Influence of EGR and Acoustic Waves on Particles and Other Emissions of IC Engine Powered with Diesel and RME Fuels

Abstract

1. Introduction

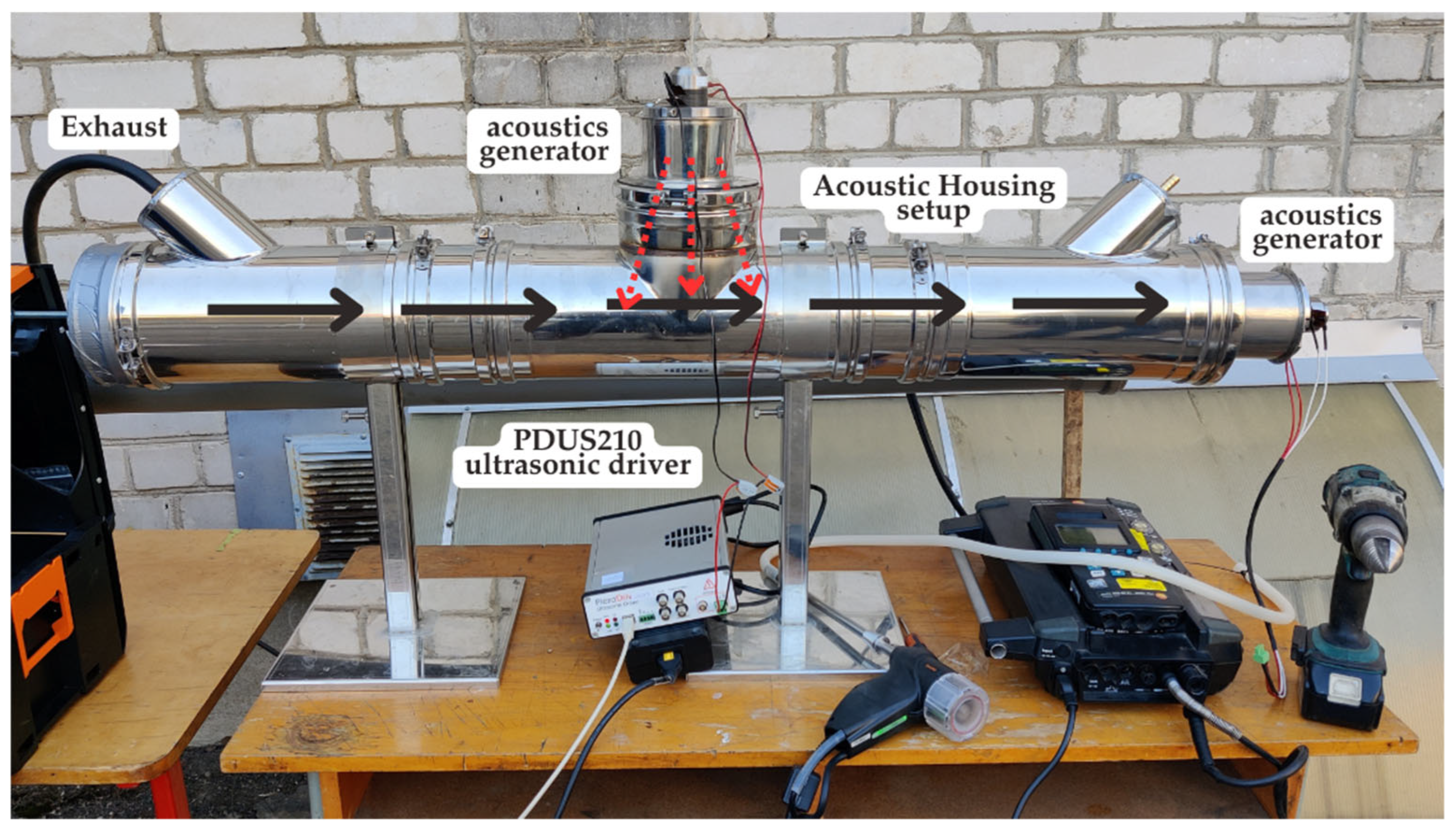

2. Materials and Methods

2.1. Testing Equipment

2.2. Fuels Used and Test Environment

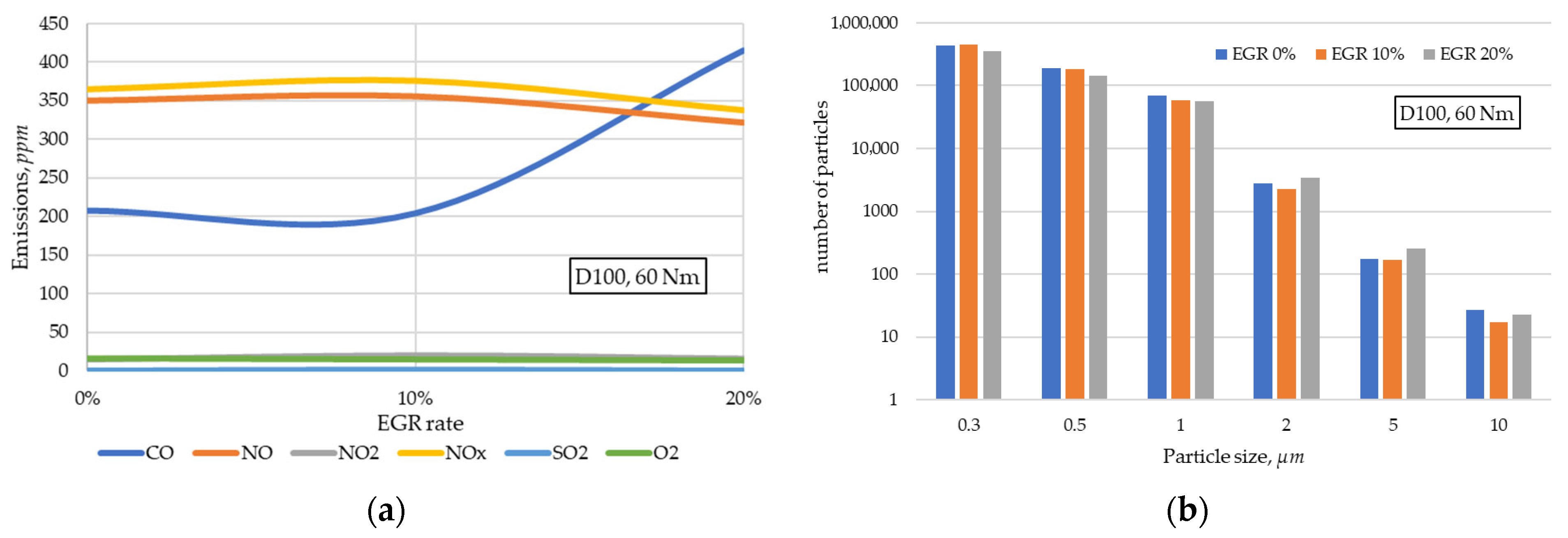

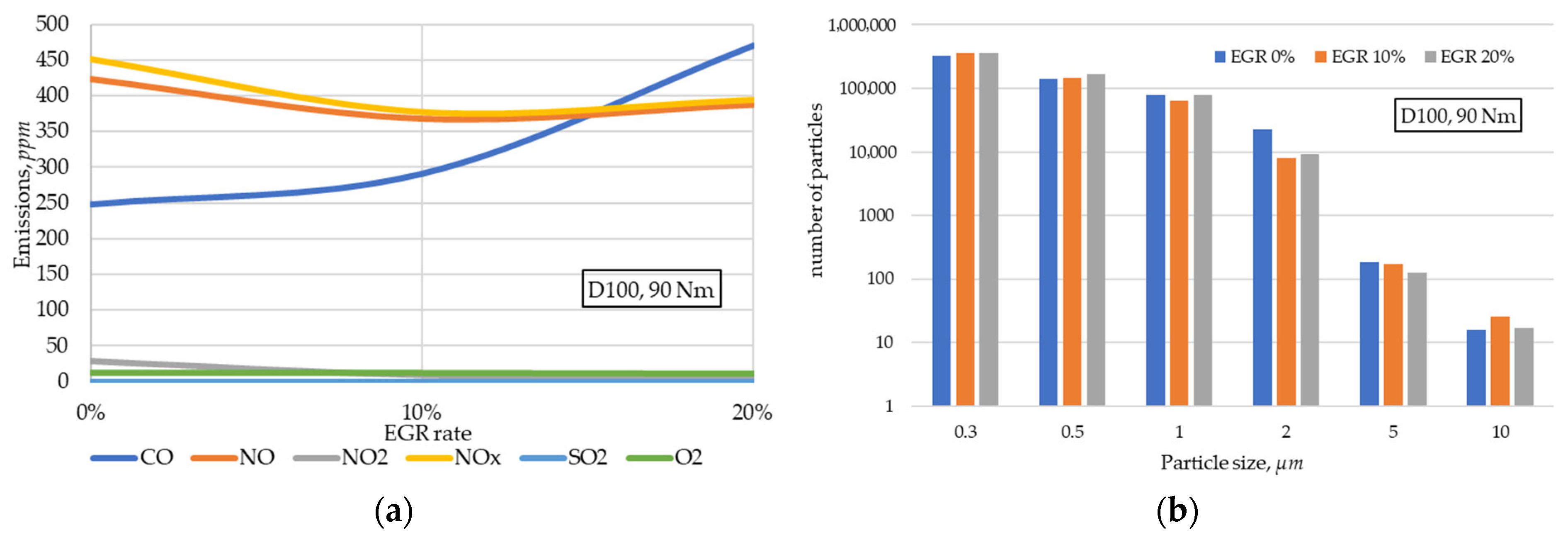

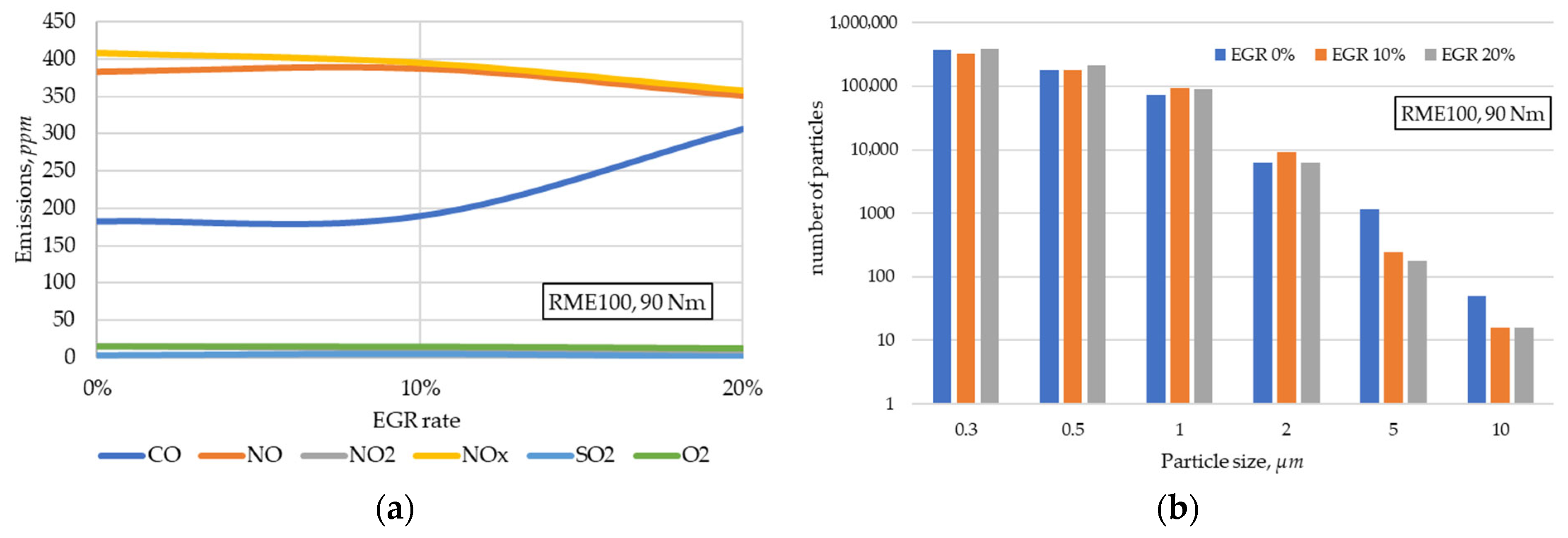

3. Results

3.1. Total Emissions of Diesel and RME Fuel

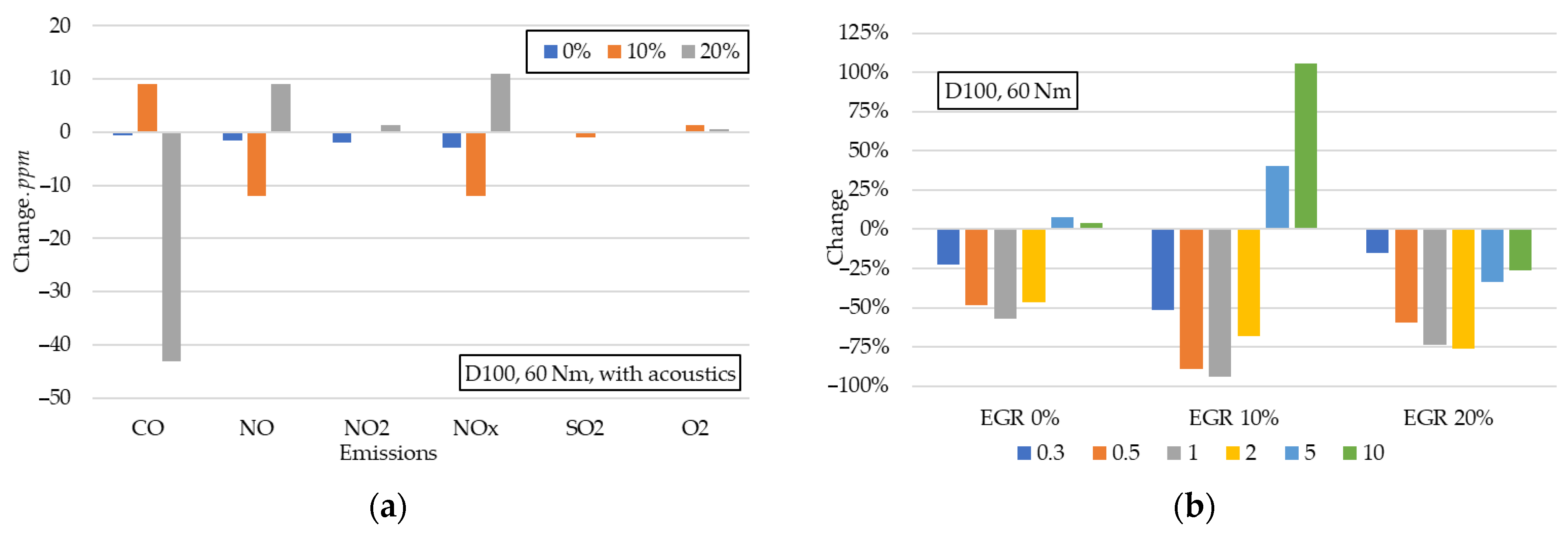

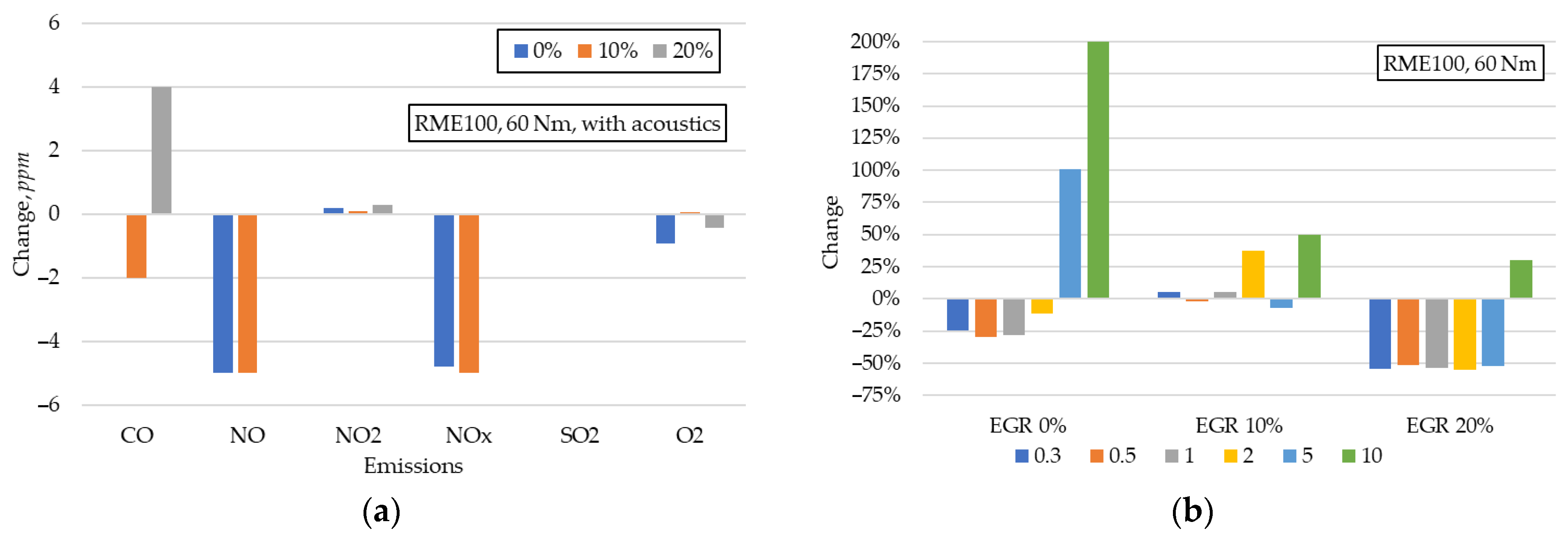

3.2. Impact of Acoustic Waves on Emissions

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Estevez, R.; Aguado-Deblas, L.; López-Tenllado, F.J.; Bautista, F.M.; Romero, A.A.; Luna, D. Internal Combustion Engines and Carbon-Neutral Fuels: A Perspective on Emission Neutrality in the European Union. Energies 2024, 17, 1172. [Google Scholar] [CrossRef]

- Pacura, W.; Szramowiat-Sala, K.; Gołaś, J. Emissions from Light-Duty Vehicles—From Statistics to Emission Regulations and Vehicle Testing in the European Union. Energies 2024, 17, 209. [Google Scholar] [CrossRef]

- Akbalık, Z.; Arpa, O. Enhancing Diesel Engine Efficiency and Emission Control: A Study on Hydrogen and Water Vapor Injection. Int. J. Hydrogen Energy 2025, 143, 1053–1067. [Google Scholar] [CrossRef]

- Pielecha, J.; Skobiej, K.; Gis, M.; Gis, W. Particle Number Emission from Vehicles of Various Drives in the RDE Tests. Energies 2022, 15, 6471. [Google Scholar] [CrossRef]

- Mulholland, E.; Miller, J.; Bernard, Y.; Lee, K.; Rodríguez, F. The Role of NOx Emission Reductions in Euro 7/VII Vehicle Emission Standards to Reduce Adverse Health Impacts in the EU27 through 2050. Transp. Eng. 2022, 9, 100133. [Google Scholar] [CrossRef]

- Soler Muniesa, J.A. Análisis de la Combinación de Los Sistemas de Recirculación de Gases de Alta y Baja Presión Sobre el Comportamiento de un Motor Diesel Sobrealimentado. Ph.D. Thesis, Universitat Politècnica de València, Valencia, Spain, 2016. [Google Scholar]

- Chaichan, M.T.; Ekab, N.S.; Fayad, M.A.; Dhahad, H.A. PM and NOX Emissions Amelioration from the Combustion of Diesel/Ethanol-Methanol Blends Applying Exhaust Gas Recirculation (EGR). In IOP Conference Series: Earth and Environmental Science; IOP: Bristol, UK, 2022; Volume 961, p. 012044. [Google Scholar]

- Fayad, M.A.; Al-Ghezi, M.K.; Hafad, S.A.; Ibrahim, S.I.; Abood, M.K.; Al-Salihi, H.A.; Mahdi, L.A.; Chaichan, M.T.; Dhahad, H.A. Emissions Characteristics and Engine Performance from the Interaction Effect of EGR and Diesel-Ethanol Blends in Diesel Engine. Int. J. Renew. Energy Dev. 2022, 11, 991–1001. [Google Scholar] [CrossRef]

- Ergen, G. Comprehensive Analysis of the Effects of Alternative Fuels on Diesel Engine Performance Combustion and Exhaust Emissions: Role of Biodiesel, Diethyl Ether, and EGR. Therm. Sci. Eng. Prog. 2024, 47, 102307. [Google Scholar] [CrossRef]

- Sahaya Surendira Babu, P.; Kumar, P. External Exhaust Gas Recirculation. In Design and Development of Heavy Duty Diesel Engines: A Handbook; Lakshminarayanan, P.A., Agarwal, A.K., Eds.; Springer: Singapore, 2020; pp. 275–311. ISBN 9789811509704. [Google Scholar]

- Kumar, M.V.; Babu, A.V.; Kumar, P.R.; Narendra, B. Reduction of Nitrogen Oxides Emissions in a Single Cylinder Compression Ignition Engine Using Cool Exhaust Gas Recirculation System. Iran. J. Energy Environ. 2016, 7, 268–273. [Google Scholar] [CrossRef]

- Choi, M.; Mohiuddin, K.; Kim, N.; Park, S. Investigation of the Effects of EGR Rate, Injection Strategy and Nozzle Specification on Engine Performances and Emissions of a Single Cylinder Heavy Duty Diesel Engine Using the Two Color Method. Appl. Therm. Eng. 2021, 193, 117036. [Google Scholar] [CrossRef]

- Deng, B.; Cai, W.; Zhang, W.; Bian, L.; Che, X.; Xiang, Y.; Wu, D. A Comprehensive Investigation of EGR (Exhaust Gas Recirculation) Effects on Energy Distribution and Emissions of a Turbo-Charging Diesel Engine under World Harmonized Transient Cycle. Energy 2025, 316, 134506. [Google Scholar] [CrossRef]

- Shivashimpi, M.M.; Alur, S.A.; Banapurmath, N.R. Exhaust Gas Recirculation as a NOx Reduction Technique for Modified POME Fuelled Diesel Engine. Int. J. Veh. Struct. Syst. 2022, 14, 169–173. [Google Scholar] [CrossRef]

- Youssef, A.; Ibrahim, A. NOx Emissions Reduction through Applying the Exhaust Gas Recirculation (EGR) Technique for a Diesel Engine Fueled with a Diesel-Biodiesel-diethyl Ether Blend. Energy Storage Sav. 2024, 3, 318–326. [Google Scholar] [CrossRef]

- Karimi, M.; Wang, X.; Hamilton, J.; Negnevitsky, M. Numerical Investigation on Hydrogen-Diesel Dual-Fuel Engine Improvements by Oxygen Enrichment. Int. J. Hydrogen Energy 2022, 47, 25418–25432. [Google Scholar] [CrossRef]

- Kumar, M.V.; Babu, A.V.; Reddy, C.R.; Pandian, A.; Bajaj, M.; Zawbaa, H.M.; Kamel, S. Investigation of the Combustion of Exhaust Gas Recirculation in Diesel Engines with a Particulate Filter and Selective Catalytic Reactor Technologies for Environmental Gas Reduction. Case Stud. Therm. Eng. 2022, 40, 102557. [Google Scholar] [CrossRef]

- Khmelev, V.N.; Golykh, R.N.; Shalunov, A.V.; Nesterov, V.A. Numerical Model of Ultrasonic Coagulation of Dispersed Particles in Eckart Flows. Interfacial Phenom. Heat Transf. 2023, 11, 1–23. [Google Scholar] [CrossRef]

- Hasan, A.O.; Osman, A.I.; Al-Muhtaseb, A.H.; Al-Rawashdeh, H.; Abu-jrai, A.; Ahmad, R.; Gomaa, M.R.; Deka, T.J.; Rooney, D.W. An Experimental Study of Engine Characteristics and Tailpipe Emissions from Modern DI Diesel Engine Fuelled with Methanol/Diesel Blends. Fuel Process. Technol. 2021, 220, 106901. [Google Scholar] [CrossRef]

- Cui, X.; Zhao, Y.; Ji, Y.; Liu, J.; Gao, T.; Yang, G.; Wang, Y.; Xiao, R.; Chuai, X.; Zhang, J. Demonstration and Application of Heterogeneous Agglomeration Technology in a 350 MW Coal-Fired Power Plant: Removal of Particulate Matter and Trace Elements. Fuel 2022, 309, 122361. [Google Scholar] [CrossRef]

- Liu, Y.; Pan, C.; Zhang, L.; Ding, H.; Huang, H.; Xu, F.; Bu, S.; Jin, H.; Xu, W. Experimental and Numerical Study on the Acoustic Coagulation of Charged Particles. Powder Technol. 2022, 410, 117780. [Google Scholar] [CrossRef]

- Shi, Y.; Wei, J.; Qiu, J.; Chu, H.; Bai, W.; Wang, G. Numerical Study of Acoustic Agglomeration Process of Droplet Aerosol Using a Three-Dimensional CFD-DEM Coupled Model. Powder Technol. 2020, 362, 37–53. [Google Scholar] [CrossRef]

- Ng, B.F.; Xiong, J.W.; Wan, M.P. Application of Acoustic Agglomeration to Enhance Air Filtration Efficiency in Air-Conditioning and Mechanical Ventilation (ACMV) Systems. PLoS ONE 2017, 12, e0178851. [Google Scholar] [CrossRef]

- Rayapureddy, S.M.; Maknickas, A.; Matijošius, J.; Vainorius, D.; Kilikevičius, A. Computational Study of Frequency Impact Onto the Particle Parameters and Change in Acoustic Agglomeration Time with the Number of Particles. Facta Univ. Ser. Mech. Eng. 2024, 30, 741–757. [Google Scholar] [CrossRef]

- Gallego-Juárez, J.A.; Sarabia, E.R.-F.D.; Hoffmann, T.L.; Gálvez-Moraleda, J.C. Application of the Acoustic Agglomeration to Reduce Fine Particle Emissions in Coal Combustion Plants. Environ. Sci. Technol. 1999, 33, 3843–3849. [Google Scholar] [CrossRef]

- Hoffmann, T.L. Environmental Implications of Acoustic Aerosol Agglomeration. Ultrasonics 2000, 38, 353–357. [Google Scholar] [CrossRef]

- Zhou, D.; Luo, Z.; Jiang, J.; Chen, H.; Lu, M.; Fang, M. Experimental Study on Improving the Efficiency of Dust Removers by Using Acoustic Agglomeration as Pretreatment. Powder Technol. 2016, 289, 52–59. [Google Scholar] [CrossRef]

- Kadyrov, A.; Bembenek, M.; Sarsembekov, B.; Kukesheva, A.; Nurkusheva, S. The Influence of the Frequency of Ultrasound on the Exhaust Gas Purification Process in a Diesel Car Muffler. Appl. Sci. 2024, 14, 5027. [Google Scholar] [CrossRef]

- Kilikevičienė, K.; Chlebnikovas, A.; Matijošius, J.; Kilikevičius, A. Investigation of the Acoustic Agglomeration on Ultrafine Particles Chamber Built into the Exhaust System of an Internal Combustion Engine from Renewable Fuel Mixture and Diesel. Heliyon 2023, 9, e16737. [Google Scholar] [CrossRef]

- Kilikevičienė, K.; Kačianauskas, R.; Kilikevičius, A.; Maknickas, A.; Matijošius, J.; Rimkus, A.; Vainorius, D. Experimental Investigation of Acoustic Agglomeration of Diesel Engine Exhaust Particles Using New Created Acoustic Chamber. Powder Technol. 2020, 360, 421–429. [Google Scholar] [CrossRef]

- Rayapureddy, S.; Matijošius, J.; Rimkus, A. Comparison of Research Data of Diesel–Biodiesel–Isopropanol and Diesel–Rapeseed Oil–Isopropanol Fuel Blends Mixed at Different Proportions on a CI Engine. Sustainability 2021, 13, 10059. [Google Scholar] [CrossRef]

- Rayapureddy, S.; Matijošius, J.; Rimkus, A.; Caban, J.; Słowik, T. Comparative Study of Combustion, Performance and Emission Characteristics of Hydrotreated Vegetable Oil–Biobutanol Fuel Blends and Diesel Fuel on a CI Engine. Sustainability 2022, 14, 7324. [Google Scholar] [CrossRef]

- Rimkus, A.; Matijošius, J.; Manoj Rayapureddy, S. Research of Energy and Ecological Indicators of a Compression Ignition Engine Fuelled with Diesel, Biodiesel (RME-Based) and Isopropanol Fuel Blends. Energies 2020, 13, 2398. [Google Scholar] [CrossRef]

- Elkelawy, M.; El Shenawy, E.A.; Mohamed, S.A.; Elarabi, M.M.; Bastawissi, H.A.-E. Impacts of Using EGR and Different DI-Fuels on RCCI Engine Emissions, Performance, and Combustion Characteristics. Energy Convers. Manag. X 2022, 15, 100236. [Google Scholar] [CrossRef]

- Yang, B.; Liu, L.; Jia, S.; Zhang, F.; Yao, M. Experimental Study on Particle Size Distribution of Gasoline Compression Ignition (GCI) at Low-Load Condition. Fuel 2021, 294, 120502. [Google Scholar] [CrossRef]

- Guo, Z.; Wang, B.; Liu, S.; Zhang, Z.; Wang, B.; Chang, C.-T.; Wang, P.; He, X.; Sun, X.; Shuai, S. Experimental Investigation on Emission Characteristics of High Reactivity Gasoline Compression Ignition with Different EGR and Injection Pressure Strategies. Fuel 2023, 332, 126176. [Google Scholar] [CrossRef]

- Su, X.; Chen, H.; Gao, N.; Ding, M.; Wang, X.; Xu, H.; Zhang, P. Combustion and Emission Characteristics of Diesel Engine Fueled with Diesel/Cyclohexanol Blend Fuels under Different Exhaust Gas Recirculation Ratios and Injection Timings. Fuel 2023, 332, 125986. [Google Scholar] [CrossRef]

- Kurczyński, D. Effect of the RME Biodiesel on the Diesel Engine Fuel Consumption and Emission. Komunik225cie-Vedeck233 Listy Žilinskej Univerzity V Žiline 2021, 23, 308–316. [Google Scholar] [CrossRef]

- Ezzi, A.A.; Fayad, M.A.; Al Jubori, A.M.; Jaber, A.A.; Alsadawi, L.A.; Dhahad, H.A.; Chaichan, M.T.; Yusaf, T. Influence of Fuel Injection Pressure and RME on Combustion, NOx Emissions and Soot Nanoparticles Characteristics in Common-Rail HSDI Diesel Engine. Int. J. Thermofluids 2022, 15, 100173. [Google Scholar] [CrossRef]

- Nazir, M.S.; Ahmad, S.; Tahir, Z.; Hassan, S.U.; Ali, Z.; Akhtar, M.N.; Azam, K.; Abdullah, M.A. A Review on the Methods in Diesel Desulfurization. Curr. Anal. Chem. 2021, 17, 815–830. [Google Scholar] [CrossRef]

- Olszewski, W.; Dzida, M.; Nguyen, V.G.; Cao, D.N. Reduction of CO2 Emissions from Offshore Combined Cycle Diesel Engine-Steam Turbine Power Plant Powered by Alternative Fuels. Pol. Marit. Res. 2023, 30, 71–80. [Google Scholar] [CrossRef]

- Tsolakis, A.; Megaritis, A.; Wyszynski, M.L.; Theinnoi, K. Engine Performance and Emissions of a Diesel Engine Operating on Diesel-RME (Rapeseed Methyl Ester) Blends with EGR (Exhaust Gas Recirculation). Energy 2007, 32, 2072–2080. [Google Scholar] [CrossRef]

- Labecki, L.; Lindner, A.; Winklmayr, W.; Uitz, R.; Cracknell, R.; Ganippa, L. Effects of Injection Parameters and EGR on Exhaust Soot Particle Number-Size Distribution for Diesel and RME Fuels in HSDI Engines. Fuel 2013, 112, 224–235. [Google Scholar] [CrossRef]

- De Serio, D.; De Oliveira, A.; Sodré, J.R. Application of an EGR System in a Direct Injection Diesel Engine to Reduce NOx Emissions. J. Phys. Conf. Ser. 2016, 745, 032001. [Google Scholar] [CrossRef]

| Properties | D100 | RME100 |

|---|---|---|

| Density (kg/m3) | 843 | 877 |

| Mass fraction (% mass): carbon | 86.3 | 77.5 |

| Hydrogen | 13.7 | 12 |

| Oxygen | 0 | 10.5 |

| C/H | 6.30 | 6.46 |

| Lower heating value (LHV) (MJ/kg) | 42.3 | 37.8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rayapureddy, S.M.; Matijošius, J. Influence of EGR and Acoustic Waves on Particles and Other Emissions of IC Engine Powered with Diesel and RME Fuels. Fuels 2025, 6, 67. https://doi.org/10.3390/fuels6030067

Rayapureddy SM, Matijošius J. Influence of EGR and Acoustic Waves on Particles and Other Emissions of IC Engine Powered with Diesel and RME Fuels. Fuels. 2025; 6(3):67. https://doi.org/10.3390/fuels6030067

Chicago/Turabian StyleRayapureddy, Sai Manoj, and Jonas Matijošius. 2025. "Influence of EGR and Acoustic Waves on Particles and Other Emissions of IC Engine Powered with Diesel and RME Fuels" Fuels 6, no. 3: 67. https://doi.org/10.3390/fuels6030067

APA StyleRayapureddy, S. M., & Matijošius, J. (2025). Influence of EGR and Acoustic Waves on Particles and Other Emissions of IC Engine Powered with Diesel and RME Fuels. Fuels, 6(3), 67. https://doi.org/10.3390/fuels6030067