Real-Time Drilling Performance Optimization Using Automated Penetration Rate Algorithms with Vibration Control

Abstract

1. Introduction

1.1. ROP Modeling

1.2. ROP Optimization

1.3. Research Objectives

- The continuous, real-time optimization of drilling parameters based on formation characteristics integrated with vibration monitoring and control to maintain safe and efficient operations.

- The implementation of a lightweight formation change detection algorithm enabling timely adjustments to drilling strategies as subsurface conditions evolve, thereby supporting proactive vibration control and overall system stability.

- To develop a simple yet effective method for detecting geological formation changes, enabling rapid recognition of downhole condition shifts for proactive drilling control.

- To enhance the ROP optimization model with a safety-focused perspective, balancing performance improvements with minimized vibration risks to ensure operational reliability.

2. Formulation-Based Penetration Rate Model

2.1. ROP Model

2.1.1. Demo Model

2.1.2. Discussions

2.2. Formation Detection

2.2.1. Mechanical Specific Energy Calculation

2.2.2. Discussions

3. Drillstring Dynamic Model

3.1. Modeling

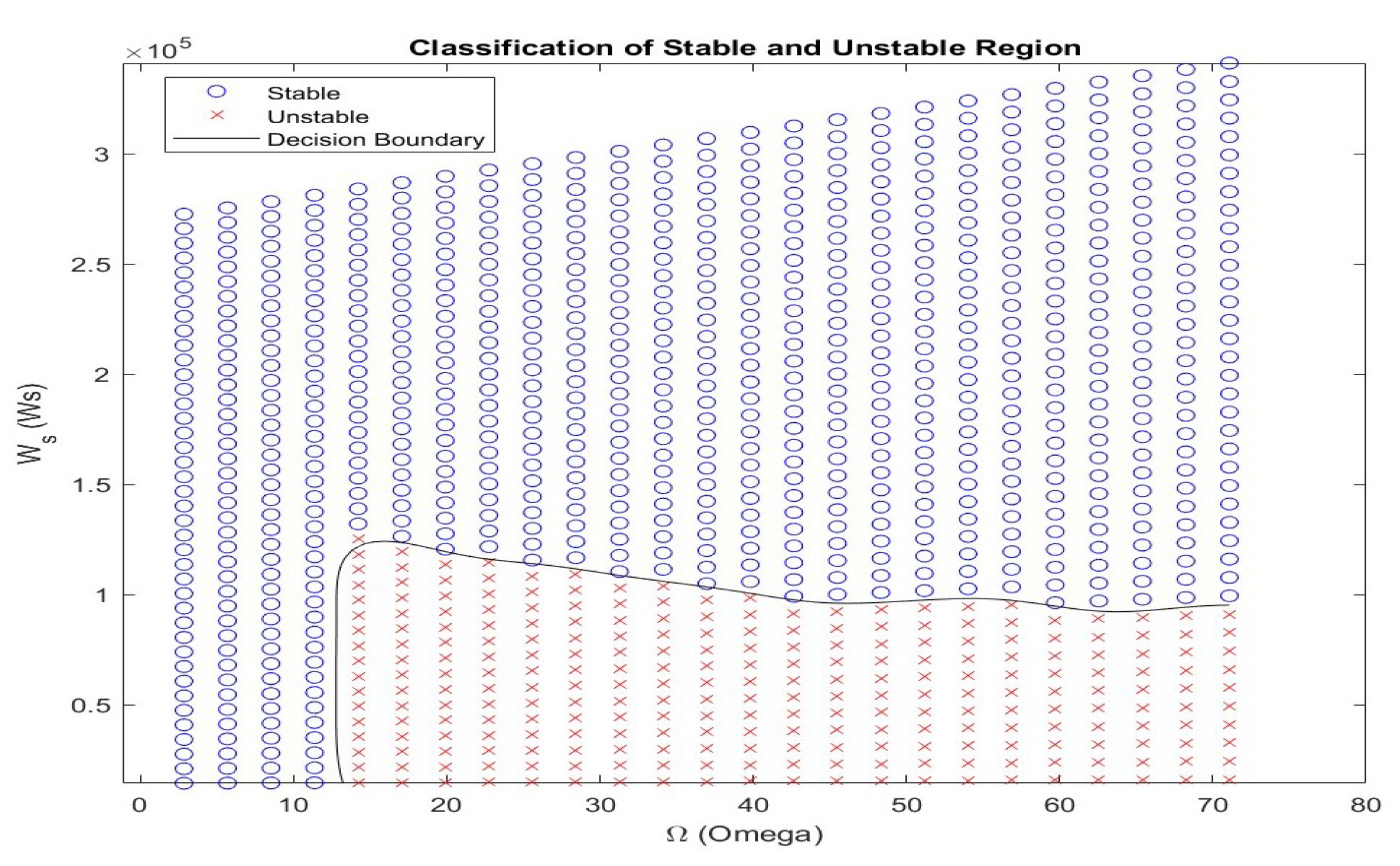

3.2. Safe Operational Region

4. ROP Optimization and Control

4.1. ROP Optimization

4.2. ROP Control Systems

5. Modules Integration

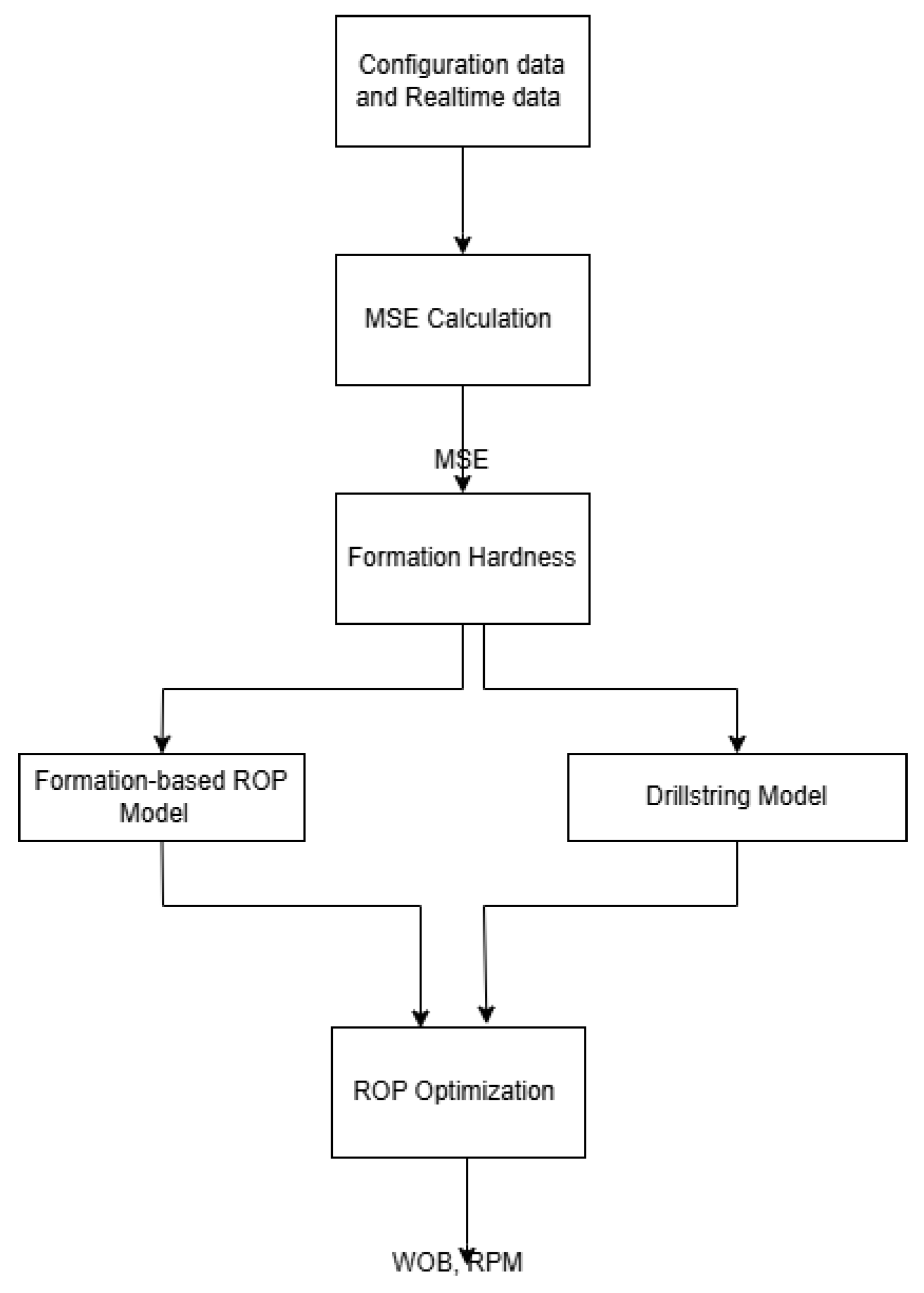

5.1. Flow Chart

- MSE Estimation: The process begins with calculating the MSE, including the WOB, RPM, torque, and ROP. The ROP is computed by measuring the drilling distance over a fixed time interval. The MSE serves as the foundational metric for subsequent analysis.

- Formation Hardness Estimation: Using the MSE, the CCS is estimated, allowing for preliminary classification of formation hardness. This helps anticipate potential drilling challenges and tailor control strategies accordingly.

- Drillstring Dynamic Modeling: Based on the formation classification, the drillstring model is adapted to reflect downhole conditions. Model parameters are fine-tuned to capture vertical and torsional vibration behavior, enabling definition of the safe operational envelope.

- ROP Model Adaptation: An appropriate K value is selected for the ROP model according to formation characteristics. This step ensures that the model aligns with the current geological conditions for effective parameter control.

- ROP Optimization: The optimal WOB and RPM are computed by solving a constrained optimization problem, aiming to maximize the ROP or minimize the MSE while remaining within safety limits.

5.2. Applicable Boundaries of the Method

6. Case Study

6.1. Problem Description

- K: A constant representing the formation’s response to the WOB and RPM.

- and : Exponents that indicate the influence of the WOB and RPM, respectively, on the ROP.

- WOB and RPM bounds: Upper and lower technique bounds of the WOB and RPM suitable for each formation.

- UCS: Rock strength, reflecting formation hardness.

- : Stable region to maintain safe operation.

6.2. Formation Settings

- Formation 1: Soft rock with low UCS (100 MPa) but higher K values, requiring a low RPM to reduce the MSE.

- Formation 2: A UCS of 120 MPa with moderate K, , and values. Optimal performance is expected at 60–120 RPM.

- Formation 3: A UCS of 80 MPa, highest values for K, and broader RPM bounds (30–150 RPM).

- Formation 4: Hard rock with a high UCS (150 MPa) suitable for high RPM values within 50–120 RPM.

6.3. Drillstring Dynamic Model

6.4. Optimization Workflow

- Formation Check: The current formation is determined based on time. Formation changes introduce significant shifts in optimal settings. When a new formation is detected, the model adjusts the coefficients used in MSE.

- Objective and Constraints Evaluation: If a new formation is encountered, the MSE objective and constraints are re-evaluated.

- Optimization: Using MATLAB’s fmincon, the optimization seeks WOB and RPM values that minimize the MSE given the formation’s constraints.

- Simulation of ROP and MSE: With optimized values, the ROP and MSE are calculated for the current time step.

6.5. Results and Discussions

7. Conclusions

8. Future Work

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Bourgoyne, A.T.; Millheim, K.K.; Chenevert, M.E.; Young, F.S. Applied Drilling Engineering; SPE Textbook Series; Society of Petroleum Engineers, Inc.: Calgary, AB, Canada, 1986. [Google Scholar]

- Duklet, C.P.; Bates, T.R. An Empirical Correlation to Predict Diamond Bit Drilling Rates. In Proceedings of the SPE Annual Technical Conference and Exhibition, Dallas, TX, USA, 21–24 September 1980. [Google Scholar] [CrossRef]

- de Moura Junior, J. Universal Physics-based Rate of Penetration Prediction Model for Rotary Drilling. Ph.D. Thesis, Faculty of Engineering and Applied Science, Memorial University of Newfoundland, St. John’s, NL, Canada, 2021. [Google Scholar]

- Jalakani, R.; Tabatabaee Moradi, S.S. Rate of penetration prediction with uncertainty assessment: Case study of a middle-east oil field. Results Eng. 2024, 21, 101793. [Google Scholar] [CrossRef]

- Hegde, C.; Daigle, H.; Millwater, H.; Gray, K. Analysis of rate of penetration (ROP) prediction in drilling using physics-based and data-driven models. J. Pet. Sci. Eng. 2017, 159, 295–306. [Google Scholar] [CrossRef]

- Hegde, C.; Gray, K. Evaluation of Coupled Machine Learning Models for Drilling Optimization. J. Nat. Gas Sci. Eng. 2018, 56, 397–407. [Google Scholar] [CrossRef]

- Wood, D.A. Chapter 6—Real-time monitoring and optimization of drilling performance using artificial intelligence techniques: A review. In Sustainable Natural Gas Drilling; Wood, D.A., Cai, J., Eds.; The Fundamentals and Sustainable Advances in Natural Gas Science and Eng; Elsevier: Amsterdam, The Netherlands, 2024; Volume 4, pp. 169–210. [Google Scholar] [CrossRef]

- Singh, K.; Siddiqui, F.; Braga, D.; Kamyab, M.; Cheatham, C.; Harclerode, B. ROP Optimization using a Hybrid Machine Learning and Physics-Based Multivariate Objective Function with Real-Time Vibration and Stick-Slip Filters. In Proceedings of the IADC/SPE International Drilling Conference and Exhibition, Galveston, TX, USA, 8–10 March 2022. [Google Scholar] [CrossRef]

- Tunkiel, A.T.; Sui, D.; Wiktorski, T. Training-while-drilling approach to inclination prediction in directional drilling utilizing recurrent neural networks. J. Pet. Sci. Eng. 2021, 196, 108128. [Google Scholar] [CrossRef]

- Madasu, S. A Hybrid Physics/Data Driven Modeling Approach for Virtual Sensors. In Proceedings of the 2020 IEEE International Symposium on Signal Processing and Information Technology (ISSPIT), Louisville, KY, USA, 9–11 December 2020; pp. 1–6. [Google Scholar] [CrossRef]

- Wang, Y.; Tan, Q.; Wu, D.; Chen, H.; Hu, N.; Zhao, Y. A Data-Driven Approach to Predict the ROP of Deep Wells in Fukang Sag. Appl. Sci. 2023, 13, 12471. [Google Scholar] [CrossRef]

- Al Dushaishi, M.F.; Abbas, A.K.; Al Saba, M.T.; Wise, J. Drilling Optimization Using Artificial Neural Networks and Empirical Models. ChemEngineering 2025, 9, 37. [Google Scholar] [CrossRef]

- Elkatatny, S. Real-time prediction of rate of penetration while drilling complex lithologies using artificial intelligence techniques. Ain Shams Eng. J. 2021, 12, 917–926. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, W.; Li, X. Application of machine learning algorithms for ROP prediction in complex geological conditions. Energy Rep. 2021, 7, 289–300. [Google Scholar]

- Salih, N.; Ksantini, M.; Hussein, N.; Halima, D.B.; Razzaq, A.A.; Ahmed, S. Prediction of ROP Zones Using Deep Learning Algorithms and Voting Classifier Technique. Int. J. Comput. Intell. Syst. 2023, 16, 86. [Google Scholar] [CrossRef]

- Lee, C.; Kim, J.; Kim, N.; Ki, S.; Seo, J.; Park, C. Evaluating the Rate of Penetration with Deep-Learning Predictive Models. Int. J. Energy Res. 2025. [Google Scholar] [CrossRef]

- Jiao, S.; Li, W.; Li, Z.; Gai, J.; Zou, L.; Su, Y. Hybrid Physics-Machine Learning Models for Predicting Rate of Penetration in the Halahatang Oil Field, Tarim Basin. Sci. Rep. 2024, 14, 5957. [Google Scholar] [CrossRef] [PubMed]

- Hegde, C.; Soares, C.; Gray, K. Rate of Penetration (ROP) Modeling Using Hybrid Models: Deterministic and Machine Learning. In Proceedings of the SPE/AAPG/SEG Unconventional Resources Technology Conference, Houston, TX, USA, 23–25 July 2018. [Google Scholar] [CrossRef]

- Yang, Y.; Cen, X.; Ni, H.; Liu, Y.; Chen, Z.J.; Yang, J.; Hong, B. A highly accurate and robust prediction framework for drilling rate of penetration based on machine learning ensemble algorithm. Geoenergy Sci. Eng. 2025, 244, 213423. [Google Scholar] [CrossRef]

- Bourgoyne, A.T.; Young, F.S. A new approach to the analysis of the performance of roller cone bits. J. Pet. Technol. 1974, 26, 497–505. [Google Scholar]

- Hareland, G.; Rampersad, K. Application of drilling optimization using response surface methodology. J. Can. Pet. Technol. 1994, 33, 38–45. [Google Scholar]

- Joy, G.; Abish, J.; Samuel, R. Fast Drilling Optimizer for Drilling Automation. In Proceedings of the SPE Western Regional Meeting, Virtual, 20–22 April 2021. [Google Scholar] [CrossRef]

- Duru, D.; Kerunwa, A.; Odo, J. Application of Genetic Algorithm on Data Driven Models for Optimized ROP Prediction. Presented at the SPE Nigeria Annual International Conference and Exhibition, Lagos, Nigeria, 1–3 August 2022. [Google Scholar] [CrossRef]

- Chen, X.; Du, X.; Weng, C.; Yang, J.; Gao, D.; Su, D.; Wang, G. A real-time drilling parameters optimization method for offshore large-scale cluster extended reach drilling based on intelligent optimization algorithm and machine learning. Ocean. Eng. 2024, 291, 116375. [Google Scholar] [CrossRef]

- Wang, J.; Yan, Z.; Pan, T.; Zhu, Z.; Song, X.; Yang, D. Drilling Parameters Multi-Objective Optimization Method Based on PSO-Bi-LSTM. Appl. Sci. 2023, 13, 11666. [Google Scholar] [CrossRef]

- Sobhi, I.; Dobbi, A.; Hachana, O. Prediction and Analysis of Penetration Rate in Drilling Operation Using Deterministic and Metaheuristic Optimization Methods. J. Pet. Explor. Prod. Technol. 2022, 12, 1341–1352. [Google Scholar] [CrossRef]

- Huang, X.; Luu, T.P.; Furlong, T.; Bomidi, J. Deep Reinforcement Learning for Automatic Drilling Optimization Using an Integrated Reward Function. In Proceedings of the IADC/SPE International Drilling Conference and Exhibition, Galveston, TX, USA, 5–7 March 2024. [Google Scholar] [CrossRef]

- Teale, R. The concept of specific energy in rock drilling. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1965, 2, 57–73. [Google Scholar] [CrossRef]

- Dupriest, F.E.; Koederitz, W.L. Maximizing drill rates with real-time surveillance of mechanical specific energy. In Proceedings of the SPE Annual Technical Conference and Exhibition, Dallas, TX, USA, 9–12 October 2005. [Google Scholar]

- Anemangely, M.; Ramezanzadeh, A.; Mohammadi Behboud, M. Geomechanical parameter estimation from mechanical specific energy using artificial intelligence. J. Pet. Sci. Eng. 2019, 175, 407–429. [Google Scholar] [CrossRef]

- Hammoutene, C.; Bits, S. FEA Modelled MSE/UCS Values Optimise PDC Design for Entire Hole Section. In Proceedings of the North Africa Technical Conference and Exhibition, Cairo, Egypt, 20–22 February 2012. [Google Scholar] [CrossRef]

- Deere, D.U.; Miller, R.P. Engineering Classification and Index Properties for Intact Rock; Technical Report; University of Illinois: Urbana, IL, USA, 1996. [Google Scholar]

- Navarro-López, E.M.; Suárez, R. Practical Approach to Modelling and Controlling Stick-Slip Oscillations in Oilwell Drillstrings. In Proceedings of the IEEE International Conference on Control Applications, Taipei, Taiwan, 2–4 September 2004; Volume 2, pp. 1454–1460. [Google Scholar]

- Leine, R.I.; van Campen, D.H. Stick-Slip Whirl Interaction in Drillstring Dynamics. In IUTAM Symposium on Chaotic Dynamics and Control of Systems and Processes in Mechanics; Rega, G., Vestroni, F., Eds.; Solid Mechanics and Its Applications; Springer: Dordrecht, The Netherlands, 2005; Volume 122. [Google Scholar] [CrossRef]

- Richard, T.; Germay, C.; Detournay, E. A simplified model to explore the root cause of stick–slip vibrations in drilling systems with drag bits. J. Sound Vib. 2007, 305, 432–456. [Google Scholar] [CrossRef]

- Yigit, A.S.; Christoforou, A.P. Stick-Slip and Bit-Bounce Interaction in Oil-Well Drillstrings. J. Energy Resour. Technol. 2006, 128, 268–274. [Google Scholar] [CrossRef]

- Liu, X.; Vlajic, N.; Long, X.; Meng, G.; Balachandran, B. Coupled axial-torsional dynamics in rotary drilling with state-dependent delay: Stability and control. J. Sound Vib. 2014, 333, 2365–2380. [Google Scholar] [CrossRef]

- Faghihi, M.A.; Mohammadi, H.; Yazdi, E.A.; Eghtesad, M.; Tashakori, S. Distributed model for the drill-string system with multiple regenerative effects in the bit-rock interaction. J. Sound Vib. 2024, 571, 118120. [Google Scholar] [CrossRef]

- Li, B.; Zhu, X.; Dong, L. Axial transfer characteristics of a drillstring in conjunction with bit penetration behavior in horizontal wells. Geoenergy Sci. Eng. 2024, 240, 212989. [Google Scholar] [CrossRef]

- Han, Y.; Kuang, Y.; Yang, B.; Ai, Z. Nonlinear Dynamic Modeling of Drillstring-Bit-Rock Coupling System Based on Bit/Rock Interaction Simulation. SPE J. 2022, 27, 2161–2182. [Google Scholar] [CrossRef]

- Khulief, Y.; Al-Naser, H. Finite element dynamic analysis of drillstrings. Finite Elem. Anal. Des. 2005, 41, 1270–1288. [Google Scholar] [CrossRef]

- Feng, T.; Vadali, M.; Ma, Z.; Chen, D.; Dykstra, J. A Finite Element Method with Full Bit-Force Modeling to Analyze Drillstring Vibration. J. Dyn. Syst. Meas. Control 2017, 139, 091016. [Google Scholar] [CrossRef]

- Tucker, W.; Wang, C. On the Effective Control of Torsional Vibrations in Drilling Systems. J. Sound Vib. 1999, 224, 101–122. [Google Scholar] [CrossRef]

- Noabahar Sadeghi, A.; Arıkan, K.B.; Özbek, M.E. Modelling and controlling of drill string stick slip vibrations in an oil well drilling rig. J. Pet. Sci. Eng. 2022, 216, 110759. [Google Scholar] [CrossRef]

- Germay, C.; Van de Wouw, N.; Nijmeijer, H.; Sepulchre, R. Nonlinear Drillstring Dynamics Analysis. SIAM J. Appl. Dyn. Syst. 2009, 8, 527–553. [Google Scholar] [CrossRef]

- Cunha, A., Jr.; Soize, C.; Sampaio, R. Analysis of the Nonlinear Dynamics of a Horizontal Drillstring. In Proceedings of the 9th International Conference on Structural Dynamics, EURODYN 2014, EASD, Porto, Portugal, 30 June–2 July 2014; pp. 2057–2061. [Google Scholar]

- Detournay, E.; Defourny, P. A phenomenological model for the drilling action of drag bits. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1992, 29, 13–23. [Google Scholar] [CrossRef]

- Løken, E.A.; Løkkevik, J.; Sui, D. Implementation of Automated Drilling Algorithms on a Laboratory Drilling Rig. Model. Identif. Control 2020, 41, 1–11. [Google Scholar] [CrossRef]

- Tengesdal, N.K.; Hovda, S.; Holden, C. A discussion on the decoupling assumption of axial and torsional dynamics in bit-rock models. J. Pet. Sci. Eng. 2021, 202, 108070. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sui, D. Real-Time Drilling Performance Optimization Using Automated Penetration Rate Algorithms with Vibration Control. Fuels 2025, 6, 33. https://doi.org/10.3390/fuels6020033

Sui D. Real-Time Drilling Performance Optimization Using Automated Penetration Rate Algorithms with Vibration Control. Fuels. 2025; 6(2):33. https://doi.org/10.3390/fuels6020033

Chicago/Turabian StyleSui, Dan. 2025. "Real-Time Drilling Performance Optimization Using Automated Penetration Rate Algorithms with Vibration Control" Fuels 6, no. 2: 33. https://doi.org/10.3390/fuels6020033

APA StyleSui, D. (2025). Real-Time Drilling Performance Optimization Using Automated Penetration Rate Algorithms with Vibration Control. Fuels, 6(2), 33. https://doi.org/10.3390/fuels6020033