholar] [CrossRef]

- He, D.; Wu, J.; Yu, C.; Huang, B.; Tu, X.; Li, D.; Jia, X.; Dan, J.; Fang, Z.; Dai, Z. Synthesis of corncob biochar with high surface area by KOH activation for VOC adsorption: Effect of KOH addition method. J. Chem. Technol. Biotechnol. 2023, 98, 2051–2064. [Google Scholar] [CrossRef]

- Gabhi, R.; Basile, L.; Kirk, D.W.; Giorcelli, M.; Tagliaferro, A.; Jia, C.Q. Electrical conductivity of wood biochar monoliths and its dependence on pyrolysis temperature. Biochar 2020, 2, 369–378. [Google Scholar] [CrossRef]

- Marrot, L.; Candelier, K.; Valette, J.; Lanvin, C.; Horvat, B.; Legan, L.; DeVallance, D.B. Valorization of hemp stalk waste through thermochemical conversion for energy and electrical applications. Waste Biomass Valorization 2022, 13, 2267–2285. [Google Scholar] [CrossRef]

- Zhou, S.; Xue, Y.; Sharma, A.; Bai, X. Lignin valorization through thermochemical conversion: Comparison of hardwood, softwood and herbaceous lignin. ACS Sustain. Chem. Eng. 2016, 4, 6608–6617. [Google Scholar] [CrossRef]

- Arous, S.; Koubaa, A.; Bouafif, H.; Bouslimi, B.; Braghiroli, F.L.; Bradai, C. Effect of pyrolysis temperature and wood species on the properties of biochar pellets. Energies 2021, 14, 6529. [Google Scholar] [CrossRef]

- Alkharabsheh, H.M.; Mwadalu, R.; Mochoge, B.; Danga, B.; Raza, M.A.; Seleiman, M.F.; Khan, N.; Gitari, H. Revitalizing the biochemical soil properties of degraded Coastal soil using Prosopis juliflora biochar. Life 2023, 13, 2098. [Google Scholar] [CrossRef]

- Zhang, J.; Ye, L.; Chang, J.; Wang, E.; Wang, C.; Zhang, H.; Pang, Y.; Tian, C. Straw soil conditioner modulates key soil microbes and nutrient dynamics across different maize developmental stages. Microorganisms 2024, 12, 295. [Google Scholar] [CrossRef]

- Bednik, M.; Medyńska-Juraszek, A.; Ćwieląg-Piasecka, I. Effect of six different feedstocks on biochar’s properties and expected stability. Agronomy 2022, 12, 1525. [Google Scholar] [CrossRef]

- Spokas, K.A. Review of the stability of biochar in soils: Predictability of O: C molar ratios. Carbon Manag. 2010, 1, 289–303. [Google Scholar] [CrossRef]

- Wijitkosum, S.; Sriburi, T. Aromaticity, polarity, and longevity of biochar derived from disposable bamboo chopsticks waste for environmental application. Heliyon 2023, 9, e19831. [Google Scholar] [CrossRef] [PubMed]

- Lehmann, J.; Joseph, S. Biochar for Environmental Management: Science, Technology and Implementation; Taylor & Francis: Abingdon, UK, 2024. [Google Scholar]

- Schmidt, M.W.; Noack, A.G. Black carbon in soils and sediments: Analysis, distribution, implications, and current challenges. Glob. Biogeochem. Cycles 2000, 14, 777–793. [Google Scholar] [CrossRef]

- Shyam, S.; Ahmed, S.; Joshi, S.J.; Sarma, H. Biochar as a Soil amendment: Implications for soil health, carbon sequestration, and climate resilience. Discov. Soil 2025, 2, 18. [Google Scholar] [CrossRef]

- Waqas, M.; Asam, Z.; Rehan, M.; Anwar, M.; Khattak, R.A.; Ismail, I.; Tabatabaei, M.; Nizami, A. Development of biomass-derived biochar for agronomic and environmental remediation applications. Biomass Convers. Biorefinery 2021, 11, 339–361. [Google Scholar] [CrossRef]

- Sharma, P. Biochar application for sustainable soil erosion control: A review of current research and future perspectives. Front. Environ. Sci. 2024, 12, 1373287. [Google Scholar] [CrossRef]

- Samia Qadeer, S.Q.; Muzammil Anjum, M.A.; Azeem Khalid, A.K.; Muhammad Waqas, M.W.; Aniqa Batool, A.B.; Tariq Mahmood, T.M. A dialogue on perspectives of biochar applications and its environmental risks. Water Air Soil Pollut. 2017, 228, 281. [Google Scholar] [CrossRef]

- Xie Tao, X.T.; Sadasivam, B.; Reddy, K.; Wang ChengWen, W.C.; Spokas, K. Review of the effects of biochar amendment on soil properties and carbon sequestration. J. Hazard. Toxic Radioact. Waste 2016, 20, 04015013. [Google Scholar]

- Li, S.; Tasnady, D. Biochar for soil carbon sequestration: Current knowledge, mechanisms, and future perspectives. C 2023, 9, 67. [Google Scholar] [CrossRef]

- Kassa, Y.; Amare, A.; Nega, T.; Alem, T.; Gedefaw, M.; Chala, B.; Freyer, B.; Waldmann, B.; Fentie, T.; Mulu, T. Water hyacinth conversion to biochar for soil nutrient enhancement in improving agricultural product. Sci. Rep. 2025, 15, 1820. [Google Scholar] [CrossRef] [PubMed]

Figure 1.

Laboratory downdraft gasifier used in this work.

Figure 1.

Laboratory downdraft gasifier used in this work.

Figure 2.

Images of biomass pellets: (a) oak biomass, (b) pinewood, (c) RDF, and (d) gasified biochar.

Figure 2.

Images of biomass pellets: (a) oak biomass, (b) pinewood, (c) RDF, and (d) gasified biochar.

Figure 3.

SEM images of the three biochar samples at 10 μm: (a) HW, (b) HW/SW, and (c) HW/SW/RDF.

Figure 3.

SEM images of the three biochar samples at 10 μm: (a) HW, (b) HW/SW, and (c) HW/SW/RDF.

Figure 4.

Graphs showing particle size distribution. (a) HW biochar, (b) HW/SW, and (c) HW/SW/RDF.

Figure 4.

Graphs showing particle size distribution. (a) HW biochar, (b) HW/SW, and (c) HW/SW/RDF.

Figure 5.

Adsorption–desorption isotherms for the three biochar samples (a) HW, (b) HW/SW, and (c) HW/SW/RDF.

Figure 5.

Adsorption–desorption isotherms for the three biochar samples (a) HW, (b) HW/SW, and (c) HW/SW/RDF.

Figure 6.

TGA graph for (a) HW, (b) HW/SW, and (c) HW/SW/RDF samples.

Figure 6.

TGA graph for (a) HW, (b) HW/SW, and (c) HW/SW/RDF samples.

Figure 7.

Diffractogram of HW, HW/SW, and HW/SW/RDF.

Figure 7.

Diffractogram of HW, HW/SW, and HW/SW/RDF.

Figure 8.

Raman graphs of the three biochar samples—(a) HW, (b) HW/SW, and (c) HW/SW/RDF.

Figure 8.

Raman graphs of the three biochar samples—(a) HW, (b) HW/SW, and (c) HW/SW/RDF.

Table 1.

Summary of BET analysis for the three samples.

Table 1.

Summary of BET analysis for the three samples.

| Sample | Surface Area Analysis (m2/g) | Pore Width Distribution (nm) | Cumulative Pore Volume (cm3/g) | The Volume of N2 Adsorbed at STP (cm3/g) |

|---|

| HW | 107.735 ± 9.38 | 1.868–77.698 | 0.0786 ± 0.0058 | 82.950 ± 7.83 |

| HW/SW | 72.821 ± 2.1 | 1.868–77.698 | 0.0671± 0.0015 | 60.57 ± 1.77 |

| HW/SW/RF | 0.861 ± 0.045 | 1.78–77.698 | 0.00214 ± 0.00186 | 2.26 ± 0.08 |

Table 2.

Proximate analysis of the three samples.

Table 2.

Proximate analysis of the three samples.

| Sample | Moisture (%) | Volatile (%) | Fixed Carbon (%) | Ashes (%) |

|---|

| HW | 2 | 10.67 | 79.94 | 7.39 |

| HW/SW | 1.54 | 10.59 | 80.44 | 7.43 |

| HW/SW/RDF | 2 | 25.12 | 64.26 | 8.62 |

Table 3.

Values of the ID and IG ratios.

Table 3.

Values of the ID and IG ratios.

| Sample | ID/IG Ratio |

|---|

| HW | 1.001 |

| HW/SW | 0.965 |

| HW/SW/RDF | 1.013 |

Table 4.

CHN analysis of the samples.

Table 4.

CHN analysis of the samples.

| Elements | HW Composition % | HW/SW Composition % | HW/SW/RDF Composition % |

|---|

| Carbon | 78.3 ± 0.2 | 74.9 ± 0.8 | 68 ± 0.06 |

| Hydrogen | 2.52 ± 0.056 | 2.79 ± 0.18 | 4.06 ± 0.017 |

| Nitrogen | 0.141 ± 0.0046 | 0.0796 ± 0.004 | 0.188 ± 0.069 |

Table 5.

Summary of the elemental ratios of the three biochar samples (Ultimate Analysis).

Table 5.

Summary of the elemental ratios of the three biochar samples (Ultimate Analysis).

| Sample | Oxygen–Carbon (O/C) Ratio | Hydrogen–Carbon (H/C) Ratio | Carbon–Nitrogen (C/N) Ratio |

|---|

| HW | 0.1825 | 0.3834 | 555.31 |

| HW/SW | 0.2228 | 0.4437 | 940.95 |

| HW/SW/RF | 0.1297 | 0.7113 | 361.70 |

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).