Hydrocracking of Various Vacuum Residues

Abstract

1. Introduction

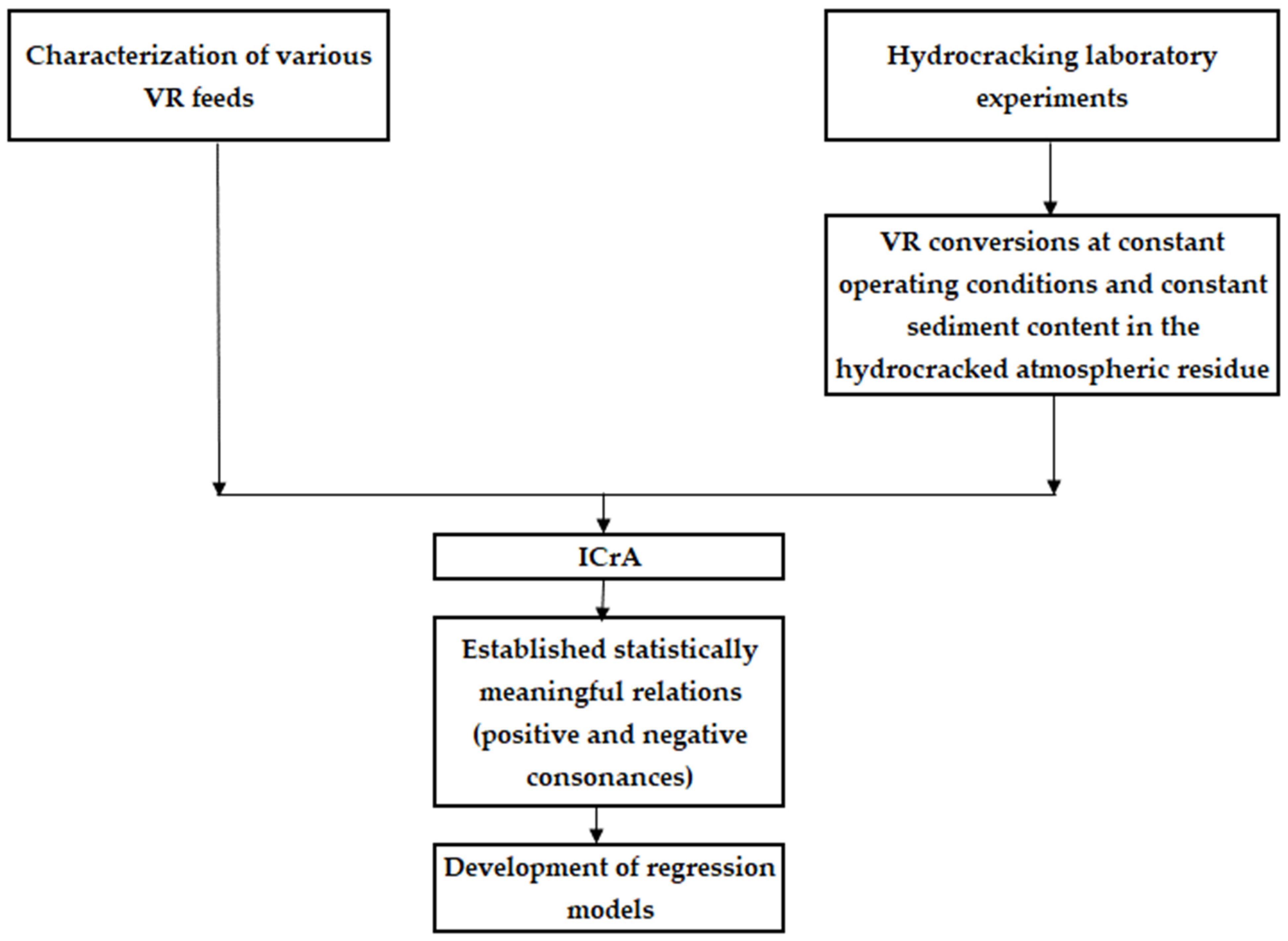

2. Materials and Methods

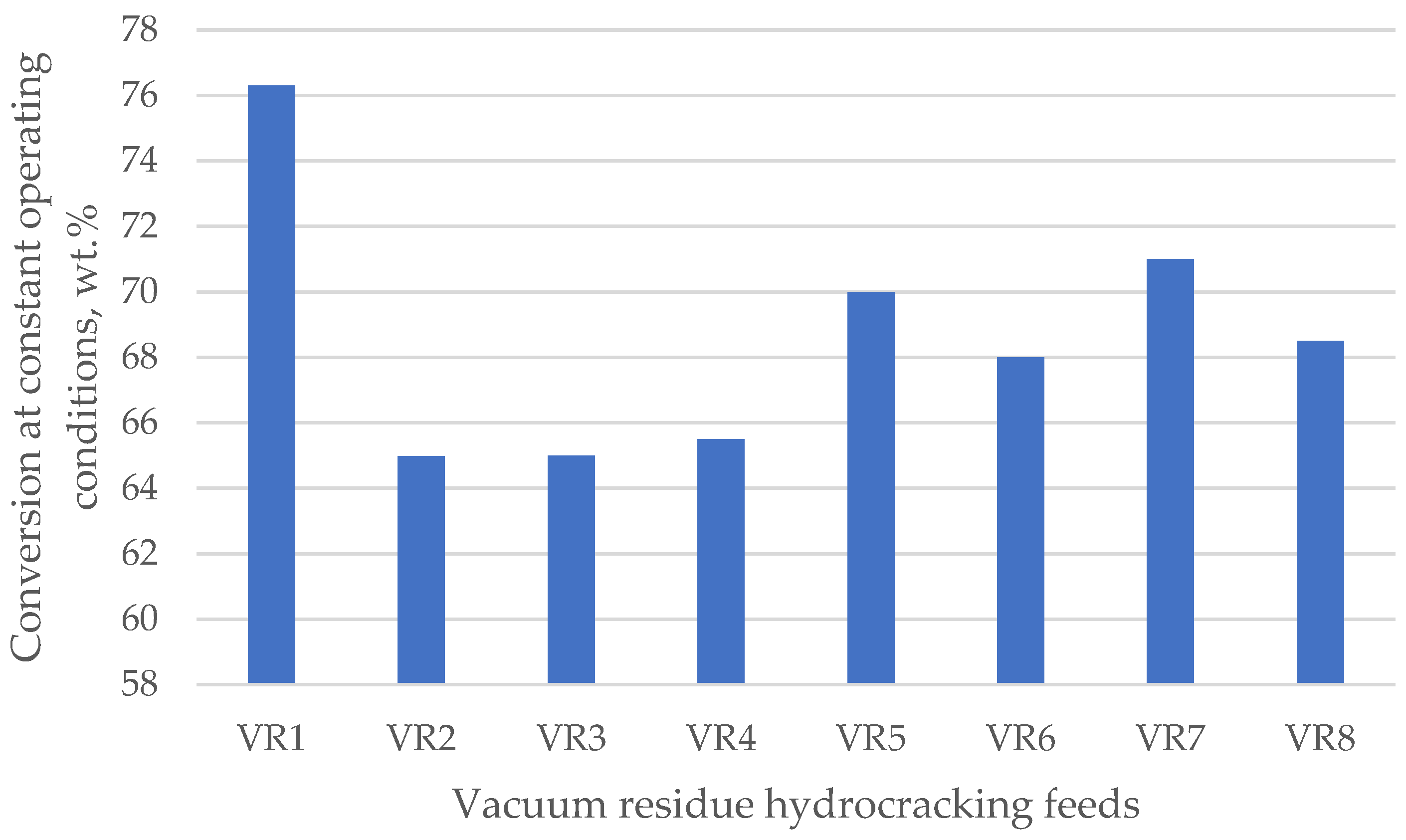

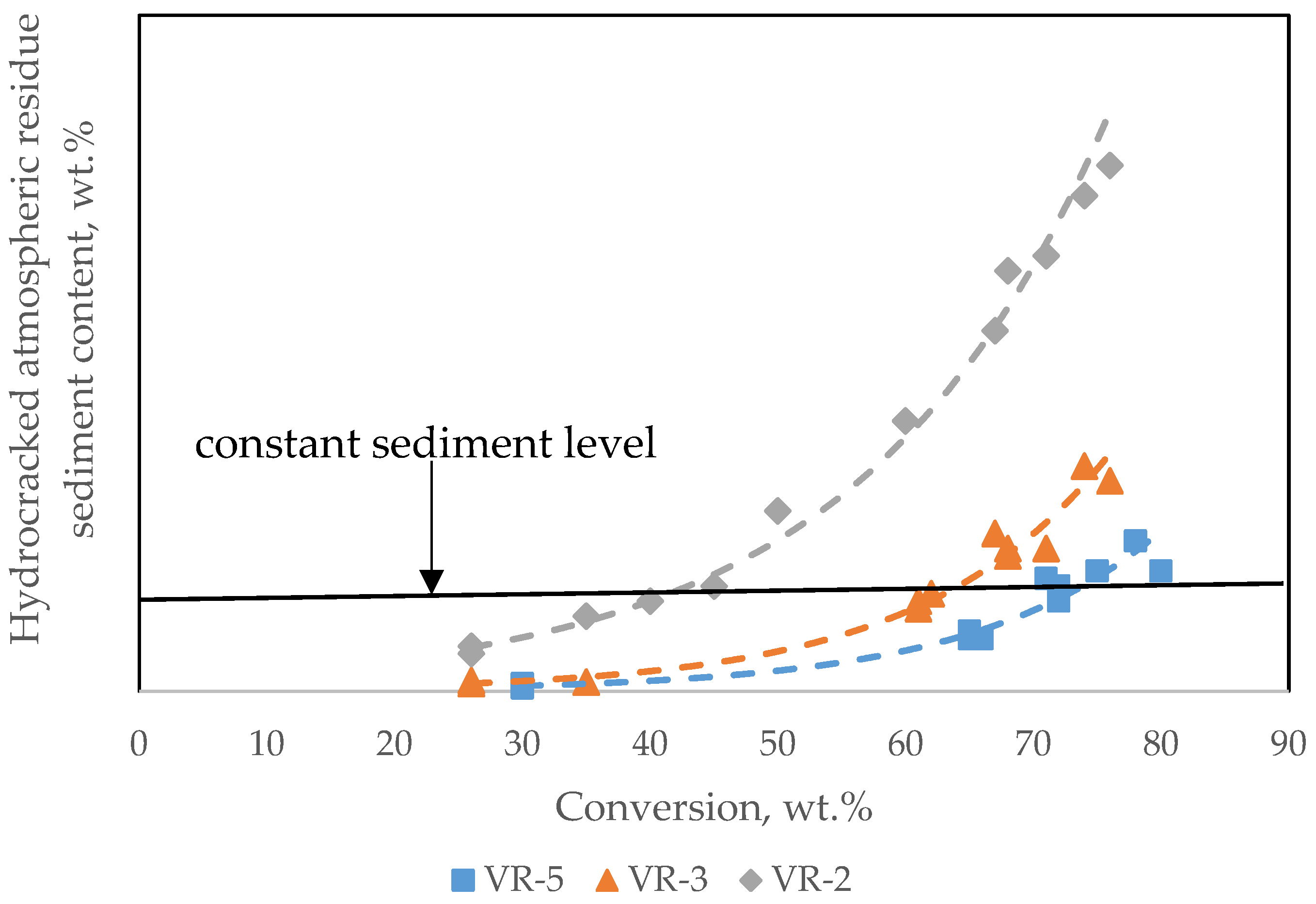

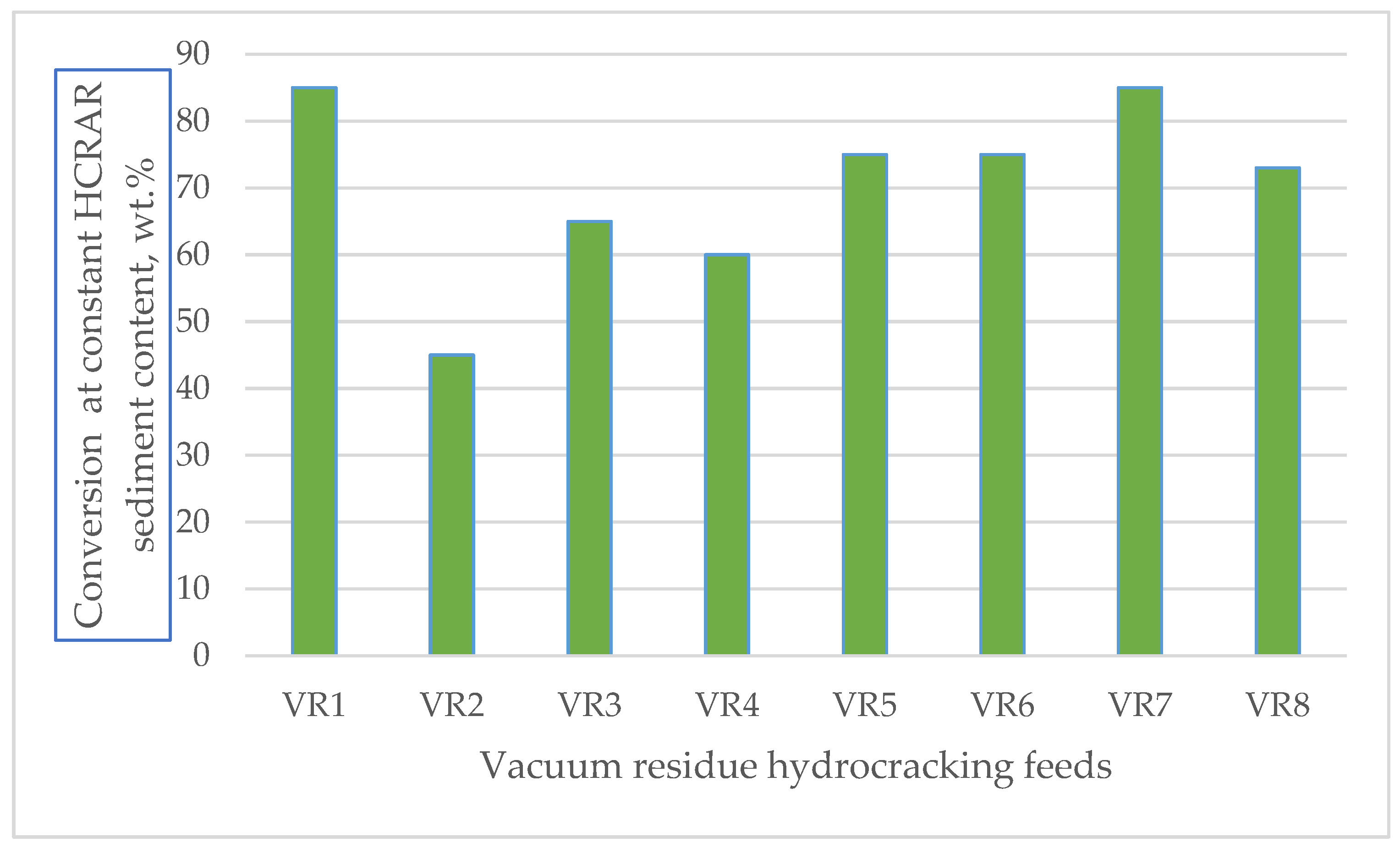

3. Results and Discussion

4. Conclusions

Funding

Data Availability Statement

Conflicts of Interest

References

- Shi, Q.; Zhang, Y.; Chung, K.H.; Zhao, S.; Xu, C. Molecular Characterization of Fossil and Alternative Fuels Using Electrospray Ionization Fourier Transform Ion Cyclotron Resonance Mass Spectrometry: Recent Advances and Perspectives. Energy Fuels 2021, 35, 18019–18055. [Google Scholar] [CrossRef]

- Li, S.; Wu, J.; Chen, J.; Li, Y.; Hu, M.; Huang, S.; Ren, X.; Zhang, W.; Zhang, Y.; Xu, C.; et al. Semiquantitative Molecular Characterization of Crude Oil. Energy Fuels 2024, 38, 3769–3783. [Google Scholar] [CrossRef]

- Abdykarimov, B.; Alimzhanova, M.; Lopez-Serna, R.; Syrgabek, Y. Green analytical procedure index assessment for total petroleum hydrocarbons determination methods in soil and sediments. A review. Trends Environ. Anal. Chem. 2025, 46, e00262. [Google Scholar] [CrossRef]

- Shi, Q.; Wu, J. Review on Sulfur Compounds in Petroleum and Its Products: State-of-the-Art and Perspectives. Energy Fuels 2021, 35, 14445–14461. [Google Scholar] [CrossRef]

- Prado, C.H.C.; Rao, Y.; de Klerk, A. Nitrogen Removal from Oil: A Review. Energy Fuels 2017, 31, 14–36. [Google Scholar] [CrossRef]

- Romanczyk, M.; Loegel, T. Qualitative characterization of oxygen-containing compounds in fuel extracts by using (-) electrospray ionization coupled to a linear quadrupole ion trap/orbitrap mass spectrometer. Fuel 2024, 359, 130502. [Google Scholar] [CrossRef]

- Li, S.; Wu, J.; Chen, J.; Li, Y.; Hu, M.; Huang, S.; Ren, X.; Zhang, W.; Zhang, Y.; Xu, C.; et al. Rapid On-Column Esterification and Separation of Carboxylic Acids in Petroleum Fractions. Energy Fuels 2024, 38, 10737–10743. [Google Scholar] [CrossRef]

- Zito, P.; Sihota, N.; Mohler, R.E.; Podgorski, D.C. The formation, reactivity, and fate of oxygen-containing organic compounds in petroleum-contaminated groundwaters: A state of the science review and future research directions. Sci. Total Environ. 2024, 918, 170619. [Google Scholar] [CrossRef]

- Strelnikova, E.B.; Goncharov, I.V.; Serebrennikova, O.V. Concentration and distribution of oxygen-containing compounds in crude oils from the southeastern part of Western Siberia. Pet. Chem. 2012, 52, 278–283. [Google Scholar] [CrossRef]

- Zhang, J.; Cao, J.; He, W. Porphyrin protonation induces decoupling of trace metals in petroleum. Org. Geochem. 2024, 198, 104878. [Google Scholar] [CrossRef]

- López, L.; Mónaco, S.L. Vanadium, nickel and sulfur in crude oils and source rocks and their relationship with biomarkers: Implications for the origin of crude oils in Venezuelan basins. Org. Geochem. 2017, 104, 53–68. [Google Scholar] [CrossRef]

- Chacon-Patino, M.I.; Nelson, J.; Rogel, E.; Hench, K.; Poirie, L.; Lopez-Linares, F.; Ovalles, C. Vanadium and nickel distributions in Pentane, In-between C5–C7 Asphaltenes, and heptane asphaltenes of heavy crude oils. Fuel 2021, 292, 120259. [Google Scholar] [CrossRef]

- Attia, M.; Farag, S.; Jaffer, S.A.; Chaouki, J. Metal and sulfur removal from petroleum oil using a novel demetallization-desulfurization agent and process. J. Clean. Prod. 2020, 275, 124177. [Google Scholar] [CrossRef]

- Wilhelm, S.M.; Bloom, N. Mercury in petroleum. Fuel Process. Technol. 2000, 63, 1–27. [Google Scholar] [CrossRef]

- Vasudevan, H.; Zolghadri, S.; Makarem, M.A. Introduction to oil, gas, and petrochemical industries: Importance to the current world. In Crises in Oil, Gas and Petrochemical Industries; Volume 2: Loss Prevention and Disaster Management; Elsevier: Amsterdam, The Netherlands, 2023. [Google Scholar]

- Wang, Y.; Zhang, Y.; Wang, Y.; Zhang, Y.; Xu, C.; Xu, Z.; Shi, Q.; Zhang, L. C10–C50 Olefins in Thermal Cracking Products of Heavy Petroleum: Characterization Using Ag+ ESI High-Resolution Mass Spectrometry. Energy Fuels 2025, 39, 6803–6811. [Google Scholar] [CrossRef]

- Kornienko, V.; Avtonomov, P. Application of Neutron Activation Analysis for Heavy Oil Production Control. Procedia—Soc. Behav. Sci. 2015, 195, 2451–2456. [Google Scholar] [CrossRef]

- IEA. IEA Oil Market Report. May 2024. Available online: www.iea.org/reports/oil-market-report-may-2024 (accessed on 15 April 2025).

- Rana, M.S.; Saman, V.; Ancheyta, J.; Diaz, A.I. A review of recent advances on process technologies for upgrading of heavy oils and residua. Fuel 2007, 86, 1216–1231. [Google Scholar] [CrossRef]

- Demirbas, A.; Bafail, A.; Nizami, A.-S. Heavy oil upgrading: Unlocking the future fuel supply. Petrol. Sci. Technol. 2016, 34, 303–308. [Google Scholar] [CrossRef]

- Yatimi, Y.; Mendil, J.; Marafi, M.; Alalou, A.; Al-Dahhan, M.H. Advancement in heavy oil upgrading and sustainable exploration emerging technologies. Arab. J. Chem. 2024, 17, 105610. [Google Scholar] [CrossRef]

- Stratiev, D.; Shishkova, I.; Argirov, G.; Dinkov, R.; Ivanov, M.; Sotirov, S.; Sotirova, E.; Bureva, V.; Nenov, S.; Atanassov, K.; et al. Roles of Catalysts and Feedstock in Optimizing the Performance of Heavy Fraction Conversion Processes: Fluid Catalytic Cracking and Ebullated Bed Vacuum Residue Hydrocracking. Catalysts 2024, 14, 616. [Google Scholar] [CrossRef]

- Sahu, R.; Song, B.J.; Im, J.S.; Jeon, Y.-P.; Lee, C.W. A review of recent advances in catalytic hydrocracking of heavy residues. J. Ind. Eng. Chem. 2015, 27, 12–24. [Google Scholar] [CrossRef]

- Muñoz, J.A.D.; Aguilar, R.; Castañeda, L.C.; Ancheyta, J. Comparison of Correlations for Estimating Product Yields from Delayed Coking. Energy Fuels 2013, 27, 7179–7190. [Google Scholar] [CrossRef]

- Navarro, U.; Ni, M.; Orlicki, D. Understanding the Potential for FCC Feed to Generate Valuable Products and How This Knowledge Can Benefit Refinery Operation. Available online: www.digitalrefining.com/article/1001054 (accessed on 25 March 2025).

- Joshi, J.B.; Pandit, A.B.; Kataria, K.L.; Kulkarni, R.P.; Sawarkar, A.N.; Tandon, D.; Ram, Y.; Kumar, M.M. Petroleum residue upgradation via visbreaking: A review. Ind. Eng. Chem. Res. 2008, 47, 8960–8988. [Google Scholar] [CrossRef]

- Stratiev, D.; Nedelchev, A.; Shishkova, I.; Ivanov, I.; Sharafutdinov, I.; Nikolova, R.; Mitkova, M.; Yordanov, D.; Rudnev, N.; Belchev, Z.; et al. Dependence of visbroken residue viscosity and vacuum residue conversion in a commercial visbreaker unit on feedstock quality. Fuel Process. Technol. 2015, 138, 595–604. [Google Scholar] [CrossRef]

- Prajapati, R.; Kohli, K.; Maity, S.K. Residue upgradation with slurry phase catalyst: Effect of feedstock properties. Fuel 2019, 239, 452–460. [Google Scholar] [CrossRef]

- Shishkova, I.; Stratiev, D.; Sotirov, S. Petroleum Chemistry and Processing Investigated by the Use of Intercriteria Analysis; Marin Drinov Publishing House of Bulgarian Academy of Sciences: Sofia, Bulgaria, 2024; pp. 124–141. [Google Scholar]

- Atanassov, K.; Vassilev, P. On the Intuitionistic fuzzy sets of n-th type. Advances in data analysis with computational intelligence methods. Stud. Comput. Intell. 2018, 738, 265–274. [Google Scholar]

- Roeva, O.; Vassilev, P.; Fidanova, S.; Paprzycki, M. InterCriteria Analysis of Genetic Algorithms Performance. Stud. Comput. Intell. 2016, 655, 235–260. [Google Scholar]

- Atanassov, K.; Szmidt, E.; Kacprzyk, J.; Atanassova, V. An approach to a constructive simplification of multiagent multicriteria decision making problems via intercriteria analysis. Comptes Rendus l’Acad. Bulg. Sci. 2017, 70, 1147–1156. [Google Scholar]

- Stratiev, D.; Shishkova, I.; Nikolaychuk, E.; Atanassova, V.; Atanassov, K. Investigation of relations of properties of straight run and H-Oil unconverted vacuum residual oils. Pet. Coal 2019, 61, 763–776. [Google Scholar]

- ASTM D4294-21; Standard Test Method for Sulfur in Petroleum and Petroleum Products by Energy Dispersive X-Ray Fluorescence Spectrometry. ASTM International: West Conshohocken, PA, USA, 2021.

- Shishkova, I.; Stratiev, D.; Kirov, P.; Dinkov, R.; Sotirov, S.; Sotirova, E.; Bureva, V.; Atanassov, K.; Toteva, V.; Vasilev, S.; et al. Root Cause Analysis for Observed Increased Sedimentation in a Commercial Residue Hydrocracker. Processes 2025, 13, 674. [Google Scholar] [CrossRef]

- ASTM D6560-17; Standard Test Method for Determination of Asphaltenes (Heptane Insolubles) in Crude Petroleum and Petroleum Products. ASTM International: West Conshohocken, PA, USA, 2017.

- ASTM D4124-09; Standard Test Method for Separation of Asphalt into Four Fractions. ASTM International: West Conshohocken, PA, USA, 2018.

- ASTM D189-06; Standard Test Method for Conradson Carbon Residue of Petroleum Products. ASTM International: West Conshohocken, PA, USA, 2019.

- ASTM D5291-21; Standard Test Methods for Instrumental Determination of Carbon, Hydrogen, and Nitrogen in Petroleum Products and Lubricants. ASTM International: West Conshohocken, PA, USA, 2021.

- ISO 10307-1; Petroleum Products—Total Sediment in Residual Fuel Oils—Part 1: Determination by Hot Filtration. ISO: Geneva, Switzerland, 1993.

- IP 501-19; Determination of Aluminium, Silicon, Vanadium, Nickel, Iron, Sodium, Calcium, Zinc and Phosphorus in Residual Fuel Oil by Ashing, Fusion and Inductively Coupled Plasma Emission Spectrometry. EI: London, UK, 2019.

- ASTM D7169-20; Standard Test Method for Boiling Point Distribution of Samples with Residues Such as Crude Oils and Atmospheric and Vacuum Residues by High Temperature Gas Chromatography. ASTM International: West Conshohocken, PA, USA, 2020.

- Stratiev, D.; Nenov, S.; Shishkova, I.; Georgiev, B.; Argirov, G.; Dinkov, R.; Yordanov, D.; Atanassova, V.; Vassilev, P.; Atanassov, K. Commercial investigation of the ebullated bed vacuum residue hydrocracking in the conversion range 55–93%. ACS Omega 2020, 51, 33290. [Google Scholar] [CrossRef] [PubMed]

- Stratiev, D.; Shishkova, I.; Argirov, G.; Yankov, V.; Mountainland, D.; Silverman, B.; Toteva, V. Improving H-Oil ebullated bed vacuum residue hydrocracking performance by the use of molecularly dispersed HCAT Catalyst. Pet. Coal 2021, 63, 655–667. [Google Scholar]

- Stratiev, D.S.; Shishkova, I.K.; Dinkov, R.K.; Petrov, I.P.; Kolev, I.V.; Yordanov, D.; Sotirov, S.; Sotirova, E.; Atanassova, V.; Ribagin, S.; et al. Crude Slate, FCC slurry oil, Recycle, and Operating Conditions Effects on H-Oil product quality. Processes 2021, 9, 952. [Google Scholar] [CrossRef]

- Atanassov, K.; Mavrov, D.; Atanassova, V. Intercriteria Decision Making: A New Approach for Multicriteria Decision Making, Based on Index Matrices and Intuitionistic Fuzzy Sets. In Issues in Intuitionistic Fuzzy Sets and Generalized Nets; Atanassov, K., Kacprzyk, J., Krawczak, M., Szmidt, E., Eds.; Warsaw School of Information Technology: Warsaw, Poland, 2014; Volume 11, pp. 1–8. [Google Scholar]

- Atanassov, K.; Atanassova, V.; Gluhchev, G. Intercriteria Analysis: Ideas and Problems. NIFS 2015, 21, 81–88. [Google Scholar]

- Mavrov, D. Software for InterCriteria Analysis: Implementation of the Main Algorithm. NIFS 2015, 21, 77–86. [Google Scholar]

- Mavrov, D. Software for Intercriteria Analysis: Working with the Results. Annu. Inform. Sect. Union Sci. Bulg. 2015, 8, 37–44. [Google Scholar]

- Ikonomov, N.; Vassilev, P.; Roeva, O. ICrAData—Software for InterCriteria Analysis. Int. J. Bioautomation 2018, 22, 1–10. [Google Scholar] [CrossRef]

- Atanassova, V.; Doukovska, L.; De Tré, G.; Radeva, I. Intercriteria analysis and comparison of innovation-driven and efficiency-to-innovation driven economies in the European Union. NIFS 2017, 23, 54–68. [Google Scholar]

- Atanassova, V.; Doukovska, L.; Sotirova, A.; Kacprzyk, E.; Radeva, I.; Vassilev, P. Inter-Criteria analysis of the global competitiveness reports: From efficiency-to innovation-driven economies. J. Mult.-Valued Log. Soft Comput. 2018, 31, 469–494. [Google Scholar]

- Atanassova, V.; Doukovska, L.; Krawczak, M. Intercriteria analysis of countries in transition from factor-driven to efficiency-driven economy. NIFS 2018, 24, 84–96. [Google Scholar] [CrossRef]

- Angelova, M.; Pencheva, T. Intercriteria analysis of multi-population genetic algorithms performance. Ann. Comput. Sci. Inf. Syst. 2017, 13, 77–82. [Google Scholar]

- Jereva, D.; Pencheva, T.; Tsakovska, I.; Alov, P.; Pajeva, I. Exploring applicability of inter-criteria analysis to evaluate the performance of MOE and GOLD scoring functions. In Advanced Computing in Industrial Mathematics; Georgiev, I., Kostadinov, H., Lilkova, E., Eds.; BGSIAM 2018; (Studies in Computational Intelligence); Springer: Cham, Switzerland, 2021; Volume 961. [Google Scholar] [CrossRef]

- Roeva, O.; Zoteva, D. Knowledge discovery from data: InterCriteria analysis of mutation rate influence. NIFS 2018, 24, 120–130. [Google Scholar] [CrossRef]

- Krumova, S.; Todinova, S.; Mavrov, D.; Marinov, P.; Atanassova, V.; Atanassov, K.; Taneva, S. Intercriteria analysis of calorimetric data of blood serum proteome. Biochim. Biophys. Acta Gen. Subj. 2017, 1861, 409–417. [Google Scholar] [CrossRef]

- Ribagin, S.; Grozeva, A.; Popova, G.; Stoyanova, Z. InterCriteria analysis of body composition measurements data, associated with obesity among college students. NIFS 2019, 25, 78–82. [Google Scholar] [CrossRef]

- Ribagin, S.; Stavrev, S. InterCriteria analysis of data from intellectual and physical evaluation tests of students practicing sports activities. NIFS 2019, 25, 83–89. [Google Scholar] [CrossRef]

- Bureva, V.; Michalíková, A.; Sotirova, E.; Popov, S.; Riecan, B.; Roeva, O. Application of the InterCriteria analysis to the universities rankings system in the Slovak Republic. In Proceedings of the 21st International Conference on Intuitionistic Fuzzy Sets, Burgas, Bulgaria, 22–23 May 2017; Volume 23, pp. 128–140. [Google Scholar]

- Parvathi, R.; Atanassova, V.; Doukovska, L.; Yuvapriya, C.; Indhurekha, K. InterCriteria analysis of rankings of Indian universities. NIFS 2018, 24, 99–109. [Google Scholar] [CrossRef]

- Georgieva, V.; Angelova, N.; Roeva, O.; Pencheva, T. Intercriteria analysis of wastewater treatment quality. J. Int. Sci. Publ. Ecol. Saf. 2016, 10, 365–376. [Google Scholar]

- Ilkova, T.; Petrov, M. Application of Intercriteria analysis to the Mesta river pollution modelling. NIFS 2015, 21, 118–125. [Google Scholar]

- Ilkova, T.; Petrov, M. Using intercriteria analysis for assessment of the pollution indexes of the Struma river. Adv. Intell. Syst. Comput. 2016, 401, 351–364. [Google Scholar]

- Angelova, M. InterCriteria analysis of control parameters relations in artificial bee colony algorithm. WSEAS Trans. Math. 2019, 18, 123–128. [Google Scholar]

- Atanassova, V.; Roeva, O. Computational complexity and influence of numerical precision on the results of intercriteria analysis in the decision making process. NIFS 2018, 24, 53–63. [Google Scholar] [CrossRef]

- Marinov, P.; Fidanova, S. Intercriteria and correlation analyses: Similarities, differences and simultaneous use. Ann. Inf. Sect. 2015, 8, 45–53. [Google Scholar]

- Shiskova, I.; Stratiev, D.; Sotirov, S.; Sotirova, E.; Dinkov, R.; Kolev, I.; Stratiev, D.D.; Nenov, S.; Ribagin, S.; Atanassov, K.; et al. Predicting Petroleum SARA Composition from Density, Sulfur Content, Flash Point, and Simulated Distillation Data Using Regression and Artificial Neural Network Techniques. Processes 2024, 12, 1755. [Google Scholar] [CrossRef]

- Gray, M.R.; McCaffrey, W.C. Role of Chain Reactions and Olefin Formation in Cracking, Hydroconversion, and Coking of Petroleum and Bitumen Fractions. Energy Fuels 2002, 16, 756–766. [Google Scholar] [CrossRef]

- Chang, J.; Tsubaki, N.; Fujimoto, K. Elemental sulphur as an effective promoter for the catalytic hydrocracking of Arabian vacuum residue. Fuel 2001, 80, 1639–1643. [Google Scholar] [CrossRef]

- Chang, J.; Fan, L.; Fujimoto, K. Enhancement Effect of Free Radical Initiator on Hydro-Thermal Cracking of Heavy Oil and Model Compound. Energy Fuels 1999, 13, 1107–1108. [Google Scholar] [CrossRef]

- Fortain, P.D. Étude de la réactivité des résidus pétroliers en hydroconversion. Ph.D. Thesis, University of Bordeaux, Talence, France, 18 October 2010. [Google Scholar]

- Stratiev, D.; Dinkov, R.; Shishkova, I.; Sharafutdinov, I.; Ivanova, N.; Mitkova, M.; Yordanov, D.; Rudnev, N.; Stanulov, K.; Artemiev, A.; et al. What is behind the high values of hot filtration test of the ebullated bed residue H-Oil hydrocracker residual oils? Energy Fuels 2016, 30, 7037–7054. [Google Scholar] [CrossRef]

- Ovalles, C.; Rogel, E.; Hurt, M.; Duma, V.; Morazan, H.; Hench, K.; Moir, M.E. Nitrogen speciation: Application to reactivity of feeds to hydroprocessing and catalyst deactivation. Chem. Solut. Chall. Pet. Ind. 2019, 1320, 261–280. [Google Scholar]

- Rogel, E.; Ovalles, C.; Pradhan, A.; Leung, P.; Chen, N. Sediment formation in residue hydroconversion processes and its correlation to asphaltene behavior. Energy Fuels 2013, 27, 6587–6593. [Google Scholar] [CrossRef]

- Chung, K.H.; Xu, C. Narrow-cut characterization reveals resid process chemistry. Fuel 2001, 80, 1165–1177. [Google Scholar] [CrossRef]

- Yang, C.; Du, F.; Zheng, H.; Keng, H.C. Hydroconversion characteristics and kinetics of residue narrow fractions. Fuel 2005, 84, 675–684. [Google Scholar] [CrossRef]

- Manek, E.; Haydary, J. Hydrocracking of vacuum residue with solid and dispersed phase catalyst: Modeling of sediment formation and hydrodesulfurization. Fuel Process. Technol. 2017, 159, 320–327. [Google Scholar] [CrossRef]

- Stanislaus, A.; Hauser, A.; Marafi, M. Investigation of the mechanism of sediment formation in residual oil hydrocracking process through characterization of sediment deposits. Catal. Today. 2005, 109, 167–177. [Google Scholar] [CrossRef]

- Nguyen, T.-H.; Nguyen, Q.-A.; Cao, A.N.T.; Ernest, T.; Nguyen, T.B.; Pham, P.T.; Nguyen, T.M. Hydrodemetallization of heavy oil: Recent progress, challenge, and future prospects. J. Pet. Eng. 2022, 216, 110762. [Google Scholar] [CrossRef]

- Tailleur, R.G.; Caprioli, L. Catalyst pore plugging effects on hydrocracking reactions in an ebullated bed reactor operation. Catal. Today 2005, 109, 185–194. [Google Scholar] [CrossRef]

| Residue Conversion Technology | Per Cent of Total |

|---|---|

| Coking | 32 |

| Visbreaking | 30 |

| Fluid catalytic cracking (FCC) | 19 |

| Hydroprocessing | 15 |

| Solvent deasphalting | 4 |

| Crude Oil Properties | Crude Oil 1 | Crude Oil 2 | Crude Oil 3 | Crude Oil 4 | Crude Oil 5 | Crude Oil 6 | Crude Oil 7 | Crude Oil 8 |

|---|---|---|---|---|---|---|---|---|

| Density at 15 °C, g/cm3 | 0.878 | 0.923 | 0.877 | 0.959 | 0.889 | 1.009 | 0.858 | 0.877 |

| Sulfur, wt. % | 2.85 | 3.40 | 1.53 | 3.38 | 2.91 | 4.64 | 1.89 | 1.93 |

| Total acid number, mg KOH/g | 0.20 | 0.16 | 0.11 | 2.30 | 0.28 | 2.70 | 0.06 | 0.14 |

| C5-asphaltenes, wt. % | 6.0 | 19.0 | 4.5 | 12.2 | 14.7 | 17.5 | 3.5 | 3.8 |

| C7-asphaltenes, wt. % | 3.3 | 12.8 | 2.7 | 7.7 | 8.9 | 12.1 | 2.2 | 2.9 |

| Pour point, °C | −36.0 | −28.2 | −9.0 | −28.5 | −36.0 | −36.0 | −17.1 | |

| kinematic viscosity at 40 °C, mm2/s | 36.1 | 82.6 | 12.6 | 99.6 | 10.8 | 10.1 | 19.7 | |

| True boiling point distillation fraction yields, wt. % | ||||||||

| IBP–110 °C | 9.0 | 4.2 | 8.1 | 2.2 | 6.4 | 0.0 | 9.3 | 8.3 |

| 110–180 °C | 10.1 | 8.3 | 9.5 | 5.0 | 8.6 | 1.0 | 11.6 | 9.7 |

| 180–240 °C | 8.7 | 7.6 | 8.9 | 4.5 | 7.8 | 3.0 | 10.1 | 8.8 |

| 240–360 °C | 19.3 | 16.2 | 22.0 | 23.3 | 18.6 | 11.0 | 21.6 | 21.2 |

| IBP−360 °C | 47.1 | 36.3 | 48.5 | 35.0 | 41.5 | 15.0 | 52.6 | 48.0 |

| 360–540 °C | 24.4 | 23.2 | 27.8 | 32.0 | 24.4 | 31.5 | 24.4 | 26.7 |

| ˃540 °C | 27.5 | 39.6 | 22.8 | 32.8 | 33.1 | 53.0 | 21.9 | 24.2 |

| Vacuum Residue Properties | VR 1 | VR 2 | VR 3 | VR 4 | VR 5 | VR 6 | VR 7 | VR 8 |

|---|---|---|---|---|---|---|---|---|

| Density at 15 °C, g/cm3 | 1.049 | 1.080 | 1.018 | 1.040 | 1.045 | 1.061 | 1.022 | 1.019 |

| Sulfur, wt. % | 6.6 | 6.3 | 2.7 | 3.96 | 5.56 | 6.2 | 4.22 | 3.9 |

| Nitrogen, wt. % | 0.357 | 0.853 | 0.702 | 0.6253 | 0.387 | 0.63 | 0.4011 | 0.56 |

| Conradson carbon content, wt. % | 26.9 | 33.5 | 20.4 | 19 | 23 | 22.5 | 19.8 | 18.6 |

| Saturates, wt. % | 5.0 | 13.4 | 15.00 | 10.5 | 7.2 | 6.5 | 11.6 | 12 |

| Aromatics, wt. % | 36.5 | 17 | 37.3 | 32.7 | 38.9 | 26.4 | 48.6 | 39.7 |

| Resins, wt. % | 48.0 | 40 | 39.7 | 43.6 | 37.1 | 47.8 | 32.1 | 41.2 |

| C5-asphaltenes, wt. % | 19.8 | 44.1 | 15.3 | 22.6 | 28.0 | 31.8 | 14.3 | 13.5 |

| C7-asphaltenes., wt. % | 10.5 | 29.6 | 8 | 13.2 | 16.8 | 19.3 | 7.7 | 7.1 |

| Nickel, ppm | 49 | 154 | 58 | 209 | 50 | 95 | 20 | 71.4 |

| Vanadium, ppm | 179 | 841 | 197 | 890 | 150 | 290 | 60 | 232.5 |

| μ | D15 | Sul | N | CCR | Sat. | Aro | Res. | C5-Asp | C7-Asp | Ni | V | Conv. at Constant Sediment Level | Conv. at Constant Op. Cond. |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| D15 | 1.00 | 0.89 | 0.50 | 0.79 | 0.25 | 0.21 | 0.64 | 0.86 | 0.86 | 0.61 | 0.64 | 0.46 | 0.43 |

| Sul | 0.89 | 1.00 | 0.39 | 0.82 | 0.21 | 0.32 | 0.68 | 0.75 | 0.75 | 0.50 | 0.54 | 0.57 | 0.54 |

| N | 0.50 | 0.39 | 1.00 | 0.50 | 0.75 | 0.29 | 0.50 | 0.64 | 0.64 | 0.75 | 0.71 | 0.14 | 0.11 |

| CCR | 0.79 | 0.82 | 0.50 | 1.00 | 0.39 | 0.29 | 0.57 | 0.79 | 0.79 | 0.46 | 0.50 | 0.50 | 0.50 |

| Sat. | 0.25 | 0.21 | 0.75 | 0.39 | 1.00 | 0.54 | 0.25 | 0.39 | 0.39 | 0.57 | 0.54 | 0.21 | 0.29 |

| Aro | 0.21 | 0.32 | 0.29 | 0.29 | 0.54 | 1.00 | 0.29 | 0.14 | 0.14 | 0.25 | 0.21 | 0.68 | 0.71 |

| Res. | 0.64 | 0.68 | 0.50 | 0.57 | 0.25 | 0.29 | 1.00 | 0.57 | 0.57 | 0.68 | 0.71 | 0.46 | 0.43 |

| C5-asp | 0.86 | 0.75 | 0.64 | 0.79 | 0.39 | 0.14 | 0.57 | 1.00 | 1.00 | 0.68 | 0.64 | 0.32 | 0.29 |

| C7-asp | 0.86 | 0.75 | 0.64 | 0.79 | 0.39 | 0.14 | 0.57 | 1.00 | 1.00 | 0.68 | 0.64 | 0.32 | 0.29 |

| Ni | 0.61 | 0.50 | 0.75 | 0.46 | 0.57 | 0.25 | 0.68 | 0.68 | 0.68 | 1.00 | 0.96 | 0.14 | 0.11 |

| V | 0.64 | 0.54 | 0.71 | 0.50 | 0.54 | 0.21 | 0.71 | 0.64 | 0.64 | 0.96 | 1.00 | 0.18 | 0.14 |

| Conv. at constant sediment level | 0.46 | 0.57 | 0.14 | 0.50 | 0.21 | 0.68 | 0.46 | 0.32 | 0.32 | 0.14 | 0.18 | 1.00 | 0.82 |

| Conv. at constant op. cond. | 0.43 | 0.54 | 0.11 | 0.50 | 0.29 | 0.71 | 0.43 | 0.29 | 0.29 | 0.11 | 0.14 | 0.82 | 1.00 |

| ν | D15 | Sul | N | CCR | Sat. | Aro | Res. | C5-Asp | C7-Asp | Ni | V | Conv. at Constant Sediment Level | Conv. at Constant Op. Cond. |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| D15 | 0.00 | 0.11 | 0.50 | 0.21 | 0.75 | 0.79 | 0.36 | 0.14 | 0.14 | 0.39 | 0.36 | 0.46 | 0.50 |

| Sul | 0.11 | 0.00 | 0.61 | 0.18 | 0.79 | 0.68 | 0.32 | 0.25 | 0.25 | 0.50 | 0.46 | 0.36 | 0.39 |

| N | 0.50 | 0.61 | 0.00 | 0.50 | 0.25 | 0.71 | 0.50 | 0.36 | 0.36 | 0.25 | 0.29 | 0.79 | 0.82 |

| CCR | 0.21 | 0.18 | 0.50 | 0.00 | 0.61 | 0.71 | 0.43 | 0.21 | 0.21 | 0.54 | 0.50 | 0.43 | 0.43 |

| Sat. | 0.75 | 0.79 | 0.25 | 0.61 | 0.00 | 0.46 | 0.75 | 0.61 | 0.61 | 0.43 | 0.46 | 0.71 | 0.64 |

| Aro | 0.79 | 0.68 | 0.71 | 0.71 | 0.46 | 0.00 | 0.71 | 0.86 | 0.86 | 0.75 | 0.79 | 0.25 | 0.21 |

| Res. | 0.36 | 0.32 | 0.50 | 0.43 | 0.75 | 0.71 | 0.00 | 0.43 | 0.43 | 0.32 | 0.29 | 0.46 | 0.50 |

| C5-asp | 0.14 | 0.25 | 0.36 | 0.21 | 0.61 | 0.86 | 0.43 | 0.00 | 0.00 | 0.32 | 0.36 | 0.61 | 0.64 |

| C7-asp | 0.14 | 0.25 | 0.36 | 0.21 | 0.61 | 0.86 | 0.43 | 0.00 | 0.00 | 0.32 | 0.36 | 0.61 | 0.64 |

| Ni | 0.39 | 0.50 | 0.25 | 0.54 | 0.43 | 0.75 | 0.32 | 0.32 | 0.32 | 0.00 | 0.04 | 0.79 | 0.82 |

| V | 0.36 | 0.46 | 0.29 | 0.50 | 0.46 | 0.79 | 0.29 | 0.36 | 0.36 | 0.04 | 0.00 | 0.75 | 0.79 |

| Conv. at constant sediment level | 0.46 | 0.36 | 0.79 | 0.43 | 0.71 | 0.25 | 0.46 | 0.61 | 0.61 | 0.79 | 0.75 | 0.00 | 0.04 |

| Conv. at constant op. cond. | 0.50 | 0.39 | 0.82 | 0.43 | 0.64 | 0.21 | 0.50 | 0.64 | 0.64 | 0.82 | 0.79 | 0.04 | 0.00 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Stratiev, D. Hydrocracking of Various Vacuum Residues. Fuels 2025, 6, 35. https://doi.org/10.3390/fuels6020035

Stratiev D. Hydrocracking of Various Vacuum Residues. Fuels. 2025; 6(2):35. https://doi.org/10.3390/fuels6020035

Chicago/Turabian StyleStratiev, Dicho. 2025. "Hydrocracking of Various Vacuum Residues" Fuels 6, no. 2: 35. https://doi.org/10.3390/fuels6020035

APA StyleStratiev, D. (2025). Hydrocracking of Various Vacuum Residues. Fuels, 6(2), 35. https://doi.org/10.3390/fuels6020035