Engine Response and Emission Optimization of Ceramic-Oxide-Doped Diesel Blends with Reclaimed Waste Energy

Abstract

1. Introduction

- To examine the performance and combustion properties of a single-cylinder diesel engine running on blends of tyre oil, diesel, and CeO2 under various load scenarios.

- To forecast cylinder pressure, the heat release rate, and emission behaviour by simulating an engine cycle with the Diesel-RK (D-RK) tool.

- To assess how various loads affect pollution reduction, combustion stability, and efficiency and to validate the model and optimize performance by contrasting simulation and experimental data.

- To determine the ideal blend composition and compression ratio in order to maximize efficiency and reduce hazardous emissions.

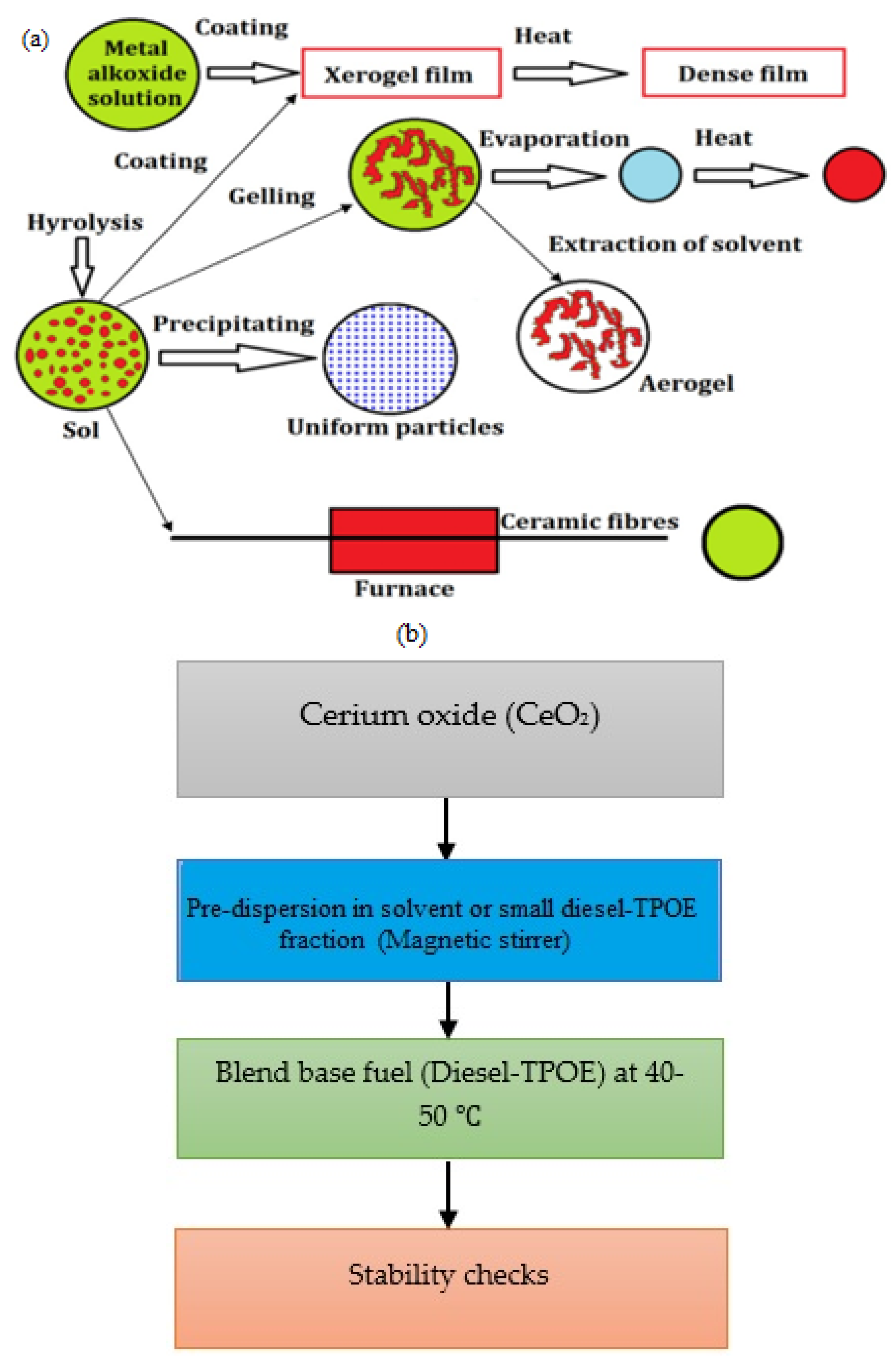

2. Material and Procedure

2.1. Material and Properties

2.2. Experimental Setup

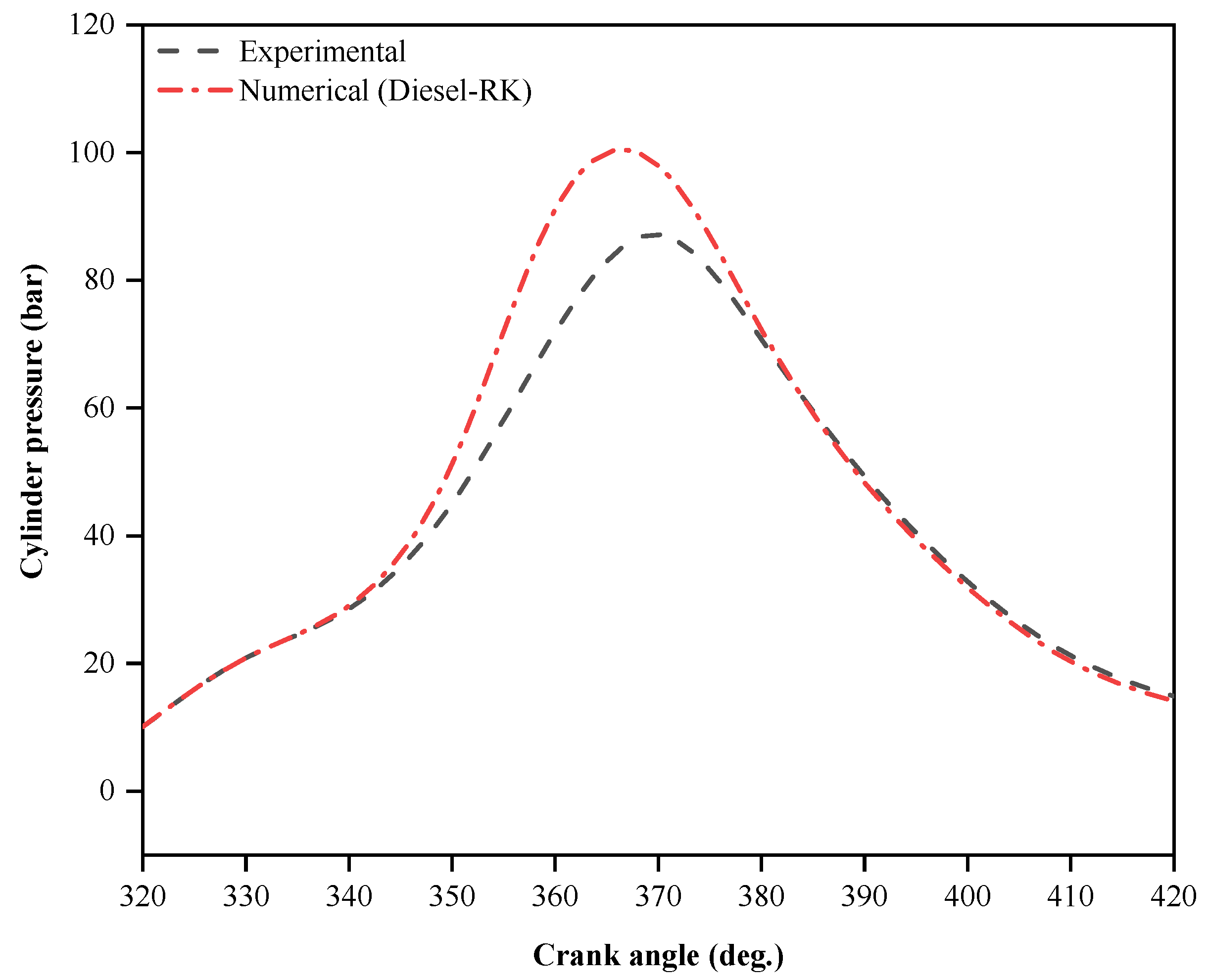

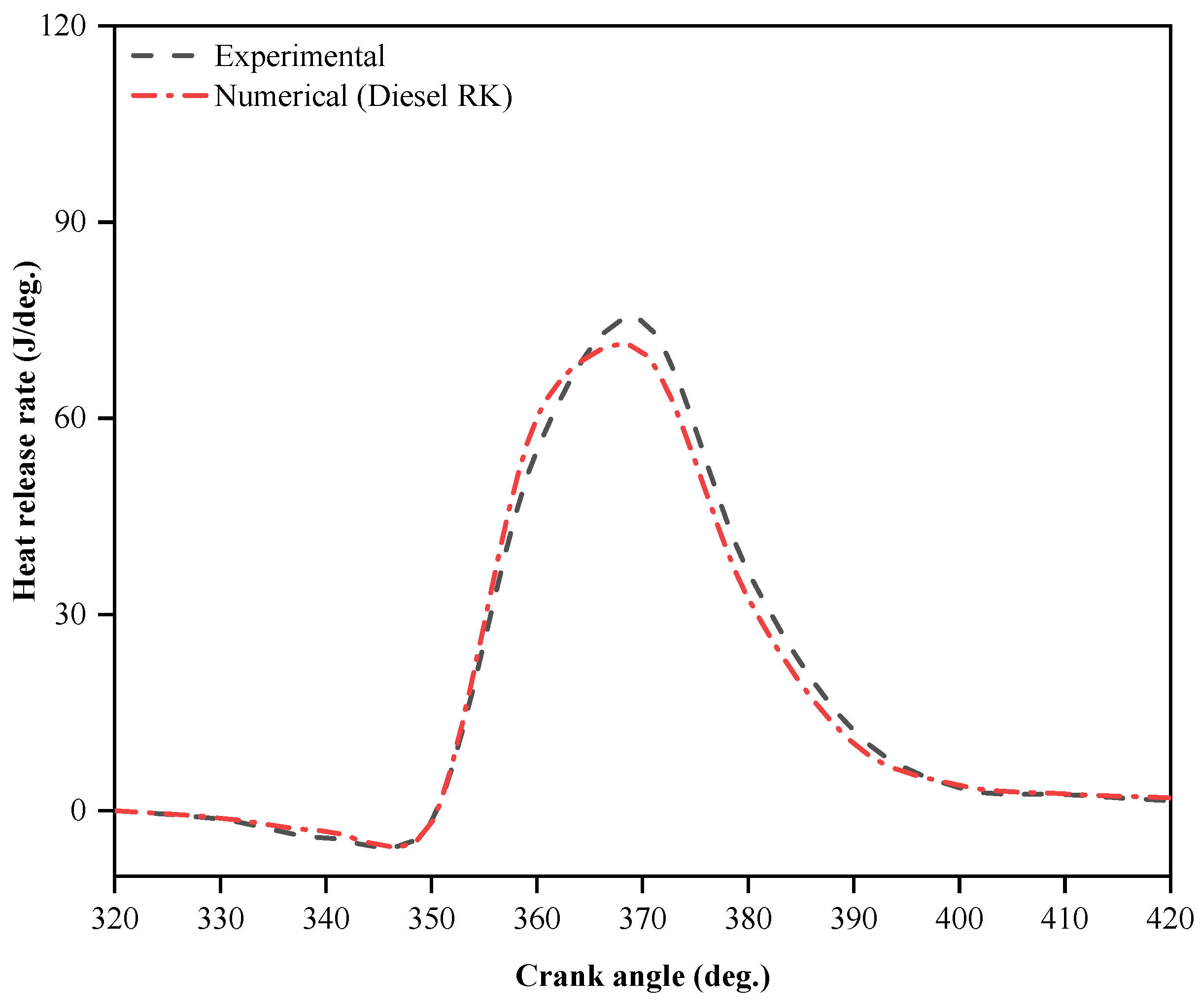

2.3. Model Descriptions

2.3.1. Governing Equations

2.3.2. Validation Tool

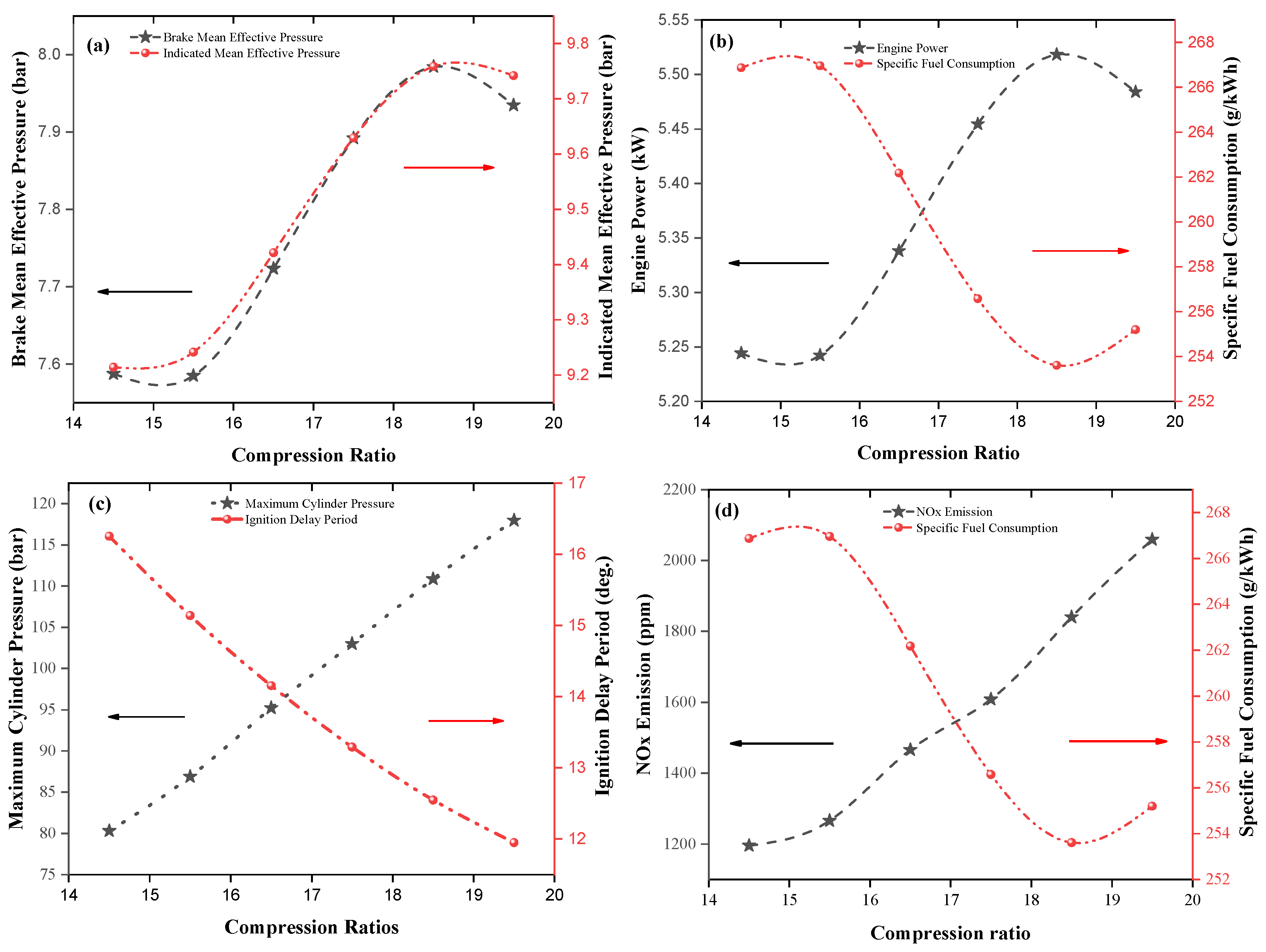

2.3.3. Optimization Results

3. Result and Discussion

3.1. Performance Characteristics

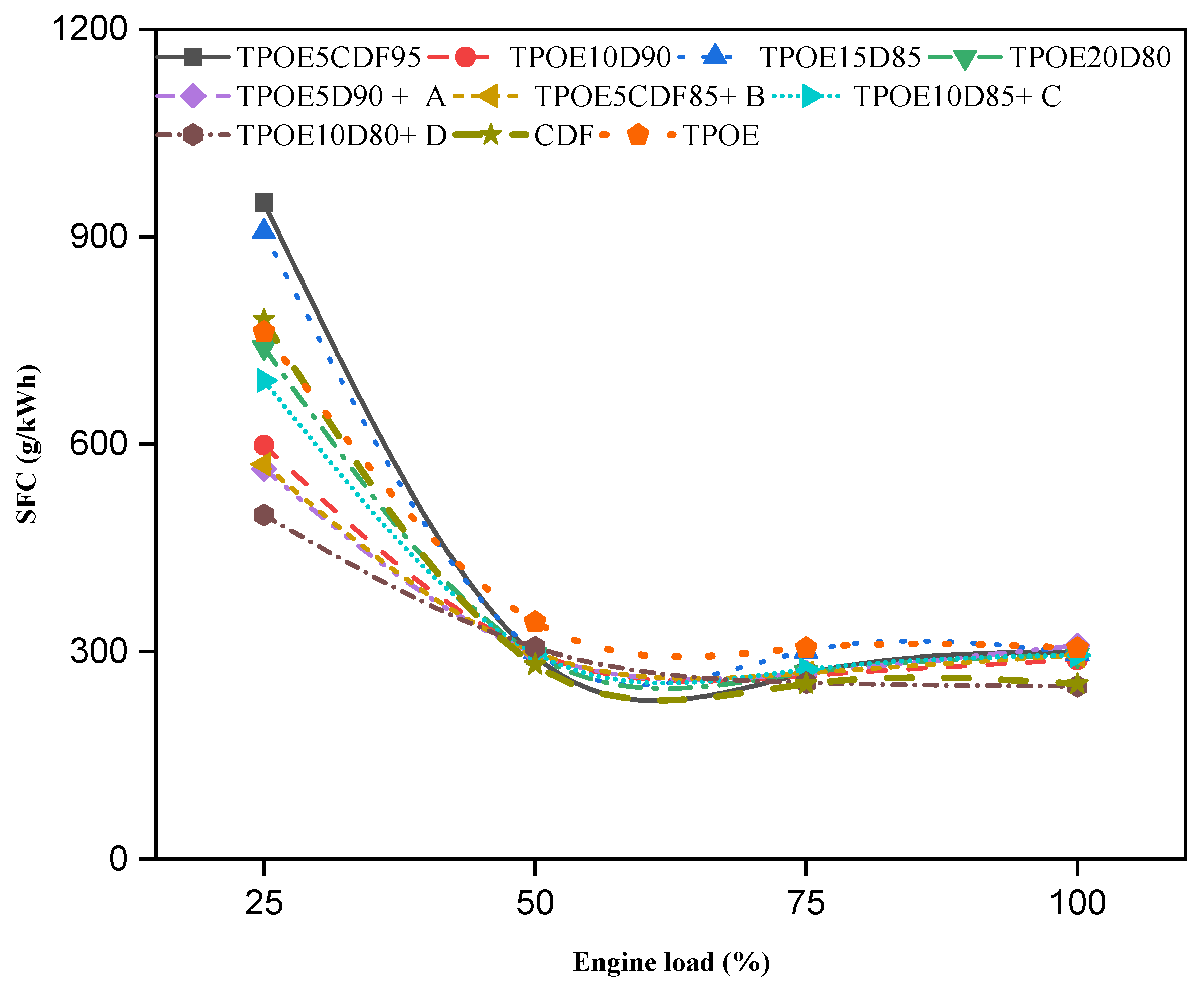

3.1.1. Specific Fuel Consumption

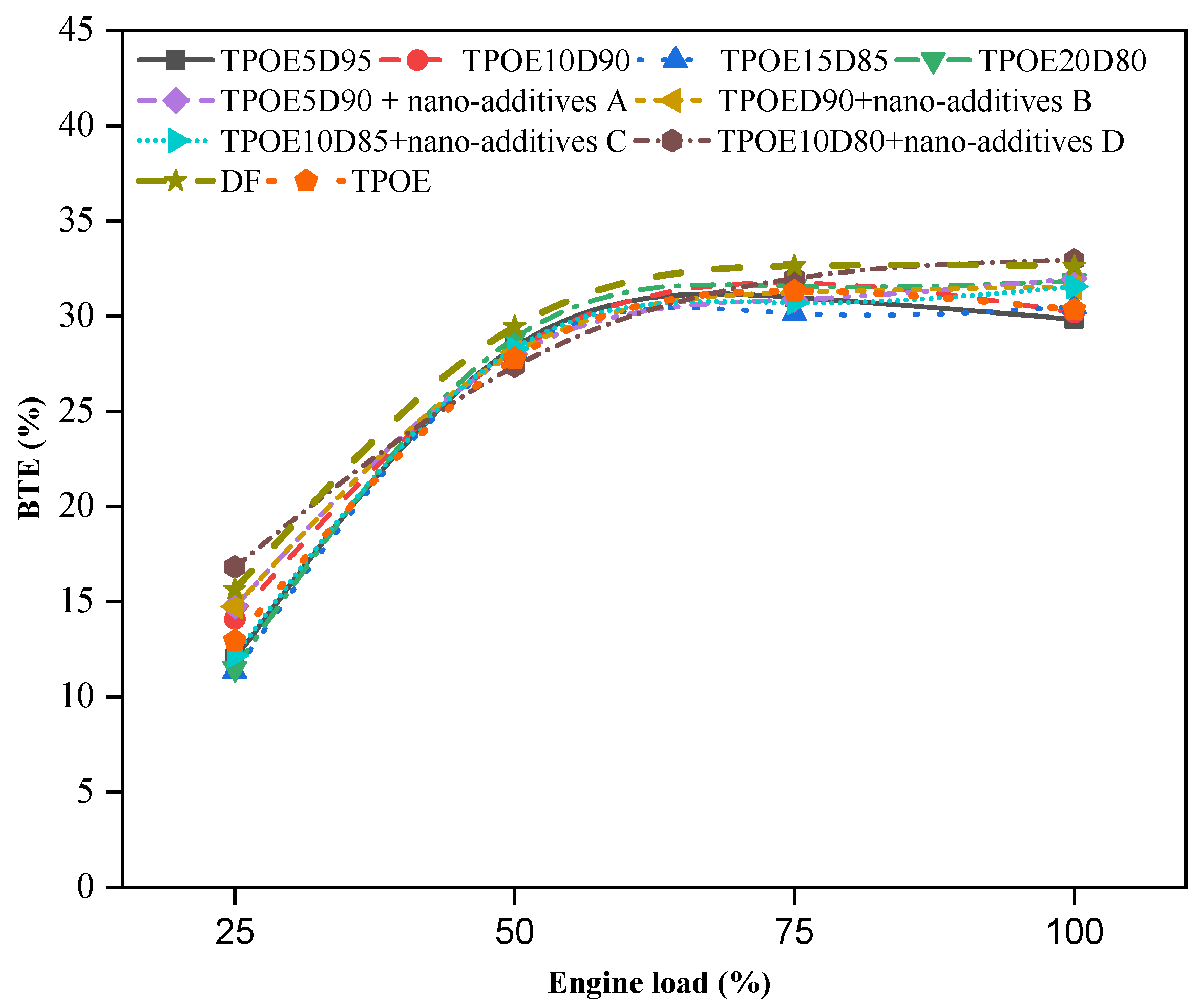

3.1.2. Brake Thermal Efficiency

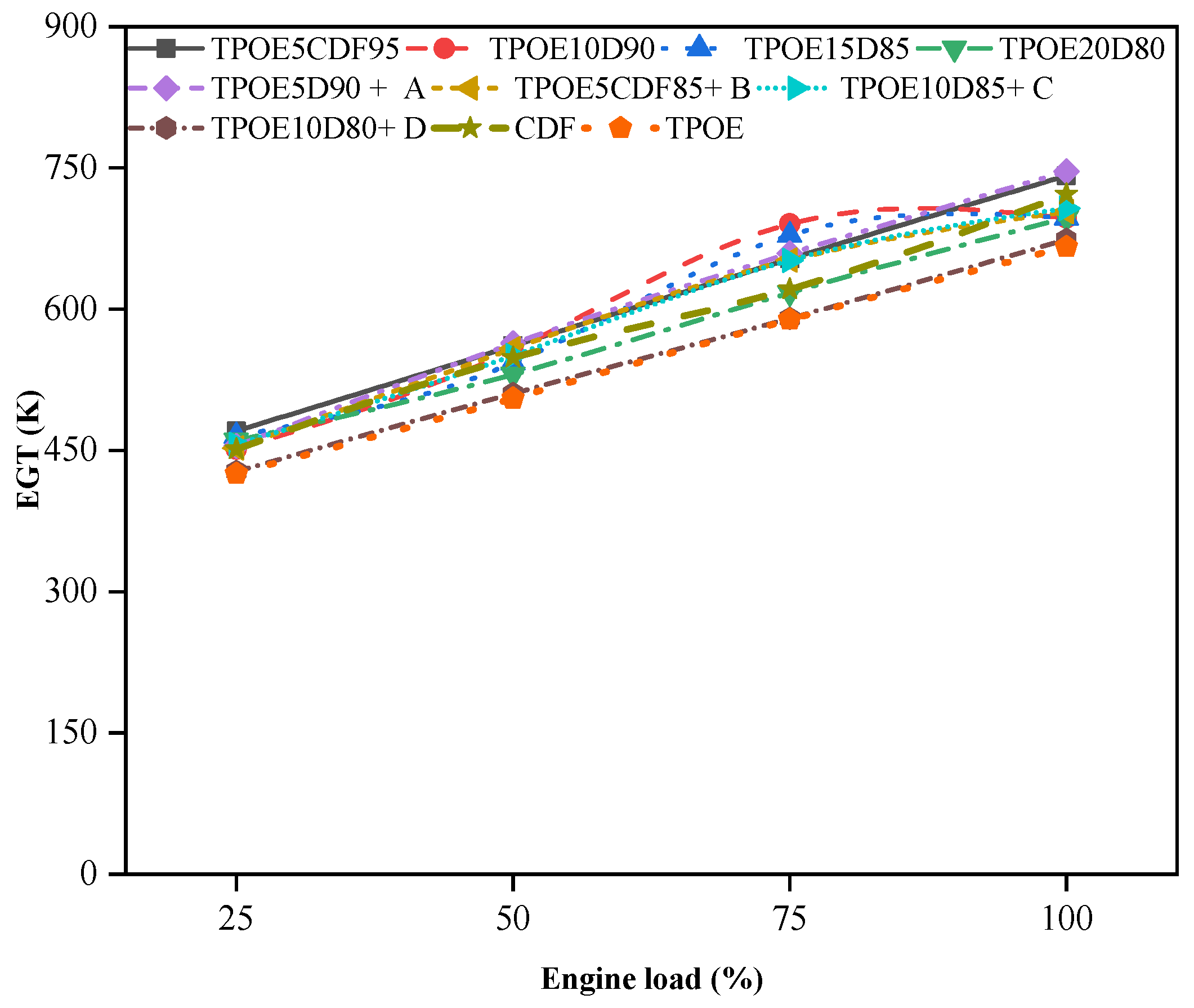

3.1.3. Exhaust Gas Temperature

3.2. Combustion Characteristics

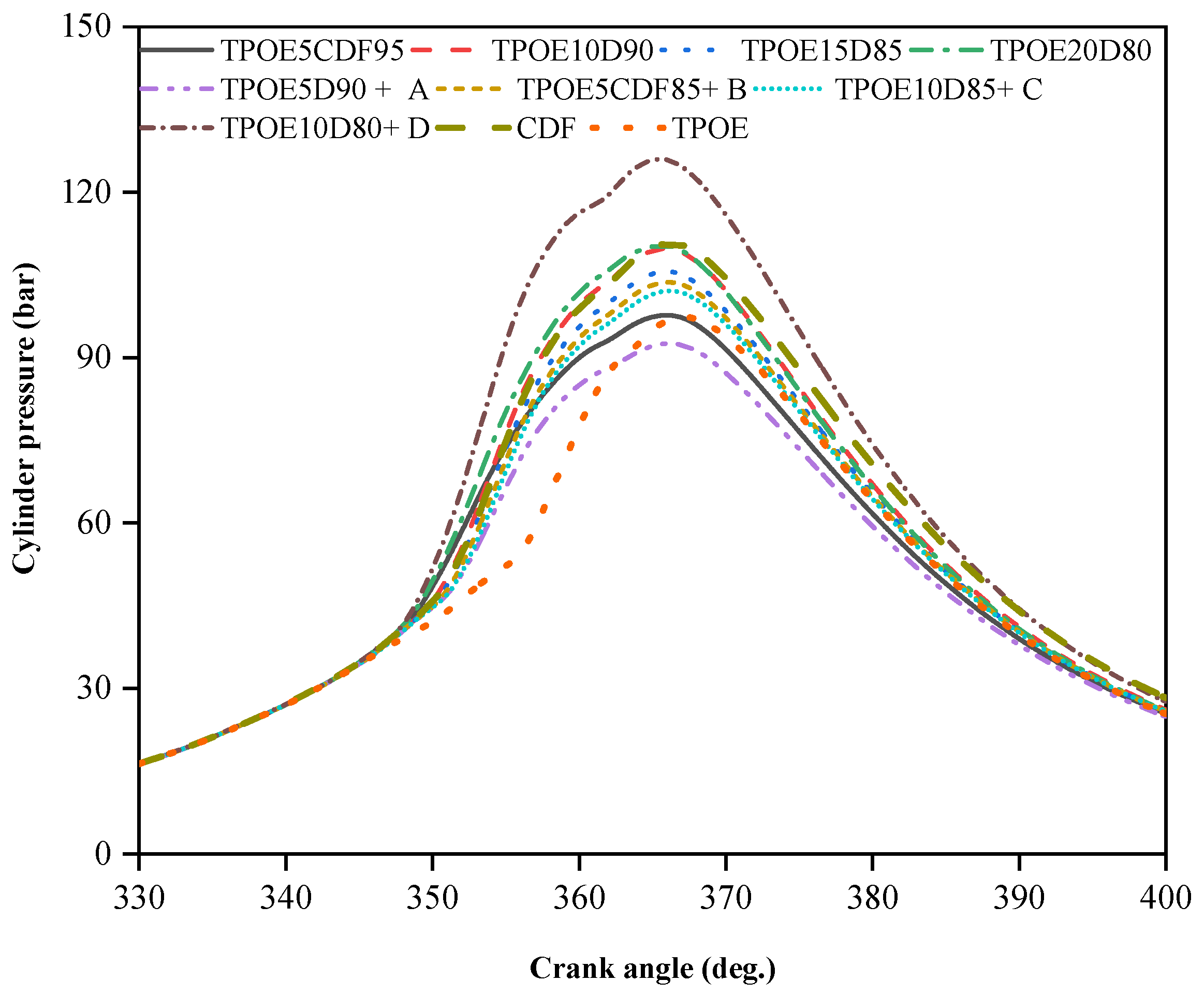

3.2.1. Chamber Pressure

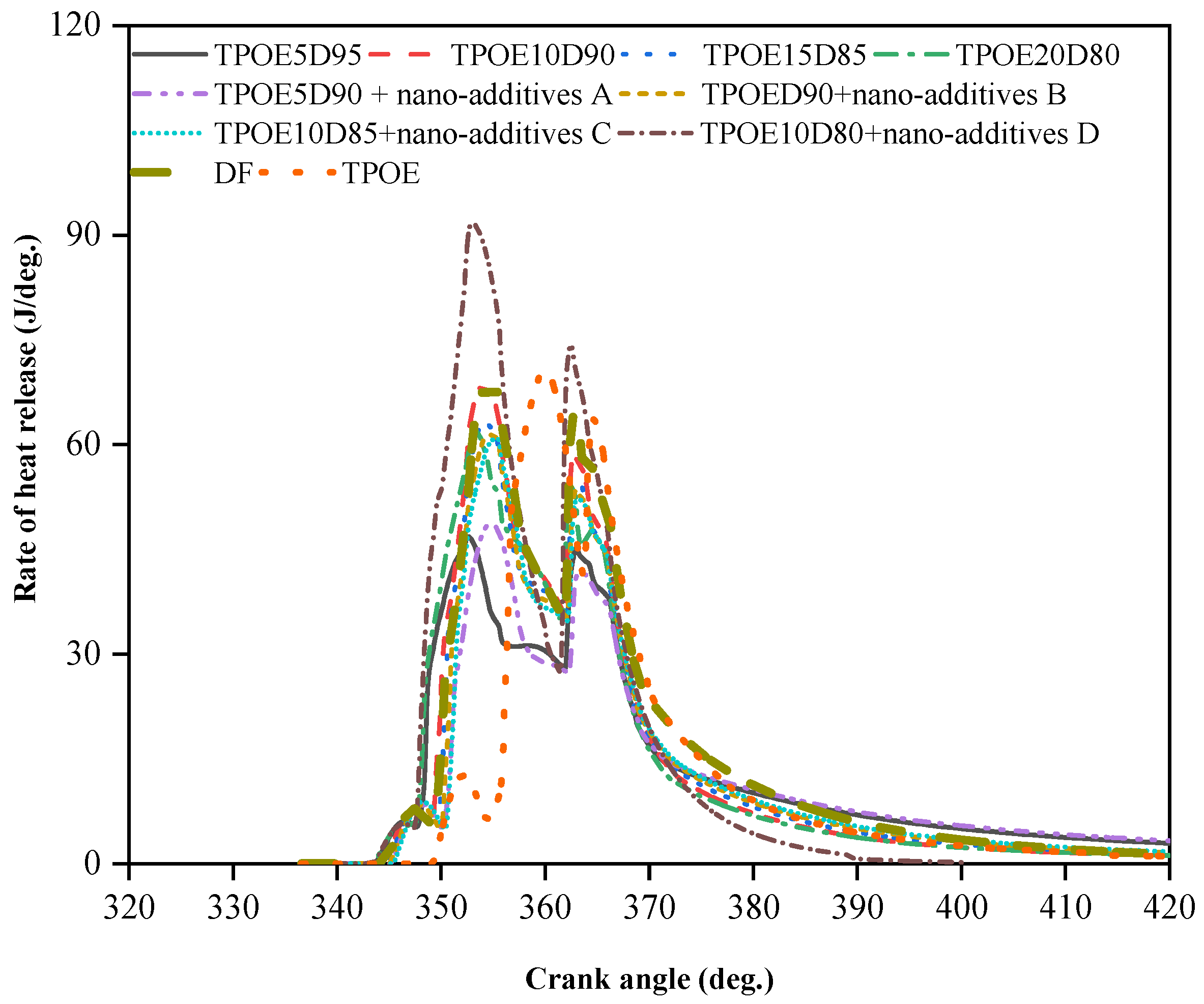

3.2.2. Heat Release Rate

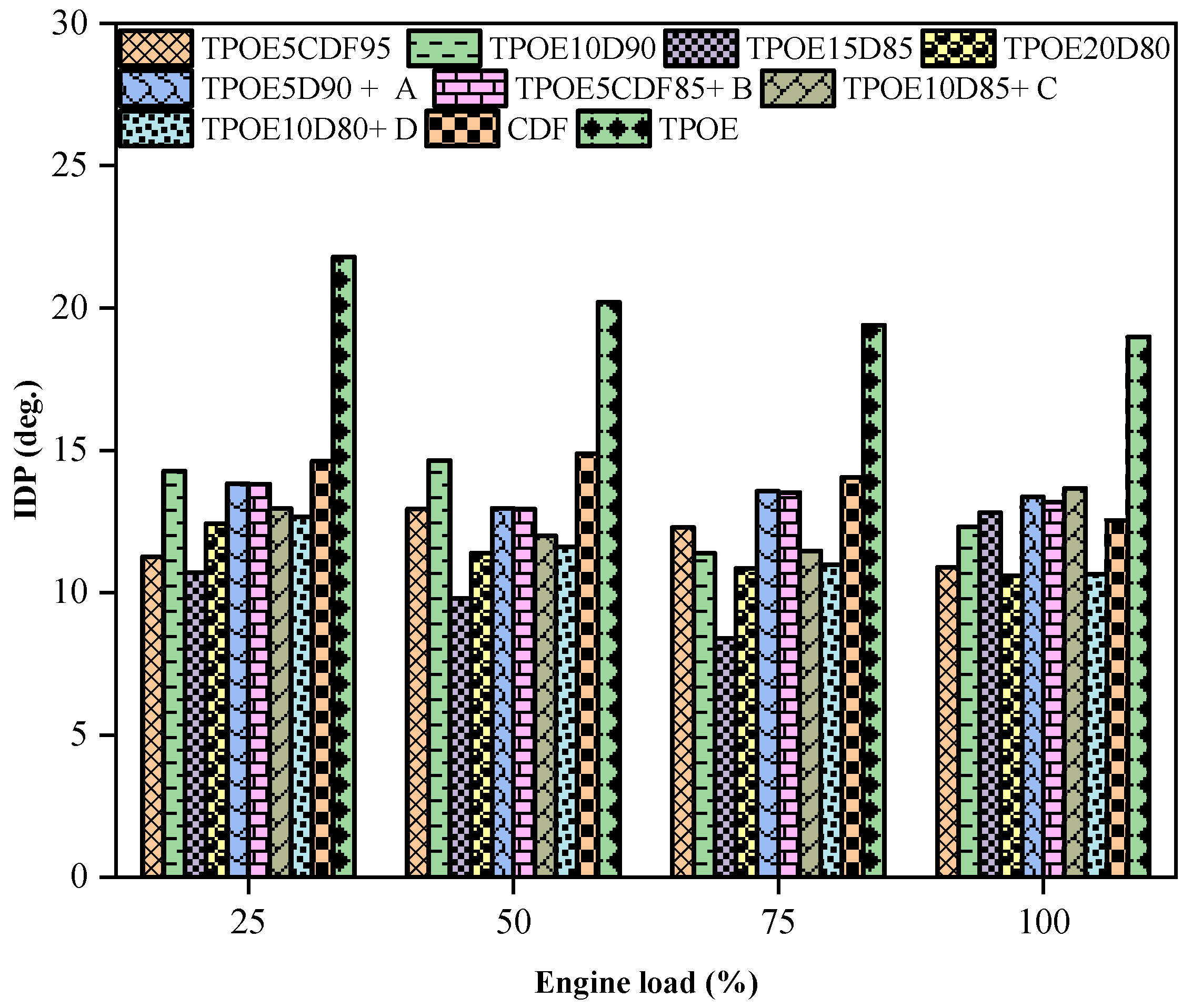

3.2.3. Ignition Delay Period

3.3. Emission Characteristics

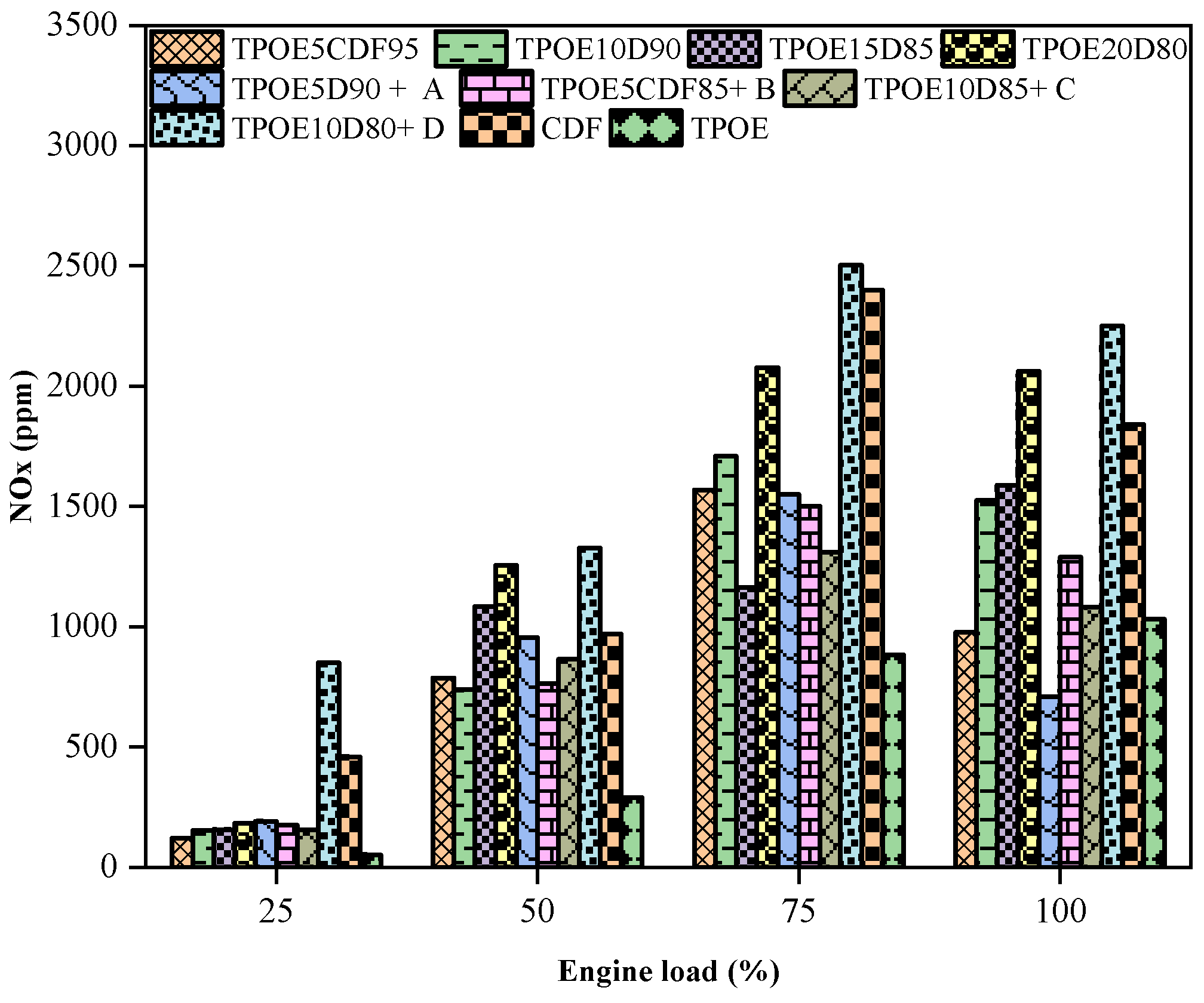

3.3.1. Oxides of Nitrogen Discharge

3.3.2. Smoke Emission

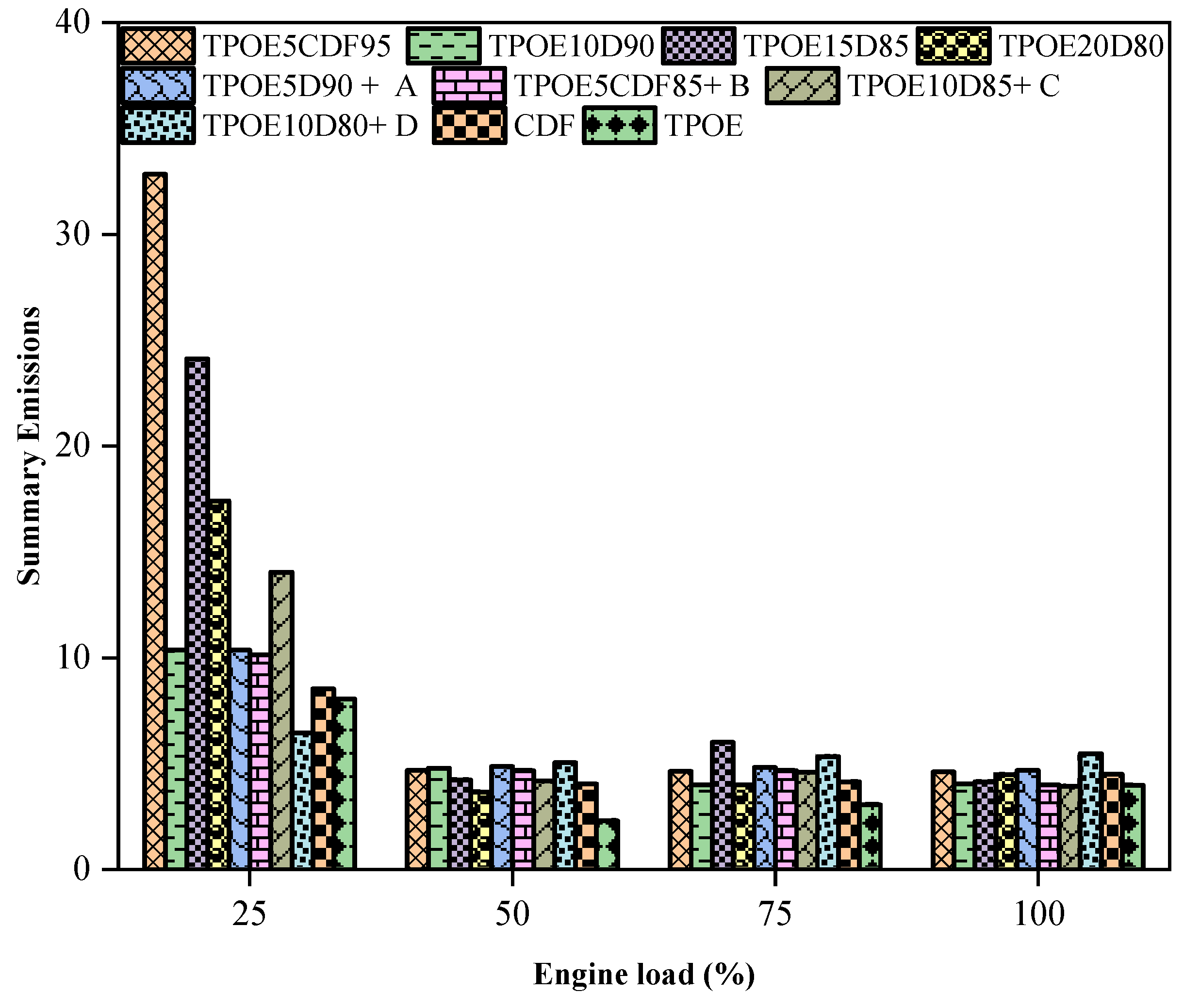

3.3.3. Summary of Emission

4. Conclusions

- Utilizing tyre pyrolysis oil for alternative production will contribute greatly to environmental compensations and provide an alternative to releasing the tyre pyrolysis oil into the environment.

- Adding nano-additive (CeO2) particles to diesel–tyre pyrolysis oil enhances brake thermal efficiency and chamber pressure while reducing SFC.

- Increasing the proportion of tyre pyrolysis oil in blends has negative effects, including lengthening the ignition delay duration, increasing SFC, and decreasing EGT.

- With the TPOE10D80 + D nano-additive gasoline sample, reduced fuel consumption and enhanced thermal brake efficiency were observed (100 ppm).

- As the amount of tyre pyrolysis oil in blends increases, emissions of nitrogen oxide and smoke are decreased. Additionally, the addition of CeO2 to TPOE blends demonstrates an inverse propensity for NOX emission.

- When increasing volumes of tyre pyrolysis oil are added to blends, the total discharges are lower than when 50 ppm and 100 ppm CDF and ceramic oxide are added, respectively.

- This research may increase the use of compression ignition engines and a unique mix that blends 100 ppm of tyre pyrolysis oil alternative with ceramic oxide.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Correction Statement

Nomenclature

| BTE | Brake thermal efficiency |

| BMEP | Brake mean effective pressure |

| IMEP | Indicated mean effective pressure |

| SFC | Specific fuel consumption |

| D-RK | Diesel-RK |

| CDF | Conventional diesel fuel |

| CeO2 | Ceramic oxide |

| CI | Compression ignition |

| EGT | Exhaust gas temperature |

| SMD | Diameter of drops |

| TPOE5D95 | 5% of TPOE + 95% CDF |

| TPOE10D90 | 10% of TPOE and 90% CDF |

| TPOE15D85 | 15% of TPOE and 85% CDF |

| TPOE20D80 | 20% of TPOE and 80% CDF |

| TPOE5CDF90 + A | 5% of TPOE and 90% CDF + CeO2 50 ppm |

| TPOE5CDF85 + B | 5% of TPOE and 85% CDF + CeO2 100 ppm |

| TPOE10CDF85 + C | 10% of TPOE and 85% CDF + CeO2 50 ppm |

| TPOE10CDF80 + D | 10% of TPOE and 80% CDF + CeO2 100 ppm |

| TPOE | Tyre pyrolysis oil energy |

| SOE | Summary of emission |

| A0, A2, A3 | Empirical factors |

| BSN | Bosch Smoke Number |

| BN | Bosh number |

| C | Carbon |

| CN | Cetane number |

| Ea | Activation energy, kJ/k. mole |

| KT | Temperature, K |

| m | Total mass, kg |

| Mass flow rate, kg/s | |

| n | Speed, rpm |

| p | Pressure, bar |

| Pb | Engine power, kW |

| Pmax | Maximum chamber pressure, bar |

| PM | Particulate matter |

| qc | Cycle fuel mass |

| R | Gas constant, J/mole. K |

| T | Temperature, K |

| Tb | Burnt gas zone, K |

| V | Volume chamber, cm3 |

| Mean velocity of piston, m/s | |

| x0 | Fraction of burnt fuel (ignition delay) |

| x | Fraction of fuel burnt |

| α, β, λ | Constants |

| τ | Time, s |

| ξb | Air charge usage efficiency |

| ρ | Density, kg/m3 |

| Φ0, Φ1, Φ2, Φ3 | Constant |

| σu, σud | Fuel fractions evaporated during ignition delay period |

| dx/dt | Heat release rate, 1/degree |

| ω | Angular crank velocity, rpm |

References

- Kumar, K.; Kannan, M.; Nataraj, G. A study on performance, emission and combustion characteristics of diesel engine powered by nano-emulsion of waste orange peel oil biodiesel. Renew. Energy 2020, 146, 1781–1795. [Google Scholar] [CrossRef]

- Yaşar, A.; Keskin, A.; Yıldızhan, Ş.; Uludamar, E. Emission and vibration analysis of diesel engine fuelled diesel fuel containing metallic based nanoparticles. Fuel 2019, 239, 1224–1230. [Google Scholar] [CrossRef]

- Vinukumar, K.; Azhagurajan, A.; Vettivel, S.C.; Vedaraman, N.; Lenin, A.H. Biodiesel with nano additives from coconut shell for decreasing emissions in diesel engines. Fuel 2018, 222, 180–184. [Google Scholar] [CrossRef]

- Ghanbari, M.; Najafi, G.; Ghobadian, B.; Yusaf, T.; Carlucci, A.P.; Kiani, D.K.M. Performance and emission characteristics of a CI engine using nano particles additives in biodiesel-diesel blends and modeling with GP approach. Fuel 2017, 202, 699–716. [Google Scholar] [CrossRef]

- Ardebili, S.M.S.; Taghipoor, A.; Solmaz, H.; Mostafaei, M. The effect of nano-biochar on the performance and emissions of a diesel engine fueled with fusel oil-diesel fuel. Fuel 2020, 268, 117356. [Google Scholar] [CrossRef]

- Gharehghani, A.; Pourrahmani, H. Performance evaluation of diesel engines (PEDE) for a diesel-biodiesel fueled CI engine using nano-particles additive. Energy Convers. Manag. 2019, 198, 111921. [Google Scholar] [CrossRef]

- Khalife, E.; Tabatabaei, M.; Najafi, B.; Mostafa, S. A novel emulsion fuel containing aqueous nano cerium oxide additive in diesel—Biodiesel blends to improve diesel engines performance and reduce exhaust emissions: Part I—Experimental analysis. Fuel 2017, 207, 741–750. [Google Scholar] [CrossRef]

- Perumal, V.; Ilangkumaran, M. The influence of copper oxide nano particle added pongamia methyl ester biodiesel on the performance, combustion and emission of a diesel engine. Fuel 2018, 232, 791–802. [Google Scholar] [CrossRef]

- Örs, I.; Sar, S.; Atabani, A.E.; Ünalan, S.; Akansu, S.O. The effects on performance, combustion and emission characteristics of DICI engine fuelled with TiO2 nanoparticles addition in diesel/biodiesel/n-butanol blends. Fuel 2019, 234, 177–188. [Google Scholar] [CrossRef]

- Ettefaghi, E.; Ghobadian, B.; Rashidi, A.; Naja, G.; Hadi, M.; Rashtchi, M.; Sadeghian, S. A novel bio-nano emulsion fuel based on biodegradable nanoparticles to improve diesel engines performance and reduce exhaust emissions. Renew. Energy 2018, 125, 64–72. [Google Scholar] [CrossRef]

- Hasannuddin, A.K.; Yahya, W.J.; Sarah, S.; Ithnin, A.M.; Syahrullail, S.; Sidik, N.A.C.; Ramlan, N.A. Nano-additives incorporated water in diesel emulsion fuel: Fuel properties, performance and emission characteristics assessment. Energy Convers. Manag. 2018, 169, 291–314. [Google Scholar] [CrossRef]

- Dhanasekar, K.; Sridaran, M.; Arivanandhan, M.; Jayavel, R. A facile preparation, performance and emission analysis of pongamia oil based novel biodiesel in diesel engine with CeO2: Gd nanoparticles. Fuel 2019, 255, 115756. [Google Scholar] [CrossRef]

- Kumaravel, S.T.; Murugesan, A.; Vijayakumar, C.; Thenmozhi, M. Enhancing the fuel properties of tyre oil diesel blends by doping nano additives for green environments. J. Clean. Prod. 2019, 240, 118128. [Google Scholar] [CrossRef]

- Qi, D.H.; Ding, X.Q.; Zhao, W.B.; Yang, K. Spray characteristics and engine performance of vegetable oil–diesel–ethanol hybrid fuel. J. Energy Eng. 2021, 145, 04019011. [Google Scholar] [CrossRef]

- Datta, A.; Mandal, B.K. Engine performance, combustion and emission characteristics of a compression ignition engine operating on different biodiesel-alcohol blends. Energy 2017, 125, 470–483. [Google Scholar] [CrossRef]

- Kuleshov, A.; Mahkamov, K. Multi-zone diesel fuel spray combustion model for the simulation of a diesel engine running on biofuel. Part A: J. Power Energy 2016, 222, 309–321. [Google Scholar] [CrossRef]

- Mishra, S.; Anand, K.; Santhosh, S.; Mehta, P.S. Comparison of biodiesel fuel behavior in a heavy duty turbocharged and a light duty naturally aspirated engine. Appl. Energy 2017, 202, 459–470. [Google Scholar] [CrossRef]

- Khan, M.M.; Kadian, A.K.; Sharma, R.P.; Hasnain, S.M.M.; Mohamed, A.; Ragab, A.E.; Zare, A.; Pandey, S. Emission Reduction and Performance Enhancement of CI Engine Propelled by Neem Biodiesel-Neem Oil-Decanol-Diesel Blends at High Injection Pressure. Sustainability 2023, 15, 9084. [Google Scholar] [CrossRef]

- Karagöz, M.; Ümit, A.; Sar, S. Waste to energy: Production of waste tire pyrolysis oil and comprehensive analysis of its usability in diesel engines. Fuel 2020, 275, 117844. [Google Scholar] [CrossRef]

- Kuleshov, A.S. Model for Predicting Air-Fuel Mixing, Combustion and Emissions in DI Diesel Engines over Whole Operating Range (No. 2005-01-2119); SAE Technical Paper; SAE International: Warrendale, PA, USA, 2005. [Google Scholar]

- Sharma, A.; Murugan, S. Investigation on the behaviour of a DI diesel engine fueled with Jatropha Methyl Ester (JME) and Tyre Pyrolysis Oil (TPO) blends. Fuel 2013, 108, 699–708. [Google Scholar] [CrossRef]

- Rajak, U.; Nashine, P.; Chaurasiya, P.K.; Verma, T.N.; Dasore, A.; Pathak, K.K.; Dwivedi, G.; Shukla, A.K.; Saini, G. The effects on performance and emission characteristics of DI engine fuelled with CeO2 nanoparticles addition in diesel/tyre pyrolysis oil blends. Environ. Dev. Sustain. 2022. [Google Scholar] [CrossRef]

- Zheng, F.; Cho, H. Combustion and Emission of Castor Biofuel Blends in a Single-Cylinder Diesel Engine. Energies 2023, 16, 5427. [Google Scholar] [CrossRef]

- Rehman, M.; Kesharvani, S.; Dwivedi, G. Numerical Investigation of Performance, Combustion, and Emission Characteristics of Various Microalgae Biodiesel on CI Engine. Fuels 2023, 4, 132–155. [Google Scholar] [CrossRef]

- Venu, H.; Subramani, L.; Raju, V.D. Emission reduction in a DI diesel engine using exhaust gas recirculation (EGR) of palm biodiesel blended with TiO2 nano additives. Renew. Energy 2019, 140, 245–263. [Google Scholar] [CrossRef]

- Nanthagopal, K.; Ashok, B.; Raj, R.T.K. Influence of fuel injection pressures on Calophyllum inophyllum methyl ester fuelled direct injection diesel engine. Energy Convers. Manag. 2016, 116, 165–173. [Google Scholar] [CrossRef]

- Sidhu, M.S.; Roy, M.M.; Wang, W. Glycerine emulsions of diesel-biodiesel blends and their performance and emissions in a diesel engine. Appl. Energy 2018, 230, 148–159. [Google Scholar] [CrossRef]

- Mikky, Y.A.; Bhran, A.A.; El-Araby, R.Y.; Mohamed, A.M.A.; Gadallah, A.G.; Shoaib, A.M. Optimization of Biodiesel–Nanoparticle Blends for Enhanced Diesel Engine Performance and Emission Reduction. Processes 2024, 12, 2471. [Google Scholar] [CrossRef]

- Srihari, S.; Thirumalini, S.; Prashanth, K. An experimental study on the performance and emission characteristics of PCCI-DI engine fuelled with diethyl ether-biodiesel-diesel blends. Renew. Energy 2017, 107, 440–447. [Google Scholar] [CrossRef]

- Zheng, Z.; Xia, M.; Liu, H.; Shang, R.; Ma, G.; Yao, M. Experimental study on combustion and emissions of n-butanol / biodiesel under both blended fuel mode and dual fuel RCCI mode. Fuel 2018, 226, 240–251. [Google Scholar] [CrossRef]

- Li, X.; Liu, Q.; Ma, Y.; Wu, G.; Yang, Z.; Fu, Q. Simulation Study on the Combustion and Emissions of a Diesel Engine with Different Oxygenated Blended Fuels. Sustainability 2024, 16, 631. [Google Scholar] [CrossRef]

- Ooi, J.B.; Ismail, H.M.; Tan, B.T.; Wang, X. Effects of Graphite Oxide and Single-Walled Carbon Nanotubes as Diesel Additives on the Performance, Combustion, and Emission Characteristics of a Light-Duty Diesel Engine. Energy 2018, 161, 70–80. [Google Scholar] [CrossRef]

- Nour, M.; Attia, A.M.A.; Nada, S.A. Combustion, performance and emission analysis of diesel engine fuelled by higher alcohols (butanol, octanol and heptanol)/ diesel blends. Energy Convers. Manag. 2019, 185, 313–329. [Google Scholar] [CrossRef]

- Koc, A.B.; Abdullah, M. Performance of a 4-cylinder diesel engine running on tire oil—Biodiesel—Diesel blend. Fuel Process. Technol. 2014, 118, 264–269. [Google Scholar] [CrossRef]

- Petranovic, Z.; Edelbauer, W.; Duic, N.; Vujanovic, M. Modelling spray and combustion processes in diesel engine by using the coupled Eulerian—Eulerian and Eulerian—Lagrangian method. Energy Convers. Manag. 2016, 125, 15–25. [Google Scholar] [CrossRef]

- Kumar, M.; Tsujimura, T.; Suzuki, Y. NOx model development and validation with diesel and hydrogen/diesel dual-fuel system on diesel engine. Energy 2018, 145, 496–506. [Google Scholar] [CrossRef]

- Rangabashiam, D.; Logesh, K.; Yashvanth, U.; Subbiah, G. Detailed study on the effect of nano-particle size on emission characteristics of diesel engine. Pet. Sci. Technol. 2019, 37, 2018–2024. [Google Scholar] [CrossRef]

- Dhinesh, B.; Annamalai, M. A study on performance, combustion and emission behaviour of diesel engine powered by novel nano nerium oleander biofuel. J. Clean. Prod. 2018, 196, 74–83. [Google Scholar] [CrossRef]

- Malik, M.A.I.; Kalam, M.A.; Abbas, M.M.; Silitonga, A.S.; Ikram, A. Recent advancements, applications, and technical challenges in fuel additives-assisted engine operations. Energy Convers. Manag. 2024, 313, 118643. [Google Scholar] [CrossRef]

- Ulagarjun, U.; Varma, V.V.; Menon, A.K.; Gobinath, N.; Palanivelrajan, A.R.; Khan, T.Y.; Almakayeel, N. Investigation on effect of cerium oxide additive in waste plastic oil fueled CI engine. Heliyon 2024, 10, e26146. [Google Scholar] [CrossRef]

- Zheng, Y.; Cheng, P.; Li, Z.; Fan, C.; Wen, J.; Yu, Y.; Jia, L. Efficient removal of gaseous elemental mercury by Fe-UiO-66@ BC composite adsorbent: Performance evaluation and mechanistic elucidation. Sep. Purif. Technol. 2025, 372, 133463. [Google Scholar] [CrossRef]

- Qi, D.H.; Chen, H.; Geng, L.M.; Bian, Y.Z. Effect of diethyl ether and ethanol additives on the combustion and emission characteristics of biodiesel-diesel blended fuel engine. Renew. Energy 2011, 36, 1252–1258. [Google Scholar] [CrossRef]

| Authors | Nano-additives | Performance | Discharge | ||||||

| Power | Torque | BTE | SFC | CO | HC | NOx | Smoke | ||

| Yaşar et al. [2] | TiO2, (Cu(NO3)2), (Ce(CH3CO2)3·H2O) | - | - | - |  |  |  |  | - |

| Vinukumar et al. [3] | Coconut shell (CS) |  |  | - |  |  | - |  | - |

| Gharehghani et al. [6] | Cerium oxide (CeO2) | - | - | - | - |  |  | - | |

| Ardebili et al. [5] | Sugarcane nano-biochar (SNB) |  |  | - |  |  |  |  | - |

| Ghanbari et al. [4] | Carbon nanotubes (CNTs) |  |  | - |  |  |  |  | - |

| Khalife et al. [7] | Aqueous nano cerium oxide [7] | - | - |  |  |  |  |  | - |

| Perumal and Ilangkumaran [8] | Copper oxide (CuO) [8] | - | - |  |  |  | - |  |  |

| Örs et al. [9] | Titanium dioxide (TiO2) |  |  |  | - |  |  |  | |

| Ettefaghi et al. [10] | Carbon quantum dots |  |  | - |  |  |  | - | - |

| Hasannuddin et al. [11] | Aluminium oxide (Al2O3) |  | - | - |  |  |  | - | |

| Dhanasekar et al. [12] | CeO2 and CeO2 | - | - | - | - |  | - | - |  |

| Kumaravel et al. [13] | CeO2 | - | - |  | - | - | - |  |  |

| Present investigation | Cerium oxide (CeO2) with tyre oil–diesel fuel at different loads | - | - |  |  | - | - |  |  |

= Increase value of parameter and

= Increase value of parameter and  = decrease value of parameter.

= decrease value of parameter.| Sr. No. | Name | Values |

| 1. | Compound | Cerium oxide (CeO2) |

| 2. | Colour | Pale yellow-white |

| 4. | Producer | M/s. Sigma–Aldrich (Burlington, MA, USA) |

| 5. | Purity | 99.97% |

| 6. | Surface area | 11–17 m2/g |

| Properties/Fuel | TPOE | Diesel |

| Heating value (MJ/kg) | 36.5 | 43.5 |

| Flash point (°C) | 35 | 51 |

| Fire point (°C) | 40 | 56 |

| Surface tension (N/m) | 0.0451 | 0.028 |

| Density (kg/m3) | 910 | 810 |

| Viscosity (cSt.) | 12.74 | 5.665 |

| Fuel | TPOE5D90 + A | TPOE5D85 + B | TPOE10D85 + C | TPOE10D80 + D |

| Density (kg/m3) | 817 | 819 | 822 | 824 |

| Flash point (°C) | 51 | 52 | 50 | 51 |

| Fire point (°C) | 55 | 56 | 54 | 56 |

| Heating value (MJ/kg) | 43.28 | 43.28 | 42.94 | 42.98 |

| Viscosity (cSt.) | 6.35 | 6.4 | 6.65 | 6.72 |

| Parameter | Value |

| Engine type | Single-cylinder, 4-stroke, DI diesel |

| Bore × stroke | 87.5 mm × 110 mm |

| Compression ratio | 18.5:1 |

| Rated power | 5.2 kW @ 1500 rpm |

| Cooling system | Water-cooled |

| Injection pressure | 220 bars |

| Injection timing | 23.5° b TDC |

| speed | Constant 1500 rpm |

| Load conditions | 25%, 50%, 75%, and 100% of rated load |

| Intake air temperature | 30 ± 2 °C |

| cooling water temperature | 80 ± 2 °C |

| Lubricating oil temperature | 75 ± 3 °C |

| Test repetitions | 3 per load condition |

| Instrument | Uncertainty (%) |

| Air flow | ±1.0 |

| Encoder | ±0.2 |

| Dynamometer | ±0.15 |

| Fuel consumption | ±0.6 |

| CO2 NOx CO | ±1.0 ± 0.5 ±1.2 |

| Load cell | ±0.2 |

| Pressure sensor | ±0.5 |

| Smoke meter | ±1.0 |

| Speed sensor | ±1.0 |

| Temperature sensor | ±0.15 |

| Thermal efficiency | ±0.9 |

| Equation | Equation |

| (3) | |

| (4) | |

| (5) | |

| (6) | |

| (7) | |

| (8) | |

| (9) | |

| (10) | |

| (11) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Madhuri, K.S.; Hussain, S.A.; Kumar, R.; Rajak, U.; Nath Verma, T. Engine Response and Emission Optimization of Ceramic-Oxide-Doped Diesel Blends with Reclaimed Waste Energy. Fuels 2025, 6, 70. https://doi.org/10.3390/fuels6030070

Madhuri KS, Hussain SA, Kumar R, Rajak U, Nath Verma T. Engine Response and Emission Optimization of Ceramic-Oxide-Doped Diesel Blends with Reclaimed Waste Energy. Fuels. 2025; 6(3):70. https://doi.org/10.3390/fuels6030070

Chicago/Turabian StyleMadhuri, K. Sudha, Syed Altaf Hussain, Rohit Kumar, Upendra Rajak, and Tikendra Nath Verma. 2025. "Engine Response and Emission Optimization of Ceramic-Oxide-Doped Diesel Blends with Reclaimed Waste Energy" Fuels 6, no. 3: 70. https://doi.org/10.3390/fuels6030070

APA StyleMadhuri, K. S., Hussain, S. A., Kumar, R., Rajak, U., & Nath Verma, T. (2025). Engine Response and Emission Optimization of Ceramic-Oxide-Doped Diesel Blends with Reclaimed Waste Energy. Fuels, 6(3), 70. https://doi.org/10.3390/fuels6030070